Page 1

ME-AGS-S

Automatic Generator Start

For Standalone Systems

Owner’s Manual

Page 2

Disclaimer of Liability

Since the use of this manual and the conditions or methods of installation,

operation, use and maintenance of the ME-AGS-S (Auto Generator Start –

Standalone) is beyond the control of Magnum Energy Inc. , this company does

not assume responsibility and expressly disclaims liability for loss, damage or

expense, whether direct, indirect, consequential or incidental, arising out of

or anyway connected with such installation, operation, use, or maintenance.

Due to continuous improvements and product updates, the images shown in

this manual may not exactly match the unit purchased.

Restrictions on Use

The ME-AGS-S may only be used in life-support devices or systems with the

express written approval of Magnum Energy. Failure of the ME-AGS-S can

reasonably be expected to cause the failure of that life-support device or

system, or to affect the safety or effectiveness of that device or system. If

the ME-AGS-S fails, it is reasonable to assume that the health of the user or

other persons may be endangered.

Copyright Notice

Copyright © 2013 by Magnum Energy , Inc. All rights reserved. P ermission to

copy, distribute, and/or modify this document is prohibited without express

written permission by Magnum Energy, Inc.

Safety Symbols

To reduce the risk of electrical shock, fi re, or other safety hazard, the fol-

lowing safety symbols have been placed throughout this manual to indicate

dangerous and important safety instructions.

WARNING: This symbol indicates that failure to take a specifi ed ac-

tion could result in physical harm to the user.

CAUTION: This symbol indicates that failure to take a specifi ed action

could result in damage to the equipment.

Info: This symbol indicates information that emphasizes or supplements important points of the main text.

IMPORTANT PRODUCT SAFETY INSTRUCTIONS

This manual contains important safety instructions that must be followed

during the installation and operation of this product. Read all instructions

and safety information contained in this manual before installing or using

this product.

WARNINGS:

• All electrical work must be performed in accordance with local,

state, and federal electrical codes.

• This product is designed for indoor/compartment installation. It

must not be exposed to rain, snow, moisture, or liquids of any type.

• Use insulated tools to reduce the chance of electrical shock or accidental short circuits.

• Remove all jewelry such as rings, watches, bracelets, etc., when

installing or performing maintenance on the ME-AGS-S and generator system.

• Disconnect the generator’s starting battery to prevent accidental

starting during installation of this product.

i © 2013 Magnum Energy, Inc.

Page 3

Table of Contents

1.0 Introduction .......................................................................... 1

1.1 ME-AGS-S Components/Features .............................................2

2.0 Installation ........................................................................... 4

2.1 Installation Requirements .......................................................4

2.2 Required Components and Tools ..............................................6

2.3 Mounting Procedure ...............................................................6

2.4 Connecting the Communication Cable ......................................8

2.5 ME-AGS-S Terminal Block Wiring .............................................9

2.6 Warning Label ..................................................................... 13

2.7 Common ME-AGS-S Generator Wiring Diagrams ...................... 13

3.0 Setup .................................................................................. 17

3.1 Internal Settings ................................................................. 17

3.2 External Settings ................................................................ 19

3.3 AGS Functional Tests ...........................................................21

4.0 Operation ............................................................................ 22

4.1 AGS Controller Operation LED Indicators ................................ 22

4.2 Remote Switch Operation ..................................................... 23

4.3 AGS System Operation.........................................................24

5.0 Troubleshooting .................................................................. 25

6.0 Limited Warranty ................................................................ 26

6.1 How to Receive Repair Service ..............................................27

A-1 Appendix ............................................................................. 28

List of Figures

Figure 1-1, ME-AGS-S Remote Switch Features ......................................2

Figure 1-2, ME-AGS-S Communications Cable .......................................2

Figure 1-3, ME-AGS-S Controller Features .............................................3

Figure 2-1, ME-AGS-S System Diagram ................................................5

Figure 2-2, Controller Dimensions ........................................................7

Figure 2-3, Remote Dimensions ...........................................................7

Figure 2-4, Communication Cable Connection ........................................8

Figure 2-5, Communication Cable (Data Type) .......................................8

Figure 2-6, Generator Run Sense Options ........................................... 10

Figure 2-7, Wiring to the AGS Controller’s Terminal Block ...................... 12

Figure 2-8,

Figure 2-9, Two-wire Start Type Generators ........................................ 14

Figure 2-10, Three-wire Momentary Type Generators ........................... 15

Figure 2-11, Three-wire Maintain Type Generators ...............................16

Figure 3-1, Inside the AGS Controller .................................................17

Figure 3-2, DC Voltage Settings ......................................................... 17

Figure 3-3, External Settings ............................................................. 19

Figure 4-1, Controller Front Panel Controls and Indicators ..................... 22

Figure 4-2, Remote Switch Controls and Indicators .............................. 23

Warning Label ................................................................. 13

List of Tables

Table 3-1, GEN TYPE Settings ............................................................ 18

Table 3-2, ME-AGS-S Default Settings ................................................ 19

Table 6-1, Troubleshooting Guide ....................................................... 25

© 2013 Magnum Energy, Inc. ii

Page 4

Introduction

1.0 Introduction

The Automatic Generator Start – Standalone version (ME-AGS-S) from Mag-

num Energy is designed as a standalone device. It will automatically start your

generator based on low battery voltage and/or a high temperature condition.

Info: This manual is for the ME-AGS-S with revision 5.0 or higher; see

Figure 3-1 on page 17 for info on how to locate your revision level.

Info: If you are using a Magnum inverter/charger (provided with a

network port) and a ME-RC or ME-ARC remote, use the ME-AGS-N

(AGS – Network version) for full network capability of the AGS system.

This AGS is used to continuously monitor your battery system and/or the

surrounding area temperature, and to automatically start the generator when

the battery requires charging and/or power is needed to run an air conditioner

to cool down the surrounding area.

The temperature turn-on feature is useful in many applications. For example,

if you have an RV (recreational vehicle) coach in a hot environment, the AGS

monitors the coach temperature and turns on the generator to power the air

conditioner. This allows you to leave pets and precious items in your coach

while you enjoy a day away golfi ng, touring, or just sightseeing—all the while

knowing your coach will stay cool and comfortable. Even if you don’t have pets,

there’s nothing better than returning to a nice cool coach while dry camping

in hot weather. Plus, no more worrying about dead batteries.

The AGS system includes a controller with on-board adjustments and interfaces with a user-friendly remote control switch. The controller provides the

wiring interface for the battery bank and generator start/stop circuits. It has

adjustments for setting the generator’s run time, high temperature start,

and low battery voltage start; and if needed, the “Clock” and “Quiet Time”

adjustments can be set to comply with RV park and rest area nighttime low

noise requirements. The remote switch allows testing and activating the AGS

system and provides a LED indicator to display AGS system status information.

This AGS is compatible with most AC or DC generators with either two-wire or

three-wire start controls; such as Onan, Power T ech, Gener ac, Martin, Kohler,

Honda, Westerbeke, Y amaha, and many others. A list of gener ators that have

been successfully used with the AGS (along with their respective wiring diagrams) can be found at: www.magnumenergy.com/GenWiringDiagrams.htm

The standalone AGS is equipped with the following features:

• Compatible with 12, 24, or 48-volt systems

• Easily adjustable settings for run-time, low voltage, and high temperature start

• Quiet Time setting available to prevent generator oper ation during nighttime hours

• Compatible with any inverter/charger-based system

• Compatible with most AC or DC generators with either two-wire or threewire start controls

• TEST switch provides immediate confi rmation of installation wiring

• Removable 8-port terminal block – for easy wiring and power-down

• Front panel LED indicators for generator start/stop status and generator faults

1 © 2013 Magnum Energy, Inc.

Page 5

Introduction

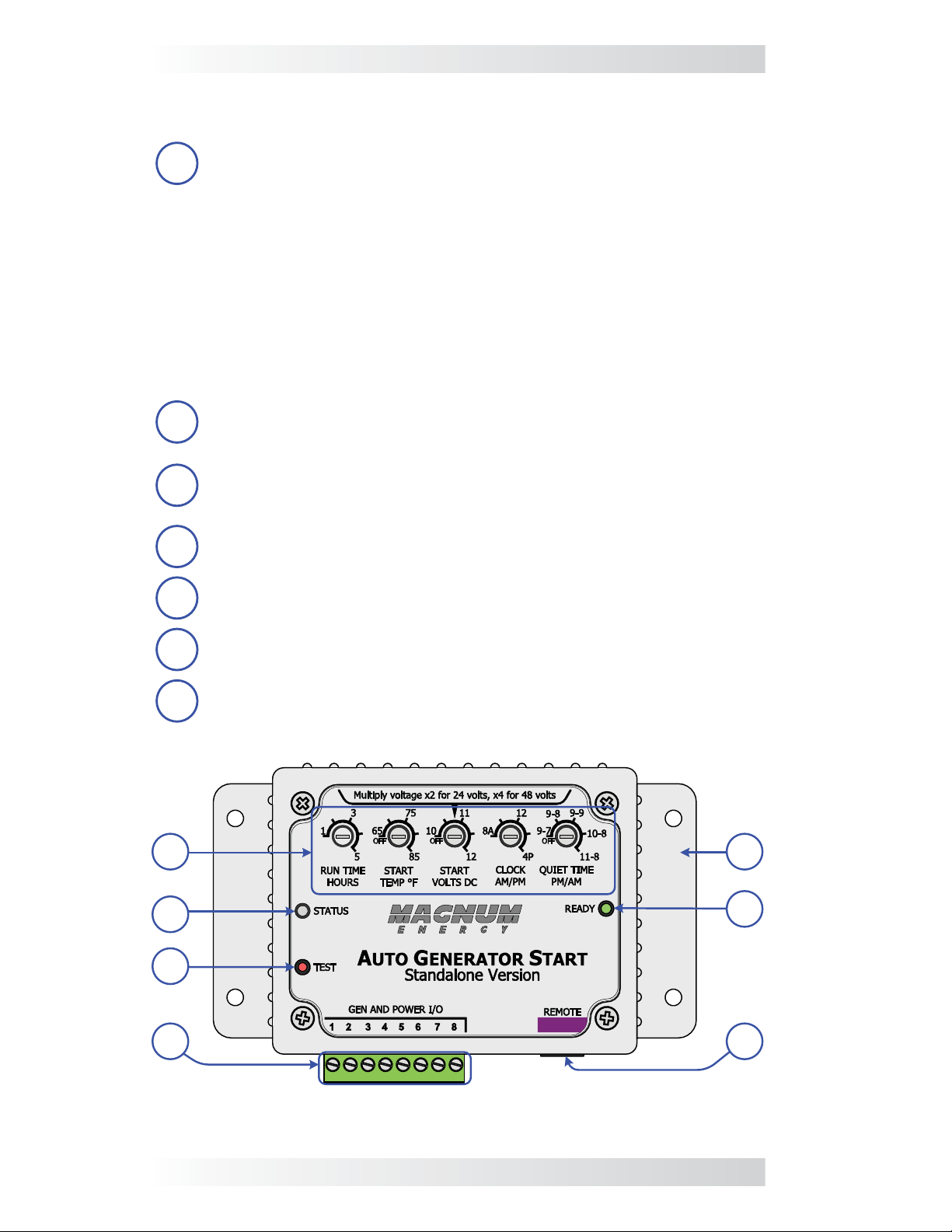

1.1 ME-AGS-S Components/Features

The ME-AGS-S is equipped with the following components and features:

