Page 1

ME-SBC

TM

Smart Battery Combiner

TM

Owner’s Manual

Page 2

Disclaimer of Liability

Since the use of this manual and the conditions or methods of installation,

operation, and maintenance of the ME-SBC

TM

are beyond the control of Magnum

Energy Inc., this company does not assume responsibility and expressly

disclaims liability for loss, damage or expense, whether direct, indirect,

consequential or incidental, arising out of or anyway connected with such

installation, operation, use, or maintenance.

Due to continuous improvements and product updates, the images shown in

this manual may not exactly match the unit purchased.

Restrictions on Use

The ME-SBCTM shall not be used in connection with life support systems, life

TM

saving or other medical equipment or devices. Use of the ME-SBC

with this

particular equipment is at your own risk.

IMPORTANT PRODUCT SAFETY INSTRUCTIONS

This manual contains important safety instructions that must be followed

during the installation and operation of this product. Read all instructions

and safety information contained in this manual before installing or using

this product.

WARNINGS:

• All electrical work must be performed in accordance with local, state and

federal electrical codes.

• This product is designed for indoor / compartment installation. It must not

be exposed to rain, snow, moisture or liquids of any type.

• Use insulated tools to reduce the chance of electrical shock or accidental

short circuits.

• Remove all jewelry such as rings, watches, bracelets, etc., when installing

or performing maintenance on the ME-SBC

TM

system.

• Always disconnect the batteries or energy source prior to installing or performing maintenance on the ME-SBC

TM

system.

Safety Symbols

To reduce the risk of electrical shock, fi re, or other safety hazard, the fol-

lowing safety symbols have been placed throughout this manual to indicate

dangerous and important safety instructions.

WARNING: This symbol indicates that failure to take a specifi ed

action could result in physical harm to the user.

CAUTION: This symbol indicates that failure to take a specifi ed ac-

tion could result in damage to the equipment.

Info: This symbol indicates information that emphasizes or supple-

ments important points of the main text.

ii ©2009 Magnum Energy Inc.

Page 3

List of Sections

1.0 Introduction ............................................................................. 1

2.0 Installation ............................................................................... 3

TM

3.0 Adjusting the ME-SBC

.......................................................... 11

4.0 Limitations of Throughput ..................................................... 12

5.0 LED Indicators ........................................................................ 13

6.0 Troubleshooting .................................................................... 14

7.0 Specifi cations ......................................................................... 15

8.0 Limited Warranty ................................................................... 16

List of Tables

Table 2-4, Recommended Wires Sizes for 3% loss ......................... 5

Table 3-2, Battery Combining Operation ....................................... 12

Table 5-1, LED Indicators ............................................................. 13

Table 6-1, Troubleshooting Table ................................................ 14

Table 7-1, Specifications .............................................................. 15

List of Figures

Figure 1-1, Front Panel Interface ................................................... 2

Figure 2-1, ME-SBC

Figure 2-2, Power Terminal Block ................................................... 4

Figure 2-3, Accessories Terminal Block .......................................... 4

Figure 2-5, ME-SBC

Figure 2-6, Solenoid Drive .............................................................. 8

Figure 2-7, Remote Volt Sense ..................................................... 10

Figure 3-1, Battery Combining Setpoints ...................................... 11

Figure 3-2, Battery Combining Operation ..................................... 12

©2009 Magnum Energy Inc. iii

TM

Dimensions ................................................... 3

TM

- 25 Amp Combiner Mode .............................. 6

Page 4

Introduction

1.0 Introduction

The Magnum Smart Battery CombinerTM (ME-SBCTM) is designed to monitor

and charge a second battery using a portion of the current that is charging

a main battery.

The ME-SBC

circuit that eliminates a signifi cant voltage drop and provides automatic turn

on and off based on adjustable voltage setpoints; allowing different batteries

to be charged from a single charging source and preventing over or under

charging.

TM

uses MOSFETs, which is a bidirectional electronic switch, control

1.1 Product Features

• Compatible with 12 or 24 volt Systems

• Very easy install and setup

• Auto-detecting input voltage (12, 24V)

• Transfers up to 25 Amps

• Solenoid drive for ampacity requirement greater than 25 Amps

• Over-temp shutdown

• Wide voltage range allows maximum charging fl exibility

• Adjustable Voltage settings

• Over-current shutdown

• Front panel LED’s for status and troubleshooting

• Reverse polarity protection

Virtually zero voltage loss

•

Bidirectional charging

•

Sense lead for long run applications

•

1 ©2009 Magnum Energy Inc.

