Page 1

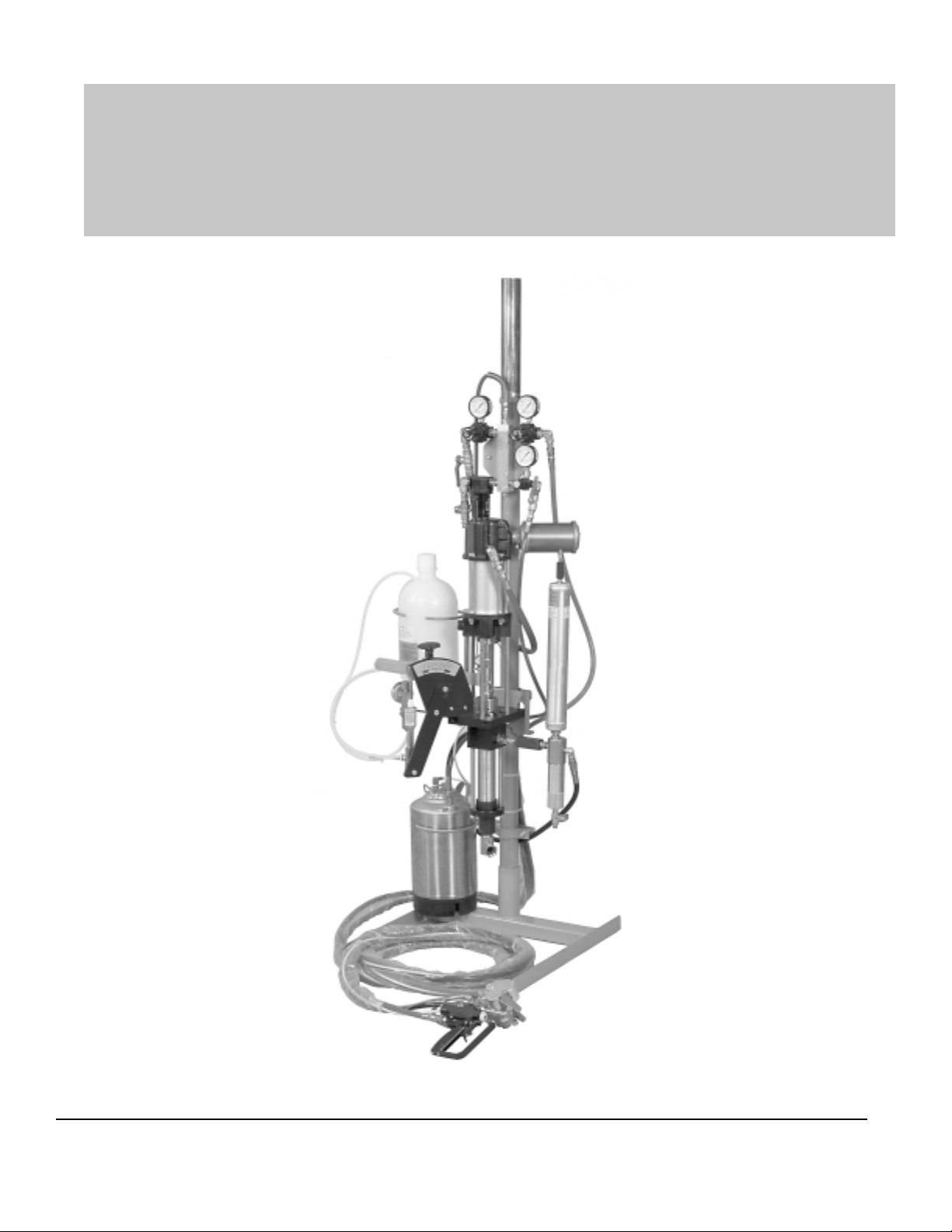

FRP SystemOne

1100-1-1 CHOPPER OPERATION MANUAL

MAGNUM VENUS PRODUCTS

Operation Manual

Part No. M1 100-1-1

Revision 04.10.01

FRP SystemOne

Page 2

Unit #

Type Of:

FRP SystemOne

Operation Manual

Unit Information

Power Cylinder

Metering Pump

Gun

Roving Cutter

Fluid Section

Corporate HQ & Mfg.

