Page 1

ACLD-40

AC Load Diversion Controller - 4.0kW

Owner’s Manual

Page 2

Thank you from all of us at Sensata Technologies for purchasing this ACLD-40 controller. The

ACLD-40 (also know as the ACLD) is a product under the Magnum-Dimensions brand from Sensata

Technologies. We understand that you have many purchasing options in the marketplace, and we

are pleased that you have decided on this product. This ACLD was proudly assembled and tested

in the United States at our facility in Everett, Washington.

At Sensata, we are committed to providing you with quality products and services, and hope that

your experience with us is pleasant and professional.

Disclaimer of Liability

The use of this manual and the conditions or methods of installation, operation, use and maintenance

of the ACLD controller is beyond the control of Sensata Technologies. Therefore, this company does

not assume responsibility and expressly disclaims liability for loss, damage, or expense whether

direct, indirect, consequential or incidental that may arise out of or be any way connected with

such installation, operation, use, or maintenance.

Due to continuous improvements and product updates, the images shown in this manual may not

exactly match the unit purchased.

Restrictions on Use

The ACLD may only be used in life support devices and systems with the express written approval

of Sensata Technologies. Failure of this load diversion controller can reasonably be expected to

cause failure of that life support device or system, or to affect the safety or effectiveness of that

device or system. If the ACLD fails, it is reasonable to assume the health of the user or other

persons may be endangered.

Copyright Notice

Copyright © 2015 by Sensata Technologies. All rights reserved. Permission to copy, distribute, and/

or modify this document is prohibited without express written permission from Sensata Technologies.

Document Information

Description – ACLD-40 Owner’s Manual

Part Number and Revision – 64-0062 Rev A

Date Published – February 2015

This manual is printed without color for cost savings. However, this entire manual is available

for download—with many of the fi gures available in color—under the Document Library tab at

www.Magnum-Dimensions.com.

Contact Information

For Magnum-Dimensions Products:

Sensata Technologies

2211 West Casino Rd.

Everett, WA 98204

Phone: 425-353-8833

Fax: 425-353-8390

Web:

www.Magnum-Dimensions.com

Record the ACLD’s serial number in case you need to provide this information in the future.

Model: Serial Number:

ACLD-40 TA

© 2015 Sensata Technologies

Page i

Page 3

Safety Information

IMPORTANT PRODUCT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

THIS MANUAL CONTAINS IMPORTANT INSTRUCTIONS FOR THE ACLD-40 CONTROLLER THAT SHALL

BE FOLLOWED DURING THE INSTALLATION AND OPERATION OF THIS PRODUCT. Before using

the ACLD, read all instructions and cautionary markings. Also, be sure to follow the instructions

provided for each component of the system. Do not perform any installation or service described

in this owner’s manual unless properly trained and capable. Incorrect installation or service may

result in the risk of electric shock, fire, or other safety hazard.

Safety Symbols

The following safety symbols have been placed throughout this manual to indicate dangerous and

important safety instructions.

WARNING: This symbol indicates that failure to take a specifi ed action could result in

physical harm to the user.

CAUTION: This symbol indicates that failure to take a specifi ed action could result in

damage to the equipment.

Info: This symbol indicates information that emphasizes or supplements important

points of the main text.

Safety Precautions

• All electrical work must be performed in accordance with local and national electrical codes.

• This product is designed for indoor/compartment installation. It must not be exposed to rain,

snow, moisture, or liquids of any type.

• Use insulated tools to reduce the chance of electrical shock or accidental short circuits.

• There are no user-serviceable parts contained in this product.

• This unit is provided with integral protection against overloads.

• Use Class 1 wiring methods for field wiring connections to terminals of a Class 2 circuit.

• Listed or labeled equipment shall be installed and used in accordance with any instructions

included in the listing or labeling.

• Always verify proper wiring prior to turning on the ACLD.

• Use only copper wires with a minimum temperature rating of 75°C (167°F).

• AC wiring must be no less than #10 AWG (5.3 mm

• Torque all AC wiring connections to the required values.

• The ACLD must be properly mounted, see Section 2.3 “Mounting the ACLD” in this manual.

• Protection for the AC output wiring against overcurrent is not included in the ACLD and must

be provided as part of the system installation. Refer to Section 2.8 “Wiring the ACLD” for more

information.

• The AC output neutral conductor is not connected (bonded) to the ACLD chassis. Both the input

and output conductors are isolated from the ACLD chassis. System grounding, if required, is

the responsibility of the system installer and must comply with local and national electrical

codes and standards.

2

) gauge copper wire.

Page ii

Page 4

Safety Information

CONSIGNES DE SÉCURITÉ IMPORTANTES

CONSERVER CES INSTRUCTIONS

CE MANUEL CONTIENT DES INSTRUCTIONS IMPORTANTES POUR LE CONTRÔLEUR ACLD-40 AU

COURS DE L’INSTALLATION ET FONCTIONNEMENT DU PRODUCT. Before utilisant le ACLD, lire

toutes les instructions et mises en garde. Aussi, assurez-vous de suivre les instructions fournies

pour chaque composant du système. Ne pas effectuer toute installation ou service décrit dans le

manuel du propriétaire, à moins bien formé et capable. Mauvaise installation ou entretien peuvent

entraîner des risques de choc électrique, d’incendie ou autre danger pour la sécurité.

