Page 1

MMS Series

Inverters/Chargers

Owner’s Manual

Page 2

Disclaimer of Liability

The use of this manual and the conditions or methods of installation,

operation, use, and maintenance of the MMS Series inverter/

charger are beyond the control of Magnum Energy, Inc. Therefore,

this company assumes no responsibility and expressly disclaims

any liability for loss, damage, or expense whether direct, indirect,

consequential, or incidental that may arise out of or be in any way

connected with such installation, operation, use, or maintenance.

Due to continuous improvements and product updates, the images

shown in this manual may not exactly match the unit purchased.

Restrictions on Use

The MMS Series inverter/charger may only be used in life support

devices or systems with the express written approval of Magnum

Energy. Failure of this inverter can reasonably be expected to cause

the failure of that life support device or system, or to affect the safety

or effectiveness of that device or system. If the MMS Series inverter

fails, it is reasonable to assume that the health of the user or other

persons may be endangered.

Copyright Notice

Copyright © 2014 by Magnum Energy, Inc. All rights reserved.

Permission to copy, distribute, and/or modify this document is

prohibited without express written permission from Magnum Energy.

Document Information

Description – MMS Series Owner’s Manual

Part Number and Revision – 64-0036 Rev B

Date Published – March 2014

This entire manual is available for download—with many of the

diagrams available in color—under the Document Library tab on our

website at:

www.magnumenergy.com

Contact Information

Magnum Energy, Inc.

2211 West Casino Rd.

Everett, WA 98204

Phone: (425) 353-8833

Fax: (425) 353-8390

Record the unit’s model and serial number in case you need to

provide this information in the future.

Model: Serial Number:

MMS1012 U1

MMS1012-G U1

i

© 2014 Magnum Energy, Inc.

Page 3

Conventions Used in this Manual (terminology)

Shorepower or External AC power – refers to alternating current

(AC) provided by the utility electric power grid or from a generator.

Mobile application – refers to inverters used in a recreational vehicle

(RV), boat, or a truck installation.

Safety Symbols

To reduce the risk of electrical shock, fi re, or other safety hazard, the

following safety symbols have been placed throughout this manual

to indicate dangerous and important safety instructions.

WARNING: This symbol indicates that failure to take a

specifi ed action could result in physical harm to the user.

CAUTION: This symbol indicates that failure to take a

specifi ed action could result in damage to the equipment.

Info: This symbol indicates information that emphasizes

or supplements important points of the main text.

IMPORTANT PRODUCT SAFETY INSTRUCTIONS

This manual contains important safety instructions that must be followed during the installation and operation of this product. Read all

instructions and safety information contained in this manual before

installing or using this product.

• All electrical work must be performed in accordance with local,

state, and federal electrical codes.

• This product is designed for indoor/compartment installation.

DO NOT expose to rain, snow, moisture, or liquids of any type.

• Use insulated tools to reduce the chance of electrical shock or

accidental short circuits.

• Remove all jewelry (such as rings, watches, bracelets, etc.,) when

installing or performing maintenance on the inverter.

• Always disconnect the batteries or energy source prior to installing or performing maintenance on the inverter. Live power may

be present at more than one point since an inverter utilizes both

batteries and AC. Turning off the inverter may not reduce this

risk. As long as AC power is connected, it will pass through the

inverter regardless of the ON/OFF power switch setting.

• Always verify proper wiring prior to starting the inverter.

• Do not operate the inverter if it has been damaged.

• Do not dismantle the inverter; there are no user-serviceable parts

contained in this product. Attempting to service the unit yourself

could cause electrical shock. Internal capacitors remain charged

after all power is disconnected.

© 2014 Magnum Energy, Inc.

ii

Page 4

• No AC or DC disconnects are provided as an integral part of this

inverter. Both AC and DC disconnects must be provided as part

of the system installation.

• No overcurrent protection for the battery supply is provided as

an integral part of this inverter. Overcurrent protection of the

battery cables must be provided as part of the installation.

• No overcurrent protection for the AC output wiring is provided

as an integral part of this inverter. Overcurrent protection of the

AC output wiring must be provided as part of the installation.

IMPORTANT BATTERY SAFETY INSTRUCTIONS

• Wear eye protection (safety glasses) when working with batteries.

• Remove all jewelry such as rings, watches, bracelets, etc., when

installing or performing maintenance on the batteries.

• Never work alone. Always have someone near you when working

around batteries.

• Use proper lifting techniques when working with batteries.

• Never use old or untested batteries. Check each battery’s label

for age, type, and date code to ensure all batteries are identical.

• Batteries are sensitive to changes in temperature. Always install

batteries in a stable environment.

• Install batteries in a well ventilated area. Batteries can produce

explosive gasses. For compartment or enclosure installations,

always vent batteries to the outside.

• Provide at least one inch (2.5 cm) of air space between batteries

to provide optimum cooling.

• Never smoke when in the vicinity of batteries.

• To prevent a spark at the battery and to reduce the chance of

explosion, always connect the cables to the batteries fi rst. Then

connect the cables to the inverter.

• Use insulated tools at all times.

• Always verify proper polarity and voltage before connecting the

batteries to the inverter.

• To reduce the chance of fi re or explosion, do not short-circuit

the batteries.

• In the event of accidental exposure to battery acid, wash thoroughly with soap and water. In the event of exposure to the eyes,

fl ood them for at least 15 minutes with running water and seek

immediate medical attention.

• Recycle old batteries.

SAVE ALL INSTRUCTIONS

iii

© 2014 Magnum Energy, Inc.

Page 5

Table of Contents

1.0 Introduction ................................................................1

1.1 MMS Series Models ................................................... 1

1.2 How an Inverter/Charger Works ................................. 2

1.2.1 Inverter Applications for Mobile Installations ................ 2

1.3 Advantages of a Pure Sine vs Modifi ed Sine Inverter ..... 2

1.4 Appliances and Run Time .......................................... 2

1.5 Standard Features and Benefi ts ................................. 3

1.5.1 Battery Temperature Sensor ...................................... 6

2.0 Installation .................................................................7

2.1 Pre-Installation ........................................................ 7

2.1.1 Unpacking and Inspection ......................................... 7

2.1.2 Locating and Mounting the Inverter ...........................10

2.1.3 Wiring Guidelines ....................................................13

2.2 DC Wiring ..............................................................14

2.2.1 DC Wire Sizing ........................................................14

2.2.2 DC Overcurrent Protection ........................................14

2.2.3 DC Grounding .........................................................16

2.2.4 DC Cable Connections ..............................................16

2.3 Battery Bank Wiring ................................................18

2.3.1 Inverter to Battery Bank Wiring ................................18

2.4 AC Wiring ..............................................................20

2.4.1 Neutral to Safety Ground Bonding .............................20

2.4.2 AC Wiring Connections .............................................20

2.4.3 AC Wire Size and Overcurrent Protection ....................21

2.4.4 AC Input Wiring ......................................................22

2.4.5 AC Output Wiring ....................................................24

2.5 Functional Test .......................................................25

3.0 Operation ..................................................................27

3.1 Operating Modes .....................................................27

3.1.1 Inverter Mode .........................................................27

3.1.2 Standby Mode ........................................................28

3.2 Battery Temperature Sensor Operation.......................31

3.3 Protection Circuitry Operation ...................................32

3.4 Inverter Startup ......................................................33

3.5 Factory Default Settings ...........................................34

4.0 Maintenance and Troubleshooting ............................36

4.1 Recommended Inverter and Battery Care ...................36

4.2 RV/Marine Off-Season Storage ..................................36

4.3 Resetting the Inverter ..............................................37

4.4 Troubleshooting ......................................................38

5.0 Specifi cations ............................................................39

© 2014 Magnum Energy, Inc.

iv

Page 6

Table of Contents (cont.)

A-1 Optional Equipment and Accessories .........................40

B-1 Battery Information ..................................................41

C-1 Warranty/Service Information ..................................44

C-1.1 Limited Warranty ....................................................44

C-1.2 How to Receive Repair Service ..................................45

List of Figures

Figure 1, MMS1012 Model Inverter/Charger .............................. 3

Figure 2, MMS1012-G Model Inverter/Charger ........................... 3

Figure 3, Top and Left Side Features ........................................ 4

Figure 4, Front and Back Side Features ..................................... 5

Figure 5, Battery Temperature Sensor (BTS) ............................. 6

Figure 6, MMS1012 Model Basic Installation Diagram ................. 8

Figure 7, MMS1012-G Model Basic Installation Diagram .............. 9

Figure 8, Approved MMS1012 (-G) Mounting Orientations .........12

Figure 9, MMS1012 Model Inverter/Charger Dimensions ............12

Figure 10, MMS1012-G Model Inverter/Charger Dimensions .......13

Figure 11, DC Cable to Battery Terminals .................................17

Figure 12, DC Cable to Inverter’s DC Terminals .........................17

Figure 13, AC Wiring Connections (MMS1012 model) .................23

Figure 14, AC Hardwiring Connections (MMS1012-G model) .......23

Figure 15, Warning Label .......................................................25

Figure 16, Automatic 4-Stage Charging Graph ..........................30

Figure 17, BTS Temperature to Charge Voltage Change ..............31

Figure 18, Resetting the Inverter ............................................37

Figure 19, Series Battery Wiring .............................................41

Figure 20, Parallel Battery Wiring ............................................42

Figure 21, Series-Parallel Battery Wiring ..................................42

Figure 22, Battery Bank Wiring Examples (12 volt) ...................43

List of Tables

Table 1, Recommended DC Wire/Overcurrent Device .................15

Table 2, DC Wire Size For Increased Distance ...........................15

Table 3, Wire Color to AC Wire Connection ...............................21

Table 4, Minimum Wire Size to Circuit-breaker Size ...................22

Table 5, Inverter Battery Turn On/Off Levels .............................33

Table 6, Inverter/Charger Default Settings ...............................35

Table 7, Troubleshooting Guide ...............................................38

Table 8, MMS Series Specifi cations ..........................................39

v

© 2014 Magnum Energy, Inc.

