Page 1

ME-BMK/ME-BMK-NS

Battery Monitor Kit

Owner’s Manual

Page 2

Disclaimer of Liability

The use of this manual and the conditions or methods of installation, operation, use, and maintenance of the ME-BMK is beyond the control of Magnum

Energy, Inc. Therefore, this company assumes no responsibility and expressly

disclaims any liability for loss, damage, or expense whether direct, indirect,

consequential, or incidental that may arise out of or be in anyway connected

with such installation, operation, use, or maintenance.

Due to continuous improvements and product updates, the images shown in

this manual may not exactly match the unit purchased.

Restrictions on Use

The ME-BMK may only be used in life-support devices or systems with the

express written approval of Magnum Energy. Failure of the ME-BMK can

reasonably be expected to cause the failure of that life-support device or

system, or to affect the safety or effectiveness of that device or system. If

the ME-BMK fails, it is reasonable to assume that the health of the user or

other persons may be endangered.

IMPORTANT PRODUCT SAFETY INSTRUCTIONS

This manual contains important safety instructions that must be followed

during the installation and operation of this product. Read all instructions

and safety information contained in this manual before installing or using

this product.

• All electrical work must be performed in accordance with local, state, and

federal electrical codes.

• This product is designed for indoor/compartment installation. It must

not be exposed to rain, snow, moisture, or liquids of any type.

• Use insulated tools to reduce the chance of electrical shock or accidental

short circuits.

• Remove all jewelry such as rings, watches, bracelets, etc., when

installing or performing maintenance on the ME-BMK and the inverter

system.

• Always disconnect the batteries or energy source prior to installing or

performing maintenance on the ME-BMK and inverter system. Live power

may be present at more than one point since an inverter utilizes both batteries and AC. Turning off the inverter may not reduce this risk. As long

as AC power is connected, it will pass through the inverter regardless of

the power switch on the inverter or the ON/OFF INVERTER pushbutton on

the remote.

Safety Symbols

To reduce the risk of electrical shock, fi re, or other safety hazard, the fol-

lowing safety symbols have been placed throughout this manual to indicate

dangerous and important safety instructions.

WARNING: This symbol indicates that failure to take a specifi ed

action could result in physical harm to the user.

CAUTION: This symbol indicates that failure to take a specifi ed

action could result in damage to the equipment.

Info: This symbol indicates information that emphasizes or supplements important points of the main text.

© 2010 Magnum Energy, Inc. i

Page 3

List of Contents

1.0 Introduction ............................................................................. 1

1.1 Product Features ........................................................................ 1

1.2 Identifi cation and Compatibility .................................................... 1

2.0 Installation ............................................................................... 3

2.1 Required Components and Tools ................................................... 3

2.2 Installation Procedure ................................................................. 5

2.3 Network Connection with Multiple Devices ..................................... 7

2.4 Network Connections Using the ME-RTR Router .............................. 8

3.0 Using the ME-RC50 Remote with the BMK ................................ 9

3.1 Accessing the Charge Effi ciency Menu Item ...................................9

3.2 Adjusting the Charge Effi ciency Setting ....................................... 10

3.3 Adjusting the Batt AmpHrs Setting ............................................. 10

3.4 ME-RC50 Remote’s BMK METER Menu Maps ................................. 11

3.5 Operating the BMK using the ME-RC50 ........................................ 12

3.6 ME-RC50 METER Menu Items and Settings for BMK ...................... 13

4.0 Using the ME-ARC50 Remote with the BMK ............................ 16

4.1 Accessing the Charge Effi ciency Menu Item ................................. 16

4.2 Adjusting the Charge Effi ciency Setting ....................................... 17

4.3 Adjusting the AmpHr Size Setting .............................................. 17

4.4 ME-ARC50 Remote’s BMK Menu Maps ......................................... 18

4.5 Operating the BMK using the ME-ARC50 ...................................... 20

4.6 ME-ARC50 METER Menu Items and Settings for BMK..................... 21

5.0 Using the ME-RTR Router with the BMK .................................. 23

5.1 Accessing the Charge Effi ciency Menu Item ................................. 23

5.2 Adjusting the Charge Effi ciency Setting ....................................... 24

5.3 Adjusting the AmpHrs Setting .................................................... 24

5.4 ME-RTR Router’s BMK Menu Maps .............................................. 25

5.5 Operating the BMK using the ME-RTR ......................................... 26

5.6 ME-RTR METER Menu Items and Settings for BMK ........................ 27

6.0 Using the LED Indicator to Determine the BMK’s Status ......... 30

7.0 Troubleshooting .................................................................... 31

8.0 Specifi cations ......................................................................... 32

9.0 Limited Warranty ................................................................... 33

9.1 How to Receive Repair Service ................................................... 34

List of Figures

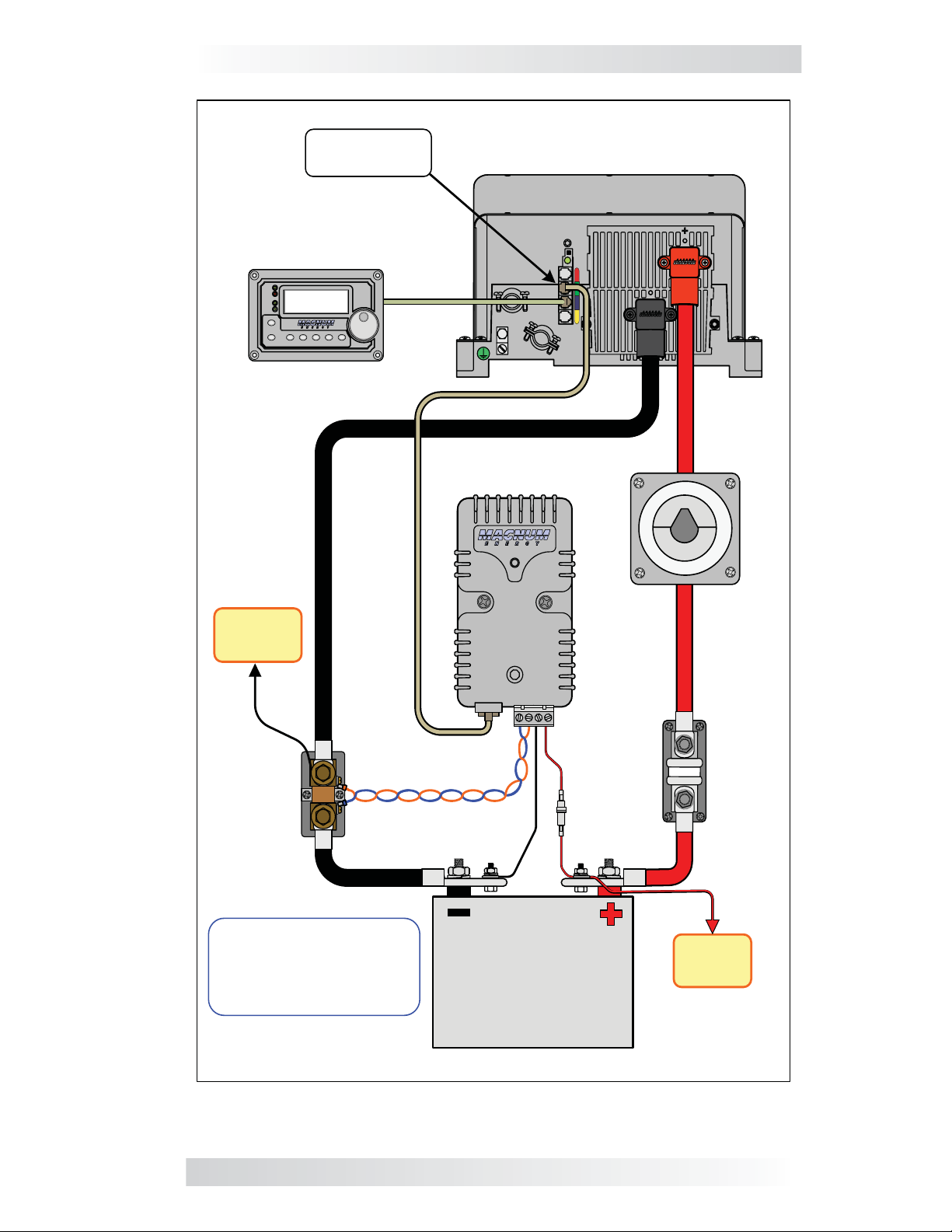

Figure 2-1, ME-BMK Installation Diagram .............................................. 4

Figure 2-2, DC Shunt Connections ....................................................... 5

Figure 2-3, Sense Module Connections .................................................6

Figure 2-4, Multiple Network Devices - Star Confi guration ....................... 7

Figure 2-5, Multiple Network Devices - Daisy Chain Confi guration ............ 7

Figure 2-6, BMK Connected Directly to Router ....................................... 8

Figure 2-7, BMK and Router w/ Separate Connections to Inverter.............8

Figure 3-1, Accessing the Charge Effi ciency Menu Item (ME-RC50) ...........9

Figure 3-2, Adjusting the Charge Effi ciency Setting (ME-RC50) .............. 10

Figure 3-3, ME-RC50 METER Menu Map (Displays w/BMK Settings) ........ 11

Figure 3-4, Accessing the METER Menu Items (ME-RC50) ...................... 13

Figure 4-1, Accessing the Charge Effi ciency Menu Item (ME-ARC50) ....... 16

Figure 4-2, Adjusting the Charge Effi ciency Setting (ME-ARC50) ............ 17

Figure 4-3, ME-ARC50 SETUP Menu Map (Displays w/BMK Settings) ....... 18

ii © 2010 Magnum Energy, Inc.

Page 4

List of Figures (Cont.)

Figure 4-4, ME-ARC50 METER Menu Map (Displays w/BMK Settings) ....... 19

Figure 4-5, Accessing the METER Menu Items (ME-ARC50) .................... 21

Figure 5-1, Accessing the Charge Effi ciency Menu Item (ME-RTR) .......... 23

Figure 5-2, Adjusting the Charge Effi ciency Setting (ME-RTR) ................ 24

Figure 5-3, ME-RTR SETUP Menu Map (Displays w/BMK Settings) ........... 25

Figure 5-4, ME-RTR METER Menu Map (Displays w/BMK Settings) .......... 26

Figure 5-5, Accessing the METER Menu Items (ME-RTR) ....................... 27

Figure 8-1, Dimensional Specifi cations ............................................... 32

List of Tables

Table 6-1, LED Indicator Guide .......................................................... 30

Table 7-1, Troubleshooting Guide ....................................................... 31

Table 8-1, Specifi cations ................................................................... 32

© 2010 Magnum Energy, Inc. iii

Page 5

Introduction

1.0 Introduction

The ME-BMK/ME-BMK-NS is a single battery bank amp-hour meter that moni-

tors and provides important information about the condition of the battery.

