Page 1

ME-RTR

Router Control

25 .6 VDC 20 Amps

Sys te m Ho me

Inverti ng

Owner’s Manual

(for Revision 2.2 or higher)

Page 2

Disclaimer of Liability

The use of this manual and the conditions or methods of installation, operation, use, and maintenance of the ME-RTR are beyond the control of Magnum

Energy, Inc. Therefore, this company does not assume responsibility and

expressly disclaims liability for loss, damage or expense, whether direct,

indirect, consequential or incidental, arising out of or in any way connected

with such installation, operation, use, or maintenance.

Due to continuous improvements and product updates, the images shown in

this manual may not exactly match the unit purchased.

Restrictions on Use

The ME-RTR may only be used in life-support devices or systems with the

express written approval of Magnum Energy. Failure of the ME-RTR can reasonably be expected to cause the failure of that life-support device or system, or

to affect the safety or effectiveness of that device or system. If the ME-RTR

fails, it is reasonable to assume that the health of the user or other persons

may be endangered.

Important Product Safety Instructions

This manual contains important safety instructions to follow during the installation and operation of this product. Read all instructions and safety information

contained in this manual before installing or using this product.

All electrical work must be performed in accordance with local, state,

•

and federal electrical codes.

This product is designed for indoor/compartment installation. It must not

•

be exposed to rain, snow, moisture, or liquids of any type.

Use insulated tools to reduce the chance of electrical shock or accidental

•

short circuits.

Remove all jewelry such as rings, watches, bracelets, etc., when installing

•

or performing maintenance on the inverter.

Always disconnect the batteries or energy source prior to installing or

•

performing maintenance on the inverter. Live power may be present at

more than one point since an inverter utilizes both batteries and AC.

Turning off the inverter may not reduce this risk. As long as AC power is

connected, it will pass through the inverter regardless of the power switch

on the inverter or the ON/OFF INVERTER button on the router.

Safety Symbols

To reduce the risk of electrical shock, fi re or other safety hazard, the following

safety symbols have been placed throughout this manual to indicate dangerous and important safety instructions.

WARNING: This symbol indicates that failure to take a specifi ed

action could result in physical harm to the user.

CAUTION: This symbol indicates that failure to take a specifi ed

action could result in damage to the equipment.

Info: This symbol indicates information that emphasizes or

supplements important points of the main text.

Remedy: This symbol provides possible solutions for related

issues.

i © 2010 Magnum Energy, Inc.

Page 3

Table of Contents

1.0 Overview .................................................................................. 1

2.0 Installation ............................................................................... 3

2.1 Installation Guidelines ............................................................... 3

2.2 Tools Required ..........................................................................3

2.3 Installation Overview ................................................................. 3

2.4 Mounting the Router .................................................................. 6

2.5 Connecting the CAT 5 Parallel Stacking Cables .............................. 7

2.6 Connecting the Communication Cables ......................................... 8

2.6.1 Optional Cable Connection Routes ......................................... 9

2.7 Wiring the Auxiliary Relay ........................................................ 10

2.8 Installing the Router Cover ....................................................... 11

2.9 Power-up Routine .................................................................... 11

3.0 Setup ...................................................................................... 12

3.1 Navigating the Router .............................................................. 12

3.2 Router Pushbuttons and Menu Items ......................................... 13

3.2.1 PORT Button ..................................................................... 13

3.2.2 CTRL (Control) Button ....................................................... 14

01 AC In Control .................................................................... 15

02 CHG (Charge) Control ........................................................ 16

03 Gen Control ...................................................................... 17

3.2.3 METER Button ................................................................... 18

01 DC Meters......................................................................... 19

02 AC Meters ......................................................................... 19

03 AGS Meters ....................................................................... 20

04 BMK Meters ...................................................................... 20

3.2.4 SETUP Button .................................................................. 22

01 Router Setup ..................................................................... 23

02 Invert Setup .................................................................... 26

03 Charger Setup ................................................................... 30

3.2.4.1 Accessory Setup .......................................................... 37

04 AGS Setup ..................................................................... 37

05 BMK Setup ..................................................................... 38

06 REM Setup ..................................................................... 38

3.2.5 TECH Button ..................................................................... 39

4.0 ME-RTR Menu Maps ................................................................ 43

5.0 Operation ............................................................................... 52

5.1 Front Panel ............................................................................ 52

5.1.1 LED Indicators .................................................................. 52

5.1.2 LCD Display ...................................................................... 52

5.1.3 ON/OFF Pushbuttons ......................................................... 53

5.1.4 Menu Pushbuttons ............................................................. 53

5.1.5 Rotary SELECT Knob .......................................................... 53

5.2 Operating the Inverter/Charger ................................................. 54

5.2.1 Inverter Mode ................................................................... 54

5.2.2 Charger Mode ................................................................... 54

5.3 System Status Messages .......................................................... 55

5.3.1 Inverter Mode Messages .................................................... 56

5.3.2 Charger Mode Messages ..................................................... 57

5.3.3 AC In Control Messages ..................................................... 61

© 2010 Magnum Energy, Inc. ii

Page 4

Table of Contents (cont.)

5.3.4 Fault Mode Messages ......................................................... 61

5.3.4.1 System Fault Messages ............................................... 62

5.3.4.2 Stacking Fault Messages ............................................... 66

5.3.4.3 Internal Fault Messages ............................................... 67

5.3.5 LED Indicator Guide .......................................................... 69

6.0 Troubleshooting ..................................................................... 70

6.1 Troubleshooting Tips................................................................ 71

6.1.1 Inverter Problems ............................................................. 71

6.1.2 Charger Problems ............................................................. 71

6.2 Performing an Inverter Reset .................................................... 72

6.3 Powering Down the Inverter ..................................................... 72

7.0 Warranty and Service Info ...................................................... 73

7.1 Limited Warranty .................................................................... 73

7.2 How to Receive Repair Service .................................................. 74

List of Figures

Figure 1-1, Front Panel Features .......................................................... 1

Figure 1-2, Router Connections Overview..............................................2

Figure 2-1, System Overview .............................................................. 4

Figure 2-2, Router Dimensions ............................................................ 5

Figure 2-3, Router Mounting Holes ....................................................... 6

Figure 2-4, Internal Router Dimensions ................................................ 6

Figure 2-5, Connecting CAT 5 and Communication Cables to Inverters ...... 7

Figure 2-6, Connecting the CAT 5 Cables to the Router ........................... 7

Figure 2-7, Concealed Mounted Communication Cables ........................... 9

Figure 2-8, Surface Mounted Communication Cables ..............................9

Figure 2-9, Router Cover’s Cable Connection Cutouts ........................... 10

Figure 2-10, Wiring the Auxiliary Relay ............................................... 10

Figure 2-11, Installing the Router Cover ............................................. 11

Figure 2-12, Power-up Routine .......................................................... 11

Figure 3-1, Up and Down Arrows for Hidden Lines ................................ 12

Figure 3-2, PORT Button ................................................................... 13

Figure 3-3, CTRL (Control) Button ...................................................... 14

Figure 3-4, METER Button ................................................................. 18

Figure 3-5, SETUP Button ................................................................. 22

Figure 3-6, Aux Relay LED ................................................................ 25

Figure 3-7, TECH Button ................................................................... 39

Figure 3-8, Fault History ................................................................... 40

Figure 4-1 PORT/CTRL Button Menu Maps (page 1 of 9) ........................ 43

Figure 4-2 METER Button Menu Map (page 2 of 9) ............................... 44

Figure 4-3 SETUP Button Menu Map - Router (page 3 of 9).................... 45

Figure 4-4 SETUP Button Menu Map - Router (page 4 of 9).................... 46

Figure 4-5 SETUP Button Menu Map - Inverter (page 5 of 9).................. 47

Figure 4-6 SETUP Button Menu Map - Charger (page 6 of 9) .................. 48

Figure 4-7 SETUP Button Menu Map - Charger (page 7 of 9) .................. 49

Figure 4-8 SETUP (Accs)/TECH Menu Map (page 8 of 9) ........................ 50

Figure 4-9 TECH Button Menu Map (page 9 of 9) ................................. 51

Figure 5-1, ME-RTR Front Panel Controls and Indicators ........................ 52

Figure 5-1.1, SYSTEM Screen Status Messages .................................... 55

iii © 2010 Magnum Energy, Inc.

Page 5

List of Figures (cont.)

Figure 5-1.2, PORT Screen Status Messages ........................................ 55

Figure 5-2, OFF Mode...................................................................... .56

Figure 5-3, Searching Mode............................................................... 56

Figure 5-4, Inverting Mode............................................................... 56

Figure 5-5, Inverter Standby Mode .................................................... 57

Figure 5-6, Charging Mode ................................................................ 57

Figure 5-7, Bulk Charging Mode ......................................................... 57

Figure 5-8, Absorb Charging Mode ..................................................... 58

Figure 5-9, Float Charging Mode ........................................................ 58

Figure 5-10, Full Charge Mode ........................................................... 58

Figure 5-11, Charger Standby Mode ................................................... 59

Figure 5-12, Silent Mode .................................................................. 59

Figure 5-13, Force Float Mode ........................................................... 59

Figure 5-14, Equalizing Mode ............................................................ 60

Figure 5-15, VDC Connect Mode ........................................................ 61

Figure 5-16, Time Connect Mode ....................................................... 61

Figure 5-17, AC In - Disabled Mode .................................................... 61

Figure 5-18, Low Battery Fault .......................................................... 62

Figure 5-19, High Battery Fault ......................................................... 62

Figure 5-20, Overtemp Fault ............................................................. 63

Figure 5-21, AC Overload Fault .......................................................... 63

Figure 5-22, Hi Volts AC Fault ............................................................ 63

Figure 5-23, Dead Battery Charge Fault .............................................. 64

Figure 5-24, Overcurrent Fault .......................................................... 64

Figure 5-25, FET Overload Fault......................................................... 64

Figure 5-26, Breaker Tripped Fault ..................................................... 65

Figure 5-27, Unknown Fault xx .......................................................... 65

Figure 5-28, Transformer Overtemp Fault ............................................ 65

Figure 5-29, No Inverter Comm Fault ................................................. 66

Figure 5-30, StackClock Fault ............................................................ 66

Figure 5-31, Stack Mode Fault ........................................................... 66

Figure 5-32, StackPhase Fault ........................................................... 67

Figure 5-33, Internal Bridge Fault ...................................................... 67

Figure 5-34, Internal Charger Fault .................................................... 67

Figure 5-35, Internal NTC Fault ......................................................... 68

Figure 5-36, Internal Relay Fault ....................................................... 68

Figure 6-1, Performing an Inverter Reset ............................................ 72

List of Tables

Table 3-1, Battery Type to Charge Voltages ......................................... 31

Table 3-2, Battery Amp/Hrs Capacity to Suggested Absorption Time ....... 33

Table 5-1, LED Indicator Guide .......................................................... 69

Table 6-1, Router Control Troubleshooting Guide .................................. 70