Page 7

Introduction

1.0 Introduction

Congratulations on your purchase of an MMS Series inverter/charger

from Magnum Energy, Inc. This product is designed especially for

your mobile application. Powerful, yet simple to use, this product will

provide you with years of trouble-free use.

1.1 MMS Series Models

MMS1012 – a 1000 watt inverter/charger with 20-amp AC transfer

capability and a 50-amp, 4-stage Power Factor Correction (PFC)

charger. The AC input and output are provided with pigtail wires to

allow hardwiring to a main AC distribution panel and to an inverter

sub-panel. Features isolated input/output neutrals for mobile

applications. Includes a 15-foot battery temperature sensor.

Figure 1, MMS1012 Model Inverter/Charger

MMS1012-G – a 1000 watt inverter/charger with 20-amp AC transfer

capability and a 50-amp, 4-stage PFC charger. The AC input is

provided by a standard 3-foot plug-in power cord, and the AC output

is provided by a standard GFCI two plug outlet. Features isolated

input/output neutrals for mobile applications. Includes a 15-foot

battery temperature sensor.

Figure 2, MMS1012-G Model Inverter/Charger

© 2014 Magnum Energy, Inc.

1

Page 8

Introduction

1.2 How an Inverter/Charger Works

An inverter takes direct current (DC) from your batteries and turns

it into alternating current (AC), like you use at home. With MMS

Series models, it also takes alternating current (when connected to

a generator or to shorepower) and transforms it into direct current

to recharge your batteries.

The two modes of operation associated with this inverter/charger

are referred to in this document as:

Inverter Mode: DC from the batteries is transformed into pure sine

wave AC for powering your mobile applications.

Standby Mode: The unit operates as a battery charger to convert

incoming AC power into DC power to recharge the batteries while

continuing to pass the incoming AC power directly to the inverter’s

output, to power any AC loads.

1.2.1 Inverter Applications for Mobile Installations

Inverters can be used to provide power in mobile situations—RV,

truck, or boat. In these applications, the inverter provides power to

the AC loads using the energy stored in the batteries and recharges

the batteries when shorepower or an onboard generator is available.

1.3 Advantages of a Pure Sine Wave vs Modifi ed Sine

Wave Inverter

Today’s inverters come in two basic output waveforms: modifi ed sine

wave (which is actually a modifi ed square wave) and pure sine wave.

Modifi ed sine wave inverters approximate a pure sine waveform and

will run most appliances and electronics without any problems. These

inverters are less expensive and, therefore, offer a viable alternative

to more expensive pure sine wave inverters.

The output of a pure sine wave inverter is equal to, or in many

cases, better than the shorepower used in your home. Virtually any

electronic device will operate from a pure sine wave inverter. Motors run cooler, microwaves usually cook faster, and clocks keep

better time just to name a few examples. Without compromising

quality or performance, the MagnaSine provides you with all of the

advantages of a pure sine wave inverter at a much lower cost than

many on the market.

1.4 Appliances and Run Time

The MMS Series inverter/charger can power a wide range of household

appliances. As with any appliance using batteries for power, there

is a certain length of time that it can run—this is called “run time”.

Actual run time depends on several variables including the size and

the type of appliance, the type of batteries installed in your application, as well as the battery’s capacity and age. Other factors such

as the battery’s state of charge and temperature can also affect the

length of time your appliances can run.

2

© 2014 Magnum Energy, Inc.

Page 9

Introduction

Depending on your inverter capacity, larger electrical appliances such

as coffee pots and hair dryers can be used for short durations. However, loads that are used for longer periods such as stoves or water

heaters can quickly drain your batteries and are not recommended

for inverter applications.

All electrical appliances are rated by the amount of power they

consume. The rating is printed on the product’s nameplate label,

usually located on its chassis near the AC power cord. Even though

it is diffi cult to calculate exactly how long an inverter will run a par-

ticular appliance, the best advice is trial and error. Your MMS Series

inverter/charger has a built-in safeguard that automatically protects

your batteries from being over-discharged.

1.5 Standard Features and Benefi ts

The MMS Series inverter/charger converts 12 volts of direct cur-

rent (VDC) power from your battery to 120 volts alternating current

(VAC) power.

power using Power Factor Correction (PFC) technology to keep the

inverter’s battery bank fully charged. This inverter is designed to allow

easy installation and use, and with its die-cast aluminum baseplate

it ensures maximum durability and cooler, more effi cient operation.

The multi-stage battery charger optimizes incoming AC

The inverter/charger provides the following:

• 1000 watts continuous at 25°C.

• Numerous protection features to provide a safe and peace-of-

mind operation.

• AC transfer switch circuitry; allowing incoming AC power to

continue to pass-thru to power loads even if the inverter is off.

• Dead battery charging for batteries that are extremely low.

• Automatic 4-stage battery charger with power factor correction

and temperature compensation—for optimum battery charging

(using the temperature sensor).

• Modern and aesthetically pleasing design with a large AC wiring

compartment (provides easy access to AC wiring for simple and

quick connections) and 360° DC connection terminals with color

coded insulating covers.

• True RMS output voltage regulation to ensure the inverter will

deliver the correct amount of power—within the DC input voltage

range and the continuous output power level.

• Quick connection accessory and remote ports—easily accepts sev-

eral optional remote controls and the battery temperature sensor.

© 2014 Magnum Energy, Inc.

3

Page 10

Introduction

1 2

12

5

3

8

6

4

11

10

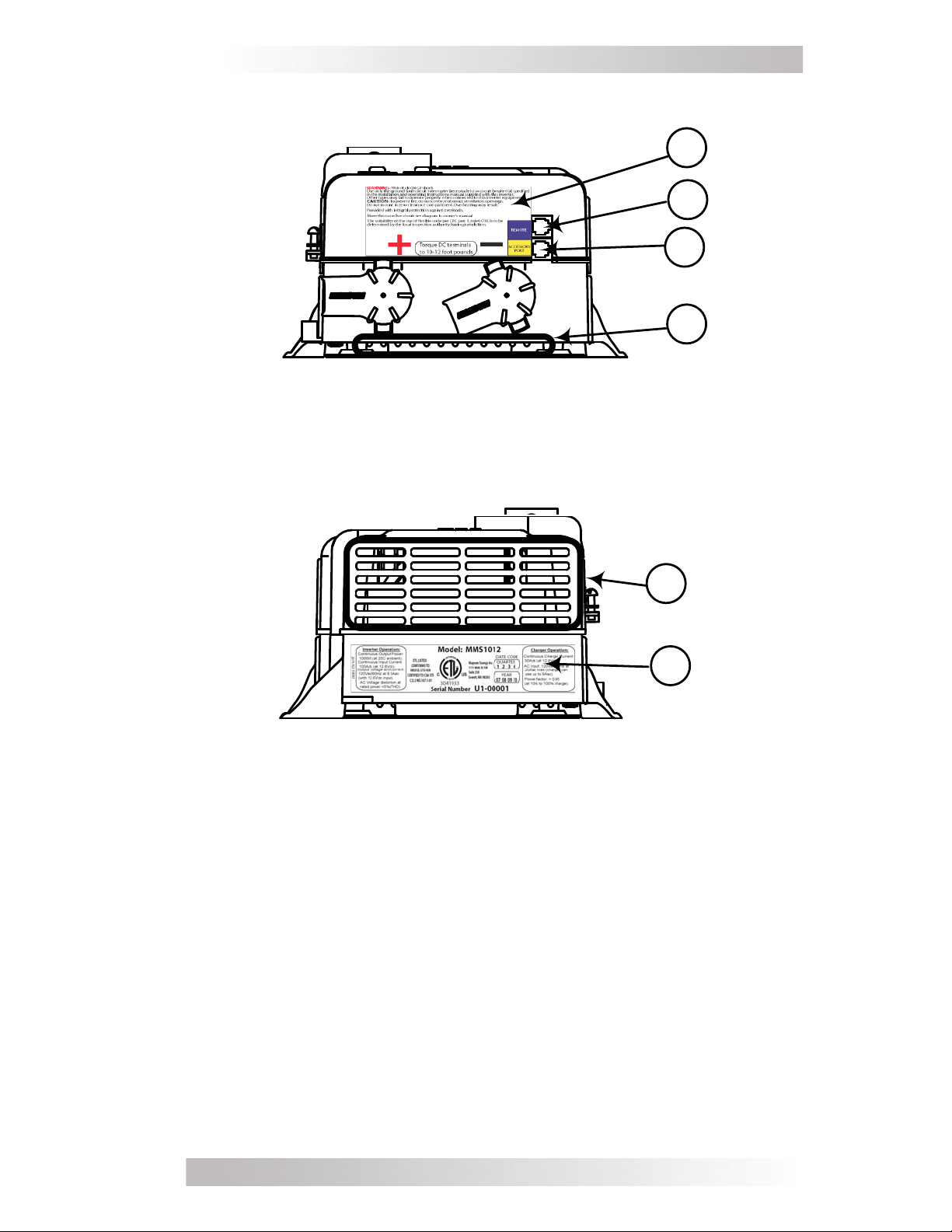

Figure 3, Top and Left Side Features

1. Inverter Status Indicator – a green LED that illuminates to

provide information on the inverter’s operation.

2. Power Switch – a momentary pushbutton switch that turns the

inverter on or off.

3. Negative DC Terminal (black) – the inverter’s connection to

the negative terminal on the battery bank.

9

7

4. Positive DC Terminal (red) – the inverter’s connection to the

positive terminal on the battery bank.

