Page 1

Magnum Panels (MP) AC/DC Distribution Enclosures

Owner’s Manual

Page 2

Disclaimer of Liability

The

use of this manual and the conditions or methods of installation, operation, use and maintenance

of the Magnum Panel is beyond the control of Magnum Energy, Inc. Therefore, this company does

not assume responsibility and expressly disclaims liability for loss, damage, or expense, whether

direct, indirect, consequential or incidental, arising out of or anyway connected with such installation,

operation, use, or maintenance.

Note as well that while every precaution has been taken to ensure the accuracy of the contents

of this manual, the specifi cations and product functionality may change without notice. Magnum

Energy, Inc. assumes no responsibility for errors or omissions.

Restrictions on Use

Magnum Energy, Inc. does not recommend the use of any o

life saving, or other medical equipment or devices designated as “critical” by the U.S. FDA where

failure or malfunction of the Magnum Energy product can be reasonably expected to cause failure

of the life support device, or to signifi cantly affect its safety or effectiveness. Using Magnum Energy

products with this particular equipment is at your own risk.

f its products with life support systems,

Copyright Notice

Copyright © 2011 by Magnum Energy, Inc. All rights reserved. Permission to copy, distribute and/

or m

odify this document is prohibited unless express written permission from Magnum Energy, Inc.

is provided.

Contact Information

Magnum Energy, Inc.

2211 West Casino Rd.

Everett, WA 98204

Phone: 425-353-8833

F

ax: 425-353-8390

Web: www.MagnumEnergy.com

Statement of Appreciation

From all of us at Magnum Energy -

Thank you for purchasing this Magnum Panel (MP).

We

understand that you have many purchasing options in the marketplace, and are pleased that you

have decided on a Magnum Energy product. This MP enclosure was proudly designed, assembled

and tested in the United States at our Everett, Washington facility.

At Magnum, we are committed to providing you with quality products and services; we hope that

your experience with us is pleasant and professional.

Page i

Magnum Energy® is a registered trademark of Magnum Energy, Inc.

© 2010 Magnum Energy, Inc.

Page 3

Table of Contents

1.0 Safety Information

1.1 Safety Symbols .................................................................................... v

1.2 General Safety ..................................................................................... v

1.3 Battery Safety ......................................................................................vi

................................................................... v

2.0 Introduction ............................................................................. 1

2.1 MP Series Overview .............................................................................. 1

2.2 Regulatory Compliance .......................................................................... 6

2.3 MP External Components ....................................................................... 7

2.4 MP Internal Components ........................................................................ 9

3.0 Installation ............................................................................ 17

3.1 Pre-Installation ................................................................................... 17

3.2 Location ............................................................................................ 22

3.3 Preparing the MP Enclosure and Inverter ................................................ 25

3.4 Mounting the MP/Inverter System ......................................................... 31

3.5 Wiring the MP Enclosures ..................................................................... 36

3.6 AC Wiring .......................................................................................... 38

3.7 DC Wiring .......................................................................................... 44

3.8 Wiring Accessories .............................................................................. 51

3.9 Removing the NEUTRAL-GROUND Wire .................................................. 53

3.10 Removing the NEGATIVE-GROUND Busbar ............................................. 54

3.11 MP/Inverter System Grounding ............................................................. 55

3.12 Installation Checklist ........................................................................... 59

3.13 Functional Test ................................................................................... 61

3.14 Attaching Front Covers ........................................................................ 66

3.15 Master/Slave Identifi cation Label Set ..................................................... 67

4.0 Wiring Diagrams .................................................................... 68

5.0 Operation ............................................................................... 93

5.1 Inverter DC Disconnect Breaker ............................................................ 94

5.2 Inverter AC Input Breaker .................................................................... 94

5.3 Bypass Switch Assembly ...................................................................... 94

Appendix A - Misc. Info and Optional Equipment/Accessories ........ 97

A1 Installing the Charge Controller Bracket ................................................. 97

A2 Installing a Battery Monitor .................................................................100

A3 Inverter Hood Info .............................................................................102

A4 Router Bracket Info ...........................................................................102

A5 Knockout Plate ..................................................................................104

A6 Installing Optional DC Breakers ...........................................................105

A7 Installing Optional AC Load Breakers ....................................................107

A8 Aligning Front Breaker Face Plate .........................................................108

A9 Optional Router Front Top Cover ..........................................................109

A10 Installing Lightning Arrestors ...............................................................110

Appendix B - Warranty and Service .............................................. 112

B1 Limited Warranty ...............................................................................112

B2 How to Receive Repair Service .............................................................112

© 2010 Magnum Energy, Inc.

Page ii

Page 4

List of Figures

Figure 2-1a, MPSL-30D as Shipped ................................................................................................

Figure 2-1b, MPSL-30D with Field Installed Options ..........................................................................2

Figure 2-2a, MPSL-60S as Shipped .................................................................................................3

Figure 2-2b, MPSL-60S with Field Installed Options ..........................................................................3

Figure 2-3a, MPSH-30D as Shipped ................................................................................................4

Figure 2-3b, MPSH-30D with Field Installed Options .........................................................................4

Figure 2-4a, MPDH-30D as Shipped ...............................................................................................5

Figure 2-4b, MPDH-30D with Field Installed Options .........................................................................5

Figure 2-5, MPSL and MPSH External Components ...........................................................................7

Figure 2-6, MPDH External Components .........................................................................................8

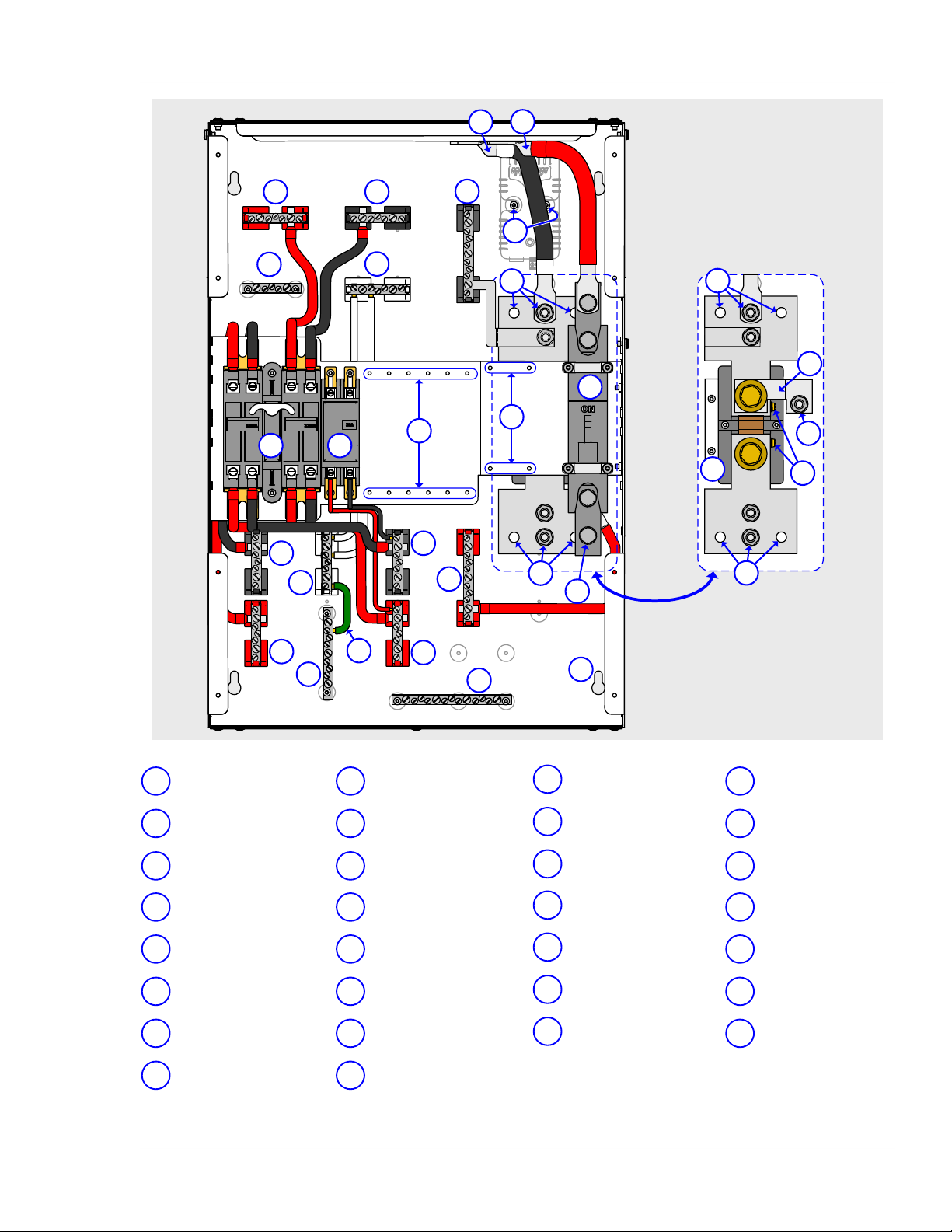

Figure 2-7, MPSL-30D Internal Components .................................................................................. 12

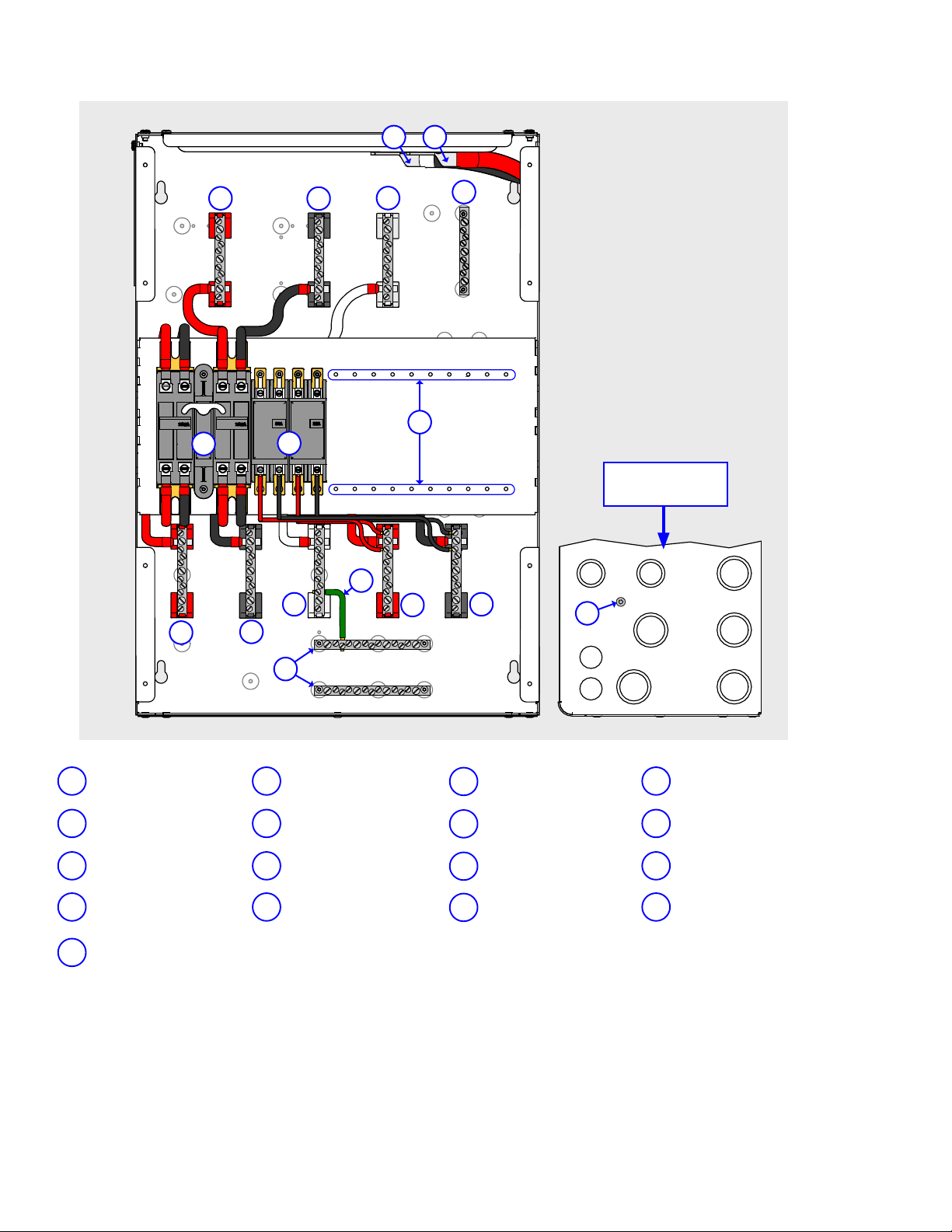

Figure 2-8, MPSL-60S Internal Components .................................................................................. 13

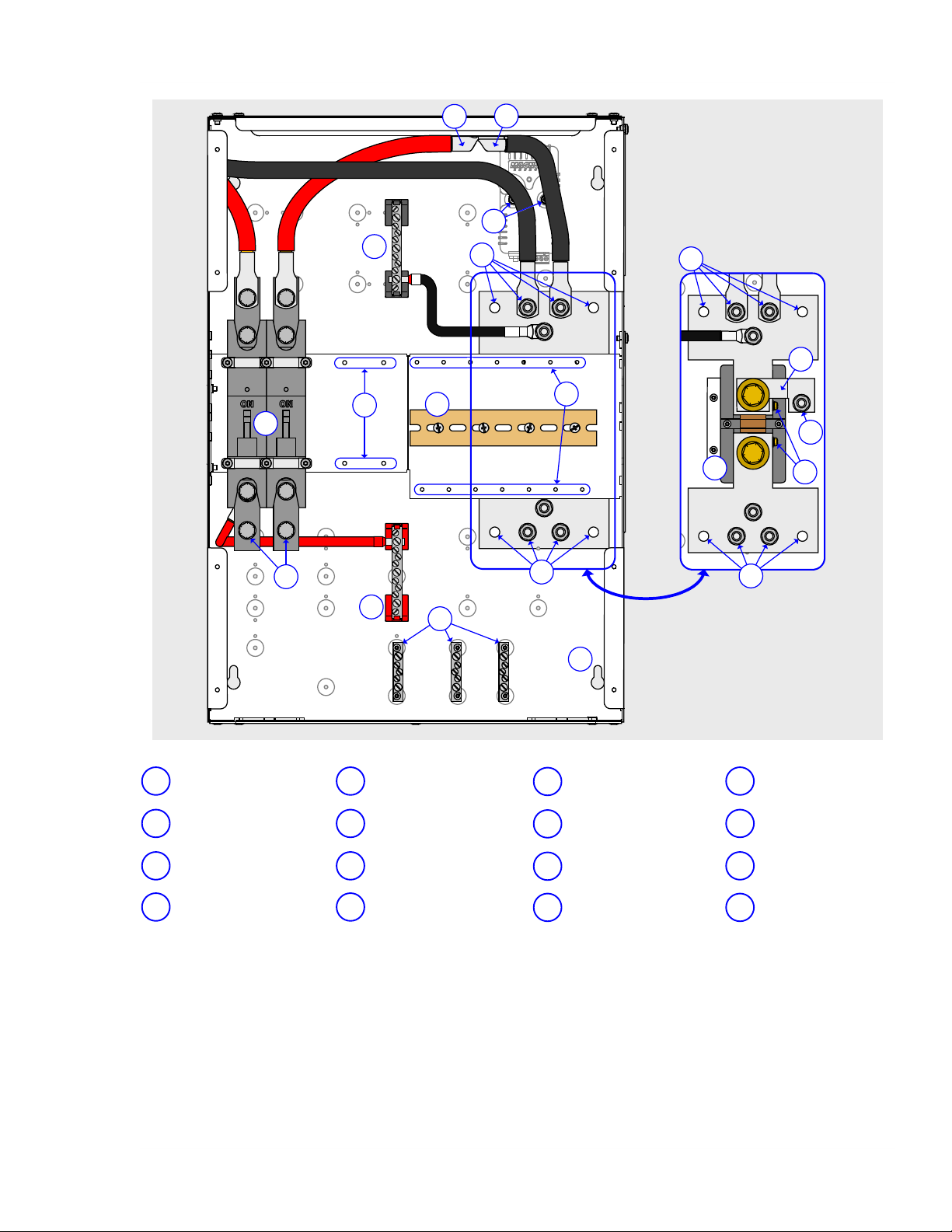

Figure 2-9, MPSH-30D Internal Components ................................................................................. 14