This information will let you know how much energy you have available, and

let you plan your electrical usage to ensure the battery is not being overdischarged.

The ME-BMK is easy to install and is designed to be networked with a Magnum

Energy inverter/charger using a remote (ME-RC50 or ME-ARC50) or router

(ME-RTR) to display information about your battery bank.

Info: The ME-BMK-NS is identical to the ME-BMK except the NS

version does not have the DC shunt.

1.1 Product Features

• Compatible with 12, 24, or 48 volt systems

• Adjustable settings – very easy set up

• All battery meter and Magnum inverter/charger setup and

monitoring features are in a single convenient display – doesn’t

require multiple displays for inverter and battery system info

• Displays reliable and pertinent information, such as:

•

Battery State of Charge (SOC)

•

Battery Voltage

•

Battery Current

• Auto-detecting input voltage

• Temperature and battery bank capacity automatically compensated

and coordinated between inverter and battery monitor

• Precision 500A/50mv DC shunt (not included w/ ME-BMK-NS model)

• Automatic effi ciency calculation

1.2 Identifi cation and Compatibility

The ME-BMK is compatible with all Magnum inverters/chargers that have been

provided with a Magnum Net or Network port (see Figure 2-1). The ME-BMK

requires either an ME-RC50 (revision 2.0 or higher) remote, ME-ARC50 remote,

or an ME-RTR router to access the available settings and features.

Info: You can view the revision level of your ME-RC50 when you fi rst

power-up the remote, or by pushing the TECH button and accessing

the 02 Revisions menu.

If your ME-RC50 remote’s revision is not 2.0 or higher, refer to one of the two

options below to obtain the required revision.

1) If the ME-BMK is being installed at the same time as a newly purchased

Magnum inverter and ME-RC50 remote system, contact your Magnum Energy

dealer to obtain the ME-RC50 with a revision of 2.0 or higher.

2) If the ME-BMK is being added to a previously installed Magnum inverter

and ME-RC50 remote system, contact Magnum Energy about the ME-RC50

upgrade options.

1 © 2010 Magnum Energy, Inc.

Page 6

Introduction

Why should I use the Magnum Battery Monitor? To ensure your batteries

perform satisfactorily and have a long life, they need to be properly maintained

and charged. There are several devices that help to determine if the batteries

are being fully charged:

• DC Voltmeter: An accurate DC voltmeter can be used to measure the

Open Circuit Voltage (OCV) across the battery terminals and compare the

readings with the OCV values from the battery manufacturer. A DC voltmeter

is the least costly, but is also the least accurate and requires the batteries to

be “at rest”. This rest requirement means the voltage measurement should

only be done when there is no current moving through the battery for a period of time (most experts say a minimum of 1 hour). Using a DC voltmeter

when the batteries are at rest is generally impractical because the batteries

are usually always powering loads or being charged.

• Hydrometer: A good hydrometer can be used to measure the concentra-

tion of battery electrolyte in each individual cell, and compare these readings

with the specifi c gravity values from the battery manufacturer. A hydrometer

is very accurate, but can be time-consuming and becomes unpleasant when

working with sulfuric acid. A hydrometer won’t work with sealed batteries.

• Amp-hour Meter: An amp-hour meter is an electronic measuring device

that uses a precision shunt to calculate the amp-hours going into (charging)

and coming out of (discharging) a battery. This meter tracks the amp-hour

usage and compares it against the amp-hour capacity of the battery to de-

termine its charge condition. Calculating amp-hours in vs. amp-hours out is

fairly accurate and easily displayed, but doesn’t provide an accurate State

Of Charge (SOC) under all charge and discharge conditions.

These devices have both advantages and disadvantages based on accuracy and

ease of use. The Magnum Energy battery monitor combines the advantages of

these devices with additional functionality (such as monitoring battery temperature and calculating battery effi ciencies) to provide an easy and more accurate

means to determine the battery’s SOC condition. Therefore, you are more likely

to keep the batteries properly charged, and in turn be satisfi ed with your battery

system performance.

What is the difference between Amps and Amp-Hrs? “Amps” indicate

the fl ow of current going in or out of the battery. “Amp-hours” indicate the

amount of current returned to or removed from the battery. Amp-hrs are a

common rating used to calculate the battery’s available capacity. For example,

if a constant 3 amperes were removed from a 100 AH battery each hour, the

battery bank’s capacity would be 94 AH after 2 hours (6 amp-hours less).

To help understand the difference, imagine the battery bank is equivalent to

a water tank. Viewing the amps display would be similar to watching a water

gauge. You can see that the water is fl owing a little or a lot, but this doesn’t

indicate how much water is left. When viewing the SOC display, it would be

similar to viewing the water tank’s level indicator, which tells you how much

water is left in the tank.

For example: You have a 10 gallon water tank, and you remove water from

the tank with a one gallon bucket. The water level indicator would show the

available water has decreased by 10% – leaving 90% of the water still available. If this was a battery bank, then you would know that 10 percent of the

battery’s capacity has been used and its SOC is now 90%.

© 2010 Magnum Energy, Inc. 2

Page 7

Installation

2.0 Installation

Before installing the ME-BMK, read this entire section so you can thoroughly

plan the details to ensure the overall system requirements are accomplished.

To assist in planning and designing your installation, review the basic system diagram in Figure 2-1. If another network device besides the ME-BMK

is to be installed, refer to Section 2.3 to determine your specifi c network

confi guration.

WARNING: Installations should be performed by qualifi ed person-

nel, such as a licensed or certifi ed electrician. It is the installer’s

responsibility to determine which safety codes apply and to ensure

that all applicable installation requirements are followed. Applicable

installation codes vary depending on the specifi c location and ap-

plication. Review the “Important Product Safety Information” on

page ii before any installation.

The ME-BMK Sense Module is connected to the inverter by a 10’ communications cable, and to the DC shunt using a 5’ twisted-pair signal wire. Before

installing and connecting any wires, determine the following routes:

1) The communications cable route throughout the home or vehicle/

boat to the inverter.

2) The twisted-pair signal wire route to the shunt.

Info: The communications cable may be extended beyond the supplied 10’, but to ensure voltage accuracy do not extend the 5’ twistedpair wire used between the DC shunt and the Sense Module.

Info:

protection device to be used in the installation, refer to the inverter

owner’s manual.

For information on the size of the battery cable and overcurrent

2.1 Required Components and Tools

2.1.1 List of Supplied Components in the ME-BMK/ME-BMK-NS:

• ME-BMK/ME-BMK-NS Owner’s Manual

• Sense Module (with two #8 x 3/4” Phillips mounting screws)

• 500A/50mv DC shunt (with two #8 x 3/4” Phillips mounting screws)*

• 10ft Communications cable

• 5ft Twisted-pair (blue and orange color) signal wires

2.1.2 List of Other Required Equipment and Materials:

• Magnum inverter with a network port

• ME-RC50 (revision ≥ 2.0) remote, ME-ARC50 remote, or an

ME-RTR router

• Batteries (with appropriately sized cables)

• Short (~18”) battery cable (to connect shunt to battery negative)

• In-line fuse holder (with 2-amp DC fuse)

• 4-Wire phone-splitter (if using multiple network devices)

2.1.3 Tools Required to Install the ME-BMK:

• Flat-blade screwdrivers (1/4” and 1/8” blades)

• #2 Phillips screwdriver

• 9/16” open-end wrench or adjustable crescent wrench

*The ME-BMK includes a shunt, the ME-BMK-NS does not.

3 © 2010 Magnum Energy, Inc.

Page 8

Installation

Network Port

(green label)

Remote Control

(ME - RC50 with revision ≥ 2.0,

ME - ARC50, ME - RTR)

PWR

FA ULT

Inverting

CHG

INV

ON/OFF

CHARG ER

ON/OFF

DC 12.6V 5A

SELECT

TECHAGS MET ER SETUPSHOREINVERTER

(ME -BMK/ME -BMK -NS)

Magnum Energy Inverter/Charger

(with NETWORK port )

Sense Module

ON

OFF

DC

Negative

Distribution

load

DC Shunt *

load

side

side

(ME - BMK )

battery

battery

side

side

*NOTE: The ME - BMK - NS

model does not include a

DC shunt. The shunt must

be provided in the system.

(from ME -BMK/ME -BMK -NS)

Communications Cable (10')

Twisted-Pair

Cable (5')

(ME - BMK/

ME - BMK - NS)

Battery

Bank

DC Fuse

(2 amp s)

Battery

Disconnect

Switch

Battery /

Inverter

U

L

S

F

T

A

C

E

S

S

DC

Po sitive

Distribution

Cable

Fuse

Figure 2-1, ME-BMK Installation Diagram

© 2010 Magnum Energy, Inc. 4

Page 9

Installation

2.2 Installation Procedure

Select a location that is dry and away from extreme temperatures to mount the

ME-BMK Sense Module and DC shunt. Use the supplied #8 x 3/4 screws (x4).

Allow ample room to view the LED on the Sense Module, access the screws

and bolts on the shunt, and to access the terminal block and the RJ11 port.

CAUTION: Do not mount the ME-BMK Sense Module in a closed

battery compartment, or in an area

can enter the ME-BMK Sense Module and cause shorting or corrosion. The internal circuit board is conformal coated to help prevent

corrosion, but this failure is not covered by the warranty.

Info: Shunts should be mounted in an area where freely circulating

air is available. For continuous operation, it is recommended that

shunts are not used at more than 2/3 of their rated current.

is not possible, adequate forced ventilation should be provided to

keep the shunt operating temperature below 60°C.