5. Input Circuit Breaker – a circuit breaker that protects the unit’s

internal wiring and pass-thru relay.

6. Output Circuit Breaker – a circuit breaker that provides another

layer of overload protection. Not a branch circuit-rated breaker.

Separate AC output breakers may be required on the output.

7. Mounting Flanges (x4) – secure the inverter to shelf/wall.

8. AC Wiring Compartment - provides access for all AC input and

output connections on the inverter.

9. AC Output Connection – AC knockout for hardwiring AC output.

10. AC Input Connection

input. The strain relief comes with an attached fl exible AC input

power cord on the MMS1012-G model.

11. DC Ground Terminal – a connection that is used to tie the

exposed chassis of the inverter to the DC grounding system. This

terminal accepts CU/AL conductors from #14 AWG (2.1 mm²) to

#6 AWG (13.3 mm²).

12. GFCI Outlet – Ground Fault Circuit Interrupter outlet (with test

and reset capability). Only available on MMS1012-G model.

– a strain relief clamp for hardwiring AC

4

© 2014 Magnum Energy, Inc.

Page 11

Introduction

Front Side

14

13

15

16

Back Side

17

18

Figure 4, Front and Back Side Features

13. Warning and Information Label – provides pertinent

information for safely using the inverter.

14. REMOTE Port Connection – a RJ11 connector that allows an

optional remote control to be connected.

15. ACCESSORY PORT Connection – a RJ11 connector to allow

the Battery Temperature Sensor (BTS) or MMS accessories (e.g.,

MM-DCLD, MM-ISA) to be connected.

16. Intake Vent – ventilation openings to pull in air to keep the

inverter cool for peak performance.

17. Exhaust Vent – ventilation openings that allow heated air to be

removed by the internal cooling fan.

18. Model/Serial Number Label – includes model/serial number

and provides specifi cations and information on the inverter and

charger. See the MMS Series Specifi cations on page 39 for more

information and the different models available.

© 2014 Magnum Energy, Inc.

5

Page 12

FRONT VIEW

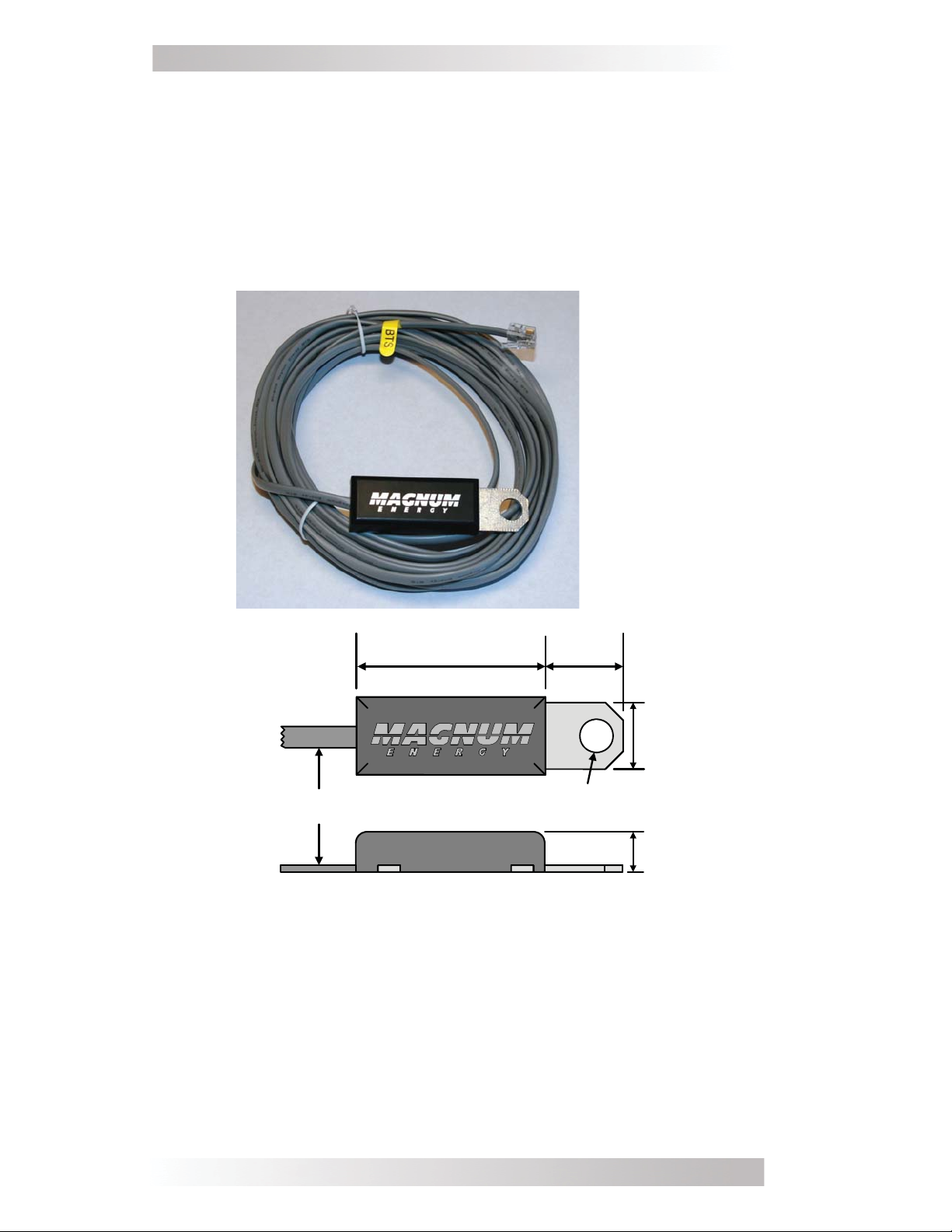

SIDE VIEW

~2" (5.1 cm)

~1"

~½”

0.375" diameter

Cable

~¾”

(2.5 cm)

(.95 cm)

(1.9 cm)

(1.3 cm)

Introduction

1.5.1 Battery Temperature Sensor

A plug-in external Battery Temperature Sensor (BTS) is provided

for units with the battery charger feature. When installed, the BTS

automatically adjusts the battery charger’s BULK, ABSORB, and

FLOAT voltage set-points (based on temperature) for better charging performance and longer battery life. If the temperature sensor is

NOT installed and the batteries are subjected to large temperature

changes, battery life may be shortened.

Figure 5, Battery Temperature Sensor (BTS)

6

© 2014 Magnum Energy, Inc.

Page 13

Installation

2.0 Installation

2.1 Pre-Installation

Before installing the inverter, read the entire Installation section. The

more thorough you plan in the beginning, the better your inverter

needs will be met.

WARNING: Installations should be performed by qualifi ed

personnel, such as a licensed or certifi ed electrician. It

is the installer’s responsibility to determine which safety

codes apply and to ensure that all applicable installation

requirements are followed. Applicable installation codes

vary depending on the specifi c location and the type of

installation.

Info: Review the Important Product Safety Information

on page ii and the Important Battery Safety Instructions

on page iii before any installation.