Figure 2-10a, MPDH-30D (AC Side) Internal Components ............................................................... 15

Figure 2-10b, MPDH-30D (DC Side) Internal Components ............................................................... 16

Figure 3-1, Parts Included - MPSL and MPSH Models ...................................................................... 18

Figure 3-2, Parts Included - MPDH Models ..................................................................................... 18

Figure 3-3, MP Series Simplifi ed Parallel-Stacked Installation Diagram .............................................. 20

Figure 3-4, MP Series Simplifi ed Series-Stacked Installation Diagram ............................................... 21

Figure 3-5, System Dimensions (Single Enclosure) ......................................................................... 23

Figure 3-6, System Dimensions (Dual Enclosure) ........................................................................... 24

Figure 3-7, Front Cover Screws to Remove .................................................................................... 25

Figure 3-8, Removing Front Cover - Single Enclosure...................................................................... 26

Figure 3-9, Removing Front Covers - Dual Enclosure ...................................................................... 26

Figure 3-10, Conduit/Wire Routing ............................................................................................... 27

Figure 3-11, Removing Knockouts ................................................................................................ 28

Figure 3-12, Connect and Separate Inverter AC Wires .................................................................... 28

Figure 3-13, MPSL/MPSH Dimensions and Knockout Location/Sizes .................................................. 29

Figure 3-14, MPDH Dimensions and Knockout Location/Sizes ........................................................... 30

Figure 3-15a, Mounting the MP Single Enclosure ............................................................................ 31

Figure 3-15b, Mounting Inverter - MP Single Enclosure ................................................................... 32

Figure 3-15c, Mounting Inverter Hood - MP Single Enclosure ........................................................... 32

Figure 3-16a, Mounting the MP Dual Enclosure (DC Side) ................................................................ 33

Figure 3-16b, Mounting the MP Dual Enclosure (AC Side) ................................................................ 33

Figure 3-16c, Connecting the Two Sides Together - MP Dual Enclosure .............................................. 34

Figure 3-16d, Mounting First Inverter - MP Dual Enclosure .............................................................. 34

Figure 3-16e, Mounting Second Inverter - MP Dual Enclosure .......................................................... 35

Figure 3-16f, Mounting the Inverter Hoods - MP Dual Enclosure ....................................................... 35

Figure 3-17, MPSL-30D and MPSH-30D AC Wiring Connections ........................................................ 41

Figure 3-18, MPSL-60S AC Wiring Connections .............................................................................. 42

Figure 3-19, MPDH-30D AC Wiring Connections ............................................................................. 43

Figure 3-20, DC Hardware Connections ........................................................................................ 46

Figure 3-21, DC Wiring Connection Points for MPSL Models ............................................................. 48

Figure 3-22, DC Wiring Connection Points for MPSH-30D ................................................................. 49

Figure 3-23, DC Wiring Connection Points for MPDH-30D (DC Side) .................................................. 50

Figure 3-24, REMOTE Communication Cable (300V Rated) .............................................................. 51

Figure 3-25, NETWORK Communication Cable (300V Rated) ............................................................. 51

Figure 3-26, Extension Cable (300V Rated) .................................................................................... 51

Figure 3-27, Accessory Wiring Using 300 Volt Communications Cables .............................................. 52

Figure 3-28, Removing the NEUTRAL-GROUND Wire ....................................................................... 53

Figure 3-29, Removing the NEGATIVE-GROUND Busbar .................................................................. 54

Figure 3-30, Grounding System for Inverter with MP Enclosure ........................................................ 55

Figure 3-31, Single Connection to DC Ground Rod (Method 1) ......................................................... 56

Figure 3-32, Multiple Connections to DC Ground Rod (Method 2) ...................................................... 57

Figure

3-33, Multiple Connections to DC Ground Rod (Method 3) ...................................................... 57

Figure 3-34, DC V

Figure 3-35, DC V

Figure 3-36, AC Voltage Checks - MPSL-30D and MPSH-30D Models ................................................. 63

Figure 3-37, AC Voltage Checks - MPSL-60S Models ....................................................................... 64

Figure 3-38, AC Voltage Checks - MPDH-30D (AC Side) Models ........................................................ 65

Figure 3-39, Attaching Front Cover - MPSL/MPSH Models ................................................................ 66

oltage Checks - Single Enclosures

oltage Checks - Dual Enclosures (DC Side) ........................................................... 61

.......................................................................

61

2

Page iii

© 2010 Magnum Energy, Inc.

Page 5

Figure 3-40, Attaching Front Covers - MPDH Models ....................................................................... 66

Figure 3-41, Applying Master/Slave Identifi cation Labels ................................................................. 67

Figure 4-1, Inverter AC Input and Output Wiring Diagram - MS4024................................................. 69

Figure 4-2, Inverter AC Input and Output Wiring Diagram - MS-PAE Series ........................................ 70

Figure 4-3a, MPSL-30D Inverter AC Wiring .................................................................................... 71

Figure 4-3b, MPSL-30D External AC Wiring .................................................................................... 72

Figure 4-3c, MPSL-30D DC Wiring ................................................................................................ 73

Figure 4-3d, MPSL-30D Communications Wiring ............................................................................. 74

Figure 4-3e, MPSL-30D Full System Wiring Diagram ....................................................................... 75

Figure 4-4a, MPSL-60S Inverter AC Wiring .................................................................................... 76

Figure 4-4b, MPSL-60S External AC Wiring .................................................................................... 77

Figure 4-4c, MPSL-60S DC Wiring ................................................................................................ 78

Figure 4-4d, MPSL-60S Communications Wiring ............................................................................. 79

Figure 4-4e, MPSL-60S Full System Wiring Diagram ....................................................................... 80

Figure 4-5a, MPSH-30D Inverter AC Wiring ................................................................................... 81

Figure 4-5b, MPSH-30D External AC Wiring ................................................................................... 82

Figure 4-5c, MPSH-30D DC Wiring ............................................................................................... 83

Figure 4-5d, MPSH-30D Communications Wiring ............................................................................ 84

Figure 4-5e, MPSH-30D Full System Wiring Diagram ...................................................................... 85

Figure 4-6a, MPDH-30D Inverter AC Wiring ................................................................................... 86

Figure 4-6b, MPDH-30D External AC Wiring ................................................................................... 87

Figure 4-6c, MPDH-30D Inverter DC Wiring ................................................................................... 88

Figure 4-6d, MPDH-30D External DC Wiring .................................................................................. 89

Figure 4-6e, MPDH-30D Communications Wiring ............................................................................ 90

Figure 4-6f.1, MPDH-30D Full System Wiring Diagram (AC Side) ...................................................... 91

Figure 4-6f.2, MPDH-30D Full System Wiring Diagram (DC Side) ...................................................... 92

Figure 5-1, MP Functional Diagram............................................................................................... 93

Figure 5-2, 60A Bypass Switch Operation (MPSL-30D and MPSL-60S) ............................................... 95

Figure 5-3, 125A Bypass Switch Operation (MPSH-30D and MPDH-30D) ............................................ 96

Figure A1-1, Charge Controller Bracket - Physical Dimensions.......................................................... 97

Figure A1-2, Charge Controller Bracket Mounting Holes .................................................................. 98

Figure A1-3, Holes Used to Mount Bracket on MP Enclosure ............................................................. 99

Figure A2-1, Accessing the DC Shunt .......................................................................................... 100

Figure A2-2, Wiring the ME-BMK-NS ............................................................................................ 100

Figure A2-3, Mounting the Sense Module ..................................................................................... 101

Figure A2-4, Close-up of Wiring the Sense Module and DC Shunt .................................................... 101

Figure A3-1, Inverter Hood Dimensions ....................................................................................... 102

Figure A4-1, Router Bracket Dimensions ...................................................................................... 102

Figure A4-2, Router Bracket Kit .................................................................................................. 103

Figure A4-3, Mounting the Router Bracket and Router.................................................................... 103

Figure A5-1, Attaching Knockout Plate ......................................................................................... 104

Figure A5-2, Knockout Plate Dimensions and Knockouts ................................................................. 104

Figure A6-1, Installing DIN Rail-Mounted DC Breakers ................................................................... 105

Figure A6-2, Installing Back-Mounted DC Breakers ........................................................................ 106

Figure A6-3, Wiring DC Breakers to Controller/PV Array ................................................................. 106

Figure A7-1, Installing AC Load Breakers - Single MP Enclosure ...................................................... 107

Figure A7-2, Installing AC Load Breakers - Dual MP Enclosure ........................................................ 107

Figure A8-1, Removing the Front Breaker Face Plate ..................................................................... 108

Figure A9-1, Router Front Top Cover ........................................................................................... 109

Figure A10-1, Installing Lightning Arrestor on MP Enclosure ........................................................... 110

Figure A10-2, Wiring Lightning Arrestor to MP Enclosure ................................................................ 111

List of Tables

Table 3-1, T

Table 3-2, Torque Values for 3/8-16 Bolts ..................................................................................... 37

Table 3-3, Torque Values for Terminal Screws on AC Input Breakers ................................................. 37

Table 3-4, MP AC Wire Kits .......................................................................................................... 39

Table 3-5, Minimum AC Wire Size for AC Output Breaker ................................................................. 40

Table 3-6, AC Grounding Electrode Conductor Sizing ...................................................................... 56

Table 3-7, Equipment Grounding Conductor Sizing ......................................................................... 58

Table 4-1, MP Wiring Diagrams .................................................................................................... 68

Table A-1, Mounting Holes Used for Charge Controllers ................................................................... 97

© 2010 Magnum Energy, Inc.

orque Values for Dual Hole Busbars ............................................................................. 37

Page iv

Page 6

1.0 Safety Information

1.0 Safety Information

IMPORTANT SAFETY INSTRUCTIONS

his manual contains important safety instructions that

T

and operation of this product. Before using the Magnum Panel (MP), read all instructions

and cautionary markings on: (1) the MP enclosure, (2) the inverter/charger, and (3) the

batteries, as well as the individual manuals provided for each component of the system.

These installation instructions are for use by qualifi ed personnel only. Do not perform any

installation or servicing other than that specifi ed in this owner’s manual unless qualifi ed to do so.

Incorrect installation or servicing may result in a risk of electric shock, fi re, or other safety hazard.

must be followed during the installation

1.1 Safety Symbols

The following safety symbols have been placed throughout this manual to indicate dangerous

conditions and important safety instructions.

WARNING: This symbol

physical harm to the user.

CAUTION: This symbol indicates that failure to take a specifi ed action could result in

damage to the equipment.

Info: This symbol indicates information that emphasizes or supplements important

points of the main text.

indicates that failure to take a specifi ed action could result in

1.2 General Safety

• All electrical work must be performed in accordance with local and national electrical codes.

This product is designed for indoor/compartment installation. It must not be exposed to rain,

•

snow, moisture or liquids of any type.

• Use insulated tools to reduce the chance of electrical shock or accidental short circuits.

• Remove all jewelry such as rings, watches, bracelets, etc., when installing or performing

maintenance on the inverter.

• Both AC and DC overcurrent protection must be provided as part of the installation.

• Use Class 1 wiring methods for fi eld wiring connections to terminals of a Class 2 circuit.

• Listed or labeled equipment shall be installed and used in accordance with any instructions

included in the listing or labeling.

• To reduce risk of electric shock, disconnect all wiring before attempting any maintenance or

cleaning. Turning off the inverter will not reduce this risk, the inverter bypass must be used or

the panel should be totally disconnected from all sources.

• All wiring must have a minimum rating of 150V, 75°C when using 120V AC inverters; or 300V,

75°C when using 120/240V AC inverters.

• AC wiring must be no less than 10 AWG (5.3 mm2) gauge copper wire.

• Battery cables should be no less than #4/0 AWG unless fused close to the battery bank for

smaller sized cables.

• Crimped and sealed copper ring terminal lugs with a 3/8” hole should be used to connect to

the DC terminals inside the MP enclosure. Soldered cable lugs are also acceptable.

• Torque all AC wiring connections and DC cable connections to the required torque values.

READ AND SAVE THESE INSTRUCTIONS

© 2011 Magnum Energy, Inc.Page v

Page 7

1.0 Safety Information

1.3

Battery Safety

IMPORTANT BATTERY SAFETY INSTRUCTIONS

• Be very careful when working around batteries, they can produce extremely high currents if

short-circuited. Read

inverter and batteries.

• Wear eye protection such as safety glasses when working with batteries.

• Remove all jewelry such as rings, watches, bracelets, etc., when installing or performing

maintenance on the batteries.

• Never work alone. Always have someone near you when working around batteries.

• Use proper lifting techniques when working with batteries.

• Never use old or untested batteries. Check each battery’s label for age, type, and date code

to ensure all batteries are identical.

• Batteries are sensitive to changes in temperature. Always install batteries in a stable

environment.

• Install batteries in a well ventilated area. Batteries can produce explosive gasses. For

compartment or enclosure installations, always vent batteries to the outside.

• Provide at least one inch of air space between batteries to provide optimum cooling.

• Never smoke when in the vicinity of batteries.

• To prevent a spark at the battery and reduce the chance of explosion, always connect the

cables to the batteries fi rst. Then connect the cables to the MP enclosure/inverter system.

• Use insulated tools at all times.

• Always verify proper polarity and voltage before connecting the batteries to the MP enclosure/

inverter system.

• To reduce the chance of fi re or explosion, do not allow the battery terminals to be shortcircuited.

• In the event of accidental exposure to battery acid, wash thoroughly with soap and water. In

the event of exposure to the eyes, fl ood them for at least 15 minutes with running water and

seek immediate medical attention.

• Recycle old batteries.

• Be extra cautious to reduce the risk of dropping a metal tool onto batteries. It could short-circuit

the batteries or other electrical parts, resulting in sparks that could cause a fi re or an explosion.

the battery supplier’s precautions before installing and connecting the

• Cover the terminals to prevent accidental shorting.

READ AND SAVE THESE INSTRUCTIONS

© 2011 Magnum Energy, Inc.

Page vi

Page 8

2.0 Introduction

2.0 Introduction

The Magnum P

dardize inverter installations and allow for the ability to expand the inverter system in the future.

Specifi cally designed for multiple inverter applications, the MP enclosures ensure safety and reliability by combining all of the major components required for a renewable energy system — inverter/

battery disconnect, AC overcurrent protection, grounding connections, and a full-system bypass

switch — into an easy to install pre-wired enclosure. The modular design of the MP enclosure with

the Magnum Energy inverter allows it to be UPS shipped and easily assembled on site.

Installing an inverter system is now as simple as mounting the MP enclosure, installing the inverters, connecting the battery bank, and if needed, bringing in AC power from a generator or the

utility grid. Now all of the inverter’s required AC and DC disconnects and wire connection points

are all together, and integrated in the self-contained MP enclosure.

anels (MP) are part of a new line of enclosures from Magnum Energy that stan-

2.1 MP Series Overview

The MP enclosures are available in four basic confi gurations: the MPSL-30D, MPSH-30D, and

MPDH-30D are designed to be used with the Magnum MS-PAE inverter models when stacked in

parallel; and the MPSL-60S, which is designed for use with two MS4024 inverters when stacked

in series. These confi gurations provide different maximum power abilities to meet present and

future requirements.