© 2010 Magnum Energy, Inc. iv

Page 6

1.0 Overview

1.0 Overview

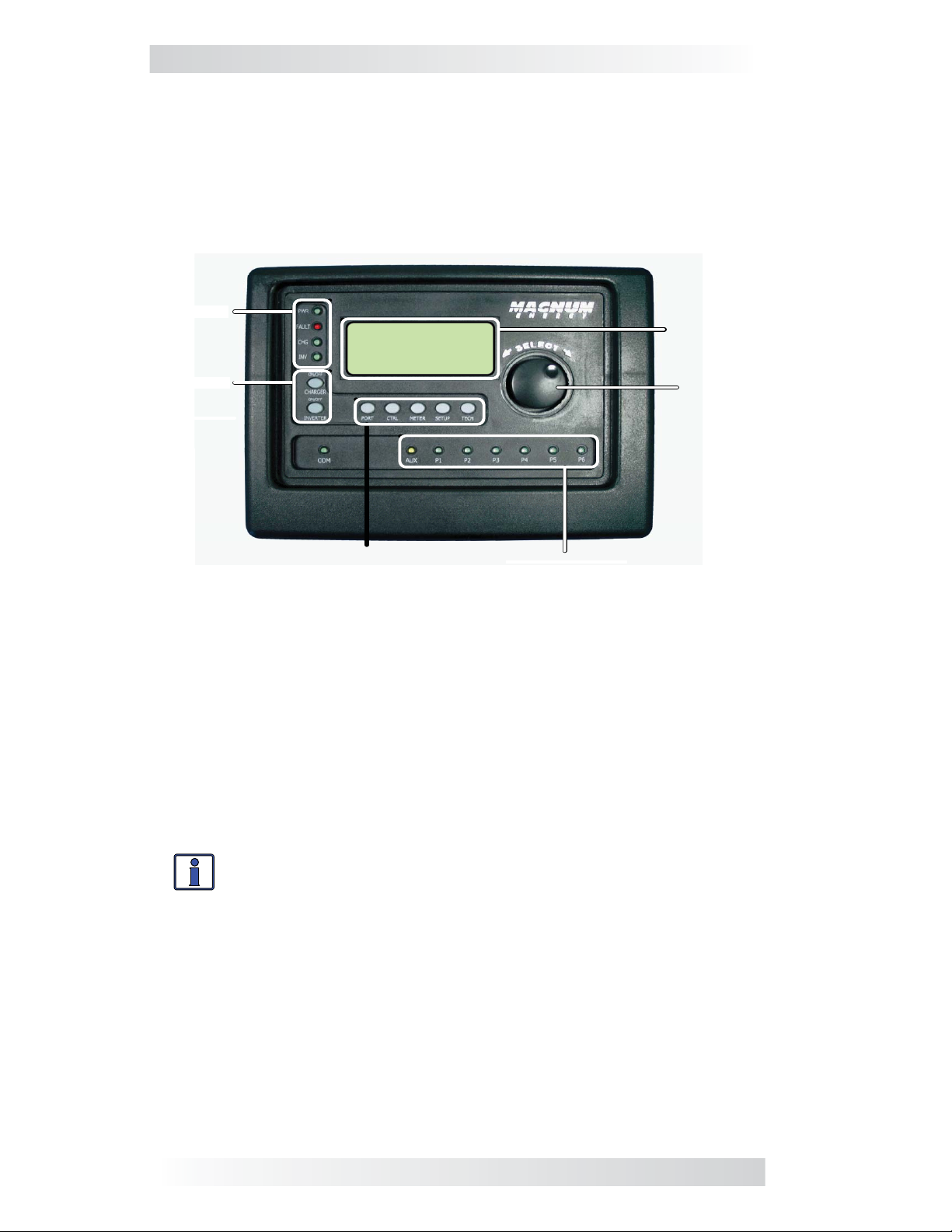

The ME-RTR, or “router” hereafter, has many of the same features as the

ME-ARC50 advanced remote with the added functionality required to parallel Magnum MS-PAE inverter/chargers. The router is designed to easily and

quickly connect the MS-PAE series inverter/charger in parallel without the

need to program each inverter. The router will accommodate up to four MSPAE inverter/chargers in parallel plus accessories.

LED

LCD Display

Rotary

SELECT Knob

ON/OFF

Inverti ng

25 .6 VDC 20 Amps

Sys te m Home

PORT, CTRL, METER, SETUP,

TECH Buttons

LED Indicators

Figure 1-1, Front Panel Features

The ME-RTR is equipped with the following features:

LED Indicators - The at-a-glance LEDs provide the inverter/charger,

•

router, communication ports, and auxiliary relay statuses in a

straightforward way.

LCD Display - The LCD display is a 20 x 4 line (80 characters total)

•

alphanumeric display used for setting up the inverter/charger operation,

as well as viewing current status or fault messages.

ON/OFF Pushbuttons (x2) - Allows all the inverters or chargers to be

•

quickly enabled or disabled.

Info: The router’s ON/OFF INVERTER and ON/OFF CHARGER

buttons function normally when a ME-ARC is connected

through a router in a parallel system.

PORT Button - This button scrolls through the six communication and

•

accessory ports and displays information.

CTRL Button - This button is used to select inverter, charger, and AGS

•

functions previously set up using the SETUP button.

METER Button - This button is used to access the ‘read only’ meters for

•

DC, AC, AGS, and BMK.

SETUP Button - This button is used to access the setup menus for the

•

inverter, charger, AGS, and BMK. The SETUP button may be password

protected to keep unauthorized users from accessing the SETUP

menus.

1 © 2010 Magnum Energy, Inc.

Page 7

1.0 Overview

TECH Button - This button is used to access technical information, fault

•

history, and to set a password for the SETUP button.

Rotary Knob/SELECT Button - The rotary encoder knob is similar to

•

a dash radio knob and is used to quickly scroll through Ports 1-6, or to

select various menu items and settings. Pressing this rotary knob allows

you to select a menu item or to save a setting, once it is displayed on

the LCD screen.

A

B

ED

F

Mounting tabs for top cover

A

Parallel CAT 5 jacks (x4)

B

C

LEDs for communication (P1-P6)

LED for Comm (not functional,

D

for future use)

G

Figure 1-2, Router Connections Overview

H

E

LED for Aux Relay operation

F

Mounting screw holes (x4)

Aux Relay 2-wire terminal

G

w/ removable plug

H

Communication ports (P1-P6)

C

© 2010 Magnum Energy, Inc. 2

Page 8

2.0 Installation

2.0 Installation

Review this entire section before proceeding with the installation of your router.

The more thorough you plan in the beginning, the better your router/parallel

system needs will be met.

WARNING: Installations should be performed by qualifi ed

personnel, such as a licensed or certifi ed electrician. It is the

installer’s responsibility to determine which safety codes apply

and to ensure that all applicable installation requirements are

followed. Applicable installation codes vary depending on the

specifi c location and application.

Info: Review the Important Product Safety Information section

on the front inside cover page before any installation.

2.1 Installation Guidelines

•

Before connecting any wires determine the router’s cable route throughout

the home or vehicle/boat, both to and from the inverter.

•

Always check for existing electrical, plumbing, or other areas of potential

damage BEFORE drilling or cutting into walls to mount the router.

Make sure all wires have a smooth bend radius and do not become

•

kinked.

If installing this router in a boat, RV, or truck ensure the conductors

•

passing through walls, bulkheads, or other structural members are

protected. This minimizes insulation damage such as chafi ng, which can

be caused by vibration or constant rubbing.

2.2 Tools Required

Installing the router is a simple process and requires the following tools:

• Phillips screwdriver • Level • Drill

• Cut-out tool (knife/saw) • Pencil • Drill bit (7/64”)

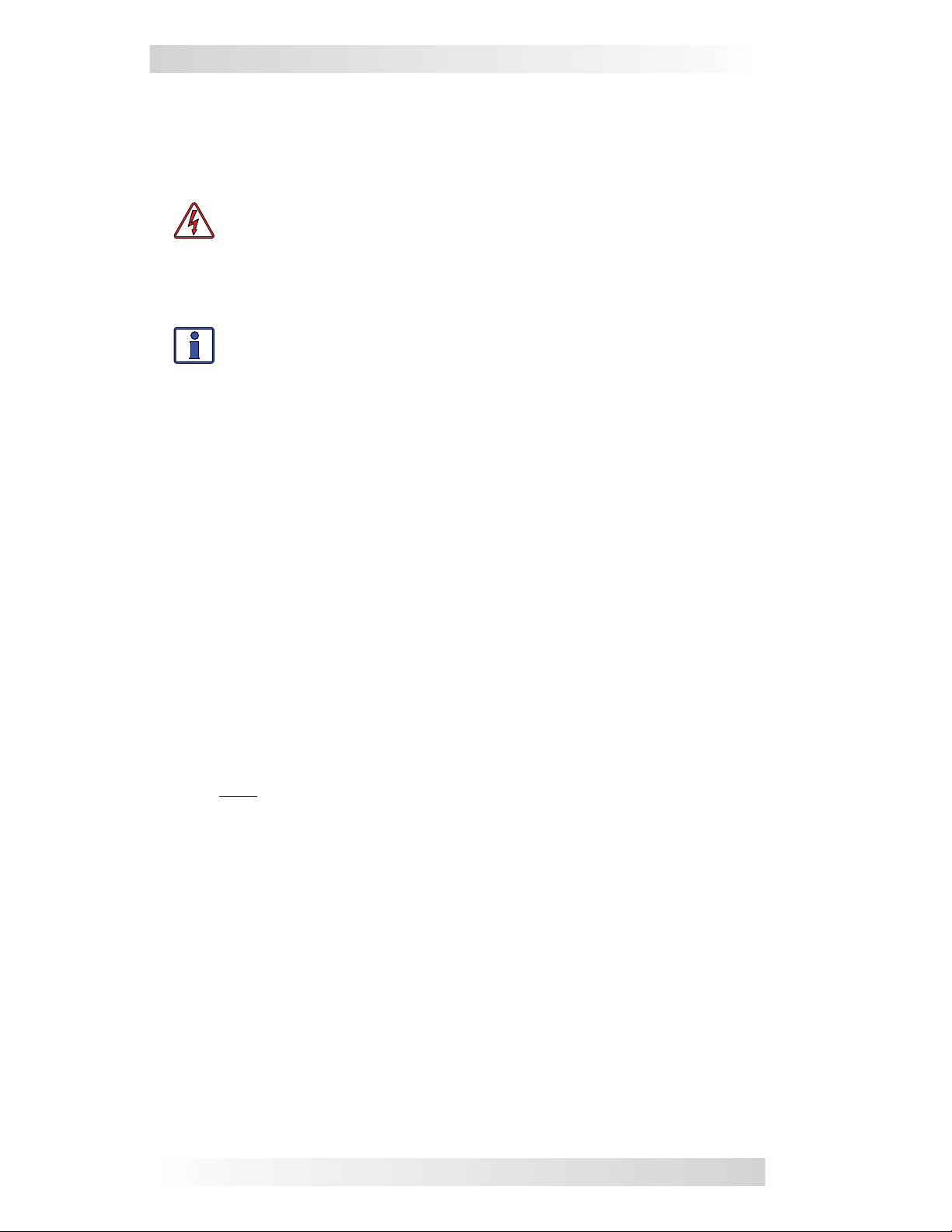

2.3 Installation Overview

The ME-RTR is required in order to parallel stack the MS-PAE Series inverter/

charger. Each inverter/charger must be connected directly to the router using

the supplied CAT 5 and RJ11 communication cables. DO NOT substitute for

the supplied cables. The router comes with four 6 ft. CAT 5 cables and four 6

ft. RJ11 communication cables rated at 300 VAC – which is required to meet

NEC/CEC codes when installing the router in a Magnum Panel system.

Each paralleled inverter/charger requires a CAT 5 high speed communication

cable to be connected to the router’s parallel stacking ports marked MA (Master), SL1 (Slave 1), SL2 (Slave 2), and SL3 (Slave 3). One inverter/charger

will always be designated the Master, and subsequently any other connected

inverter/chargers will be designated as Slaves. You can stack up to four MSPAE Series inverter/chargers using one router.

The router must be located close to the inverter/chargers (within fi ve feet) and

acts as the system control panel. If a remote monitoring location is required,

a ME-RC50 or ME-ARC50 may be connected to one of the communication

ports (P1-P6) on the router, and will act as a remote on/off switch and assist

in monitoring the system.

3 © 2010 Magnum Energy, Inc.

Page 9

2.0 Installation

Info: It is recommended that you set up the master inverter/

charger as the fi rst unit on the left so that the CAT 5 and

communication cables are connected to the inverter/chargers

in order from left to right – MA (Master), SL1, SL2, and SL3.

This confi guration makes it easy to identify the master and slave

units without having to trace the wires from the router to each

inverter/charger.