• AGS Remote Switch • Communications Cable • AGS-S Controller

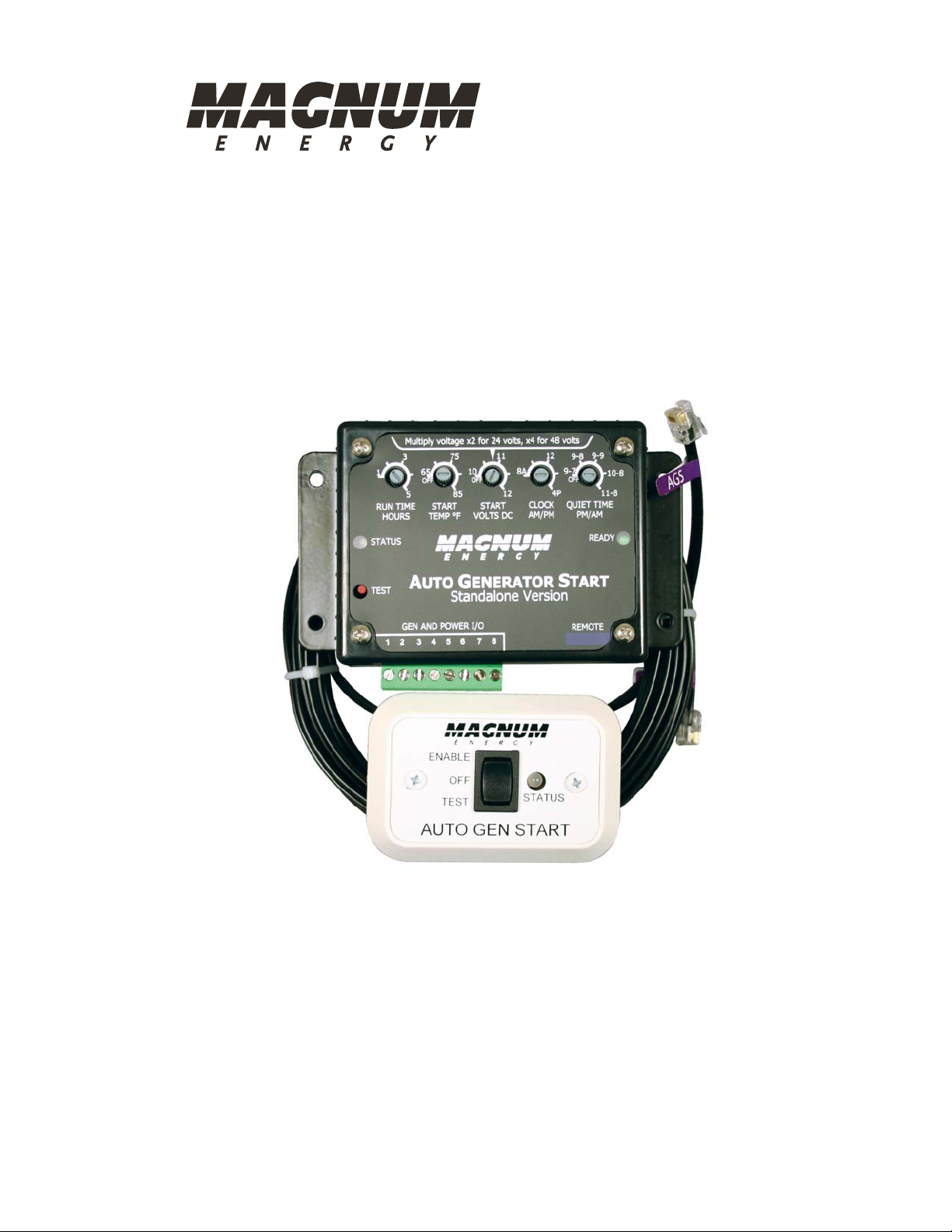

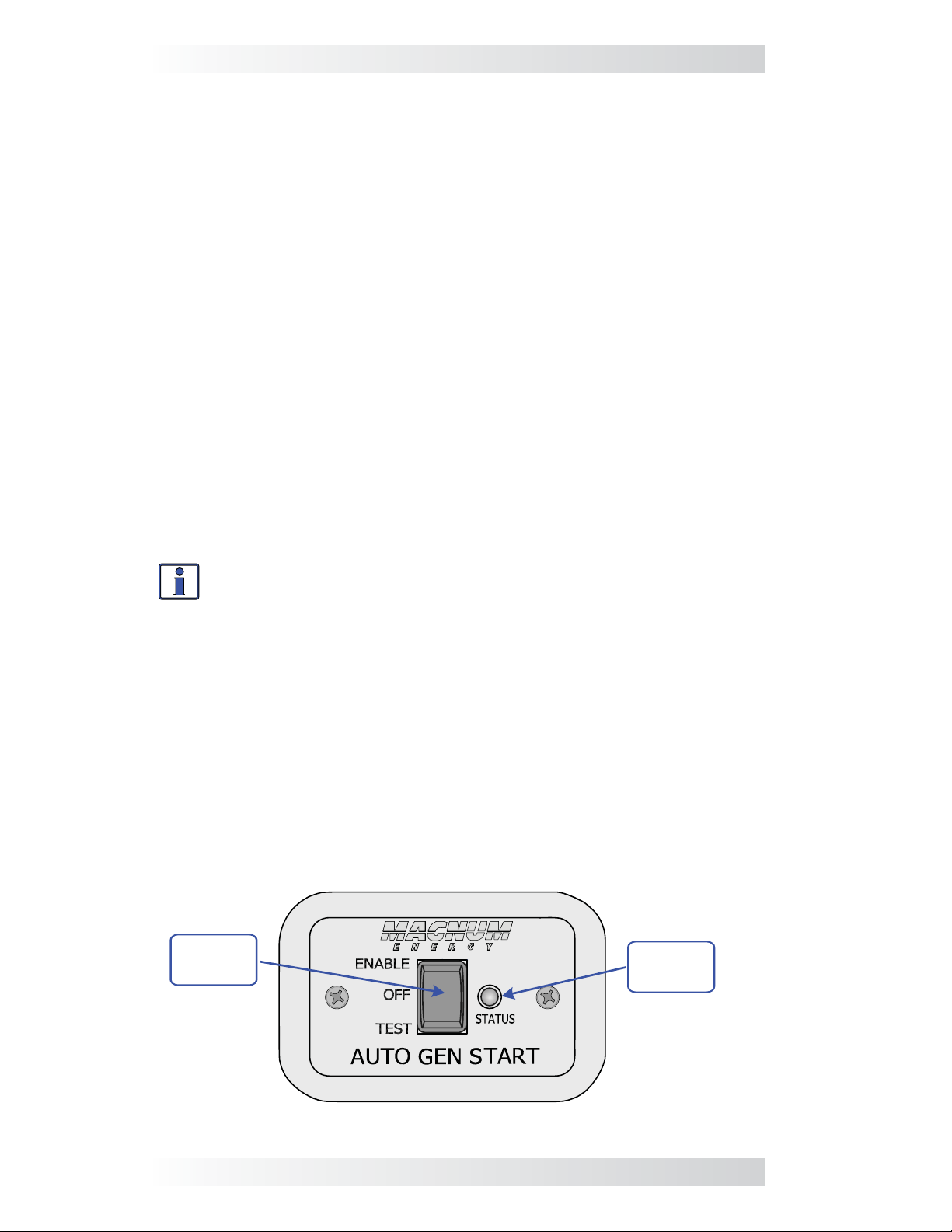

1.1.1 AGS Remote Switch

The AGS Remote Switch is the user interface display and connects to the

AGS controller through the communications cable.

Selector Switch – a switch that allows the AGS system to be

1

enabled for automatic generator operation and tested for correct

wiring.

• ENABLE – activates the AGS to monitor voltage and/or temperature to determine when to automatically start the generator.

• OFF – disables the AGS generator start/stop functions.

• TEST – initiates an automatic generator start/stop sequence for

testing generator wiring and operation.

STATUS Indicator – this bi-color (green or red) LED indicator

2

illuminates to provide information on AGS operation.

Temperature Sensor (internal) – location of the internal sensor

3

used to start the generator based on high temperature.

2

STATUS

1

Indicator

Selector

Switch

3

Temperature

Sensor (internal)

Figure 1-1, ME-AGS-S Remote Switch Features

1.1.2 AGS Communication Cable

A six-conductor, 25-foot cable used to carry power and data between the

remote and the controller.