2.1.1 Models

MPSL-30D (Magnum Panel,

MPSL-60S (Magnum Panel, Single Enclosure, Low Capacity, Single-pole 60A AC input breaker)

MPSH-30D (Magnum Panel, Single Enclosure, High Capacity, Double-pole 30A AC input breakers)

MPDH-30D (Magnum Panel, Dual Enclosure, High Capacity, Double-pole 30A AC input breakers)

Single Enclosure, Low Capacity, Double-pole 30A AC input breakers)

2.1.2 Standard Features

The main components and features for the MP Series enclosures are:

• Standard confi gur

• Enclosure is steel construction with a durable, white powder coat fi nish to help prevent corrosion

• Built-in, pre-wired, full system bypass switch for inverter isolation/battery maintenance

• Front-mounted AC and DC breakers for quick and easy operation

• AC, DC, and Ground busbars with set-screw type compression terminals (no lugs required)

• Full system capacity shunt (500 or 1000 DCA), allows easy connection to battery monitor

• Enclosure and components are certifi ed for indoor use to UL/CSA standards

• DC negative and ground busbars (negative can be isolated if PV-GFP device installed)

• Battery positive busbar for DC loads and PV arrays included (not available on MPSH-30D)

• Space available to add DC load/disconnect breakers (not available on MPSH-30D)

• Standalone top plate provided to allow other (non-Magnum) inverter installations

• Knockouts for inverter and battery cables, PV in/out, DC breakers

• Data cables with 300-volt rated insulation provided to allow 240V AC inverter installations

• Easy accessibility for fi eld installation/wiring of additional breakers/components

• Pre-wired AC over-current circuit breaker protection to the inverter’s input

• Space for additional AC breakers (depends on enclosure confi guration)

• Inverter DC disconnect with inverter-to-breaker battery cables included

• Plated copper busbars included for up to six additional battery positive and negative circuits

ations allow future expansion using MPX enclosures for increased power

© 2011 Magnum Energy, Inc.Page 1

Page 9

2.0 Introduction

MPSL-30D

MPXS-30D-L

MS-PAE

I

NVERTER

MPSL-30D

BP-D

ME-RTR

MS-PAE

I

NVERTER

MPXS-30D-L

MPSL-30D

MPXS-30D-R

MPSL-30D

MPXS-30D-R

MS-PAE

I

NVERTER

BP-D

ME-RTR

MS-PAE

INVERTER

MPSL-30D

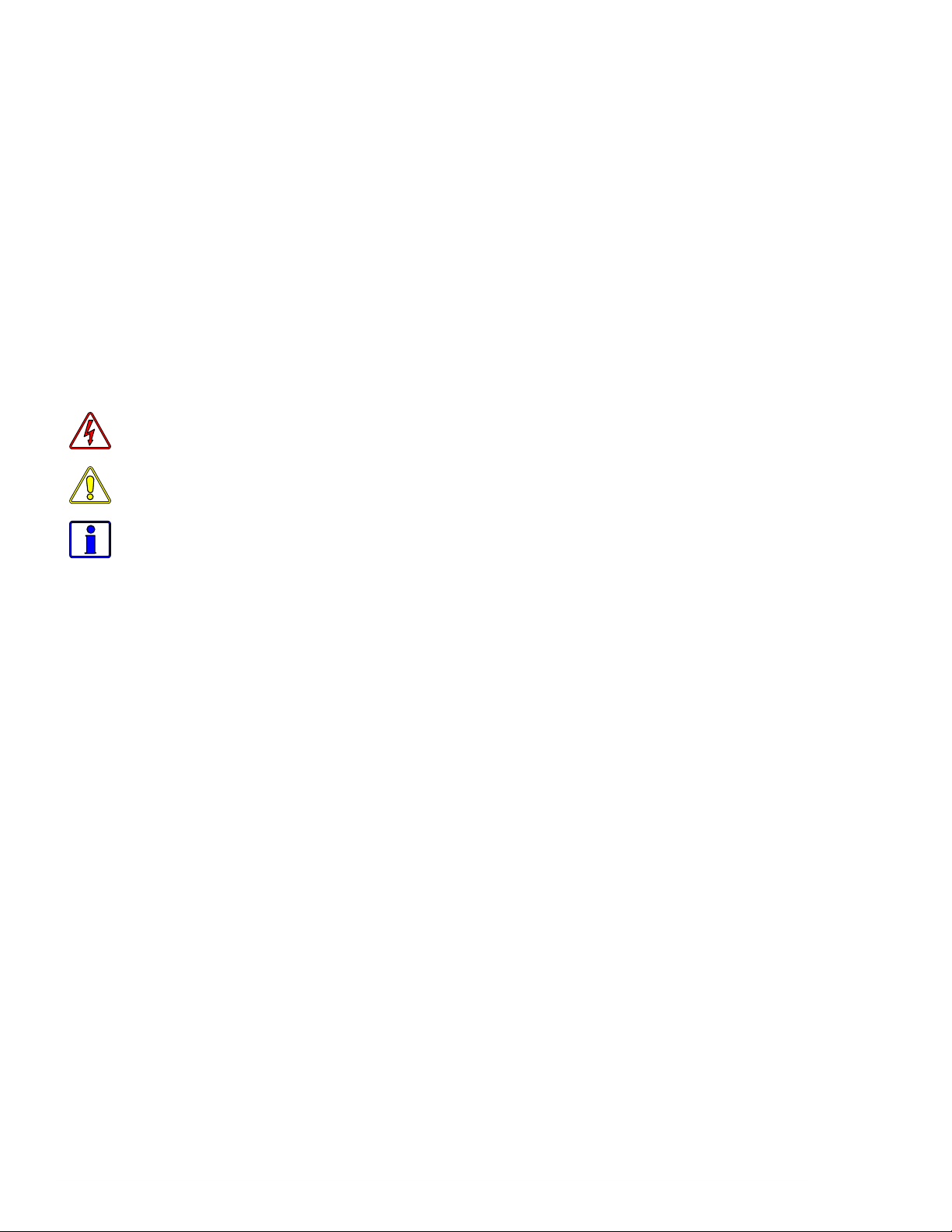

2.1.3 Individual Features

MPS

L-30D (Magnum Panel, Single Enclosure, Low Capacity, Double 30A AC Inverter Input Breaker)

Capability for one MS-PAE Series inverter (expandable to a maximum of two MS-PAE Series

inverters stacked in parallel using an optional MPX extension box).

MPSL-30D (as shipped)

Includes:

• D

30A AC Inverter Input

Breaker (x1)

• 250A DC Disconnect

(x1)

• Inverter AC Input/

Output wires

• Data cables rated for

120/240V AC circuits

Figure 2-1a, MPSL-30D as Shipped

• D60A AC System

Bypass

• 500A/50mV DC

Shunt

• Inverter Hood (x1)

• Router Bracket

MPSL-30D

with MPXS-30D-L

Includes:

30A AC Inverter Input Breakers (x2) • D60A AC System Bypass

• D

• 250A DC Disconnects (x2) • 500A/50mV DC Shunt

• Inverter AC Input/Output wires • Inverter Hoods (x2)

• Data cables rated for 120/240V AC circuits • Router Bracket

Field Installed Options Shown (not included):

• PAE Series parallel-stack inverters (x2) • BP-D Dual Mounting Backplate

• ME-RTR R

outer

(MPX - Left Side)

with MPXS-30D-R (MPX - Right Side)

MPSL-30D

Figure 2-1b, MPSL-30D with Field Installed Options

© 2011 Magnum Energy, Inc.

Page 2

Page 10

2.0 Introduction

MPSL-30D

MPXS-30D-L

MS4024

INVERTER

MPSL-60S

BP-D

MS4024

INVERTER

MPXS-60S-L

ME-ARC

MPSL-30D

MPXS-30D-R

MPSL-60S

MPXS-60S-R

MS4024

I

NVERTER

BP-D

MS4024

I

NVERTER

ME-ARC

MPSL-30D

MPSL-60S (Ma

Capability for one MS4024 inverter (expandable to two MS4024’s stacked in series using an

optional MPX extension box)

gnum Panel, Single Enclosure, Low Capacity, Single 60A AC Inverter Input Breaker)

MPSL-60S

Includes:

S60A AC Inverter Input

•

Breaker (x1)

• 250A DC Disconnect

(x1)

• Inverter AC Input/

Output wires

• Data cables rated for

120/240V AC circuits

(as shipped)

• D60A AC System

Bypass

• 500A/50mV DC

Shunt

• Inverter Hood (x1)

• Router and Charge

Controller Bracket

Figure 2-2a, MPSL-60S as Shipped

MPSL-60S

with MPXS-60S-L

Includes:

60A AC Inverter Input Breakers (x2) • D60A AC System Bypass

• S

• 250A DC Disconnects (x2) • 500A/50mV DC Shunt

• Inverter AC Input/Output wires • Inverter Hoods (x2)

• Data cables rated for 120/240V AC circuits • Series Stacking Cable

Field Installed Options Shown (not included):

• MS4024 series-stack inverters (x2) • BP-D Dual Mounting Backplate

• ME-ARC Adv

anced Remotes (x2)

(MPX - Left Side)

Figure 2-2b, MPSL-60S with Field Installed Options

MPSL-60S

with MPXS-60S-R (MPX - Right Side)

© 2011 Magnum Energy, Inc.Page 3

Page 11

2.0 Introduction

MPXS-30D-L

MPXS-30D-R

MPSH-30D

MS-PAE

I

NVERTER

MPXS-30D-L

BP-S

ME-RTR

MS-PAE

I

NVERTER

MPXS-30D-R

BP-D

MPSH-30D

MS-PAE

I

NVERTER

MPSH-30D

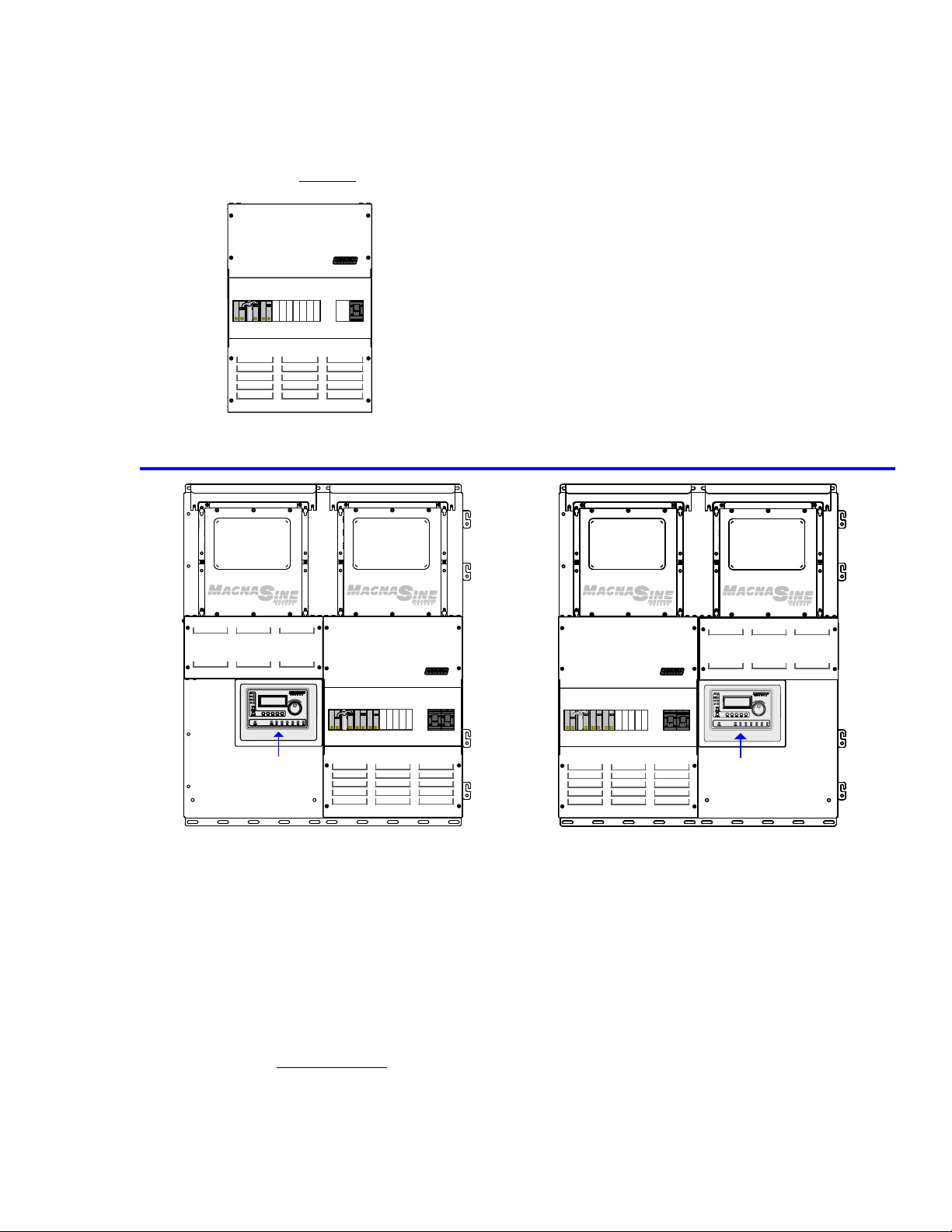

MPSH-30D (M

Capability for one MS-PAE Series inverter (expandable to a maximum of three MS-PAE Series

inverters stacked in parallel using optional MPX extension boxes)

agnum Panel, Single Enclosure, High Capacity, Double 30A AC Inverter Input Breaker)

MPSH-30D (as shipped)

Includes:

• D

30A AC Inverter Input

Breaker (x1)

• 250A DC Disconnect

(x1)

• Inverter AC Input/

Output wires

• Data cables rated for

120/240V AC circuits

• D125A AC System

Bypass

• 1000A/100mV DC

Shunt

• Inverter Hood (x1)

• Router and Charge

Controller Bracket

Figure 2-3a, MPSH-30D as Shipped

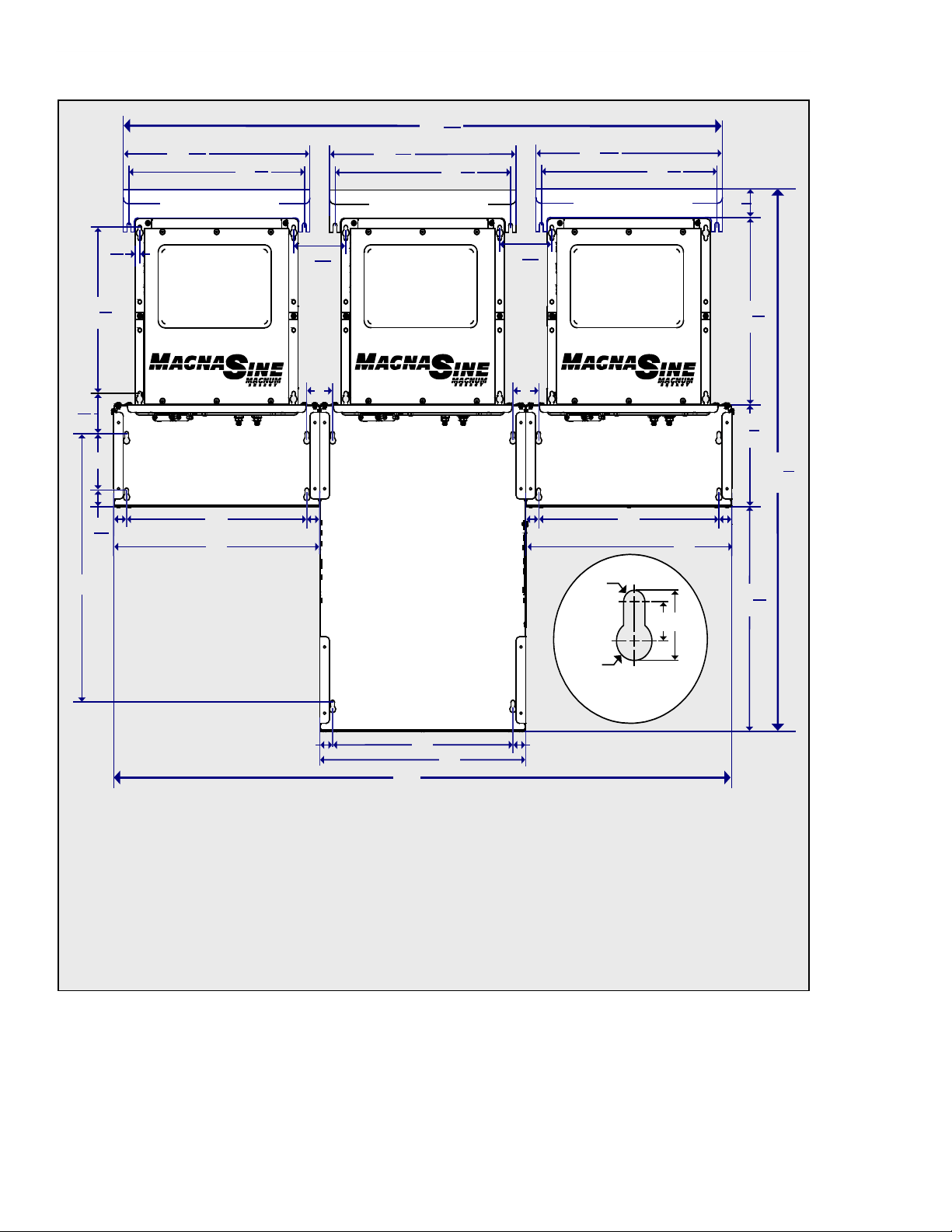

MPSH-30D with MPXS-30D-L (MPX - Left Side) and MPSX-30D-R (MPX - Right Side)

Includes:

30A AC Inverter Input Breakers (x3) • D125A AC System Bypass

• D

• 250A DC Disconnects (x3) • 1000A/100mV DC Shunt

• Inverter AC Input/Output wires • Inverter Hoods (x3)

• Data cables rated for 120/240V AC circuits • Router and Controller Bracket

Field Installed Options Shown (not included):

• PAE Series parallel-stack inverters (x3) • BP-S Single Mounting Backplate

• ME-RTR R

outer • BP-D Dual Mounting Backplate

Figure 2-3b, MPSH-30D with Field Installed Options

© 2011 Magnum Energy, Inc.