ME - AGS - N

Cable from ME - AGS - N

to Network Port (green)

Cables

(x4) from

router to

each

inverter’s

Remote

Port

(blue)

#1

MS-PAE

I

NVERTER

(M

ASTER

#2

MS-PAE

I

NVERTER

(S

LAVE

)

1)

#3

MS-PAE

I

NVERTER

(S

LAVE

2)

MA

SL1

SL2

SL3

#4

MS-PAE

I

NVERTER

(S

LAVE

3)

Cables

(x4) from

router to

P1 P2 P3 P4 P5 P6

each

inverter’s

Stack Port

(red)

ME - ARC

ME - BMK

Cables from router to ME - BMK/ME - BMK - NS and

ME - ARC, or to ME - AGS - N

Figure 2-1, System Overview

© 2010 Magnum Energy, Inc. 4

Page 10

2.0 Installation

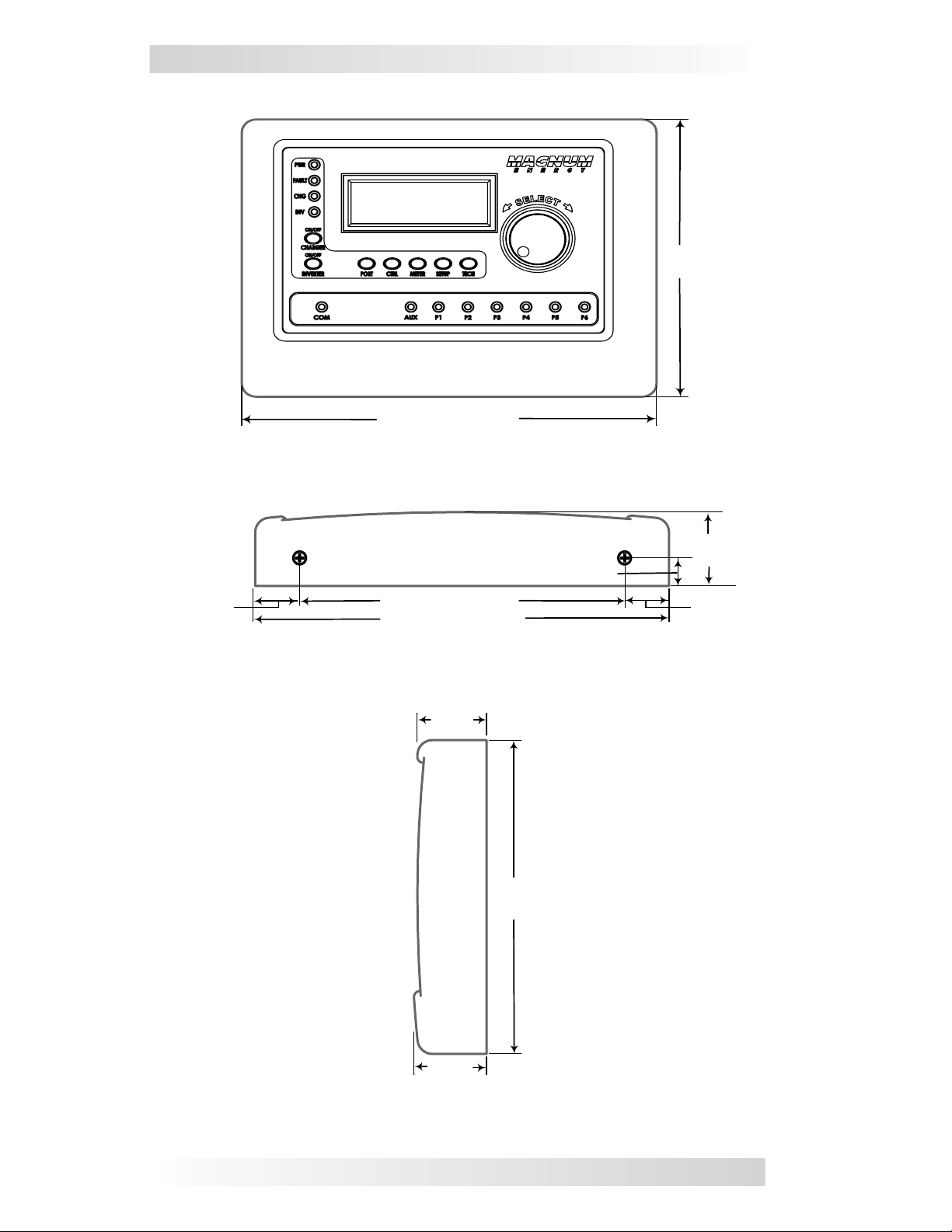

15/16" (22.7 cm)

8

FRONT VIEW

6

5/8"

(16. 8 cm )

15/16"

(2.4 cm)

7

1/16" (17.9 cm)

8

15/16" (22.7 cm)

BOTTOM VIEW

(3.8 cm)

1 ½

”

6

5/8"

(16. 8 c m)

5/8"

(1.6 cm)

1

9/16"

(4 cm)

15/16"

(0.9 cm)

1

9/16

"

(4 cm)

RIGH T SIDE

Figure 2-2, Router Dimensions

5 © 2010 Magnum Energy, Inc.

Page 11

2.0 Installation

2.4 Mounting the Router

To mount the router:

1.

Select an appropriate location to install the router.

2.

Mount the router base to the wall using the 4 screws provided. See

Figure 2-3.

Info: If the router is being installed on a Magnum Panel en-

closure (MP), it can be attached to either the left or right-hand

side using the bracket (ME-RTR-B) provided. Refer to the MP

manual (PN: 64-0028) for information on mounting the router

on a MP panel.

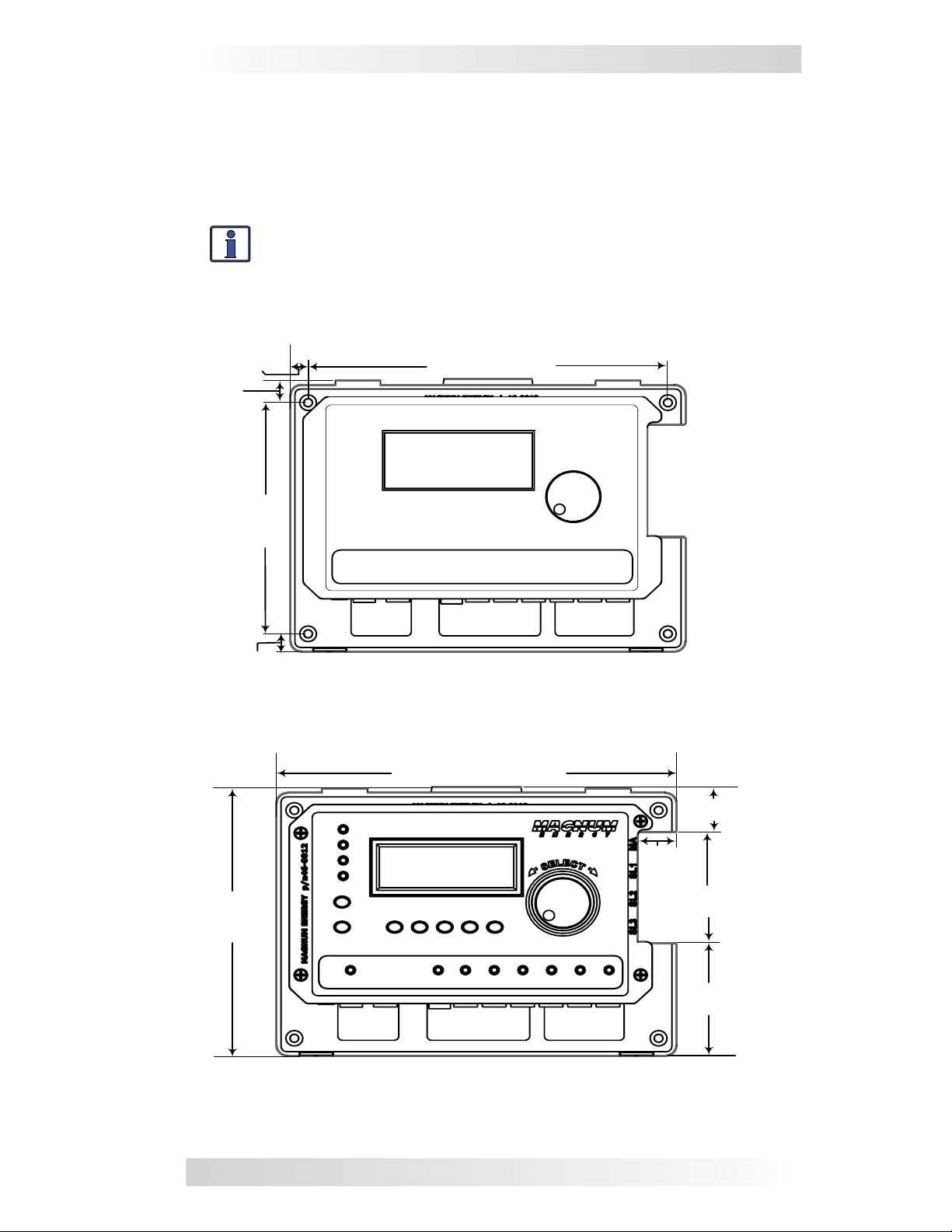

3/8"

(0.9 cm)

½

"

(1.3 cm)

8"

(20.3 cm)

5

½

(14 cm )

7/16"

(1.1 cm)

6 ½

(16. 5 c m)

"

"

Figure 2-3, Router Mounting Holes

8

13/16" (22.4 cm)

1

1/16"

(2.7 cm)

7/8"

(2.2cm)

2

11/16"

(6.8 cm)

2 ¾

"

(7 cm)

FRONT - BEZEL

REMOVED

Figure 2-4, Internal Router Dimensions

© 2010 Magnum Energy, Inc. 6

Page 12

2.0 Installation

2.5 Connecting the CAT 5 Parallel Stacking Cables

The router comes with four 6 ft. CAT 5 cables for parallel stacking. These

cables must be used when installing the router. They are like standard CAT 5

cables, but are rated for 300 VAC to allow their use with the MS-PAE inverters,

and they meet the electrical safety code requirements.

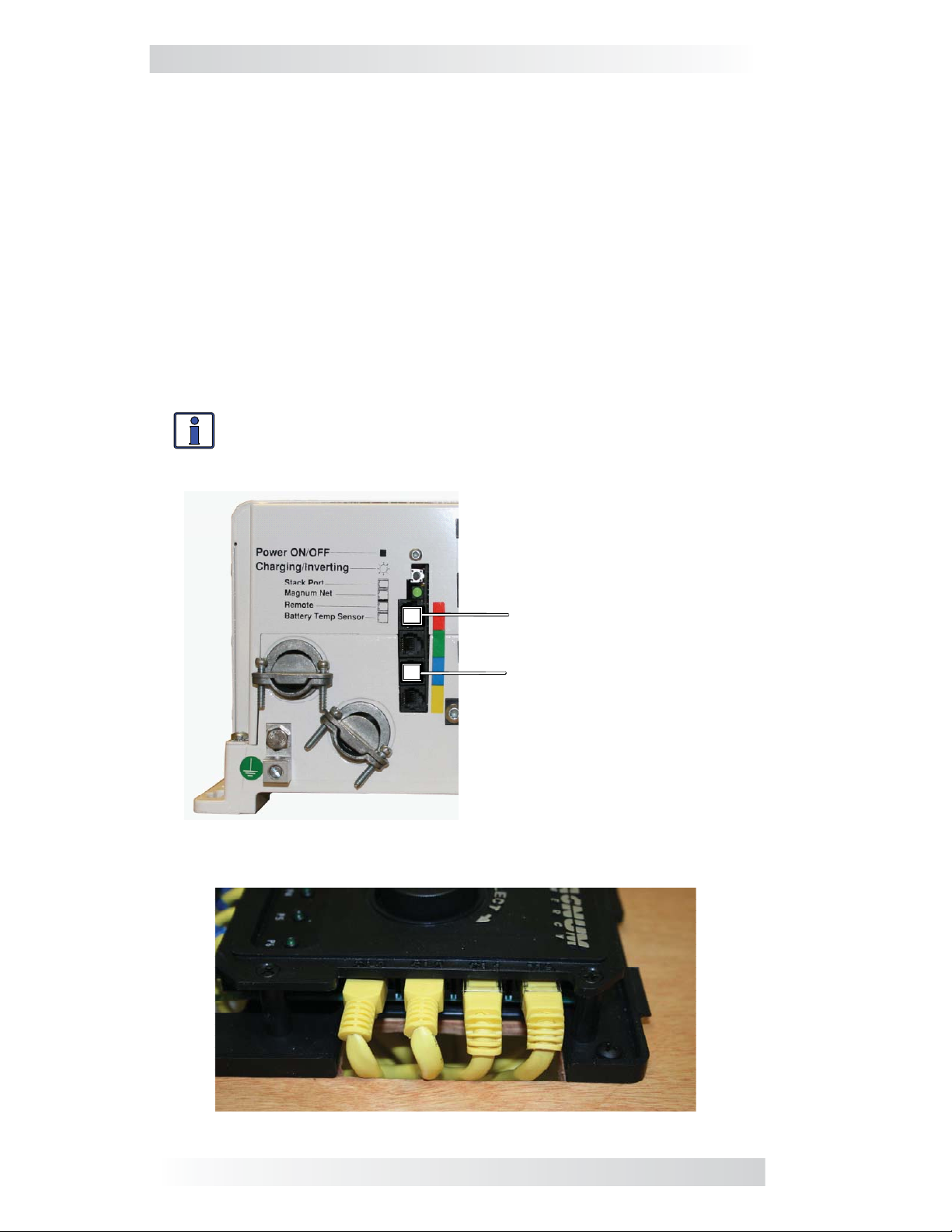

To connect the CAT 5 parallel stacking cables:

Connect a CAT 5 cable to the Stack Port on every inverter installed in

1.

parallel (see Figure 2-5).

