Page 1

MS-CEFB

Filter Box

Magnum Energy, Inc.

2211 West Casino Rd.

Everett, WA 98204

Phone: 425-353-8833

Fax: 425-353-8390

Web:

http://magnumenergy.com

Installation Guide

Page 2

Introduction

Introduction

The CE Filter Box (PN: MS-CEFB) is an EMI (electromagnetic interference)

fi lter designed to control conducted emissions on the AC and DC side of

Magnum Energy’s MS-E and MS-PE Series inverters. It is used to ensure that

stringent international standards for electromagnetic compatibility (EMC)

are met. For specifi c EU directives and standards see info on the back page.

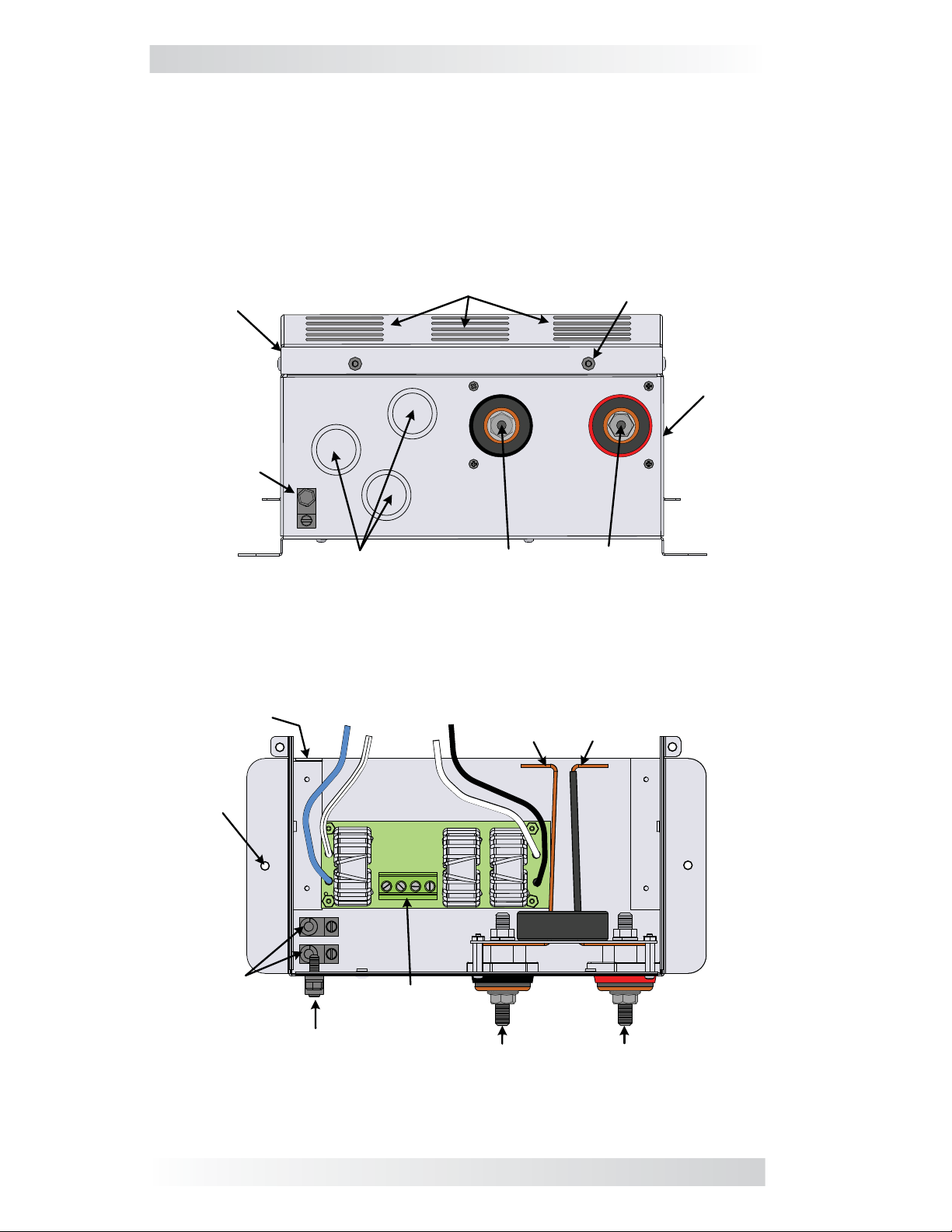

Refer to Figures 1 & 2 below to identify the MS-CEFB fi lter box’s features.