Figure 1-2, ME-AGS-S Communications Cable

© 2013 Magnum Energy, Inc. 2

Page 6

Introduction

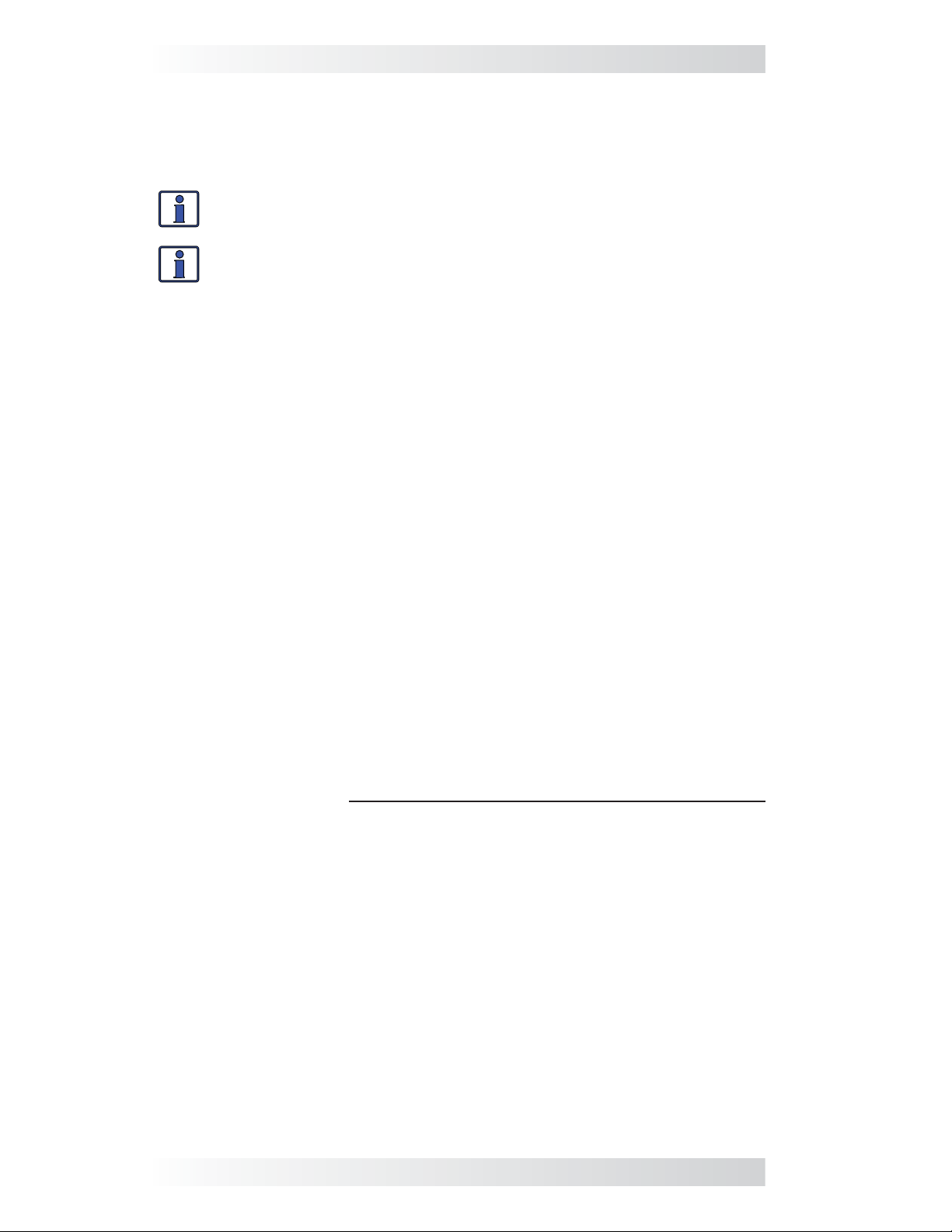

1.1.3 AGS Controller

The controller provides adjustments and the generator’s wiring connections.

AGS Adjustments (x5) – The thumb wheel adjustments allow the

1

AGS to be confi gured to your specifi c system preferences.

• RUN TIME HOURS – determines the length of time the generator

runs once the generator has automatically started.

• START TEMP °F – allows you to

value that causes the generator to automatically start.

• START VOLTS DC – allows you to enable and set a low battery

voltage value that causes the generator to automatically start.

• CLOCK AM/PM – determines the correct time, which in turn

allows the Quiet Time feature to function correctly.

• QUIET TIME PM/AM – used to prevent the generator from

starting during specifi c hours.

STATUS Indicator – this bi-color (green or red) LED indicator

2

illuminates to provide information on AGS operation.

TEST Switch – a momentary pushbutton switch that allows the

AGS system to be tested for correct wiring and generator start/stop

3

operation.

enable and set a high temperature

2

3

Wiring Terminal Block – this 8-port friction-fi t connector powers

4

the AGS and connects the generator’s start/stop and run sense wires.

Mounting Flange – used to secure the inverter to a shelf or wall.

5

READY Indicator – this green LED indicator illuminates to indicate

6

that the AGS is powered and the remote switch is connected.

REMOTE Connection Port (purple label) – a RJ12 port which

7

provides the connection point for the remote switch.

51

6

4

Figure 1-3, ME-AGS-S Controller Features

3 © 2013 Magnum Energy, Inc.

7

Page 7

Installation

2.0 Installation

Installing the ME-AGS-S is a simple process. Before installing, read this entire

section to familiarize yourself with all aspects of the installation; then, you

can thoroughly plan the details to ensure the overall system requirements

are accomplished. To assist you in planning and designing your installation,

review the basic system diagram shown in Figure 2-1.

WARNING: The ME-AGS-S is not an ignition-protection rated device

and should not be installed in any location that requires ignitionprotected equipment. To prevent fi re or explosion, do not install

the Auto Gen Start controller in any area with extremely fl ammable

liquids like gasoline or propane; or, in an area that contains connections between components of a fuel system.

CAUTION: Installations should be performed by qualifi ed personnel,

such as a licensed or certifi ed electrician. It is the installer’s respon-

sibility to determine which safety codes apply and to ensure that all

applicable installation requirements are followed. Applicable installation codes vary depending on the specifi c location and application.

CAUTION: Review the “Important Product Safety Information” on

the front inside cover page before any installation.

2.1 Installation Requirements

Review the following requirements before installing this device:

• For the AGS to automatically start and stop the generator properly, the

generator must include an electric start and an automatic choke. To

prevent generator damage and obtain reliable operation, use generator

models designed for unattended operation. These models should also

be equipped with remote operation connections and have protective

systems that cause the generator to shut down from low oil pressure,

over-temperature, starter lockout, and over-crank conditions.

• The ME-AGS-S controller is connected to the switch by a 25’ communica-

tions cable. Before installing the ME-AGS-S and connecting any wires,

determine: 1) the communications cable route throughout the home or

vehicle/boat from the controller to the switch, 2) the start/stop signal

wire route from the AGS controller to the generator, and 3) the wire route

from the AGS controller to the monitored battery bank.

Info: Two pigtail adapters (ME-PT1 and ME-PT2) are available to

externally enable the ME-AGS-S to automatically turn the generator on/off through a manually controlled switch or an automatically

controlled switching device. See Appendix A for more information.

• Always check for existing electrical, plumbing, or other areas of potential

damage BEFORE drilling or cutting into walls.

• If installing this device in a boat, RV , or truck, ensure the conductors passing through walls, bulkheads, or other structural members are protected

to minimize insulation damage such as chafi ng—which can be caused by

vibration or constant rubbing.

• Do not mount the AGS controller in a closed battery compartment or in

an area where water or any other liquid can enter the AGS and cause

shorting or corrosion.

• The AGS should be wired to not interfere with your air conditioner controls

or the manual start/stop switches on your generator.

© 2013 Magnum Energy, Inc. 4

Page 8

Installation

Automatic Generator Start (Standalone version)

ME-AGS-S

Remote connection

Generator start/stop wiring

Generator run signal

Battery voltage

Common battery negatives

(Monitored battery and

Generator starting battery)

Monitored Battery Bank Auto-Start Generator

Figure 2-1, ME-AGS-S System Diagram

5 © 2013 Magnum Energy, Inc.

Page 9

Installation

2.2 Required Components and Tools

2.2.1 List of supplied components in the ME-AGS-S:

• ME-AGS-S Owner’s Manual

• AGS controller (with four #8 x 3/4” Phillips mounting screws)

• AGS switch/bezel (with two #6 x 1” Phillips mounting screws)

• 25 ft communications cable

2.2.2 List of other required equipment and materials:

• 16 to 12 AWG wire for connecting the ME-AGS-S to the gener ator start/

stop circuit and to the battery bank

• In-line fuse holders (with 5-amp DC fuse)

2.2.3 Tools that may be required to install the ME-AGS-S:

• Phillips screwdriver (#2)

• Flat-blade screwdrivers

(1/4” and 1/8” blades)

• Wire stripper

• Cut-out tool (knife/saw)

• Drill bits (7/64” & 1/8”)

• Drill

• Level

• Pencil

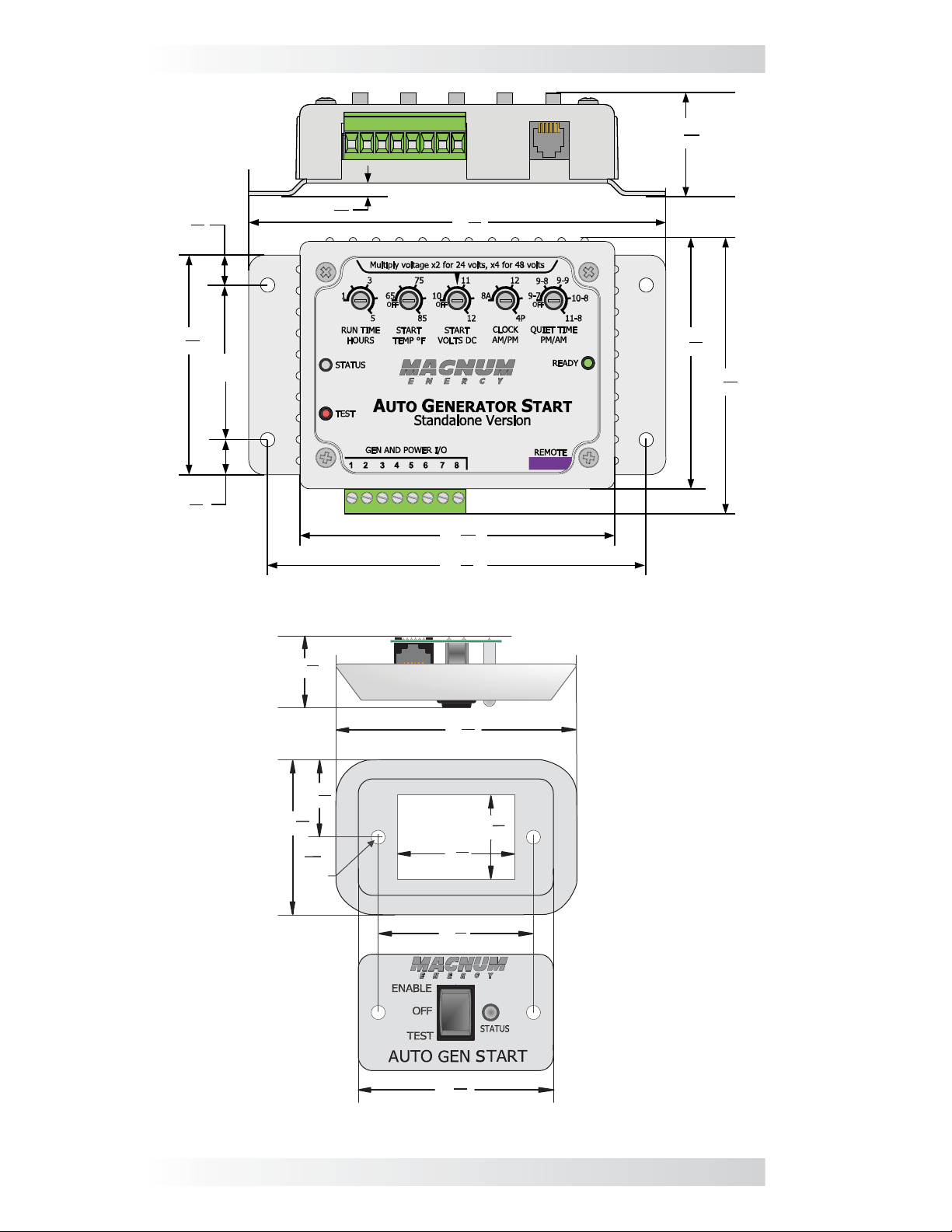

2.3 Mounting Procedure

2.3.1 Mounting the AGS Controller

1. Select a location that is clean, dry, and protected from extreme

temperatures to mount the controller

controller is mounted within easy access to the generator’s remote

switch wiring. Refer to Figure 2-2 for the controller’s dimensions.