Route the inverter-connected CAT 5 cables from each inverter/charger

2.

to your router. Depending on your particular setup, the cables may need

to be routed through walls or the MP Panel enclosure system.

Connect each CAT 5 cable to its respective CAT 5 port on the router (MA,

3.

SL1, SL2, and SL3 ports for the appropriate number of inverters installed

in parallel). See Figure 2-6.

Info: At least one CAT 5 cable must be plugged into the router’s

MA port in order for the router to operate any inverters.

Connect the CAT 5 cable to the

top port marked “Stack Port .”

Connect the communication cable

to the port marked “Remote.”

Figure 2-5, Connecting CAT 5 and Communication Cables to the

Inverters

Figure 2-6, Connecting the CAT 5 Cables to the Router

7 © 2010 Magnum Energy, Inc.

Page 13

2.0 Installation

2.6 Connecting the Communication Cables

To connect the communication cables:

Connect a communication cable to the Remote port on every inverter

1.

installed in parallel (see Figure 2-5), using the supplied remote cables.

Route the inverter-connected communication cables from each inverter/

2.

charger to your router. Follow the same route you used for the CAT 5

cables.

Connect each communication cable to its respective communication port

3.

on the router. (P1-P6 for the appropriate number of inverters installed in

parallel.) Refer to Section 2.6.1 and Figures 2-7 through 2-9.

Connect any accessories to the remaining open communication ports

4.

on the router.

Info: It is recommended that the Master inverter be connected

to remote communication Port 1, Slave 1 to remote communication Port 2 etc., in order to more easily keep track of which

inverter is displayed on each port.

Info: It is recommended that all accessories be connected

directly to the router using any available communication ports

(P1-P6). Except for remotes (i.e., ME-RC or ME-ARC), if there

are additional accessories to connect, but all the router’s communication ports are being used, the additional accessories may

be connected to the Network ports on the stacked inverter/chargers. Any accessory connected directly to the Network port on

an inverter/charger will display as an accessory on the router

port to which the inverter/charger is connected.

Example: A ME-AGS-N connected to the Network port on the

master inverter (P1) will display as P1Acc on the router.

Info: Multiple accessories of the same type may be connected

to the system, but there are some limitations to the number

of accessories. You may connect a maximum of one ME-RC or

ME-ARC remote, two ME-AGS-N modules, and any number of

ME-BMK/ME-BMK-NS accessories.

Info: The ME-ARC or ME-RC remote must be connected directly

to the router and programmed to indicate which port the remote

is monitoring. It is recommended that the ME-RC or ME-ARC

is set to monitor “System” in most installations. The ME-RC

or ME-ARC must not be directly connected to the Remote or

Network ports on the MS -PAE inverter when the router is also

connected.

Info: When used in conjunction with a router, a ME-RC or ME-

ARC has limited functions. The remote control monitors the port

it is designated to display, turns all parallel inverter/chargers

on/off, and displays METER and TECH information. The ME-ARC

does not control the inverter/chargers via the CTRL button.

© 2010 Magnum Energy, Inc. 8

Page 14

2.0 Installation

2.6.1 Optional Cable Connection Routes

You can either surface mount or conceal the cable connections to the router.

The cables can be fl ush mounted through an opening in a wall (Figure 2-7);

or, if there is insuffi cient room behind the wall or no desire to cut into the

wall, the cables can be surface mounted (Figures 2-8).

Figure 2-7, Concealed Mounted Communication Cables

Figure 2-8, Surface Mounted Communication Cables

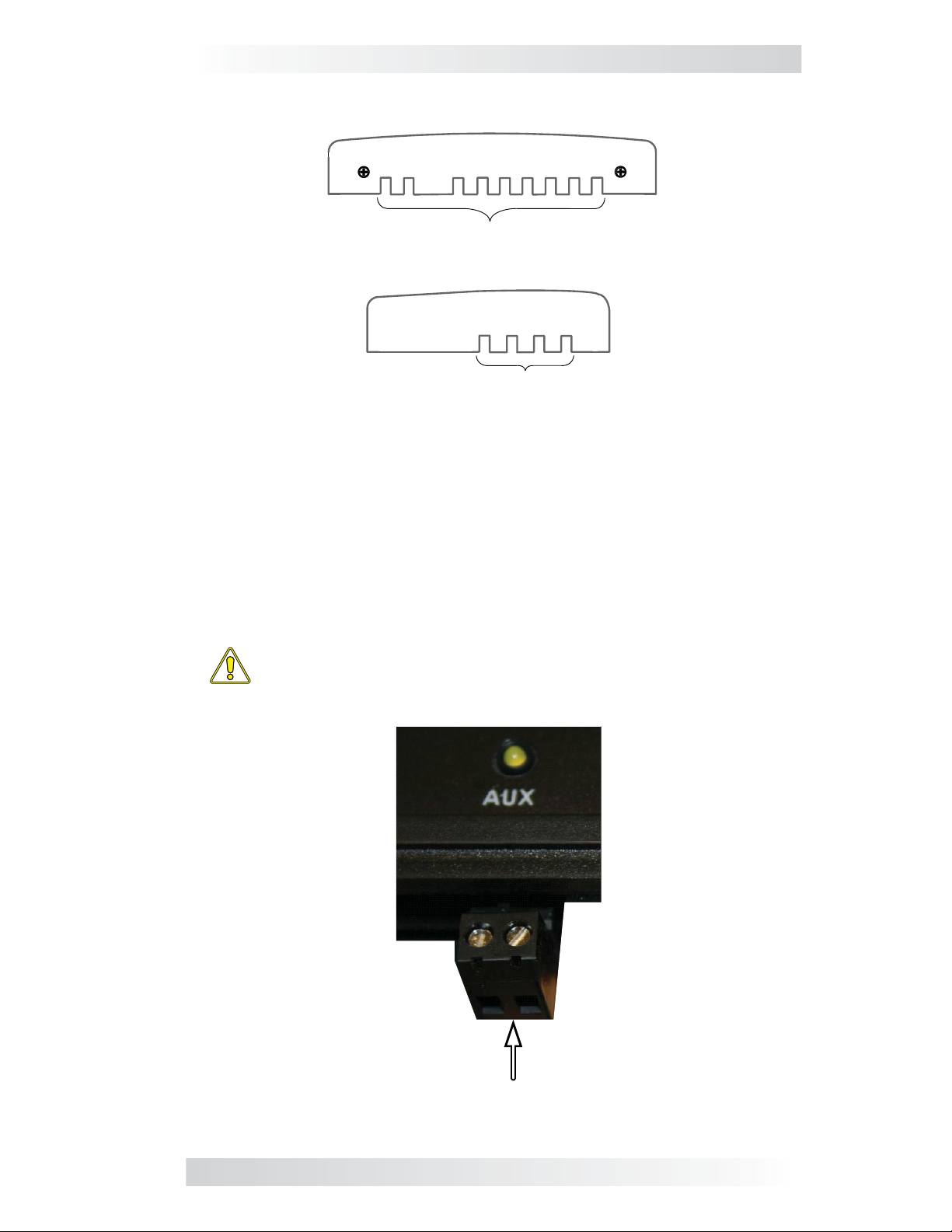

Info: The CAT 5 and communication cables may be installed

on the mounting surface or through the wall. If the cables are

installed on the surface, the router cover has cutout sections to

accommodate the cables (see Figure 2-9). These cutout sections

are made thinner to allow them to be easily broken or cut. Only

remove those cutout sections needed for the number of cable

connections you are installing.

9 © 2010 Magnum Energy, Inc.

Page 15

2.0 Installation

BOTTOM VI EW – ROUTER COVER

Communication cable cutouts (x9)

RIGHT SIDE VIE W – ROUTER COVER

CAT 5 cable cutouts (x4)

Figure 2-9, Router Cover’s Cable Connection Cutouts

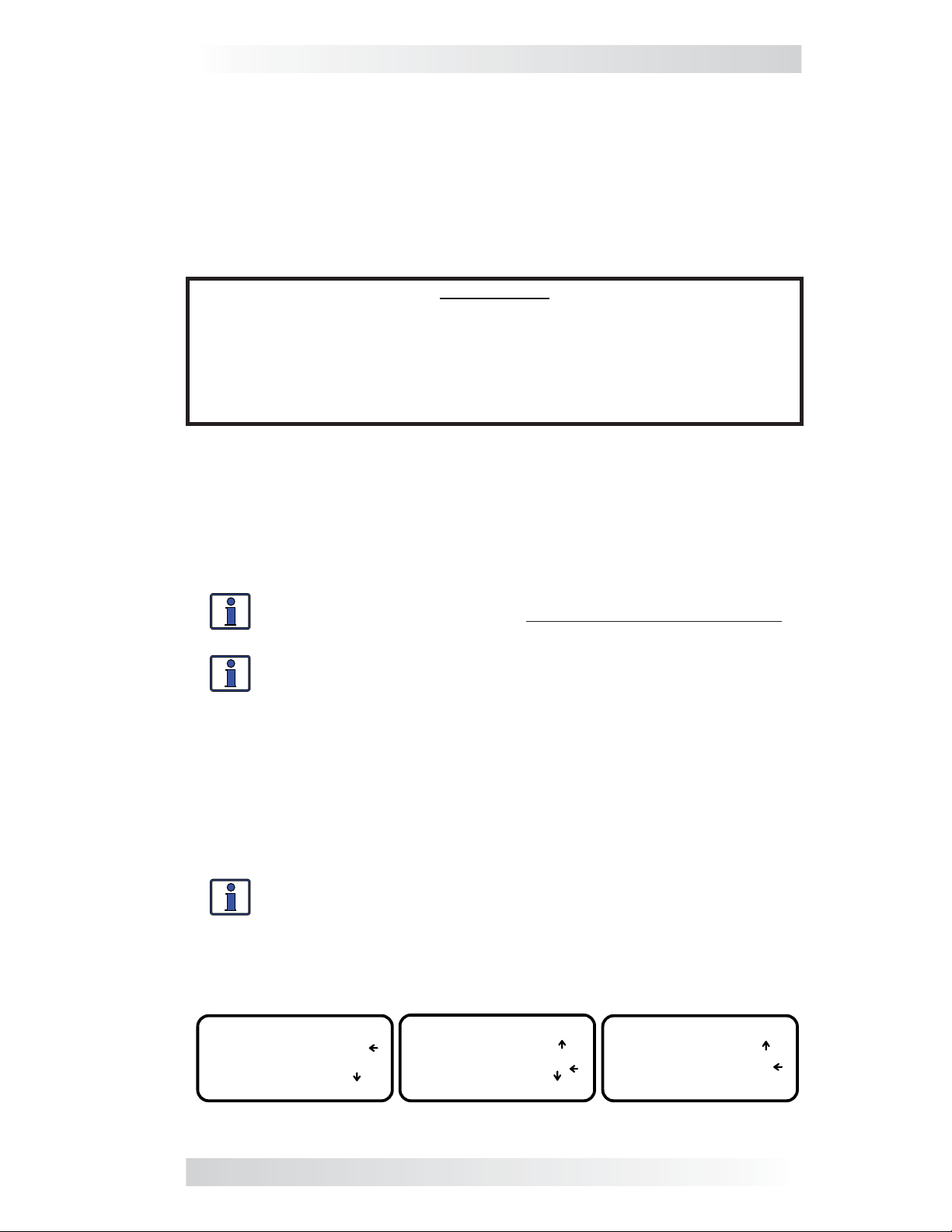

2.7 Wiring the Auxiliary Relay

The Aux Relay is a 2-wire dry contact relay that is either normally open or

closed. The Aux Relay may be wired to any device requiring a contact closure that draws no more than 0.1 amp of current. The Aux Relay is a voltage

controlled relay and may be programmed to open or close on VDC, with an

adjustable delay.

CAUTION: When wiring the Aux Relay, use an inline 0.5 amp

fuse to protect the relay. Damage to this relay is not covered

by warranty.

2-wire dry contact terminal

Figure 2-10, Wiring the Auxiliary Relay

© 2010 Magnum Energy, Inc. 10

Page 16

2.0 Installation

2.8 Installing the Router Cover

Once all the wiring is completed, you are ready to install the router cover.

Tip the top of the cover down and hook it over the router top (protruding

horizontal tabs on inside top of cover go under corresponding mounting tabs

at top of router), and then drop the cover down (cover the router’s bottom

vertical tabs). Install the two fl athead Phillips screws into the bottom tabs to

hold the router cover in place.