Phone: (727) 573-2955

Fax: (727) 571-3636

Email: info@magind.com

Web: www .magind.com

Manufacturing

Phone: (253) 854-2660 (800) 448-6035

Fax: (253) 854-1666

Email: info@venusmagnum.com

Web: www .venusmagnum.com

FRP SystemOne

© 2001 Magnum Venus Product s Manual Part No: M1100-1-1

Page 3

T able of Contents

FRP SystemOne

Operation Manual

CHAPTER 1 - QUICK LIST

Start Up

Installation & Setup

CHAPTER 2 - INST ALLATION AND SET-UP

Pre-Operation Checklist

Wetting Unit

Proper Operating Pressures

Installation

CHAPTER 3 - MAINTENANCE

CHAPTER 4 - PARTS DRAWINGS

Cart Assembly

Mounting Column Assembly

12’ Boom Assembly

Pneumatic Manifold Assembly

3-Gallon Flush T ank Assembly

FRP SystemOne

Page 4

Chapter

1

FRP SystemOne Quick List

Quick List Instructions

Start-Up Sheet

1. Check & fill solvent system

2. Check & fill resin & catalyst supply

3. Place suction wand in resin supply

4. Prime resin pump

5. Prime catalyst pump and set catalyst percentage

6. Check system for fluid leaks

7. Set air pressure to gun/chopper

8. Install turbulent mixer in mix chamber

9. Select spray tip, flow nozzle or convergence tip

10. Check chopper motor, rubber roller adjustment

1 1. Attach chute & cover

12. Adjust fan pattern

13. Adjust chop pattern

NOTE: These instructions include resin and catalyst pressurization procedures.

T o avoid equipment malfunction or possible injury , please follow these

instructions. If you have any questions, please contact our Technical Service

Department at 800-448-6035.