Symboles de sécurité

Les symboles de sécurité suivants ont été placéstout au long de ce manuel pour indiquer des

conditions dangereuses et les consignes de sécurité importantes.

AVERTISSEMENT: Ce symbole indique que le défaut de prendre une action spécifi ée

pourraitcauser des dommages physiques à l’utilisateur.

ATTENTION: Ce symbole indique que le défaut de prendre une action spécifi ée peut

entraîner des dommages à l’équipement.

Info: Ce symbole indique une information qui met l’accent ou des suppléments points

importants du texte principal.

Consignes de sécurité

• Tous les travaux électriques doivent être effectués en conformité avec les codes locaux et

nationaux électriques.

• Ce produit est conçu pour l’installation / du compartiment intérieur. Il ne doit pas être exposé

à la pluie, la neige, l’humidité ou des liquides de tout type.

• Utiliser des outils isolés pour réduire le risque de choc électrique ou courts-circuits accidentels.

• Il n’y a pas réparable par l’utilisateur contenues dans ce produit.

• Cet appareil est fourni avec une protection intégrale contre les surcharges.

• Utiliser des méthodes de câblage Classe 1 pour les connexions de câblage sur le terrain aux

bornes d’un circuit de Classe 2.

• Coté ou étiquetés équipement doit être installé et utilisé conformément aux instructions

fi gurant dans la liste ou l’étiquetage.

• Toujours vérifi er le câblage avant de mettre sur le ACLD.

• Utilisez des fi ls de cuivre seulement avec une cote de température minimale de 75°C (167°F).

• AC câblage ne doit pas être inférieure à #10 AWG (5.3 mm

• Serrer toutes les connexions de câblage ca aux valeurs requises.

• Le ACLD doit être correctement monté, voir la Section 2.3 “Montage du ACLD” dans ce manuel.

• Protection pour le câblage de sortie AC contre les surintensités n’est pas inclus dans le ACLD

et doivent être fournis dans le cadre de l’installation du système. Reportez-vous à la Section

2.8 “Câblage du ACLD “ pour plus d’informations .

• Le conducteur de sortie CA neutre n’est pas connecté (collé) sur le châssis ACLD. À la fois

l’entrée et la sortie des conducteurs sont isolés du châssis ACLD. Sol, si nécessaire, est

de la responsabilité de l’installateur du système et doit être conforme aux codes locaux et

nationaux et des normes électriques.

2

) de cuivre de calibre.

© 2015 Sensata Technologies

Page iii

Page 5

Table of Contents

1.0 Introduction ............................................................................. 1

1.1 What is an AC Load Diversion Controller (ACLD)? ...................................... 1

1.2 What is an AC Coupled system, and why do I need an ACLD? ..................... 1

1.3 How an AC Coupled System Works .......................................................... 2

1.4 Battery Regulation Methods ................................................................... 4

1.5 ACLD Features and Benefi ts ................................................................... 6

2.0 Installation .............................................................................. 8

2.1 Pre-Installation .................................................................................... 8

2.2 Locating the ACLD Controller ................................................................ 10

2.3 Mounting the ACLD Controller ............................................................... 11

2.4 General Wiring Requirements ............................................................... 13

2.5 Torque Requirements .......................................................................... 14

2.6 ACLD Terminal Block Connections ......................................................... 15

2.7 Electrical System Wiring Diagrams ........................................................ 15

2.8 Wiring the ACLD ................................................................................. 18

2.9 ACLD Load Requirements ..................................................................... 19

2.10 Connecting the ACLD to a MS-PAE Series Inverter ................................... 21

2.11 Using a Remote Control with the ACLD Controller .................................... 22

3.0 Operation ............................................................................... 23

3.1 ACLD Operation .................................................................................. 23

3.2 Three-Stage Regulation ....................................................................... 25

3.3 Operation Scenarios - Utility Connected ................................................. 26

3.4 Power Flow Scenarios - Utility Not Connected ......................................... 27

3.5 Power Switch Operation ....................................................................... 30

3.6 Inverter Fan Operation ........................................................................ 30

3.7 Operating Modes ................................................................................ 31

3.8 Monitoring the ACLD Controller with a ME-ARC Remote Display ................. 31

3.9 ACLD Startup ..................................................................................... 32

4.0 Troubleshooting ..................................................................... 33

Appendix A – Specifi cations and Optional Equipment ..................... 35

A-1 ACLD-40 Load Diversion Controller Specifi cations .................................... 35

A-2 Regulatory Compliance ........................................................................ 36

A-3 Optional Equipment and Accessories...................................................... 36

Appendix B – Warranty and Service .............................................. 37

B-1 Limited Warranty ................................................................................ 37

B-2 How to Receive Repair Service .............................................................. 37

Page iv

© 2015 Sensata Technologies

Page 6

List of Figures

Figure 1-1, ACLD Inactive (Utility Power Available) ............................................................2

Figure 1-2, ACLD Active (Utility Power NOT Available) ........................................................ 3

Figure 1-3, Intake Fan, Status LED, Connection Ports, and Knockouts .................................. 6

Figure 1-4, ON/OFF Power Switch, Info Label and Exhaust Vents ......................................... 7

Figure 1-5, Wiring Access Cover ..................................................................................... 7

Figure 2-1, Simplifi ed ACLD System ................................................................................ 8

Figure 2-2, Removing Knockouts ...................................................................................10

Figure 2-3, Approved Mounting Positions ........................................................................11

