Magnum Energy MMS-E User Manual

Owner’s Manual

MMS-E Series

Inverters/Chargers

© 2011 Magnum Energy, Inc.

Disclaimer of Liability

The use of this manual and the conditions or methods of installation,

operation, use, and maintenance of the MMS-E Series inverter/charger

are beyond the control of Magnum Energy, Inc. Therefore, this company

assumes no responsibility and expressly disclaims any liability for

loss, damage, or expense whether direct, indirect, consequential, or

incidental that may arise out of or be in any way connected with such

installation, operation, use, or maintenance.

Due to continuous improvements and product updates, the images

shown in this manual may not exactly match the unit purchased.

Restrictions on Use

The MMS-E Series inverter/charger may only be used in life-support

devices or systems with the express written approval of Magnum

Energy. Failure of the MMS-E Series inverter/charger can reasonably

be expected to cause the failure of that life-support device or system,

or to affect the safety or effectiveness of that device or system. If the

MMS-E Series inverter/charger fails, it is reasonable to assume that

the health of the user or other persons may be endangered.

Contact Information

Magnum Energy, Inc.

2211 West Casino Rd.

Everett, WA 98204

Phone: +011-425-353-8833

Fax: +011-425-353-8390

Web: www.magnumenergy.com

Record the unit’s model and serial number in case you need to provide

this information in the future. It is much easier to record this information

now, instead of trying to gather it after the unit has been installed.

Model: Serial Number:

MMS912E AK

Conventions Used in this Manual

Terminology

Shore power or External AC power - refers to alternating current

(AC) provided by the utility electric power grid or from a generator.

Mobile application - refers to inverters used in a caravan, boat, or a

truck installation.

i

© 2011 Magnum Energy, Inc.

Safety Symbols

To reduce the risk of electrical shock, fi re or other safety hazard, the

following safety symbols have been placed throughout this manual

to indicate dangerous and important safety instructions.

WARNING: This symbol indicates that failure to take a

specifi ed action could result in physical harm to the user.

CAUTION: This symbol indicates that failure to take a

specifi ed action could result in damage to the equipment.

Info: This symbol indicates information that emphasizes

or supplements important points of the main text.

IMPORTANT PRODUCT SAFETY INSTRUCTIONS

This manual contains important safety instructions that must be followed during the installation and operation of this product. Read all

instructions and safety information contained in this manual before

installing or using this product.

• All electrical work must be performed in accordance with local,

state, and federal electrical codes.

• This product is designed for indoor/compartment installation.

DO NOT expose to rain, snow, moisture, or liquids of any type.

• Use insulated tools to reduce the chance of electrical shock or

accidental short circuits.

• Remove all jewelry such as rings, watches, bracelets, etc., when

installing or performing maintenance on the inverter.

• Always disconnect the batteries or energy source prior to installing or performing maintenance on the inverter. Live power may

be present at more than one point since an inverter utilizes both

batteries and AC. Turning off the inverter may not reduce this

risk. As long as AC power is connected, it will pass through the

inverter regardless of the ON/OFF power switch setting.

• Always verify proper wiring prior to starting the inverter.

• Do not operate the inverter if it has been damaged.

• Do not dismantle the inverter; there are no user-serviceable parts

contained in this product. Attempting to service the unit yourself

could cause electrical shock. Internal capacitors remain charged

after all power is disconnected.

• No AC or DC disconnects are provided as an integral part of this

inverter. Both AC and DC disconnects must be provided as part

of the system installation.

ii

© 2011 Magnum Energy, Inc.

• Overcurrent protection for the battery supply is not provided as

an integral part of this inverter. Overcurrent protection of the

battery cables must be provided as part of the installation.

• Overcurrent protection for the AC output wiring is not provided

as an integral part of this inverter. Overcurrent protection of the

AC output wiring must be provided as part of the installation.

IMPORTANT BATTERY SAFETY INSTRUCTIONS

• Wear eye protection (safety glasses) when working with batteries.

• Remove all jewelry such as rings, watches, bracelets, etc., when

installing or performing maintenance on the inverter.

• Never work alone. Always have someone near you when working

around batteries.

• Use proper lifting techniques when working with batteries.

• Never use old or untested batteries. Check each battery’s label

for age, type, and date code to ensure all batteries are identical.

• Batteries are sensitive to changes in temperature. Always install

batteries in a stable environment.

• Install batteries in a well ventilated area. Batteries can produce

explosive gasses. For compartment or enclosure installations,

always vent batteries to the outside.

• Provide at least one inch of air space between batteries to provide

optimum cooling.

• Never smoke when in the vicinity of batteries.

• To prevent a spark at the battery and reduce the chance of ex-

plosion, always connect the cables to the batteries fi rst. Then

connect the cables to the inverter.

