Page 1

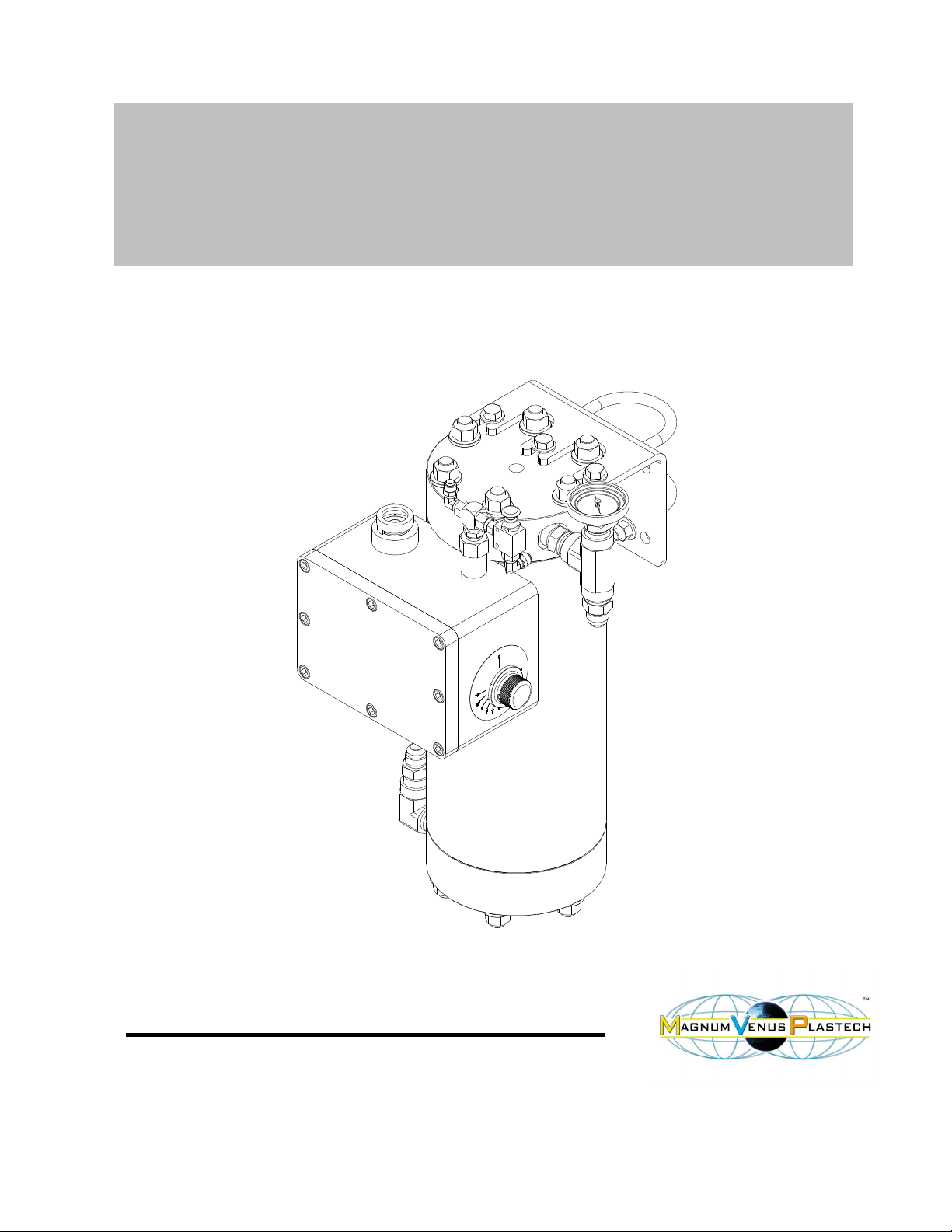

CLEAN FLOW HEATER (CFH)

MANUAL

MAGNUM VENUS PLASTECH

CFH-4000 IN-LINE RESIN HEATER MANUAL

Revision: 07/2007

Page 2

2

Page 3

3

TABLE OF CONTENTS

CHAPTER 1 - INTRODUCTION

CHAPTER 2 - OPERATION

CHAPTER 3 - MAINTENANCE

CHAPTER 4 - TROUBLESHOOTING

CHAPTER 5 - PARTS DRAWINGS

Page 4

4

CHAPTER

1

CFH-4000 IN-LINE RESIN HEATER MANUAL

INTRODUCTION

The MVP Clean Flow Heater (CFH) is designed to allow higher flow rates, give better

control over temperature change and boasts a new easy maintenance design.