Figure 2-4, ACLD Dimensions and Side Reference ............................................................12

Figure 2-5, ACLD Terminal Block ....................................................................................15

Figure 2-6, ACLD System Wiring ....................................................................................16

Figure 2-7, AC Wiring from Inverter to ACLD ...................................................................17

Figure 2-8, ACLD to Inverter Communications Cable Connection ........................................21

Figure 2-9, ACLD/NETWORK Communication Cable ..........................................................21

Figure 3-1, Automatic 3-Stage Graph .............................................................................25

Figure 3-2, Utility Connected - Surplus Power Fed to the Utility Grid ...................................26

Figure 3-3, Utility Connected - Additional Power Provided by the Utility Grid ........................26

Figure 3-4, Utility not Connected - RE Powers Critical Loads ..............................................27

Figure 3-5, Utility not Connected - Additional Power Provided to Critical Loads .....................27

Figure 3-6, Utility not Connected - Excess Current Charging Battery Bank ...........................28

Figure 3-7, Utility not Connected - Diverting some Power to Primary Load ...........................28

Figure 3-8, Utility not Connected - Diverting all Power to Primary Load ...............................29

Figure 3-9, Utility not Connected - Diverting Power to Secondary Load ...............................29

Figure 3-10, Power Switch ............................................................................................30

Figure 3-11, Checking Load Resistance ...........................................................................33

List of Tables

Table 2-1, Torque Values for Ground Busbar ....................................................................14

Table 2-2, Torque Values for the AC Terminal Blocks .........................................................14

Table 3-1, LED Blinks to Fault Condition ..........................................................................32

© 2015 Sensata Technologies

Page v

Page 7

Page vi

© 2015 Sensata Technologies

Page 8

Introduction

1.0 Introduction

Congratulations on your purchase of the ACLD-40 (AC Load Diversion - 4.0kW) controller. The

ACLD-40 (also know as the ACLD) is designed to be used in an AC coupled system—networked

with a MS-PAE Series

power to a resistive load.

The ACLD-40 controller includes the following features:

• Automatic three-stage battery regulation (with adjustable voltage and charging parameters).

• Controls up to 4000 watts of excess power to prevent battery overcharge.

• Automatic battery temperature compensation—provides optimum charging even during

extreme temperature changes (when using the inverter’s Battery Temperature Sensor).

• A networked diversion device—using inverter and network ports.

• ON/OFF mounted switch with status/fault indicator LED; operation and power information

is provided when using the inverter’s remote.

• Designed to work with MS-PAE Series inverters to prevent battery overcharging.

• Diversion load is isolated from in-home AC loads and receives PWM (Pulse Width Modulation)

voltage—prevents AC line disturbance by providing smooth transition when regulating.

• Allows the use of resistive AC household loads (i.e., water heater tanks) instead of expensive

and hard to fi nd DC loads to divert excess current.

• Does not require additional/external sensors to monitor battery inverter output current,

battery voltage, or battery type.

1.1 What is an AC Load Diversion Controller (ACLD)?

The basic operating concept of an AC or DC diversion controller is quite simple. Monitor the battery

bank, and if an energy source (e.g. solar panel, wind generator, etc.) should cause the battery

to rise to a predetermined voltage level, connect a diversion load of suffi cient size to prevent the

battery from being overcharged. By diverting the unused energy that your solar panel or wind

generator is producing, you can make use of it—such as heating a hot water or heating a room.

The ACLD-40 is an AC load diversion controller that maximizes the use of onsite-generated power

(i.e., renewable energy) by diverting any excess energy to resistive loads on the AC side. By

diverting the excess current on the AC side and not on the DC side (through the battery-based

inverter), there is less strain on the battery-based inverter. Also, since the wiring is on the AC

side, there is less voltage drop, less expensive system wires and diversion loads, and fewer issues

when trying to determine how to size the diversion loads/hardware.

1

inverter—to provide three-stage battery charging and to divert any excess

1.2 What is an AC Coupled system, and why do I need an ACLD?

Many homeowners utilize renewable energy (i.e., PV, wind, etc.) by installing a high effi ciency,

battery-less, grid-tie inverter (also known as an utility-interactive inverter) to offset their power

consumption from the utility grid. However, these homeowners soon learn that when a utility

power outage occurs, the grid-tie inverter is required to shut down. This can cause considerable

frustration as the homeowner realizes that the critical loads in the home (refrigerator, lights, water

pump, etc.) are no longer powered and all the energy produced by the renewable energy source

is being wasted while the utility power is out.

To overcome some of the disadvantages of a battery-less, grid-tie inverter; homeowners add a

battery-based inverter and batteries to power critical loads during a utility power outage. However,

the generated power from the renewable energy continues to be wasted until the utility power

returns.

1 This manual will specifi cally refer to the MS-PAE Series to work with the ACLD-40. How-

ever, the ACLD will work with any battery-based inverter that provides a MagNet communications

port and has an output of 230 or 240 VAC (50 or 60 Hz). This means the MS-PAE Series, MS-E

Series, or MS-PE Series inverters will work with the ACLD-40.

© 2015 Sensata Technologies

Page 1

Page 9

Introduction

Traditionally, when a battery-based inverter is used, the renewable energy system is connected

or ‘coupled’ to the battery (or DC) side of the inverter. In a DC coupled system, the renewable

energy is wired at a lower voltage to better match the battery bank, and a DC controller is used to

manage the energy to prevent the battery from being overcharged. This type of system is usually

more costly and complex to install because of more components; and because the voltage is lower,

there are more effi ciency losses as a whole (when compared to a grid-tie inverter-only system).