Top

Cover

DC

Ground

Connection

Inner Flange

Air Intake Vents

Dual knockouts (x3)

(1.9 and 2.5 cm)

Negative DC

Terminal

Cover screws (x4)

(#25 Torx)

Positive DC

Terminal

Figure 1, MS-CEFB Front Side Features

AC Output

Wires

AC Input

Wires

Negative DC

Busbar

Positive DC

Busbar

Filter

Base

Mounting

Holes (x2)

Toroid

AC

Ground

Connections

Ground

Connection

AC Input/Output

Terminal Block

DC

Negative DC

Terminal

Positive DC

Terminal

Figure 2, MS-CEFB Inside Features

1 © 2014 Magnum Energy, Inc.

Page 3

Introduction

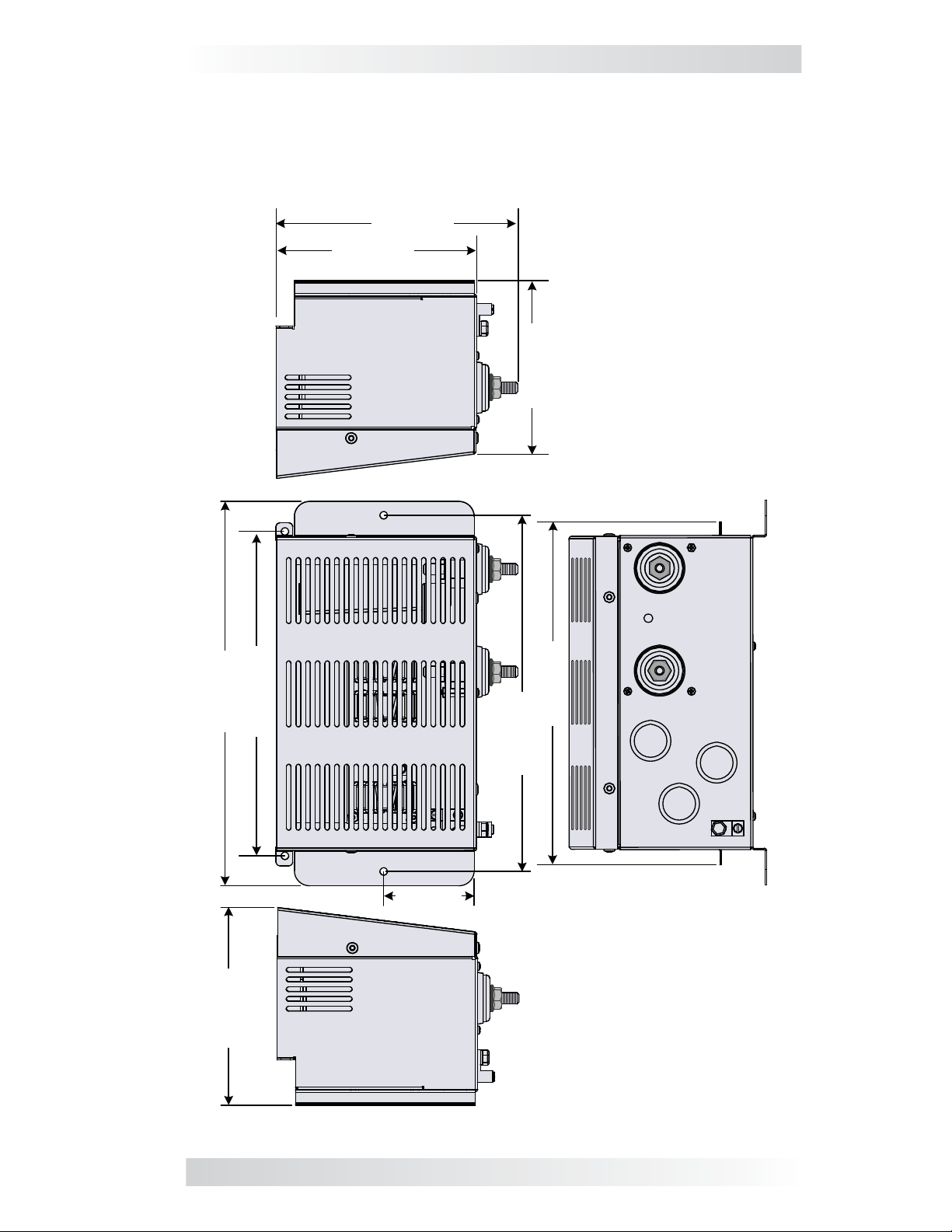

Knockouts and Dimensions

The MS-CEFB provides knockouts for use with ¾” and 1” trade size* conduit,

and adds just over 20 cm to the length of the inverter (see Figure 3).

* – “Trade size” refers to standard North American conduit. Actual openings

are approximately 2 cm and 2.7 cm.

20.3 cm

16.8 cm

14.5 cm

Right Side

Note: All four mounting

holes are approx. 6.4 mm (¼”)

Top

32.1 cm

16.5 cm

27.1 cm

28.7 cm

29.8 cm

7.6 cm

Left Side

Figure 3, MS-CEFB Dimensions

Front

© 2014 Magnum Energy, Inc. 2

Page 4

Installation

AC

RANSFER

T

S

WITCH

UTILITY POWER

(230VAC OUTPUT)

GENERATOR POWER

(230VAC OUTPUT)

MS-CEFB WITH

M

AGNUM INVERTER

230VAC POWER

TO INVERTER

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

MAIN PANEL

230VAC PASS-THRU

POWER TO SUB-PANEL

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

SUB-PANEL

ME-ARC

DC

HUNT

S

BTS

BATTERY BANK

DC

REAKER

B

Figure 4, Simplifi ed Installation Diagram

3 © 2014 Magnum Energy, Inc.

Page 5

Installation

Installation

CAUTION: Before installation, closely read and review all safety

information and procedures in this guide and in your inverter

owner’s manual.

WARNING: The inverter uses power from both AC and DC sources.

Before beginning the installation, ensure all AC power (utility/generator) and any negative/positive battery cables are safely disconnected from the inverter.