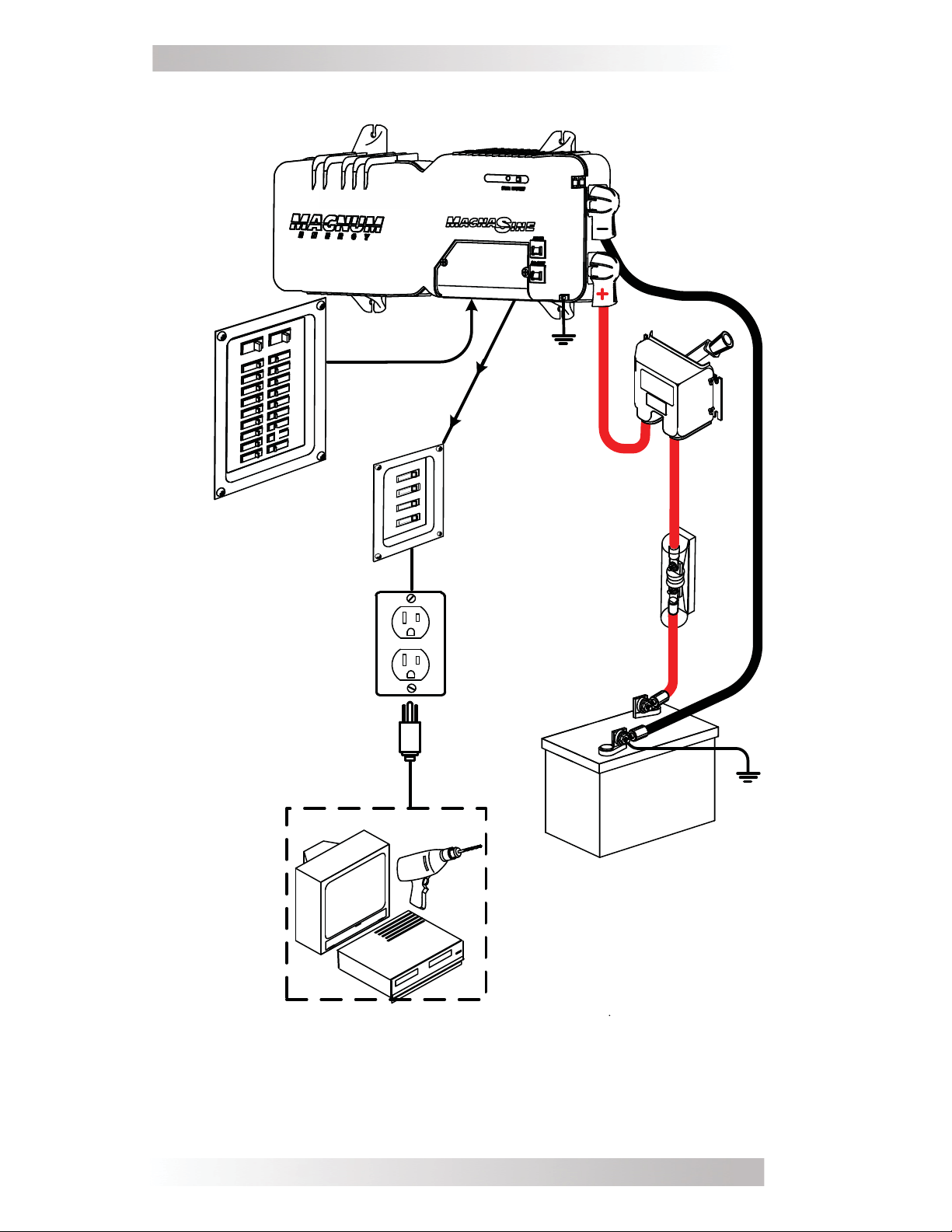

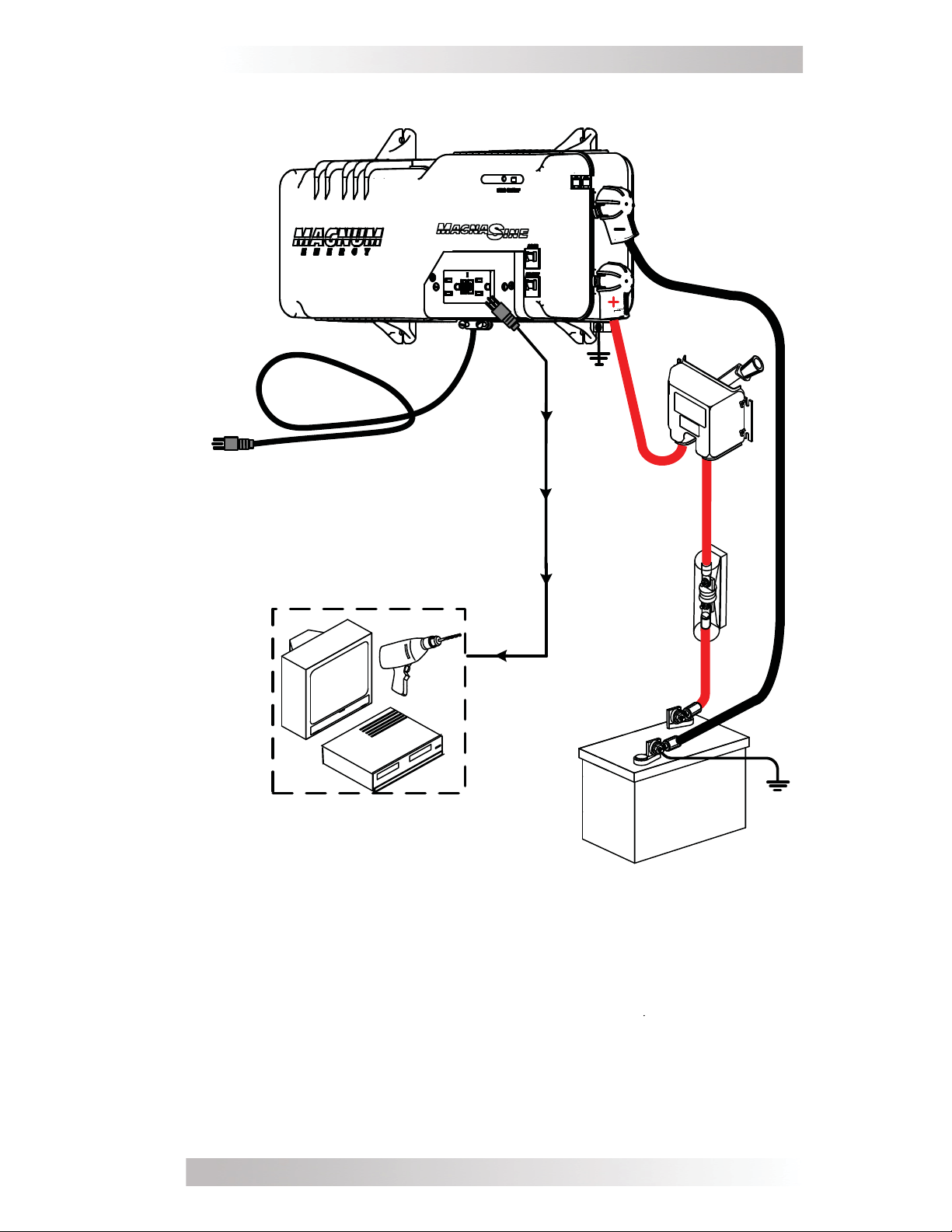

The basic system diagrams shown in Figures 6 and 7

reviewed to assist you in planning and designing your installation.

2.1.1 Unpacking and Inspection

Carefully remove the MMS inverter/charger from its shipping container

and inspect all contents. Verify the following items are included:

• MMS Series inverter/charger

• Red and black DC terminal covers

• AC access cover with two screws

• Two 5/16-18 hex-head kep nuts (installed on the DC terminals)

• Battery Temperature Sensor (BTS)

• MMS Series Owner’s Manual

• Warning Label

If items appear to be missing or damaged, contact your authorized

Magnum Energy dealer or Magnum Energy.

If at all possible, keep your shipping box. It will help protect your

inverter from damage if it ever needs to be returned for service.

Save your proof-of-purchase as a record of your ownership; it will

also be needed if the unit should require in-warranty service.

should be

Record the unit’s model and serial number in the front of this manual

in case you need to provide this information in the future. It is much

easier to record this information now, instead of trying to gather it

after the unit has been installed.

© 2014 Magnum Energy, Inc.

7

Page 14

Installation

AC

Main Panel

Sub-Panel

(optional)

AC

AC IN

AC

OUT

DC

Ground

DC

disconnect

and

overcurrent

device

AC

Outlet

Battery

Bank

TV

VCR

Tools

AC Loads

Figure 6, MMS1012 Model Basic Installation Diagram

8

© 2014 Magnum Energy, Inc.

Page 15

Installation

AC IN

AC Loads

TV

VCR

Tools

AC

OUT

DC

Ground

DC

disconnect

and

overcurrent

device

Battery

Bank

Figure 7, MMS1012-G Model Basic Installation Diagram

© 2014 Magnum Energy, Inc.

9

Page 16

Installation

2.1.2 Locating and Mounting the Inverter

WARNINGS:

• Do not mount the inverter near any fl ammable or

combustible fl uid or components.

• Provide adequate clearance/ventilation to the inverter.

• Mount only on a non-combustible surface.

• Maximum ambient temperature around the inverter

must not exceed 77°F (25°C) to meet power specifi -

cations.

The inverter should only be installed in a location that meets the

following requirements:

Clean and Dry – The inverter should not be installed in an area that

allows

ventilation openings. The area also must be free from any risk of

condensation, water,

inverter. The inverter uses stainless steel fasteners, plated copper

busbars, and a power-coated aluminum base. Also, the internal circuit

boards are conformal coated. The above measures are undertaken to

help fi ght the harmful effects of corrosive environments. However,

the life of the inverter is uncertain if used in any of these types of

environments, and inverter failure under these conditions is not

covered under warranty.

dust, fumes, insects, or rodents to enter or block the inverter’s

or any other liquid that can enter or fall on the

Cool – The inverter should be

sun or any equipment that produces extreme heat.

protected from direct exposure to the

The ambient air

temperature should be between 32°F (0°C) and 104°F (40°C); keep

in mind that the inverter’s output specifi cations are rated at 77°F

(25°C), so the cooler the better within this range.

Ventilated – In order for the inverter to provide full output power

and avoid over-temperature fault conditions, do not cover or block

the inverter’s ventilation openings or install this inverter in an area

with limited airfl ow. Allow as much clearance around the inverter’s

intake and exhaust ventilation openings as possible (see Figure 4,

Items 16 & 17). At the minimum, allow an airspace clearance of

3” (7.5 cm) on all sides to provide adequate ventilation.

If installed in an enclosure, a fresh air intake opening must be provided directly to the front side (intake vent) and an exhaust opening on the back side (exhaust vent) of the inverter. This will allow

cool air from the outside to fl ow into the inverter, and heated air to

exit away from the inverter and the enclosure. When mounted in an

enclosed compartment, airfl ow must be at least 59 cfm in order to

maintain no more than a 68°F (20°C) rise in compartment temperature. Minimum clearances can be reduced if airfl ow is increased, but

in no case should clearance around the inverter be less than 2” (5

cm) on all sides.

10

© 2014 Magnum Energy, Inc.

Page 17

Installation

Safe – Keep any fl ammable/combustible material (e.g., paper, cloth,

plastic, etc.) that may be ignited by heat, sparks, or fl ames at a

minimum distance of 2 feet (60 cm) from the inverter.

WARNING: The MMS inverter/charger is not an ignition-

protection rated device and should not be installed in

any location that requires ignition-protected equipment.

To prevent fi re or explosion, do not install the MMS

inverter in any area with extremely fl ammable liquids

like gasoline or propane; or, in an area that contains

connections between components of a fuel system.

Close to the battery bank – As with any inverter, it should be

located as close to the batteries as possible. Long DC wires tend to

lose effi ciency and reduce the overall performance of an inverter.

However, the unit should not be installed in the same compartment as

the batteries or mounted where it will be exposed to gases produced

by the batteries. These gases are corrosive and will damage the

inverter. Also, if these gases are not ventilated and allowed to collect,

they could ignite and cause an explosion.

Accessible –

Do not block access to the inverter’s remote control

and accessory ports. Also, allow enough room to access the AC and

DC wiring connections, as they will need to be checked and tightened

periodically. See Figure 9 & 10 for the MMS inverter’s dimensions.