However, using a concept known as AC Coupling, a four quadrant (bi-directional) battery-based

inverter (such as Sensata’s MS-PAE Series) can be installed that utilizes the renewable energy to

power the home’s critical loads during a power outage from the AC side. With the addition of a

battery bank, a critical-loads sub-panel, and a diversion controller with load, coupling a MS-PAE

Series inverter on the AC side can be very advantageous. The existing renewable energy system

does not need to be rewired to the DC side, and the high conversion effi ciency of the grid-tie

inverter is maintained while the utility power is available.

1.3 How an AC Coupled System Works

Described below is how an AC-Coupled system works when utility power is available, and when

there is an utility power outage.

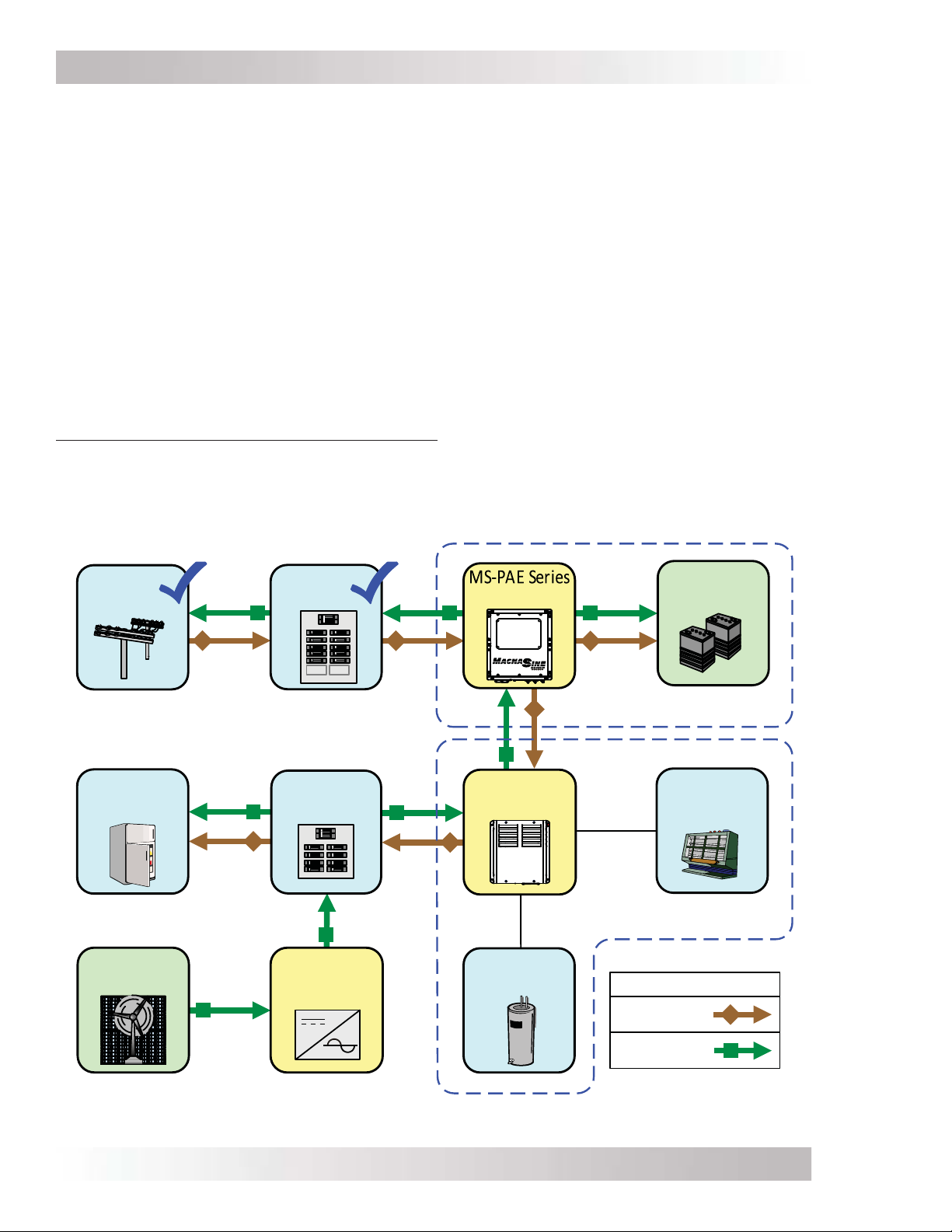

When utility power is available (see Figure 1-1): Normally, when utility power is available and a

MS-PAE Series inverter is installed, the grid-tie inverter converts the renewable energy to work in

parallel with the utility to power the loads in the home (main-panel and critical loads sub-panel),

charge the battery system, and feed any surplus renewable energy back into the utility grid.