Info: The controller/switch can be mounted in any direction. However,

allow ample room to

to view the LEDs for operational status and troubleshooting.

2. Remove the green 8-pin friction fi t connector from the controller by

pulling it straight out. Wait to plug this 8-pin connector back into the

AGS controller until after the installation is completed and the AGS

functional tests are performed in Section 3.3.

3. Mount the AGS controller using the four #8 x 3/4” screws provided.

2.3.2 Mounting the AGS Remote Switch

1. Select a location that is

extreme temperatures to mount the

access the switch and the

convenient,

. Wiring is much easier if the

adjustment dials, and

clean, dry, and protected from

remote switch.

Info: The temp sensor used to activate the temperature turn-on

feature is located on the back of the AGS switch. If using the temperature turn-on feature, the switch must be placed where the room

temperatures can be accurately determined by the sensor. DO NOT

mount the switch near window drafts, or heating and air conditioning

ducts, and avoid mounting it on exterior walls.

2. Cut a hole for the switch. See Figure 2-3 for switch and cutout dimensions.

3. Plug the communications cable into the RJ12 connector on the back of

the AGS switch (Section 2.4), and then feed the communication cable

(6-conductor data cable) through the opening and route it to the AGS.

Info: Use care in routing the cable to ensure the cable does not

become pinched or cut by rough or sharp edges. Leave enough slack

to allow movement of the cable once the installation is complete.

4. Mount the switch with its bezel to the wall using the two #6 x 1” screws

provided.

© 2013 Magnum Energy, Inc. 6

Page 10

9

16

3

”

7

8

4

”

3

16

2

”

1

16

4

”

3

8

”

3

8

5

”

1

4

3

”

7

16

”

2

”

5

16

1

”

3

16

”

cutout

"

drill

bit

2

"

1

"

1

"

1

"

3

"

1

"

2

"

2

"

1

8

7

16

1

4

5

16

7

64

1

8

3

4

5

8

3

16

Installation

Figure 2-2, Controller Dimensions

Remote

side

Remote

Bezel

Remote

face-plate

Figure 2-3, Remote Dimensions

7 © 2013 Magnum Energy, Inc.

Page 11

Installation

123

4

56

123

4

56

white

blue

TAB

TAB

2.4 Connecting the Communication Cable

After connecting one end of the communication cable to the back of the

AGS remote switch, connect the other end of the cable to the REMOTE port

(purple label) on the AGS controller (see Figure 2-4).

Info: The communication cable is a 6-conductor, fl at, data stan-

dard with RJ12 (6-position/6-wire) connectors on each end

(see Figure 2-5).

Info: The 25’ communications cable may be extended to a maximum

of 250 feet if needed.

ME-AGS-S Controller

Communications

Cable

Remote Switch

(backside)

Figure 2-4, Communication Cable Connection

2.4.1 Communication Cable

The 6-conductor communications cable has a RJ12 (6-position/6-wire) connector on each end and is wired as a data type cable. This means that when

the RJ12 connectors are held side by side with both of the connector tabs

facing the same way, the color of the conductors in each connector is the

same from top to bottom (as shown in Figure 2-5).

same colors

from top

to bottom

(tabs facing

toward you)

Figure 2-5, Communication Cable (Data Type)

© 2013 Magnum Energy, Inc. 8

Page 12

Installation

2.5 ME-AGS-S Terminal Block Wiring

The controller should now be mounted. For the following steps, refer to Figure

2-7 for reference when wiring the generator to the controller’s terminal block:

1. Unplug the green 8-port friction-fi t terminal block from the controller

by pulling it straight out. Ensure the openings are unscrewed enough to

allow the wires to be inserted.

CAUTION: DO NOT plug in the 8-port terminal block. After all

the wiring to the controller is complete and all the settings have been

confi gured, a power-up test will be performed Section 4: Operation.

DO NOT plug in the 8-port terminal block until then.

CAUTION: A fuse rated at 5 amps or less must be used to protect

all power circuits (except for ground connections) connected to the

AGS controller. Ensure the fuse is correctly rated for the wire size

used. Refer to national and local codes for rating and type. Normally ,

a minimum #16 AWG wire is required to use a 5-amp fuse.

Info: The green 8-port terminal block accepts CU/AL conductors from

2

#30 to #12 AWG (0.05 to 3.3 mm

).

2.5.1 Power Connections (Terminals 3 and 4)

2. Connect a wire (black) from the monitored battery bank’s negative terminal to Terminal #4 on the 8-port terminal block.

3. Connect a wire (red) with a 5-amp, in-line fuse from the monitored battery bank’s positive terminal to T erminal #3 on the 8-port terminal block.

2.5.2 Generator Run Sense Connection (Terminal 2)

T erminal #2 on the 8-port terminal block is used as a generator run sense (i.e. ,

switched B+ or a positive battery signal from the hour meter or gen running

light). This run sense voltage is used to determine that the generator is running

and to prevent another starter crank while the generator is already running.

Info: The run sense signal from the generator to Terminal #2 (positive) and Terminal #4 (negative) must be between 10-40 VDC and

only while the generator is running.

4. Connect a wire (preferably not black or red) from the generator’s run

sense output to Terminal #2 on the 8-port terminal block.

5. Connect the negative terminal of the monitored battery bank to Terminal

#4 (power negative) on the 8-port terminal block. Ensure the negative

terminal on the generator battery is referenced/connected to the negative terminal on the monitored battery.

Info: The negative side of the run sense signal from the generator

must be in common with the negative side of the monitored battery

bank. This ensures that the positive battery voltage (to T erminal #3)

and the positive run sense voltage (to Terminal #2) have a common

negative reference (to Terminal #4) and are correctly measured by

the ME-AGS-S.

9 © 2013 Magnum Energy, Inc.

Page 13

Installation

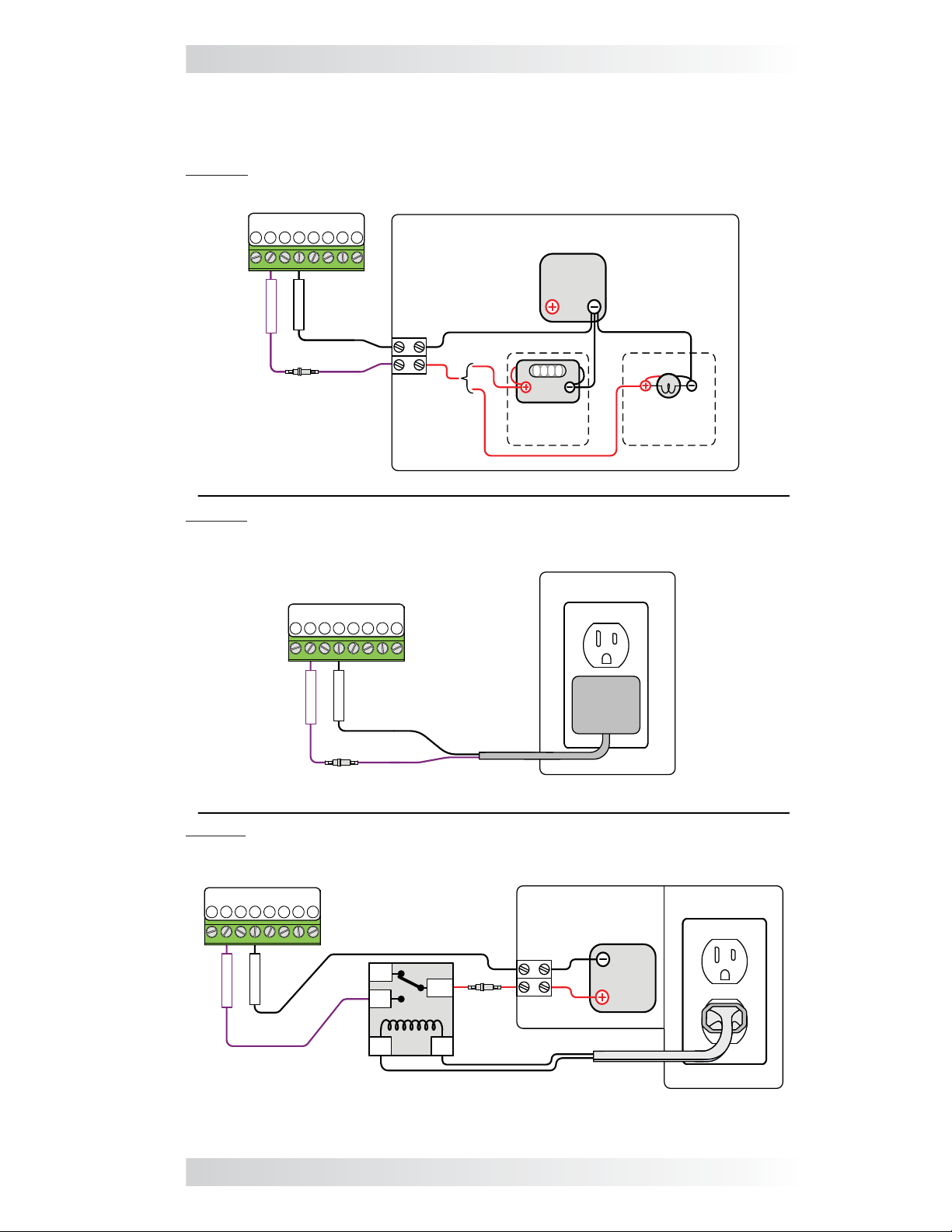

What if my generator does not have a run sense output? If your gen-

erator is not equipped with a generator run sense output, review Figure 2-6

for alternative options.

Option 1 – Tap into the positive side of the generator’s hour meter or running light;

Option 1 - Tap into the positive side of the generator’s hour meter or running light; ensure

ensure the voltage is only 10-40 VDC while the generator is running.

the voltage is 10 to 40 VDC only while the generator is running.

AGS Terminal Block Ports:

1 2 3 4 567 8

negative

run sense

DC Fuse

(5A max)

Option 2 – Use a 120 VAC to 12 VDC step-down transformer (normally used to charge

Option 2 - Use a 120VAC to 12VDC step-down transformer (normally used to charge power

power equipment batteries) and plug into the generator’s 120 VAC output. The step-

equipment batteries) and plug into the generator’s 120VAC output. The step-down

down transformer provides 12 VDC output only while the generator is running.

transformer provides 12 VDC output only while the generator is running.

Inside Generator

OR

Generator

Hour Meter

Generator

Battery

0123

Generator

Running Lamp

On Generator

AGS Terminal Block Ports:

1 2 3 4 567 8

120VAC Outlet

120VAC IN

negative

run sense

DC Fuse

(5A max)

Option 3 – Use an external 120 VAC coiled relay to bring the generator’ s battery voltage

Option 3 – Use an external 120VAC coiled relay to bring the generator's battery voltage to

to the AGS run sense port (AGS Terminal Block Port #2) only while the generator is

the AGS run sense port (AGS Terminal Block Port #2) only while the generator is running.

running. The generator’s battery voltage must be 10-40 VDC.