• Use insulated tools at all times.

• Always verify proper polarity and voltage before connecting the

batteries to the inverter.

• To reduce the chance of fi re or explosion, do not short-circuit

the batteries.

• In the event of accidental exposure to battery acid, wash thor-

oughly with soap and water. In the event of exposure to the eyes,

fl ood them for at least 15 minutes with running water and seek

immediate medical attention.

• Recycle old batteries.

SAVE ALL INSTRUCTIONS

iii

© 2011 Magnum Energy, Inc.iv

Table of Contents

1.0 Introduction ..................................................................1

1.1 MMS-E Series Models ..................................................... 1

1.2 How an Inverter/Charger Works ...................................... 1

1.3 Inverter Applications for Mobile Installations ..................... 2

1.4 Advantages of Pure Sine Wave vs Modifi ed Sine Wave ........ 2

1.5 Appliances and Run Time ............................................... 2

1.6 Standard Features and Benefi ts ....................................... 3

1.6.1 Battery Temperature Sensor ................................... 6

2.0 Installation ....................................................................7

2.1 Pre-Installation ............................................................. 7

2.2 Unpacking and Inspection ............................................... 7

2.3 Locating and Mounting the Inverter ................................. 9

2.4 Wiring Guidelines .........................................................12

2.5 DC Wiring ...................................................................12

2.5.1 DC Wire Sizing .....................................................12

2.5.2 DC Overcurrent Protection .....................................14

2.5.3 DC Grounding ......................................................14

2.5.4 DC Cable Connections ...........................................15

2.6 Battery Bank Wiring .....................................................16

2.7 Inverter to Battery Bank Wiring ......................................16

2.7.1 DC Ground Wire ...................................................17

2.7.2 DC Negative Wire .................................................17

2.7.3 Battery Temperature Sensor ..................................17

2.7.4 DC Positive Wire ..................................................17

2.8 AC Wiring ....................................................................18

2.8.1 Neutral to Safety Ground Bonding ..........................18

2.8.2 AC Wiring Connections ..........................................18

2.8.3 AC Wire Size and Overcurrent Protection .................19

2.8.4 AC Input Wiring ...................................................20

2.8.5 AC Output Wiring .................................................21

2.9 Functional Test .............................................................22

© 2011 Magnum Energy, Inc.

v

Table of Contents (cont.)

3.0 Operation ....................................................................24

3.1 Operating Modes ..........................................................24

3.1.1 Inverter Mode ......................................................24

3.1.2 Standby Mode .....................................................25

3.2 Protection Circuitry Operation ........................................29

3.3 Inverter Start-up ..........................................................30

3.4 Factory Default Settings ................................................31

4.0 Maintenance and Troubleshooting ...............................33

4.1 Recommended Inverter and Battery Care ........................33

4.2 Caravan/Marine Off-Season Storage ................................33

4.3 Resetting the Inverter ...................................................34

4.4 Troubleshooting ...........................................................35

5.0 Specifi cations ..............................................................36

Appendix A - Optional Equipment and Accessories ............37

Appendix B - Wiring Color Codes for Eur. & US/Canada .....38

Appendix C - Battery Information ......................................39

C1 Battery Bank Sizing .......................................................39

C2 Battery Types ...............................................................39