Page 4

Page 12

2.0 Introduction

MPXD-30D-L

MPXD-30D-R

MPDH-30D

MS-PAE

I

NVERTER

MPXD-30D-L

BP-D

ME-RTR

MS-PAE

I

NVERTER

MS-PAE

I

NVERTER

MS-PAE

I

NVERTER

MPXD-30D-R

BP-D

MPDH-30D

AC Side

DC Side

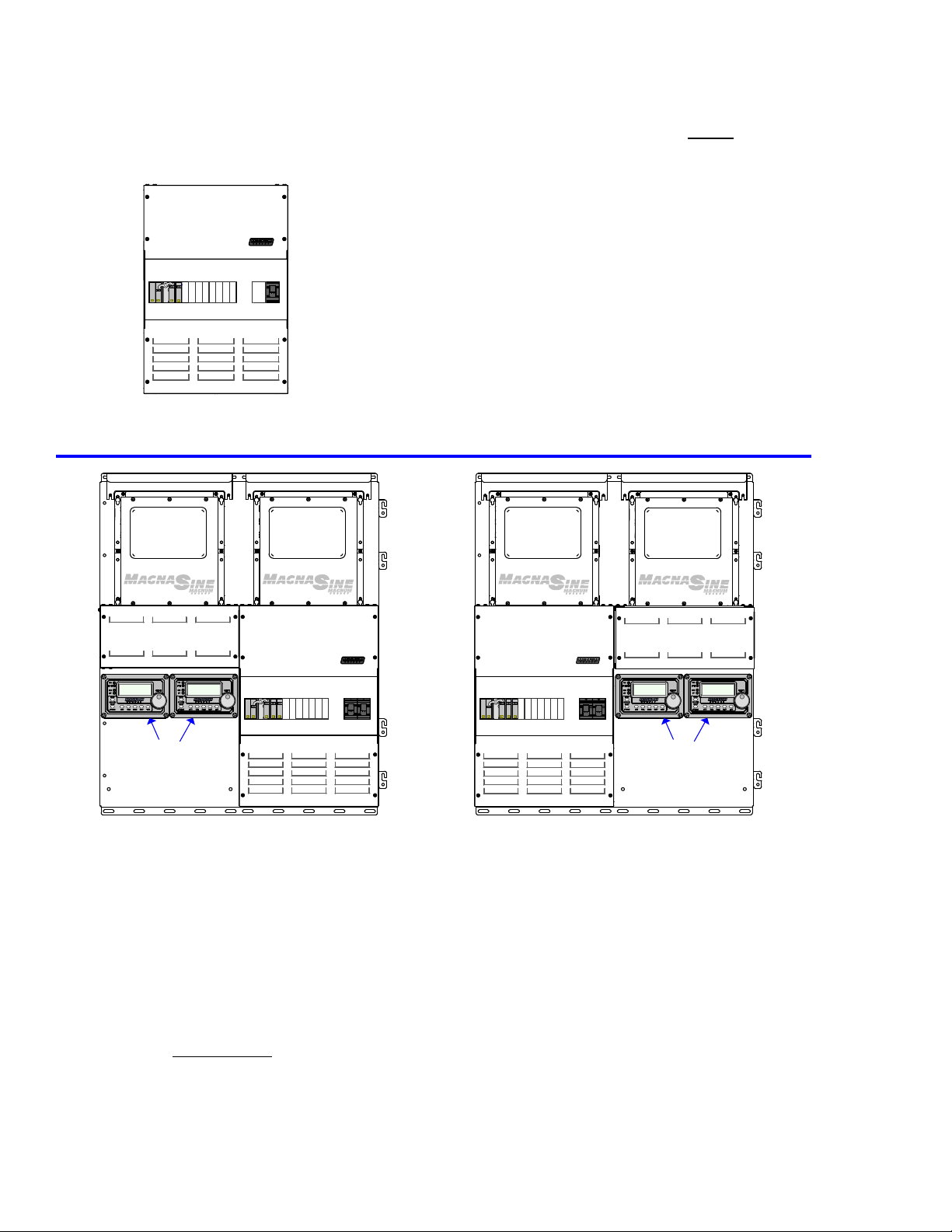

MPDH-30D

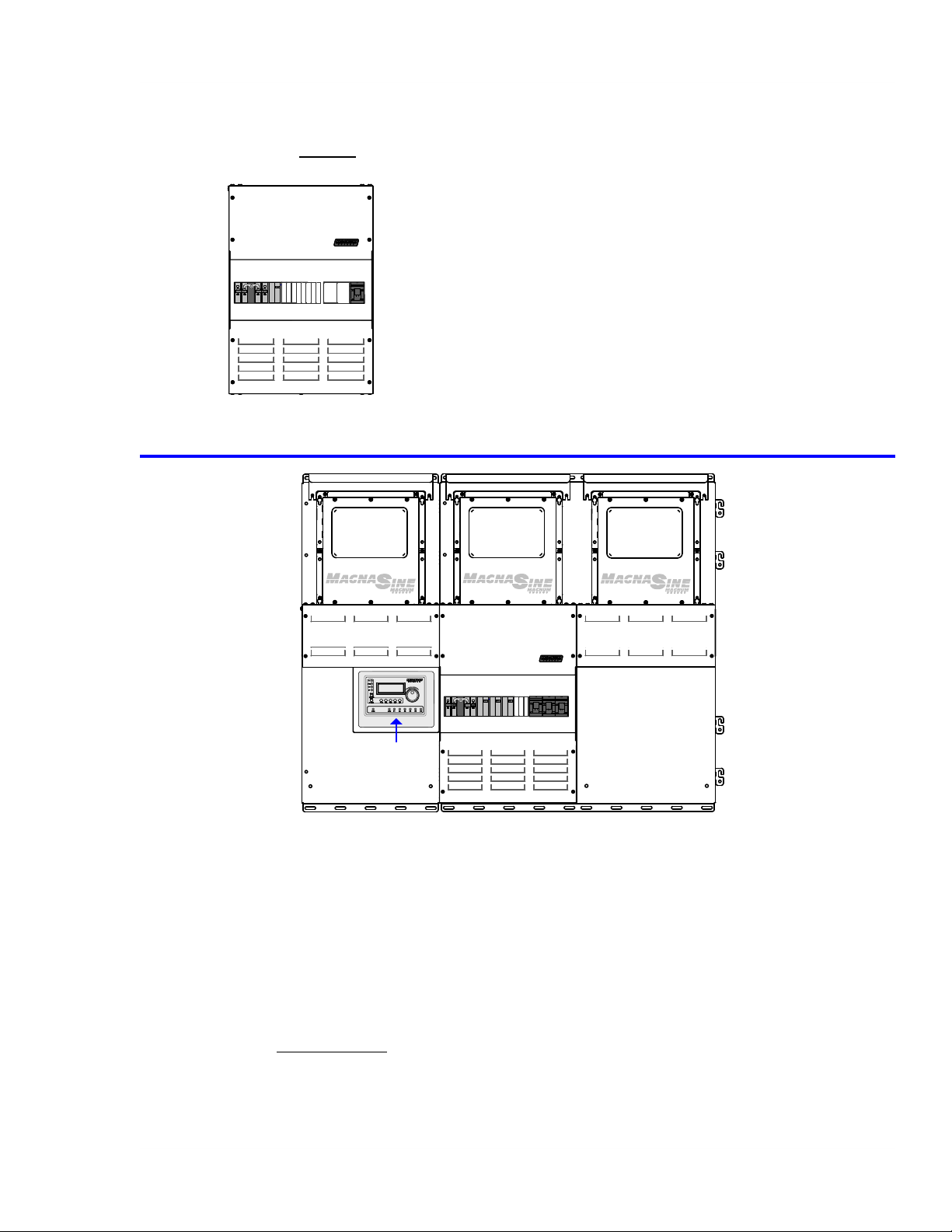

MPDH-30D (M

Capability for one or two MS-PAE Series inverters (expandable to a maximum of four MS-PAE

Series inverters stacked in parallel using optional MPX extensions).

agnum Panel, Dual Enclosure, High Capacity, Double 30A AC Inverter Input Breakers)

MPDH-30D (as shipped)

Includes:

• D

30A AC Inverter Input

Breakers (x2)

• 250A DC Disconnects

(x2)

• Inverter AC Input/

Output wires

• Data cables rated for

120/240V AC circuits

• D125A AC System

Bypass

• 1000A/100mV DC

Shunt

• Inverter Hoods (x2)

• Router and Charge

Controller Bracket

Figure 2-4a, MPDH-30D as Shipped

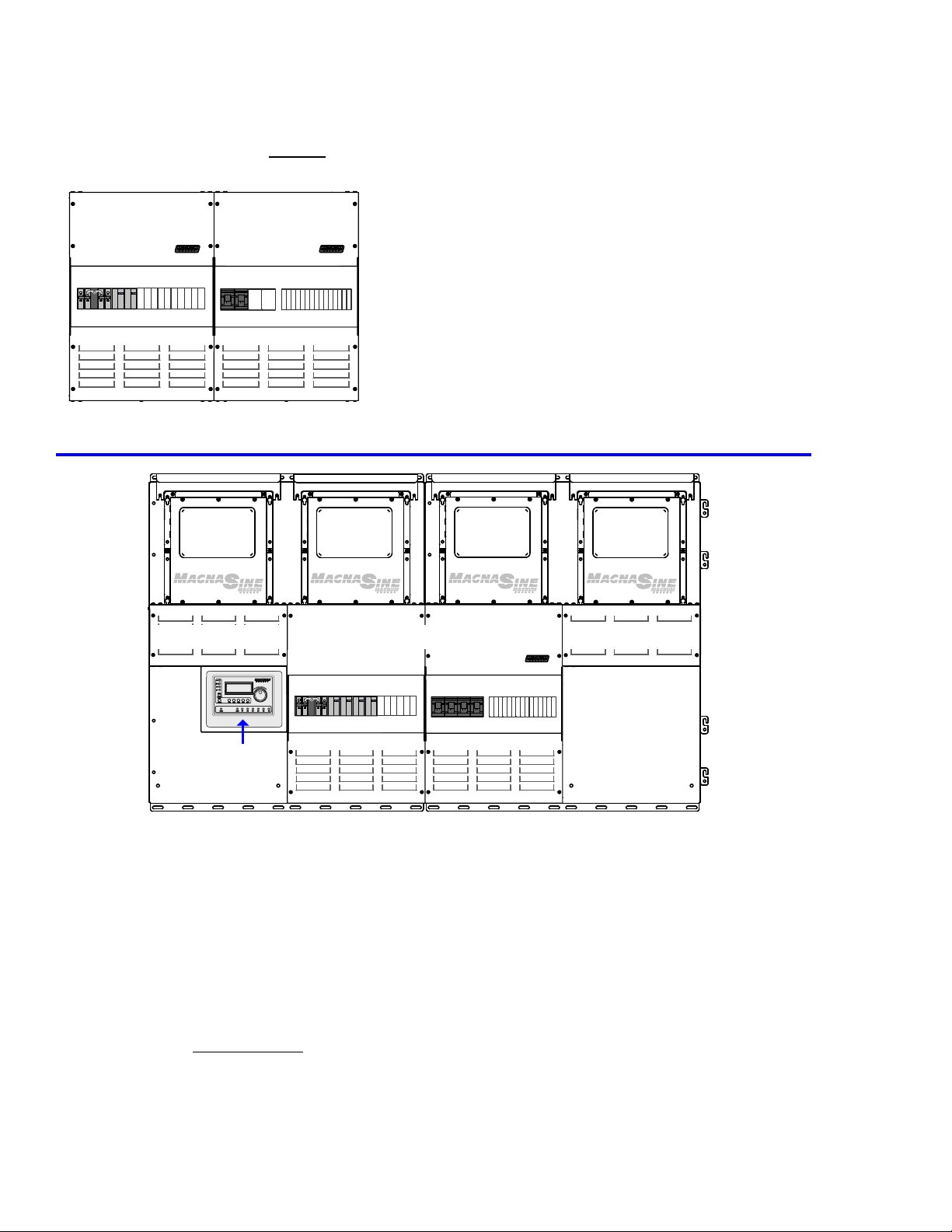

MPDH-30D with MPXD-30D-L (MPX - Left Side) and MPXD-30D-R (MPX - Right Side)

Includes:

30A AC Inverter Input Breakers (x4) • D125A AC System Bypass

• D

• 250A DC Disconnects (x4) • 1000A/100mV DC Shunt

• Inverter AC Input/Output wires • Inverter Hoods (x4)

• Data cables rated for 120/240V AC circuits • Router and Controller Bracket

Field Installed Options Shown (not included):

• PAE Series parallel-stack inverters (x4) • BP-D Dual Mounting Backplates (x2)

• ME-RTR R

outer

Figure 2-4b, MPDH-30D with Field Installed Options

© 2011 Magnum Energy, Inc.Page 5

Page 13

2.0 Introduction

2.1.4

• MP Dimensions (H x W x D): Each Enclosure = 18” x 13” x 6.75” (45.7cm x 33cm x 17.1cm)

MP Weight:

•

(20 kg), MPDH (D Side) = 46 lbs. (20.7 kg)

• Shipping Dimensions (H x W x D): 26.75” x 17.75” x 14.75” (56.9cm x 38.1cm x 31.8cm)

• Shipping Weight: MPSL = 50 lbs. (22.7 kg), MPSH = 53 lbs. (24 kg), MPDH (AC Side) = 46 lbs.

(20.7 kg), MPDH (D Side) = 48 lbs. (21.8 kg)

Physical Features

MPSL = 48 lbs. (21.8 kg), MPSH = 51 lbs. (23.1 kg), MPDH (AC Side) = 44 lbs.

2.1.5 Optional Accessories/Components

• ME-RC – R

confi gured and monitored, and maintains the critical settings in nonvolatile memory.

• ME-ARC – Advanced Remote Control with LCD display; has all the features of the ME-RC remote,

but also confi gures the advanced features of the inverter (or any connected accessory).

• ME-RTR – The ME-RTR, or “router” provides parallel capability for the MS-PAE Series inverters

and includes many of the same features as the ME-ARC advanced remote control. The router

is designed with a user-friendly LCD display and rotary SELECT knob that allows all connected

MS-PAE series inverter/chargers to be programmed in sync without the need to program

each inverter separately. The router will accommodate up to four MS-PAE inverter/chargers

in parallel, plus accessories.

• ME-BMK-NS – Battery Monitor; determines battery State of Charge (DC shunt not included).

• ME-AGS-N – Automatic Generator Start Controller (Network version); automatically starts/

stops generators.

