Page 1

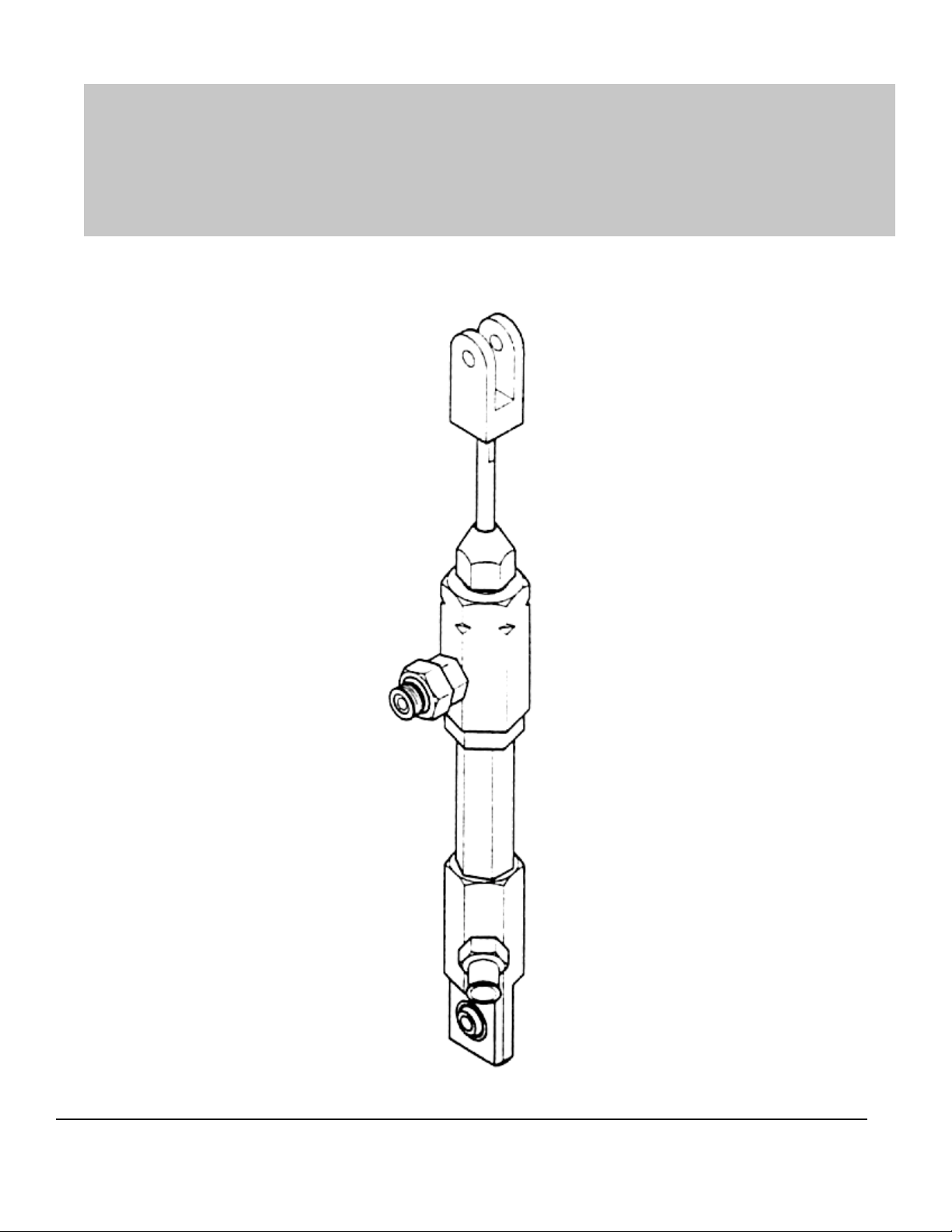

FRP SystemOne

4101-00-01 Gelcoat Metering Pump

MAGNUM VENUS PRODUCTS

Maintenance & Repair Manual

Part No. M6704-4-1

FRP SystemOne

Revision 04.09.01

Gelcoat

Page 2

FRP SystemOne

Maintenance & Repair Manual

Gelcoat Metering Pump Module

FRP SystemOne

Gelcoat

MVP Manufacturing/Sales

Phone: (253) 854-2660 (800) 448-6035

Fax: (253) 854-1666

Email: info@venusmagnum.com

Web: www .venusmagnum.com

MVP Corporate HQ/Manufacturing

Phone: (727) 573-2955

Fax: (727) 571-3636

Email: info@magind.com

Web: www .magind.com

© 2001 Magnum Venus Product s Manual Part No: M6704-4-1

Page 3

Table of Contents

FRP SystemOne

Maintenance & Repair Manual

Gelcoater Metering Pump Module

CHAPTER 1 - GETTING ST ARTED

T ools Required

CHAPTER 2 - INSTRUCTIONS

Disassembly of Metering Pump

CHAPTER 3 - INSTRUCTIONS

Disassembly of Catalyst Surge Chamber

CHAPTER 4 - INSTRUCTIONS

Reassembly of Metering Pump

CHAPTER 5 - INSTRUCTIONS

Reassembly of Catalyst Surge Chamber

CHAPTER 6 - APPENDIX

Parts Drawings

FRP SystemOne

Gelcoat

Page 4

Chapter

1

FRP SystemOne

Gelcoat Metering Pump

Getting Started

Tools Required

1. 1” Open End Wrench

2. 3/4” Open End Wrench

3. 5/8” Open End Wrench

4. 6” Adjust able Wrench (2 required)

5. 12” Adjustable Wrench

6. 1/4” Wood Dowel – 6” long

FRP SystemOne

Gelcoat

1

Page 5

Chapter

2

FRP SystemOne

Disassembly of MP.057S1 Gelcoat

Metering Pump

W ARNING

Before removing Metering Pump and Surge Chamber assembly

from the Slide Drive, be sure to bleed the fluid pressure from the

system; before disconnecting any hoses or tubes. System may be

under pressure and could cause injury.

1. Remove 4101-15-1 (Check V alve Body) from 4101-14-1 (Outlet