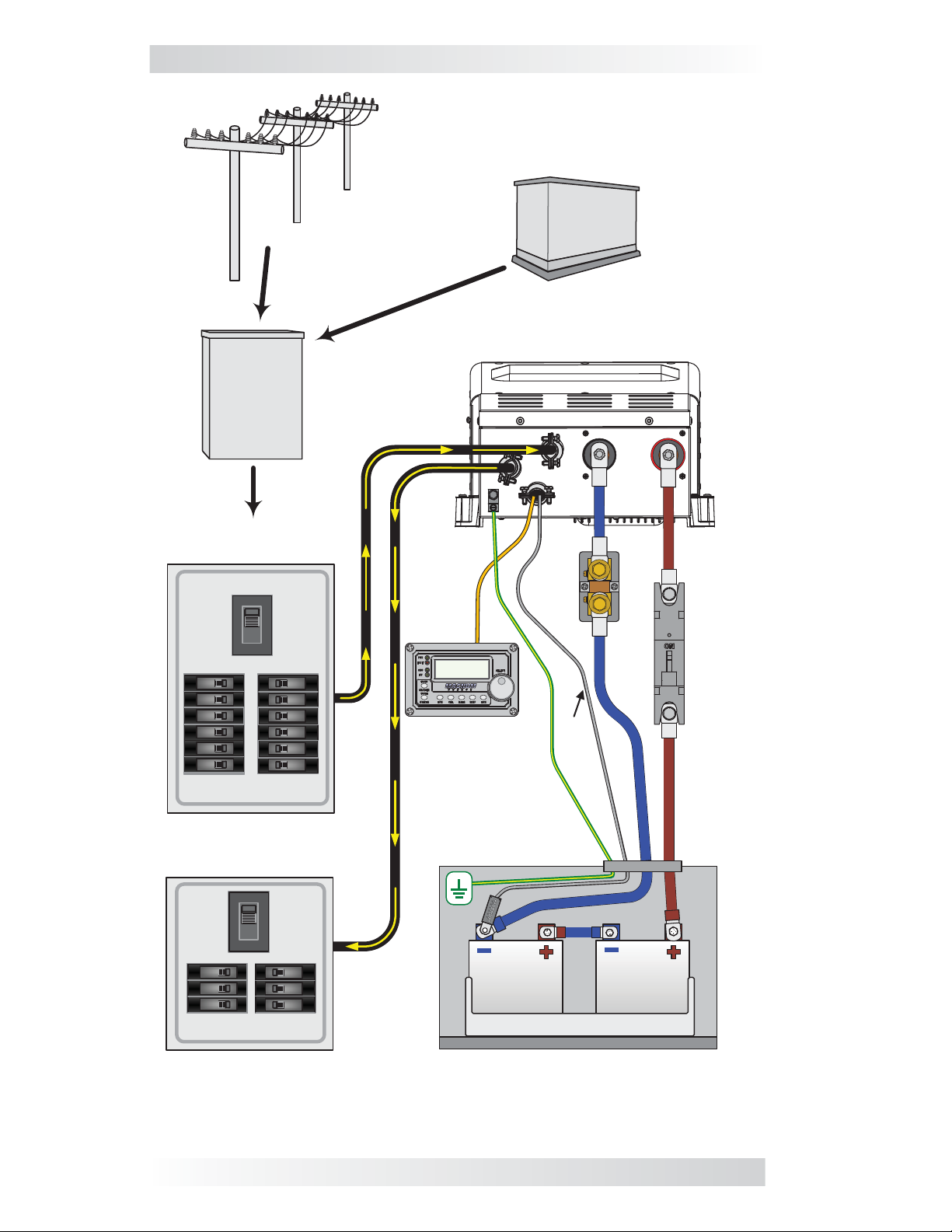

Review the simplifi ed system diagram shown in Figure 4 to assist you in

planning and designing your installation. This drawing is not intended to

override or restrict any national or local electrical codes. This drawing should

not be the determining factor as to whether the installation is compliant,

that is the responsibility of the electrician and the on-site inspector.

Safety Requirements

• The MS-CEFB should be reliably and permanently grounded (i.e., earthed)

to the system’s earth terminal. No plug or socket connection of the ground

wire is allowed.

• The EMI (electromagnetic interference) fi lter should be grounded before

connecting any power to the MS-CEFB. This bleeds relatively high leakage

currents through the fi lter common-mode capacitors to safety ground,

and removes hazardous voltage potentials from the fi lter body.

Installation Considerations

• In all installations, the inverter and the MS-CEFB should be installed

on the same metallic ground plane. Ensure all metal mating surfaces

used for connecting the inverter to the MS-CEFB are clean of paint, oil

or grease.

• It is recommended that equipment sensitive to EMI should be kept at

least 25 cm away.

• Any communication cable (remote, network, stacking and BTS) should

be separated from the AC IN and AC OUT power cables. Parallel runs of

cables should be avoided when possible. Cross-over of all cables should

be done at 90 degrees.

Unpacking and Inspection

Carefully remove the MS-CEFB fi lter box from the shipping container and

inspect all contents. Verify the following are included:

• MS-CEFB fi lter box

• Ferrite core

• DC terminal insulators (one black, one red)

• MS-CEFB Owner’s Manual

If items appear to be missing or damaged, contact your authorized Magnum

dealer or Magnum Energy. Save your proof-of-purchase as a record of ownership;

it will be needed if the unit should require in-warranty service.