• BP-S – Single Mounting Backplate; for mounting a Magnum inverter and MP/MPX enclosures.

It can be combined with the BP-D for additional mounting surface area. UPS shippable.

• BP-D – Dual Mounting Backplate; for mounting a Magnum inverter and MP/MPX enclosures,

It can be combined with the BP-S for additional mounting surface area. UPS shippable.

• DC Breakers – MP enclosure has space for E-Frame/back-mounted (1” width) or Q-Frame/

DIN rail-mounted (1/2” width) DC breakers (not applicable for the MPSH-30D model).

• MPX Extensions – These enclosures allow additional Magnum inverters to be mounted and

electrically wired to the Magnum Panel to allow an integrated panel system. The top of the

MPX is designed to allow Magnum inverters to fi t seamlessly into the top. The MPX Series

enclosures come with the AC and DC breakers and wiring to install another Magnum inverter.

An inverter hood is also included with each MPX extension to allow the inverter to be mounted

vertically.

• ME-MW-W - The MagWeb Wireless allows Magnum Energy’s inverters and accessories to be

remotely monitored. Installed on the Magnum network, the MagWeb provides live Internet

monitoring of the inverter, battery monitor, and automatic generator start module. Using your

always on Internet connection, the MagWeb makes live and historical conditions available to

you through a web browser at

emote Control with LCD display; allows inverter (or connected accessory) to be

http://data.magnumenergy.com

.

2.2 Regulatory Compliance

The MP enclosure

Equipment (ISE) for use with inverters. It has been independently tested and certifi ed by Intertek

Testing Services (known as ETL) to UL 1741, 2nd Edition, and is also CSA certifi ed to C22.2 No.

107.1-01 (R2006). These certifi cations mean the MP enclosure meets the minimum requirements

of prescribed product safety standards.

Note: ETL is a Nationally Recognized Testing Laboratory (NRTL). NRTL’s are qualifi ed organizations

that meet the requirements of Occupational Safety and Health Administration (OSHA) regulations

to perform independent safety testing and product certifi cation.

© 2011 Magnum Energy, Inc.

carries the ETL Listed Mark and is designated as Interconnection System

Page 6

Page 14

2.0 Introduction

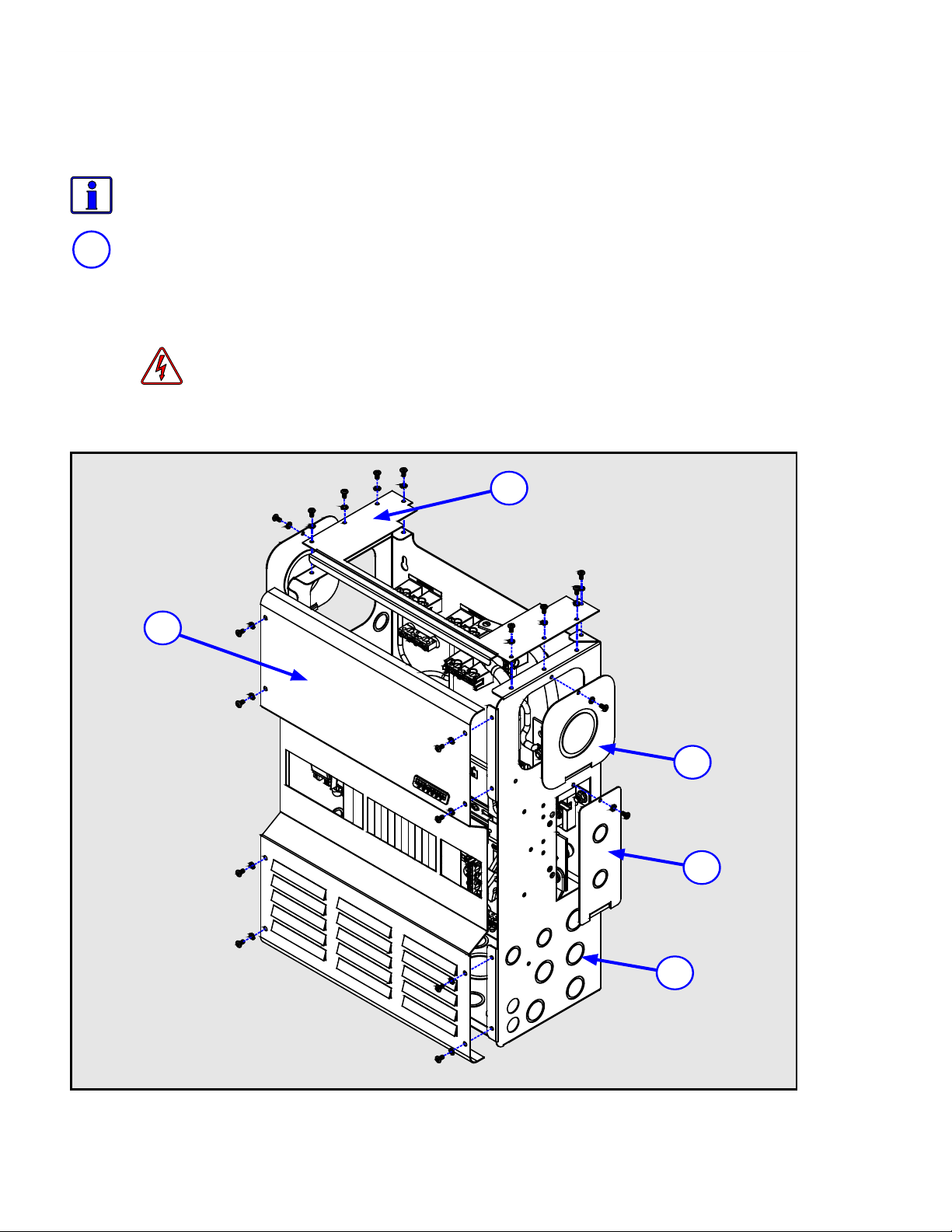

2.3 MP External Components

The main external

the MPDH enclosure (as shown in Figure 2-6) are described below:

components of the MPSL and MPSH enclosures (as shown in Figure 2-5) and

Info:

head, T25 T

1

Inv

This plate allows a Magnum inverter to sit on top of the MP enclosure, and allow the AC

and DC wiring to be easily routed from the inverter to the MP enclosure.

The inverter plate can be replaced with the Knockout Plate, which is used as an upper

conduit/safety plate. See Section A5 for more information on the Knockout Plate.

The external components are secured to the enclosure using #10-32 x 3/8” (Pan

orx driv

erter Plate - The MP enclosure is factory shipped with the inverter plate installed.

WARNING: To

MP enclosure, the Knockout Plate must be installed if the Magnum inverter is

removed for service and the AC bypass breaker is switched ON.

2

e) thread cutting screws and #10 lock washers.

prevent accidental access to live electrical circuits inside the

1

Figure 2-5, MPSL and MPSH External Components

© 2011 Magnum Energy, Inc.Page 7

3

4

5

Page 15

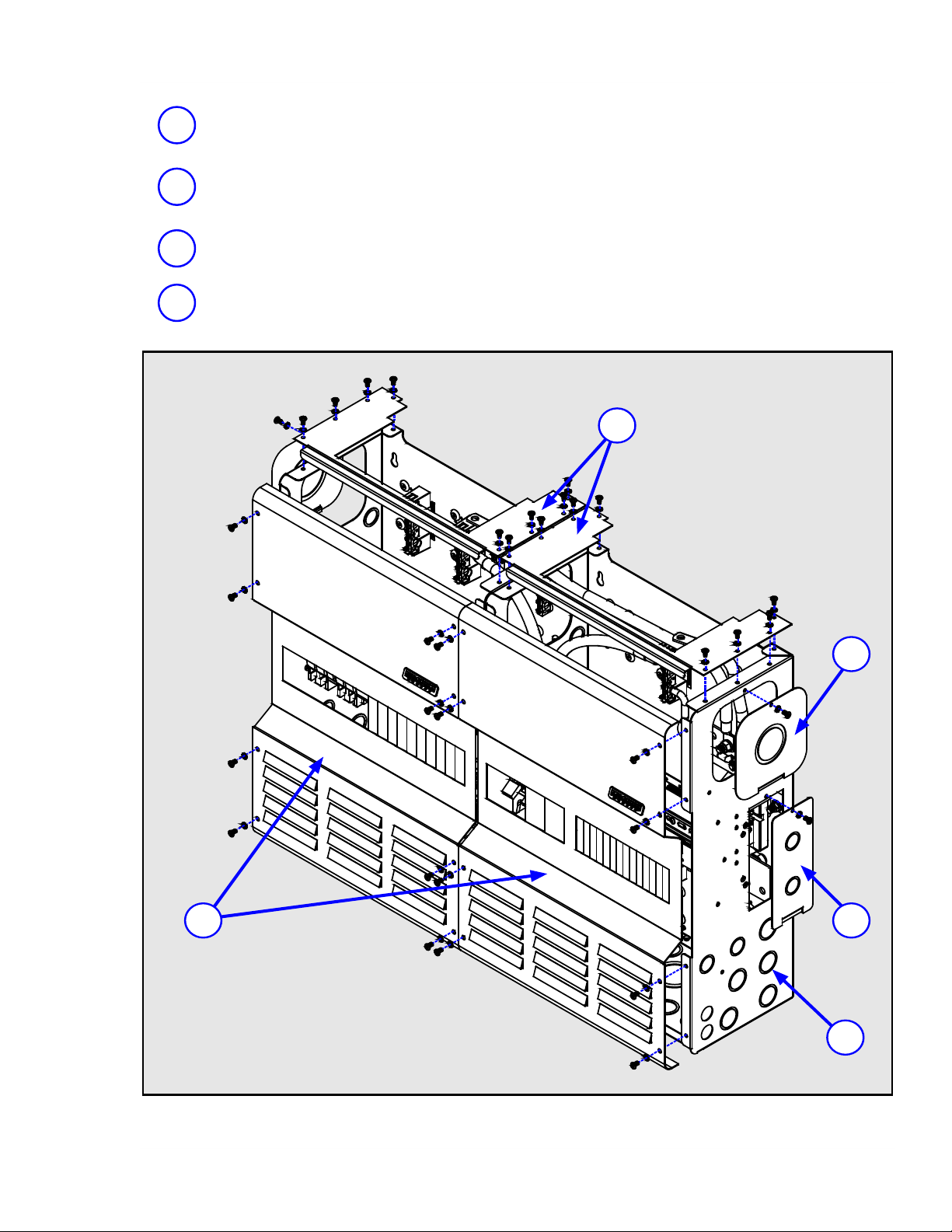

2.0 Introduction

2

3

4

5

Front Panel Cover

access the internal components. The front cover panels are equipped with rectangular

knockouts, to allow additional AC and DC circuit breakers to be installed.

Side

MP

and communications conductors to be routed from the main MP enclosure to a MPX

extension box (when used).

DC

battery monitor) and the DC ground stud.

Conduit

enclosure are provided to allow metal and PVC conduits. For dimensions and sizes, see

Figures 3-13 and 3-14.

Access

Shunt

Access

Knockouts

- The cover(s) on the front of the MP enclosures can be removed to

Plate (x2) - These access plates (one on each side) allow the power

Plate - This plate allows access to the DC shunt (for connecting a

Multiple sized knockouts on the side and bottom of the MP

-

1

3

2

4

5

Figure 2-6, MPDH External Components

© 2011 Magnum Energy, Inc.