The CFH-4000 Heater is heated with a single 3000 watt cartridge type heating

element, requiring 240 Volt, single phase electrical service at 15 amps. Material

temperature is indicated on the thermometer on the outlet side of the heater.

The rheostat circuit consists of a bimetal timer that can be adjusted from 0 to 100% of

the heater’s wattage. The rheostat circuit is wired through a thermal limiter. This is a

safety feature that breaks the circuit to the heating element if heater block

temperature exceeds a safe level. In addition, all heaters contain 15 amp fuses in the

electrical enclosure for protection.

There are two models of the CFH-4000 in-line resin heater:

CFH-4000-B Basic Clean Flow Heater – In-Line Resin Heater

CFH-4000-AI Clean Flow Heater – In-Line Resin Heater – Air Interlock

The CFH-4000-B Basic Clean Flow Heater is the base model of the CFH heater with

a single temperature adjustment knob which allows for simple operation. Just adjust

the temperature control to the desired level to maintain the desired temperature

indicated on the thermometer.

The CFH-4000-AI Clean Flow Heater – Air Interlock is unique in that it is an on

demand type heater and uses electrical power only when there is flow. The heater is

controlled by triggering the gun, the system regulator supplies pressure to the gun

valve which in turn activates the heater when the trigger is pulled. Once material is

flowing, an air signal is supplied to heater which engages the thermostat circuit.

When controlled with the air/electrical interlock heater switch, The CFH heaters

require a minimum of 15 psi air. The heat element is supplied with current from two

separate air circuits: the preheat circuit and gun trigger circuit. A preheat circuit is

operated to manually warm the heater block to desired operating temperature before

start-up.

Page 5

5

CHAPTER

2

CFH-4000 IN-LINE RESIN HEATER MANUAL

OPERATION

To operate the CFH heater, just set the temperature control to mid-position or to the

desired position if the setting is known.

Heater is now ready.

To preheat the CFH-4000-AI (system with air interlock) press the preheat button and

hold until heater block feels warm to the touch. This insures resin is heated from

start-up to stop. If this system sets idle for a long period of time it may need to be

preheated again before use.

Using heat with polyester resin systems allows control of the spray pattern through

reduced viscosity while breaking up material particles, thereby giving better, more

desirable wetting characteristics. As it is highly accurate, material can be controlled

within plus or minus 3° F in continuous use.

If the spray pattern is too coarse and narrow, set heat higher, If too fine and thin, set

heat lower. Once resin in hose has been replaced by resin in heater, it will be

possible to determine if block heat has been set properly. The thermometer on outlet

side will also determine what temperature it is operating at. DO NOT EXCEED 135° F

OUTLET TEMPERATURE.

(Proper setting will vary with ambient room temperatures, flow rates and

characteristics of each resin or gel coat)

When highly promoted resins are used, it is advisable to pump cool resin through

heater after power has been removed from the heater. These resins could easily gel

if left at high temperature in block for an extended period. Anticipate your cut-off and

you will be able to use it all. Use preheat button again before starting.

When used on automatic heads, the heater should be connected to automatic gun

trigger circuit; if preheat transfer pump, connect to pump control.

Page 6

6

CHAPTER

3

CFH-4000 IN-LINE RESIN HEATER MANUAL

MAINTENANCE

(Refer to Parts Drawings)

1. Periodically, the heater should be flushed out by pumping solvent through,

2. Inspect electrical cord for wear or damage and repair or replace as necessary.

3. Inspect hoses attached to the heater for wear of damage and replace

4. Check heater and hoses for leaks and replace periodically.

ALWAYS DISCONNECT POWER AND NEVER FLUSH WITH SOLVENT UNTIL

HEATER HAS COOLED TO ROOM TEMPERATURE. PRESSURE NOT TO

EXCEED 2500 PSI

especially with gel coat or filled resin systems.

periodically.

Page 7

7

CHAPTER

4

CFH-4000 IN-LINE RESIN HEATER MANUAL

TROUBLESHOOTING INSTRUCTIONS

Two basic problems may occur with the MVP Resin Heater:

Loss of electrical current or heat

Material flow blockage or leakage.

Loss of Electrical Current or Heat:

1. Indicator Light: If indicator light is not sequencing during operation, try preheat

button to see if light comes on. If not, inspect bulb and replace if defective. Also,

check diodes for continuity. If light does not operate and no heat is generated in the

heater and diodes are OK, then

DISCONNECT POWER FROM THE UNIT.

2. Fuses: Remove lid to electrical enclosure and check all fuses to insure they have

not blown out. If so, replace.