The generator’s battery voltage must be 10 to 40 VDC.

AGS Terminal Block Ports:

1 2 3 4 567 8

negative

run sense

NO

NC

COM

DC Fuse

(5A max)

NEUHOT

Inside Generator

12VDC OUT

TRANSFORMER

Generator

Battery

On Generator

120VAC Outlet

120VAC Coil Relay

Figure 2-6, Generator Run Sense Options

© 2013 Magnum Energy, Inc. 10

Page 14

Installation

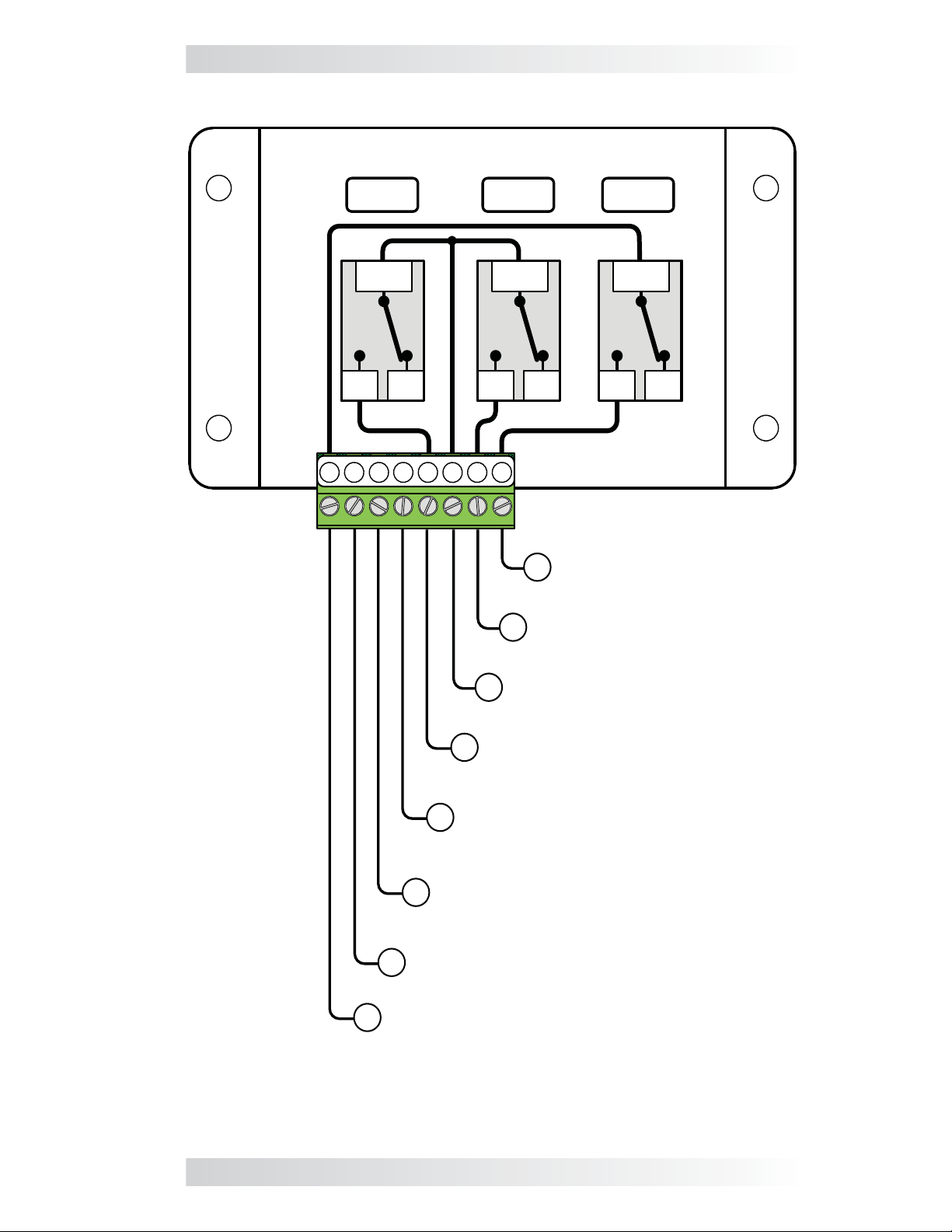

2.5.3 Gen Start/Stop Connections (Terminals 1, 5, 6, 7, & 8)

This section details the control relays inside the AGS controller and provides

information on wiring these relays to the generator’s start/stop circuit. You

must identify the generator’s start and stop wiring requirements to determine

how many relays you require, the amount of wires you connect, and in what

combination.

If the generator is equipped with a remote control terminal or connector,

the connections to the AGS control relays are made much easier if the

generator‘s optional remote control panel is purchased. Connecting to the

generator’s remote panel also eliminates the need to make connections

inside the generator (and possibly violating the generator’s warranty).

The AGS controller provides three control relays (RY1, RY2, and RY3) to

operate the autostart/autostop functions of your generator. These relays are

dry contacts (does not provide any voltage or current) and operate only as

switches that turn on and off low amperage devices. They are not intended

to directly provide power to starter motors or ignition systems, rather they

are used to send a signal to operate the coil of another higher amperage

device which does the actual switching of power.

CAUTION: A fuse rated at 5 amps or less must be used to protect

each of the relays. The warranty does not cover damage to these

relays. Fuses should be located as close as possible to the generator

connection. A fuse must be used even if the circuit is providing only

a “dry contact” or “ground” connection—it will prevent damage if the

connection is miswired or damaged.

Info: To set the generator type—which determines the operation of

the AGS relays—see “GEN TYPE Setting” in the Setup section.

Info: Due to the different generator types and the various starting/

stopping wiring confi gurations used by generator manufacturers,

detailed wiring instructions are not provided in this manual. Please

refer back to your generator’s documentation for wiring details.

Info: For more information and to view diagrams on connecting

the AGS to the start/stop circuit on many generators, refer to the

“Generator Wiring Diagrams” section at www.magnumenergy.com.

Depending on your generator’s start and stop wiring requirements, you may

only need to use one relay (RY1) for fully automatic two-wire generators; two

relays (RY1 and RY2) for 3-wire generators; or all three relays (RY1, RY2,

RY3) for generators that require an independent bypass or preheat circuit.

The connection points to each relay is as follows (see Figure 2-7):

• Relay 1 (RY1) and Relay 2 (RY2)

Terminal #5: This is the Normally Open (N.O.) position of the RY1 relay.

Terminal #6: This is the Common (COM) position of both Relay 1 (RY1) and

Relay 2 (RY2).

Terminal #7: This is the Normally Open (N.O.) position of Relay 2 (RY2).

• Relay 3 (RY3)

Terminal #1: This is the Normally Open (N.O.) position of Relay 3 (RY3).

Terminal #8: This is the Common (COM) position of Relay 3 (RY3).

11 © 2013 Magnum Energy, Inc.

Page 15

Installation

Relays Inside the AGS controller

1

RY1

COM

NO

2 3 4

5 6

RY2 RY3

COM

NONC

8

7

8

Normally Open (N.O.)

7

contact on Relay 2 (RY2)

NONC

Normally Open (N.O.)

contact on Relay 3 (RY3)

COM

NC

Common (COM) contact on

6

Relay 1 (RY1) and Relay 2 (RY2)

Normally Open (N.O.) contact

5

on Relay 1 (RY1)

Negative DC voltage input

(negative/ground terminal from

4

monitored battery bank)

Positive DC voltage input

3

[(positive terminal from monitored

battery bank (9-64 VDC)]

Run Sense input (10 - 40 volts DC only

2

when gen is running)

Common (COM) contact on Relay 3 (RY3)

1

Figure 2-7, Wiring to the AGS Controller’s Terminal Block

© 2013 Magnum Energy, Inc. 12

Page 16

Installation

2.6 Warning Label

It might be falsely assumed that it is safe to perform maintenance on the

generator or the electrical panel because the generator is off. However, the

AGS system can automatically turn on the generator and power the panel.

Two warning labels (Figure 2-8) are provided to inform all personnel that an

Automatic Generator Starting device is installed in your electrical system.

Place one label in a clearly visible location at the generator and the other

label at the electrical panel that is being powered by the generator.

WARNING: T o prevent harm to servicing personnel, ensure the gen-

erator and AGS are properly disabled (i.e. , remove the starting battery

from the generator and remove all power to the AGS by u

the green 8-port friction-fi t terminal block from the controller

performing maintenance on the generator or electrical panel.

nplugging

) prior to

WARNING

This electrical system is equipped with an

Automatic Generator Starting (AGS) device and/or

an inverter. Disconnect all AC and DC power to the

AGS and/or inverter before performing any service

to the electrical system. Failure to do so can result

in shock causing serious injury or death.

PN: 62-0002 Rev A

Figure 2-8, Warning Label

2.7 Common ME-AGS-S Generator Wiring Diagrams

The most common generator starting/run/stop circuits can be divided into

three major types: two-wire, three-wire “momentary”, or three-wire “maintain” . The following generator wiring diagr ams are provided to give examples

of these generator types.

Info: The term “three-wire” refers to the minimum number of wires

required to control the starter motor and to run the generator—more

than three wires may actually be needed.

Shown in Figure 2-9, the “two-wire” generator types integrate the control

circuits for start-up, running and stopping. The generator starts and runs when

two “control” wires are connected, and stops when they are disconnected.

Shown in Figure 2-10, the “three-wire momentary” generator types use a

three-position momentary type switch that controls their operation. To start

the generator, the switch is momentarily held to the START position. This

energizes the ignition system and cranks the starter motor. Once the engine

has started, the START switch is released and it returns to a center position

(i.e., “momentary” run control). To shut down the generator, the switch is

held to the STOP position until the engine dies. Once the switch is released,

it returns to the center position (i.e., “momentary” stop control).

Shown in Figure 2-11, the “three-wire maintain” generator types use an automotive type starting circuit. Operating a switch that is fi rst turned to a RUN

position and then momentarily held to a START position to start the generator.

Once the engine has started, the switch is released and it returns to the RUN

position (i.e., “maintain” run control). To shut down the generator, the switch

is moved to the OFF position (i.e., “maintain” stop control).

13 © 2013 Magnum Energy, Inc.

Page 17

INSIDE

INSIDE

Installation

INPUT DC

VOLTAGE JUMPER

- set to monitored

battery bank voltage

12/24/48V

(on 24V setting)

GEN TYPE

4321

(2-Wire

Maintain

ON

Mode)

≤5

amp

fuse

battery bank

(12V/24V/48V)

GEN AND POWER I/O

Relay 1

(Terminals 5 & 6)

Relay 2

(Terminals 6 & 7)

Relay 3

(Terminals 1 & 8)

R2 (Relay 2) Time

Delay time

Relay timing for GEN TYPE: 2-Wire Maintain Mode

≤5

amp

fuse

Monitored

≤5

amp

fuse

Ground

OFF

Delay

R2

Timing Information

10 sec.