C3 Battery Confi guration.....................................................39

C3.1 Series Wiring ........................................................39

C3.2 Parallel Wiring ......................................................40

C3.3 Series-Parallel Wiring ............................................40

Appendix D - Warranty/Service Information .....................42

D1 Limited Warranty ..........................................................42

D2 How to Receive Repair Service ........................................43

© 2011 Magnum Energy, Inc.vi

List of Figures

Figure 1-1, MMS-912E Model Inverter/Charger .......................... 1

Figure 1-2, Top and Left Side Features ..................................... 4

Figure 1-3, Front and Back Side Features .................................. 5

Figure 1-4, Battery Temperature Sensor (BTS) .......................... 6

Figure 2-1, MMS-912E Model Basic Installation Diagram ............. 8

Figure 2-2, Approved Mounting Orientations .............................11

Figure 2-3, MMS-912E Model Inverter/Charger Dimensions ........11

Figure 2-4, DC Cable to Battery Terminals ................................15

Figure 2-5, DC Cable to Inverter’s DC Terminals .......................15

Figure 2-6, AC Wiring Connections ..........................................21

Figure 3-1, Automatic 4-Stage Charging Graph .........................27

Figure 3-2, BTS Temperature to Charge Voltage Change ............28

Figure 4-1, Resetting the Inverter ...........................................34

Figure C3-1, Series Battery Wiring ..........................................39

Figure C3-2, Parallel Battery Wiring ........................................40

Figure C3-3, Series-Parallel Battery Wiring ...............................40

Figure C3-4, Battery Bank Wiring Examples (12-volt) ................41

List of Tables

Table 2-1, Recommended DC Wire/Overcurrent Device ............. 13

Table 2-2, DC Wire Size for Increased Distance ........................ 14

Table 2-3, Wire Color to AC Wire Connection ........................... 19

Table 2-4, Minimum Wire Size to Circuit Breaker Size ............... 20

Table 3-1, Inverter Battery Turn On/Off Levels ......................... 30

Table 3-2, Inverter/Charger Default Settings ........................... 32

Table 4-1, Troubleshooting Guide ........................................... 35

Table 5-1, MMS-E Series Specifi cations ................................... 36

Table B-1, AC Wiring Color Codes .......................................... 38

Table B-2, DC Wiring Color Codes .......................................... 38

© 2011 Magnum Energy, Inc.

1

1.0 Introduction

Congratulations on your purchase of an MMS-E Series inverter/charger from Magnum Energy, Inc. This product is designed especially

for your mobile application. Powerful, yet simple to use, this product

will provide you with years of trouble-free use.

1.1 MMS-E Series Model

MMS912E - a 900 watt inverter/charger with 20 amp AC transfer

capability and a 40 amp/12 VDC, 4-stage Power Factor Correction

(PFC) charger. The AC input and output are provided with pigtail

wires to allow hardwiring to a main AC distribution panel and to an

inverter sub-panel. Features isolated input/output neutrals for mobile

applications. Includes a Battery Temperature Sensor (BTS) with a

15’ cable extension.

Figure 1-1, MMS912E Model Inverter/Charger

1.2 How an Inverter/Charger Works

An inverter takes direct current (DC) from your batteries and turns it

into alternating current (AC), like you use at home. With the MMS-E

Series model, it also takes alternating current (when connected to

a generator or to shore power) and transforms it into direct current

to recharge your batteries.

The two modes of operation associated with this inverter/charger are

referred to in this document as:

Inverter Mode: DC from the batteries is transformed into pure sine

wave AC for powering your mobile applications.

Standby Mode: The unit operates as a battery charger to convert incoming AC power into DC power to recharge the batteries while continuing

to pass the incoming AC power directly to the inverter’s output – to

power any AC loads.

1.0 Introduction

© 2011 Magnum Energy, Inc.2

1.0 Introduction

1.3 Inverter Applications for Mobile Installations

Inverters can be used to provide power in mobile situations, such

as in a caravan, truck, or boat. In these applications the inverter

provides power to the AC loads using the energy stored in the batteries, and recharges the batteries when shore power or an onboard

generator is available.

1.4 Advantages of a Pure Sine Wave vs Modifi ed Sine

Wave Inverter

Today’s inverters come in two basic output waveforms: modifi ed sine

wave (which is actually a modifi ed square wave) and pure sine wave.

Modifi ed sine wave inverters approximate a pure sine waveform and

will run most appliances and electronics without any problems. These

inverters are less expensive, and therefore offer a viable alternative

to more expensive pure sine wave inverters.

The output of a pure sine wave inverter is equal to or, in many

cases, better than the shore power used in your home. Virtually

any electronic device will operate from a pure sine wave inverter.

Motors run cooler, microwaves usually cook faster, and clocks keep

better time just to name a few examples. Without compromising

quality or performance, the MagnaSine provides you with all of the

advantages of a pure sine wave inverter at a much lower cost than

many on the market.

1.5 Appliances and Run Time

The MMS-E Series inverter/charger can power a wide range of household appliances. As with any appliance using batteries for power,

there is a certain length of time that it can run – this is called “run

time”. Actual run time depends on several variables including: the

size and the type of appliance, the type of batteries installed in your

application, as well as the battery’s capacity and age. Other factors

such as the battery’s state of charge and temperature can also affect

the length of time your appliances can run.

Depending on your inverter capacity, larger electrical appliances such

as coffee pots and hair dryers can be used for short durations. However, loads that are used for longer periods such as stoves or water

heaters can quickly drain your batteries and are not recommended

for inverter applications.

All electrical appliances are rated by the amount of power they

consume. The rating is printed on the product’s nameplate label,

usually located on its chassis near the AC power cord. Even though

it is diffi cult to calculate exactly how long an inverter will run a particular appliance, the best advice is trial and error. Your MMS-E Series

inverter/charger has a built-in safeguard that automatically protects

your batteries from being over-discharged.

© 2011 Magnum Energy, Inc.

1.0 Introduction

3

1.6 Standard Features and Benefi ts

The MMS-E Series inverter/charger converts 12 volts of direct current (VDC) power from your battery to 230 volts alternating current

(VAC) power.