Page 8

Page 16

2.0 Introduction

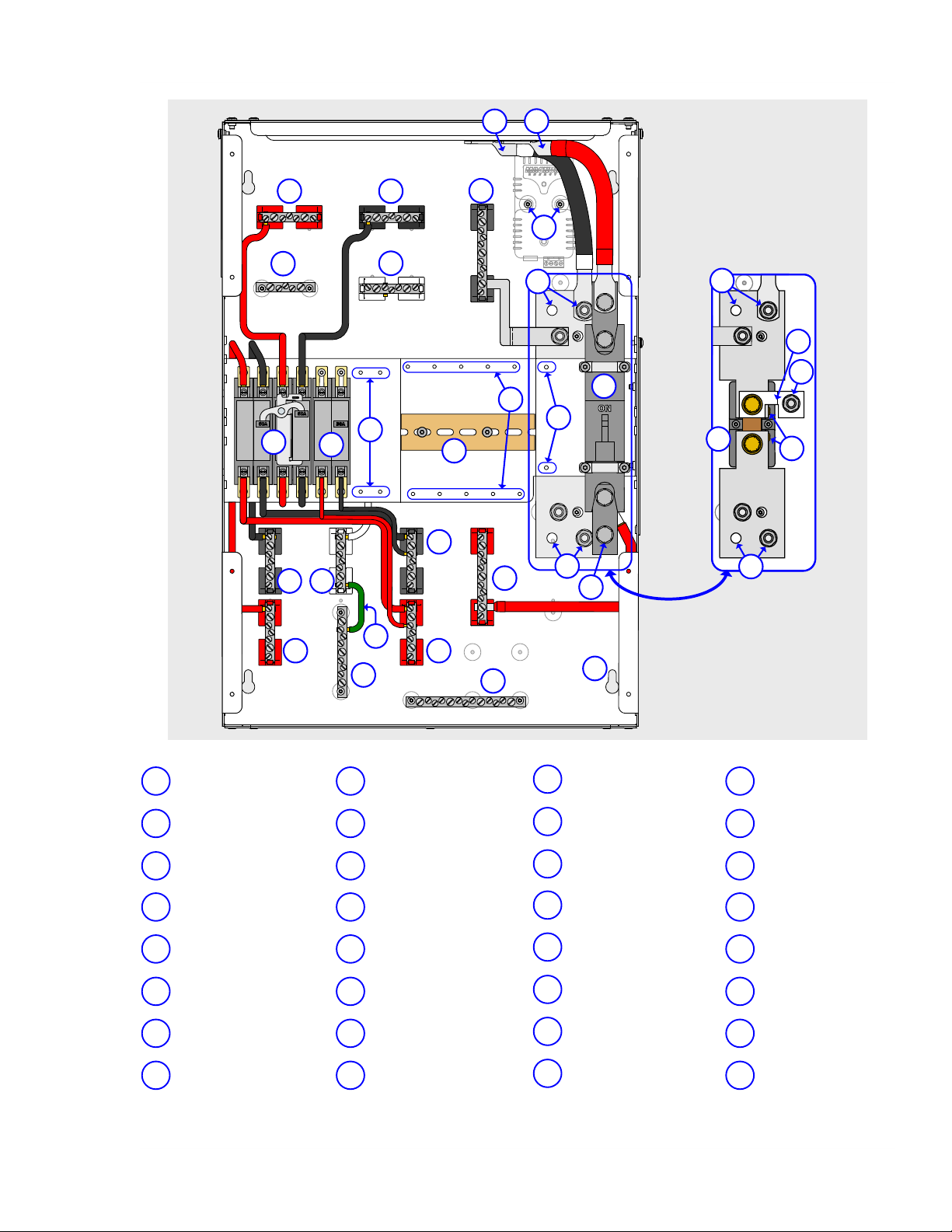

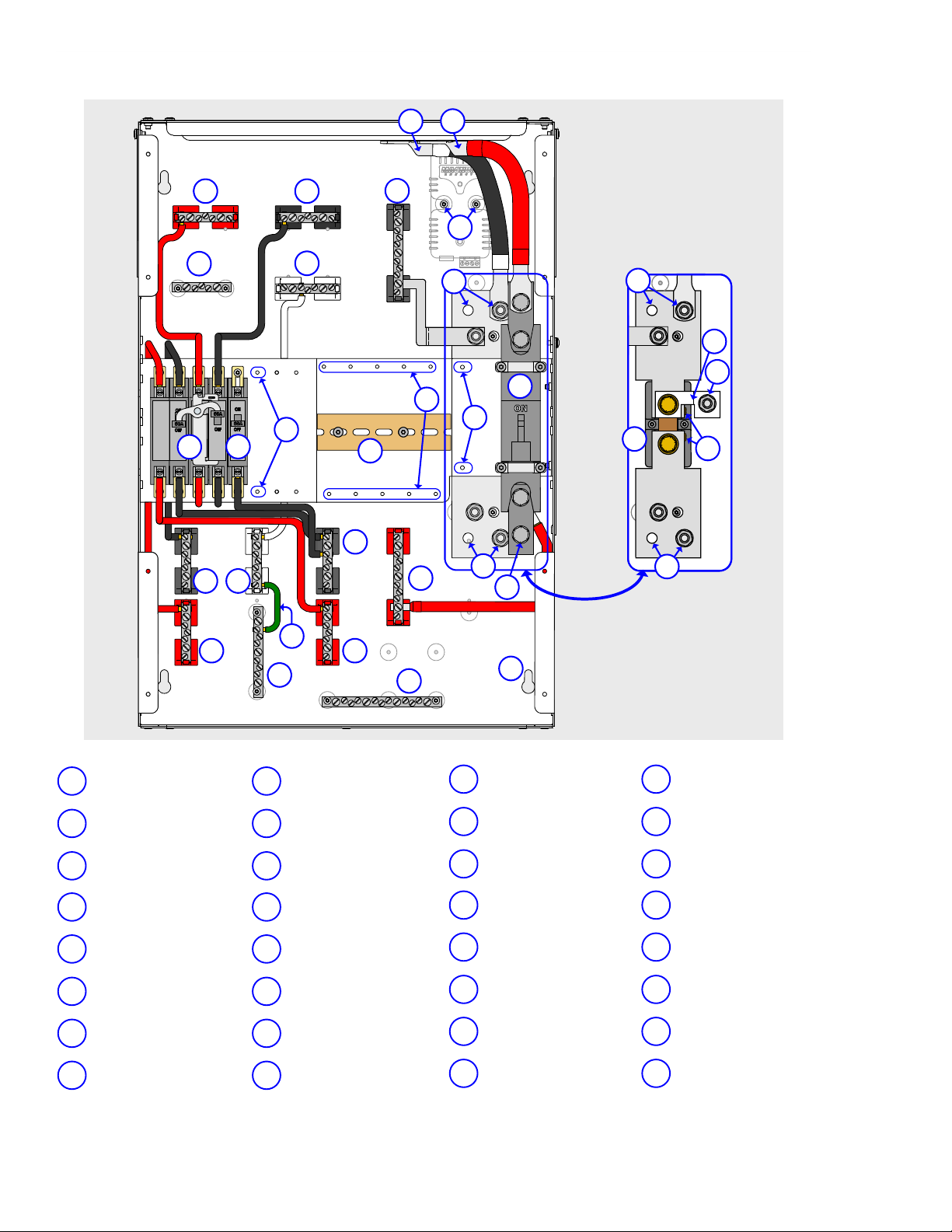

2.4 MP Internal Components

Additional

MPSL-30D (see Figure 2-7), the MPSL-60S (see Figure 2-8), the MPSH-30D (see Figure 2-9), and

the MPDH-30D (see Figures 2-10a and 2-10b) are listed alphabetically and described below:

components are located inside the MP enclosure. The components found inside the

Info:

A

compression terminals (no ring lugs required). The number of terminals available

depends on the particular busbar and the MP model.

Info:

common to each other as they are all connected to the MP chassis.

AC

GROUND

used to connect the incoming and outgoing AC circuit grounds to a common ground point.

AC LEG 1 IN Busbar - Connects incoming LEG 1 AC power from the grid or a generator to the

MP/inverter system. This busbar is used to connect the LEG 1 output of a 120/240V AC external

source (grid power or AC generator) to the MP enclosure. The AC LEG 1 IN busbar is connected to

the HOT 1 input of the inverter system (thru the inverter’s AC input breaker). The external source

is used by the inverter to charge the batteries and power downstream loads thru the inverter.

AC LEG 1 OUT Busbar - Supplies the LEG 1 power from the MP/inverter system to the AC loads.

This busbar is the connection point from the MP enclosure to the LEG 1 terminal in the electrical

panel powered by the inverter.

AC LEG 2 IN Busbar - Connects incoming LEG 2 AC power from the grid or a generator to the

MP/inverter system. This busbar is used to connect the LEG 2 output of a 120/240V AC external

source (AC generator or grid power) to the MP enclosure. The AC LEG 2 IN busbar is connected to

the HOT 2 input of the inverter system (thru the inverter’s AC input breaker). This external source

is used by the inverter to charge the batteries and power downstream loads thru the inverter.

AC LEG 2 OUT Busbar - Supplies the LEG 2 power from the MP/inverter system to the AC loads.

This busbar is the connection point from the MP enclosure to the LEG 2 terminal in the electrical

panel powered by the inverter.

AC NEUTRAL Busbars - The neutral leg for loads powered from the MP/inverter system and the

neutral leg for AC power supplied to the MP/inverter system by either a generator or grid. These

two busbars are the connection points for the AC neutrals in the system. The system neutrals

include: the neutral output from the external AC source (generator/grid), the neutral terminal in

the electrical panel that is powered by the inverter, and the input and output neutral terminals of

each inverter. Note: Both AC NEUTRAL busbars are electrically connected to each other.

All the busbars have dual hole sizes — the larger holes accept #14 to #1/0

WG

and the smaller holes accept #14 to #6 AWG — these holes have set-screw type

All AC Ground Busbars, DC Ground Busbars, and the DC Ground Stud are electrically

Busbar(s) - These busbars are connected to the MP enclosure chassis and are

• Installing MS-PAE Series inverters: Both neutral terminals are common with each other

within the MS-PAE Series, this means only one neutral from each MS-PAE inverter needs to

connect to the AC NEUTRAL busbar.

• Installing MS4024 inverters: The Neutral In and Neutral Out are not common with each

other within the MS4024; this means both input and output neutrals from each MS4024

inverter needs to connect to the AC NEUTRAL busbar.

AC NEUTRAL-GROUND Connection - A wire (green) connects the AC neutral to the system

ground. This green wire can be removed from the GROUND busbar if the primary AC neutral to

ground connection is made elsewhere in the system (see Section 3.10).

Battery Negative Connection - The bottom of the DC Shunt busbar is the connection point to

the negative terminal of the battery bank. This busbar is supplied with a 3/8-16 bolt and lock

washer to allow the battery cable to be connected.

© 2011 Magnum Energy, Inc.Page 9

Page 17

2.0 Introduction

Battery

point to the positive terminal of the battery bank. The DC disconnect provides a rear captive nut

to allow the battery cable to be front-connected using a 3/8-16 bolt and lock washer.

DC GROUND Busbar - This busbar is connected to the MP enclosure chassis and is used to tie

DC equipment grounds to a common point. This terminal is also used to connect the inverter/

MP/inverter system to the DC grounding electrode. If the DC grounding electrode conductor

is greater than #1/0 AWG, use the DC Ground Stud to connect to the DC grounding electrode

(i.e., ground rod).

DC Ground Stud - This 5/16-18 stud is connected to the MP enclosure chassis, and is provided

as a connection point to the DC grounding electrode when the conductor is larger than #1/0 AWG.

This stud also connects to the DC shunt through a busbar and serves as the DC negative to

ground connection point. If installing a PV-GFP device, this busbar must be removed (see Section 3.11). Note: For ground wires #1/0 AWG or smaller, use the DC GROUND busbar.

DC NEGATIVE Busbar - This busbar is connected to the battery bank negative through the

load side of the DC shunt. This busbar is the battery negative connection point for additional

DC circuits, such as from the DC negative output of a charge controller or when combining the

negatives of DC load circuit breakers. This busbar is rated to handle 120 amps.

DC NEGATIVE-GROUND Connection - This busbar connects the DC negative to the system

ground. It must be removed if the primary DC negative to ground connection is made elsewhere

in the system (see Section 3.11).

DC POSITIVE Busbar - This busbar is connected to the battery bank positive through the

bottom of the inverter DC disconnect. This busbar is the battery positive common point for

connecting additional DC circuits, such as from the output of a charge controller disconnect, the

DC positive feed to DC load breakers, and the positive connection to a battery status monitor.

This busbar is rated to handle 120 amps.

DC Shunt - A DC shunt installed in the DC negative side that is used to measure the amperage fl owing between the battery and the inverter (and any DC loads connected). This shunt is

pre-installed so that a battery monitor may be easily connected to display the current fl ow. See

Section A-2 for information on installing and wiring the ME-BMK-NS battery monitor inside the

MP enclosure. The MPSL-30D and MPSL-60S are supplied with a 500 amp/50mV DC shunt, and

the MPSH-30D and MPDH-30D have a 1000A/100mV DC shunt.

DC Shunt Voltage Sense Terminals - These two shunt terminals/screws serve as the sense

connections to the optional ME-BMK-NS battery monitor. When current is passed through the

shunt, the IR drop (AKA voltage drop) developed across it can be read by the battery monitor

to provide an accurate indication of the current fl owing through the shunt.

DIN Rail Track - For installing up to 1/2” (12.7mm) wide, DIN rail-mounted, Q-Frame type,

DC breakers. These breakers can be used for connecting DC loads or installing a PV-GFP device.

The track may be removed to allow 1” (25.4mm) wide, back-mounted, E-Frame type breakers

to be installed instead.

Enclosure Joining Screw/Washer - A #10-32 x 3/8” (Pan head, T25 Torx drive) thread

cutting screw and #10 lock washers are provided to join the two enclosures of the MPDH-30D

together – to have them at the same electrical potential. See Figure 3-16c for more information.

INV HOT 1 OUT Busbar - This busbar is the connection point for the HOT 1 output from each

installed inverter. The total output power combined from every inverter on this busbar is fed thru

the Inverter Bypass Breaker Assembly to the AC LEG 1 OUT Busbar.

INV HOT 2 OUT Busbar - This busbar is the connection point for the HOT 2 output from each

installed inverter. The total output power combined from every inverter on this busbar is fed thru

the Inverter Bypass Breaker Assembly to the AC LEG 2 OUT Busbar.

Positive Connection - The bottom of the inverter’s DC disconnect is the connection

© 2011 Magnum Energy, Inc.

Page 10

Page 18

2.0 Introduction

Inverter AC

circuit, a way to disconnect the AC input to the inverters, and overcurrent protection to the

inverter’s input wires when the minimum recommended AC wire sizes are used. Depending on

your MP model, the breaker provided for the inverter input will be either a double-pole 30 amp

(D30A) or a single-pole 60 amp (S60A) AC breaker.

The double-pole 30 amp AC breaker is provided on the MPSL-30D, MPSH-30D, and MPDH-30D

models to allow 120/240V AC inverters — up to 30 AC amps per leg pass-thru capability — to be

connected. The MPSL-30D and MPSH-30D come with one double-pole 30A input breaker and the

MPDH-30D comes with two double-pole 30A breakers. These three models require a double-pole

30A breaker for each additional inverter installed in a parallel-stacked confi guration.

The single 60 amp AC breaker is provided on the MPSL-60S models to allow 120V AC inverters

— up to 60 AC amps pass-thru capability — to be connected. If connecting MS4024’s in a

series-stacked confi guration, an additional single pole 60A breaker for the second MS4024 will

be required (as provided in the MPX extension kit).

Inverter Bypass Breaker Assembly - The Inverter AC Bypass Breaker Assembly is pre-wired

at the factory and consists of the inverter bypass switch and the inverter AC output disconnect

breaker. This breaker assembly provides a way to disconnect the AC output of the inverter

system, and to directly connect the AC input to the AC output by bypassing the inverter system.

The MPSL-30D and MPSL-60S are installed with a double-pole 60-amp AC bypass breaker

assembly, and the MPSL-30D and MPDH-30D are equipped with a double-pole 125-amp AC

bypass breaker assembly.

Inverter DC Disconnect Breaker - This 250 amp DC disconnect is a high interruption capacity,

magnetic-hydraulic, DC circuit breaker. These breakers were specifi cally designed and tested

to work with Magnum inverters to provide the delay time needed to minimize nuisance breaker

tripping. It provides an easy and convenient way to isolate the inverter from the battery, and

meets the NEC/CEC requirements for DC overcurrent protection when the size and length of the

battery-to-inverter cables are installed in accordance with the installation instructions in this

manual. These breakers have front-accessible connections, each provided with 3/8-16 Hex head

bolts with lock washers.

Inverter’s DC Negative Connection - Connects to Magnum inverter’s DC negative terminal.

Inverter’s DC Positive Connection - Connects to Magnum inverter’s DC positive terminal.

Mounting Dimples, BMK (x2) - These dimples allow the optional ME-BMK-NS (Battery Monitor

Kit without DC shunt) to be installed. Two #8-32 x 1/2” (T20 Torx drive) thread cutting screws

are provided to mount the battery monitor. See Section A2 for more information on mounting

the battery monitor.

Mounting Holes, Inv AC Input Breakers - Used to install additional Inverter AC Input

Breakers, which provide protection to each inverter’s AC input circuit.

Mounting Holes, Inv DC Backmount Breakers - For installing 1” (25.4mm) wide, back-

mounted, E-Frame type, DC breakers. These breakers can be used for connecting DC loads or

installing a PV-GFP device.

Mounting Holes, Inv DC Disconnect Breakers - Used to install additional Inverter DC

Disconnect Breakers, which isolate the inverter from the battery. These breakers meet the NEC/

CEC requirements for DC overcurrent protection when used in accordance with the installation

instructions in this manual.

Mounting Keyholes, MP Enclosure (x4) - Four keyholes for mounting the enclosure. See

Figures 3-5 or 3-6 for size information on these keyholes.

Input Breakers - These breakers provide protection to the inverter’s AC input

© 2011 Magnum Energy, Inc.Page 11

Page 19

2.0 Introduction

29

30

32

3 4

16

10

11

8

5

7

17

26

25

24

21

18

20

27

6

14

15

12

19

28

23

1

13

9

22

31

9

22

2

DC SHUNT

(

MOUNTED TO ENCLOSURE

UNDER INVERTER DC

OMPONENTS

C

DISCONNECT BREAKERS)

IN/OUT)

TIVE

Figure 2-7, MPSL-30D Internal Components

INVERTER’S DC NEGA

1

CONNECTION (CABLE)

DC NEGATIVE BUSBAR

5

INVERTER DC NEGATIVE

9

ONNECTIONS (BUSBAR)

C

DIN RAIL TRACK

13

AC LEG 1 OUT BUSBAR

17

AC LOAD PANEL)

(TO

DC POSITIVE BUSBAR

21

AC GROUND BUSBAR

25

(SOURCE/LOAD

DC NEGATIVE-

29

GROUND CONNECTION

© 2011 Magnum Energy, Inc.