Page 5

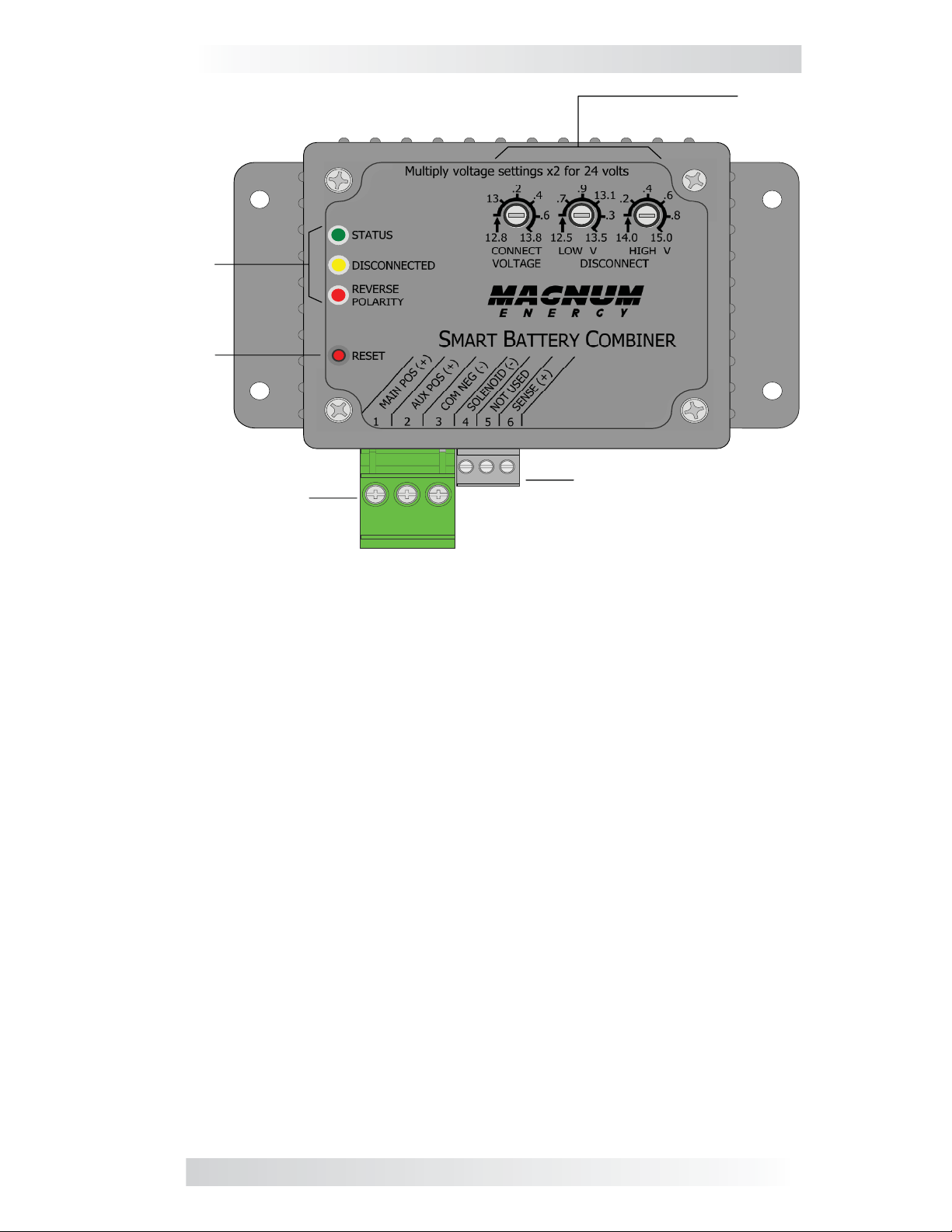

1

3

Introduction

2

5

4

Figure 1-1, Front Panel Interface

1.2 Front Panel

1. LED Indicators - The at-a-glance LEDs provide status and operation in

a straightforward way.

2. Adjustable Voltage Settings - Three dials for adjusting the CONNECT

VOLTS DC and the LOW and HIGH VDC DISCONNECT settings for maximum

charging fl exibility.