3. Loose Wire: Check all connections for loose or disconnected terminals.

4. Rheostat: NOTE: Air must be ON for rheostat check. If rheostat controlled function

is not working, disconnect wires and check continuity through rheostat when it is cool.

If there is continuity-check that it’s getting current from normally open contacts of

microswitch. If no continuity through rheostat, it is faulty and must be replaced. If

neither preheat or thermostat function works, check fuses first, then make sure pilot

light is not burned out (remove bulb and inspect).

5. Thermal Limiter: Once fuses and rest of circuit has checked out, disconnect wires

and check continuity through thermal limiter when it is cool. If there is no continuity

through switch when cool (room temp. 70° F) it is faulty and must be replaced.

Heat limiter may be adjusted to trip at different levels and may need readjustment.

MVP factory setting is to trip at approx. 120° F.

Page 8

8

6. Heating Element: If all components to this point check out, heating element is

faulty. Heater element should be checked for leakage to ground and continuity

through element.

CFH-4000-AI Air Interlock units:

7. Air Switch: Disconnect wires and check microswitch to ensure continuity through

normally closed contacts when air supply is off.

If there is no continuity, inspect air actuator to insure it is disengaging. If air actuator

disengages properly, switch is faulty and must be replaced. Next apply air pressure

(at least 30 psi) to air actuator.

Check continuity through normally open contacts. If none, check actuator to insure it

is engaging switch. If not, a small amount of oil may free actuating cylinder or it may

be adjusted if not engaging far enough. If actuator is engaging switch properly but

there is no continuity through normally open contacts, switch is faulty and must be

replaced.

8. Preheat Air Valve / Button: Check that the air valve has a constant air supply,

20psi minimum. Disconnect the outlet air line and make sure that an air signal is sent

when the button is pushed. If no signal air is sent when the button is pushed, check

the valve for blockages and replace as necessary.

Material Flow Blockage and Leakage Problems:

1. If heater is completely blocked, the end caps should be removed and resin

passages thoroughly cleaned. Make sure the passages in the end caps are clean as

well. Fittings into and out of heater should also be cleaned.

2. In case of leakage, check that perimeter end cap bolts are correctly tightened at 60

ft/lb. If so, remove end caps and inspect O-rings, Clean O-ring groove thoroughly.

Page 9

9

CHAPTER

5

PATRIOT TESTING AND ADJUSTING MANUAL

PARTS DRAWINGS:

CFH-4000-B BASIC CLEAN FLOW HEATER

CFH-4000-AI CLEAN FLOW HEATER – AIR INTERLOCK

CFH-AIDS CLEAN FLOW HEATER – DOUBLE STACK

Page 10

10

MAGNUM VENUS PRODUCTS

Resin Heater - Basic Clean Flow Heater

CFH-4000-B

14

2

3

4

5

6

7

7

8

9

10

11

12

13

1

15

16

16

17

18

19

20

21

22

21

22

23

23

24

25

26

27

28

28

29

3031

32

33

34

36

37

L1

G

L2

240V AC

MOUNTING SCREW

GROUND BOX

2

33

33

34

4

14

ELECTRICAL

DIAGRAM

PART OF 34

47

38

REV.

1 BRUSH ANTI SEIZE ON CHF-3079 TIE RODS

TO FILL THE THREADS. TORQUE THE

F-HN-08F NUTS TO 60 FT/LBS

1

1

C = ADDED ANTI SEIZE FLAG NOTE 02/08/06 JEM

REV.

D = TORQUE VALUVE IN FLAG NOT WAS 80 FT/LBS 03/02/07 JEM

E = ADDED ITEMS NOT SHOWN TO P/L 03/22/07 JEM

REV.

46

Page 11

11

1

MPD-9750-03

14

MIXER ELEMENT

PARTS LIST

Resin Heater - Basic Clean Flow Heater CFH-4000-B

PART NO.