INVERTER’S DC POSITIVE

2

CONNECTION (CABLE)

MOUNTING DIMPLES, BMK

6

10

14

18

22

26

30

ME-BMK-NS)

(FOR

INVERTER BY

ASSEMBLY (60A)

MOUNTING HOLES, DC

BACKMOUNT BREAKERS

AC NEUTRAL BUSBAR

(SOURCE/LOAD

BATTERY NEGATIVE

CONNECTIONS

AC LEG 2 IN BUSBAR

GEN OR GRID)

(FROM

DC GROUND STUD

PASS BREAKER

IN/OUT)

INV HOT 2 OUT BUSBAR

3

7

11

15

NVERTER OUTPUT)

(FROM I

AC GROUND BUSBAR

(INVERTER INPUT/O

INVERTER AC INPUT

BREAKER (

D30A)

MOUNTING HOLES, INV DC

DISCONNECT BREAKER

AC NEUTRAL-

19

GROUND CONNECTION

BATTERY POSITIVE

23

CONNECTION

DC GROUND BUSBAR

27

DC SHUNT

31

(500A/50MV)

UTPUT)

INV HOT 1 OUT BUSBAR

4

8

12

16

20

24

28

32

NVERTER OUTPUT)

(FROM I

AC NEUTRAL BUSBAR

(INVERTER INPUT/O

MOUNTING HOLES, TO ADD

AC INPUT BREAKER

INV

INVERTER DC DISCONNECT

BREAKER

AC LEG 1 IN BUSBAR

GEN OR GRID)

(FROM

AC LEG 2 OUT BUSBAR

AC LOAD PANEL)

(TO

MOUNTING KEYHOLES,

MP ENCLOSURE (

DC SHUNT VOLT

SENSE TERMINALS/SCREWS

Page 12

UTPUT)

X4)

AGE

Page 20

2.0 Introduction

29

30

32

3 4

16

10

8

5

7

17

26

25

24

21

18

20

27

6

14

15

12

19

28

23

1

13

9

22

31

9

22

11

2

DC SHUNT

MOUNTED TO ENCLOSURE

(

UNDER INVERTER DC

C

OMPONENTS

DISCONNECT BREAKERS)

INVERTER’S DC NEGA

1

CONNECTION (CABLE)

DC NEGATIVE BUSBAR

5

INVERTER DC NEGATIVE

9

ONNECTIONS (BUSBAR)

C

DIN RAIL TRACK

13

AC LEG 1 OUT BUSBAR

17

AC LOAD PANEL)

(TO

DC POSITIVE BUSBAR

21

AC GROUND BUSBAR

25

(SOURCE/LOAD

DC NEGATIVE-

29

GROUND CONNECTION

IN/OUT)

TIVE

Figure 2-8, MPSL-60S Internal Components

INVERTER’S DC POSITIVE

2

CONNECTION (CABLE)

MOUNTING DIMPLES, BMK

6

10

14

18

22

26

30

ME-BMK-NS)

(FOR

INVERTER BY

ASSEMBLY (60A)

MOUNTING HOLES, DC

BACKMOUNT BREAKERS

AC NEUTRAL BUSBAR

(SOURCE/LOAD

BATTERY NEGATIVE

CONNECTIONS

AC LEG 2 IN BUSBAR

GEN OR GRID)

(FROM

DC GROUND STUD

PASS BREAKER

IN/OUT)

INV HOT 2 OUT BUSBAR

3

7

11

15

19

23

27

31

NVERTER OUTPUT)

(FROM I

AC GROUND BUSBAR

(INVERTER INPUT/O

INVERTER AC INPUT

BREAKER (

MOUNTING HOLES, INV DC

DISCONNECT BREAKER

AC NEUTRALGROUND CONNECTION

BATTERY POSITIVE

CONNECTION

DC GROUND BUSBAR

DC SHUNT

(500A/50MV)

UTPUT)

SINGLE 60A)

© 2011 Magnum Energy, Inc.Page 13

INV HOT 1 OUT BUSBAR

4

8

12

16

20

24

28

32

NVERTER OUTPUT)

(FROM I

AC NEUTRAL BUSBAR

(INVERTER INPUT/O

MOUNTING HOLES, TO ADD

AC INPUT BREAKER

INV

INVERTER DC DISCONNECT

BREAKER

AC LEG 1 IN BUSBAR

GEN OR GRID)

(FROM

AC LEG 2 OUT BUSBAR

AC LOAD PANEL)

(TO

MOUNTING KEYHOLES,

MP ENCLOSURE (

DC SHUNT VOLT

SENSE TERMINALS/SCREWS

UTPUT)

X4)

AGE

Page 21

2.0 Introduction

`

3 4

14

10 11

8

5

7

15

24

22

21

18

16

17

25

6

12

23

26

20

1

19

29

27

28

30

19

13

9

9

2

DC SHUNT

MOUNTED TO ENCLOSURE

(

UNDER INVERTER DC

C

OMPONENTS

DISCONNECT BREAKER)

INVERTER’S DC NEGA

1

CONNECTION (CABLE)

DC NEGATIVE BUSBAR

5

INVERTER DC NEGATIVE

9

ONNECTIONS (BUSBAR)

C

MOUNTING HOLES, INV DC

13

DISCONNECT BREAKER

AC LEG 1 IN BUSBAR

17

(FROM

AC LEG 2 OUT BUSBAR

21

(TO

DC GROUND BUSBAR

25

DC SHUNT

29

(1000A/100MV)

GEN OR GRID)

AC LOAD PANEL)

TIVE

Figure 2-9, MPSH-30D Internal Components

© 2011 Magnum Energy, Inc.

INVERTER’S DC POSITIVE

2

CONNECTION (CABLE)

MOUNTING DIMPLES, BMK

6

10

14

18

22

26

30

ME-BMK-NS)

(FOR

INVERTER BY

ASSEMBLY (125A)

INVERTER DC DISCONNECT

BREAKER

DC POSITIVE BUSBAR

AC GROUND BUSBAR

(SOURCE/LOAD

MOUNTING KEYHOLES,

MP ENCLOSURE (

DC SHUNT VOL

SENSE TERMINALS/SCREWS

PASS BREAKER

IN/OUT)

X4)

TAGE

INV HOT 2 OUT BUSBAR

3

7

11

15

19

23

27

NVERTER OUTPUT)

(FROM I

AC GROUND BUSBAR

(INVERTER INPUT/O

INVERTER AC INPUT

BREAKER (D30A)

AC LEG 1 OUT BUSBAR

AC LOAD PANEL)

(TO

BATTERY NEGATIVE

CONNECTIONS

AC NEUTRALGROUND CONNECTION

DC NEGATIVEGROUND CONNECTION

UTPUT)

INV HOT 1 OUT BUSBAR

4

8

12

16

20

24

28

NVERTER OUTPUT)

(FROM I

AC NEUTRAL BUSBAR

(INVERTER INPUT/O

MOUNTING HOLES, TO ADD

AC INPUT BREAKER

INV

AC NEUTRAL BUSBAR

SOURCE/LOAD

BATTERY POSITIVE

CONNECTION

AC LEG 2 IN BUSBAR

GEN OR GRID)

(FROM

DC GROUND STUD

Page 14

UTPUT)

IN/OUT)

Page 22

2.0 Introduction

3

4

8

5

7

10

14

11

12

6

13

15

9

16

1

2

17

INVERTER’S DC NEGA

1

CONNECTION (CABLE)

AC NEUTRAL BUSBAR

5

(INVERTER INPUT/O

MOUNTING HOLES, TO ADD

9

AC INPUT BREAKERS

INV

AC NEUTRAL-

13

GROUND CONNECTION

ENCLOSURE JOINING

17

CREW/WASHER

S

RIGHT SIDE VIEW

(LOWER

UTPUT)

INV HOT 2 OUT BUSBAR

3

7

11

15

NVERTER OUTPUT)

(FROM I

INVERTER BY

PASS BREAKER

ASSEMBLY (125A)

AC LEG 1 OUT BUSBAR

AC LOAD PANEL)

(TO

AC LEG 1 IN BUSBAR

GEN OR GRID)

(FROM

TIVE

UTPUT)

2

6

10

14

INVERTER’S DC POSITIVE

CONNECTION (CABLE)

AC GROUND BUSBAR

(INVERTER INPUT/O

AC LEG 2 OUT BUSBAR

AC LOAD PANEL)

(TO

AC LEG 2 IN BUSBAR

GEN OR GRID)

(FROM

SECTION)

INV HOT 1 OUT BUSBAR

4

8

12

16

NVERTER OUTPUT)

(FROM I

INVERTER AC INPUT

BREAKERS (D30A

AC NEUTRAL BUSBAR

(SOURCE/LOAD

AC GROUND BUSBARS

(SOURCE/LOAD

X2)

IN/OUT)

IN/OUT)

Figure 2-10a, MPDH-30D (AC Side) Internal Components

© 2011 Magnum Energy, Inc.Page 15

Page 23

2.0 Introduction

31

30

32

33

28

20

28

23

21

18

26

19

22

1

2

24

20

27

25

28

29

DC SHUNT

MOUNTED TO ENCLOSURE

(

UNDER INVERTER DC

C

OMPONENTS

DISCONNECT BREAKERS)

DC NEGATIVE BUSBAR

18

MOUNTING HOLES, INV DC

22

DISCONNECT BREAKER

DC POSITIVE BUSBAR

26

DC NEGATIVE-

30

GROUND CONNECTION

Figure 2-10b, MPDH-30D (DC Side) Internal Components

© 2011 Magnum Energy, Inc.

MOUNTING DIMPLES, BMK

19

23

27

31

ME-BMK-NS)

(FOR

DIN RAIL TRACK

DC GROUND BUSBARS

(X3)

DC SHUNT

(1000A/100MV)

INVERTER DC NEGATIVE

20

ONNECTIONS (BUSBAR)

C

MOUNTING HOLES, DC

24

BACKMOUNT BREAKERS

BATTERY NEGATIVE

28

CONNECTIONS

DC GROUND STUD

32

INVERTER DC DISCONNECT

21

BREAKERS (X

BATTERY POSITIVE

25

CONNECTIONS (X

MOUNTING KEYHOLES

29

33

EACH ENCLOSURE)

(X4 FOR

DC SHUNT VOLT

SENSE TERMINALS/SCREWS

2)

2)

AGE

Page 16

Page 24

3.0 Installation

3.0 Installation

This section describes the requirements and recommendations for installing the MP enclosure.

Info:

MPSL/MPSH

inverters are required, the optional MPX enclosures are used. Refer to the MPX Extension

Owner’s Manual (PN:64-1015) for information on installing these additional inverters.

This installation section primarily explains the installation of one inverter on the

enclosure,

and two inverters on the MPDH enclosure. When additional

3.1 Pre-Installation

Before proceeding with the installation:

• Please read and familiarize yourself with the entire Installation section.

• Read and ensure you understand the “Important Product Safety Information” and the “Important

Battery Safety Instructions” at the beginning of this manual.

• Be aware of all safety and electrical codes which must be met.

• Inspect all shipping cartons for evidence of physical damage. If a shipping carton is damaged,

request that the shipping agent be present for inspection when the carton is opened.

• Unpack the MP enclosure box and remove the components. Verify that you have the components

and hardware as listed below in Section 3.1.1 (and shown in Figures 3-1 and 3-2).

• Use the information in Section 3.1.2 to help identify most of the materials and tools required

for the installation.

• Read the information provided in Section 3.1.3 to properly plan for the installation.

3.1.1 MP Parts Included

Refer to Figures 3-1 or 3-2 (and the item list below) for you particular MP model to verify the

nece

ssary parts are included. If items are missing, contact your authorized Magnum Energy dealer

or Magnum Energy.

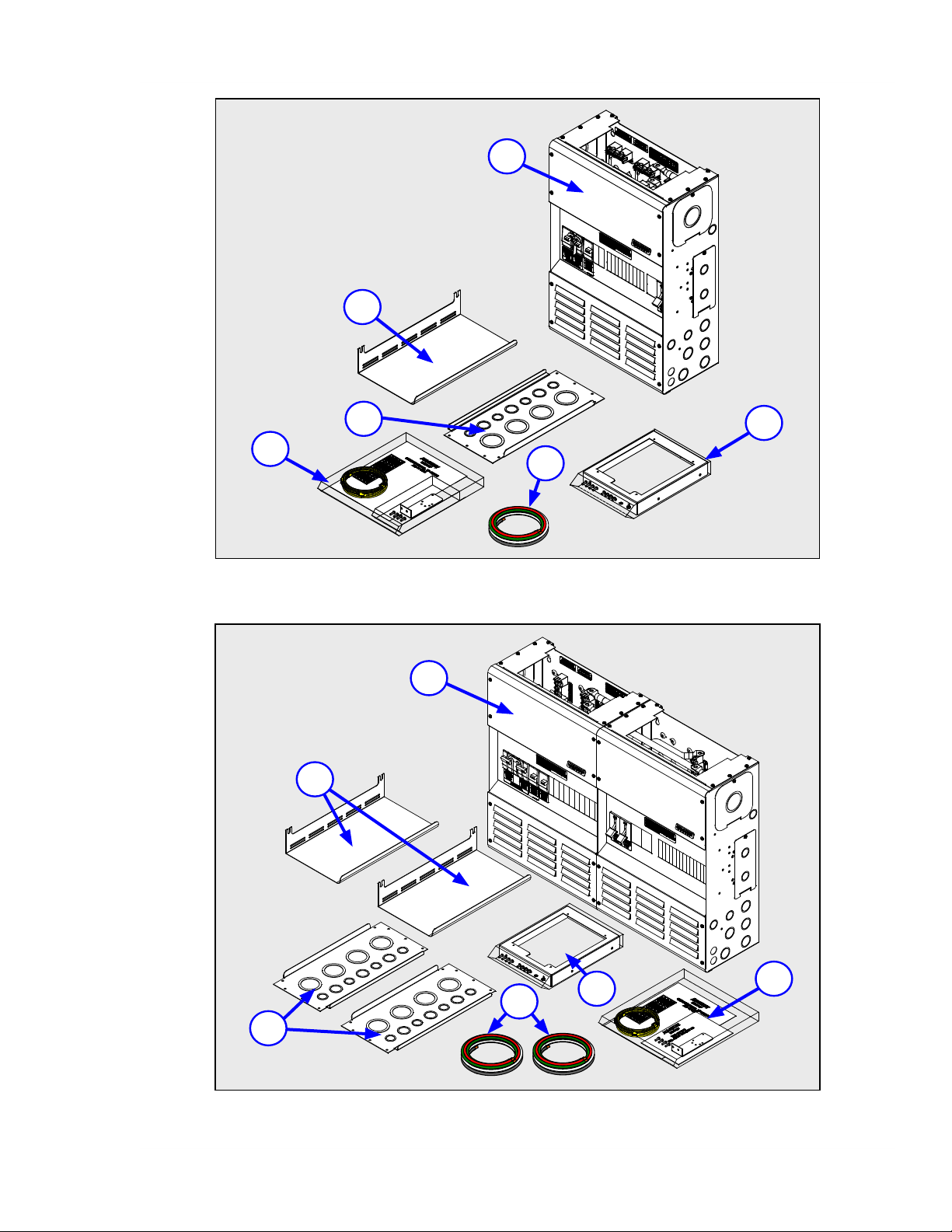

1a

1b

2

3

4

5

6

Info: Save your proof-of-purchase as a record of your ownership; it will be needed if

the unit should require in-w

L or MPSH Models - The MPSL-30D, MPSL-60S, and MPDH-30D use a single enclosure

MPS

to provide the AC/DC breakers, busbars, and wiring for the inverter’s AC and DC circuits.

H Model - The MPDH-30D uses two enclosures, one enclosure (AC Side) provides

MPD

the AC breakers, busbars, and wiring for the inverters AC circuits; and, the other

enclosure (DC Side) provides the DC breakers, busbars, and wiring for the inverter’s

DC circuits.

Inverter Hood - The

that is mounted on a Magnum Panel to prevent items from falling into the ventilation

openings at the top of the inverter. See Section A3 for more information on this hood.

Knockout Plate -

safety plate. See Section A5 for more information on this plate.

RTR (Router) Bracket Kit - This kit consists of the router bracket and the hardware

ME-

to attach the ME-RTR (i.e., Router) to the side of the MP enclosure. This kit is not

provided with the MPSL-60S model. See Section A4 for more information on this kit.

Hardware Kit - This hardware kit consists of the Charge Controller bracket and

MP

hardware (see Section A1), the owner’s manual, communications cables (see Section

3.8), and a front cover label set (see Section 3.15).

MP AC Wiring

the inverter’s AC input and output terminals to the MP enclosure. See Section 3.6.3 for

more information on this kit.