CAUTION: Before beginning the installation, ensure all AC power is

disconnected from the inverter, and all negative

cables are disconnected from the battery bank.

where water or any other liquid

If this

and positive battery

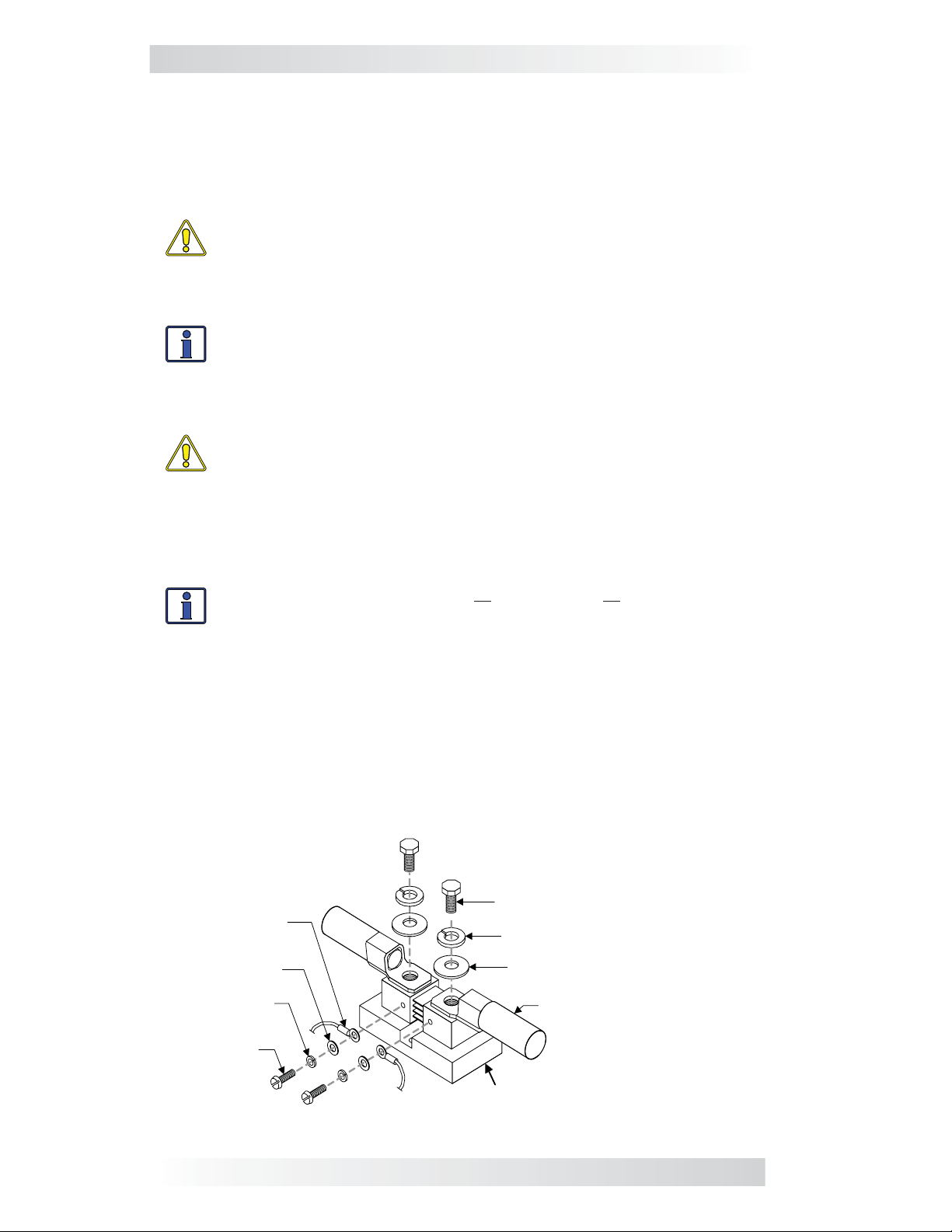

2.2.1 DC Cable Connections

1. Using an appropriate sized cable, wire the inverter’s DC negative terminal

to the DC shunt (load side).

Info: For the ME-BMK to monitor all load currents, all DC loads — including the inverter — must be connected to the load side of the shunt.

2.

Wire the other side of the DC shunt (battery side) to the battery negative ter-

minal. Connect cables/hardware to the shunt exactly as shown in Figure 2-2.

3. Using an appropriate sized cable, wire the inverter’s DC positive terminal

to the load side of an appropriate DC disconnect/overcurrent protection device

(i.e., DC circuit breaker, or DC disconnect and fuse).

4. Open the DC circuit breaker (or remove the fuse) and wire its other side

to the positive terminal of the battery bank.

Sense wire with

ring terminal to

Sense Module (x2)

Flat washer (x2)

Split -lock

washer (x2)

8-32 x 3/8"

screw (x2)

3/8"-16 bolt with 9/16" head (x2)

Split-lock washer (x2)

Flat washer (x2)

Cable (x2) – one side to

inverter, other to battery

(use ring lug w/ 3/8" opening)

DC Shunt

Figure 2-2, DC Shunt Connections

5 © 2010 Magnum Energy, Inc.

Page 10

Installation

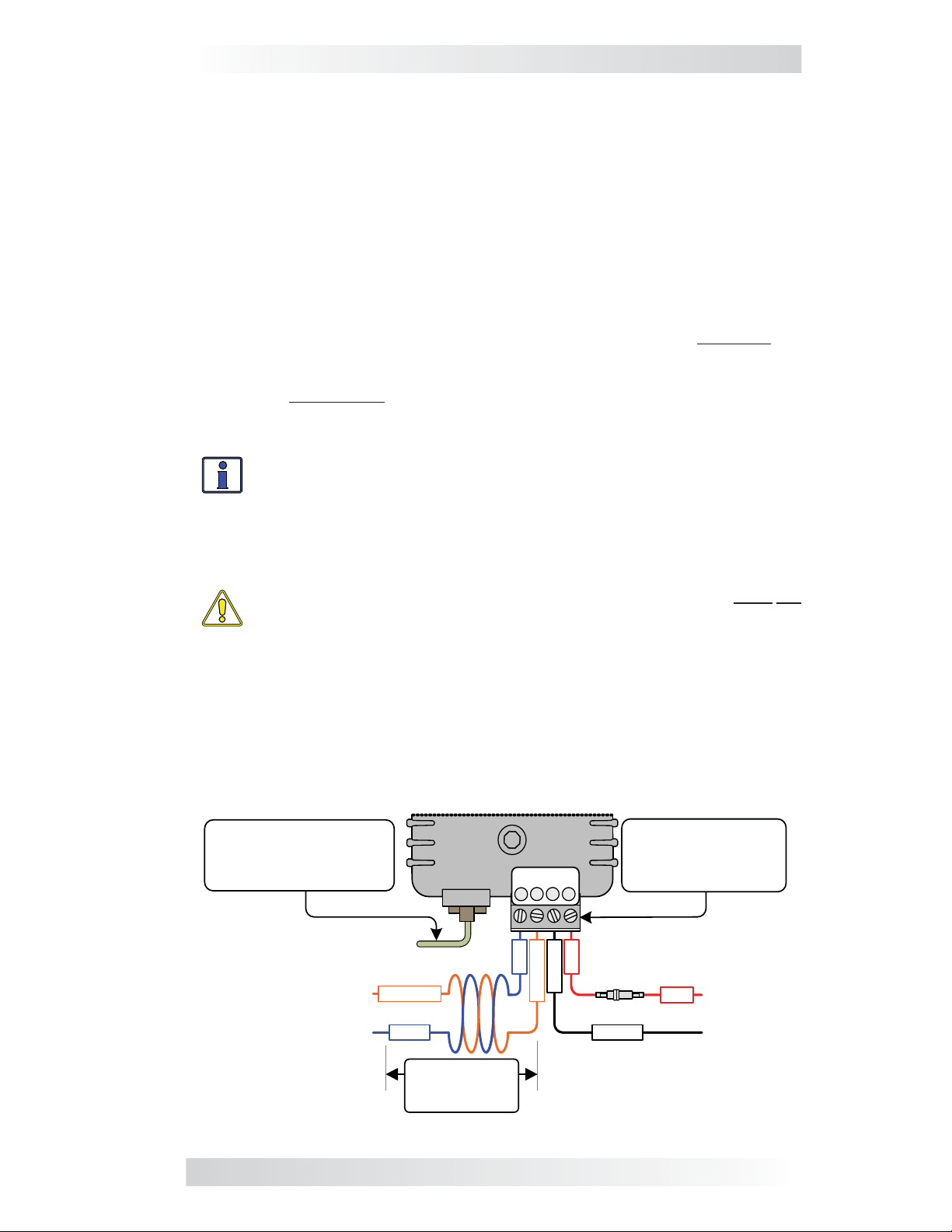

2.2.2 ME-BMK Sense Module Connections

Once mounted, complete the following steps to connect the BMK (Fig. 2-3):

1. Run the communications cable between the ME-BMK Sense Module and the

inverter/charger. This cable is a 2-wire, twisted-pair, telephony standard with

RJ11 connectors on each end. A standard telephone cable may be substituted

if the provided remote cable is not able to be used or needs to be longer.

2. Connect the communications cable to the RJ11 Net port beside the green

label (Network port) on the Magnum inverter/charger (see Figure 2-1).

3. Unplug the 4-port terminal block from the Sense Module and

ensure the openings are unscrewed enough to allow wire insertion.

4. Using the supplied 5 foot twisted-pair wire: 1) Connect the blue wire

from the #1 terminal on the 4-port terminal block to the small screw on

the battery side of the shunt (negative shunt sense connection); then, 2)

Connect the orange wire from the #2 terminal on the 4-port terminal block

to the small screw on the load side of the shunt (positive shunt sense

connection).

Info: Ensure these blue and orange wires stay twisted together up

to the shunt to maintain accuracy.

5. Connect a wire (black) from terminal #3 on the 4-port terminal block to

the negative terminal of the battery. Then, connect a wire (red) with a 2-amp

in-line fuse from terminal #4 on the 4-port terminal block to the positive

terminal of the battery.

CAUTION: To prevent damage, the black and red power wires must not

be connected to the input sense terminals (terminals #1 and #2).

6. When all the connections are made and checked, plug the 4-port terminal

block into the Sense Module and then close the DC circuit breaker (or DC

disconnect) to supply power to the inverter and Sense Module.

7. Immediately after applying DC power, the LED on the Sense Module should

come on as the unit goes through a power-up self-test. After the initial selftest completes, the LED should be green. If so, your battery monitor system

is now ready for setup; if not, please refer to the Troubleshooting section.

Communications Cable

(2-conductor twisted pair;

a telephone-type cable

may be substituted ).

Terminals :

1 2 43

4-Port Terminal Block

(can be removed, and

each terminal accepts

30 to 12 AWG wire).