Mounting Orientation – To meet regulatory requirements, the MMS

Series inverter/charger can only be mounted

on a horizontal surface

(shelf or table) or a vertical surface (wall or bulkhead) either rightside up or upside-down, as shown in Figure 8. The inverter must be

mounted on a non-combustible surface, and this surface and the

mounting hardware must be capable of supporting at least twice the

weight of the inverter. After determining your mounting position,

use the base of the inverter’s chassis as a template to mark your

mounting screw locations. Remove the inverter and drill pilot holes

into the mounting surface.

If this unit is used in a mobile application, you may want to place

fl exible washers or bushings between the mounting surface and the

inverter’s mounting fl anges to reduce vibration.

© 2014 Magnum Energy, Inc.

11

Page 18

Installation

Mounting holes x4

[¼” (0.25") diameter]

10.0"

~ 16 "

(16.59")

~ 6 " (6.71")

~ 8 " (8.41")

~ 7 " (7.51")

~ 4 "

(4.625")

3

4

7

16

1

2

5

8

5

8

Shelf Mounted

(right-side up)

Shelf Mounted

(up-side down)

Wall Mounted (up-side down)

Wall Mounted (right-side up)

Figure 8, Approved MMS1012 (-G) Mounting Orientations

Figure 9, MMS1012 Model Inverter/Charger Dimensions

12

© 2014 Magnum Energy, Inc.

Page 19

Installation

Mounting holes x4

[¼” (0.25") diameter]

10"

5

~ 16 "

8

(16.59")

5

~ 4 "

8

(4.625")

3

~ 6 " (6.71")

4

1

~ 7 " (7.51")

2

7

~ 8 " (8.41")

16

~ 5"

1

~ 5 "

8

(5.125")

Figure 10, MMS1012-G Model Inverter/Charger Dimensions

2.1.3 Wiring Guidelines

• Before connecting any wires, determine all wire routes to and

from the inverter throughout the RV, vehicle, or boat.

• Conductors passing through walls or other structural members

must be protected to minimize insulation damage such as chafi ng,

which can be caused by vibration or constant rubbing.

• Always check for existing electrical, plumbing, or other areas of

potential damage prior to cutting into structural surfaces or walls.

• Make sure all wires have a smooth bend radius and do not be-

come kinked.

• Both AC and DC overcurrent protection must be provided as part

of the installation.

• Do not attempt to use a vehicle metal frame in place of the nega-

tive connection or DC ground. The inverter requires a reliable

negative and ground return path directly to the battery.

© 2014 Magnum Energy, Inc.

13

Page 20

Installation

• DC wires and cables should be tied together with wire ties or

electrical tape approximately every 6 inches (15.2 cm). This

helps improve the surge capability and reduces the effects of

inductance, which improves the inverter waveform and reduces

wear on the inverter’s fi lter capacitors.

• Use only copper wires with a minimum temperature rating of

75°C (167°F).

• To ensure maximum performance from the inverter, all connections from the battery bank to the inverter should be minimized

(Exception: the DC overcurrent disconnect in the positive line).

2.2 DC Wiring

This section describes the MMS Series inverter’s required DC wire

sizes, the recommended disconnect/overcurrent protection, and how

to make the DC connections to the inverter and the battery bank.

2.2.1 DC Wire Sizing

It is important to use the correct DC wire to achieve maximum effi ciency from the system and to reduce fi re hazards associated with

overheating. Use Table 1 to select the minimum DC wire size needed

based on your inverter model. If the distance from the inverter to

the battery bank is greater than 3 feet (91.4 cm), use Table 2 to

help determine the minimum recommended cable sizes for longer

distances. Always keep your wire runs as short as practical to help

prevent low voltage shutdowns and to keep the DC breaker from

nuisance tripping (or open fuses) because of increased current draw.

Undersized cables can also lower the inverter’s peak output voltage,

as well as reduce its ability to surge heavy loads.

Info: The DC wires must be color coded with colored

tape or heat shrink tubing; RED for positive (+), BLACK

for negative (-), and GREEN for DC ground.

The DC wires must have soldered and crimped lugs, crimped copper

compression lugs, or aluminum mechanical lugs. Soldered connections alone are not acceptable for this application.

If the inverter is expected to operate at a distance greater than 3 feet

(91.4 cm) from the battery bank, the DC wire size will need to be

increased to overcome the increase in resistance—which affects the

performance of the inverter. Continue to use the overcurrent device

and DC ground wire previously determined from Table 1 and then,

refer to Table 2 to determine the minimum DC wire size you need

for various distances based on your inverter model.

2.2.2 DC Overcurrent Protection

For safety and to comply with NEC (National Electrical Code) electrical

code regulations, you must install a DC overcurrent protection device

in the positive DC cable line to protect your DC cables. This DC

overcurrent device can be a fuse or circuit-breaker, but must be DC

14

© 2014 Magnum Energy, Inc.

Page 21

Installation

rated. It must be correctly sized according to the size of DC cables

being used, which means it is required to open before the cable

reaches its maximum current carrying capability, thereby preventing

a fi re.

See Table 1 to select the DC overcurrent device based on the

minimum wire size for your inverter model.

Table 1, Recommended DC Wire/Overcurrent Device

Inverter Model

MMS1012 MMS1012-G

Maximum Continuous

Current¹

DC Grounding

Electrode Wire Size²

Minimum DC Wire Size³

(75˚C rating in free air)

Maximum DC Fuse Size

Note¹ – Maximum Continuous Current is based on the inverter’s continuous

power rating at the lowest input voltage with an ineffi ciency factor.

Note² – Per the NEC, the DC grounding electrode conductor can be a #6

AWG conductor if that is the only connection to the grounding electrode and

that grounding electrode is a pipe, rod, or plate electrode.

Note³ – Wire size is based on the requirements needed to increase effi ciency

and reduce stress to the inverter.

Note – The next larger standard size overcurrent device may be used if

the de-rated cable ampacity falls between the standard overcurrent devices

found in the NEC.

133 amps 133 amps

#6 AWG

(13.3 mm²)

#2 AWG

(33.6 mm²)

[170 amps]

150 amps with

time delay

#6 AWG

(13.3 mm²)

#2 AWG

(33.6 mm²)

[170 amps]

150 amps with

time delay

Info: The term “in free air” is defi ned by the NEC as not

encased in conduit or raceway.

Table 2, DC Wire Size For Increased Distance

Minimum recommended DC wire size (one way)

5 ft or less

(≤1.5 m)

MMS1012

MMS1012-G

© 2014 Magnum Energy, Inc.

#2 AWG

(33.6 mm²)

#2 AWG

(33.6 mm²)

5 to 10 ft

(1.5 m - 3.0 m)

#2 AWG

(33.6 mm²)

#2 AWG

(33.6 mm²)

10 to 15 ft

(3.0 m - 4.6 m)

#1 AWG

(42.4 mm²)

#1 AWG

(42.4 mm²)

15

Page 22

Installation

Electrical systems in mobile installations typically do not require

using a DC disconnect, although an overcurrent protection device is

still required. Because the DC disconnect is not required, a fuse is

usually used as the disconnect device in these installations. These

installations also do not normally use conduit, so the fuse must be

installed in the ungrounded conductor (usually the positive DC cable

line) within 18 inches (45.7 cm) of the battery—to protect the DC

wiring system.

If using a fuse, we recommend using a

This fuse type is rated for DC operation, can

circuit currents, and

allows for momentary current surges from the

class-T type or equivalent.

handle the high short-

inverter without opening.

2.2.3 DC Grounding

The inverter/charger should always be connected to a permanent,

grounded wiring system.

The idea is to connect the metallic chassis

of the various enclosures together to have them at the same voltage

potential, which reduces the possibility for electric shock.

For the

majority of installations, the inverter chassis and the negative battery

conductor are connected to the system’s ground bond via a safetygrounding conductor (bare wire or green insulated wire) at only one

point in the system. Per the NEC, the size for the grounding conductor

is usually based on the size of the overcurrent device used in the DC

system.

Refer to Table 1 to select the appropriate DC ground wire

based on the overcurrent device used for your inverter model.

If the inverter is in a vehicle, DO NOT connect the battery negative

(-) cable to the vehicle’s safety ground. Only connect to the inverter’s

negative battery terminal. If there are any non-factory installed

appliances onboard the vehicle, DO NOT ground them at safety

ground. Only ground them at the negative bus of the DC load center

(as applicable).

2.2.4 DC Cable Connections

When connecting the DC cable to the battery or to the inverter’s DC

terminals, the hardware should be installed in the correct order to

prevent high resistance connections from heating up and possibly

causing the connections to melt. Follow Figures 11 and 12 to stack

the hardware correctly. Tighten the terminal connections from 10

to 12 ft-lbs.

CAUTION: Don’t put anything between the DC cable ring

lug and the battery terminal post or the inverter’s DC

terminal. If antioxidant grease or spray is used, apply

it after all the connections have been made and are

properly tightened.

CAUTION: Overtightening or misthreading nuts on the DC

terminals will cause the bolts to strip and snap/break-off.

16

© 2014 Magnum Energy, Inc.

Page 23

Installation

BATTERY

DC cable

with ring lug

bolt

flat washer

Nut

(½” wrench)

lock washer

battery

post

battery terminal

Temperature sensor

Verify that the DC cable lugs

are flush with the battery

terminals. Torque the battery

terminals from 10 to 12 ft-lbs.

DC cable

with ring lug

DC

terminal cover

(snaps on)

Inverter’s

DC terminal

5/16" (Kep nut with star-washer)

or Flange nut

Figure 11, DC Cable to Battery Terminals

CAUTION: The inverter is NOT reverse polarity protected

(negative and positive connected backwards). You must

verify the correct voltage polarity BEFORE connecting the

DC wires or damage may occur.

Crimped and sealed copper ring terminal lugs with a 5/16” hole should

be used to connect the DC wires to the inverter’s DC terminals.