FRP SystemOne

1

Page 5

FRP

System

One

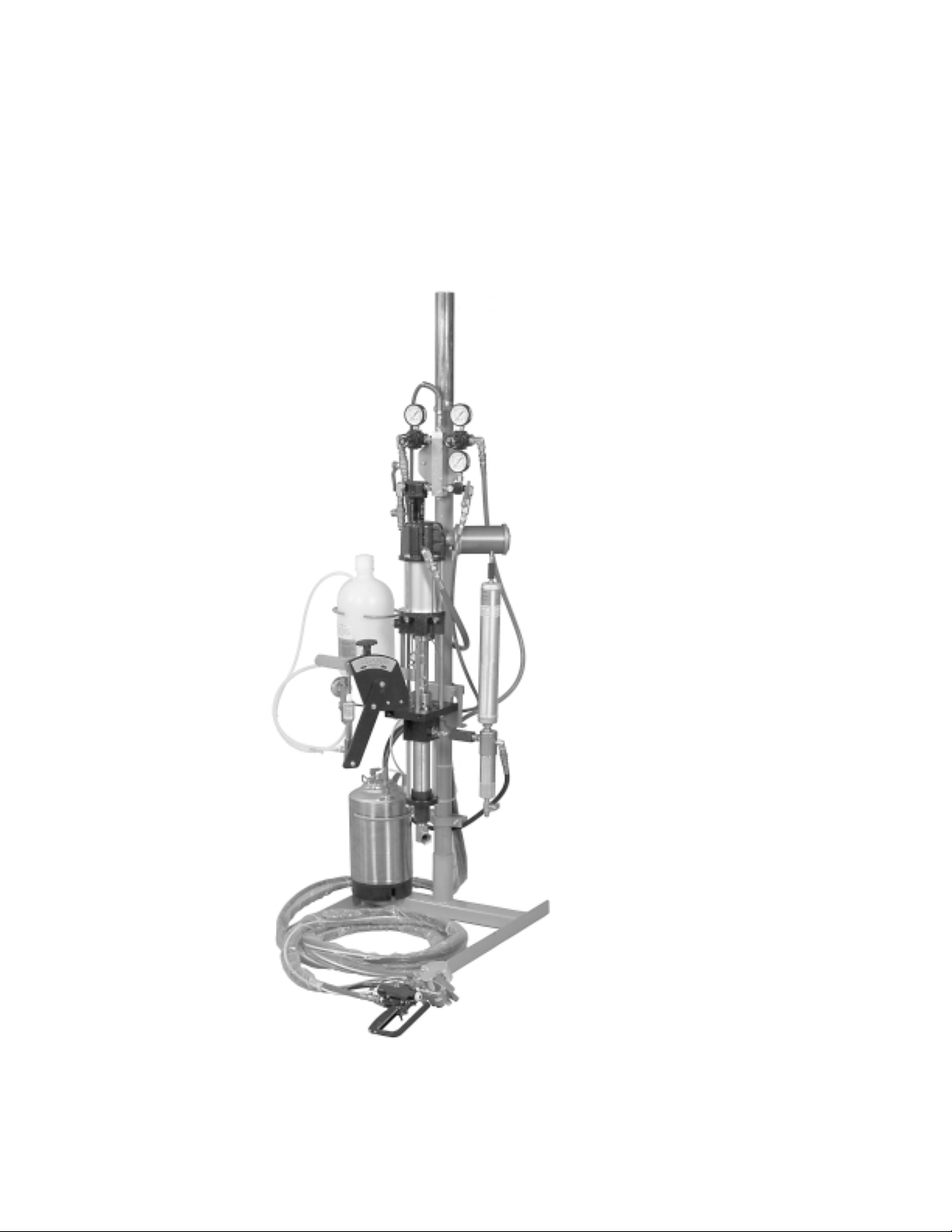

Pumping System

Quick List Instructions

Installation & Setup

1. Unpack unit &

components

2. Place unit & stand pipe in

base plate or portable cart (or

mount to wall with wall brackets)

Tighten bolts to secure

3. Install catalyst jug

4. Install resin surge chamber &

filter assembly

5. Install manifold air hose to power

cylinder

6. Attach hose fittings to resin

pump, catalyst pump, air &

flush tank

7. Install boom to mast

(if applicable)

8. Hang hose on boom

(if applicable)

9. Attach pickup hose

10 . Place flush tank in holder and

attach air hose from manifold

1 1. Double check all hose fittings

2

FRP SystemOne

Page 6

Chapter

2

FRP SystemOne

Installation & Set-Up

Checklist

1. Tighten all hose fittings and fluid connections to make sure they are

tight.

2. Check electrical grounds, gun to pump and pump to earth ground.

3. Check all clamp brackets, pump column, slave arm bracket, manifold

clamp, etc. T o make sure they will not move when unit is in operation.

4. Check the mounting of catalyst pump to make sure clevis pins are

secure.

5. Make sure exhaust silencer is secured to the power cylinder of the

resin pump.

6. IMPORTANT: Snug up the p acking nut at the top of the catalyst

pump Approximately ¼ turn.

7. Snug up, tighten, the resin pump packing be inserting two rods into

the holes in the oil cup at the top of the resin pump fluid section. Turn

clockwise until packing is snug.

8. Tighten the gun valve rod packing nut until it is very snug.

IMPORT ANT: Activate the gun trigger 10 - 15 times then tighten

the packing nut. Repeat this tightening procedure 3 times to make

sure the gun valve rod packing is tight.

FRP SystemOne

3

Page 7

Wetting Out Unit

Air Supply:

1. Use minimum ½” air hose supply to the system. Air requirements,

18 CFM

2. Open incoming air supply ball valve.

3. Set regulator labeled gun at 90 to 100 psi. T ighten packing nuts on

the gun and trigger the gun 15 to 20 times. Tighten p acking nuts

again and repeat gun triggering.

Priming Solvent:

1. Open solvent tank lid and fill tank ¾ full. Install lid on tank and

close the relief valve located on the top of the lid. Set flush tank

pressure at 50 to 60 psi.