To Network Port

(on Magnum inverter)

To small shunt screw

(load side)

To small shunt screw

(battery side)

orange

blue

blue

orange

black

DC Fuse

red

(2 amps)

black

red

To Battery

Positive

To Battery

Negative

Tw isted-p air

cab le 5 feet

maximum

Figure 2-3, Sense Module Connections

© 2010 Magnum Energy, Inc. 6

Page 11

Installation

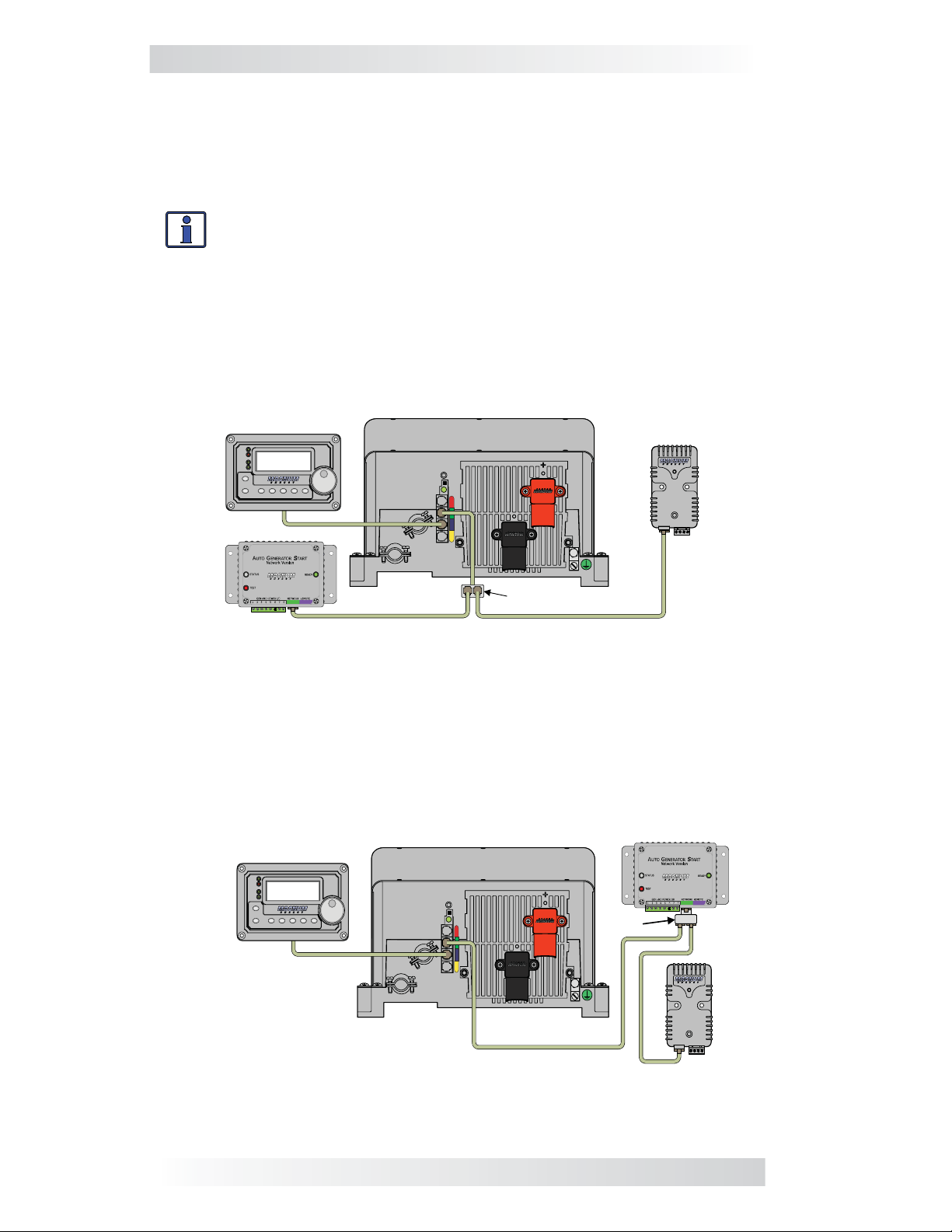

2.3 Network Connection with Multiple Devices

If you are using more than one Magnum Energy networked device, a 4-wire

phone-splitter is required to connect the network devices. It is possible to

interconnect the devices in two confi gurations; either in a Star or a Daisy

Chain confi guration.

Info: Before deciding on which confi guration to use, review the dif-

ferences in installation and ease of troubleshooting.

• Star Confi guration - In this arrangement, all the network devices con-

nect to the inverter’s Network port via a phone-splitter, using individual cable

runs (see Figure 2-4). Since each device is independently connected to the

inverter’s Magnum Net or Network port, problems in a cable or a device can

be easily isolated; and, if there is a cable failure to one device it does not

bring down all the other devices.

Remo te Control

(ME - RC 50 w ith revision of ≥2.0,

ME - AR C 50, or M E - R T R router)

PWR

FAULT

Inverting

CHG

INV

ON/OFF

CHARGER

ON/OFF

DC 12.6V 5A

SELECT

TECHAGS METER SETUPSHOREINVERTER

Magnum Inverter /C harger

ME-BMK

M E-AG S-N

Ph o n e-splitter

Figure 2-4, Multiple Network Devices - Star Configuration

• Daisy Chain Confi guration – In this arrangement, the network devices are

linked in a series (see Figure 2-5). If using this confi guration, the ME-AGS-N

must be the fi rst device connected to the inverter’s Magnum Net or Network

port – followed by the ME-BMK.

Remo te Control

(ME - RC 50 w ith revision of ≥2.0,

ME - AR C50, or ME - RTR router)

PWR

FAULT

Inverting

CHG

DC 12.6V 5A

INV

ON/OFF

CHARGER

ON/OFF

SELECT

AGS METER SETUPSHOREINVERTER

TECH

Magnum Inverter /Charger

M E-AGS- N (1st device)

Phone

splitter

ME-BMK (2nd device)

Figure 2-5, Multiple Network Devices - Daisy Chain Configuration

7 © 2010 Magnum Energy, Inc.

Page 12

Installation

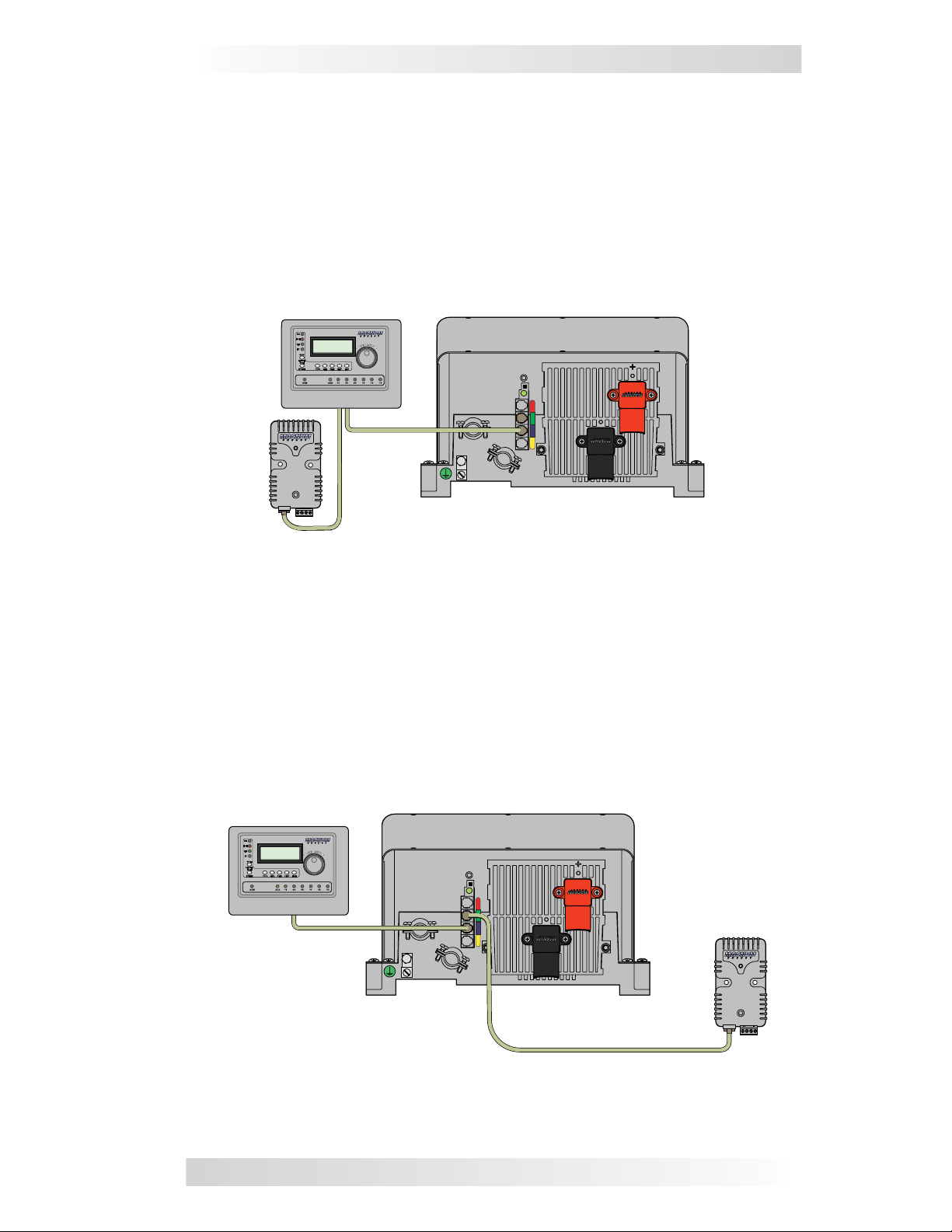

2.4 Network Connections Using the ME-RTR Router

If you are using a Magnum Energy router it is possible to connect the BMK

either directly to the router, or directly to the inverter.

•

Direct to Router Configuration – In this arrangement, the BMK

device is directly connected to the router which is in turn connected to

the inverter.

Magnum Energy Router

(ME-RTR)

ME-BMK

Magnum Inverter/Charger

Figure 2-6, BMK Connected Directly to Router

Direct to Inverter – In this arrangement, the router and BMK device

•

are each directly connected to the inverter via separate ports.

Magnum E nergy Router

(M E- RT R )

Magnum Inverter/Charger

ME-BMK

Figure 2-7, BMK and Router w/ Separate Connections to Inverter

© 2010 Magnum Energy, Inc. 8

Page 13

Using the ME-RC50 Remote with the BMK

3.0 Using the ME-RC50 Remote with the BMK

This section discusses how to set up and operate the BMK using the ME-RC50 remote. It also shows what BMK menu options are available using this remote.

The fi rst section provides information about Charge Effi ciency and how to

manually access/adjust this setting. Normally, the ME-BMK battery monitor

automatically calculates the battery’s effi ciency.

Info: The factory default charge effi ciency setting is Auto. This set-

ting allows the charging effi ciency to be automatically calculated.

In most circumstances, the Auto setting will determine the best

charge effi ciency.

CAUTION: If you do not know your battery’s charging effi ciency,

leave it at the factory default setting. If the setting is manually set

but incorrect, the state-of-charge information will become more

inaccurate with every charge.