Body) and remove and discard the two 7301-4-013 (O-Rings).

2. Remove the 4107-17-1 (Spring Ret ainer) and 4101-16-1

(Compression Spring) from the 4101-15-1 (Check V alve Body),

and remove and discard the 9201-1-7 (7/32” SS Ball).

3. Loosen 4101-1-1 (Lock Nut) and unscrew the 4101-14-1 (Outlet

Body) from the 4101-2-1 (Cylinder).

4. Remove the 4101-61 (Seal Retainer) from the 4101-4-1 Piston

Body .

5. Remove and discard the 7304-2-1 (Piston Seal).

6. Remove the 4101-4-1 (Piston Body) from the 4101-10-1 (Piston

Rod).

2

FRP SystemOne

Gelcoat

Page 6

WARNING

Use wrench flats provided in order to avoid damaging the Piston

Rod.

7. Remove and discard the 9201-1-5 (5/32” SS Ball).

8. Remove and retain the 4101-3-1 (Piston Rod Spring).

9. Unscrew the 4101-1 1-1 (Packing Nut) and pull the 4101-10-1

(Piston Rod) out of the 4101-14-1 (Outlet Body).

NOTE

Carefully pull the Piston Rod out of Cylinder to avoid damaging

the interior surface of Cylinder. Inspect the Piston Rod for

scratches or other damage. Replace if necessary .

10. Insert a 1/4” diameter dowel into the bottom of the 4101-14-1

(Outlet Body), force the 4101-13-01 (Piston Rod Packings) and

4101-12-1(Upper Guide) out through the top of the Outlet Body and

discard.

NOTE

Care must be taken to not damage the inside of the Outlet Body .

1 1. Unscrew the 4101-2-1 (Cylinder) from the 4101-7-1 (Inlet Body).

Remove and discard the two 7301-9-014 (O-Rings). Inspect the

Cylinder for scratches, or other damage, and replace if necessary .

12. Remove and discard the 9201-1-14 (7/16” SS Ball). Inspect the

seat inside the 4101-7-1 (Inlet Body), for nicks, scratches, or other

damage, and lap, or replace if necessary .

13. Remove the 4101-8-1 (Tube Fitting). Remove and discard the

7301-9-013 (O-Ring).