2. Push the flush valve on the side of the gun block to test solvent

flush.

Priming Catalyst to Gun:

1. Tighten the catalyst packing nut ¼ turn.

2. Fill the two gallon catalyst jug ¾ full, purge the air out of the

catalyst feed line by slightly tilting the catalyst jug.

3. Lock the gun in the open position. Remove the pivot pin from

the catalyst slide arm linkage. Use the slide arm to hand prime

catalyst out to the gun until a steady stream is achieved. Do not

reinstall pivot pin at this time.

Priming Resin to Gun:

1. Insert the resin suction wand into a 55-gallon drum or resin.

2. Tighten the resin pump packing nut until tight. Fill packing nut

cavity ¾ full with suitable oil.

3. With gun locked in the open position, slowly increase resin pump

regulator pressure until pump is running at a slow but steady rate.

Allow pump to run until a fairly steady stream of resin is being

dispensed. Close the gun and flush the gun head.

4. Increase resin pump pressure to 100 psi. Allow the unit to set

under static load for 15 to 30 minutes to seat the resin packing set.

5. Clamp or tape the resin return hose coming from the bottom of the

in-line resin filter to the resin pickup wand, into the resin drum. Turn

the resin pump regulator to zero. Slowly open the ball valve at the

bottom of the resin filter to drain the fluid pressure.

4

FRP SystemOne

Page 8

Charging the Resin Surge Chamber:

1. Open ball valve below inline resin filter.

2. T o charge the resin surge chamber , use the air hose with the

female quick disconnect (charging hose) and insert over the male

quick disconnect at the top of the resin surge chamber . Push down

on female quick disconnect for 5 to 10 seconds and disengage.

3. Close ball valve below in-line resin filter.

Pressurizing Fluids:

1. Slowly increase resin pump regulator , 50 psi would be a good

starting point.

2. Pull the pivot pin using the slide arm. Use slow up and down

motion to pressurize the catalyst pump for several strokes or until

firm.

3. Pin the pivot pin into the slide arm.

Gun Set-Up:

1. Install turbulent mixer into mix chamber and install tip. For

longer turbulent mixer life, do not over tighten the nozzle cap.

2. T est the spray pattern, make pump pressure adjustment for

required resin outputs.

3. Thread either one or two strands of glass into chopper motor. Use

chopper motor pivot to adjust glass entry into resin fan. Center the

glass into the resin fan using the eccentric stud.

Start-Up Instructions

1. Removing Unit From Crate.

With the crate laying flat. Open the top panel and remove the

components as needed.

a. Cart

b. Pump and Column Assembly .

c. Boom, Hose, and Gun Assembly .

d. Resin Filter/Surge Chamber Assembly .

e. Suction Wand Assembly .

f. Component Box.

g. Catalyst Jug.

h . Solvent T ank.

FRP SystemOne

5

Page 9

2. Assemble Cart.

a. Attach Handle to Cart.

3. Assemble Pump and Column Assembly to cart.

a. Insert Column into column support hole in top of cart.

b. Orient the column until pump faces the front of the cart.

c. Tighten the lock screws to retain pump/column assemble to cart.

Lock screws are located under cart on the front side.

4. Assemble Boom, Hoses, and Gun Assembly to pump column.

a. With the boom folded, hose coiled, and gun attached as the

assembly comes out the crate. Lift the boom up and insert the

base pivot over the column.

b. With the boom installed on column. Remove the ties holding the

two sections of boom together .

c. Remove the ties that hold the gun and hoses in the coil. T ake care

not to drop the gun.

d. Remove the boom spring from the diagonal angle support at the

base of the boom.

e. Swivel the boom back over the rear of the cart (barrel location

area). Unfold the boom sections so both inner and outer sections

are straight over back of cart.

f. With the boom sections stretched out to their full reach. Attach

one end of the boom extension spring to the support chain attached at the boom knuckle.

g. While lifting the outer section of the boom upward, attach the other

end of the extension spring to the link welded to the top of the

outer boom.