What is Charge Effi ciency? When a certain amount of energy is removed or

discharged from the battery, this removed energy will need to be returned to

keep the batteries at a 100% state of charge. As batteries are being charged,

they lose energy; either in the form of heat, or while gassing. This loss of

energy while charging means the battery will not be fully charged if you only

return the current that was removed. To compensate for the battery’s ineffi ciencies while charging, a charge effi ciency setting is provided. The charge

effi ciency setting compensates the AH I/O (Amp-Hrs In/Out) reading by

ensuring the amp-hrs returned to the battery are greater than the amp-hrs

removed.

For example, if your AH I/O display reads 000 and you begin powering a 25

amp load for two hours, the display will show -050. This indicates that you

have discharged 50 amp-hrs (2 x 25) from the battery. If the charge effi ciency

setting is set to 95%, then as you begin charging and return 50 amp-hrs, the

AH I/O reading will be less than zero, indicating that the amp-hours removed

have not been fully returned. The 95% charge effi ciency setting requires 52.5

amp-hours (50/95) to be returned before the AH I/O returns to 0.

3.1 Accessing the Charge Effi ciency Menu Item

On the ME-RC50 remote, press the METER pushbutton and rotate the

SELECT knob until the 05 BM: Setup menu appears. Once the 05 BM: Setup

menu appears, press the SELECT knob to access the BM Charge Eff menu

item (see Figure 3-1).

METER

rotate

press

Status…

05 BM: Setup

Figure 3-1, Accessing the Charge Effi ciency Menu Item (ME-RC50)

Info: For additional information on navigating the remote display,

see the ME-RC50 (PN: 64-0003) Owner’s Manual. See Figure 3-4 for

a complete map of the menu items and adjustable settings available

for the ME-BMK when using the ME-RC50 remote control.

9 © 2010 Magnum Energy, Inc.

to

press to

select

Page 14

Using the ME-RC50 Remote with the BMK

3.2 Adjusting the Charge Effi ciency Setting

The Charge Effi ciency setting allows the battery monitor to calculate the battery’s

charge effi ciency. The charge effi ciency can be calculated automatically using the

Auto setting, or can be manually programmed by the user (see Figure 3-2).

The battery monitor is shipped with the charge effi ciency set to Auto. This allows

the battery monitor to automatically calculate variables that affect the charging

effi ciency such as battery type, battery age, and how the batteries are maintained

– which is not always constant. With the Auto setting, the effi ciency is recalculated

each time the batteries reach a 100% state of charge.

This setting can also be manually adjusted from 50% to 97% if the battery’s

charge effi ciency is known. When using a setting other than the Auto setting, the

battery monitor will use the manual setting to calculate the AH I/O display. For

example, if you set the charge effi ciency to 90% and 100 amp-hrs are removed

from the battery, the AH Net display would read 000 only after 111AH have been

returned to the battery.

METER

press

Status ...

Chg Eff=Auto

rotate to

Status…

05 BM: Setup

Status...

Chg Eff= 5 0%

press to select

(pre ss x 2 for ME -R C50 's

wit h Re v. 2.6 or l at er)

Status...

Chg Eff= 6 0%

rotate to

desired

selection:

.......

press to

save

Status ...

Chg Eff= 9 7%

Figure 3-2, Adjusting the Charge Efficiency Setting (ME-RC50)

If the charge effi ciency is manually set and inaccurate, the SOC information will

be more inaccurate with every charge. For this reason, continually monitor the

AH I/O reading under the remote’s METER pushbutton.

To access the AH I/O reading: press the METER pushbutton, turn the SELECT

knob until the 03 BM: Meters menu appears, press the SELECT knob again,

and then turn the SELECT knob until the AH I/O: display appears.

After several charge and discharge cycles (below 80% SOC), the AH I/O read-

ing should be slightly positive when the SOC display reads 99%.

To view the SOC display: press the METER pushbutton, turn the SELECT knob

until the 02 BM: SOC menu appears. If the AH I/O reading is below 000 (negative number) when the SOC display reads 99%, then increase the charge ef-

fi ciency setting. If you fi nd that the AH I/O reading is substantially above zero

when the SOC display reads 99%, then decrease the charge effi ciency setting.

3.3 Adjusting the Batt AmpHrs Setting

It’s important that the Batt Amphrs setting is correct or else the calculations used

to determine the battery’s SOC display will be inaccurate.

•

ME-RC50 Remote (Revision 2.0-2.5): To adjust this setting, press the

SETUP pushbutton on the ME-RC50 remote control, and then rotate the

SELECT knob until the display shows the 03 Batt AmpHrs menu. When the

03 Batt AmpHrs menu appears, press the SELECT knob to display the

current Batt AmpHrs setting. Turn the SELECT knob to adjust the

Batt AmpHrs setting. Press the SELECT knob to select and save the new

setting.

© 2010 Magnum Energy, Inc. 10

Page 15

Using the ME-RC50 Remote with the BMK

(press and hold the SELECT knob for 5 seconds to reset values)

ME-RC50 Remote (Revision 2.6 or later): Press the

•

METER pushbutton on the ME-RC50 remote control, and then rotate the

SELECT knob until the display shows the 05 BM: Setup menu. When the

05 BM: Setup menu appears, press the SELECT knob to display

the BM Charge Eff menu item. Turn the SELECT knob until the BM

Amp Hours menu item appears. Press the SELECT knob to display

the current Batt Amphr setting. Turn the SELECT knob to adjust the

Batt AmpHr setting. Press the SELECT knob to select and save the new

setting.

3.4 ME-RC50 Remote’s BMK METER Menu Maps

The diagram below is a complete overview of the battery monitor settings and

information displays available from the ME-RC50 remote’s METER menu.

METER

Status...

02 BM: SOC

S

Status...

03 BM: Meters

S

Status...

DC Volts: **

Status...

04 BM: Status

S

Status...

BM: Status...

Status...

05 BM: Setup

S

Status...

BM Charge Eff

Status...

BM Amp Hours

S

METER

Status...

Batt SOC:** %

S

Status...

Chg Eff=Auto*

Status...

Batt Amphr=200

ME – RC50 LEGEND

METER

Status...

01 Search Watts

Status...

Search= 5W

* = indicates default setting

S = denotes pressing SELECT knob

= Resettable Menu Selections

Status...

DC Amps: **

Status...

BM: No Comm

Status...

Chg Eff=50%

Status…

Batt Amphr=210

(press and hold the SELECT knob for 5 seconds to reset values)

(press & hold SELECT knob for 5 secs to reset values )

Status...

AH I/O: *

Menu Button

Inverter/Charger Status

Menu Items

Inverter/Charger Status

Menu Selections

Status...

BM: Pwr-up Fault

Status...

Chg Eff=60%

.....

** = read only data

Status...

rAH Out: **

Status...

BM: Ready

Status...

Chg Eff=97%

.....

Status...

Batt Amphr=2500

Status...

tAH Out: **

NOTE: The BM Amp Hours menu items are ONLY avail able

on ME-RC50 remote s with Revisi on 2. 6 or later.

Status...

06 BM: TECH

S

Status...

BM Rev: **

Status...

Min DC: **

Status...

Max DC: **

Figure 3-3, ME-RC50 METER Menu Map (Displays w/BMK Settings)

11 © 2010 Magnum Energy, Inc.

Page 16

Using the ME-RC50 Remote with the BMK

3.5 Operating the BMK using the ME-RC50

This section explains how the ME-BMK battery monitor works, and how to use

the Magnum Energy RC50 remote control to obtain battery bank information.

It also covers the various LCD displays that are related to the battery monitor

and the status of the Sense Module’s LED indicator.

Info: For additional information on navigating this remote control,

see the ME-RC50 (PN: 64-0003) Owner’s Manual.

3.5.1 How does the Battery Monitor (ME-BMK) Operate? The

ME-BMK battery monitor uses a precision resistor known as a shunt to measure

current fl ow into and out of the battery. The shunt provides a small voltage

to the Sense Module that is proportional to the current fl ow. When current

starts fl owing into or out of the battery, the Sense Module measures the cur-

rent fl ow and determines the amount of current removed from and returned

to the battery. The amount of current (or amp-hours) removed or returned

is displayed on the remote control as the AH I/O (Amp-Hours In/Out). The

AH I/O number is compensated by a charging effi ciency value that accounts

for energy loses while charging, and is one of the factors used to determine

the battery’s State Of Charge (SOC).

The battery’s state of charge — which is the best indicator of the condition

of the batteries — is indicated on the SOC display. This display will show that

the batteries are fully charged (i.e., SOC = 100%) once the following three

conditions have been met:

The charging voltage has stabilized over a period of time.

1.

The charging current has decreased to a low percentage of the amp-

2.

hour capacity – normally less than 2%.

The amp-hours that were removed from the battery are within 1% of

3.

fully being returned.

After the batteries have reached 100% SOC and have discharged ≥ 0.5% of

the battery capacity setting, the charge effi ciency value will be recalculated

and the AH I/O read-out will reset to the recalculated value.

Info: To help maintain the accuracy of the SOC display and to keep

the batteries in good condition, they must on occasion be 100%

charged (approximately once a week).

Info: Charging from a generator (non-inverter topology) adds some

concern about the cost of fuel. A balance should be considered

between the use of fuel and the need to charge your batteries to

100% SOC – to maintain the full service life of a battery. Batteries

discharged to 50% SOC and then normally recharged to 85-90% SOC

would be an effi cient compromise between fuel cost and battery life.

Trying to restore the last 10-15% of a full battery charge requires a

long time – typically several hours.

© 2010 Magnum Energy, Inc. 12

Page 17

Using the ME-RC50 Remote with the BMK

3.6 ME-RC50 METER Menu Items and Settings for BMK

Press the METER pushbutton on the ME-RC50 to access the different meters

that determine the status of the inverter/charger and battery system.

Press the

METER

pushbutton

MET ER

Rotate the

SELECT knob to

find your desired

menu item

Sta tus …

01 INV/CHG Meter

Sta tus …

06 BM: TECH

Press the SELECT

knob to “select”

your desired menu

item

Figure 3-4, Accessing the METER Menu Items (ME-RC50)

01 INV/CHG Meter – This menu provides the DC voltage and current of the

inverter/charger when inverting or charging. These are not BMK readings.

02 BM: SOC – This display is the best way to monitor the actual state of

the battery. The read only display shows the State Of Charge (SOC) for the

connected battery bank. The SOC represents the condition of the battery as

a percentage of the available capacity left in the battery. The range is 0% to

100%, where 100% represents a fully charged battery and 0% means the

battery is completely discharged.