Figure 12, DC Cable to Inverter’s DC Terminals

© 2014 Magnum Energy, Inc.

17

Page 24

Installation

2.3 Battery Bank Wiring

WARNING: Lethal currents will be present if the positive

and negative cables attached to the battery bank touch

each other. During the installation and wiring process,

ensure the cable ends are insulated or covered to prevent

touching/shorting the cables.

Info: DO NOT connect the DC wires from the battery

bank to the inverter until: 1) all DC/AC wiring is complete,

2) the correct DC and AC overcurrent protections have

been installed, and 3) the correct DC voltage and polarity

have been verifi ed.

Info: For optimum performance, a minimum battery bank

of 200 AHr is recommended.

Depending upon the type of batteries you use in the installation

(6 or 12 VDC), the batteries must be wired in series, parallel, or

series-parallel (see Appendix B – Battery Information for guidance

on wiring batteries together). The interconnecting DC wires must be

sized and rated exactly the same as those that are used between

the battery bank and the inverter.

Place the batteries as close as practical to the inverter, preferably in

an insulated and ventilated enclosure. Allow adequate space above

the batteries to access the terminals and vent caps (as applicable).

Also, allow at least 1” (2.5 cm) of space between the batteries to

provide good air fl ow. DO NOT mount the batteries directly under

the inverter.

Info: To ensure the best performance from your inverter

system, do not use old or untested batteries. Batteries

should be of the same size, type, rating, and age.

CAUTION: Install batteries in a well ventilated area. Bat-

teries can produce explosive gasses. For compartment or

enclosure installations, always vent batteries to the outside.

2.3.1 Inverter to Battery Bank Wiring

WARNING: Ensure all sources of DC power (i.e., batter-

ies) and AC power (shorepower or AC generator) are deenergized (i.e., breakers opened, fuses removed) before

proceeding.

18

© 2014 Magnum Energy, Inc.

Page 25

Installation

CAUTION: The inverter is NOT reverse polarity protected.

If this happens, the inverter will be damaged and will not

be covered under warranty.

from the batteries to the inverter, verify the correct battery

voltage and polarity using a voltmeter. If the positive terminal of the battery is connected to the negative terminal

of the inverter and vice versa, severe damage will result.

If necessary, color code the cables with colored tape or

heat shrink tubing; RED for positive (+), and BLACK for

negative (-) to avoid polarity confusion.

Info: The DC overcurrent device (i.e., fuse or circuit

breaker) must be placed in the positive (RED) DC cable

line between the inverter’s positive DC terminal and the

battery’s positive terminal (RED); as close to the battery

as possible.

DC Ground Wire

Route an appropriately sized DC grounding wire (GREEN or bare

wire) from the inverter’s DC Ground Terminal (see Figure 3, Item

11) to a dedicated system ground. Recommended tightening torque

is 45 in-lbs.

Before connecting the DC wires

DC Negative Wire

Route an appropriately sized DC negative wire (BLACK) from the

negative terminal of the last battery string to the inverter’s negative

terminal (see Figure 21 for reference).

Battery Temperature Sensor

Connect the RJ11 connector end of the BTS to the ACCESSORY PORT

(see Figure 4, Item 15) on the inverter. Connect the other end of the

BTS to the negative terminal of the fi rst battery string (in same place

as the DC negative wire above); refer to Figure 11 for the correct

hardware placement.

DC Positive Wire

Mount the DC fuse block and disconnect (or circuit breaker assembly)

as near as practical to the batteries, and then open the disconnect

(or circuit breaker).

WARNING: DO NOT close the DC fuse/DC disconnect (or

close the DC circuit breaker) to enable battery power to

the inverter at this time. This will occur in the Functional

Test after the installation is complete.

Route and connect an appropriately sized DC positive wire (RED)

from the DC fuse block (or circuit breaker assembly) to the inverter’s

positive DC terminal.

Connect a wire (same rating as the DC wires) to one end of the fuse

block and the other end of this wire to the positive terminal of the

fi rst battery string (see Figure 21). This is essential to ensure even

charging and discharging across the entire battery bank.

© 2014 Magnum Energy, Inc.

19

Page 26

Installation

Ensure the DC wire connections (to batteries, inverter, and fuse lugs/

DC circuit breaker) are fl ush on the surface of the DC terminals, and

the hardware (lock washer and nut) used to hold these connections

are stacked correctly (see Figures 11 and 12).

Verify all DC connections are torqued from 10 to 12 ft-lbs.

Once the DC connections are completely wired and tested, coat the

terminals with an approved anti-oxidizing spray.

Press the red and black terminal covers onto the inverter’s DC con-

nectors to secure them in place.

If batteries are in an enclosure, perform a fi nal check of the hold down

brackets and all connections. Close and secure the battery enclosure.

2.4 AC Wiring

This section describes the MMS Series’ required AC wire size and

overcurrent protection. It also provides information on how to make

the AC connections.

Info: The MMS1012-G model has a power cord for AC

input and dual outlets on top of the inverter for AC output

(has hardwiring capability as well).

WARNING: All wiring should be done by a qualifi ed per-

son or a licensed electrician following all local/NEC codes.

2.4.1 Neutral to Safety Ground Bonding

The NEC/CEC (National Electric Code/Canadian Electrical Code)

provide the standards for safely wiring mobile (RV, boat, or truck)

installations. These wiring standards require the AC source (inverter,

shorepower, or a generator) to have the neutral conductor tied to

ground. These standards also require that the AC neutral be connected to safety ground (often called a “bond”) in only one place at

any time.

If more than one bond is established, currents can circulate

between neutral and ground and cause ground-loop currents. These

“ground-loops” can trip GFCIs and cause an electric shock hazard.

In mobile installations, there may be multiple AC sources (i.e.,

shorepower, generator, or inverter), which means there may be the

potential of having multiple neutral-to-ground connections.

2.4.2 AC Wiring Connections

For the MMS1012 model, the AC input and output wiring is performed

in the AC wiring compartment. This compartment is accessed via the

top panel (Figure 3, Item 8). If the panel cover is installed, remove

the two Phillips screws on the cover to access the AC wiring compartment and locate the inverter’s AC wiring. There is a label located in

the AC access compartment which gives information on which wires

are used for AC input and output. You can also refer to Table 3 to

match the inverter’s AC wires to the appropriate AC wire connection.

20

© 2014 Magnum Energy, Inc.

Page 27

Installation

Table 3, Wire Color to AC Wire Connection

Wire Color (label) Wire Connection

AC IN

Black (HOT IN) Hot In

White (NEUT IN) Neutral In

Red (HOT OUT) Hot Out

AC OUT

White with black

stripe (NEUT OUT)

Neutral Out

AC Ground Green (GROUND) AC IN & AC OUT Ground

The AC wires inside the AC compartment are #16 AWG (1.3 mm²)

with a temperature rating of 105°C (221°F). All AC connections should

be made using an approved connector for your application (e.g., split

bolt, twist-on wire connectors, etc.). Ensure the wire connectors

used are rated for the size and number of wires you are connecting.

After connecting the wires together, gently pull on the wires to ensure

they are securely held together. In a proper connection, no bare wire

should be exposed

.

Info: Per UL certifi cation, non-metallic sheathed cable

(i.e., Romex™) or an SO fl exible cord with listed strain

reliefs are allowed to be used to connect to the inverter;

conduit connections are not allowed.

After all AC wiring in the inverter is complete (and before reattaching the AC access cover), ensure all the connections are correct and

secure.

2.4.3 AC Wire Size and Overcurrent Protection

The AC input and output wiring must be sized per NEC and local electrical safety code requirements

handle the inverter’s

maximum load current. After determining the

to ensure the wire’s ability to safely

proper AC wire sizes, the inverter’s AC input (unless you are using a

fl exible cord) and output wires are required to be protected against

overcurrent and have a means to disconnect the AC circuits.

All inverter AC input and output wiring is required to be protected

by an overcurrent protection device. Overcurrent protection must

be provided by fuses or circuit-breakers, and must

be properly sized

and rated for the wire they are protecting and the appliances being

powered.

Most inverter’s that are hardwired use a service/distribution panel

wired to the inverter’s input (main panel), and a dedicated panel

between the inverter’s output wiring and the AC loads (sub-panel).

These systems use the circuit breakers provided in the panels as the

overcurrent protection and the AC disconnect. If fuses are used, then

separate AC disconnect switches will be needed.

© 2014 Magnum Energy, Inc.

21

Page 28

Installation

Based on information from the NEC, Table 4 provides the minimum

AC wire size and the suggested breaker size based on inverter model.

H

owever, a larger wire size may be required because of voltage drop.

The

AC wire sizes provided in this table assume using only copper

wire and a temperature rating of 75°C (167°F) or higher. A minimum

of #14 AWG

Table 4, Minimum Wire Size to Circuit-breaker Size

Inverter

Model

(2.1 mm²) is required for all AC wiring.

AC Input AC Output

Input

Breaker

Minimum

Wire

Size

Suggested

Breaker

Size

Output

Breaker

Minimum

Wire

Size

Suggested

Breaker

Size

MMS1012

MMS1012

-G

20 amps

20 amps

#12 AWG

(3.3 mm²)

#12 AWG

(3.3 mm²)

20 amps 15 amps

20 amps 15 amps

#14 AWG

(2.1 mm²)

#14 AWG

(2.1 mm²)

15 amps

15 amps

2.4.4 AC Input Wiring

Your inverter has an AC transfer feature that passes the AC input

power to the inverter’s output. Connection to the AC input is made

by hardwiring from a distribution panel as described below:

1. Run an appropriately sized 2-conductor plus ground cable (from

the AC distribution panel) through the strain relief clamp on the AC

IN opening (Figure 3, Item 10). Refer to Table 4 for minimum wire

size and overcurrent protection required for the AC input wiring.