3. Reset Switch - Performs a full reset of the ME-SBC

4. Power Terminal Block- The oversized, removable terminal block allows

fast and easy wire connections from the battery banks and makes provision

for large wires to accomodate for long wire runs.

5. Accessories Terminal Block - Easy wire terminal block adds functionality

to drive a solenoid, or run a seperate Remote Voltage Sense line to

compensate for systems with long wire runs.

TM

.

©2009 Magnum Energy Inc. 2

Page 6

Installation

2.0 Installation

Before installing the ME-SBCTM, read this entire section to be aware of all aspects of the installation; then you can thoroughly plan the details to ensure

the overall system requirements are accomplished.

To assist you in planning and designing your installation; you should review

the basic system diagram shown in Figure 2-2 and Figure 2-3.

Info: Installations should be performed by qualifi ed personnel, such

as a licensed or certifi ed electrician. It is the installer’s responsibility

to determine which safety codes apply and to ensure that all applicable installation requirements are followed.

Info: Review the “Important Product Safety Information” on the

front inside cover page before any installation.

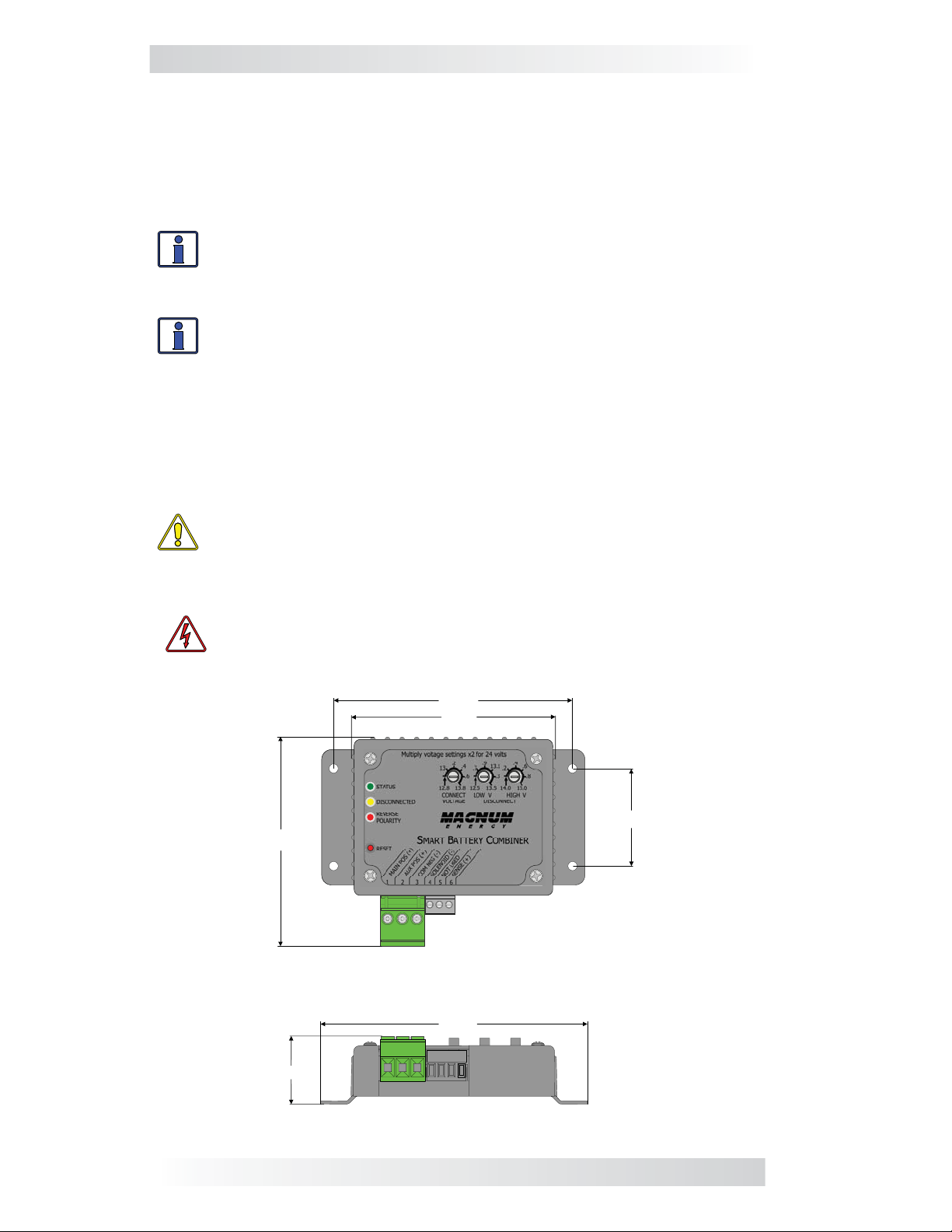

2.2 Location and Mounting

Select a location that is dry and away from extreme temperatures to mount

TM

the ME-SBC

; using the supplied #8 x 3/4 screws (x4).

