Page 1

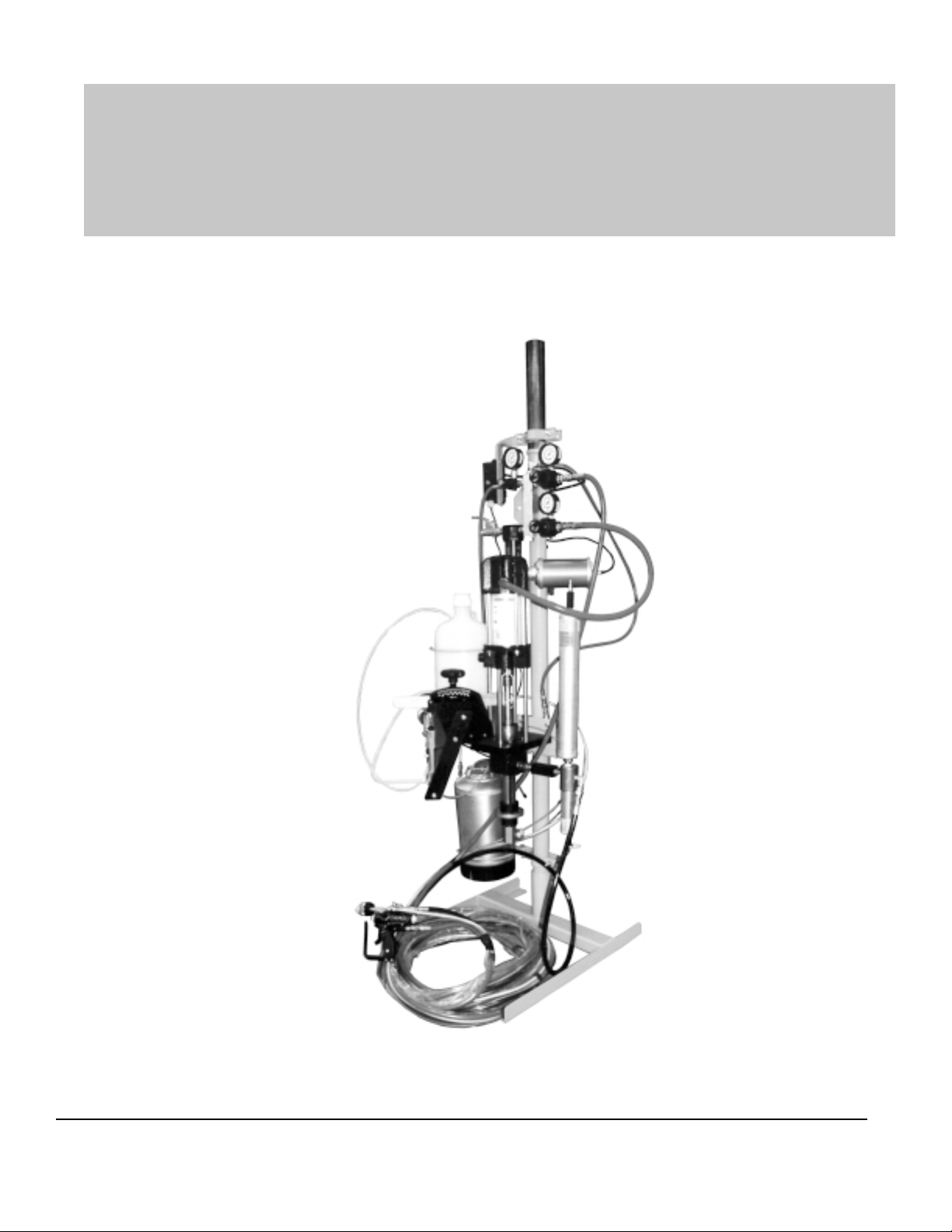

FRP SystemOne

1300-1-1 GELCOA TER OPERA TION MANUAL

MAGNUM VENUS PRODUCTS

Operation Manual

Part No. M1300-1-1

Revision 04.26.01

FRP SystemOne

Gelcoater

Page 2

Unit #

Type Of:

FRP SystemOne

Gelcoater Operation Manual

Unit Information

Power Cylinder

Metering Pump

Gun

Fluid Section

FRP SystemOne

Gelcoater

Page 3

T able of Contents

FRP SystemOne

Gelcoater Operation Manual

CHAPTER 1 - QUICK LIST

Start Up

Installation & Setup

CHAPTER 2 - GETTING ST ARTED

Installation & Setup

Pre-Operation Checklist

CHAPTER 3 - OPERATION

Wetting Unit

Proper Operating Pressures

Gun Set-Up

CHAPTER 4 - MAINTENANCE

CHAPTER 5 - PARTS DRAWINGS

Unit Assembly

Mounting Column Assembly

Cart Assembly

Pneumatic Manifold Assembly

3-Gallon Flush T ank Assembly

Catalyst Jug Assembly

Power Cylinder (4.25”) Assembly

Resin Filter Assembly

Drum Suction Wand Assembly

Surge Chamber Assembly

FRP SystemOne

Gelcoater

Page 4

Chapter

1

FRP SystemOne Gelcoater

Quick List Instructions

Start-Up Sheet

1. Check & fill solvent system

2. Check & fill resin & catalyst supply

3. Place suction wand in resin supply

4. Prime resin pump

5. Prime catalyst pump and set catalyst percentage

6. Check system for fluid leaks

7. Set air pressure to gun

8. Install turbulent mixer in mix chamber

9. Select & install nozzle

10. Adjust fan pattern

NOTE: These instructions include resin and catalyst pressurization

procedures. To avoid equipment malfunction or possible injury, please follow

these instructions. If you have any questions, please contact our Technical

Service Department at 800-448-6035.

FRP SystemOne

Gelcoater

1

Page 5

FRP

System

One Gelcoater

Quick List Instructions

Installation & Setup

1. Unpack unit &

components

2. Place unit & stand pipe in

base plate or portable cart (or

mount to wall with wall brackets)

Tighten bolts to secure

3. Install catalyst jug

4. Install resin surge chamber &

filter assembly

5. Install manifold air hose to power

cylinder

6. Attach hose fittings to resin

pump, catalyst pump, air &

flush tank

7. Install boom to mast

(if applicable)

8. Hang hose on boom

(if applicable)

9. Attach pickup hose

10. Place flush tank in holder and

attach air hose from manifold

11. Double check all hose fittings

2

FRP SystemOne

Gelcoater

Page 6

Chapter

2

FRP SystemOne Gelcoater

Getting St arted

Installation

1. Remove unit from crate.

With the crate lying flat, open the top panel and remove the

components:

a. Floor mount assembly

b. Gelcoat pump and pump column

c. Gun and hose set

d. Resin filter and surge chamber assembly

e. Suction wand assembly

f. Catalyst jug

g. Solvent tank

h. Catalyst pump

i. Air manifold

2. Assemble pump and column to floor mount assembly.

a. Slide pump column into floor mount and tighten the two hex bolts

in floor mount.

3. Assemble resin filter/surge chamber assembly to pump.

a. Check to make sure all Filter/Surge chamber connections are

tight.

b . Attach the filter/surge chamber assembly to the swivel fitting

located at the outlet of the resin pump.

c. With the filter/surge chamber assembly vertical. Tighten the

fitting with a wrench until it is tight.

FRP SystemOne

Gelcoater

3

Page 7

4. Mount catalyst jug bracket.

a. Attach the Catalyst jug bracket to the base of the catalyst pump

slide drive support.

b . Mount the bracket so it extends to the left side of the slide drive

support as you stand facing the end of the slide drive.

5. Mount solvent tank retainer bracket.

a. Attach the tank bracket to the column approximately 2 to 3

inches from the top of the floor mount frame round tube.

b. The bracket should be on the left side of the column as you face

the unit. Position the bracket so the tank will sit on the floor

mount square tubing. Tighten the flush t ank bracket bolts to the

column.

c. Remove the solvent tank from the carton and place into bracket.