Tools Needed

• #2 Phillips screwdriver • 1/2” wrench/socket

• 3/16” (≤4.8 mm) fl at-bladed screwdriver • 11/16” wrench/socket

• 7/16” wrench/socket

© 2014 Magnum Energy, Inc. 4

Page 6

Installation

MS-PE or MS-E inverter

Remove AC access cover

(#2 Phillips*)

Remove DC +/-

(1/2” Hex*)

Remove DC ground hardware

(7/16" Hex*)

Remove cover screws on each side

(#25 Torx*)

Stage I – Prepare Inverter

* Tool needed

to remove

terminal nuts

Stage II – Connect Filter Box to Inverter

Note: Before

re-attaching the

inverter’s DC

terminal nuts,

ensure the filter’s

DC busbars are

properly fitted over

the terminal bolts.

Stage III – Attach & Tighten Hardware

Figure 5, Attaching the MS-CEFB to the Inverter

5 © 2014 Magnum Energy, Inc.

Page 7

Installation

Installing the MS-CEFB

Prior to installation of the fi lter box, the inverter/charger must be prepared.

To prepare the inverter (Figure 5, Stage I):

1. Remove the inverter’s AC access cover (will need access to inside the

inverter to remove the DC ground connection and to wire AC connections).

2. Remove the inverter’s DC positive and negative terminal nuts/washers.

3. Remove the DC ground connection from the bottom left corner on the

front side of the inverter (reach into the AC terminal block compartment

to secure the hex nut while unscrewing the bolt on the outside of the

inverter using a 7/16” wrench/nut driver). Refer to Figure 6.

4. Remove the two #25 Torx screws that hold the inverter cover to the

base—located on each side of the inverter’s front.

To prepare the MS-CEFB fi lter box:

5. Detach the top cover of the fi lter box by removing the four #25 Torx

screws that secure the cover to the base.

6. Determine the AC and DC wiring through the fi lter box, and then remove

the appropriate knockouts (Figure 3).

Note: Magnum does not provide additional strain reliefs or conduit for

the knockout holes; to add either, you must supply the hardware.

To attach the MS-CEFB to the inverter (Figure 5, Stages II & III):

7. Attach the fi lter box to the inverter using the two #25 Torx screws that

were removed from the inverter cover in Step 4. Ensure the fi lter box’s

DC busbars align over the inverter’s positive and negative DC terminals.

8. Secure the fi lter box’s mounting fl anges—preferably to the same mount-

ing surface used for the inverter.

9. Re-attach the DC ground connection removed in Step 3—the ground’s

Hex screw fi ts through the inner fl ange on the fi lter box (Figure 6).

10. Re-attach and tighten the inverter’s DC positive and negative terminal

nuts/washers that were removed in Step 2—securing the fi lter box’s

DC busbars to their respective DC terminals on the inverter. Torque to

between 13.6 and 16.3 N-m (10 to 12 ft lbf).

¼-20 Hex nut*

Inverter

Int. tooth

¼”

lock washer (x2)

* Use 7/16"

wrench (or socket)

¼-20 x ¾

MS-CEFB

inner flange

Figure 6, Re-Attaching the DC Ground Hardware

© 2014 Magnum Energy, Inc. 6

Ground lug

Hex screw*

Page 8

Installation

To wire the inverter’s AC terminal block (top of Figure 7):

11. Route the fi lter box’s AC input/output wiring through the appropriate

knockouts/strain reliefs on the inverter, and then connect to the inverter’s

AC terminal block.

• Connect wire A (white w/ black stripe) to Terminal #1 (AC NEUT OUT).

• Connect wire B (blue) to Terminal #2 (AC HOT OUT).

• Connect wire C (black) to Terminal #3 (AC HOT IN).

• Connect wire D (white) to Terminal #4 (AC NEUT IN).

Tighten all to a maximum torque of 3.6 N-m (32 in lbf).

To wire the fi lter box’s AC terminal block (bottom of Figure 7):

12. Route the AC input source/output load wiring through the appropriate

knockouts/strain reliefs on the fi lter box, and then connect to the fi lter

box’s AC terminal block.

• Connect wire F (brown) to Terminal #1 (INV HOT OUT), and then

route and connect to the sub-panel.

• Connect wire G (blue) to Terminal #2 (INV NEUT OUT), and then

route and connect to the sub-panel.

• Connect wire H (blue) to Terminal #3 (INV NEUT IN), and then route

and connect to the main panel.

• Connect wire I (brown) to Terminal #4 (INV HOT IN), and then route

and connect to the main panel.