access the three adjustment dials, to view the LEDs

blocks

; refer to Figure 2-1 for dimensions on the ME-SBCTM.

TM

CAUTION: Do not mount the ME-SBC

ment or in an area

TM

ME-SBC

and cause shorting or corrosion. The internal circuit board

where water or any other liquid can enter the

in a closed battery compart-

Allow ample room to

and to access the terminal

is conformal coated to help prevent corrosion. However, a failure that

is caused by corrosion is not covered by the warranty.

WARNING: This device is not tested for Ignition Protection. Do not

install this device in a gasoline engine room or any other area that

requires an ignition protection rating.

4.9"

4.2"

2.0"

4.2"

5.4"

1.4"

Figure 2-1, ME-SBCTM Dimensions

3 ©2009 Magnum Energy Inc.

Page 7

Installation

2.3 Connections

Please refer to the diagrams below for connectivity information.

ME-SBC™

To Main Battery

Positive

To Auxiliary

Battery Positive

Figure 2-2, Power Terminal Block

ME-SBC™

The Power

Termi nal B lock is

removable and

each port accepts

12 to 8 AWG wire

To Common

Battery

Negative

The Accessories

Termi nal B lock is

removable and each

port accepts

18 to 12 AWG wire

Remote Voltage Sense

Not Used

Negative to the

Solenoid Drive

Figure 2-3, Accessories Terminal Block

2.4 Confi gurations

The ME-SBCTM can be confi gured to accomplish battery combining in a simple,

fl exible way. There are two methods and they are as follows:

25 Amp Combiner - This confi guration is simple to install and use. The

3-wire connection system is similar to connection methods used by other

battery combining products. One of the the advantages of this controller is

the advanced combining options that are available to the installer. It is best

to choose this method when designing systems where 25 amps or less are

required. For this confi guration see Figure 2-5.

Solenoid Drive - If more battery combining capacity (or Ampacity) is required

the installer can employ any solenoid, so long as the coil of that solenoid

consumes less than 2 Amps. The source that provides power to the solenoid

must not exceed 40 VDC. This circuit switches DC Negative to the accessory

terminal block position #4 entitled Solenoid (-). For this confi guration please

see Figure 2-6.

©2009 Magnum Energy Inc. 4

Page 8

Installation

2.4.1 ME-SBCTM Wiring Connections - 25 Amp

CAUTION: Before connecting any wires, turn off any battery charger

and loads that are connected to the battery banks that the ME-SBCTM

will be combining.

Info: If installing in a boat, RV or truck, ensure the conductors

passing through walls, bulkheads or other structural members are

protected to minimize insulation damage such as chafi ng; which can

be caused by vibration or constant rubbing.

The ME-SBC

TM

should now be mounted if not please refer to section 2.2.

During installation please refer to Figures 2-5 during the following steps:

TM

1. Unplug the Power Terminal Block from ME-SBC

and ensure the open-

ings are unscrewed enough to allow the wires to be inserted.

1

2. Select and connect an appropriately sized red wire

from terminal #1

- MAIN POS (+) on the Power Terminal Block to the positive terminal of

the Main Battery.

3. Select and Connect an appropriately sized red wire with a white stripe

from terminal #2 - AUX POS (+) on the Power Terminal Block to the positive

terminal of the Auxiliary Battery.

1

4. Select and connect an appropriately sized a black wire

from terminal #3

- COM NEG (-) on the Power Terminal Block to the Negative bus-bar or

vehicle chassis.

Info: The Negative busbar must connect the negative terminals on

the Main and Auxiliary Batteries together.

5. When all the connections are made and checked, plug the Power Terminal

TM

Block into the ME-SBC

to supply DC power.

Info: If there is a miswire in the system the “Reverse Polarity” LED

will be on. Correct the polarity of the wires connected to the Main

Terminal.