The multi-stage battery charger optimizes incoming AC

power using power factor correction (PFC) technology to keep the

inverter’s battery bank fully charged. This inverter is designed to allow

easy installation and use, and with its die-cast aluminum baseplate

it ensures maximum durability and cooler, more effi cient operation.

The inverter/charger provides the following:

• 900 watts continuous at 25°C

• numerous protection features to provide a safe and peace-of-

mind operation

• AC transfer switch circuitry; allowing incoming AC power to con-

tinue to pass-thru to power loads even if the inverter is off

• dead battery charging for batteries that are extremely low

• automatic 4-stage battery charger with power factor correction

and temperature compensation – for optimum battery charging

(using the temperature sensor)

• modern and aesthetically pleasing design with a large AC wiring

compartment (provides easy access to AC wiring for simple and

quick connections) and 360° DC connection terminals with color

coded insulating covers

• true RMS output voltage regulation to ensure the inverter will

deliver the correct amount of power – within the DC input voltage

range and the continuous output power level

• quick connection accessory and remote ports – easily accepts

several optional remote controls and the Battery Temperature

Sensor

The MMS-E Series inverter/chargers are equipped with the following

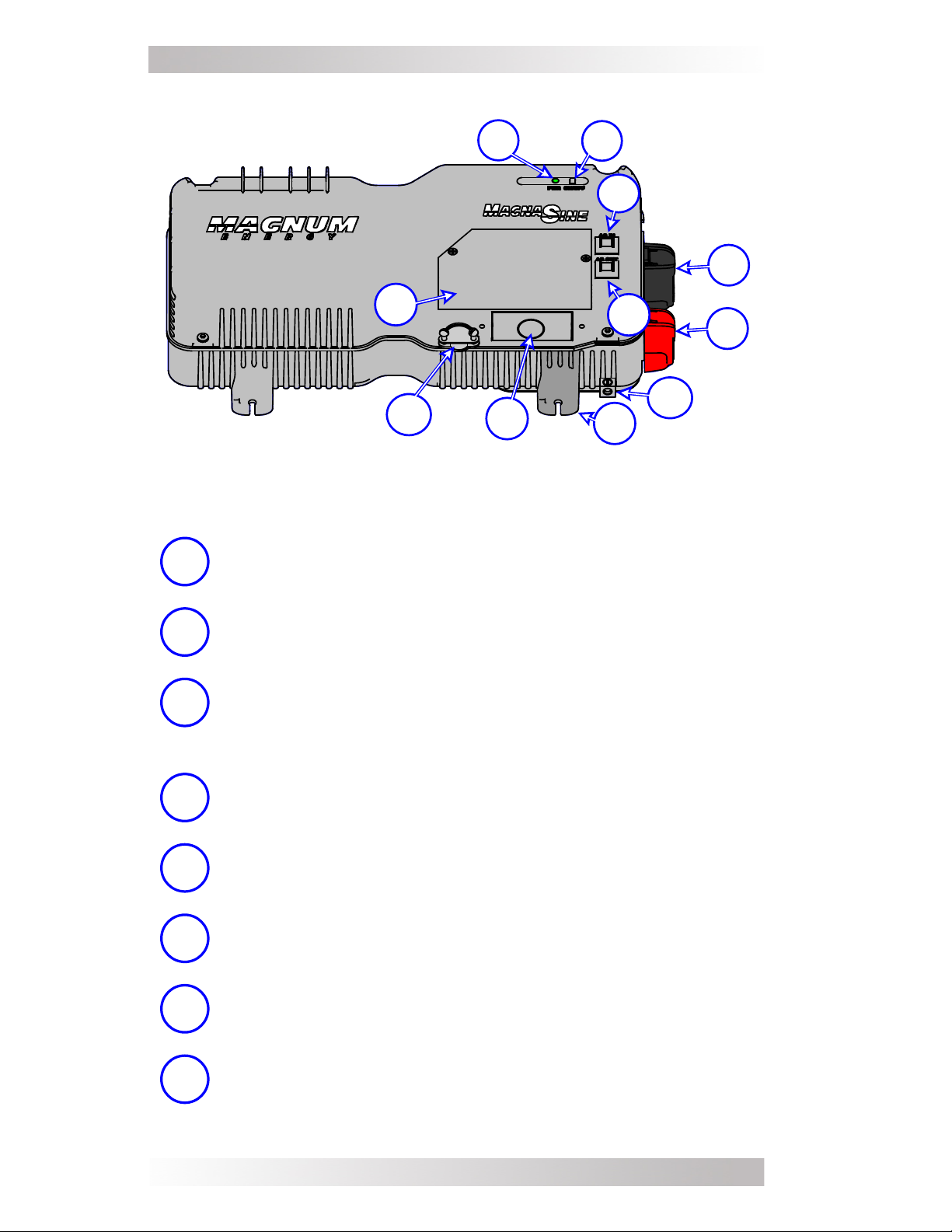

features (see Figures 1-2 & 1-3):

1

Inverter Status Indicator - this green LED illuminates to

provide information on the inverter’s operation.