6. Attach catalyst pump.

NOTE

If SystemOne Gelcoater unit is configured with a catalyst

alarm, please refer to the catalyst alarm manual when you

reach this stage of set-up.

a. Mount the Catalyst pump to the slide drive bracket using the

clevis pins and keepers provided.

b. The bottom of the catalyst pump is pinned to the lower leg of the

slide drive bracket.

c. The upper clevis, (piston rod), is pinned to the slide drive using

the forward of the long slot in the slide drive.

d. Hold the clevis pins in place with the wire keepers by placing

them in the holes in the clevis pins.

7. Mount air supply manifold.

a. Clamp manifold assembly to the pump column above the power

cylinder of the resin pump.

b. Regulators and gauges should face to the pump side of the

column.

c. Clamp yoke tight enough so the assembly does not move

around the column.

8. Attach suction wand to gelcoat pump.

a. Check all fittings on the wand assembly to make sure they are

airtight.

b. Attach the wand assembly to the foot valve swivel fitting and

tighten.

4

FRP SystemOne

Gelcoater

Page 8

9. Make hose connections.

a. Connect the black resin hose from the gun to the outlet fitting on

the resin filter.

b . Connect the catalyst hose from the gun to the outlet of the

catalyst pump assembly .

c. Attach the red air hose from the gun to the fitting on the regulator

labeled gun.

d. Attach the yellow poly flush hose from the gun to the outlet fitting

of the solvent tank.

e. Attach the small red air supply hose from the flush regulator to

the input fitting on the flush tank.

f. Attach the red air hose from the pump regulator to the power

cylinder or the gelcoat pump.

g. Attach the ground wire from the gun to the electrical grounding

lug on the pump power head.

h. Remove the catalyst poly tubes from the component box. Cut

the ½” inch diameter poly line with the clamps to 26 inches long.

Clamp one end to the outlet of the catalyst jug and the other end

to the inlet of the catalyst pump. Make sure the clamps are

airtight.

i. Connect the 3/8-inch poly line to the relief valve on the catalyst

relief valve and insert the other end into the hole in the top of the

catalyst jug.

j. Connect the green hose from side of the gun handle to the blue

valve on air manifold.

10. Mount exhaust muffler to the power head of the gelcoat pump.

a. Remove the exhaust deflector from the power head of the

gelcoat pump, (4 screws). Screw silencer into the pipe threads

of the exhaust port.

FRP SystemOne

Gelcoater

5

Page 9

Chapter

3

FRP SystemOne Gelcoater

Operation

Wetting Out Unit

Air supply:

1. Use minimum ½” air hose supply to the system. Air requirements, 9

to 10 CFM

2. Open incoming air supply ball valve.

3. Set regulator labeled gun at 90 to 100 psi. T ighten packing nuts on

the gun and trigger the gun 15 to 20 times. Snug packing nuts again

and repeat gun triggering.

Priming Solvent:

1. Open solvent tank lid and fill ¾ full. Install lid on tank and close the

relief valve located on the top of the lid. Set flush tank pressure at

50 to 60 psi.

2. Push the flush valve on the side of the gun block to test solvent

flush.

Priming Catalyst to Gun:

1. Tighten the catalyst packing nut ¼ turn.

2. Fill the two gallon catalyst jug ¾ full, purge the air out of the catalyst

feed line by slightly tilting the catalyst jug.

6

FRP SystemOne

Gelcoater

Page 10

3. Lock the gun in the open position. Remove the pivot pin from the

catalyst slide arm linkage. Use the slide arm to hand prime catalyst

out to the gun until a steady stream is achieved. Do not reinstall

pivot pin at this time.

Priming Resin to Gun:

NOTE

The resin pump was tested using oil. It may require up to 1/2

gallon of gelcoat to be run through the unit to purge any

remaining oil from the system.

1. Insert the gelcoat suction wand into container of gelcoat.

2. Tighten the gelcoat pump packing nut until snug only. Fill packing

nut cavity ¾ full with suitable oil.

3. With the gun locked in the open position, slowly increase pump

regulator pressure until pump is running at a slow but steady rate.