1

TM

6. Immediately after applying DC power, the LED’s on the ME-SBC

should

come on as the unit goes through a power-up self-test. After the initial self-

test completes, the Status LED should be illuminated. If so, your ME-SBC

TM

is now ready for set-up; if not, please refer to the troubleshooting section.

10 ft 15 ft 20 ft 30 ft

12 V

10 AWG 8 AWG not recommended not recommended

24 V 12 AWG 12 AWG 10 AWG 8 AWG

Table 2-4, Recommended Wires Sizes for 3% loss

note 1 : The wires connected to #1 - MAIN POS (+), #2 - AUX POS (+)

and #3 - COM NEG (-) should be sized for 30 amps and the same size.

The battery positive #1 - MAIN POS (+) and #2 - AUX POS (+) lines

should be protected with a 30 Amp fast blow fuse. Wire size should be

appropriate for the application.

5 ©2009 Magnum Energy Inc.

Page 9

Installation

Magnum Energy

Inverter/Charger

ME-RC

Remote Control

PWR

FA ULT

Inverting

CHG

DC 12.6V 5A

INV

ON/OFF

CHARG ER

ON/OFF

AGS MET ER SETUPSHOREINVERTER

TECH

ME-SBC

S m art Battery Co m bin er

SELECT

U

S

E

F

T

S

C

S

L

A

Main

Battery Bank

A uxiliary (A U X)

Battery Bank

Negative Bus-bar

Figure 2-5, ME-SBC - 25 Amp Combiner Mode

©2009 Magnum Energy Inc. 6

Page 10

Installation

2.4.2 ME-SBCTM Wiring Connections - Solenoid Drive

CAUTION: Before connecting any wires, turn off any battery charger

and loads that are connected to the

will be combining.

Info: If installing in a boat, RV or truck, ensure the conductors

passing through walls, bulkheads or other structural members are

protected to minimize insulation damage such as chafi ng; which can

be caused by vibration or constant rubbing.

battery banks that the ME-SBCTM

The ME-SBC

TM

should now be mounted, if not please refer to section 2.2.

During installation please refer to Figures 2-6 during the following steps:

TM

1. Unplug the Power Terminal Block from ME-SBC

and ensure the open-

ings are unscrewed enough to allow the wires to be inserted.

1

2. Select and connect an appropriately sized red wire

from terminal #1 -

MAIN POS (+) on the Power Terminal Block to the positive terminal of

the Main Battery.

1

3. Select and connect an appropriately sized red with white stripe wire

from

terminal #2 - AUX POS (+) on the Power Terminal Block to the positive

terminal of the Auxiliary Battery.

1

4. Select and connect an appropriately sized black wire

from terminal #3

- COM NEG (-) on the Power Terminal Block to the negative busbar or

vehicle chassis.

Info: The negative busbar must connect the negative terminals on

the Main and Auxiliary Batteries together.

2

5. Use an appropriately sized wire

to connect each terminal of the solenoid

to the appropriate battery terminal. Please refer to Figure 2-4 for more

information

6. Connect one side of the solenoid coil to a positive post on the Main or Aux-

iliary Battery or one of the main terminal on the solenoid. Use the appropriate

fuse to protect the wire (2 Amp fast blow maximum). For more information,

please consult the solenoid manufacturers installation instructions.

7. Connect the other side of the solenoid coil to # 4 - SOLENOID (-) on the

Accessories Terminal Block.

8. When all the connections are made and checked, plug the Power Terminal

TM

Block into the ME-SBC

9. Immediately after applying DC power, the LED’s on the ME-SBC

to supply DC power.

TM

should

come on as the unit goes through a power-up self-test. After the initial self-

test completes, the Status LED should be Illuminated. If not, please refer to

the troubleshooting section.

note 1 : The wires connected to #1 - MAIN POS (+), #2 - AUX POS (+)

and #3 - COM NEG (-) should be sized for 30 amp. The battery positive

lines should be protected with a 30 Amp fast blow fuse. Wire size should be

appropriate for the application.

note 2 : The size of this wire will likely be determined by considering the

3% voltage drop requirements of the charging circuit. Always consult the

solenoid manufacturers installation documentation.

7 ©2009 Magnum Energy Inc.