2

Power Switch - a momentary pushbutton switch that turns

the inverter on or off.

3

Negative DC Terminal (black) - the inverter’s connection

to the negative terminal on the battery bank.

© 2011 Magnum Energy, Inc.

Figure 1-2, Top and Left Side Features

4

Positive DC Terminal (red) - the inverter’s connection to

the positive terminal on the battery bank.

5

Input Circuit Breaker - this circuit breaker protects the

unit’s internal wiring and pass-thru relay.

6

Output Circuit Breaker - this circuit breaker provides

another layer of overload protection. This is not a branch

circuit-rated breaker. Separate AC output breakers may be

required on the output.

7

Mounting Flanges (x4) - secures the inverter to shelf/

wall.

8

AC Wiring Compartment - provides access for all AC input

and output connections on the inverter.

9

AC Output Connection - AC knockout for hardwiring AC

output.

10

AC Input Connection - a strain relief clamp for hardwiring

AC input.

11

DC Ground Terminal - this connection is used to tie the

exposed chassis of the inverter to the DC grounding system.

This terminal accepts CU/AL conductors from 2.08 mm² to

13.29 mm² (#14 AWG to #6 AWG).

4

1.0 Introduction

1

2

3

4

5

6

7

8

10

9

11

© 2011 Magnum Energy, Inc.