4 sec.

Inside Generator

Run / Off

Switch

0 1 2 3

Gen

Battery

RUN TIME HOURS

RUN

Time between start attempts

Total start attempts 4

Hour Meter

Gen

OFF

2 min.

Figure 2-9, Two-wire Start Type Generators

© 2013 Magnum Energy, Inc. 14

Page 18

Installation

≤5

amp

fuse

≤5

amp

fuse

≤5

amp

fuse

INSIDE

INSIDE

Inside Generator

INPUT DC

VOLTAGE JUMPER

- set to monitored

battery bank voltage

12/24/48V

(on 24V setting)

4321

GEN TYPE

(5-wire mode)

ON

PREHEAT

≤5

amp

fuse

Monitored

battery bank

(12V/24V/48V)

GEN AND POWER I/O

Relay 1

(Terminals 5 & 6)

Relay 2

(Terminals 6 & 7)

Relay 3

(Terminals 1 & 8)

STOP Time

START Time

PREHEAT Time 25 sec.

Start Delay Time 14 sec

Relay timing for GEN TYPE: 5-wire Mode

0 1 2 3

Gen

Hour Meter

Start

STOP

Delay

Delay

PREHEAT

Timing Information

10 sec.

10 sec.

.

Gen

Battery

START

RUN TIME

HOURS

Preheat delay time

Time between start attempts

Total start attempts

STOP

START

STOP

4 sec.

2 minutes

4

Figure 2-10, Three-wire Momentary Type Generators

15 © 2013 Magnum Energy, Inc.

Page 19

INSIDE

INSIDE

Installation

INPUT DC

VOLTAGE JUMPER

- set to monitored

battery bank voltage

12/24/48V

(on 24V setting)

4321

GEN TYPE

(Portable

ON

Mode)

≤5

amp

fuse

≤5

amp

fuse

Monitored

battery bank

(12V/24V/48V)

amp

fuse

GEN AND POWER I/O

Relay 1

(Terminals 5 & 6)

Relay 2

(Terminals 6 & 7)

Relay 3

(Terminals 1 & 8)

START Time

T1 Time

Delay time 2 sec.

Relay timing for GEN TYPE: Portable Mode

≤5

Inside Generator

0 1 2 3

Gen

Hour Meter

Delay

START

Delay

Timing Information

10 sec.

5 sec.

Time between start attempts

19

50

30

Gen

Battery

19

50

30

OFF

RUN

START

RUN

RUN TIME HOURS

T1

Total start attempts 4

Switch

30 50 19

OFF

2 min.

Figure 2-11, Three-wire Maintain Type Generators

© 2013 Magnum Energy, Inc. 16

Page 20

Setup

3.0 Setup

This section provides information on AGS settings and shows you how to

adjust these settings.

3.1 Internal Settings

On the AGS controller, unscrew the four top screws and remove the plastic

cover to access an input DC voltage jumper and a 4-position DIP (Dual In-line

Package) switch. The INPUT DC VOLTAGE jumper position determines the controller’s DC operating voltage. The DIP switch confi guration is used to select the

GEN TYPE which determines how the internal relays operate to automatically

start and stop the generator.

INPUT DC

VOLTAGE

Setting

12/24/48V

(Default: 12V)

4321

GEN

TYPE

Setting

(Default: QD mode)

Revision

Label

RY1 RY2 RY3

Rev

##

ON

4321

12/24/48V

2

134

ON

Figure 3-1, Inside the AGS Controller

INPUT DC VOLTAGE Setting: The INPUT DC VOLTAGE setting is determined

by connecting two small pins with a small black plastic box (i.e. , jumper). This

setting can be confi gured for 12, 24, or 48 VDC operation, which is determined

by the nominal DC voltage connected to Terminals 3 and 4 on the AGS.

• For 12-volt DC operation, position the jumper on the bottom two pins.

• For 24-volt DC operation, position the jumper on the middle two pins.

• For 48-volt DC operation, position the jumper on the top two pins.

12 VDC Operation

(jumper on bottom

two pins)

24 VDC Operation

(jumper on middle

two pins)

48 VDC Operation

(jumper on top

two pins)

**default setting**

Figure 3-2, DC Voltage Settings

GEN TYPE Setting: The GEN TYPE setting is determined by a DIP switch,

which is actually 4 small switches that can be turned to the ON or OFF

position. The position of each of these 4 small switches is used to determine

the open and close timing sequence for the three internal AGS relays (RY1,

RY2 and RY3). The multiple positions of the DIP switch allow a wide range of

generator start/stop circuit confi gurations.

After determining the appropriate start/stop timing sequence for your

generator, use Table 3-1 to determine and set the correct GEN TYPE setting

for your generator’s start/stop requirements.

For examples and assistance in viewing which GEN TYPE setting is used for

specific generators, view the “ Generator Wiring Diagrams” under the Service

and Support area at www.magnumenergy.com.

17 © 2013 Magnum Energy, Inc.

Page 21

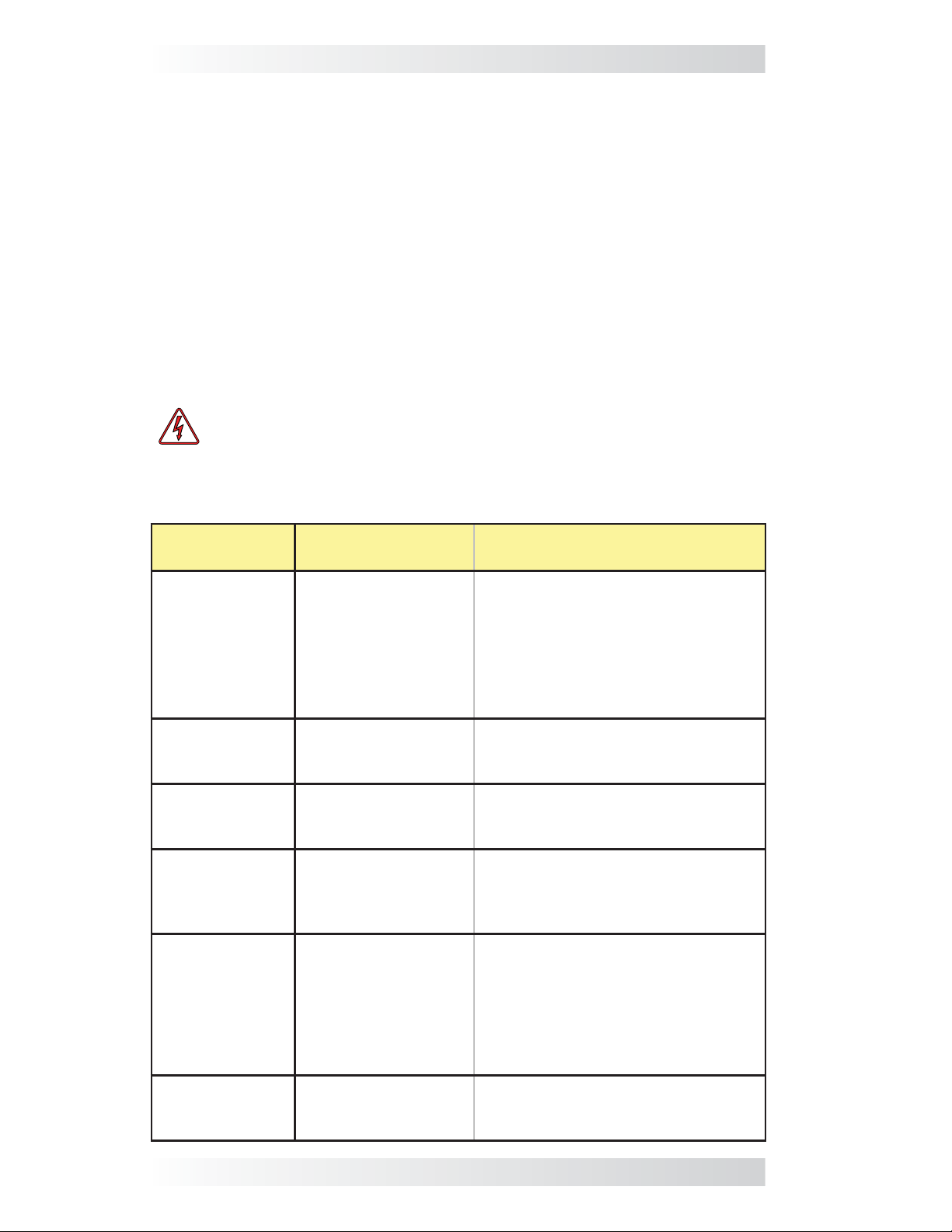

Table 3-1, GEN TYPE Settings

Setup

GEN

TYPE

ON

QD Mode

(default)

ON

3-Wire

Mode

ON

Portable

Mode

ON

2-Wire

Momentary

Mode

ON

2-Wire

Maintain

Mode

ON

5-Wire

Mode

Relay Timing/Operation (RY1/RY2/RY3)

RY1

4321

(N.O.)

RY2

(N.O

RY3

N.O.)

(

.)

T3

T2

Generator: Quiet Diesel (

RY1

4321

(N.O.)

T1

T3

T2

T1

T2

T1

T1

T3

RY2

(N.O.)

RY3

(N.O.)

Generators: Marquis, Emerald, and Microquiet (Onan); Quiet Pack

Series (Generac).

1

RY

4321

(N.O.)

RY2

(N.O.)

RY3

(N.O.)

Generator: EM Series with remote control (Honda).

RY1

4321

(N.O.)

RY2

(N.O.)

RY3

(N.O.)

Generator: PT-ECU-63 controller with 2-wires (Powertech).

RY1

4321

(N.O.)

RY2

(N.O.)

RY3

(N.O.)

Generators: RMY Series (Kohler); DynaGen Controllers

RY1

4321

(N.O.)

RY2

(N.O.)

RY3

(N.O.)

Generators: BTDA / BEG (Westerbeke), 205-DS (Martin Diesel), NL-

673 (Northern Lights)

T2

T1

T1

Onan).

T2

RUN TIME

T1

T4

RUN TIME

T1

RUN TIME

RUN TIME

RUN TIME

T3

RUN TIME

T3

T3

T2

T1

Time

Period

T1 =

20 sec.

T2 =

4 sec.

T3 =

10 sec.

T1 =

5 sec.

T2 =

2 sec.

T3 =

10 sec.

T1 =

2 sec.

T2 =

10 sec.

T3 =

5 sec.

T1 =

2 sec.

T2 =

10 sec.

T1 =

4 sec.

T2 =

10 sec.

T1 =

10 sec.

T2 =

14 sec.

T3 =

4 sec.

T4 =

25 sec.

© 2013 Magnum Energy, Inc. 18

Page 22

Setup

3.2 External Settings

The generator run time, temperature, and voltage settings come pre-set

directly from the factory. For the majority of customers, the factory default

settings as shown in Table 3-2 are appropriate. If you need to make changes

to the factory settings, you can do so by rotating the knobs on the front panel

of the AGS controller either clockwise or counterclockwise (see Figure 3-3).