When the Sense Module is fi rst connected, the batteries will need to be fully

charged (i.e., SOC = 100%) at least once to establish a SOC reference point.

While this reference point is being calculated, the display will show “Think’n”,

to indicate that the SOC reference point is being calculated. After the batteries are fully charged, the display will change from “Think’n” to “100%” and

begin to provide accurate SOC percentage values.

Info: “Think’n” can take up to several days depending on the charge

source and its ability to completely recharge the batteries (e.g., a

small PV array may not be large enough to replace all the amp-hrs

in a reasonable amount of time).

If the Sense Module is disconnected from power, this display resets to “Think’n”

and the batteries will require another full charge before this display begins

providing SOC percentage information.

Info: Try to limit battery discharging to 50% of capacity (keep

battery above 50% SOC). If batteries are allowed to be continually

discharged below 50% SOC, their effective service life will be considerably shorter. This 50% rule has been determined to be the best

compromise between available energy and the maximum number of

discharge cycles a battery can provide.

13 © 2010 Magnum Energy, Inc.

Page 18

Using the ME-RC50 Remote with the BMK

03 BM: Meters – This menu shows the battery bank’s DC voltage, DC current,

and AH information that has been provided by the battery meter. The values

for these meter displays are updated each second.

DC Volts – This meter displays the real-time battery voltage from

•

07.00 to 70.00 volts (± 0.02 volts).

DC Amps – This meter displays the real-time charge current (amps into

•

the battery) or discharge current (amps out of the battery). Charging is

shown as a positive (+) number and discharging is shown as a negative (-)

number. The range is from ±0.1 to 999 amps, with a 1.0% accuracy.

AH I/O (Amp-Hours In/Out) – This meter displays the amp-hours

•

returned to or removed from the battery. When this value is positive, it

represents amp-hours returned to the battery during any subsequent

charging. A negative value represents amp-hours removed from a full

battery. The range is ±32,768 AH.

When using the charge effi ciency’s Auto setting, the AH I/O value is

recalculated after the battery has been fully charged (reaching 100%

SOC) and ≥0.5% of the battery capacity has been discharged. If the

Sense Module is disconnected from power, the displayed AH I/O value

resets to zero.

Info: The AH I/O display correlates with the battery amp-hours setting

to help determine the 02 BM: SOC display.

Info: AH I/O example; if you run a 10 amp load for three hours, the

display will show -30 AH. When you begin charging, the display will

count from -30 AH back toward 0 AH.

rAH Out (Resettable Amp-Hours Removed) – This meter displays

•

the total amp-hours removed from the battery since it was last reset.

This display can be used as a battery load indicator to help identify

and monitor the battery load consumption. The range is 0 to 65,535.0

amp-hours (0.1 amp-hour resolution).

To reset the AmpHrs value to zero, press and hold the rotary SELECT

knob for >5 seconds when this display is shown. After this display

has been reset, it will begin calculating and displaying new rAH Out

values. This display automatically resets to zero if the Sense Module is

disconnected from power.

tAH Out (Total Amp-Hours Removed) – This meter displays the total

•

amp-hours removed from the battery since the Sense Module was fi rst

connected. This display can be used as a battery service life indicator.

The value is displayed in 0.1k [or 100 amp-hours (“k” equals 1000)]

resolution up to a maximum of 6,553.5k amp-hours (6,553,500 amphours). The displayed number resets to 0.0k when the Sense Module is

disconnected from power.

© 2010 Magnum Energy, Inc. 14

Page 19

Using the ME-RC50 Remote with the BMK

04 BM: Status – This menu selection offers read only displays that give the

current operating status of the battery monitor. This selection also provides

information to determine if there is a power-up fault condition.

•

BM: Pwr-up Fault – The battery monitor faulted when it was powered-

up. The fault occurred because the power-up self-test failed. See the

Troubleshooting section.

•

BM: No Comm – The battery monitor is not communicating with the

remote. This typically means a ME-BMK is not installed in the system.

If installed, view the Sense Module LED and use Table 6-1 to help determine the issue.

•

05 BM: Setup – This menu allows the battery’s charging effi ciency to be au-

tomatically calculated or manually selected. Normally, the charging effi ciency

is automatically calculated (default setting is Auto). If you know your battery’s

effi ciency and want information on changing this setting from the Auto selec-

tion, return to the Setup section of this manual.

06 BM: TECH – These menu selections allow you to access the system information used to assist service technicians in troubleshooting the battery

monitor or the charging system.

•

•

: Ready – The battery monitor is connected and actively monitoring

BM

the battery system.

Info: ME-RC50 remotes with a revision of 2.6 or later have the Batt

AmpHr function also available from this menu. Refer to Section 3.3

for more info.

BM Rev – This read only menu displays the fi rmware revision level of

the connected battery monitor. If the battery monitor is not connected

or not communicating, the display will show “0.0”.

Min DC – This menu displays the lowest battery voltage since the

last reset. The voltage shown on the display is averaged each second,

and is helpful when troubleshooting or detecting an over-discharge

condition.

To reset this display, press and hold the rotary SELECT knob for 5 seconds

while the Min DC display is shown. After this value has been reset, the

display will begin monitoring and showing new minimum DC input values.

If the battery monitor is not connected or not communicating, the display

will show “0.0”.

Max DC – This menu displays the highest battery voltage since the last

•

reset. The voltage shown on the display is averaged each second, and

this allows you to check your charging system (battery charger, charge

controller, etc.) to ensure the charging voltage has been attained. This

display is also helpful when troubleshooting or detecting if an over-charge

condition has occurred.

To reset this display, press and hold the rotary SELECT knob for 5 seconds

while the Max DC display is shown. After this value has been reset, the

display will begin monitoring and showing new maximum DC input values. If

the battery monitor is not connected or not communicating, the display will

show “0.0”.

15 © 2010 Magnum Energy, Inc.

Page 20

Using the ME-ARC50 Remote with the BMK

4.0 Using the ME-ARC50 Remote with the BMK

This section discusses how to set up and operate the BMK using the ME-ARC50

remote. It also shows what BMK menu options are available using this remote.

The fi rst section provides information about Charge Effi ciency and how to

manually access/adjust this setting. Normally, the ME-BMK battery monitor

automatically calculates the battery’s effi ciency.

Info: The factory default charge effi ciency setting is Auto. This set-

ting allows the charging effi ciency to be automatically calculated.

In most circumstances, the Auto setting will determine the best

charge effi ciency.

CAUTION: If you do not know your battery’s charging effi ciency,

leave it at the factory default setting. If the setting is manually set

but incorrect, the state-of-charge information will become more

inaccurate with every charge.

What is Charge Effi ciency? When a certain amount of energy is removed or

discharged from the battery, this removed energy will need to be returned to

keep the batteries at a 100% state of charge. As batteries are being charged,

they lose energy; either in the form of heat, or while gassing. This loss of energy

while charging means the battery will not be fully charged if you only return the

current that was removed. To compensate for the battery’s ineffi ciencies while

charging, a charge effi ciency setting is provided. The charge effi ciency setting

compensates the AH I/O (Amp-Hrs In/Out) reading by ensuring the amp-hrs

returned to the battery are greater than the amp-hrs removed.

For example, if your AH I/O display reads 000 and you begin powering a 25

amp load for two hours, the display will show -050. This indicates that you

have discharged 50 amp-hrs (2 x 25) from the battery. If the charge effi ciency

setting is set to 95%, then as you begin charging and return 50 amp-hrs, the

AH I/O reading will be less than zero, indicating that the amp-hours removed

have not been fully returned. The 95% charge effi ciency setting requires 52.5

amp-hours (50/95) to be returned before the AH I/O returns to 0.

4.1 Accessing the Charge Effi ciency Menu Item

On the ME-ARC50 remote, press the SETUP pushbutton and rotate the SE-

LECT knob until the 05 BMK Setup menu appears. Once the 05 BMK Setup

menu appears, press the SELECT knob to access the 05A Charge Eff menu

item (see Figure 4-1).

SETUP

press

Figure 4-1, Accessing the Charge Efficiency Menu Item (ME-ARC50)

Info: For additional information on navigating the remote display,

see the ME-ARC50 (PN: 64-0030) Owner’s Manual. See Figures 4-3

and 4-4 for complete maps of the menu items and adjustable settings available for the ME-BMK when using the ME-ARC50 remote

control.

© 2010 Magnum Energy, Inc. 16

rotate

to

Status…

05 BMK Setup

press to

select

Page 21

Using the ME-ARC50 Remote with the BMK

4.2 Adjusting the Charge Effi ciency Setting

The Charge Effi ciency setting allows the battery monitor to calculate the battery’s

charge effi ciency. The charge effi ciency can be calculated automatically using the

Auto setting, or can be manually programmed by the user (see Figure 4-2).

The battery monitor is shipped with the charge effi ciency set to Auto. This allows

the battery monitor to automatically calculate variables that affect the charging

effi ciency such as battery type, battery age, and how the batteries are maintained

– which is not always constant. With the Auto setting, the effi ciency is recalculated

each time the batteries reach a 100% state of charge.

This setting can also be manually adjusted from 50% to 97% if the battery’s

charge effi ciency is known. When using a setting other than the Auto setting, the

battery monitor will use the manual setting to calculate the AH I/O display. For

example, if you set the charge effi ciency to 90% and 100 amp-hrs are removed

from the battery, the AH Net display would read 000 only after 111AH have been

returned to the battery.

SETUP

press

Set Charge Eff

Auto

rotate to

Status…

05 BMK Setup

Set Charge Eff

50%

press to select

(press again to adjust)

Set Charge Eff

60%

rotate to

desired

selection:

.......

press to

save

Set Charge Eff

97%

Figure 4-2, Adjusting the Charge Efficiency Setting (ME-ARC50)

If the charge effi ciency is manually set and inaccurate, the SOC information will

be more inaccurate with every charge. For this reason, continually monitor the

AH I/O reading under the ME-ARC50 remote’s METER pushbutton.

To access the AH I/O reading: press the METER pushbutton, turn the SELECT

knob until the 04 BMK Meters menu appears, and then press the SELECT

knob. Turn the SELECT knob until the 04E AH In/Out display appears.

After several charge and discharge cycles (below 80% SOC), the AH I/O read-

ing should be slightly positive when the SOC display reads 99%.

To view the SOC display: press the METER pushbutton and turn the SELECT

knob until the 04 BMK Meters menu appears. Press the SELECT knob, and

then turn the SELECT knob until the 04B SOC display appears. If the AH I/O

reading is below 000 (negative number) when the SOC display reads 99%,

then increase the charge effi ciency setting. If you fi nd that the AH I/O reading

is substantially above zero when the SOC display reads 99%, then decrease

the charge effi ciency setting.