NOTE

Once disassembly is complete all parts should be flushed in

distilled water and inspected for damage and replaced if

necessary .

FRP SystemOne

Gelcoat

3

Page 7

Chapter

FRP SystemOne

CS1S1 Gelcoat Catalyst Surge

Chamber Disassembly

W ARNING

Before removing metering pump and catalyst surge chamber

assembly from teh slide drive, be sure to bleed the fluid

pressure from the system; before disconnecting any hoses or

tubes. System may be under pressure and could cause injury .

3

1. Loosen the 4101-18-1 (Jam Nut), and remove the 4104-8-1

(Gauge Adapter) from the 4104-4-1 (Surge Relief Valve Body).

2. Remove and discard the 7301-4-013 (O-Ring).

3. Remove the 4104-6-1 (Return Tube Fitting) from the 4104-4-1

(Surge Relief V alve Body).

4. Remove and discard the 7301-4-013 (-Ring), and the 9201-1-4

(1/8” SS Ball).

NOTE

This is all the disassembly that is required to install the repair

kit. Further disassembly is required if there is a problem with

the 8701-1-1 (Burst Disc).

NOTE

Once disassembly is complete all parts should be flushed in

distilled water and inspected for damage and replaced if necessary .

4

FRP SystemOne

Gelcoat

Page 8

Chapter

4

FRP SystemOne

Reassembly of MP .057S1

Gelcoat Metering Pump

Assembly Procedures:

1. Install 7301-9-013 (O-Ring), and 4101-8-1 (Inlet Tube Fitting) onto

4101-7-1 (Inlet Body).

2. Insert the 9201-1-14 (7/16” SS Ball) into the 4101-7-1 (Inlet Body).

NOTE

Care must be taken to not scratch or dent SS Ball.

3. Position a 7301-9-014 (O-Ring) onto the notched end of the

4101-2-1 (Cylinder).

NOTE

Take care not to damage the O-ring on the threads.

4. Screw the notched end of the 4101-2-1 (Cylinder) into the 4101-7-1

(Inlet Body). T urn by hand until it bottoms on the Inlet Body, “snug

tight”.

FRP SystemOne

Gelcoat

5

Page 9

5. Thread the 4101-1-1 (Lock Nut) onto the 4101-2-1 (Cylinder) until it

bottoms on the Cylinder shoulder .

6. Install a 7301-9-013 (O-Ring) onto the long threaded end of the

4101-2-1 (Cylinder).

7. Install the 4101-7-1 (Packing Nut), 4101-12-1 (Upper Guide) and

4101-13-01 (Packing Set) onto the 4101-10-1 (Piston Rod).

NOTE

See drawing for proper orientation.

8. Carefully insert the 4101-10-1 (Piston Rod) through the 4101-14-1

(Outlet body).

NOTE

Care must be taken to not scratch the Piston Rod.

9. Carefully press the 4101-13-1 (Piston Rod Packings), and

4101 12-1 (Upper Guide) into 4101-14-1 (Outlet Body).

NOTE

Care must be taken to not damage the Piston Rod Packings.

10. Screw the 4101-1 1-1 (Packing Nut) into the 4101-14-1 (Outlet

Body). Screw the Packing Nut until the Packings bottom in the

Outlet Body cavity . Lightly snug the packing nut with a wrench.

1 1. Insert the 4101-3-1 (Piston Rod Spring) into the 4101-10-1 (Piston

Rod).

12. Insert the 9201-1-5 (5/32” SS Ball) into the 4101-4-1 (Piston Body).

13. Screw the 4101-4-1 (Piston Body) onto the 4101-10-1 (Piston

Rod), compressing the 4101-3-1 (Piston Rod Spring) onto the

9201-1-5 (5/32” SS Ball).

6

FRP SystemOne

Gelcoat

Page 10

14. Install the 7304-2-1 (Piston Seal) onto the threaded end of the

4101-4-1 (Piston Body) spring side up.

NOTE

Note orientation of seal on drawing.

15. Install the 4101-5-1 (Piston Guide) onto the 4101-4-1 (Piston Body)

below the 7304-2-1 (Piston Seal).