2. Remove about two inches of the insulating jacket from the AC

cable, and then separate the three wires and strip about 3/4”

(1.9 cm) of insulation from each wire.

3. Using approved AC wire connectors, connect the incoming Hot

In, Neutral In, and Ground wires to the MMS Series’ AC wires

colored black (HOT IN), white (NEUT IN), and green (AC GROUND)

respectively.

4. After making the AC input connections, secure the AC input cable

by tightening the strain relief clamp.

The AC input wiring in the inverter is complete. Review all AC wiring

to ensure all connections are correct and secure.

22

© 2014 Magnum Energy, Inc.

Page 29

Installation

AC IN

AC OUT

Strain

reliefs

AC

Ground

In/Out

(green)

Neutral

In

(white)

Hot

Out

(red)

Neutral Out

(white w/black

stripe)

Hot

In

(black)

Figure 13, AC Wiring Connections (MMS1012 model)

Hot

In

(black)

Neutral

Neutral

In

(white)

Ground

In

AC

(green)

AC IN

Strain

reliefs

AC OUT

Out

w/black stripe)

Ground

Out

Hot

Out

(red)

(white

AC

(green)

Figure 14, AC Hardwiring Connections (MMS1012-G model)

Info: The MMS1012-G model has a power cord for AC

input and a factory-installed dual outlet on top of the

inverter for AC output.

© 2014 Magnum Energy, Inc.

23

Page 30

Installation

2.4.5 AC Output Wiring

CAUTION: The inverter’s AC output must never be con-

nected to an AC power source. This will cause severe

damage to the inverter and is not covered under warranty.

Info: When using the MMS Series inverter in an RV appli-

cation, under certain conditions and provided that the wire

is properly sized for the protecting breaker; RVIA wiring

standards will permit the breaker in the Main distribution

panel and/or the supplemental breakers on the inverter

to provide adequate protection for the AC output wiring.

For more information on these requirements, refer to the

RVIA (www.rvia.org).

Follow the steps below to hardwire the AC output of the MMS Series

inverter:

1. Remove the 1/2” knockout on the AC Output Connection

(Figure 3, Item 9)—use a utility knife to cut thru the round slot.

2. Discard this knockout and install a 1/2” strain relief in the AC OUT

opening. You may need to fi le the opening edge for proper fi t.

3. Run a 2-conductor plus ground cable through the strain relief in

the AC OUT opening. Refer to Table 4 for the minimum wire size

and the overcurrent protection required for the AC output wiring.

4. Remove about two inches (5.1 cm) of the insulating jacket from

the AC cable, and then separate the three wires and strip about

3/4” (1.9 cm) of insulation from each wire.

5. Using approved AC wire connectors, connect the outgoing Hot

Out, Neutral Out, and AC Ground wires to the inverter’s AC wires

colored red (HOT OUT), white with black stripe (NEUT OUT), and

green (AC GROUND) respectively. Gently pull on the wires to

ensure they are securely held together, and check to see that

no bare wire is exposed.

6. After making the AC output connections, secure the AC output

cable by tightening the strain relief.

7. Connect the outgoing AC wires to either:

a) an AC load sub-panel equipped with overcurrent protection

(e.g., circuit breakers), or

b) directly to the circuit (if following RVIA requirements that

permit using breakers from the main distribution panel or the

breakers on the inverter under certain conditions).

The AC output wiring in the inverter should be complete. Before

reattaching the AC access cover, review all AC wiring to ensure all

connections are correct and secure.

24

© 2014 Magnum Energy, Inc.

Page 31

Installation

Ground-Fault Circuit Interruption (GFCI) Breakers

In compliance with UL standards, Magnum Energy tested the following GFCIs and found that they function properly when connected to

the inverter’s AC output:

Shock Sentry

Lock #8899-A, and Hubbel #GF520EMBKA.

WARNING: Risk of electric shock. Use only the

GFCIs [receptacles or circuit breaker(s)] specifi ed in this

manual. Other types may fail to operate properly when

connected to this inverter.

CAUTION: Ground Fault Circuit Interrupters (GFCIs) shall

be installed in the recreational vehicle’s wiring system to

protect all branch circuits.

Inverter Warning Label

The warning label (see Figure 15) is provided to inform all personnel that an inverter is installed in your electrical system. Affi x this

label in a clearly visible location at the electrical panel that is being

powered by the inverter. This is necessary because it might be falsely

assumed that the panel is no longer “hot” after AC power has been

shut off—when in fact power may actually still be available due to

the inverter automatically powering the panel.

TM

#XGF15V-SP, Leviton Smart

This electrical system is equipped with an

Automatic Generator Starting (AGS) device and/

or an inverter. Disconnect all AC and DC power to

the AGS and/or inverter before performing any

service to the electrical system. Failure to do so

can result in shock causing serious injury or death.

PN: 62-0002 Rev A

Figure 15, Warning Label

2.5 Functional Test

After all electrical connections to the inverter, batteries, AC source

and loads (using a sub-panel)

steps to test the installation and the inverter’s operation.

1. Check the battery voltage and polarity before connecting the

batteries to the inverter. Use a multimeter to verify 10 to 14 VDC

at the batteries’ positive and negative terminals.

2. Apply battery power to the inverter by switching the DC disconnect ON (or close the DC circuit-breaker). The inverter will remain

OFF, but the green status indicator on the front of the inverter will

quickly blink once to indicate that DC power has been connected

and is ready to be turned on.

have been completed, follow these

© 2014 Magnum Energy, Inc.

25

Page 32

Installation

3. Prior to turning on the inverter, make sure all connected loads

(e.g., appliances) are switched OFF or disconnected from the

AC outlets.

4. a) If a remote switch is connected, press the ON/OFF switch to

turn the inverter on.

b) If there is no remote switch connected, lightly press and release

the inverter’s ON/OFF power switch—located on the top of the

inverter—to turn the inverter on.

Verify the inverter’s status indicator is blinking—indicating the

inverter is providing AC power.

5. Connect a 10-25 watt light bulb to the inverter output and verify

it comes on and shines normally. DO NOT connect anything

larger than a 25-watt light bulb until all wiring and voltages are

confi rmed to be correct.

Info: The inverter’s AC output voltage will not be correct

until a load greater than 5 watts (default setting) is

connected to the inverter; or, Search mode is turned off

with a remote display (ME-RC, ME-ARC, or ME-RTR). A

10-25 watt bulb is used as it is a suffi cient load to bring

the inverter out of Search mode and up to full voltage.

6. Check the AC output voltage of the inverter by connecting a true

RMS multimeter to the outlets powered by the inverter. Verify the

voltage is 120 VAC +/- 5 VAC. If not using a true RMS meter, the

output AC voltage could indicate from 90 to 130 VAC depending

on the battery voltage.

7. Press the remote ON/OFF switch to turn the inverter off. If the

remote is not used, press and release the inverter’s ON/OFF power

switch to turn the inverter off. The inverter’s status indicator and

the connected load should go off.

8. Apply AC power to the inverter’s AC input. After the AC input

power is qualifi ed (approximately 15 seconds), the incoming AC

power will transfer through the inverter to the inverter’s AC output and power the connected light bulb. Verify that the inverter’s

status indicator and the connected light bulb come on.

9. Even though the connected light bulb is on, the inverter is currently disabled/off. Press the remote’s ON/OFF switch (or press

and release the ON/OFF power switch on the inverter) to enable/

turn on the inverter.

10. Disconnect the incoming AC power to the inverter. Verify the light

bulb remains on, but now is powered by the inverter.

If the inverter passes all the steps, the inverter is ready for use. If the

inverter fails any of the steps, refer to the Troubleshooting section.

© 2014 Magnum Energy, Inc.26

Page 33

Operation

3.0 Operation

3.1 Operating Modes

The MMS Series inverter/charger has two normal operating routines. Inverter mode, which powers the loads using the batteries,

and Standby mode, which transfers the incoming AC power (i.e.,

shorepower or a generator) to power the loads and to recharge the

batteries. This inverter also includes an extensive protection circuitry

that shuts down the inverter under certain fault conditions.

3.1.1 Inverter Mode

When the inverter is fi rst powered up, it defaults to the OFF mode.

The momentary ON/OFF power switch (Figure 3, Item 2) must be

lightly pressed to turn the inverter ON. Subsequently pressing this

switch alternately turns the inverter OFF and ON.

• Inverter OFF – When the inverter is OFF, no power is used

from the batteries to power the AC loads and

be OFF. If AC power from an external source (shorepower or

generator) is connected and qualifi ed on the inverter’s AC input,

this AC input power will pass through the inverter to power the

AC loads. However, if this AC power is lost, the AC loads will no

longer be powered because the inverter is OFF.

the status LED will

When the inverter is turned ON, it operates either by “Searching”

or “Inverting”, depending on the connected AC loads.

• Searching – When the inverter is fi rst turned ON, the automatic

Search feature is enabled. This feature is provided to conserve

battery power when AC power is not required. In this mode, the

inverter pulses the AC output looking for an AC load (i.e., electrical

appliance). Whenever an AC load (greater than 5 watts) is turned

on, the inverter recognizes the need for power and automatically

starts inverting. When there is no load (or less than 5 watts) detected, the inverter automatically goes back into Search mode to

minimize energy consumption from the battery bank. When the

inverter is “Searching”, the inverter’s green LED fl ashes.

Info: The factory default value for the Search feature is 5

watts. It can be turned off or adjusted from 5 to 50 watts

using the ME-RC50 remote display.

• Inverting –

the inverter output, the MMS Series “inverts” the DC power from

the battery and supplies 120 VAC power to your sub-panel. The

inverter’s green LED fl ashes once every 2 seconds to indicate it

is inverting. The

providing power is directly related to the amount of AC loads that

are connected and the capacity of the battery bank.