Allow pump to run until a fairly steady stream of gelcoat is being

dispensed. Close the gun and flush the gun head.

4. Increase gelcoat pump pressure to 100 psi. Allow the unit to set

under static load for 15 to 30 minutes to seat the resin packing set.

5. Clamp or tape the resin return hose coming from the bottom of the

in-line resin filter to the resin pickup wand and into the drum. Turn

the resin pump regulator to zero. Slowly open the ball valve at the

bottom of the resin filter to drain the fluid pressure.

Charging the Resin Surge Chamber:

1. Open the ball valve below inline resin filter.

2. To charge the resin surge chamber, use the air hose with the female

quick disconnect (charging hose) and insert over the male quick

disconnect at the top of the resin surge chamber . Push down on

female quick disconnect for 5 to 10 seconds and disengage.

3. Close ball valve below in-line filter.

FRP SystemOne

Gelcoater

7

Page 11

Pressurizing Fluids:

NOTE

On the air manifold, the blue valve is the safety override. The

small brass button next to the valve is the priming button.

The SystemOne Gelcoater Unit is standard with a safety override valve.

This valve opens and closes the air supply to the resin pump air motor.

The valve will be opened when the gun trigger is opened or when the

priming button is pushed down.

NOTE

Remove catalyst quick pin before pressurizing gelcoat pump.

1. Push down on the priming button and slowly increase gelcoat pump

regulator , 40 to 50 p si would be a st arting point.

2. Using the slide drive arm, use slow up and down motion to

pressurize the catalyst pump. There should be a uniform gain in

resistance between up and down strokes.

3. Pin the pivot pin into the slide arm. Set catalyst percentage.

Gun Set-Up:

1. Install turbulent mixer into mix chamber . Insert static mixer and spray

tip onto the air assist housing. Screw air-assist unto the gun mix

housing. For longer turbulent mixer life, do not over tighten the air

assist nozzle housing. Att ach short air assist house from needle

valve on side of gun handle to air-assist head.

2. Test spray pattern, make gelcoat pump pressure adjustment until a

fairly uniform pattern is achieved. Slowly open the air-assist needle

valve located on the side of the gun handle until a soft uniform

pattern is achieved.

8

FRP SystemOne

Gelcoater

Page 12

Chapter

4

FRP SystemOne

Maintenance Schedule

Daily Maintenance

1. Drain water trap.

2. Daily shutdown should include, remove air-assist tip and static

mixers from housing and clean. Remove turbulent mixer and

mix chamber from gun and clean. Lightly dampen a rag with

solvent and wipe down gun head, handle and actuator. Do not

soak gun in solvent.

Weekly Maintenance

Gelcoat Pump Packing Set

Check gelcoat pump piston rod oil reservoir, inspect for gelcoat

bypassing packing set.

1. T urn pump regulator to zero. Open ball valve at gelcoat filter to

release gelcoat pressure.

2. Insert a rod or Philips screwdriver into one of the holes in the

gelcoat-packing nut. Snug the packing nut. Do not over tighten.

Power Cylinder

Turn pump regulator to zero. Loosen the air hose fitting and add 10

to 15 drops of 90-weight non-detergent gear oil.

FRP SystemOne

Gelcoater

9

Page 13

Gun

Gun maintenance: Turn the pump regulator pressure to zero. Open

up the ball valve at filter to relieve gelcoat fluid pressure. Open gun

to relieve catalyst fluid pressure. Snug Pro gun packing nuts (light

snug on catalyst packing nut) and trigger the gun on and off to seat

the resin and catalyst seals. Repeat a second time.

Filter & Accumulator

1. T urn gelcoat pump regulator to zero. Open ball valve at the

gelcoat filter to relieve gelcoat fluid pressure. To bleed the

charge in the accumulator , insert the small diameter rod in the

charging valve on the top of the resin accumulator (check valve)

and depress to bleed the charge off. Be sure to cover the rod

with a rag.

2. To remove the gelcoat filter, remove the return hose from the ball

valve. Un-screw the resin filter, clean the filter screen and core.