ITEM

QTY DESCRIPTION

2

09302

1

PILOT LIGHT

3

CFH-3076 1

ELECT BOX LID

4

9804-1-1

1

THERMOSTAT

5

CFH-3075

1

ELECTRICAL BOX

6

PF-HN-08 1

HEX NIPPLE

7

PF-HN-08-08J 2

HEX NIPPLE

8

PF-FT-08 1

TEE

9

CFH-3079 6

TIE ROD

10

PF-RB-08-04

1

BUSHING

11

9212-1-1

1

THERMOMETER

12

F-HN-08F-GR8 12

HEX NUT

13

F-CS-05C-12 8

SOCKET HEAD CAP SCREW

14

CFH-3081

1

CARTRIDGE HEATER

15

CFH-3070 1 HEATER CORE

16

CFH-3078 2

END CAP

17

F-CS-05C-16 4

SOCKET HEAD CAP SCREW

18

CFH-3086 1

CLAMP

19

F-MS-1032-08 1

PAN HEAD SCREW

20

F-STS-632-06

4

SELF TAPPING SCREW

21

O-T-127

2

O-RING

22

O-T-154 2

O-RING

23

PF-AP-12 2

HEX SOCKET PIPE PLUG

24

F-UB-06C-40

2

U-BOLT

25

F-HN-06C 4 HEX NUT

26

F-FW-08-Z 12

WASHER

27

CFH-3089 1

MOUNT BRACKET

28

F-FW-06 7

WASHER

29

F-HB-06C-12 3

HEX BOLT

30

09592

2

DIODE

31

00353

4

CONNECTOR

32

E-FB-101 1

FUSE BLOCK

33

09603 2

15 AMP FUSE

34

CFH-3087 1 THERMOSTAT ASSY

36

CFH-3091 1 THERMOSTAT DECAL

37

PF-SE-08

1

STREET ELBOW

1

1

F-HN-08F NUTS TO 60 FT/LBS

TO FILL THE THREADS. TORQUE THE

BRUSH ANTI SEIZE ON CHF-3079 TIE RODS1

47

09806 1

LAMP

PART NO.

ITEM

QTY

DESCRIPTION

OPTIONAL PARTS AND ASSEMBLIES

43

6701-27-1 1

ELEC DECAL (NOT SHOWN)

44

CFH-DECAL-1 1

MVP DECAL (NOT SHOWN)

45

CFH-DECAL-3

1

WARNING DECAL (NOT SHOWN)

46

F-GS-832-04

1

GROUND

42

09848

2.00 FT

14 GA. WIRE (NOT SHOWN)

41

08247-W .60 FT

WIRE (NOT SHOWN)

40

08247-BK 1.25 FT

WIRE (NOT SHOWN)

39

09119 1

PLUG

38

F-RP-04-12=SS 4

ROLL PIN (INSTALLED IN END CAPS)

Page 12

12

3

39

40

41

42

43

44

45

46

47

48

48

49

50

C

AIR SIGNAL

FROM GUN

NC

NO

39

1 BRUSH ANTI SEIZE ON CFH-3079 TIE RODS

TO FILL THE THREADS. TORQUE THE

F-HN-08F-GR8 NUTS TO 60 FT/LBS

D = ADDED TORQUE VALUE FLAG NOTE TO DWG, 3/2/07 JEMREV.

58

REV. E = ADDED (NOT SHOWN ITEMS TO DWG, 3/22/07 JEM

60

60

F = ADDED ITEM 60 TO DWG 6/20/07 JEMREV.

MAGNUM VENUS PRODUCTS

Resin Heater Assy - Air Interlock

CFH-4000-AI

14

2

4

5

6

7

7

8

9

10

11

12

13

1

15

16

16

17

18

19

20

21

22

21

22

23

23

24

25

26

27

28

28

29

3031

32

33

34

36

37

L1

G

L2

240V AC

MOUNTING SCREW

GROUND BOX

2

33

33

34

4

14

ELECTRICAL

DIAGRAM

PART OF 34

59

Page 13

13

1

MPD-9750-03

14

MIXER ELEMENT

PARTS LIST

Resin Heater Assy - Air Interlock CFH-4000-AI

PART NO.