Page 11

Magnum Energy

Inverter/Charger

Installation

ME-RC

Remot e Con trol

PWR

FA ULT

CHG

INV

ON/OFF

CHARG ER

ON/OFF

Inverting

DC 12.6 V 5A

SELECT

TECHAG S M ETER SETUPSHOREINVERTER

Smart Battery Combiner

ME-SBC

Optional

Solenoid

C

U

L

S

F

T

S

A

E

S

Main

Battery Bank

A uxilia r y ( A UX )

Battery Bank

Negative B us- ba r

Figure 2-6, Solenoid Drive

©2009 Magnum Energy Inc. 8

Page 12

Installation

2.4.3 ME-SBCTM Wiring - Remote Volt Sense

The Remote Volt Sense Wire, or the wire connected to #6 - SENSE (+), can

be used to better sense when the batteries are being charged. As the ME-SBCTM

combines the Main and Auxiliary Batteries, the current path distributes

voltage drops throughout the circuit that may cause the ME-SBC

unneccessarily. The Remote Volt Sense Wire, if utilitzed, tells the ME-SBC

what the actual voltage is by bypassing the current path and therefore the

voltage drops. The Remote Volt Sense Wire can be connected at the battery

or at the charging source (i.e. Alternator, Solar, Wind, etc).

CAUTION: Before connecting any wires, turn off any connected

battery charger and ensure all negative

and positive battery cables

are disconnected from the battery bank.

Info: If installing in a boat, RV or truck, ensure the conductors

passing through walls, bulkheads or other structural members are

protected to minimize insulation damage such as chafi ng; which can

be caused by vibration or constant rubbing.

TM

to cycle

TM

1. Install and connect the ME-SBC

TM

as indicated in Section 2.2.2 or Sec-

tion 2.2.3

2. Remote Volt Sense Wire: Install a minimum of an 18 AWG wire between

the Main Battery positive and the #6 - SENSE (+) on the accesories ter-

TM

minal on the ME-SBC

. The Remote Volt Sense Wire should be fused at

0.25 Amps with a fast blow fuse.

Info: Connect the highest current cable directly to the battery ter-

minal, and in descending order in terms of ampacity, connect the

rest of the cables. The Remote Volt Sense Wire should be the last

connection on the battery. For a detail of this information, please see

the Main Battery positive post in Figure 2-7.

9 ©2009 Magnum Energy Inc.

Page 13

Magnum Energy

Inverter/Charger

Installation

ME-RC

(Remote Control )

PWR

FA ULT

Inverting

CHG

DC 12.6V 5A

INV

ON/OFF

CHARG ER

ON/OFF

ME-SBC

S m art Battery C omb iner

SELECT

TECHAGS MET ER SETUPSHOREINVERTER

F

U

S

A

T

S

C

S

L

Main

B attery B ank

E

A uxiliary (A ux)

Battery Bank

Negative Bus-bar

Figure 2-7, Remote Volt Sense

©2009 Magnum Energy Inc. 10

Page 14

Setup

3.0 Adjusting the ME-SBC

Bulk

TM

Absorption Float

H igh Voltage

D isc onnect

C onnect V oltage

D isc onnect

Low V oltage

D isc onnect

Battery Voltage

Figure 3-1, Battery combining setpoints

The above diagram represents a typical three-stage charging profi le. The fi rst

of the three stages is Bulk Charge. This is where up to 80% of the charging

is accomplished. During this stage the battery voltage increases signifi cantly

and the current that the charging source is providing to the Main Battery

is at a maximum. The second stage is Absorption, during this stage the battery voltage is held at the Absorption voltage for a period of time. By the end

of this process the charge on the battery bank is about 95% complete. The

third and fi nal stage is Float. In this stage, the remainder of the charging

is accomplished. As long as the Main Battery voltage is between the Low

Voltage Disconnect and the High Voltage Disconnect, and the Main bat-

TM

tery voltage is above the Connect Voltage, the ME-SBC

will pass charging

current through to the Auxiliary Battery.