Table 3-2, ME-AGS-S Default Settings

Adjustable Settings Factory Default Values

RUN TIME HOURS 2 (Hours)

START TEMP °F OFF (disabled)

START VOLTS DC 11 (Volts DC)

SETTINGS

EXTERNAL

CLOCK AM/PM 8A (8 AM)

QUIET TIME PM/AM OFF (disabled)

INPUT DC VOLTAGE 12 Volts (bottom two pins)

SETTINGS

INTERNAL

RUN TIME

HOURS

setting

GEN TYPE QD Mode (all 4 switches off)

START

TEMP °F

setting

START

VOLTS DC

setting

CLOCK

AM/PM

setting

QUIET TIME

PM/AM

setting

Figure 3-3, External Settings

RUN TIME HOURS: This setting determines the length of time the generator

runs once started. The generator starts because the battery voltage has

fallen to the START VOLTS DC setting for at least two continuous minutes;

or, the temperature around the remote switch has risen to the START TEMP

°F setting. The run time can be set from 1-5 hours. To change this setting,

slowly rotate the knob marked RUN TIME HOURS clockwise to increase

generator run time or counterclockwise to decrease the generator run time.

19 © 2013 Magnum Energy, Inc.

Page 23

Setup

START TEMP °F:

value that causes the generator to automatically start.

around the AGS switch increases to the START TEMP °F temperature setting,

the generator automatically starts and runs based on the

setting. The AGS attempts to start the generator immediately once the

temperature rises to this setting. The

from 65°F-85°F

adjustment knob is turned fully counterclockwise to the OFF position.

Why would I use the temperature start feature? For RV users, you could

set the air conditioner to turn on (comes on when power is provided by the

generator) and leave the RV. The generator will automatically start when

the temperature rises to your AGS temperature start setting, providing

power to the air conditioner; thereby , turning it on. This allows you to leave

pets and precious items in your coach while dry camping in hot weather;

knowing your RV will stay cool and comfortable - plus, while the generator

is on, the house batteries are being charged.

START VOLTS DC: This setting allows you to enable and set a battery

voltage value that causes the generator to automatically start. When the

battery voltage decreases to or below this setting for two continuous minutes,

the generator automatically starts and runs based on the RUN TIME HOURS

setting

jumper), 20-24 VDC (for 24 VDC jumper), or 40-48 VDC (48 VDC jumper).

If the DC voltage start feature is not needed, turn the adjustment knob fully

counterclockwise to the OFF position.

. The voltage start setting is adjustable from 10-12 VDC (12 VDC

This setting allows you to enable and adjust a temperature

When the temperature

RUN TIME HOURS

temperature start setting is adjustable

.

If the temperature start feature is not needed, ensure the

Info: This system is capable of 12 VDC, 24 VDC, or 48 VDC operation. For 24 VDC applications, double the value indicated on the cover

(i.e., 11 VDC equals 22 VDC) and for 48 VDC applications, multiply

the indicated value by four (i.e., 11 VDC equals 44 VDC).

CLOCK AM/PM: This setting is used to set the internal clock of the AGS.

The internal clock of the AGS must be set to the correct time in order for the

Quiet Time feature to function appropriately. If the Quiet Time feature is not

used, this clock setting is not required to be adjusted.

To set or change the clock, ensure the current time of day is between the

hours of 8 AM and 4 PM; then, slowly rotate the knob marked CLOCK AM/PM

clockwise to increase the time or counterclockwise to decrease the time. Once

set, the clock will continue to keep time. However, the clock must be reset if

the controller loses power, or when you change time zones.

QUIET TIME PM/AM: This setting is used to prevent the generator from

starting during specifi c hours of the evening (PM) and early morning (AM). It

is adjustable for fi ve pre-selected time ranges.

To set Quiet Time, turn the dial either counterclockwise or clockwise to the

hours required: 9-7 (9 PM to 7 AM), 9-8 (9 PM to 8 AM), 9-9 (9 PM to 9 AM),

10-8 (10 PM to 8 AM), or 11-8 (11 PM to 8 AM). The program only needs

to be set once. If the Quiet Time feature is not needed, turn the dial fully

counter-clockwise to the OFF position.

Info: If the generator is running when the Quiet Time evening hour

(PM) is reached, it automatically stops and does not automatically

start until after the Quiet Time morning hour (AM) has passed.

© 2013 Magnum Energy, Inc. 20

Page 24

Setup

3.3 AGS Functional Tests

After all electrical connections to the AGS, batteries, and generator have been

completed (and prior to connecting the 8-pin green terminal block into the

AGS controller), perform the following tests to verify that the AGS system

is functioning correctly and the wiring from the AGS to generator is correct.

If the AGS fails either test, or the STATUS indicator turns red (indicating a

fault), refer to the Troubleshooting section.

3.3.1 Power-Up Test

1. Ensure the AGS remote switch is set in the OFF position (center position)

and connected to the controller by the communication cable.

2. Before connecting the 8-pin green terminal to the AGS, use a multimeter

to verify the correct polarity and to ensure that the voltage to Terminals

3 (positive) and 4 (negative) is correct according to the position the DC

input jumper (refer to Figure 3-2).

3. Apply power to the AGS by plugging in the green 8-port friction-fi t terminal

block into the controller, and then verify that the green READY indicator

comes on (solid) and the STATUS indicator blinks green once.

Info: The READY indicator blinks when the AGS controller is powered

and the remote switch is not connected to the AGS controller.

3.3.2 Generator Wiring Test

This start/stop test is used to confi rm that all wiring from the generator to

the AGS controller is correct and that the GEN TYPE setting is confi gured

correctly for your generator type.

1. Press and release either:

a) the red TEST switch (on the Controller – see Figure 4-1); or

b) the switch to the TEST position (on the remote switch - see Figure 4-2).

2. After the TEST button/switch is pressed and released, the AGS initiates

an automatic generator start/stop sequence.

3. The STATUS indicator on the controller (and remote switch) begins to

blink green and the generator should start.

4. While the generator is running, view the STATUS indicator and ensure

it turns solid green.

5. The generator should run for approximately 30 seconds before automatically turning off.

Wait for at least 5 minutes to ensure the gener ator remains off and the AGS

does not attempt another start. If this test passes, then activate the AGS

system by setting the remote switch to ENABLE.

If the STATUS indicator shows a fault condition (solid red LED indication),

press the AGS switch to OFF and then back to the ENABLE or TEST position.

If the problem persists, refer to the Troubleshooting section.

Info: The AGS attempts to start the generator 4 times. If after 4

attempts the generator fails to start, the status LED turns red—indicating a fault.

21 © 2013 Magnum Energy, Inc.

Page 25

Operation

4.0 Operation

This section details the front panel controls and the LED indicators on the

AGS controller and remote switch; and explains the operation using these

LED indicators.

4.1 AGS Controller Operation LED Indicators

The front of the controller (Figure 4-1) provides a pushbutton to test the

AGS system operation, and two LED indicators for viewing system operation.

4.1.1 TEST Switch

The TEST switch when pressed and released attempts to turn on the connected generator and allow it to run for at least 30 seconds before turning the

generator off. This start/stop test is used to confi rm that all wiring from the

generator to the AGS is correct and that the GEN TYPE setting is confi gured

correctly for your generator type.

Info: Pushing and releasing the red TEST pushbutton switch enables

the same test as pressing and releasing the momentary TEST position

on the AGS remote switch.

4.1.2 STATUS LED Indicator

Blinking Green – Indicates that the AGS system is initiating a generator

start sequence. This can happen based on two conditions, either: 1) The TEST

switch (on the controller or remote switch) has been pressed and released;

or, 2) The remote switch has been set to the ENABLE position and the START

TEMP °F setting and/or the START VOLTS DC setting has been reached.

Solid Green – Indicates the generator has started successfully and is providing the run sense voltage to Terminals 2 (+) and 4 (-) of the AGS controller.

Solid Red – This is a fault condition to indicate that the generator has not

provided a correct run sense voltage to Terminals 2 (+) and 4 (-) of the AGS

controller after four start attempts.

4.1.3 READY LED Indicator

Solid Green (normal AGS system indication) – Indicates the AGS control-

ler has power and the remote switch is plugged in correctly.

Blinking Green – Indicates that the AGS controller has power , but the remote

switch is not sensed. This means the remote switch is either not connected,

incorrectly connected, is defective, or has an incorrect or defective cable.

STATUS

Indicator

(green/red)

TEST

Switch

READY

Indicator

(green)

Figure 4-1, Controller Front Panel Controls and Indicators

© 2013 Magnum Energy, Inc. 22

Page 26

Operation

4.2 Remote Switch Operation

The AGS remote switch (see Figure 4-2) provides information and enables

you to operate the controller. The remote switch receives its power from the

controller through the communications cable and comes on automatically

when power is applied to the AGS controller.

The remote switch provides an ENABLE position to activate the auto gen

system, an OFF position to turn the auto gen system off, and a momentary

TEST position that allows the auto gen system to be tested remotely. A

STATUS indicator is also included to remotely view system status.

4.2.1 Switch Positions

OFF – When the AGS switch is placed in the OFF position; the STATUS indica-

tor will be off and all AGS generator start functions are disabled.

ENABLE (normal operating position) – When the AGS switch is placed in

the ENABLE position, the AGS system is activated/enabled and now monitors battery voltage and/or temperature to determine when to automatically

start the generator.

TEST – When the AGS switch is pushed to the momentary TEST position, the

AGS initiates an automatic generator start/stop sequence. This test attempts

to turn on the connected generator and allow it to run for at least 30 seconds

before turning the generator off . This start/stop test is used to confi rm that all

wiring from the generator to the AGS is correct and that the AGS is confi gured

correctly for your generator type.

Info: Pushing and releasing the momentary TEST position enables

the same test as pressing and releasing the red TEST pushbutton

switch on the AGS controller.

4.2.2 STATUS LED Indicator

Blinking Green – Indicates that the AGS system is initiating a generator

start sequence. This can happen based on two conditions, either: 1) The TEST

switch (on the controller or remote switch) has been pressed and released;

or, 2) The remote switch has been set to the ENABLE position and the START

TEMP °F setting and/or the START VOLTS DC setting has been reached.

Solid Green – Indicates the generator has started successfully and is providing the required run sense voltage to Terminals 2 (+) and 4 (-) of the AGS.

Solid Red – This is a fault condition to indicate that the generator has not

provided a correct run sense voltage to Terminals 2 (+) and 4 (-) of the AGS

controller after four start attempts.

Control

Switch

STATUS

Indicator

Figure 4-2, Remote Switch Controls and Indicators

23 © 2013 Magnum Energy, Inc.