The knockout plate is provided as an upper conduit plate, or as a

Kit - This wiring kit provides the appropriate AC wires needed to connect

arranty service.

inverter hood is required to be installed over a Magnum inverter

© 2011 Magnum Energy, Inc.Page 17

Page 25

3.0 Installation

1a

2

3

5

6

Figure 3-1, Parts Included - MPSL and MPSH Models

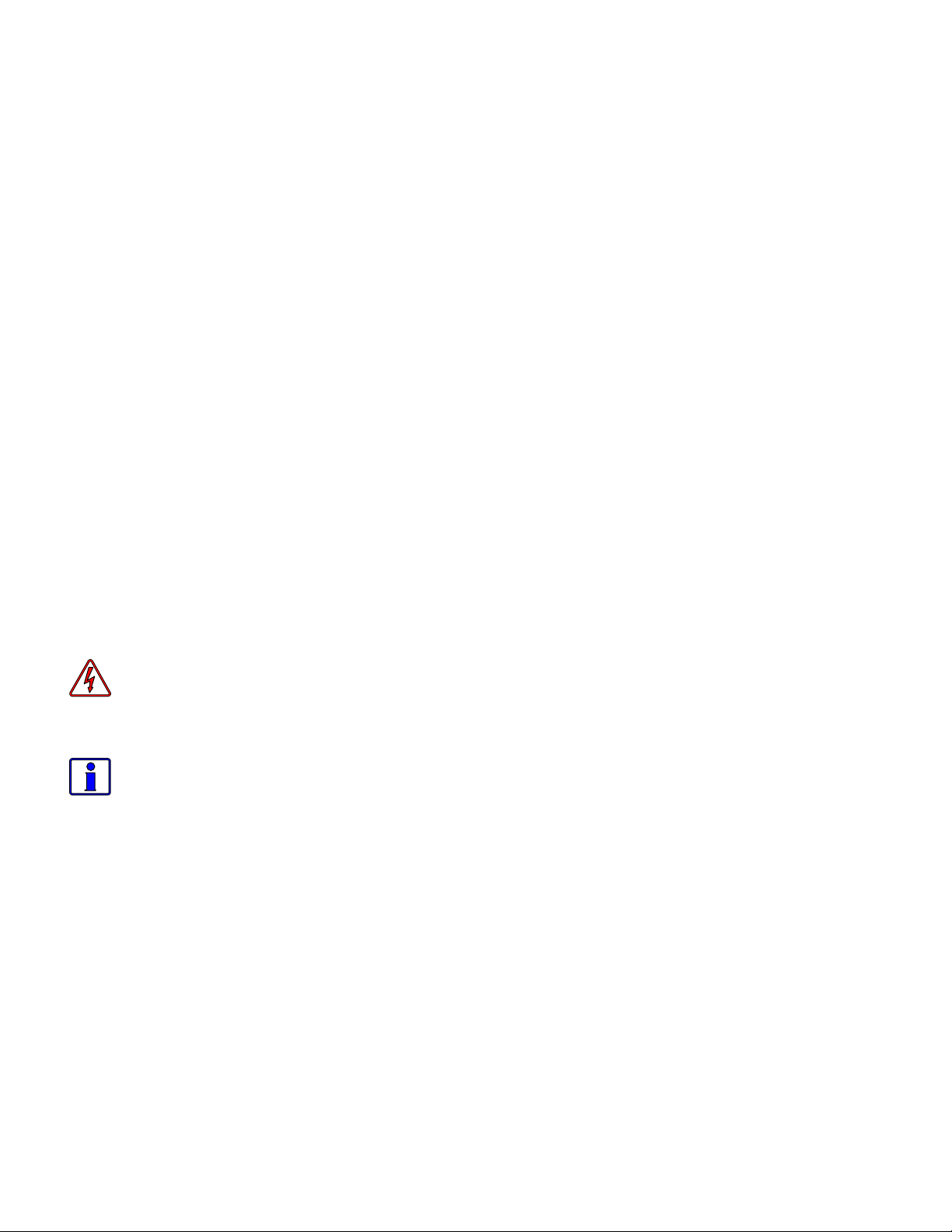

1b

2

4

3

Figure 3-2, Parts Included - MPDH Models

© 2011 Magnum Energy, Inc.

6

4

5

Page 18

Page 26

3.0 Installation

3.1.2

The following material and tools may be required for installing this equipment:

Materials

Conduit, str

•

• Electrical tape • Wire ties

• Conductors/cables for wiring AC source/load • A strong back

• Battery cables for wiring to battery bank • Conductors for system ground

Tools

• Flat-blade 1/4” screwdrivers • Insulated pliers • Wire cutters/strippers

• Phillips screwdriver • Pencil or marker • AC/DC Voltmeter

• Drill and drill bits • 1/2” open end wrench • Level

• Torque wrenches • Ratchet drives

• Torx screwdrivers (T15, T20 and T25 drive)

Required Material and Tools

ain-reliefs, and appropriate fi

ttings • 1/4” mounting bolts and lock washers

3.1.3 Planning

Installing the MP/inverter system can be fairly straightforward if you take time to plan before

the fi

turning

common, costly mistakes.

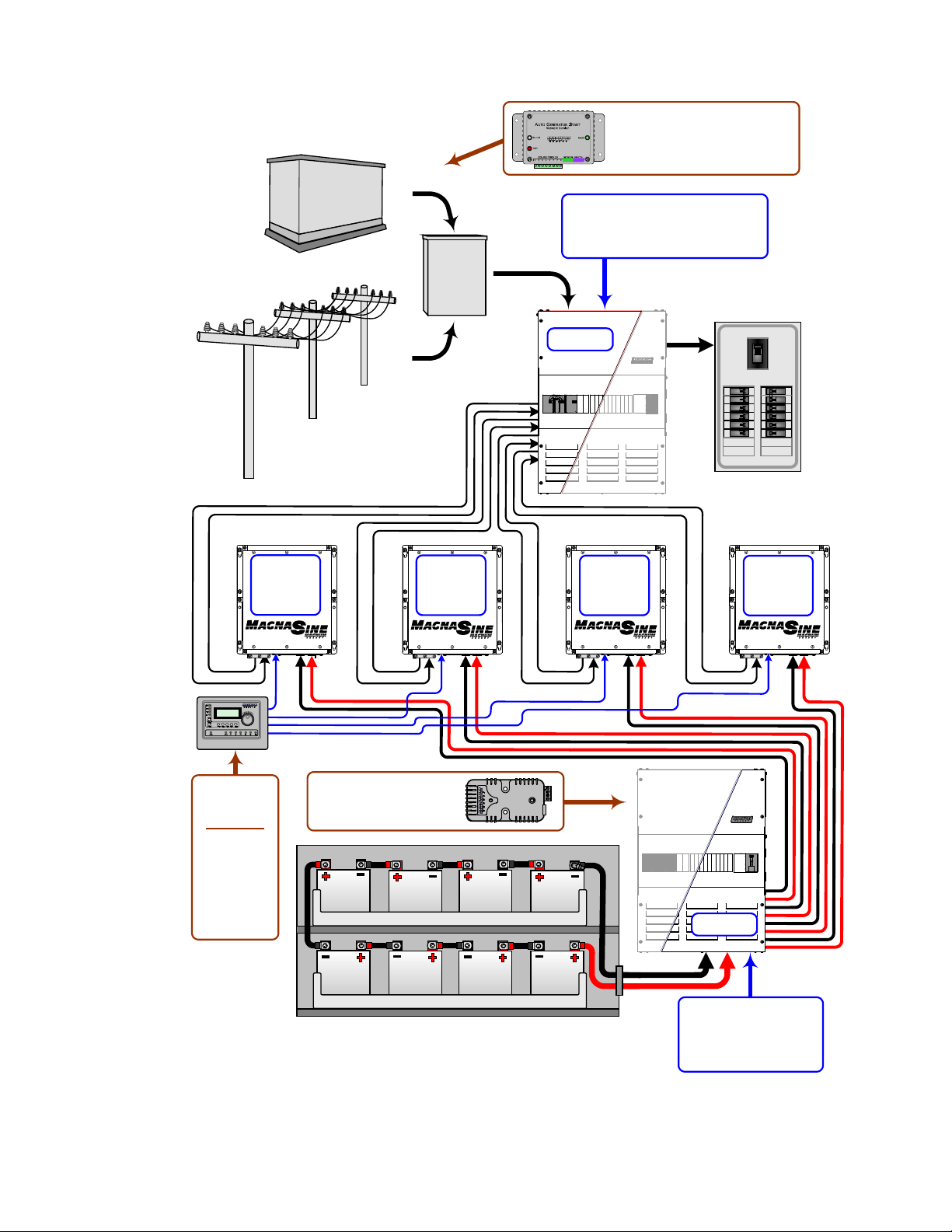

To assist you in planning and designing your installation, review the simplifi ed system diagram

shown in Figure 3-3 for parallel-stacked inverter installations, or Figure 3-4 for series-stacked

inverter installations. These drawings are a simple overview of the MP/inverter installation. They

are not intended to provide detailed information, override or restrict any national or local electrical

codes, nor should they be the determining factor as to whether the installation is compliant – that

is the responsibility of the electrician and the onsite inspector.

rst screw. The more thorough you plan, the more time you will save, and avoid

WARNING: Installations should

or certifi ed electrician. It is the installer’s responsibility to determine which safety

codes and standards apply, and to ensure that all applicable installation requirements

are followed. Applicable installation codes vary depending on the specifi c location and

application of the installation.

Info: Detailed MP/inv

depending on you MP model.

The installation section uses the following steps to perform the MP/inverter installation:

• Find the appropriate location (Section 3.2)

• Prepare the MP enclosure and inverter (Section 3.3)

• Mounting the MP enclosure and inverter (Section 3.4)

• Beware of wiring guidelines/safety (Section 3.5)

• Wire AC circuit (Section 3.6)

• Wire DC circuits (Section 3.7)

• Wire communications cables (Section 3.8)

• Removing negative or neutral to ground connections (Sections 3.9 and 3.10)

• Determine the system ground (Section 3.11)

• Perform a fi nal installation checklist (Section 3.12)

• Perform a functional test (Section 3.13)

• Attach the front covers (Section 3.14)

• Apply external labels (Section 3.15)

erter system wiring drawings are provided in Section 4.0,

be performed by qualifi ed personnel, such as a licensed

© 2011 Magnum Energy, Inc.Page 19

Page 27

ME-AGS-N

Auto Gen Start Controller

(Magnum Accessory)

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

G

ENERATOR POWER

(120/240VAC OUPUT)

UTILITY POWER

(120/240VAC OUTPUT)

AC

Transfer

Switch

#3

MS-PAE

I

NVERTER

(SLAVE)

F

l

u

x

C

a

p

a

c

i

t

o

r

G

e

n

e

r

a

t

o

r

ELECTRICAL PANEL*

(120/240VAC LOADS)

BATTERY

BANK

*A MAIN

PANEL AND SUB-PANEL

MAY BE REQUIRED

#2

MS-PAE

I

NVERTER

(SLAVE)

#4

MS-PAE

I

NVERTER

(SLAVE)

#1

MS-PAE

INVERTER

(MASTER)

AC SIDE

ME-BMK-NS

Battery Monitor

(Magnum Accessory)

DC SIDE

Magnum Panel (AC Side)

Includes Inverter Bypass &

AC Input/Output Breakers

ME-RTR

Router -

required

to stack

MS-PAE

inverters

in parallel

(Magnum

Accessory)

Maximum MS-PAE inverters that can be stacked in parallel:

MPSL-30D = maximum of two MS-PAE inverters

MPSH-30D = maximum of three MS-PAE inverters

MPDH-30D = maximum of four MS-PAE inverters

Magnum Panel

(DC side)

Includes DC Shunt

& DC Disconnects

3.0 Installation

Figure 3-3, MP Series Simplifi

© 2011 Magnum Energy, Inc.

ed Parallel-Stacked Installation Diagram

Page 20

Page 28

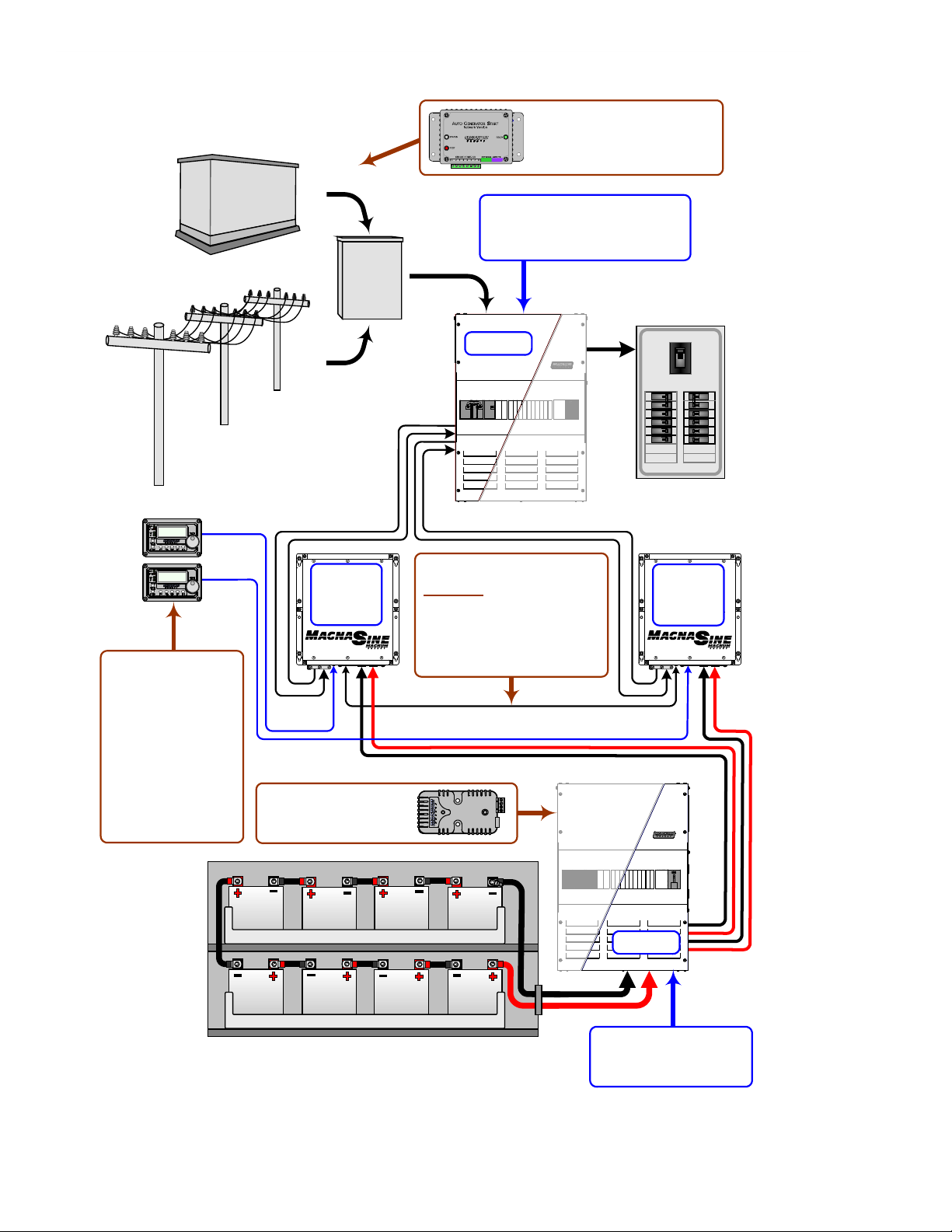

3.0 Installation

MS4024

INVERTER

ME-AGS-N

Auto Gen Start Controller

(Magnum Accessory)

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

GENERATOR POWER

(120/240VAC OUPUT)

UTILITY POWER

(120/240VAC OUTPUT)

AC

Transfer

Switch

F

l

u

x

C

a

p

a

c

i

t

o

r

G

e

n

e

r

a

t

o

r

ELECTRICAL PANEL*

(120/240VAC L

OADS)

BATTERY

BANK

*A MAIN PANEL AND SUB-PANEL

MAY BE REQUIRED

AC SIDE

ME-BMK-NS

Battery Monitor

(Magnum Accessory)

DC SIDE

MPSL-60S (AC Side)

Includes Inverter Bypass &

AC Input/Output Breakers

ME-ARC (x2)

Advanced Remotes

- for inverter set up

and monitoring

(Magnum

Accessory).

The ME-RTR may

be used if identical

settings are used

on both inverters.

Series Stacking Cable,

required to stack MS4024

inverters in series.

(Magnum Accessory).

Included with MPXS-60S

Extension.

MPSL-60S allows a maximum of two

MS4024's to be stacked in series

MPSL-60S (DC side)

Includes DC Shunt &

DC Disconnects

MS4024

INVERTER

Figure 3-4, MP Series Simplifi

ed Series-Stacked Installation Diagram

© 2011 Magnum Energy, Inc.Page 21

Page 29

3.0 Installation

3.2

Choosing an appropriate location for the MP/inverter system should be determined early in the

installation process; install it only in a location that meets the following requirements:

Indoors ment away from sources of high temperature and moisture. The MP enclosure uses plated copper