4.3 Adjusting the AmpHr Size Setting

It’s important that the AmpHr Size setting is correct or else the calculations used

to determine the battery’s SOC display will be inaccurate.

To adjust the AmpHr Size setting: press the SETUP pushbutton and turn

the SELECT knob until the 05 BMK Setup menu appears. Press the SELECT

knob to display the 05A Charge Eff menu item. Turn the SELECT knob to

display the 05B AmpHour Size menu with the current AmpHrs Size setting

shown. Press the SELECT knob to access the Set AmpHr Size function. Turn

the SELECT knob to adjust the AmpHr Size setting. Press the SELECT knob

to select and save the new setting.

17 © 2010 Magnum Energy, Inc.

Page 22

Using the ME-ARC50 Remote with the BMK

(press and hold the SELECT knob

for 5 seconds to reset values)

4.4 ME-ARC50 Remote’s BMK Menu Maps

The diagrams below are a complete overview of the battery monitor settings

and information displays available from the ME-ARC50 remote’s SETUP and

METER menus.

ME - ARC50 LEGEND

SETUP

Status…

05 BMK Setup

Menu Button

Inverter/Charger Status

Menu Item

05A Charge Eff

70%

*= indicates default setting

S = denotes pressing SELECT knob

= Resettable Menu Selections

(press and hold the SELECT knob

(press and hold the SELECT knob

for 5 seconds to reset values)

for 5 seconds to reset values)

SETUP

Menu Selection

Menu Settings

**= read only data

Status…

05 BMK Setup

S

05A Charge Eff

Auto*

S

Set Charge Eff

Auto,50% to 97%

05B AmpHour Size

400 AH*

S

Set AmpHour Size

200 AH to 2500 AH

Figure 4-3, ME-ARC50 SETUP Menu Map (Displays w/BMK Settings)

© 2010 Magnum Energy, Inc. 18

Page 23

Using the ME-ARC50 Remote with the BMK

METER

METER

Status…

04 BMK Meters

S

04A BMK Status

[Status]

04B SOC

** %

04C DC Volts-BMK

** VDC

04D DC Amps-BMK

** ADC

04E AH In/Out

** AH

04F Resettable AH

** AH

04G Total AH Out

**k AH

Status:

BMK Ready

Power-up Fault

No Comm

04H Minimum VDC

** VDC

04I Maximum VDC

** VDC

Figure 4-4, ME-ARC50 METER Menu Map (Displays w/BMK Settings)

19 © 2010 Magnum Energy, Inc.

Page 24

Using the ME-ARC50 Remote with the BMK

4.5 Operating the BMK using the ME-ARC50

This section explains how the ME-BMK battery monitor works, and how to use

the Magnum Energy ARC50 remote control to obtain battery bank information. It also covers the various LCD displays that are related to the battery

monitor and the status of the Sense Module’s LED indicator.

Info: For additional information on navigating the ARC50 remote

control, see the ME-ARC50 (PN: 64-0030) Owner’s Manual.

4.5.1 How does the Battery Monitor (ME-BMK) Operate? The

ME-BMK battery monitor uses a precision resistor known as a shunt to measure

current fl ow into and out of the battery. The shunt provides a small voltage

to the Sense Module that is proportional to the current fl ow. When current

starts fl owing into or out of the battery, the Sense Module measures the cur-

rent fl ow and determines the amount of current removed from and returned

to the battery. The amount of current (or amp-hours) removed or returned

is displayed on the remote control as the AH I/O (Amp-Hours In/Out). The

AH I/O number is compensated by a charging effi ciency value that accounts

for energy loses while charging, and is one of the factors used to determine

the battery’s State Of Charge (SOC).

The battery’s state of charge — which is the best indicator of the condition

of the batteries — is indicated on the SOC display. This display will show that

the batteries are fully charged (i.e., SOC = 100%) once the following three

conditions have been met:

The charging voltage has stabilized over a period of time.

1.

The charging current has decreased to a low percentage of the amp-

2.

hour capacity – normally less than 2%.

The amp-hours that were removed from the battery are within 1% of

3.

fully being returned.

After the batteries have reached 100% SOC and have discharged ≥ 0.5% of

the battery capacity setting, the charge effi ciency value will be recalculated

and the AH I/O read-out will reset to the recalculated value.

Info: To help maintain the accuracy of the SOC display and to keep

the batteries in good condition, they must on occasion be 100%

charged (approximately once a week).

Info: Charging from a generator (non-inverter topology) adds some

concern about the cost of fuel. A balance should be considered

between the use of fuel and the need to charge your batteries to

100% SOC – to maintain the full service life of a battery. Batteries

discharged to 50% SOC and then normally recharged to 85-90%

SOC would be an effi cient compromise between fuel cost and bat-

tery life.Trying to restore the last 10-15% of a full battery charge

requires a long time – typically several hours.

© 2010 Magnum Energy, Inc. 20

Page 25

Using the ME-ARC50 Remote with the BMK

4.6 ME-ARC50 METER Menu Items and Settings for BMK

Press the METER pushbutton, and then turn the SELECT knob to the 04 BMK

Meters menu to access the different meters that determine the status of the

battery system.

Press the

METER

pushbutton

Rotate the

SELECT knob to:

Press the SELECT

knob to “select” the

04 BMK Meter s

menu item

MET ER

Sta tus …

04 BMK Meters

Figure 4-5, Accessing the METER Menu Items (ME-ARC50)

04A BMK Status – This menu selection offers read only displays that give the

current operating status of the battery monitor. This selection also provides

information to determine if there is a power-up fault condition.

•

BM: Pwr-up Fault – The battery monitor faulted when it was powered-

up. The fault occurred because the power-up self-test failed. See the

Troubleshooting section.

•

BM: No Comm – The battery monitor is not communicating with the

remote. This typically means a ME-BMK is not installed in the system.

If installed, view the Sense Module LED and use Table 6-1 to help determine the issue.

•

04B SOC – This display is the best way to monitor the actual state of the

battery. The read only display shows the State Of Charge (SOC) for the connected battery bank. The SOC represents the condition of the battery as a

percentage of the available capacity left in the battery. The range is 0% to

100%, where 100% represents a fully charged battery and 0% means the

battery is completely discharged.

: Ready – The battery monitor is connected and actively monitoring

BM

the battery system.

When the Sense Module is fi rst connected, the batteries will need to be fully

charged (i.e., SOC = 100%) at least once to establish a SOC reference point.

While this reference point is being calculated, the display will show “Think’n”,

to indicate that the SOC reference point is being calculated. After the batteries are fully charged, the display will change from “Think’n” to “100%” and

begin to provide accurate SOC percentage values.

If the Sense Module is disconnected from power, this display resets to “Think’n”

and the batteries will require another full charge before this display begins

providing SOC percentage information.

Info: Try to limit battery discharging to 50% of capacity (keep

battery above 50% SOC). If batteries are allowed to be continually

discharged below 50% SOC, their effective service life will be considerably shorter. This 50% rule has been determined to be the best

compromise between available energy and the maximum number of

discharge cycles a battery can provide.

21 © 2010 Magnum Energy, Inc.

Page 26

Using the ME-ARC50 Remote with the BMK

04C DC Volts-BMK – This meter displays the real-time battery voltage from

07.00 to 70.00 volts (± 0.02 volts).

04D DC Amps-BMK – This meter displays the real-time charge current (amps

into the battery) or discharge current (amps out of the battery). Charging is

shown as a positive (+) number and discharging is shown as a negative (-)

number. The range is from ±0.1 to 999 amps, with a 1.0% accuracy.

04E AH In/Out – This meter displays the amp-hours returned to or removed

from the battery. When this value is positive, it represents amp-hours returned

to the battery during any subsequent charging. A negative value represents

amp-hours removed from a full battery. The range is ±32,768 AH.

When using the charge effi ciency’s Auto setting, the AH I/O value is recal-

culated after the battery has been fully charged (reaching 100% SOC) and

≥0.5% of the battery capacity has been discharged. If the Sense Module is

disconnected from power, the displayed AH I/O value resets to zero.

Info: The AH I/O display correlates with the 05B AmpHour Size set-

ting (under SETUP button) to help determine the 04B SOC display.

AH I/O example – if you run a 10 amp load for three hours, the

display will show -30 AH. When you begin charging, the display will

count from -30 AH back toward 0 AH.

04F Resetable AH – This meter displays the total amp-hours removed from

the battery since it was last reset. This display can be used as a battery load

indicator to help identify and monitor the battery load consumption. The range

is 0 to 65,535.0 amp-hours (0.1 amp-hour resolution).

To reset the AmpHrs value to zero, press and hold the rotary SELECT knob for

>5 seconds when the Resetable AH display is shown. After this display has been

reset, it will begin calculating and displaying new rAH Out values. This display

automatically resets to zero if the Sense Module is disconnected from power.

04G Total AH Out – This meter displays the total amp-hours removed from

the battery since the Sense Module was fi rst connected. This display can be

used as a battery service life indicator. The value is displayed in 0.1k [or 100

amp-hours (“k” equals 1000)] resolution up to a maximum of 6,553.5k amphours (6,553,500 amp-hours). The displayed number resets to 0.0k when the

Sense Module is disconnected from power.

04H Minimum VDC – This menu displays the lowest battery voltage since

the last reset. The voltage shown on the display is averaged each second, and is helpful when troubleshooting or detecting an over-discharge

condition. To reset this display, press and hold the rotary SELECT knob for 5

seconds while the Minimum VDC display is shown. After this value has been

reset, the display will begin monitoring and showing new minimum DC input

values. If the battery monitor is not connected or not communicating, the

display will show “0.0”.

04I Maximum VDC – This menu displays the highest battery voltage since the

last reset. The voltage shown on the display is averaged each second, and this

allows you to check your charging system (battery charger, charge controller,

etc.) to ensure the charging voltage has been attained. This display is also helpful when troubleshooting or detecting if an over-charge condition has occurred.

To reset this display, press and hold the rotary SELECT knob for 5 seconds

while the Maximum VDC display is shown. After this value has been reset, the

display will begin monitoring and showing new maximum DC input values. If

the battery monitor is not connected or not communicating, the display will

show “0.0”.

© 2010 Magnum Energy, Inc. 22

Page 27

Using the ME-RTR Router with the BMK

5.0 Using the ME-RTR Router with the BMK

This section discusses how to set up and operate the BMK using the ME-RTR router.

It also shows what BMK menu options are available using the router.