Install with two flathead Phillips

mounting screws

Figure 2-11, Installing the Router Cover

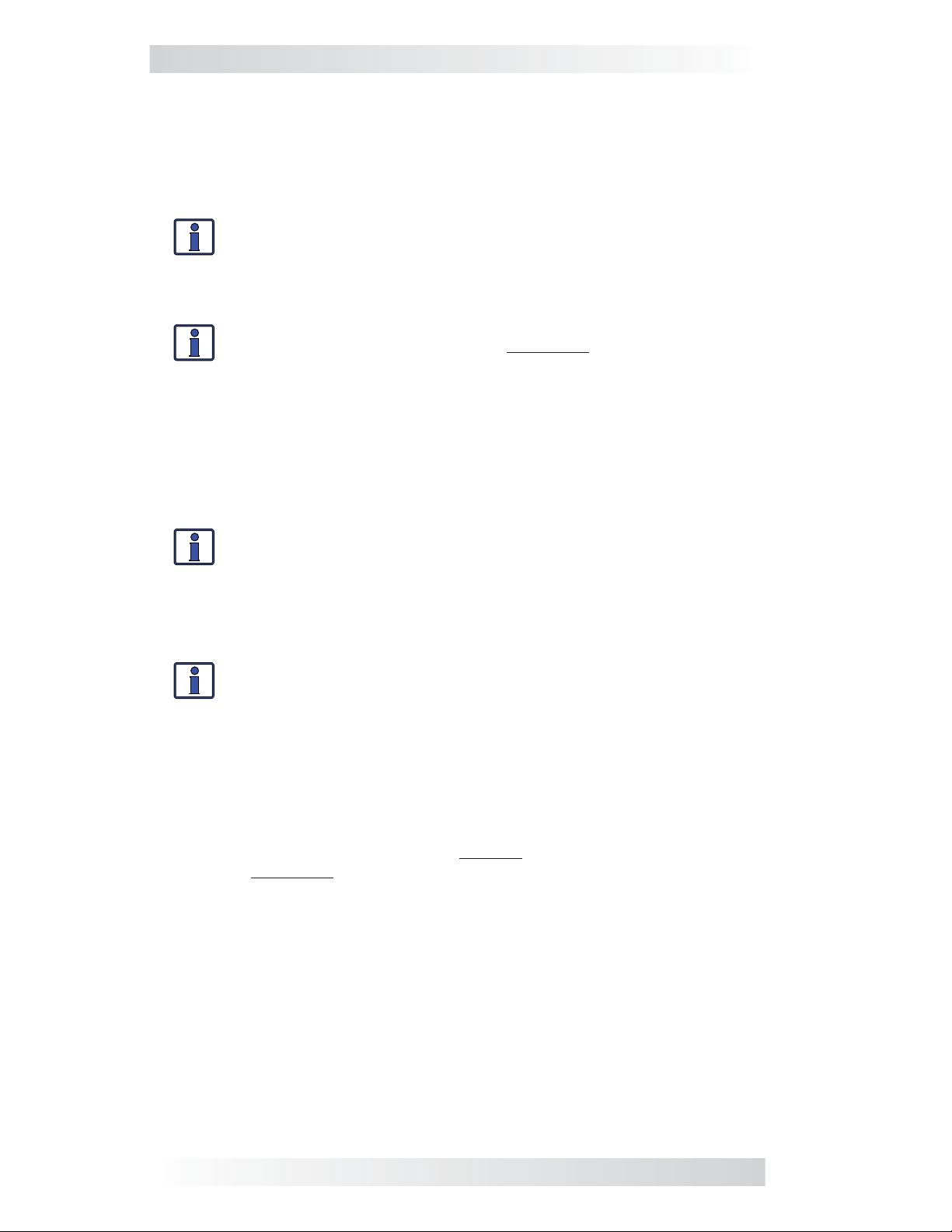

2.9 Power-up Routine

When the router is first connected to an inverter, a power-up routine is

initialized. During the power-up routine, the LCD displays “MAGNUM ENERGY

ROUTER Ver x.x”. The next three screens prompt you to set HOURS, MINUTES,

and AM/PM. Once the clock has been set, the router displays the SYSTEM

HOME screen.

Info: Pressing and holding down the METER button for three

seconds takes you back to the System Home screen from any

menu.

Set Clock

12:15 am

ALL EDIT RTR Setup

12:00 pm

MAGNUM ENERGY

ROUTER

Ver 2.1

Set Clock

12:00 am

ALL edit RTR Setup

Set Clock

MS4024PAE

System Home

Figure 2-12, Power-up Routine

11 © 2010 Magnum Energy, Inc.

ALL EDIT RTR Setup

Page 17

3.0 Setup

3.0 Setup

When a router is connected to a Magnum inverter/charger, the settings in the

router determine the inverter/charger’s operating parameters. The router’s

default settings are adequate for most installations; however, you have the

option to change some of the operating parameters. This section shows you

how to navigate the router and gives you an understanding of the function of

each adjustable setting. See Figures 4-1 thru 4-9 for complete maps of the

router’s menu items and adjustable settings.

*** IMPORTANT ***

All settings/setup menus in the router are compatible with MS-PAE Series

inverter/chargers. If you are using the router with another inverter/charger

(other than the MS-PAE Series), some features and setup menus may not

be compatible with your inverter and will not function. Contact Magnum

Energy to determine if a particular feature/setup menu provided in the

router is compatible with your inverter.

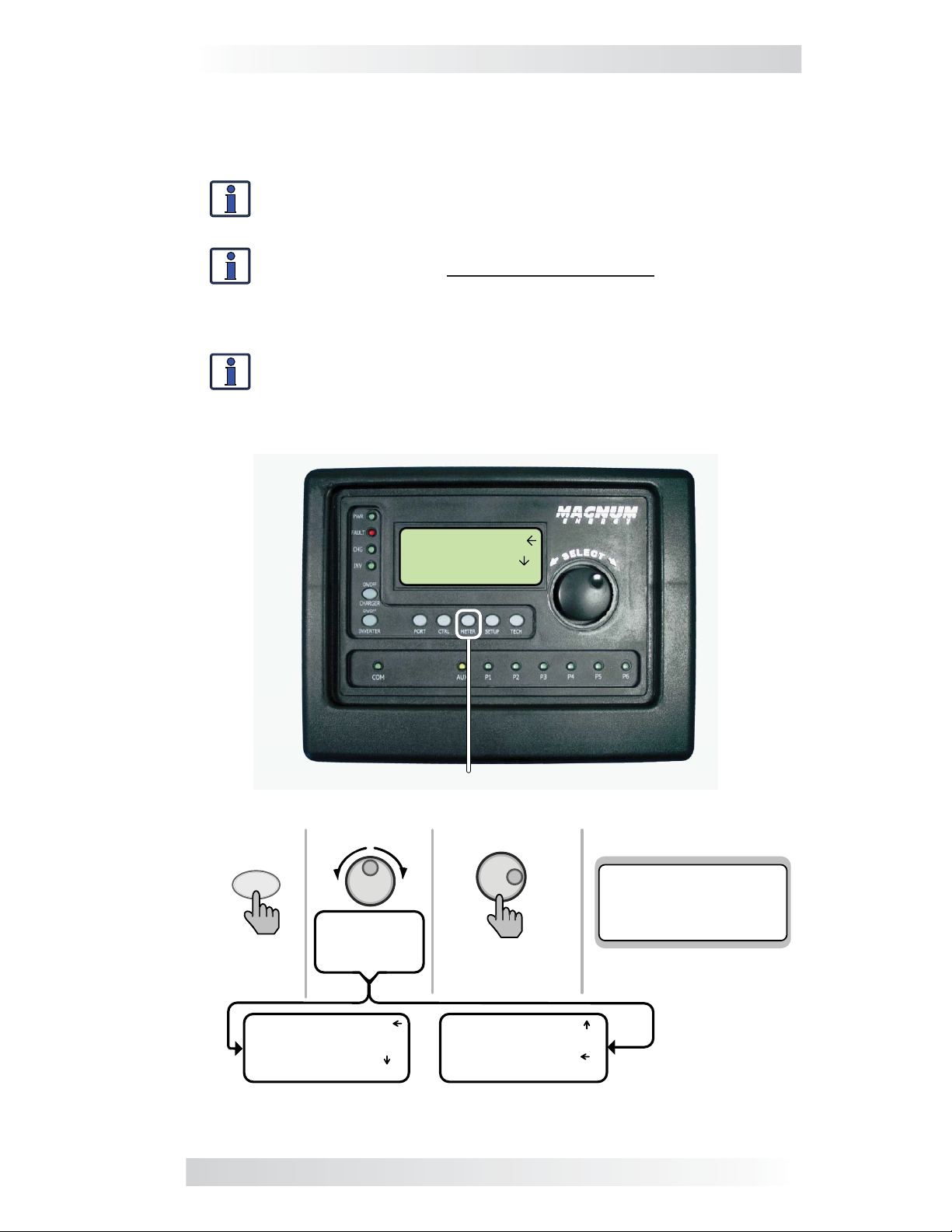

3.1 Navigating the Router

Familiarize yourself with the controls on the front panel which are used to fi nd,

adjust, and save the desired settings (refer to Figure 1-1). They are:

• LCD Display - The 4-line LCD display shows status and info for the inverter/

charger and any attached accessories. All setup menus and faults also appear

on the LCD display.

Info: The LCD display returns to the System Home screen to show

system status after 5 minutes if no buttons have been pressed.

Info: When the “←” (left facing arrow) symbol is shown on the

screen it indicates that the displayed setting has been selected

and will be used.

• Menu Pushbuttons (x5) - These buttons allow simple access to menu

items that can help with confi guring, monitoring, and troubleshooting your

inverter/charger system.

• Rotary SELECT Knob - This rotary knob allows you to quickly scroll through

and select various menu items and settings. Pressing the knob selects the

menu item to change, or saves the current selection. Refresh the LCD display

by holding the rotary knob down for seven seconds.

Info: The LCD screen features a 4-line display. If there are

more choices than will fi t on the screen, up and down arrows

are present to guide you in accessing those choices. An up arrow

indicates you must rotate the SELECT knob counterclockwise to

display the next line. A down arrow requires a clockwise rotation.

If both an up and down arrow display, rotate the SELECT knob

clockwise or counterclockwise to display all hidden lines.

Set AC In Control

Auto Connect

VDC Connect

EDIT Control

Figure 3-1, Up and Down Arrows for Hidden Lines

© 2010 Magnum Energy, Inc. 12

Set AC In Control

VDC Connect

Time Connect

EDIT Control

Set AC In Control

Time Connect

AC In – Disabled

EDIT Control

Page 18

3.0 Setup

3.2 Router Pushbuttons and Menu Items

The fi ve pushbuttons (PORT, CTRL, METER, SETUP, and TECH) located beneath

the LCD screen allow the inverter/charger system to be confi gured to your

specifi c preferences. These pushbuttons also allow you to access menu items

that can help with monitoring and troubleshooting your system.

3.2.1 PORT Button

The PORT button scrolls between the six communication ports on the bottom

of the router. Each parallel inverter/charger must be connected to a communication port in order to be programmed and to display status info.

Info: You must be on a Home screen menu (“Home” appears

in bottom right corner of router’s LCD display) in order for the

PORT button to scroll through all the active ports. If you are not

on a Home screen, pressing the PORT button will only display

devices that are related to the screen you are currently viewing

(only true for METER, SETUP, and TECH button menus, PORT

button does not work from CTRL button menus).

Info: Pressing and holding down the METER button for 3-seconds

takes you back to the System Home screen from any menu.

Any remaining open ports may be used to connect Magnum accessories such

as an ME-AGS-N, ME-BMK/ME-BMK-NS, and an ME-RC or ME-ARC remote.

Info: You can connect a maximum of four inverter/chargers

to a router. If the maximum number of inverter/chargers are

connected, two open ports remain. If more ports are needed

for accessories, the Network port on each inverter/charger may

also be used for accessories.

Info: When an accessory is plugged into a communication port

on the router, the PORT button displays the accessory as the

corresponding port (i.e., Port 5 would show “ME-AGS-N”). If an

accessory is plugged into the Network port on one of the parallel

inverter/chargers, the PORT button will display the accessory

as “P#Acc” (i.e., a ME-AGS-N plugged into a parallel inverter/

charger that is plugged into Port 1 would display as “P1Acc”).