Utility

Grid

Crit ic al

Loa ds

Renewable

Energy

Main

Panel

Sub-

Panel

Grid-Tie

Inverter

Inverter

ACLD-40

Controller

AC Load

(Primary)

Battery

Bank

Battery Back-up Section

AC Load

(Secondary)

ACLD Section

Power Flow

Utility Grid

Renewable

Energy

Figure 1-1, ACLD Inactive (Utility Power Available)

© 2015 Sensata TechnologiesPage 2

Page 10

Introduction

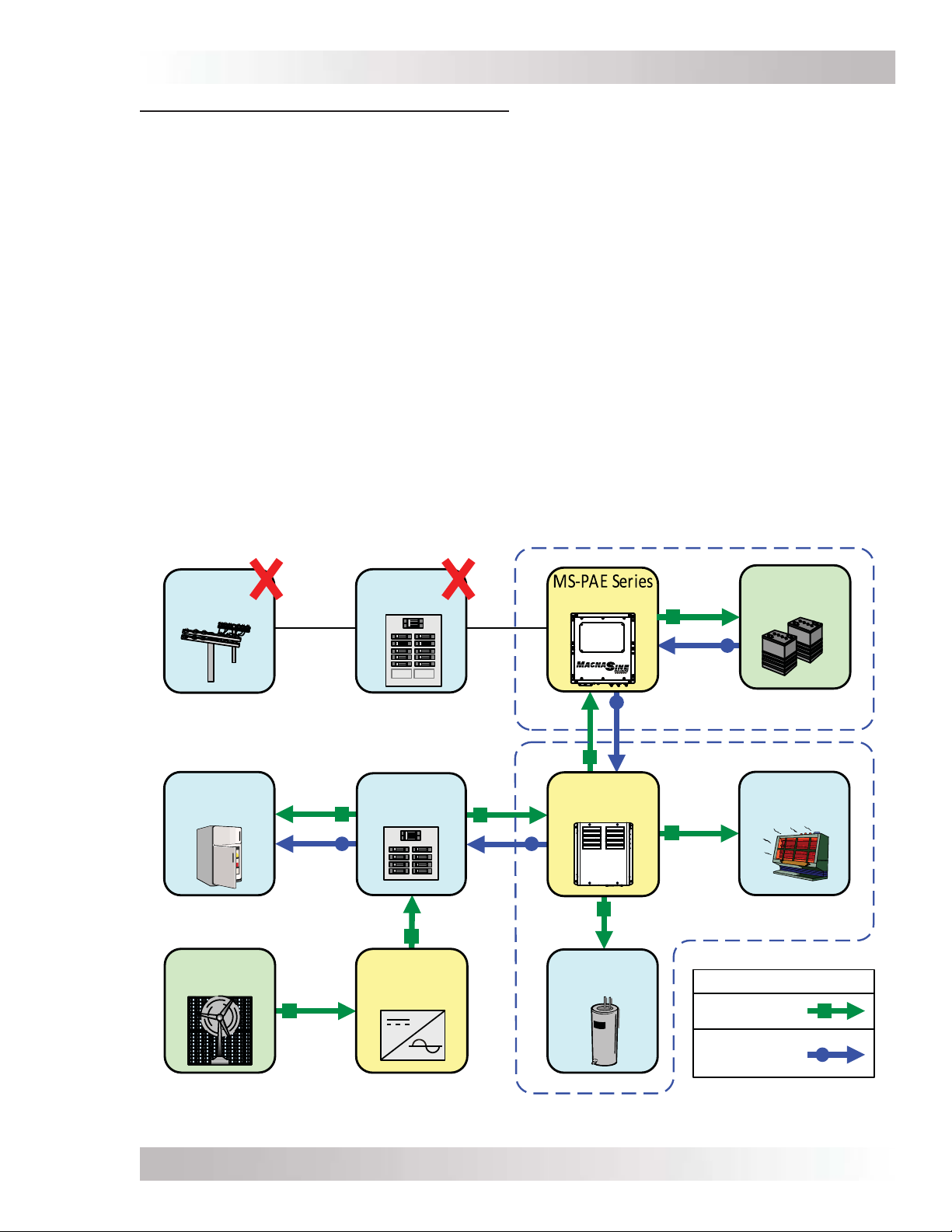

During a utility power outage (see Figure 1-2): When the utility power fails, the grid-tie inverter

disconnects (preventing the use of the renewable energy) and the MS-PAE Series inverter

automatically starts powering the critical loads. However, because the output of the MS-PAE

Series inverter is connected to the same AC bus as the grid-tie inverter and its output waveform

is compatible to the utility’s waveform, the grid-tie inverter re-synchronizes to the AC output

waveform of the MS-PAE Series inverter. After a minimum 5-minute disconnect period, the gridtie inverter reconnects and starts inverting all the energy from the renewable energy source just

like it did when it was connected to utility power.

The grid-tie inverter—now reconnected using the AC output waveform of the MS-PAE Series

inverter—converts as much of the available renewable energy as possible. However, during a

utility power interruption, the main panel loads are no longer connected and the utility grid is not

available to export any excess power that is generated. This means there may be more power on

the AC bus than the critical loads can consume, causing current to be pushed back thru the AC

output of the MS-PAE Series inverter into the battery bank. Since this is not the normal path for

the MS-PAE Series inverter to sense incoming current, it is not able to control the battery voltage

(or regulate the current, which requires the inverter to be rated to handle the full power output

of the renewable energy source). If the renewable energy provides more current that the critical

loads can use, there is the possibility that the battery voltage will rise and cause damage to the

battery. If the battery voltage is allowed to rise high enough, a High Battery Voltage fault on

the MS-PAE Series inverter will occur, causing it to turn off; which in turn shuts down the entire

system (i.e., critical loads and grid-tie inverter turn off). To prevent this from happening, there

must be a method of regulating the battery bank and ensuring it is properly charged; this is why

the ACLD-40 is needed.