1.0 Introduction

5

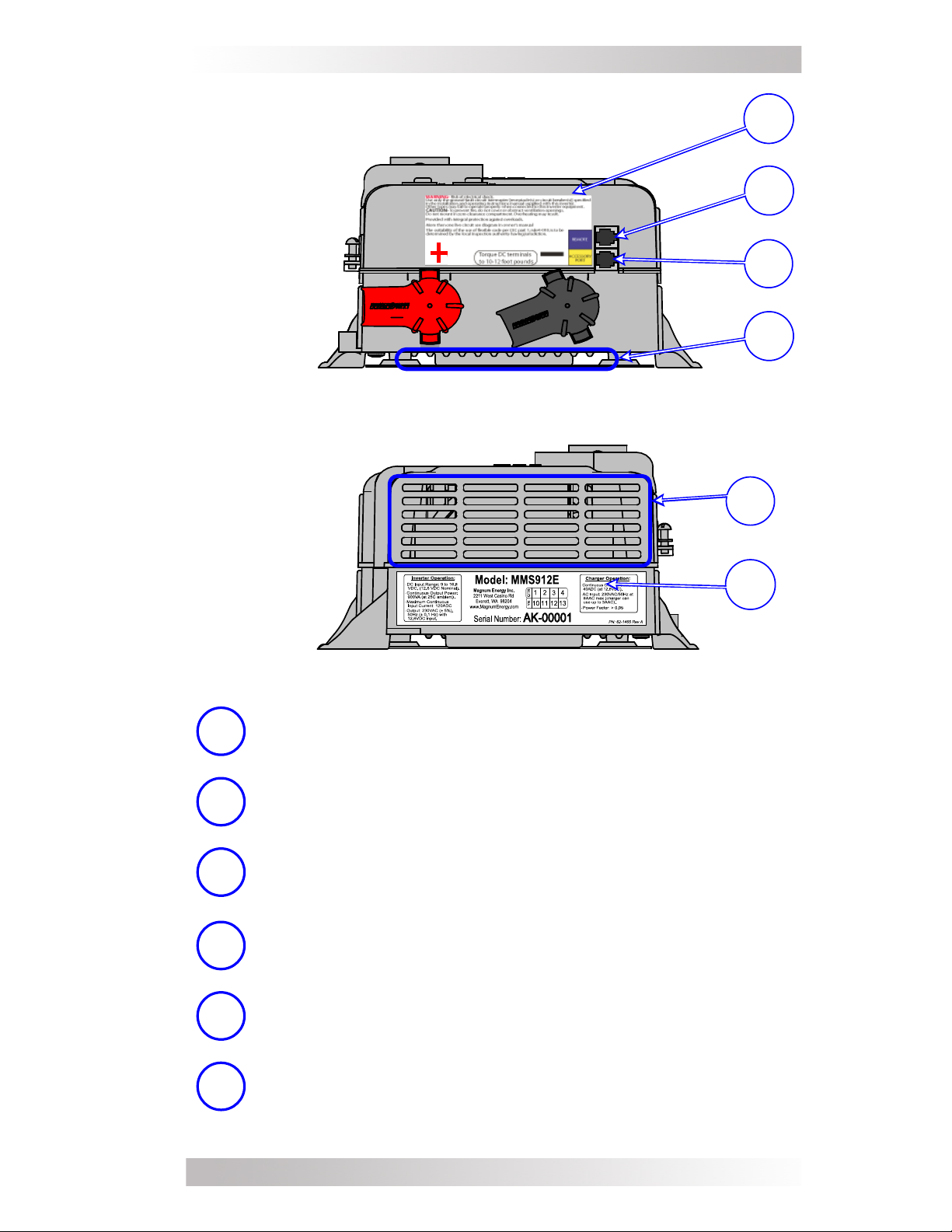

Figure 1-3, Front and Back Side Features

12

Warning and Information Label - provides pertinent

information for safely using the inverter.

13

REMOTE Port Connection - a RJ11 connector that allows

an optional remote control to be connected.

14

ACCESSORY PORT Connection - a RJ11 connector to allow

the Battery Temperature Sensor (BTS) or MMS-E accessories

(e.g., MM-DCLD, MM-ISA) to be connected.

15

Intake Vent - ventilation openings to pull in air to keep

the inverter cool for peak performance.

16

Exhaust Vent - ventilation openings that allow heated air

to be removed by the internal cooling fan.

17

Model/Serial Number Label - includes the model/serial

number and provides specifi cations and information on the

inverter and charger. See the MMS-E Series Specifi cations

on page 36 for more information.

Front Side

13

12

14

15

Back Side

16

17

© 2011 Magnum Energy, Inc.