When a load greater than 5 watts is connected to

amount of time the inverter can be inverting and

© 2014 Magnum Energy, Inc.

27

Page 34

Operation

3.1.2 Standby Mode

The MMS Series features an automatic transfer relay and an internal

battery charger when operating in Standby mode. Standby mode

begins whenever AC power (shorepower or generator) is connected

to the inverter’s AC input. Once the AC voltage and frequency of the

incoming AC power is within the AC input limits, an automatic AC

transfer relay is activated. This transfer relay passes the incoming AC

power through the inverter to power the AC loads on the inverter’s

output. This incoming power is also used to activate a powerful internal battery charger to keep the battery bank charged in case of

a power failure.

Battery charging

– The MMS Series models are equipped with an

active Power Factor Corrected (PFC) multi-stage battery charger. The

PFC feature is used to control the amount of power used to charge

the batteries in order to obtain a power factor as close as possible to

1 (or unity). This causes the battery charger to look like a resistor to

the line (forces the charge current waveshape to mirror the voltage

waveshape). This feature maximizes the real power available from

the AC power source (shorepower or generator), which translates

into less power wasted and a greater charging capability than most

chargers available today.

When an AC power source is connected to an inverter that has a

battery charger, the inverter monitors the AC input for acceptable

voltage. Once the inverter has accepted the AC input, the AC transfer

relay will close and charging will begin. Once charging, the DC voltage

is monitored to determine the charging stage. If the DC voltage is low

(≤12.9 VDC), the charger begins bulk charging. If the DC voltage is

high (>12.9 VDC), the charger skips the initial Bulk/Absorb Charging

stages and goes directly to fl oat charging.

The multi-stage charger can use up to fi ve different charging stages

to help monitor and keep the batteries healthy.

The fi ve stages

include an automatic 4-stage charging process (Bulk, Absorb, Float,

and Full Charge), and a manual Equalization (EQ) charge stage. The

automatic 4-stage charge process provides complete recharging and

monitoring of the batteries without damage due to overcharging (see

Figure 16). The Equalization stage (requires the ME-RC50 remote)

is used to stir up stratifi ed electrolyte and reverse any battery plate

sulfation that might have occurred.

While charging, the unit may go into Charger Back-off protection

which automatically reduces the charge current to the batteries.

This is caused by:

1. The internal temperature is too hot – the charger automatically

reduces the charge rate to maintain temperature; or,

2. The AC input voltage falls < 85 VAC – the charger reduces the

charge current to zero to help stabilize the incoming AC voltage; or

3. FET temperature.

28

© 2014 Magnum Energy, Inc.

Page 35

Operation

The automatic 4-stage charging process includes:

• Bulk Charging: This is the initial stage of charging. While bulk

charging, the charger supplies the battery with constant current.

The charger remains in bulk charge until the absorption charge

voltage is achieved (14.6 VDC)* —as determined by the Battery

Type selection**.

• Absorb Charging: This is the second charging stage and begins

after the bulk voltage has been reached. Absorb charging provides the batteries with a constant voltage and reduces the DC

charging current in order to maintain the absorb voltage setting.

The absorb charging time is 120 minutes—as determined by the

Battery AmpHrs selection**.

• Float Charging: The third charging stage occurs at the end of

the absorb charging time. While fl oat charging (also known as a

maintenance charge), the batteries are kept fully charged and

ready if needed by the inverter. The Float Charging stage reduces

battery gassing, minimizes watering requirements (for fl ooded

batteries), and ensures the batteries are maintained at optimum

capacity. In this stage, the charge voltage is reduced to the fl oat

charge voltage (13.4 VDC)* —as determined by the Battery Type

selection** — which can maintain the batteries indefi nitely.

• Full Charge (Battery Saver™ mode): The fourth stage occurs

after four hours of fl oat charging. The Full Charge stage maintains

the batteries without overcharging, preventing excessive loss of

water in fl ooded batteries or drying out of GEL/AGM batteries. In

this stage, the charger is turned off and begins monitoring the

battery voltage. If the battery voltage drops low (≤12.7 VDC),

the charger will automatically initiate another four hours in fl oat

charge.

* These voltage settings are based on the Battery Temperature Sensor

(BTS) being disconnected, or at a temperature of 77°F (25°C). If the

BTS is installed, these voltage settings will increase if the temperature

around the BTS is below 77°F (25°C), and decrease if the temperature

around the BTS is higher than 77°F (25°C).

** The MMS Series uses changeable settings (see Table 6, Inverter

Default Settings) that are adequate for most installations. However,

if you determine that some of your operating parameters need to

be changed, the ME-RC50 remote control can be purchased to allow

changes to those settings.

© 2014 Magnum Energy, Inc.

29

Page 36

Constant

Current

Reduced

Current

Reduced

Voltage

Absorb volts

‘Adj

Charge

Rate’

Setting

Increased

Voltage

Constant

Voltage

Monitored

Voltage

No Current

Time

Float

volts

Monitored

Current

Absorb Time

Bulk

Charging

Absorb

Charging

Float

Charging

DC

Voltage

DC

Current

Full

Charge

Goes to Full

Charge after 4

hours in Float

Charge

Absorb and Float voltage settings are

determined by the ‘Battery Type’ selection

(per the ‘Adj Batt

AmpHrs’ setting)

Operation

Figure 16, Automatic 4-Stage Charging Graph

Transfer time – While in Standby mode, the AC input is continually

monitored. Whenever AC power falls below the VAC dropout voltage

(80 VAC, default setting), the inverter automatically transfers back

to Inverter mode with minimum interruption to your appliances—as

long as the inverter is turned on. The transfer from Standby mode

to Inverter mode averages approximately 16 milliseconds. While the

MMS Series is not designed as a computer UPS system, this transfer

time is usually fast enough to hold them up. However, the VAC dropout

setting has an effect on the ability of the loads to transfer without

resetting. The lower this setting, the longer the effective transfer

will be and therefore, the higher the probability for the output loads

to reset. This occurs because the incoming AC voltage is allowed to

fall to a level that is so low that when the transfer does occur, the

voltage on the inverter’s output has already fallen to a low enough

level to reset the loads.

The disadvantage of a higher VAC dropout setting is that smaller

generators (or large generators with an unstable output) may nuisance transfer. This commonly happens when powering loads that

are larger than the generator can handle—causing the generator’s

output voltage to constantly fall below the inverter’s input VAC dropout threshold.

Info: You must use the ME-RC50 or ME-ARC50 remote to

adjust the VAC dropout setting—which in turn determines

the VAC dropout threshold.

© 2014 Magnum Energy, Inc.

30

Info: When switching from Inverter mode to Standby

mode, the inverter waits approximately 15 seconds to

ensure the AC source is stable before transferring.

Page 37

Operation

3.2 Battery Temperature Sensor Operation

The plug-in Battery Temperature Sensor (BTS) is used to determine

the battery temperature around the batteries. This information allows

the multi-stage battery charger to automatically adjust the battery

charge voltages for optimum charging performance and longer battery life.

When the BTS is installed, if the temperature around the BTS is below

77°F (25°C) the absorb and fl oat charge voltage increases. If the

temperature around the BTS is higher than 77°F (25°C), the absorb

and fl oat charge voltage decreases. See Figure 17

much the charge voltage changes (increases or decreases) as the

temperature reading of the BTS changes. For example, the nominal

absorb charge voltage for a fl ooded battery at 77°F (25°C) is 14.6

VDC. If the battery temperature is 95°F (35°C), the absorb charge

voltage would decrease to 14.3 VDC (14.6 VDC - 0.3 change).

If the temperature sensor is NOT installed, the charge voltages will

not be compensated and the battery will maintain the charge it had

at a temperature of 77°F (25°C). The life of the batteries may be

reduced if they are subjected to large temperature changes when

the BTS is not installed.

to determine how

Info: When the BTS is connected, the battery charger

uses a value of -5mV/°C/Cell from 0-50°C to change the

charge voltage based on temperature.

Temperature Compensation using BTS

12VDC units

+0.75V

+0.6V

+0.45V

+0.3V

+0.15V

No Change

-0.15V

-0.3V

-0.45V

-0.6V

-0.75V

0C

32F5C41F

10C

50F

15C

59F

20C

68F

Change to battery charging voltage

Temperature reading from BTS

25C

77F

30C

86F

no BTS

connected

40C

35C

104F

95F

45C

113F

50C

122F

Figure 17, BTS Temperature to Charge Voltage Change

© 2014 Magnum Energy, Inc.

31

Page 38

Operation

3.3 Protection Circuitry Operation

The inverter is protected against fault conditions, and in normal usage

it will be rare to see any. However, if a condition occurs that is outside

the inverter’s normal operating parameters, then it will shut down

and attempt to protect itself, the battery bank, and your AC loads. If

there is a condition that causes the inverter to shut down, it may be

one of the conditions listed below. Refer also to the Troubleshooting

section to diagnose and clear the fault.

• Low Battery – The inverter will shut off whenever the battery

voltage falls to the Low Battery Cut Out (LBCO) level to protect

the batteries from being over-discharged. After the inverter has

reached the LBCO level and turned off, the inverter will automatically restart after one of the following conditions:

1. AC power is applied and the inverter begins operating as a

battery charger.

2. Battery voltage rises to the Low Battery Cut In (LBCI) level.

The inverter’s status LED turns off when a low battery fault condition occurs. Refer to Table 5 to determine the LBCO and LBCI

levels for your particular inverter model.

• High Battery – In the event the battery voltage approaches the

High Battery Cut Out (HBCO) level, the inverter will automatically

shut down to prevent the inverter from supplying unregulated

AC output voltage. The inverter’s status LED turns off when a

high battery fault condition occurs. The inverter will automatically

restart when the battery falls to the High Battery Cut In (HBCI)