Utility

Grid

Crit ic al

Loa ds

Renewable

Energy

Main

Panel

Sub-

Panel

Grid-Tie

Inverter

Inverter

ACLD-40

Controller

AC Load

(Primary)

Battery

Bank

Battery Back-up Section

AC Load

(Secondary)

ACLD Section

Power Flow

Renewable

Energy (RE)

Inverter power

(when RE no t

available)

Figure 1-2, ACLD Active (Utility Power NOT Available)

© 2015 Sensata Technologies

Page 3

Page 11

Introduction

1.4 Battery Regulation Methods

In an AC-coupled system, there are several methods that are used to regulate the battery voltage,

as described below:

1. AC disconnect driven by DC controlled relays: When the battery voltage rises above a

maximum setpoint, a battery voltage controlled relay is activated to open the AC connection to

the grid-tie inverter. This causes the critical load sub-panel to now be powered from the batteries

through the battery-based inverter. When the battery voltage falls to the low setpoint, the relay

closes and allows the grid-tie inverter to reconnect and begin generating power from the renewable

energy. If the battery voltage rises again, this cycle repeats.

Disadvantages:

• Batteries are cycled, not regulated—does not allow the batteries to be properly charged.

• Generated power from the renewable energy is wasted while the relay is opened.

• The DC relay setpoints must be set much higher than required to ensure the DC relay

doesn’t connect or interfere with normal charging (from the battery-based inverter) and

any sell back voltage settings once the utility power returns.

• No temperature-compensated regulation while charging.

2. DC diversion driven by DC controlled relays: When the battery voltage rises above a

maximum setpoint, a battery voltage controlled relay is used to switch on a dedicated DC diversion

load to consume any excess power. When the battery voltage falls to the low setpoint, the dedicated

diversion load turns off. If the battery voltage rises again, this cycle repeats.

Disadvantages:

• Batteries are cycled, not regulated—does not allow the batteries to be properly charged.

• Diffi cult to source and size DC diversion loads to absorb the full output of the renewable

energy source.

• The regulation setpoint must be set much higher than required to ensure the diversion load

is not always in “regulation”, and that it doesn’t interfere with normal charging (from the

battery-based inverter) or any sell back voltage settings once the utility power returns.

• Since excess power is regulated on the DC side, the battery-based inverter is required to be

always on, re-converting the renewable energy from AC back to DC where it is diverted—an

extra conversion step creates energy loss and there is an unnecessary use of the inverter.

• No temperature-compensated regulation while charging.

3. DC Diversion Controller off the battery: When the battery voltage rises above a voltage

regulation setpoint, the DC Diversion Controller sends excess current to a dedicated DC diversion

load to maintain the battery voltage. When the battery voltage falls below the regulation setpoint,

current is no longer sent to the dedicated diversion load.

Disadvantages:

• Diffi cult to source and size DC diversion loads correctly. If the load is too small, it cannot divert

enough power from the source (wind, hydro, etc.), and the battery could be overcharged. If

the diversion load is too large, it will draw more current than the rating of the controller—

causing damage or causing the controller’s protection circuits to open the load.

• Multiple controllers are usually needed even for medium sized renewable energy systems

(i.e., a 4kW/48VDC system requires at least a 70-amp controller).

• The regulation setpoint must be set much higher than required to ensure the diversion load

is not always in “regulation”, and that it doesn’t interfere with normal charging (from the

battery-based inverter) or any sell back voltage settings once the utility power returns.

• Since excess power is regulated on the DC side, the battery-based inverter is required to be

always on, re-converting the renewable energy from AC back to DC where it is diverted—this

extra conversion step creates energy loss and there is an unnecessary use of the inverter.

© 2015 Sensata TechnologiesPage 4

Page 12

Introduction

4. Frequency disturbance/shift from the battery-based inverter: When the battery voltage

rises above a maximum setpoint, a battery-based inverter changes its output frequency to cause

the grid-tie inverter to limit the energy from the renewable energy source to the battery.

Disadvantages:

• Generated power from the renewable energy is limited/wasted during the frequency shift.

• Batteries are cycled, not regulated—does not allow the batteries to get properly charged

• The frequency-shift setpoint must be set higher than required to ensure it doesn’t interfere

with normal charging (from the battery-based inverter) or any sell back voltage settings

once the utility power returns

• No temperature compensated regulation while charging

1

.

1

.

Note1 – May not occur if networked to the grid-tie inverter

5. AC diversion driven by DC controlled relays: A battery voltage controlled relay is used

to switch on a dedicated AC diversion load (i.e., space heater, air conditioner, etc.) to consume

any excess power when the battery voltage rises above a maximum setpoint. When the battery

voltage falls to the low setpoint, the dedicated diversion load turns off. If the battery voltage rises

again, this cycle repeats.

Disadvantages:

• Batteries are cycled, not regulated—does not allow the batteries to be properly charged.

• AC diversion loads must be sized to absorb the full output of the renewable energy source

and confi gured to always be on (no temperature or thermostat turn-off control).

• AC diversion loads, when activated, can cause enough AC line drop/disturbance to disconnect

the grid-tie inverter—wasting generated energy.

• No temperature compensated regulation while charging.