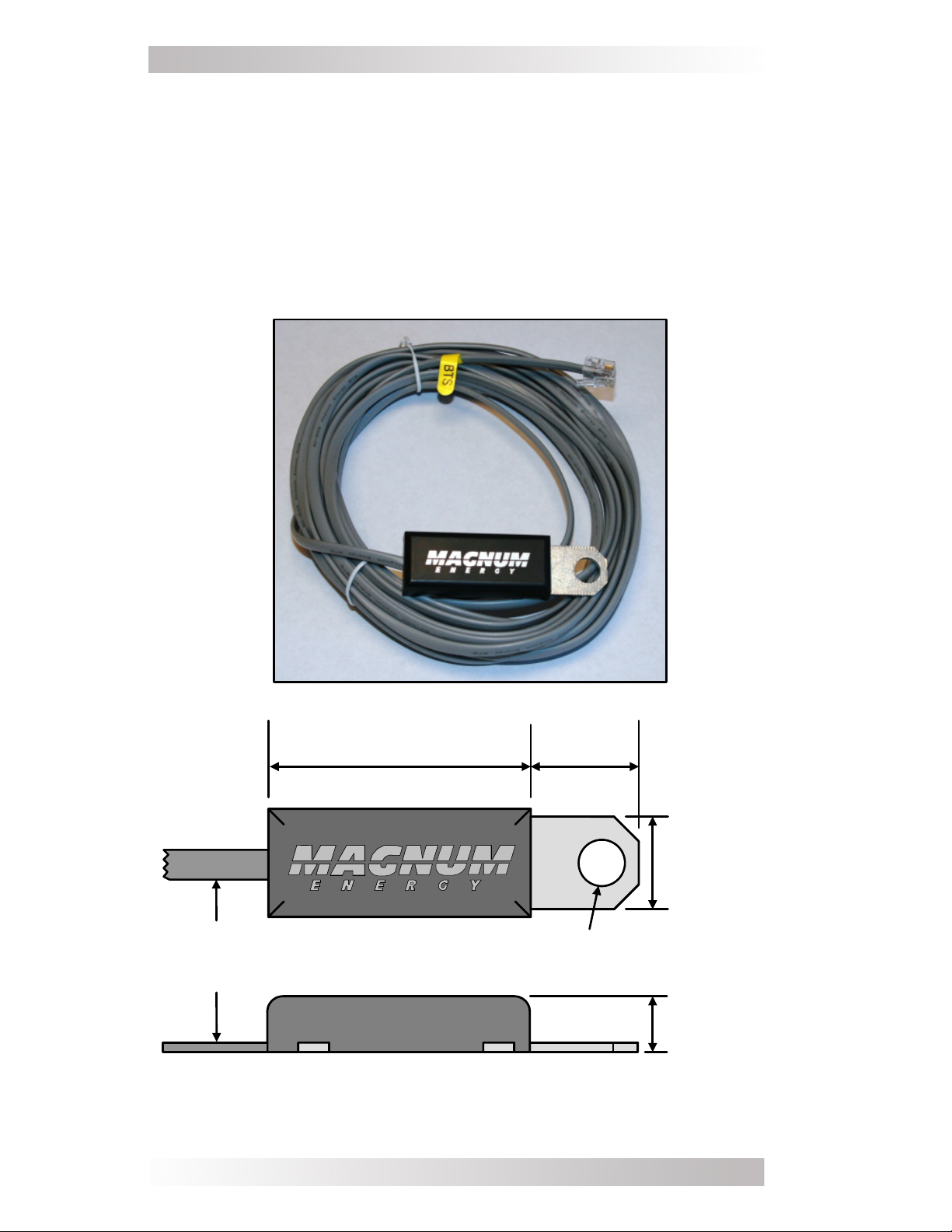

1.6.1 Battery Temperature Sensor

A plug-in external Battery Temperature Sensor (BTS) is provided with

the battery charger feature. When installed, the BTS automatically

adjusts the battery charger’s bulk, absorb, and fl oat voltage set

points (based on temperature) for better charging performance and

longer battery life. If the temperature sensor is NOT installed and

the batteries are subjected to large temperature changes, battery

life may be shortened.

FRONT VIEW

SIDE VIEW

~5.1 cm (~2")

~2.5 cm

(~1")

~1.3 cm

(~

½

”)

.95 cm diameter

(0.375")

Cable

extension

~1.9 cm

(~

¾

”)

Figure 1-4, Battery Temperature Sensor (BTS)

6

1.0 Introduction

© 2011 Magnum Energy, Inc. 7

2.0 Installation

2.0 Installation

2.1 Pre-Installation

Before installing the inverter, read

the entire Installation section. The

more thorough you plan in the beginning, the better your inverter

needs will be met.

WARNING: Installations should be performed by qualifi ed

personnel, such as a licensed or certifi ed electrician. It

is the installer’s responsibility to determine which safety

codes apply and to ensure that all applicable installation

requirements are followed. Applicable installation codes

vary depending on the specifi c location and the type of

installation.

Info: Review the Important Product Safety Instructions

on page ii and the Important Battery Safety Instructions

on page iii before any installation.