Top line shows status

OR rotate to

next port

MS4024PAE

Inverting

PORT

Press

25.6 VDC 20ADC

System INV Home

Bottom line shows current

port. Press PORT button to

access next port.

Rotate to

desired

selection:

Press to edit

setting

MS4024PAE

Inverting

25.6 VDC 10 ADC

P1 INV Home

Auto Gen Start

Ready 0.0 Hrs

25.6 VDC 70F

P1Acc AGS Home

…......

MS4024PAE

Inverting

25.6 VDC 10 ADC

P3 INV Home

Figure 3-2, PORT Button

13 © 2010 Magnum Energy, Inc.

Page 19

3.0 Setup

3.2.2 CTRL (Control) Button

The CTRL button contains the menus for 01 AC In Control, 02 CHG Control,

and 03 Gen Control (an AGS must be connected in order for the Gen Control

menu to display). The CTRL button gives you quick control of the main functions

of the inverter/charger without having to access the SETUP menus in order

to change the operation of the inverter/charger or the generator. Once the

settings have been programmed in the SETUP menus, the features can then

be enabled using the CTRL button.

Example: The SETUP menu’s 02C AC In - Time setting is used to set what

time of day (e.g., 12AM to 8AM) you want the inverter to connect to the

incoming AC. Once this time is set, use the CTRL button to access the

AC In Control menu item and select Time Connect. When Time Connect

is selected, the inverter/charger will only connect to AC when the time

is between 12AM and 8AM.

01 A C In Control

Auto Connec t

View Contr ol

Top line shows menu

01 AC In Control

CTRL

Auto Connect

View Control

Press

01 AC In Control

Auto Connect

View Control

Bottom line shows view

Figure 3-3, CTRL (Control) Button

CTRL

Button

02 CHG Control

Multi-Stage

View Control

Rotate to

desired

selection:

03 Gen Control

OFF

View Control

Press to

edit setting

© 2010 Magnum Energy, Inc. 14

Page 20

3.0 Setup

01 AC In Control

The 01 AC In Control menu has four different conditions in which the

inverter/charger will connect to incoming AC power. Only one condition may

be selected at any one time – multiple conditions can be enabled, but only

one can be active.

Info: Before the inverter allows the AC input to connect to the

AC source (grid or gen), the incoming AC must be qualified by

the inverter/charger (voltage is below the high AC input require-

ments, above the VAC Dropout setting, and between 50 Hz to

70 Hz for domestic models – 40-60 Hz for export models).

Info: The top status line of the LCD display alternates the

inverter/charger status with a secondary AC IN status when

AC is present, but is not connecting as a result of a selection

made in the SETUP menu.

•

Auto Connect: Automatically connects to incoming AC power.

•

VDC Connect: Connects to incoming AC when the DC battery voltage

is below the Set Connect Volts setting in the 02D AC IN VDC menu.

Disconnects from incoming AC when the DC battery voltage is above the

Set Disconnect Volts setting, also in the 02D AC IN VDC menu.

Info: See SETUP menu 02D on page 28 for a complete

explanation of the Set Connect Volts setting.

•

Time Connect: Connects to incoming AC when the time of day is between

the Set Connect Time and Set Disconnect Time settings per the 02C AC

In - Time menu.

Info: See SETUP menu 02C on page 27 for a complete

explanation of the Set Connect Hour/Minute/AM-PM setting.

AC In - Disabled: Disconnects incoming AC when selected. This setting

•

will prevent incoming AC from connecting to the inverter/charger.

Example: AC is present, but Time Connect has been selected from the

01 AC In Control menu, and the current time of day is 6PM. The 02C AC

In-Time menu’s current setting is 2AM - 8AM. The current time of 6PM is

outside the connect time, so the inverter/charger will not connect to the

incoming AC until after 2AM. The primary status will display “Inverting”

and the secondary status will display “Time Connect” to let you know the

reason that incoming AC has not connected.

15 © 2010 Magnum Energy, Inc.

Page 21

3.0 Setup

02 CHG (Charge) Control

02 CHG Control allows you to set the Charger mode to Multi-Stage, Force

Float, or to Restart Bulk. Most of the time the charger should be left in the

Multi-Stage setting, but to override this setting use the CTRL button and the

CHG Control menu. The charger can be forced into the Float mode or you

can start the Bulk mode using the Force Float or Restart Bulk settings from

the CTRL button’s 02 CHG Control menu item.

•

Multi-Stage: This charge profi le starts in Bulk mode (maximum cur-

rent). It transitions to the Absorption stage (constant voltage). When

the Absorption voltage is reached (as determined by the SETUP menu’s

03E Absorb Done setting), it fi nally transitions to the fi nal charge stage

as selected in the SETUP menu’s 03G Final Charge Stage menu item.

Info: Multi-Stage must be selected in order to use the fi nal

charge stage selected in the 03G Final Charge Stage menu.

Force Float: This charge profi le forces the charger to stay in the Float

•

mode as long as AC is present and the charger is active. Force Float is

most often used when another source of charging such as PV, wind, or

hydro is available to keep the batteries at or above the fl oat voltage. If

AC is disconnected and then reconnected the charger will go directly to

the Float mode, and will not initiate a Bulk or Absorption charge cycle.

CAUTION: Using the Force Float setting may not fully charge the

batteries. Most batteries require a Bulk and Absorption charge

cycle in order to fully recombine the electrolyte in the batteries

and bring the specifi c gravity to the proper level. Be sure to check

with your battery manufacturer before using this setting.

Info: If Silent is selected from the 03G Final Charge Stage menu,

you can override this selection with Force Float to temporarily

fl oat the batteries.

Restart Bulk: This selection restarts the Bulk cycle from any stage in

•

the charge cycle. The Restart Bulk setting is useful when a full Multi-

Stage charge cycle does not bring the specifi c gravity of the batteries

to the proper level.

Info: The Restart Bulk setting automatically defaults back to

the Multi-Stage setting once the inverter/charger status displays

“Bulk Charging”.

Info: If you have to continually restart the Bulk cycle in order

to bring the batteries to full charge, check the settings from the

SETUP button’s 03 Charger Setup menu items to make sure the

batteries are fully charged at the end of a regular Multi-Stage

charge cycle. Check with your battery manufacturer for proper

battery charger settings.

CAUTION: Frequently restarting the Bulk cycle may result in

overcharging of the batteries.

© 2010 Magnum Energy, Inc. 16

Page 22

3.0 Setup

03 Gen Control

03 Gen Control is used for controlling a standby generator that is connected

to the system and using the optional ME-AGS-N module. Once the ME-AGS-N

is installed in the system, the generator can be manually started and stopped,

or set to start and stop automatically from the Gen Control menu.

Info: An ME-ARC must be directly connected to one of the

router’s communication ports in order to be used (in a remote

location) to control a generator that is connected to an MEAGS-N.

Info: When the ME-ARC is connected directly to the router, the

CTRL button function of the ME-ARC is defeated. However, the

ME-ARC does contain the Gen Control selection in its FAVS menu.

This allows the generator to be controlled via the ME-ARC through

the FAVS menu, but not through the CTRL menu.

Info: The ME-AGS-N must be installed in order for the 03 Gen

Control menu to control a standby generator. Refer to the ME-

AGS-N manual (PN: 64-0039) for more information on controlling

standby generators.

OFF: The OFF selection will stop the generator by sending a ‘stop’

•

command from the ME-AGS-N control module (can be running from

either a manual start or an autostart command). When the OFF setting

is selected, the generator will not start automatically.

Info: If DC power is lost to the router, this menu resets to the

default OFF position for safety.

•

ON: The ON selection will start the generator by sending a ‘start’ com-

mand from the ME-AGS-N control module. Once the generator is start-

ed, it may be stopped by selecting OFF from the 03 Gen Control menu,

which sends a stop command from the ME-AGS-N.

Info: You can manually start and automatically stop a connected

generator by selecting ON from the Gen Control menu, and then

change the selection to AUTO. When the AUTO setting is selected

after the generator has been manually started, it will use the

stop setting in either the SETUP button’s Set Stop Gen Volts or

Set Max Gen Run Time menu items, whichever occurs fi rst.

Info: The ON selection uses warm-up time. The OFF selection

stops immediately and does not use the cool-down time.

AUTO: This selection uses the settings in the 04 AGS Setup menus to

•

automatically start and stop the generator based on battery voltage,

time of day, AC load on the inverter, high temperature, or battery state

of charge (requires a ME-BMK/ME-BMK-NS accessory). Refer to the 04

AGS Setup section on page 37 to set the start and stop parameters for

the generator.

17 © 2010 Magnum Energy, Inc.

Page 23

3.0 Setup

3.2.3 METER Button

The METER button gives you access to different meters which help determine

the status of the inverter/charger and battery system.

Info: Some METER functions may not be accessible with older

inverter software. If some meters do not function, check for

current inverter software.

Info: Most displays automatically return to the System Home

screen fi ve minutes after the last button push. When using the

METER button, the selected menus stay and do not return to

the Home screen. This feature is useful for displaying commonly

used meter readings.

Info: Pressing and holding down the METER button for 3 seconds

takes you back to the System Home screen from any menu.

METER

Press

Rotate to

desired

selection:

1 DC Meters

2 AC Meters

3 AGS Meters

All Se lect M eter

METER Button

Press to

view meters

Top line shows menu

01A DC Volts

1 25.9 2---- 3---4---- 5---- 6--- ALL View INV Meter

Bottom line shows view

1 DC Meters

2 AC Meters

3 AGS Meters

ALL SELECT Meter

2 AC Meters

3 AGS Meters

4 BMK Meters

ALL SELECT Meter

Figure 3-4, METER Button

© 2010 Magnum Energy, Inc. 18

Page 24

3.0 Setup

01 DC Meters

01A DC Volts: DC Volts provides the battery voltage. The DC Volts

•

display provides the voltage from the battery bank connected to the

inverter. Accuracy is ±1.5% with a 0.1 VDC resolution.

01B DC Amps: While inverting, the DC Amps reading displays a negative

•

number to show the battery current used by the inverter. If in Charge

mode, this setting displays a positive number to show the amount of

current delivered to the batteries. The accuracy of this display below 1

amp AC (~10 amps DC @ 12VDC) is not detected. When the current in

or out of the batteries is greater than 1 amp AC, the display accuracy

is ±20%.

01C Charge Time: This meter displays whenever the charger is in the

•

Bulk or Absorb mode. The meter does not accumulate time when in

Float, Charger Standby, Full, or Silent mode.

Info: Once the charger leaves the Absorption mode and

enters the fi nal charge stage, this timer is reset and will not

accumulate until the charger reenters the Bulk or Absorption

charge mode.

02 AC Meters

02A Output Volts: This menu provides the AC voltage measurement at

•

the inverter’s output terminals. If inverting, this measures the inverter’s

output voltage. If in Charge mode, this measures the AC voltage that is

passing through the inverter from the source (e.g., grid or generator).

02B Output Hz: While inverting, this menu displays the output frequency

•

of the inverter. When the incoming AC source is connected to an inverter,

this meter displays the frequency of the incoming AC source (i.e. grid or

generator) that is passing through the inverter to the inverter’s output

terminals. The frequency is shown in Hertz (Hz).

•

02C Load Amps: This menu displays the load the inverter is running in

AC amps – measured at the inverter’s output terminals. This number is

always displayed as a positive number.

•

02D Input Amps: This menu displays the total AC amps being used by

the inverter for charging, and any connected load at the output of the

inverter.

Example: If the charger is using 20A from the AC source and the load

connected to the inverter output is using 10A, the combined load on the

incoming AC source is 30A. So, 30A would be displayed as the input amps.

•

02E Inv/Chg Amps: While charging, this menu displays the amps the

charger is using from the AC source. When inverting, this menu displays

the current of the load the inverter is powering.

Info: The 02E Inv/Chg Amps value is determined by subtracting

the 02C Load Amps value from the 02D AC Input Amps value.

19 © 2010 Magnum Energy, Inc.

Page 25

3.0 Setup

03 AGS Meters

03A AGS Status: If there is no Automatic Generator Start (ME-AGS-N)

•

module connected, the status will read “No Comm”. If there is a ME-AGS-N

connected, please refer to the ME-AGS-N owners manual (PN: 64-0039)

for information on the status messages.

Info: These menus allow the optional ME-AGS-N (Auto Gen Start

-Network version)

— if installed — to display the status of the

generator. Refer to the ME-AGS-N Owner’s Manual (PN: 64-0039)

for detailed information on the AGS and these menus.