- C onnec ted

TM

The ME-SBC

Connect Voltage: (Settable: 12.8-13.8 VDC) adjusts the point at which the ME-

TM

passes the charge from the Main Battery bank to the Auxiliary Battery bank

SBC

or vice versa. This setting is not active until a charging source is applied to one of the

batteries and the voltage begins to increase. Once this setpoint has been reached, the

ME-SBC

tery. Default = 12.8 / 25.6 VDC (12V /24 V system)

Low Voltage Disconnect: (Settable: 12.5-13.5 VDC) once the charging process has

begun and the battery voltage has exceeded the Connect Voltage setpoint, the Low

Voltage Disconnect becomes active. If the voltage begins to decrease, this is the

point at which the ME-SBC

the other battery. Default = 12.5 / 25.0 VDC (12V /24 V system)

High Voltage Disconnect: (Settable: 14.0-15.0 VDC) This setting should be used to

prevent the ME-SBC

other. If this voltage is reached, the ME-SBC

the high voltage from affecting the other battery. Default = 14.0 / 28.0 VDC (12V /24

V system)

TM

combining setpoints as follows:

will automatically start to pass the charge current through to the other bat-

TM

disconnects and stops passing charge current through to

TM

from passing through too high of a voltage from one battery to

TM

disconnects the batteries and prevents

11 ©2009 Magnum Energy Inc.

Page 15

ME-SBC

Sm art B attery Com b iner

Operation

Main

Battery Bank

Negative B us-bar

Au xiliary (A U X)

Battery Bank

Average Amps Output Behavior Status LED

0 - 25 Amps Full output Solid steady GREEN

26 - 30 Amps in dial-back so as to

maintain some output.

>30 Amps No output Fast blink RED

Table 3-2, Battery Combining Operation

Slow blink GREEN

1

4.0 Limitations of Throughput

TM

The ME-SBC

can allow charge currents from either battery to fl ow through

to the other battery (i.e. Main Battery to Auxiliary Battery or Auxiliary

Battery to the Main Battery). When the MOSFET turns on inside the ME-

TM

and the batteries are combined and a signifi cant inrush of current

SBC

occurs. This inrush may cause the ME-SBCTM to shutdown to protect itself or

reduce how much current it actually lets through to the other battery. If the

TM

ME-SBC

tempt to recombine. If the ME-SBC

shutsdown to protect itself, it will restart in 10 Seconds and at-

TM

reduces the output in order to maintain

a stable output, it will return to full output as soon as the average amperage

through the MOSFET lowers to a safe sustainable level.

note 1: When the ME-SBC

about 1/2 of the available amperage. It will continue to operate like this until

the total available Amps safely drops to a level the ME-SBC

TM

is in the reduced output mode it only lets through

TM

can conduct con-

tinuously. With a current probe, it may look like 50% of the rated output.

©2009 Magnum Energy Inc. 12

Page 16

Operation

5.0 LED Indicators

The LEDs on the front of the ME-SBC

TM

of the ME-SBC

, Faults, and Warnings. Use the table below to determine the

status of the device.

The Reverse Polarity LED indicates that the wiring to the Main Terminal is

incorrect. Correct the reverse polarity and the LED should turn off.

TM

ME-SBC

STATUS and DISCONNECTED LED Indicators

TM

are there to communicate the status

Status LED

(bi-color Red or

Green)

Disconnected

LED (Yellow)

OFF OFF No Power

OFF ON

OFF Slow Blink

Solid Green OFF

Slow

Blinking Green

Slow Blinking

Red

OFF

ON

Description

Low Voltage Disconnect (LVD).

Disconnected

High Voltage Disconnect (HVD).

Disconnected

FET switch connects MAIN and AUX

connect voltage requirement is met

on either battery, connected

FET Temp > 80C – goes to 50% duty

cycle for charging, connected

FET Temp > 90C, temperature

disconnect. Auto reconnect when

FET temperature falls below 70C

and if voltage meets “connect” spec.

Disconnected

Fast

Blink

Red

OFF

Average current > 20 Amp. Autoreconnect after 10 Secs if voltage

meets “connect” setting. Discon-

nected

Average current >30A, current

Solid

Red

ON

disconnect. Auto reconnect after

10secs when FET temperature falls

below 70C and if voltage meets “pull-

in” spec. Disconnected

Table 5-1, LED Indicators

13 ©2009 Magnum Energy Inc.

Page 17

6.0 Troubleshooting

Symptom Solution

Check Voltages at the Power Terminal Block. If

the Voltage #1 - MAIN POS (+) and #3 - COM

NEG (-) or #2 - AUX POS (+) and #3 - COM

Not combining

No indicators

Not Disconnecting

NEG (-) are above the connect Voltage and the

difference between them is less the 10 VDC the

TM

ME-SBC

may be defective. Please call Magnum

(425) 353-8833.