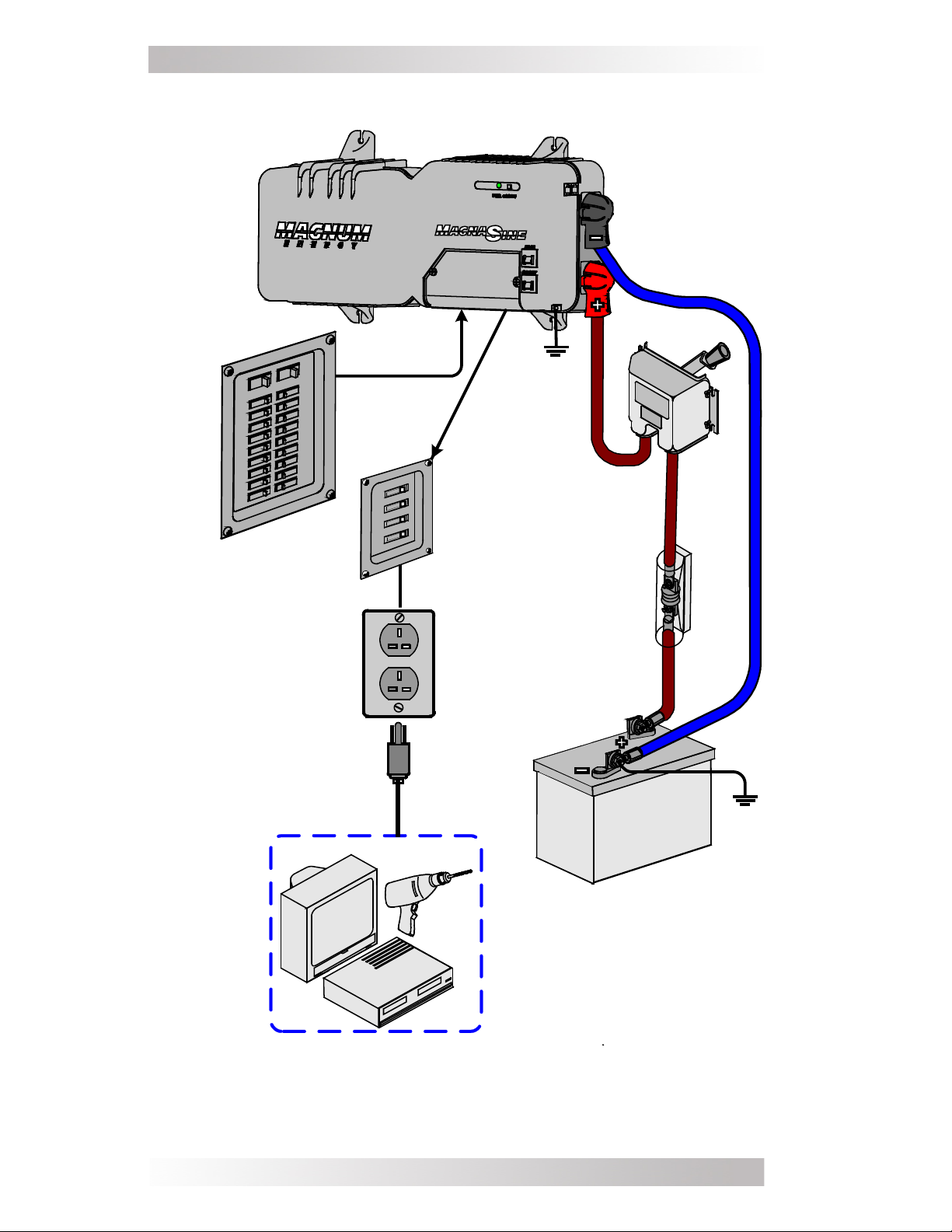

The basic system diagram shown in Figure 2-1

should be reviewed

to assist you in planning and designing your installation.

2.2 Unpacking and Inspection

Carefully remove the MMS-E Series inverter/charger from its shipping container and inspect all contents. Verify the following items

are included:

− MMS-E Series inverter/charger

− Red and black DC terminal covers

− AC access cover with two screws

− Two 1/2” hex-head Kep nuts (installed on the DC terminals)

− Battery Temperature Sensor (BTS)

− MMS-E Series Owner’s Manual

If items appear to be missing or damaged, contact your authorized

Magnum Energy dealer or Magnum Energy, Inc.

If at all possible, keep your shipping box. It will help protect your

inverter from damage if it ever needs to be returned for service.

Save your proof-of-purchase as a record of your ownership; it will

also be needed if the unit should require in-warranty service.

Record the unit’s model and serial number in the front of this manual

in case you need to provide this information in the future. It is much

easier to record this information now, instead of trying to gather it

after the unit has been installed.

© 2011 Magnum Energy, Inc.

Figure 2-1, MMS912E Model Basic Installation Diagram

AC

Main

Panel

DC

disconnect

and

overcurrent

device

Battery

Bank

AC IN

230

VAC

Loads

AC

Sub-Panel

230

VAC

Outlet

AC

OUT

DC

Ground

DVD

TV

Tools

Brown

Brown

.Brown

Blue

2.0 Installation

8

© 2011 Magnum Energy, Inc.

2.0 Installation

9

2.3 Locating and Mounting the Inverter

WARNINGS:

• Do not mount the inverter near any fl ammable or

combustible fl uid or components

• Provide adequate clearance/ventilation to the inverter

• Mount only on a non-combustible surface

• Maximum ambient temperature around the inverter

must not exceed 25° C (77° F) to meet power

specifi cations

The inverter should only be installed in a location that meets the

following requirements:

Clean and Dry - The inverter should not be installed in an area

that allows

dust, fumes, insects, or rodents to enter or block the

inverter’s ventilation openings. The area also must be free from any

risk of condensation, water,

or any other liquid that can enter or fall

on the inverter. The inverter uses stainless steel fasteners, plated

copper busbars, and a powder-coated aluminum base. Also, the

internal circuit boards are conformal coated. The above measures are

undertaken to help fi ght the harmful effects of corrosive environments.

However, the life of the inverter is uncertain if used in any of these

types of environments, and inverter failure under these conditions

is not covered under warranty.

Cool - The inverter should be

protected from direct exposure to the

sun or to any equipment that produces extreme heat.

The ambient

air temperature should be between 0° C (32° F) and 40° C (104°

F); keep in mind that the inverter’s output specifi cations are rated at

25° C (77° F), so the cooler the better within this range.

Ventilated - In order for the inverter to provide full output power

and avoid over-temperature fault conditions, do not cover or block

the inverter’s ventilation openings or install this inverter in an area

with limited air fl ow. Allow as much clearance around the inverter’s

intake and exhaust ventilation openings as possible, see Items 16

and 17 in Figure 1-3. At the minimum, allow an airspace clearance of

15 cm (6”) at the front and back, and 7.5 cm (3”) everywhere else

to provide adequate ventilation.

If installed in an enclosure, a fresh air intake opening must be provided

directly to the front side (intake vent) and an exhaust opening on

the back side (exhaust vent) of the inverter. This will allow cool air

from the outside to fl ow into the inverter, and heated air to exit away

from the inverter and the enclosure. When mounted in an enclosed

compartment, air fl ow must be at least 59 cfm in order to maintain no

more than a 20° C (68° F) rise in compartment temperature. Minimum

clearances can be reduced if air fl ow is increased, but in no case should

clearance around the inverter be less than 5 cm (2”) on all sides.

Loading...

Loading...