6. AC Load Diversion Controller (ACLD-40): When the battery voltage rises above a voltage

regulation setpoint, the ACLD-40 begins to send excess current to a dedicated AC diversion load

to maintain the battery voltage. When the battery voltage falls below the regulation setpoint,

current is no longer sent to the dedicated diversion load.

Advantages:

• Batteries are properly charged/regulated - true three-stage charging to batteries during

power outage.

• Easier to source and size AC diversion loads to absorb the full output of the renewable

energy source.

• Primary AC diversion loads can be confi gured for temperature/thermostat turn-off—primary

loads are not required to always be on.

• AC diversion loads are isolated from the grid-tie inverter’s output to provide a smooth turnon transition—prevents the inverter from disconnecting due to AC line drop/disturbance.

• ACLD-40 communicates with the MS-PAE Series inverter, this provides:

o No confusion or interference trying to coordinate the inverter’s and controller’s setpoints

once the utility power returns—controller uses same charge setpoints as the MS-PAE

Series inverter for regulation.

o Temperature compensated regulation while charging—uses temperature sensor readings

from the MS-PAE Series inverter.

o Information on diverted power and the controller’s status can be displayed using a

remote control.

o Knows when grid power returns—ensures the renewable energy is not being diverted

and is available to be fed back to the utility grid.

• Does not require multiple current sensors and devices—all current fl ow is monitored at the

controller to determine when to divert excess current.

• No AC to DC energy conversion loss when trying to regulate battery voltage—excess power

is regulated on the AC side.

1

.

© 2015 Sensata Technologies

Page 5

Page 13

Introduction

1.5 ACLD Features and Benefi ts

The ACLD controller is designed with features that allow easy access to wiring and controls.

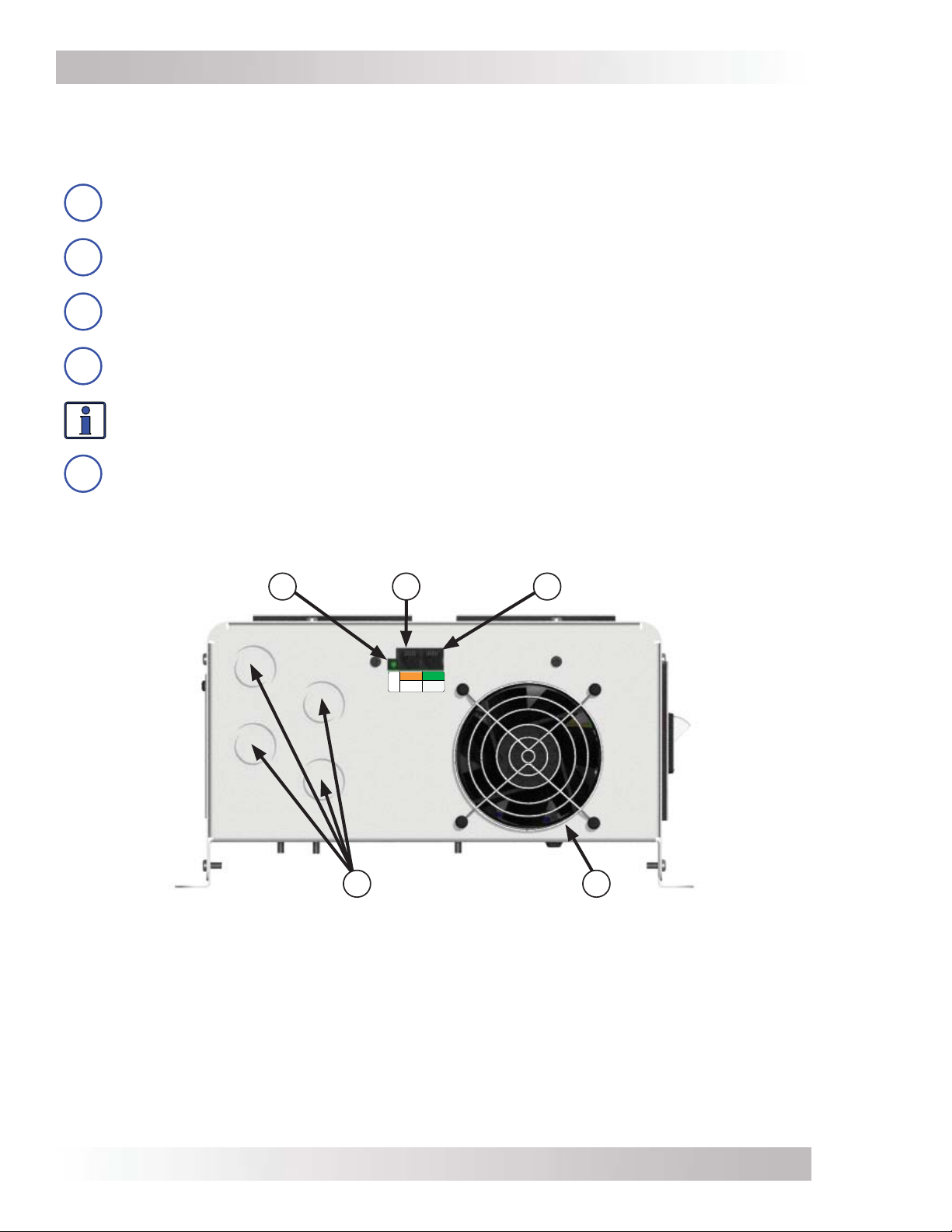

The front

1

2

3

4

5

of the ACLD controller is equipped with the following (refer to Figure 1-3):

Status LED Indicator – this green LED illuminates to provide operation and fault

information on the ACLD controller.