Check Voltages at the Power Terminal Block. If

the Voltage #1 - MAIN POS (+) and #3 - COM

NEG (-) or #2 - AUX POS (+) and #3 - COM

NEG (-). The Voltage between 1 and 3 or 1 and 2

must be more than 5VDC.

ME-SBC

TM

does not disconnect. Remove the fuse

at both batteries and check resistance at #1

- MAIN POS (+) and #2 - AUX POS (+) on the

TM

ME-SBC

. There should be about 600k Ohms (Ω).

If there isn’t the ME-SBCTM might be defective.

Please call Magnum (425) 353-8833

Troubleshooting

If the Voltage requirements are satisfi ed and

this cycling occurs, then the Current sensing

Auto Reconnecting

every 10 Sec

is corrupt or the Current exceeds continuous

capabilities. Wait for the charger to go into Float

Mode and check status again. If the ME-SBC

still toggling it may be defective, otherwise it’s

probably operating normally and protecting itself.

Adjustments are

unresponsive

Turn the knobs fully counterclockwise until they

stop and then adjust up to the setting. If they

don’t stop or don’t move call Magnum.

Table 6-1, Troubleshooting table

TM

is

©2009 Magnum Energy Inc. 14

Page 18

7.0 Specifi cations

Sense Module/Meter Specifi cations

DC Volts 12 or 24 VDC nominal

DC Amps 25 Amps Continuous;

Maximum VDC 40V peak

Average Operating Tare Loss ~150mW

Maximum Operatinng Tare Loss <220mW

Non-operating Tare Loss

(on - not combined)

Operating Range: 0-32 VDC

Shipping Weight: ~2 lbs. (Includes Manual)

Shipping Dimensions 10 x 8 x 3 inches

Unit Dimensions 4.2 x 5.4 x 1.4 inches

Maximum Operating

Temperature

Maximum Storage

Temperature

Regulatory Ignition Protected

Table 7-1, Specifications

<50mWatts

-40 to 185F (-40 to 85C)

-40 to 194F (-40 to 90C)

15 ©2009 Magnum Energy Inc.

Page 19

Service and Warranty Info

8.0 Limited Warranty

Magnum Energy, Inc., warrants the ME-SBC

defects in material and workmanship that result in product failure during

normal usage, according to the following terms and conditions:

1. The limited warranty for this product extends for 12 months from the

product’s original date of purchase.

2. The limited warranty extends to the original purchaser of the product and

is not assignable or transferable to any subsequent purchaser.

3. During the limited warranty period, Magnum Energy will repair, or replace

at Magnum Energy’s option, any defective parts, or any parts that will not

properly operate for their intended use with factory new or rebuilt replacement

items if such repair or replacement is needed because of product malfunction

or failure during normal usage. The limited warranty does not cover defects

in appearance, cosmetic, decorative or structural parts or any non-operative

parts. Magnum Energy’s limit of liability under the limited warranty shall be

the actual cash value of the product at the time the original purchaser returns

the product for repair, determined by the price paid by the original purchaser.

Magnum Energy shall not be liable for any other losses or damages.

4. Upon request from Magnum Energy, the original purchaser must prove the

product’s original date of purchase by a dated bill of sale, itemized receipt.

TM

battery monitor to be free from

5. The original purchaser shall return the product prepaid to Magnum Energy

in Everett, WA. After the completion of service under this limited warranty,

Magnum Energy will return the product prepaid to the original purchaser via a

Magnum-selected non-expedited surface freight within the contiguous United

States and Canada; this excludes Alaska and Hawaii.

6. If Magnum repairs or replaces a product (with either a new or refurbished

product), its warranty continues for the remaining portion of the original warranty period or 90 days from the date of the return shipment to the original

purchaser, whichever is greater. All replaced products and parts removed

from repaired products become the property of Magnum Energy.

7. This limited warranty is voided if:

• the product has been modifi ed without authorization,

• the serial number has been altered or removed,

• the product has been damaged through abuse, neglect, accident, high

voltage or corrosion.

• the product was not installed and operated according to the owner’s

manual.

BEFORE RETURNING ANY UNIT, CONTACT MAGNUM ENERGY FOR A

RETURN MATERIAL AUTHORIZATION (RMA) NUMBER.

©2009 Magnum Energy Inc. 16

Page 20

PN: 64-0019

Magnum Energy, Inc.

2211 West Casino Rd.

Everett, WA 98204

Phone: 425.353.8833

Fax: 425.353.8390

Web: www.magnumenergy.com

Loading...

Loading...