Tighten all to within a minimum/maximum torque of 1.2 N-m (10.6 in

lbf)/1.5 N-m (13.3 in lbf) – using a 3/16” (4.8 mm or less) fl at-bladed

screwdriver.

Note: The AC input source, output load, and grounds ( i.e., brown, blue,

and green with yellow stripe wires) are fi eld wires and must be provided

by the installer.

Info: Approved wire sizes for the MS-CEFB’s AC terminal block are

0.5-16 mm² (#20-6 AWG).

To wire the AC input/output grounds (bottom left of Figure 7):

13. Connect an AC ground wire from one of the fi lter box’s ground terminals

to the main panel’s ground busbar.

14. Connect another AC ground wire from the fi lter box’s other ground

terminal to the sub-panel’s ground busbar. Tighten both grounds to a

maximum torque of 5.1 N-m (45 in lbf).

Info: Approved wire sizes for the MS-CEFB’s ground terminals are

2 -33.6 mm² (#14-2 AWG) copper stranded.

To inspect the AC wiring:

1. Verify all wire runs are secured.

2. Verify strain reliefs or grommets are in place to prevent damage to the

wiring or conduit where it passes through walls or other openings.

3. Verify that all AC connections are correct, and all inverter and fi lter box

AC terminal screws are properly torqued.

4. Replace the inverter’s AC wiring access cover.

7 © 2014 Magnum Energy, Inc.

Page 9

Installation

AC NEUT OUT

(to Sub-Panel)

AC HOT OUT

(to Sub-Panel)

A

1 2 3

B

C

D

4

(from Main Panel)

AC HOT IN

(from Main Panel)

AC Terminal Block

(AC input/output wiring)

Note: AC GROUND

not needed

AC NEUT IN

MS-E

or

MS-PE Series

Inverter/Charger

MS-CEFB

B

AC GROUNDS

in/out

A

E

C

(from Main Panel)

(from Main Panel)

(to Sub-Panel)

INV NEUT OUT

(to Sub-Panel)

INV HOT OUT

1

F

Figure 7, AC Wiring

INV NEUT IN

2

3

4

H

G I

INV HOT IN

D

© 2014 Magnum Energy, Inc. 8

Page 10

Installation

To wire the MS-CEFB fi lter box to the battery bank:

1. Route the end of the positive DC battery cable from the battery bank

through the supplied red DC terminal insulator (do the same for the negative DC cable – using the black DC terminal insulator). The insulators protect the MS-CEFB’s DC terminals and can help prevent accidental shorts.

WARNING: Before connecting the DC cables from the battery bank

to the MS-CEFB, ensure DC overcurrent protection has been installed

and the correct DC voltage and polarity have been verified.

2. Connect the positive and negative battery cables to their respective terminal posts on the front of the fi lter box. When connecting the battery cables

to the fi lter’s DC terminals, the cable’s ring lug should be placed directly

against the fi lter terminal (Figure 8). Torque to 20.4 N-m (15 ft lbf).

3. Fit the red and black DC terminal insulators (that were routed over the

DC battery cables in Step 1) over their respective terminal posts.

WARNING: DO NOT close the DC circuit breaker or connect the fuse

to bring battery power to the inverter at this time. This will occur

in the Functional Test after the installation is complete.

Info: Refer to your inverter owner’s manual for the required DC

wiring sizes and overcurrent protection.

3/8"-16

SS Hex

Jam nut*

MS-CEFB DC terminal

(3/8"-16 bolt,

22 mm usable length)

3/8"

SS Flat

Battery cable

(with ring lug)

washer

3/8"

SS Spring

washer

CAUTION: Ensure nothing

is placed between the DC

terminal and ring lug.

Figure 8, MS-CEFB DC Hardware Installation

Communication Cables

When connecting a communication cable (remote, network, stacking or BTS)

to the inverter, a ferrite core must be connected to one end of the cable. A

ferrite core is shaped like a metal doughnut and is a passive electronic component used to suppress high frequency noise in electronic circuits. It is used

to reduce EMI that may be transmitting, and prevents the cable from acting

as an antenna and receiving interference from other devices.