The fi rst section provides information about Charge Effi ciency and how to

manually access/adjust this setting. Normally, the ME-BMK battery monitor

automatically calculates the battery’s effi ciency.

Info: The factory default charge effi ciency setting is Auto. This set-

ting allows the charging effi ciency to be automatically calculated.

In most circumstances, the Auto setting will determine the best

charge effi ciency.

CAUTION: If you do not know your battery’s charging effi ciency,

leave it at the factory default setting. If the setting is manually set

but incorrect, the state-of-charge information will become more

inaccurate with every charge.

What is Charge Effi ciency? When a certain amount of energy is removed or

discharged from the battery, this removed energy will need to be returned to

keep the batteries at a 100% state of charge. As batteries are being charged,

they lose energy; either in the form of heat, or while gassing. This loss of energy

while charging means the battery will not be fully charged if you only return the

current that was removed. To compensate for the battery’s ineffi ciencies while

charging, a charge effi ciency setting is provided. The charge effi ciency setting

compensates the AH I/O (Amp-Hrs In/Out) reading by ensuring the amp-hrs

returned to the battery are greater than the amp-hrs removed.

For example, if your AH I/O display reads 000 and you begin powering a 25

amp load for two hours, the display will show -050. This indicates that you

have discharged 50 amp-hrs (2 x 25) from the battery. If the charge effi ciency

setting is set to 95%, then as you begin charging and return 50 amp-hrs, the

AH I/O reading will be less than zero, indicating that the amp-hours removed

have not been fully returned. The 95% charge effi ciency setting requires 52.5

amp-hours (50/95) to be returned before the AH I/O returns to 0.

5.1 Accessing the Charge Effi ciency Menu Item

On the ME-RTR router, navigate to the BMK Home screen (see the ME-RTR

Owner’s Manual, PN: 64-0030, for information on how to access the router’s

BMK Home screen). Press the SETUP pushbutton, and then rotate the

SELECT knob until the 05A Charge Eff menu appears (see Figure 5-1). Press

the SELECT knob to access the Set Charge Eff function where you can adjust

the current charge effi ciency setting.

From the BMK

Home screen:

Battery Monitor

Soc=**% *Hrs

**VDC ** ADC

P## ACC BMK Home

Figure 5-1, Accessing the Charge Effi ciency Menu Item (ME-RTR)

23 © 2010 Magnum Energy, Inc.

SETUP

press

rotate

to:

05A Charge Eff

Auto

P## View BMK Setup

press to

select

Page 28

Using the ME-RTR Router with the BMK

5.2 Adjusting the Charge Effi ciency Setting

The Charge Effi ciency setting allows the battery monitor to calculate the battery’s

charge effi ciency. The charge effi ciency can be calculated automatically using the

Auto setting, or can be manually programmed by the user (see Figure 5-2).

The battery monitor is shipped with the charge effi ciency set to Auto. This allows

the battery monitor to automatically calculate variables that affect the charging

effi ciency such as battery type, battery age, and how the batteries are maintained

– which is not always constant. With the Auto setting, the effi ciency is recalculated

each time the batteries reach a 100% state of charge.

This setting can also be manually adjusted from 50% to 97% if the battery’s

charge effi ciency is known. When using a setting other than the Auto setting,

the battery monitor will use the manual setting to calculate the AH I/O display.

For example, if you set the charge effi ciency to 90% and 100 amp-hrs are

removed from the battery, the AH Net display would read 000 only after 111AH

have been returned to the battery.

From t h e BMK

Home screen:

SETUP

press

Set Charge Eff

Auto

P## edit BMK Setup

Figure 5-2, Adjusting the Charge Effi ciency Setting (ME-RTR)

If the charge effi ciency is manually set and inaccurate, the SOC informa-

tion will be more inaccurate with every charge. For this reason, continually

monitor the AH I/O reading under the router’s METER pushbutton.

To access the AH I/O reading: from the BMK Home screen, press the

METER pushbutton. The 04A BMK SOC display appears. Turn the SELECT

knob until the 04D AH In/Out menu appears.

After several charge and discharge cycles (below 80% SOC), the AH I/O

reading should be slightly positive when the SOC display reads 99%.

To view the SOC display: from the BMK Home screen, press the METER

pushbutton. The 04A BMK SOC menu appears. If the AH I/O reading is

below 000 (negative number) when the SOC display reads 99%, then

increase the charge effi ciency setting. If you fi nd that the AH I/O reading is

substantially above zero when the SOC display reads 99%, then decrease

the charge effi ciency setting.

rotate to :

05A Charge Eff

Auto

P## View BMK Setup

Set Charge Eff

50 %

P## EDIT BMK Setup

press to adjust

setting

....

rotate to

desired

setting:

Set Charge Eff

97 %

P## EDIT BMK Setup

press to

save

5.3 Adjusting the AmpHrs Setting

It’s important that the AmpHrs setting is correct or else the calculations used

to determine the battery’s SOC display will be inaccurate.

To adjust this setting: from the BMK Home screen, press the SETUP

pushbutton. Turn the SELECT knob until the 05B AmpHrs Size display

appears. Press the SELECT knob to access the Set AmpHrs Size function.

Turn the SELECT knob to adjust the AmpHrs setting. Press the SELECT

knob to select and save the new setting.

© 2010 Magnum Energy, Inc. 24

Page 29

Using the ME-RTR Router with the BMK

(press and hold the SELECT knob for 5

seconds to reset values)

5.4 ME-RTR Router’s BMK Menu Maps

The diagrams below are a complete overview of the battery monitor settings

and information displays available from the ME-RTR router’s SETUP and

METER menus.

ME - RTR LEGEND

SETUP

05B AmpHrs Size

400AH*

P## View BMK Setup

S

= denotes pressing SELECT knob

* = indicates default setting

** = read only data

= Resettable Menu Selections

( press and hold the SELECT knob for

5 seconds to reset values )

Menu Button

Menu Selection

Menu Settings

Menu Settings

Port #/Screen

(press and hold the SELECT knob for 5

seconds to reset values)

Battery Monitor

Status AmpHrs I /O

DC Volts DC Amps

Port # Screen

SETUP

05A Charge Eff

Auto*

BMK Home screen

(see ME-RTR Owner’s Manual

for info on accessing)

P## View BMK Setup

S

Set Charge Eff

Auto, 50% to 99%

P## edit BMK Setup

05B AmpHrs Size

400AH*

P## View BMK Setup

S

Set AmpHrs Size

200AH to 2500AH

P## edit BMK Setup

Figure 5-3, ME-RTR SETUP Menu Map (Displays w/BMK Settings)

25 © 2010 Magnum Energy, Inc.

Page 30

Using the ME-RTR Router with the BMK

Battery Monitor

Status AmpHrs I /O

DC Volts DC Amps

Port # Screen

METER

METER

04A BMK SOC

** %

P#A View BMK Meter

04D AH In/Out

** AHrs

P#A View BMK Meter

04E Resetable AHrs

**Ahrs

P#A View BMK Meter

04H Maximum VDC

** VDC

BMK Home screen

(see ME-RTR Owner’s Manual

for info on accessing)

04B DC Volts-BMK

** VDC

P#A View BMK Meter

04C DC Amps-BMK

** ADC

P#A View BMK Meter

04F Total kAHrs Out

** kAH

P#A View BMK Meter

04G Minimum VDC

** VDC

P#A View BMK Meter

Figure 5-4, ME-RTR METER Menu Map (Displays w/BMK Settings)

P#A View BMK Meter

5.5 Operating the BMK using the ME-RTR

This section explains how the ME-BMK battery monitor works, and how to

use the Magnum Energy RTR router to obtain battery bank information. It

also covers the various LCD displays that are related to the battery monitor

and the status of the Sense Module’s LED indicator.

Info: Battery monitor menu items are accessed via the RTR router’s

BMK Home screen. For information on how to access the BMK

Home screen or otherwise navigate the RTR router, see the ME-RTR

(PN: 64-0020) Owner’s Manual.

5.5.1 How does the Battery Monitor (ME-BMK) Operate? The

ME-BMK (battery monitor kit) uses a precision resistor known as a shunt to

measure current fl ow into and out of the battery. The shunt provides a small

voltage to the Sense Module that is proportional to the current fl ow. When

current starts fl owing into or out of the battery, the Sense Module measures

the current fl ow and determines the amount of current removed from and

returned to the battery. The amount of current (or amp-hours) removed or

returned is displayed on the router as the AH I/O (Amp-Hours In/Out). The

AH I/O number is compensated by a charging effi ciency value that accounts

for energy loses while charging, and is one of the factors used to determine

the battery’s State Of Charge (SOC).

© 2010 Magnum Energy, Inc. 26

Page 31

Using the ME-RTR Router with the BMK

The battery’s state of charge — which is the best indicator of the condition

of the batteries — is indicated on the SOC display. This display will show that

the batteries are fully charged (i.e., SOC = 100%) once the following three

conditions have been met:

1.

The charging voltage has stabilized over a period of time.

2.

The charging current has decreased to a low percentage of the amphour capacity – normally less than 2%.

3.

The amp-hours that were removed from the battery are within 1% of

fully being returned.

After the batteries have reached 100% SOC and have discharged ≥ 0.5% of

the battery capacity setting, the charge effi ciency value will be recalculated

and the AH I/O read-out will reset to the recalculated value.

Info: To help maintain the accuracy of the SOC display and to keep

the batteries in good condition, they must on occasion be 100%

charged (approximately once a week).

Info: Charging from a generator (non-inverter topology) adds some

concern about the cost of fuel. A balance should be considered

between the use of fuel and the need to charge your batteries to

100% SOC – to maintain the full service life of a battery. Batteries

discharged to 50% SOC and then normally recharged to 85-90% SOC

would be an effi cient compromise between fuel cost and battery life.

Trying to restore the last 10-15% of a full battery charge requires a

long time – typically several hours.

5.6 ME-RTR METER Menu Items and Settings for BMK

From the BMK Home screen, press the METER pushbutton, and then turn

the SELECT knob on the ME-RTR router to access the different meters that

determine the status of the battery system.

From t h e BMK

Home screen:

press the

METER

pushbutton

METER

Rotate the

SELECT knob to:

04A BMK SOC

** %

P#A View BMK Meter

04H Maximum VDC

** VDC

P#A View BMK Meter

Figure 5-5, Accessing the METER Menu Items (ME-RTR)

Press the SELECT

knob to “select” a

METER menu item

27 © 2010 Magnum Energy, Inc.

Page 32

Using the ME-RTR Router with the BMK

04A BMK SOC – This menu selection offers read only displays that give the

current operating status of the battery monitor if there is a fault condition.