NOTE

If Outer section of boom and gun hang to close the floor . Lift

the outer section of the boom again and attach the extension

spring to a new location on the support chain. Shortening the

chain will raise the outer section of the boom.

h . With the outer section of the boom supported by the spring and

chain. Fold the outer section of the boom parallel to the inner

section.

5. Assemble Resin Filter/Surge Chamber Assembly to Pump.

a. Check to make sure all Filter/Surge Chamber connections are

tight.

6

FRP SystemOne

Page 10

b. Attach the Filter/Surge Chamber Assembly to the swivel fitting

located at the outlet of the resin pump.

c. With the Filter/Surge Chamber Assembly vertical. Tighten the

fitting with a wrench until it is tight enough to prevent fluid leaks and

to support the assembly in an up right position.

6. Mount Catalyst Jug Bracket.

a. Attach the Catalyst Jug Bracket to the base of the catalyst pump

slide drive support.

b. Mount the bracket so it extends to the left side of the slide drive

support as you stand facing the end of the slide drive.

7. Mount Solvent Tank Retainer Bracket.

a. Attach the T ank Bracket to the column approximately 5 inches from

the top of the cart.

b. The bracket arm should be on the backside of the column as you

face the pump, extending to the left side of the cart.

c. Tighten the bolt s holding the yoke clamp to the bracket until the

bracket is firmly clamped to the column.

d. Remove the Solvent T ank from the carton and place into bracket.

8. Attach Catalyst Pump.

a. Mount the Catalyst Pump to the slide drive bracket using the clevis

pins and keepers provided.

b. The bottom of the catalyst pump is pinned to the lower leg of the

slide drive bracket.

c. The upper clevis, (piston rod), is pinned to the slide drive using the

hole forward of the long slot in the slide drive.

d. Hold the clevis pins in place with the wire keepers by placing them

in the holes in the clevis pins.

9. Mount Air Supply Manifold.

a. Clamp Manifold Assembly to the pump column above the power

cylinder of the resin pump.

b. Regulators and gauges should face to the pump side of the col-

umn.

c. Clamp yoke tight enough so the assembly does not move around

the column.

FRP SystemOne

7

Page 11

10.Attach Suction Wand to Resin Pump.

a. Check all fittings on the wand assembly to make sure they are

airtight.

b. Attach the wand assembly to the foot valve port of the resin pump.

11. Hose connections.

a. Connect the black resin hose from the gun to the outlet fitting on

the resin filter

b. Connect the catalyst hose from the gun to the outlet of the catalyst

pump assembly .

c. Attach the red air hose from the gun to the fitting on the regulator

labeled gun.

d. Attach the yellow poly flush hose from the gun to the outlet fitting of

the solvent tank.

e. Attach the small red air supply hose from the flush regulator to the

input fitting on the solvent tank.

f. Attach the large red air hose from the pump regulator to the power

cylinder of the resin pump.

g. Attach the ground wire from the gun to the electrical grounding lug

on the pump power head.

h . Remove the catalyst poly tubes from the component box.

i. Cut the ½ inch dia. poly line, with the clamps, to 26 inches long.

Clamp one end to the outlet of the catalyst jug and the other end to

the inlet of the catalyst pump. Make sure clamps are airtight.

j. Connect the 3/8-inch poly line to the relief valve on the catalyst

pump assembly and insert the other end into the hole in the top of

the catalyst jug.

12.Mount Exhaust Silencer to power head of resin pump.

a. Remove the exhaust deflector from the power head of the resin

pump, (4 screws). Screw silencer into the pipe threads of the

exhaust port.

NOTE

If icing of silencer becomes a problem. Remove the silencer

and replace the exhaust deflector. Noise level will be higher

with silencer removed.

8

FRP SystemOne

Page 12

Chapter

3

FRP SystemOne

Maintenance Schedule

4-Hour Oil Chopper Air Motor

For every four hours of operation, the chopper air motor should be oiled.

Push down on the quick disconnect, pull back on the clip, pull it off the bar

fitting and add one or two drops of oil for every four hours of operation.