ITEM

QTY

DESCRIPTION

2

09302 1

PILOT LIGHT

3

CFH-3076 1

ELECT BOX LID

4

9804-1-1

1

THERMOSTAT

5

CFH-3075

1

ELECTRICAL BOX

6

PF-HN-08

1

HEX NIPPLE

7

PF-HN-08-08J 2

HEX NIPPLE

8

PF-FT-08 1

TEE

9

CFH-3079

6

TIE ROD

10

PF-RB-08-04

1

BUSHING

11

9212-1-1

1

THERMOMETER

12

F-HN-08F-GR8 12

HEX NUT

13

F-CS-05C-12 8

SOCKET HEAD CAP SCREW

14

CFH-3081

1

CARTRIDGE HEATER

15

CFH-3070

1

HEATER CORE

16

CFH-3078

2

END CAP

17

F-CS-05C-16 4

SOCKET HEAD CAP SCREW

18

CFH-3086 1

CLAMP

19

F-MS-1032-08

1

PAN HEAD SCREW

20

F-STS-632-06

4

SELF TAPPING SCREW

21

O-T-127

2

O-RING

22

O-T-154 2

O-RING

23

PF-AP-12

2

HEX SOCKET PIPE PLUG

24

F-UB-06C-40 2

U-BOLT

25

F-HN-06C 4

HEX NUT

26

F-FW-08-Z

12

WASHER

27

CFH-3089 1

MOUNT BRACKET

28

F-FW-06

7

WASHER

29

F-HB-06C-12 3

HEX BOLT

30

09592 2

DIODE

31

00353

4

CONNECTOR

32

E-FB-101 1

FUSE BLOCK

33

09603

2

15 AMP FUSE

34

CFH-3087 1

THERMOSTAT ASSY

36

CFH-3091 1

THERMOSTAT DECAL

37

PF-SE-08

1

STREET ELBOW

39

9807-2-1

1

PRESSURE SWITCH

40

9807-1-1 1

PILOT OPERATOR

41

7701-3-28 1

PUSH FITTING

42

7701-3-29

1

PUSH FITTING

43

7701-3-30 1

FLAME ARRESTOR

44

PF-RB-04-02

1

PIPE BUSHING

45

8407-3-1

1

SHUTTLE VALVE

46

PF-HN-02

1

HEX NIPPLE

47

8407-4-1 1

3-WAY VALVE

48

MPH-2534

2

POLY ELBOW

49

8407-5-1 1

PUSH BUTTON

50

7102-24-16

2

SELF TAPPING SCREW

F-HN-08F-GR8 NUTS TO 60 FT/LBS

TO FILL THE THREADS. TORQUE THE

BRUSH ANTI SEIZE ON CFH-3079 TIE RODS1

1

1

OPTIONAL PARTS AND ASSEMBLIES

DESCRIPTIONQTY

ITEM

PART NO.

59

09806 1 LAMP

51

08247-BK 1.25 FT

WIRE (NOT SHOWN)

52

08247-W

.60 FT

WIRE (NOT SHOWN)

53

09848

2.00 FT

14 GA. WIRE (NOT SHOWN)

38

F-RP-04-12=SS 4 ROLL PIN (INSTALLED IN END CAPS)

58

F-GS-832-04

1

GROUND

57

CFH-DECAL-3 1

WARNING DECAL (NOT SHOWN)

56

CFH-DECAL-2

1

CE DECAL (NOT SHOWN)

55

CFH-DECAL-1 1

MVP DECAL (NOT SHOWN)

54

6701-27-1 1

ELEC DECAL (NOT SHOWN)

60

08810

.833 FT

POLY TUBE

Page 14

14

1

MAGNUM VENUS PRODUCTS

ASSY - DOUBLE STACK CFH HEATER

REV. - 11/14/06 JEM

CFH-4000-AIDS

2

3

4

5

6

6

7

8

8

8

8

11

9

9

9

11

9

10

1

F-HN-08F-GR8 NUTS TO 60 FT/LBS

TO FILL THE THREADS. TORQUE THE

BRUSH ANTI SEIZE ON CFH-3079 TIE RODS1

A = ADDED TORQUE VALUE FLAG NOTE TO DWG. 3/2/07REV.

Page 15

15

1

CFH-4000-AI

2

HEATER ASSY

PARTS LIST

ASSY - DOUBLE STACK CFH HEATER CFH-4000-AIDS

PART NO.

ITEM

QTY

DESCRIPTION

2

60950-1

1

MOUNTING BRACKET

3

COL-CLMP 2 COLUMN CLAMP

4

F-HB-06C-40-GR5

4 HEX BLOT

5

F-HB-06C-20 8

HEX BOLT

6

F-HB-06C-20 12

HEX NUT

7

F-SW-06 8

LOCK WASHER

8

HAW-08 3FT

RESIN HOSE

9

390H-08248 8

SWEDGE ON HOSE FITTING

10

2103-8-10

2

PARKER ELBOW - HOSE TO PIPE

11

033T-8-8

2

PARKER HOSE TEE

1 BRUSH ANTI SEIZE ON CFH-3079 TIE RODS

TO FILL THE THREADS. TORQUE THE

F-HN-08F-GR8 NUTS TO 60 FT/LBS

1

Page 16

16

Page 17

17

Corporate HQ/Mfg. Manufacturing/Sales

5148 113th Ave. 1862 Ives Ave.

Clearwater, FL 33760 Kent, WA 98032

Ph: 727-573-2955 Ph: 253-854-2660

Fax: 727-571-3636 Fax: 253-854-1666

E-mail: info@mvpind.com

Web: www.mvpind.com

Loading...

Loading...