Info: The BTS cable and another communication cable (e.g., remote

cable) can both fi t and be separately wrapped three times into a sin-

gle ferrite core. However, if using more than one cable with a single

ferrite, all must go in the same direction around the core.

* Use a 11/16" wrench

or socket

9 © 2014 Magnum Energy, Inc.

Page 11

Installation

To attach the ferrite core to a communication cable (Figure 9):

1. For each communication cable, route one end through the ferrite core

and wrap it several times around/through the core. There needs to be

at least three full turns around the ferrite core.

2. While wrapping the cable around the core, ensure the core is located as

close as possible to one end of the cable [within 2.5 to 5 cm (1-2 inches)

from the end]. The result should look something like Figure 9 below.

Note: Once the core is attached to the cable, plug the core-connected end of

the cable into the appropriate RJ11 port (Stack/Accessories, Remote, Network,

or BTS) on the inverter.

Communications

Cable

Note: Multiple cables can be wrapped

around a single ferrite core, but each

should have three full turns – ensure

each goes in same direction around core.

Ferrite

Core

Note: This end to be

connected to inverter port.

Figure 9, Ferrite Core Attached to a Communication Cable

Final Inspection

After all electrical connections to the inverter, batteries, AC source, and

sub-panel have been completed, follow the steps for the Functional Test as

directed in your inverter owner’s manual.

Note: When verifying the correct DC voltage, check the fi lter box’s positive

and negative DC terminals with a multimeter. When verifying the correct AC

output voltage, check the fi lter box’s AC terminal block NEUT OUT, HOT OUT,

and GROUND poles with a voltmeter (Figure 10 below).

Once your system passes all the steps, attach and secure the fi lter box’s cover.

AC Output

230 VAC

(± 5%)

Brown

Blue

Neutral to Ground

< 0.5 VAC

Figure 10, AC Voltage Checks

© 2014 Magnum Energy, Inc. 10

Page 12

EU Standards/Limited Warranty

EU Directives and Standards

A MS-CEFB (CE Filter Box) connected to a MS-E or MS-PE Series inverter/

charger conforms to the provisions of EMC Directive 1999/5/EEC, per:

• EN 55014-1 (2006) +A1, +A2, (> 1000W) Electromagnetic compat-

ibility – Requirements for household appliances, electric tools and similar

apparatus — Part 1: Emission

• EN 55014-2 (1997) +A1, +A2, Electromagnetic compatibility – Re-

quirements for household appliances, electric tools and similar apparatus

— Part 2: Immunity – Product family standard

• EN 61000-3-2 (2006) +A1, +A2, Electromagnetic compatibility (EMC)

— Part 3-2: Limits – Limits for harmonic current emissions (equipment

input current ≤16 amps per phase)

Additionally, these products conform to the C-Tick Mark requirements based

on the provisions in standard AS/NZS CISPR 14-1:2005.

Limited Warranty

Magnum Energy, Inc. warrants the CE Filter box for a maximum of 12 months

from the product’s original date of purchase according to the following terms

and conditions:

1. The limited warranty extends to the original purchaser of the product and

is not assignable or transferable to any subsequent purchaser.

2. During the limited warranty period, Magnum Energy will repair or replace

at Magnum Energy’s option any defective parts, or any parts that will not

properly operate for their intended use with factory new or remanufactured replacement items—if such repair or replacement is needed because

of product malfunction or failure during normal usage. The limited warranty does not cover defects in cosmetic appearance, or any decorative,

structural, or non-operative parts. Magnum Energy’s limit of liability

under the warranty shall be the actual cash value of the product at the

time the original purchaser returns the product for repair—determined

by the price paid by the original purchaser. Magnum Energy shall not be

liable for any other losses or damages.

3. Upon request from Magnum Energy, the original purchaser must prove

the product’s original date of purchase by providing a dated bill of sale

or itemized receipt.

4. This limited warranty is voided if:

• the product has been modifi ed without authorization;

• the product has been damaged through abuse, neglect, accident, or

corrosion;

• the product was not installed according to this installation guide.

11

PN: 64-0066 Rev A

Loading...

Loading...