Use Venus-Gusmer white grease on the filter housing threads.

3. Un-screw the gelcoat accumulator. Clean the accumulator, poly

ball and thread on the nipple. Coat nipple, o-ring and poly ball

with white grease. Inspect o-ring, replace as needed.

Catalyst Pump

1. Inspect catalyst pump packing nut for leaking coming up through

the packing set. T ighten the packing nut no more than one

eighth of a turn at a time as needed. Wipe catalyst pump piston

rod off with a clean dry towel.

Six Month Maintenance

Flush T ank

1. Release fluid pressure from flush tank and drain out solvent.

Use a clean towel to wipe the inside of the tank clean. Wipe out

any solid debris. Inspect flush tank o-ring, replace as needed.

Hose Set

1. Inspect hose set for any kinks or wear, replace hoses as needed.

The flush should be replaced once a year.

Catalyst Jug & Feed Hose

1. Drain catalyst from jug, wash the jug out with distilled water and

drain. Repeat a second time. Replace feed and return hose as

needed.

10

FRP SystemOne

Gelcoater

Page 14

IT IS ADVISED THAT THE FOLLOWING COMPONENTS BE REBUILT

AFTER 6-MONTHS OF USE IN A 8-HOUR, 5-DAY A WEEK SHOP.

Catalyst Pump

1. Minimum rebuild should include all o-rings, balls, piston seal

and packing set.

Gelcoat Pump

1. Minimum rebuild should include, packing set, piston cups and

cylinder o-rings,

Gun

1. Minimum rebuild should include all seals and o-rings.

FRP SystemOne

Gelcoater

11

Page 15

FRP SystemOne

Part s Drawings

Chapter

5

12

FRP SystemOne

Gelcoater

Page 16

MAGNUM VENUS PRODUCTS

FRP SystemOne

Gelcoater

13

Page 17

14

FRP SystemOne

Gelcoater

Page 18

MAGNUM VENUS PRODUCTS

FRP SystemOne

Gelcoater

15

Page 19

16

FRP SystemOne

Gelcoater

Page 20

MAGNUM VENUS PRODUCTS

FRP SystemOne

Gelcoater

17

Page 21

18

FRP SystemOne

Gelcoater

Page 22

MAGNUM VENUS PRODUCTS

FRP SystemOne

Gelcoater

19

Page 23

20

FRP SystemOne

Gelcoater

Page 24

MAGNUM VENUS PRODUCTS

FRP SystemOne

Gelcoater

21

Page 25

22

FRP SystemOne

Gelcoater

Page 26

MAGNUM VENUS PRODUCTS

FRP SystemOne

Gelcoater

23

Page 27

24

FRP SystemOne

Gelcoater

Page 28

MAGNUM VENUS PRODUCTS

FRP SystemOne

Gelcoater

25

Page 29

26

FRP SystemOne

Gelcoater

Page 30

MAGNUM VENUS PRODUCTS

FRP SystemOne

Gelcoater

27

Page 31

28

FRP SystemOne

Gelcoater

Page 32

MAGNUM VENUS PRODUCTS

FRP SystemOne

Gelcoater

29

Page 33

30

FRP SystemOne

Gelcoater

Page 34

MAGNUM VENUS PRODUCTS

FRP SystemOne

Gelcoater

31

Page 35

32

FRP SystemOne

Gelcoater

Page 36

FRP SystemOne

Gelcoater

Page 37

FRP SystemOne

Gelcoater

Page 38

FRP SystemOne

Gelcoater

Page 39

FRP SystemOne

Gelcoater

Page 40

MVP Magnum

Phone: (727) 573-2955

Fax: (727) 571-3636

Email: info@magind.com

Web: www.magind.com

© 2001 Magnum Venus Proeduct s Manual Part No: M1300-1-1

FRP SystemOne

Gelcoater

MVP Venus

Phone: (253) 854-2660 (800) 448-6035

Fax: (253) 854-1666

Email: info@venusmagnum.com

Web: www .venusmagnum.com

Loading...

Loading...