Page 27

Operation

4.3 AGS System Operation

When the AGS is enabled and has determined that a low battery and/or a high

temperature condition exists, it attempts an automatic generator start. This is

done by closing its internal relays (based on the GEN TYPE selection) to control

the starter much like a person does when manually starting the generator.

The starter is turned on for short periods of time and then turned off. If the

AGS determines that the engine has started while cranking (indicated by a

solid green STATUS indicator), the starter is turned off after a short delay.

If the engine does not start, another attempt to turn on the starter is made

after a long delay period. This is repeated until either the generator starts or

the maximum number of start attempts is reached, which causes the AGS to

go into a fault condition (indicated by a solid red STATUS indicator).

WARNING: Never allow the generator to start/run in an enclosed

garage or any other type of enclosed structure without proper ventilation. Carbon Monoxide, an odorless, colorless, deadly gas may

accumulate and cause serious injury or death.

4.3.1 Operational Notes

• To manually stop the generator during the run time cycle, simply press

the remote switch to the OFF position.

• If a fault condition occurs, press the AGS switch to OFF and then back

to the ENABLE or TEST position. If the problem persists, refer to the

Troubleshooting section in this manual.

• When the AGS switch is placed in the OFF position, all AGS generator

start functions are disabled. The STATUS indicator is also off when the

switch is in this position.

• Once the generator has completed the RUN TIME HOURS the AGS im-

mediately begins to monitor the START TEMP °F and START VOLTS DC

settings for the next auto start cycle.

• It is recommended that the AGS remote switch be set to the OFF position

if the connected generator is placed into storage or left unattended for

extended lengths of time.

• If using the temperature start feature in an RV coach, set the air condi-

tioner thermostat to match the START TEMP °F setting. If using two air

conditioners, it is suggested that the second air conditioner thermostat

be set 2°-5° higher than the fi rst air conditioner. This staggered setting

allows the fi rst air conditioner to start and run in an effort to keep the

coach cool. If the temperature continues to rise inside the coach, the

second air conditioner turns on to further cool the coach.

• When the generator starts successfully, the STATUS indicator turns solid

green. The generator runs until the RUN TIME HOURS setting is reached,

at which time a stop signal is sent to the generator.

• If the generator is running when the switch is pushed to the TEST posi-

tion, the generator stops and then starts again. The generator then runs

for approximately 30 seconds before shutting off.

• There is a two minute delay before the AGS attempts to start the generator

if the voltage to the AGS controller falls to the START VOLTS DC setting.

There is no delay if the AGS attempts to start the generator when the

temperature around the remote switch rises to the START TEMP °F setting.

© 2013 Magnum Energy, Inc. 24

Page 28

Troubleshooting

5.0 Troubleshooting

There are two LED (Light Emitting Diode) indicators on the front of the AGS

controller to indicate how the AGS is operating and to help troubleshoot the

AGS system. The STATUS indicator is a bi-color (green or red) LED to indicate

the AGS status. The READY indicator is a green LED to indicate if the AGS has

power and if the remote switch is connected.

The AGS controller will perform a “self test” when power is fi rst applied. The

green READY indicator comes on (solid) and at the same time, the STATUS

indicator blinks green once. If the self-test is correct, test the AGS system

for proper operation by pressing and releasing the AGS switch to the TEST

position. The STATUS indicator begins to blink green and the AGS should start

the generator. After the generator has started, the STATUS indicator should

turn on solid green and the generator should run for approximately 30 seconds

and then shut off. If the gener ator does not start and stop as expected, refer

to the troubleshooting chart below to help fi nd a solution.

WARNING: Completely unplug the green 8-port friction-fi t termi-

nal block from the AGS controller before servicing the electrical or

generator system to prevent harm to servicing personnel.

Table 6-1, Troubleshooting Guide

LED

Indication

STATUS is ON

red = Gen Fault

STATUS blinking

green = gen

start initiated

STATUS is ON

(solid) green =

Gen Run

READY is OFF =

no power connected to the

AGS controller

READY is

blinking = the

remote switch is

not connected

Symptom

1. Gen won’t start; or

2. Gen won’t run. It

starts, but is stopped

by the AGS (B+ or

run sense voltage not

sensed to Terminal

#2).

Gen start initiated. No problem – normal operation.

Gen started OK. No problem – normal operation.

DC voltage to pins

3 (+) and 4 (-) on

controller missing or

incorrect.

The remote control

switch is not sensed

or plugged into the

REMOTE port.

Check gen to AGS start wiring; or

check B+ wiring from gen to AGS.

Measure DC voltage from Terminal

2 (+) to Terminal 4 (-), ensure DC

voltage is 10-40 volts only when the

generator is running.

Switch OFF, then ENABLE to reset.

Check fuse, check DC wiring.

1. Check communications cable

connection to the remote and controller, or

2. Try a different 6-conductor telephone cable (see Figure 2-5).

Solutio

n

Switch OFF, then ENABLE to reset.

READY is ON

(solid) = power

connected

25 © 2013 Magnum Energy, Inc.

The remote control

switch is connected

to the REMOTE port.

No problem - normal operation.

Page 29

Warranty and Service

6.0 Limited Warranty

Magnum Energy, Inc. warrants the ME-AGS-S (Automatic Generator Start

- Standalone version) to be free from defects in material and workmanship

that result in product failure during normal usage, according to the following

terms and conditions:

1. The limited warranty for the product extends for twelve (12) months

beginning from the product’s original date of purchase.

2. The limited warranty extends to the original purchaser of the product

and is not assignable or transferable to any subsequent purchaser.

3. During the limited warranty period, Magnum Energy will repair, or

replace at Magnum’s option, any defective parts, or any parts that

will not properly operate for their intended use with factory new or

remanufactured replacement items if such repair or replacement is

needed because of product malfunction or failure during normal usage.

The limited warranty does not cover defects in appearance, cosmetic,

decorative or structural parts, or any non-operative parts. Magnum

Energy’s limit of liability under the limited warranty shall be the actual

cash value of the product at the time the original purchaser returns

the product for repair, determined by the price paid by the original

purchaser. Magnum shall not be liable for any other losses or damages.

4. Upon request from Magnum, the original purchaser must prove the

product’s original date of purchase by a dated bill of sale, itemized

receipt.

5. The original purchaser shall return the product prepaid to Magnum

Energy in Everett, WA. After the completion of service under this limited

warranty, Magnum Energy will return the product prepaid to the original

purchaser via a Magnum-selected non-expedited surface freight within

the contiguous United States and Canada; this excludes Alaska and

Hawaii.

6. If Magnum repairs or replaces a product (with either a new or refurbished

product), its warranty continues for the remaining portion of the original

warranty period or 90 days from the date of the return shipment to

the original purchaser, whichever is greater. All replaced products and

parts removed from repaired products become the property of Magnum

Energy.

7. This limited warranty is voided if:

• the product has been modifi ed without authorization,

• the serial number has been altered or removed,

• the product has been damaged through abuse, neglect, accident,

high voltage or corrosion.

• the product was not installed and operated according to the owner’s

manual.

BEFORE RETURNING ANY UNIT, A RETURN MATERIAL

AUTHORIZATION (RMA) NUMBER IS REQUIRED

© 2013 Magnum Energy, Inc. 26

Page 30

Warranty and Service

6.1 How to Receive Repair Service

If your product requires warranty service or repair, contact either:

• An Authorized Service Center, which are listed on the Magnum Energy

website at

• Magnum Energy, Inc. at:

If returning your product directly to Magnum Energy for repair, you must:

1. Return the unit in the original, or equivalent, shipping container.

2. R eceive a Return Materials Authorization (RMA) number from the factory

prior to the return of the product to Magnum Energy for repair.

3. Place RMA numbers clearly on the shipping container or on the packing

slip.

When sending your product for service, please ensure it is properly packaged. Damage due to inadequate packaging for shipment is not cov-

ered under warranty. We recommend sending the product by tr aceable or

insured service.

http://www.magnumenergy.com/ServiceCenters.htm, or

Telephone: 425-353-8833

Fax: 425-353-8390

Email:

warranty@magnumenergy.com

27 © 2013 Magnum Energy, Inc.

Page 31

Appendix

A-1 Appendix

Optional Accessories for the ME-AGS-S

The following two Pigtail Adapters are available from Magnum Energy for

use with the ME-AGS-S. They are

requirement to conveniently and automatically turn the generator on/off

externally through a manually controlled switch or from an automatically

controlled switching device

turn gen on to run air conditioner):

The ME-PT1 (Pigtail One-wire) adapter is designed to allow the AGS to start

the connected generator when an external +12 volt DC supply is applied.

The ME-PT2 (Pigtail Two-wire) adapter is designed to allow the AGS to start

the connected generator by an external two-contact switch.

(i.e., use air conditioner thermostat controls to

Additional Magnum Equipment/Accessories

The following components are also available from Magnum Energy:

MS Series Inverter/Chargers

The MS Series inverter/charger is a pure sine wave inverter designed

specifi cally for mobile and off-grid applications. The MS Series has a built-in

PFC (Power F actor Corrected) charger that uses 25-30% less AC current than

standard chargers. The MS Series also provides multiple ports, including an

RS485 communication port for network expansion, and a remote port.

MMP Series Enclosures

The MMP175-30D, MMP175-60S, MMP250-30D, and MMP250-60S enclosures

are specifi cally designed for single inverter applications. The MMP Series en-

closures combine all of the major components required for a renewable energy

system—inverter/battery disconnect, AC overcurrent protection, grounding

connections, and a full system inverter bypass—into a single, easy to install

pre-wired enclosure.

Advanced Remote Control Display

The ME-ARC allows advanced features of the Magnum inverter or accessory to

be confi gured. This LCD remote display includes a FA VS button to access your

favorite features quickly and provides advanced monitoring/troubleshooting.

Basic Remote Control Display

The ME-RC remote control is simple to use; an easy-to-read LCD screen

and “at a glance” LEDs display complete inverter/charger status. Soft keys

provide simple access to menus and a rotary encoder knob allows you to

scroll through and select a wide range of settings such as INVERTER ON/OFF,

CHARGER ON/OFF, SHORE power breaker setting, AGS control, and METER,

SETUP, and TECH menus.

Battery Monitor

The Battery Monitor Kit (ME-BMK) is a single battery bank amp-hour meter

that monitors the condition of the battery and provides information to let

you know how much energy you have available. It also lets you plan your

electrical usage to ensure the battery is not being over-discharged.

Fuse Block/Fuses

The Magnum fuse/fuse-blocks are used to protect the battery bank, inverter,

and cables from damage caused by DC short circuits and overloads. They

include a slow-blow fuse with mounting block and protective cover. The 125

and 200-amp models use an ANL type fuse and the 300 and 400-amp models

use a Class-T fuse.

useful in applications where there is a

© 2013 Magnum Energy, Inc. 28

Page 32

PN: 64-0004 Rev B

Magnum Energy, Inc.

2211 West Casino Rd.

Everett, WA 98204

Phone: 425-353-8833

Fax: 425-353-8390

Web:

www.magnumenergy.com

Loading...

Loading...