16. Screw the 4101-6-1 (Seal Retainer) onto the 4101-4-1 (Piston

Body), hand tight.

17. Hold the 4101-10-1 (Piston Rod) with a wrench on the wrench

flats, and tighten the 4101-6-1 (Seal Retainer) with another

wrench.

18. Insert the Piston Rod assembly into the 4101-2-1 (Cylinder) s

crewing the 4101-14-1 (Outlet Body) onto the cylinder threads.

NOTE

Screw the Outlet body down until you feel the O-Ring start to

compress.

19. Align the 4101-14-1 (Outlet Body) so the outlet port is one hex flate

to the left of the inlet port of the 4101-7-1 (Inlet Body) See Fig. 4.1

Fig. 4.1

Offeset intake and outlet

ports one flat hex as

shown in figure.

FRP SystemOne

Gelcoat

7

Page 11

20. Place the 9201-1-7 (7/32” SS Ball) down inside the 4101-15-1

(Check V alve Body) through the double threaded side.

21. Install the 4101-16-1 (Compression Spring) into the 4101-15-1

(Check V alve Body) onto the top of the 9201-1-7 (7/32” SS Ball).

22. Screw the 4101-17-1 (Spring Ret ainer) into the inside of the

4101-15-1 (Check V alve Body), Compressing the Spring between

the Retainer and the SS Ball.

23. Place a 7301-9-013 (O-Ring) over the single threaded end of the

4101-15-1 (Check V alve Body), and screw the Check V alve into

the 4101-14-1 (Outlet Body).

24. Place a 7301-97301-9-013 (O-Ring over the double threaded end

of the 4101-15-1 (Check V alve Body) until it is in the thread relief

area between the two set of threads and against the end of the

4101-18-1 (Jam Nut).

The Metering Pump assembly is complete.

8

FRP SystemOne

Gelcoat

Page 12

Chapter

5

FRP SystemOne

CS1S1Gelcoat Catalyst

Surge Chamber Reassembly

1. Install a 7301-9-013 (O-Ring) over the threaded end of the

4104-6-1 (Return Tube Fitting).

2. Insert the 9201-1-4 (1/8” SS Ball) into the 4104-4-1 (Surge Relief

V alve Body).

3. Insert the 4104-5-1 (Relief V alve S pring) into the 4104-4-1 (Surge

Relief V alve Body) over the SS Ball.

4. Thread the 4104-6-1 (Return tube Fitting) into the 4104-4-1 (Surge

Relief V alve Body) compressing the spring between the Tube

Fitting and the Ball.

5. Fasten the Catalyst Surge Chamber Assembly to the Metering

Pump Assembly.

The Surge Chamber Assembly is complete.

FRP SystemOne

Gelcoat

9

Page 13

FRP SystemOne Gelcoater

Part s Drawings

Chapter

6

10

FRP SystemOne

Gelcoat

Page 14

MAGNUM VENUS PRODUCTS

FRP SystemOne

Gelcoat

11

Page 15

The parts for this repair kit are

included in the Metering Pump

Repair Kit, PN 6702-5-1

12

FRP SystemOne

Gelcoat

Page 16

MAGNUM VENUS PRODUCTS

FRP SystemOne

Gelcoat

13

Page 17

14

FRP SystemOne

Gelcoat

Page 18

MAGNUM VENUS PRODUCTS

FRP SystemOne

Gelcoat

15

Page 19

16

FRP SystemOne

Gelcoat

Page 20

MAGNUM VENUS PRODUCTS

FRP SystemOne

Gelcoat

17

Page 21

18

FRP SystemOne

Gelcoat

Page 22

FRP SystemOne

Gelcoat

Page 23

FRP SystemOne

Gelcoat

Page 24

FRP SystemOne

Gelcoat

MVP Manufacturing/Sales

Phone: (253) 854-2660 (800) 448-6035

Fax: (253) 854-1666

Email: info@venusmagnum.com

Web: www .venusmagnum.com

MVP Corporate HQ/Manufacturing

Phone: (727) 573-2955

Fax: (727) 571-3636

Email: info@magind.com

Web: www .magind.com

© 2001 Magnum Venus Product s Manual Part No: M6704-4-1

Loading...

Loading...