03B DC Volts-AGS: This menu displays the DC voltage measured at pins

•

3 and 4 of the ME-AGS-N module. This menu is useful in setting up the

voltage start for the AGS, and for troubleshooting its operation.

Info: The DC voltage reading in this menu may vary from the

DC voltage readings in the 01A DC Volts and 04C DC Volts-

BMK menus. Each DC voltage reading is taken at a different

place in the system, and therefore there may be wire losses or

connections that make the readings differ. It is important when

troubleshooting the system to read the appropriate related meter

for each device. When troubleshooting the AGS, use the 03B DC

Volts-AGS menu item for verifi cation and testing purposes.

03C Gen Run Time: This menu displays the amount of time the

•

generator has been running since the AGS auto-started the generator.

This menu does not display run time when the generator has been

manually started.

Info: This hour meter resets each time the generator is stopped.

This is useful when trying to determine how long the generator

has been running in Auto mode if you were not present when

it started. This meter does not replace the hour meter for total

hours the generator has run.

03D AGS Temp: This menu displays the temperature of the AGS temp

•

sensor (included with ME-AGS-N, but use is optional), and is helpful in

determining proper placement and operation of the AGS temp sensor.

03E Since Gen Run: This menu displays the number of days since the

•

generator has last run. This menu is useful in determining if the AGS

start and stop settings are set up correctly.

Info: This meter resets whenever the generator is either auto-

started, exercised, or manually started. The meter reads the

B+/run signal provided by the generator to the AGS module.

04 BMK Meters

These menus display the status of the battery system from the optional

ME-BMK/ME-BMK-NS, if installed. Refer to the ME-BMK/ME-BMK-NS Owner’s

Manual (PN: 64-0013) for detailed information on the Battery Monitor Kit

and these menus.

04A BMK SOC: This display is the best way to monitor the actual state

•

of the battery. The read only display shows the State of Charge (SOC)

for the connected battery bank. The SOC represents the condition of the

battery as a percentage of the available capacity left in the battery.

© 2010 Magnum Energy, Inc. 20

Page 26

3.0 Setup

Range is 0% to 100%, where 100% represents a fully charged battery

and 0% means the battery is completely discharged.

If no % displays, there are 3 status menus to determine what state the

BMK is in:

Pwr-up Fault - The battery monitor faulted when it was powered-up.

The fault occurred because the power-up self-test failed.

No Comm - This indicates the ME-BMK/ME-BMK-NS is not communicating

with the router. The most common causes are: no ME-BMK/ME-BMK-NS

installed in the system, a bad network cable, or no power to the MEBMK/ME-BMK-NS.

Think’n - The battery monitor is connected and actively monitoring the

battery system. The router displays “Think’n” (or “n’k“in some screen

displays) to indicate that the SOC reference point is being calculated.

After the batteries are fully charged, the display changes from “Think’n”

to “100%” and begins to provide accurate SOC percentage values.

04B DC Volts - BMK: This meter displays the real-time battery voltage

•

from 07.00 to 70.00 volts (± 0.02 volts).

04C DC Amps - BMK: This meter displays the real-time charge current

•

(amps into the battery), or the discharge current (amps out of the

battery). Charging is shown as a positive (+) number and discharging is

shown as a negative (-) number. The range is from ±0.1 to 999 amps,

with a 1.0% accuracy.

04D AH In/Out: This meter displays the amp-hours returned to or

•

removed from the battery. When this value is positive, it represents

amp-hours returned to the battery during any subsequent charging. A

negative value represents amp-hours removed from a full battery. Its

range is ±32768 AH.

O4E Resettable AHrs: This meter displays the total amp-hours

•

removed from the battery since it was last reset. This display can be

used as a battery load indicator to help determine and monitor the

battery load consumption. Its range is 0 to 6,553.50 amp-hours (0.1

amp hour resolution).

04F Total kAHrs Out (Total Amp-Hours Removed): This meter

•

displays the total amp-hours removed from the battery since the Sense

Module was fi rst connected. This display can be used as a battery

service life indicator. The value is displayed in 0.1k [or 100 amp-hours

(“k” equals 1000)] resolution up to a maximum of 6,553.5k amp-hours

(6,553,500 amp-hours). The displayed number resets to 0.0k when the

Sense Module is disconnected from power.

04G Minimum VDC: This menu displays the lowest battery voltage

•

since the last reset. The voltage shown on the display is averaged each

second and is helpful when troubleshooting or detecting an over-discharge

condition.

•

04H Maximum VDC: This menu displays the highest battery voltage

since the last reset. The voltage shown on the display is averaged each

second, this allows you to check your charging system (battery charger,

charge controller, etc.) to ensure the charging voltage has been attained.

This display is also helpful when troubleshooting or detecting if an overcharge condition has occurred.

21 © 2010 Magnum Energy, Inc.

Page 27

3.0 Setup

3.2.4 SETUP Button

Pressing the SETUP button provides access to the menu items and settings

that enable you to confi gure the router display, the inverter/charger, and any

connected accessory. Review each menu item to determine if you need to

adjust any settings to meet your system requirements.

Info: The fi rst screen that may appear when the SETUP button

is pushed is a password screen. If the PIN has been set under

the TECH button’s SETUP PIN menu item, the fi rst screen is the

Set SETUP PIN menu. The proper PIN must now be entered in

order to access the SETUP menus. After 5 minutes from the last

button push, the display automatically returns to the System

Home screen and the PIN must be reentered in order to access

the SETUP menus. Refer to the TECH button’s SETUP PIN menu

item to set or change the PIN number. Refer also to Section

3.2.4.1 for more info on accessory setup.

Info: In any SETUP menu that contains a range of settings,

if the fi rst and last settings are equal (set to the same value)

the function will be disabled, even if selected/enabled from the

CTRL menu.

SETUP

Press

1 Rout er

2 Inverter

3 Charger

ALL SELECT Setup

SETUP Button

Top 3 lines show menus

1 Router

2 Inverter

3 Charger

ALL SELECT Setup

Press to

select

Rotate to

desired

selection:

01A Set Time

12:00pm

ALL View RTR Setup

01B Display

Contrast 100%

Brightness 50%

ALL View RTR Setup

01H Aux Relay Timing

Close Delay 10

Open Delay 10

ALL View RTR Setup

…

Figure 3-5, SETUP Button

© 2010 Magnum Energy, Inc. 22

Page 28

3.0 Setup

01 Router Setup

The following menus are used to set up the router screen and clock.

01A Set Time: The router contains a real time clock that must be set

•

for proper operation of some features. These features are: the SETUP

button’s 02C AC In-Time, 04B Gen Run Time, 04G Quiet Time, 04H Gen

Exercise, and the Fault History menu items under the TECH button.

**IMPORTANT**

It is very important that you set the time clock as it is a critical piece in

effectively addressing fault issues, as well as for the proper start/stop

functions of your AGS device, if installed.

Info: The clock obtains power from the inverter and will reset if

the router is disconnected from the inverter.

To Set the Current Time

From the Set Clock menu:

Rotate the SELECT knob to the hour of day, and then press

1.

SELECT.

Rotate the SELECT knob to the correct minute setting, and then

2.

press SELECT.

Rotate the SELECT knob to the appropriate AM or PM setting, and

3.

then press SELECT.

01B Display: This setting adjusts the contrast and brightness of the

•

LCD screen based on the current lighting conditions and viewing angle.

Default settings - Contrast = 100%, Brightness = 50%

01C Power Save: This setting turns off the Power Save™ feature, or

•

selects the time (from off to 60 minutes) that determines when the

display goes into Power Save mode. This setting also allows the Port LEDs

to be turned “off” or set to “Auto” mode. In Auto mode, the Port LEDs

automatically blink whenever a device is connected to a router port.

Default setting - PowerSave [min] = 15, Port LEDs = Auto

What is the Power Save feature? The Power Save feature turns off the

LCD backlight and the LEDs on the router to conserve energy. The router

goes into Power Save mode if there hasn’t been a button press or fault

message for a period of time (this time is determined by the SETUP menu’s

01C Power Save setting). Whenever the router goes into the Power Save

mode, the LCD backlight and the LEDs can be reactivated by pressing any

button. If you have a fault during the Power Save mode, the LCD backlight

and the FAULT LED will come on and stay on as long as the fault is present.

Info: If you want the LCD backlight and LEDs to always be on,

you will need to turn the Power Save feature off by selecting

PowerSave [min] = off.

Info: If you want the Port LEDs to always be off, you will need

to set the Port LEDs to Port LEDs = off.

01D Temp Display: This menu item selects whether to display

•

temperatures in Fahrenheit or Celsius. Once you select either Fahrenheit

or Celsius, the following menu items will appear with this selection:

23 © 2010 Magnum Energy, Inc.

Page 29

3.0 Setup

03D AGS Temp, 04E Gen Run Temp, and 01 Temperatures under the

TECH button.

Default setting - Fahrenheit

01E Viewing Ports: The Viewing Ports menu item sets the main screen

•

to either automatically scroll through each connected port, or requires you

to manually select each port by pressing the PORT button. Adjusting the

seconds allows you to select how long the Port screen is displayed before

it automatically scrolls to the next screen. Range is off-60 seconds.

Default setting - Auto Roll (sec) = off

01F Aux Relay State: Selections are Open, Auto, and Close.

•

Open - Manually opens the Aux Relay contacts. This setting manually

controls the device connected to the Aux Relay, or tests the Aux Relay

operation.

Auto - Uses the Relay Close and Relay Open settings from the 01G Aux

Relay V Trip menu, and the Close Delay and Open Delay settings in the

01H Aux Relay Timing menu to automatically control the Aux Relay.

Closed - Manually closes the Aux Relay. This setting manually controls the

device connected to the Aux Relay, or tests the Aux Relay operation.

Default setting - Open

Info: When the open or closed selections are made, the Aux

Relay will open or close without any time delay.

01G Aux Relay V Trip: This menu sets the Battery Voltage Trip point to

•

open and close the Aux Relay contacts. Once the battery voltage reaches

the trip point, the relay will open or close once the time set in the 01H

Aux Relay Timing menu item is satisfied.

Relay Close - Set this voltage to close the Aux Relay contacts. This range

can be below or above the Relay Open setting depending on if you want

the Aux Relay to be Active Low or Active High.

Range is 8-17 (12 VDC), 16-34 (24 VDC) and 32-51 (48 VDC)

Relay Open - Set this voltage to open the Aux Relay contacts. This range

can be below or above the Relay Close setting depending on if you want

the Aux Relay to be Active Low or Active High.

Range is 8-17 (12 VDC), 16-34 (24 VDC) and 32-51 (48 VDC)

Default settings - For both the Relay Open and Relay Close settings:

14 (12 VDC), 28 (24 VDC) and 56 (48 VDC).

Example - Active Low: Set the Relay Close voltage below the Relay

Open voltage. If the Relay Close voltage is set at 12.0 VDC and the

Relay Open voltage is set at 14.5 VDC, the relay would close when

the battery voltage dropped to 12.0 VDC and open when the battery

voltage rises to 14.5 VDC. This configuration might be used to control

a battery exhaust fan or as a simple PV charge controller.

Example - Active High: Set the Relay Open voltage below the Relay

Close voltage. If the Relay Open voltage is set at 12.0 VDC and the

Relay Close voltage is set at 14.5 VDC, the relay would open when

the battery voltage dropped to 12.0 VDC and close when the battery

voltage rises to 14.5 VDC. This configuration might be used to control

a low voltage disconnect circuit for a DC load.

© 2010 Magnum Energy, Inc. 24

Page 30

3.0 Setup

•

01H Aux Relay Timing: This setting delays the automatic closing and

opening of the Aux Relay contacts after the Relay Open and Relay Close

settings have been satisfied.

Close Delay - Use this setting to delay the close of the Aux Relay contact

once the Voltage Trip point has been reached. This sets a hysteresis so

the Aux Relay does not cycle unnecessarily. Range is 0-240 seconds

Open Delay - Use this setting to delay the opening of the Aux Relay

contact once the Voltage Trip point has been reached. This sets a

hysteresis so the Aux Relay does not cycle unnecessarily. Range is 0-

240 seconds

Default settings - Close Delay and Open Delay: 10 seconds

Auxiliary (Aux) Relay

The router contains a 2-wire dry contact Aux Relay. The Aux Relay can be

manually opened or closed, or is voltage driven and can be set to either close

on low DC voltage and open on high DC voltage, or to close on high DC voltage

and open on low DC voltage. The relay can be set to the Auto position where

it will read the open and close voltage settings with delay times, or it can be

manually either forced closed or open.