Daily Relief Valve Check

We start to get accumulating a lot of catalyst in the hose. We want to

drain that off and see how much catalyst that we accumulate in the relief

valve hose, daily . If it’s excessive, we want to replace the ball in the relief

valve.

Daily Water Trap Check

Water traps should be drained daily . Just push the bottom button and

drain any water that may have collected in line.

Weekly Power Head Lubrication

Turn the pump regulator down to zero. Loosen the air hose fitting and add

10 to 15 drops of 90-weight non-detergent gear oil.

Weekly Fluid Section Packing Nut Check

Check the fluid section for any resin coming up through the packings into

the cavity . If you see any resin, tighten the packing nut. Add oil if needed.

Weekly Catalyst Packing Nut Check

Look for any catalyst bleeding up through the packings. If you see any

leakage, tighten the packing nut an eighth of a turn.

FRP SystemOne

9

Page 13

Weekly Gun Maintenance

Weekly maintenance on the gun includes tightening the resin and the

catalyst packing nuts.

1. Turn the pump pressure down to zero. Open up the ball valve to

relieve the fluid pressure on the resin and to release the fluid

pressure on the catalyst we’ll pull the trigger on the gun.

2. T o seat the packings, tighten both the cat alyst and the resin

packing nuts and quickly trigger the gun 10 to 15 times in rapid

succession. Repeat the process. It is very important to trigger the

gun quickly .

Surge Chamber Maintenance

For weekly cleaning of the surge chamber and filter turn the pump

regulator pressure down to zero.

1. T o relieve the fluid pressure in the resin system, open the ball

valve below the resin filter.

2. T o bleed the charge in the accumulator , insert the small diameter

rod in the charging valve on the top of the resin accumulator and

bleed the charge off. Be sure to cover the rod with a rag.

3. T o remove the resin filter , move the return hose out of our way .

Push the core out of the resin screen. Clean the screen and the

core and the inside of the bottle.

4. Unscrew the resin accumulator. Clean the accumulator and filter .

Clean the threads and white ball.

5. Inspect the oil ring and replace if cut or distorted.

6. Reinstall the core into the screen. Then reinstall the screen core

into the filter bottle. It’s very important that we use V enus white

grease on the aluminum threads before re-installing. Do not over

tighten.

7. Reinstall the resin return hose to the ball valve below the filter .

Twist until there is a snug fit. Inspect the “O” ring. Replace if

necessary.

8. Place white grease on the “O” ring and on the threads. The seat

area must be clean for the polyball to seat properly when charging

the resin accumulator. Inspect the oil ring for any split s or cuts.

Replace if necessary .

10

FRP SystemOne

Page 14

9. Place polyball on seat.

10. The surge chamber is now ready for reinstalling. Insert the “O”

ring seal in the bottom of the accumulator and lightly twist the

accumulator until it is snug.

FRP SystemOne

11

Page 15

FRP SystemOne

Part s Drawings

Chapter

4

12

FRP SystemOne

Page 16

MAGNUM VENUS PRODUCTS

FRP SystemOne

13

Page 17

14

FRP SystemOne

Page 18

MAGNUM VENUS PRODUCTS

FRP SystemOne

15

Page 19

16

FRP SystemOne

Page 20

MAGNUM VENUS PRODUCTS

FRP SystemOne

17

Page 21

18

FRP SystemOne

Page 22

MAGNUM VENUS PRODUCTS

FRP SystemOne

19

Page 23

20

FRP SystemOne

Page 24

MAGNUM VENUS PRODUCTS

FRP SystemOne

21

Page 25

22

FRP SystemOne

Page 26

FRP SystemOne

12

Page 27

FRP SystemOne

Page 28

Corporate HQ & Mfg.

Phone: (727) 573-2955

Fax: (727) 571-3636

Email: info@magind.com

Web: www.magind.com

© 2001 Magnum Venus Product s Manual Part No: M1100-1-1

FRP SystemOne

Manufacturing

Phone: (253) 854-2660 (800) 448-6035

Fax: (253) 854-1666

Email: info@venusmagnum.com

Web: www .venusmagnum.com

Loading...

Loading...