What is the Aux Relay used for? The most common use is to turn on an

exhaust fan to eliminate your battery bank gasses using the VDC start and

stop settings. The Aux Relay can also be used to control the coil of a current

carrying relay.

How do I adjust the Aux Relay? The three menus used to adjust the Aux

Relay are the 01F Aux Relay State, 01G Aux Relay V Trip, and 01H Aux Relay

Timing menus. These three menus are used to select the operating state of the

Aux Relay (menu 01F), the DC voltage at which the Aux Relay automatically

opens and closes (menu 01G), and the delay timing on open and closing of

the Aux Relay (menu 01H).

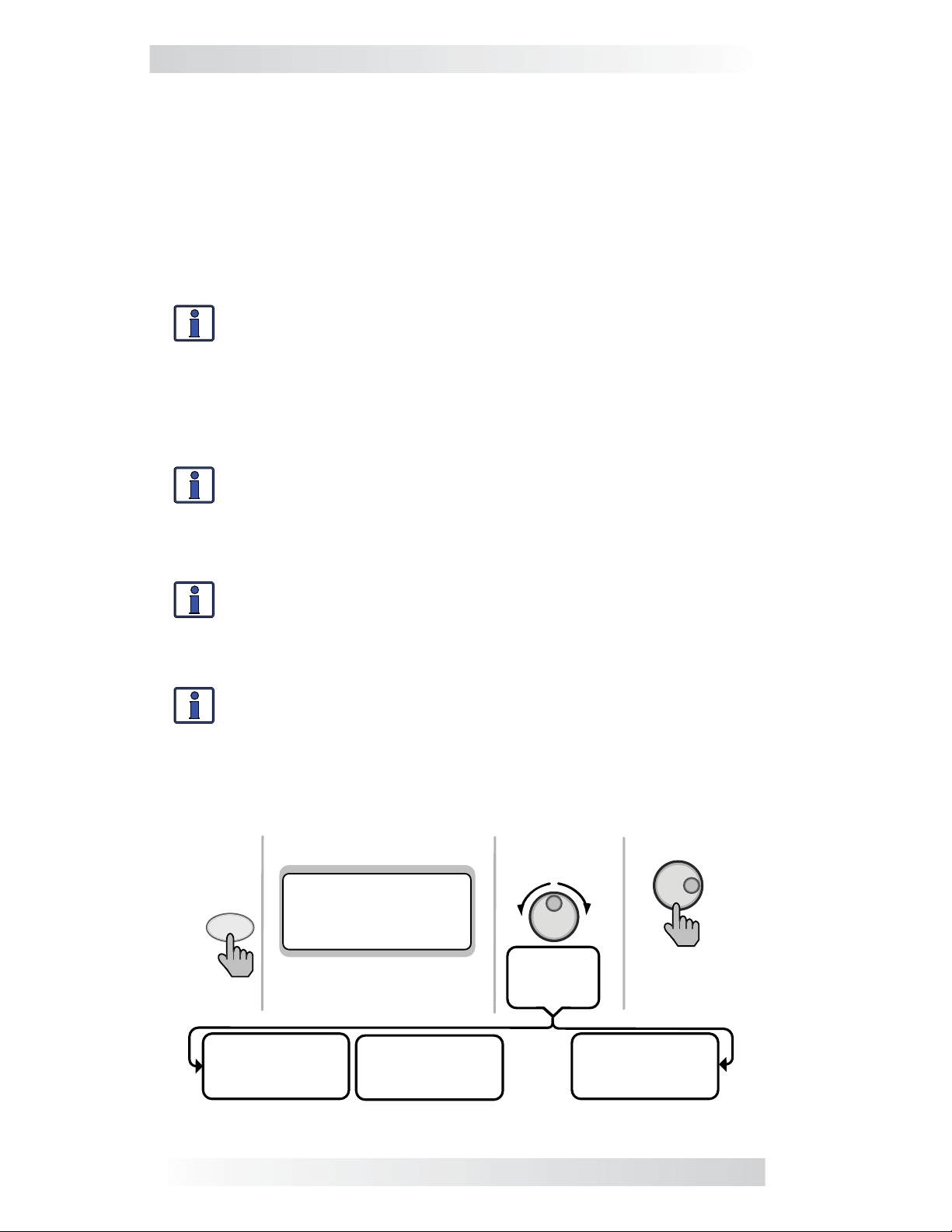

Aux Relay LED - The Aux Relay LED will illuminate in an amber color if the

relay is active (closed) in the programmed state.

Example: The Aux Relay is set to Auto in menu 01F. The 01G Aux Relay V

Trip’s Relay Close setting is 12.0 VDC and the Relay Open setting is 14.5

VDC. The 01H Aux Relay Timing menu’s Close Delay and Open Delay settings are 10 seconds.

When the battery voltage reaches 12.0 VDC after a 10 second delay, the

Aux Relay will close and the LED will illuminate amber. When the battery

voltage reaches 14.5 VDC after a 10 second delay, the Aux Relay will open

and the Aux Relay LED will turn off.

Aux Relay LED

Figure 3-6, Aux Relay LED

25 © 2010 Magnum Energy, Inc.

Page 31

3.0 Setup

02 Invert Setup

The following menus 02A - 02D are used to set up only the functions related

to the Inverting mode of the inverter/charger.

•

02A Search Watts: Allows you to turn off the Search Watts feature, or

to adjust the power level to determine when the inverter leaves Search

mode. The power level range selection is Off, 5W to 50W. If this feature

is not needed, select Search=Off. When search is turned off, the inverter

continuously provides full AC voltage to the loads.

Default setting - Search= 5W.

Info: When the Search Watts feature is active, “Searching”

appears on the top line of the LCD display and the green INV

LED will slowly fl ash.

What is the Search Watts feature? This feature is used to help save

battery power by reducing the inverter’s output to search pulses when there

is no detectable load. If a load greater than the wattage level setting turns on

while the inverter is ‘searching’, the inverter will start ‘inverting’ to provide

full voltage on its output.

Should I use the Search Watts feature? If the inverter can spend a great

deal of time searching (to reduce the power drain on your batteries) and you

can tolerate small loads (less than fi ve watts) being OFF, then the Search

mode feature should be used. However, if some small loads (i.e., digital

clocks, satellite receivers, answering machines, etc.,) are required to be on,

then this feature should be turned off (Search = Off).

Where should I set Search Watts? The Search Watts setting should be

adjusted to the same power level (or the next lower setting) of the smallest

load that you want to run. If you don’t know the wattage of the smallest load

you want to run, turn the switch for the load on and decrease the Search Watts

setting until the load comes on and stays on.

Example: You have reviewed all the loads you want to run and determined

that the smallest load is a 30 watt light. Set Search = 30W. Whenever you

turn on any load (because all the loads are greater than 30 watts), the

inverter will stop searching and start inverting to deliver power to the load.

Note: Even though the Search Watts feature is on, some connected equipment

may draw enough current even while turned off to keep the inverter in the

Inverting mode.

02B LBCO Setting: The Low Battery Cut-Out (LBCO) sets the DC voltage

•

level that turns off the inverter. This helps protect the batteries from

over-discharge damage. Selections are from 9.0 VDC to 12.2 VDC (12volt inverter models), 18.0 VDC to 24.4 VDC (24-volt inverter models),

or 36.0 to 48.8 (48-volt inverter models). If the battery voltage drops

below the LBCO set-point continuously for more than 1 minute, the FAULT

LED will come on, the inverter will turn off, and the display will show a

‘Low Battery’ status. If the battery voltage falls below 8.5 volts (12-volt

models), 17.0 volts (24-volt models) or 34.0 (48-volt models), the FAULT

LED and ‘Low Battery’ status will be immediate.

Default settings: LBCO = 10.0 VDC (12-volt models), 20.0 VDC (24-

volt models) or 40.0 VDC (48-volt models).

© 2010 Magnum Energy, Inc. 26

Page 32

3.0 Setup

Info: The inverter automatically begins inverting when the DC

voltage increases to ≥ 12.5 VDC (12-volt models), ≥ 25.0 VDC

(24-volt models), or ≥ 50.0 VDC (48-volt models). If AC power

is available and connected to the inverter’s input, the inverter

will automatically clear the low battery fault, pass the input AC

power to the output, and begin charging the batteries.

Where should I set the LBCO setting? If you want to cycle the batteries

slightly but don’t want to discharge them more than 20%*, then the

LBCO setting should be set from 11.5 to 12.2 VDC (12-volt models), 23.0

to 24.4 VDC (24-volt models), or 46.0 to 48.8 (48-volt models). In some

applications, such as those installed in an off-grid home or when doing a lot

of dry-camping in your RV, you may want to cycle down to 50%* by setting

the LBCO from 10.0 to 11.4 VDC (12-volt models), 20.0 to 22.8 VDC (24-volt

models) or 40.0 to 45.6 VDC (48-volt models). In extreme circumstances,

you have the ability to discharge the batteries to 80%* by setting the LBCO

to 9.0 or 9.5 VDC (12-volt models), 18.0 or 19.0 VDC (24-volt models), or

36.0 or 38.0 VDC (48-volt models) before recharging.

* These discharge percentages are rough estimates; for accurate battery

monitoring, a battery monitor such as Magnum’s ME-BMK/ME-BMK-NS is

required.

Info: The higher the LBCO setting, the less the inverter will

discharge the batteries; which should allow the batteries to have

a longer life. The down side to a higher LBCO setting is that you

need to charge more often to prevent the inverter from shutting

off in Fault mode.

Info: If there is an ME-AGS-N installed, it should be set to start

≥1.0 volts higher than the LBCO setting – this is to prevent the

inverter from shutting down before the generator comes on.

02C AC In-Time: This feature allows you to connect to the local power

•

utility at a predetermined time of day. When the current time falls within

the set times, the inverter/charger connects to the AC that is connected

to the AC input terminals. Once time passes outside the set times, the

inverter/charger disconnects from the AC source. If your local power

utility offers ‘time of day billing,’ this feature may save you money by

only connecting to the utility when rates are the least expensive.

Default setting - 6:00A - 6:00P

What is the AC In-Time feature? This feature allows the incoming AC to

connect to the inverter/charger and charge the batteries only during the time

of day as set in the 02C AC In-Time menu. Even if AC is present on the AC

input terminals of the inverter/charger it will only connect during those times

that were previously set up.

Should I use the AC In-Time feature? The most common use of AC In-

Time is when your local utility company offers peak rate savings. Peak rate

savings are when the utility company offers a lower rate per kWh (kilo Watt

hour) on your power bill, usually at night when there is less demand on the

local utility grid.

Where should I set AC In-Time? Check with your local utility company or

installer and see if they offer lower rates at particular times of the day. If a

lower rate is offered, try setting your connect time to coincide with the utility

companies lower rates, this will save you money.

27 © 2010 Magnum Energy, Inc.

Page 33

3.0 Setup

Example: The standard rate on your power bill is $.10 kWh. Your utility

company offers $.08 KWH between 12:00 AM and 7:00AM. Set your

connect time to coincide with the utility company’s lower rates in order

to save money when using utility power to charge the batteries.

•

02D AC In VDC: The AC In VDC setting determines when the inverter/

charger connects to incoming AC based on VDC (battery voltage). AC In

VDC is set within a range of battery voltages; the fi rst being the connect

DC voltage at which the inverter/charger will connect to incoming AC, and

the second being the disconnect DC voltage at which time the inverter

will disconnect from incoming AC. This setting is used when an alternate

charging source(s) is present. The alternate charging sources may be

PV, wind, and/or hydro. Typically, the AC In VDC setting optimizes the

alternate charging source(s) and only uses the grid to charge the batteries

if the alternate charging source is not able to maintain the batteries above

the Set Connect Volts setting.

Default setting - 11 - 14.1 VDC (12v), 22 - 28.2 (24v), 44 - 56.4 (48v)

What is the AC In VDC feature? This feature allows the incoming AC to

connect to the inverter/charger and charge the batteries once the set voltage

value in the 02D AC In VDC menu is reached. Even if AC is present on the AC

input terminals of the inverter/charger, it will only connect to incoming AC

when the Set Connect Volts setting is reached. It will disconnect when the

Set Disconnect Volts voltage setting is reached.

Should I use the AC In VDC feature? The most common use of AC In VDC is

when you have an alternate source(s) of battery charging. The most common

sources of alternate battery charging are PV, wind, and/or hydro. These sources

are directly connected to the batteries via a charge controller. In order to

optimize the alternate charge source(s), the incoming AC must be prevented

from connecting to the inverter/charger or else the inverter/charger will take

over charging the batteries and the alternate source will not be used.