Inverter Connection Port (orange) – a RJ11 port for connecting the ACLD controller

to the network port (green) on a the MS-PAE Series inverter.

Network Connection Port (green) – a RJ11 port for connecting the ACLD controller to

a Network controlled device (i.e., ME-BMK, ME-AGS-N).

Knockouts – four dual knockouts (½” and ¾”) to accommodate AC wiring access and

routing.

Info: Four additional dual knockouts (½” and ¾”) identical to the ones noted in Item 4

are located on the opposite side (eight dual knockouts total).

Intake Cooling Fan – an intake fan to pull in air to allow the ACLD controller to operate

continuously at full power.

Status LED

Indicator

Inverter

Connection Port

Network

Connection Port

321

S

T

L

A

E

T

D

U

TO

S

INVERTERTONETWORK

54

Dual Knockouts

(

½” and ¾”)

Figure 1-3, Intake Fan, Status LED, Connection Ports, and Knockouts

Intake

Cooling Fan

© 2015 Sensata TechnologiesPage 6

Page 14

Introduction

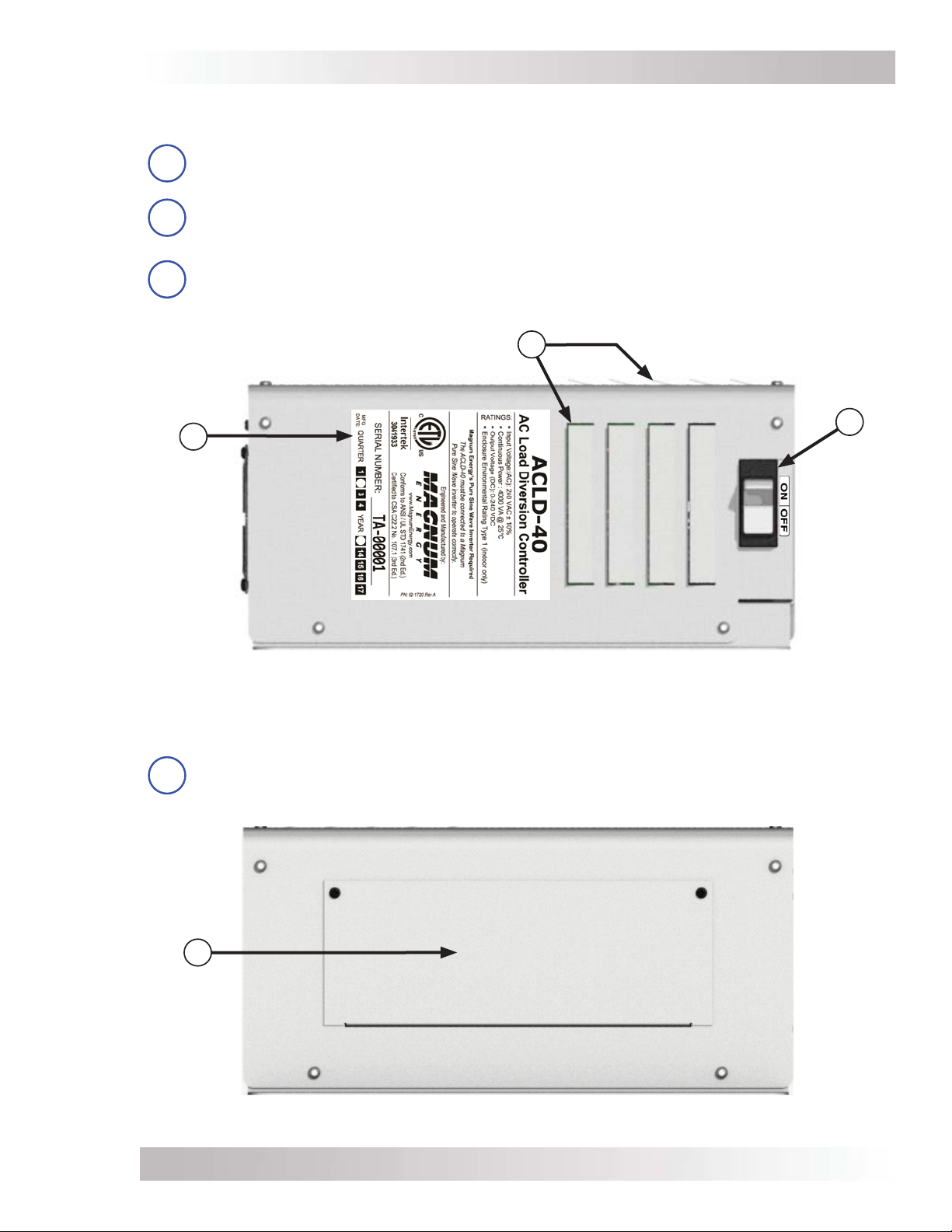

The right side of the ACLD controller has an information label, exhaust vents and an ON/OFF

switch (see Figure 1-4):

Information Label – includes model/serial number information, date of manufacture,

6

and specifi cations. See the specifi cations in Appendix A for more information.

Exhaust Vents – ventilation openings that allow heated air to be removed by the internal

7

cooling fan. The exhaust air vents are located on the right side and at the rear of the top

side.

ON/OFF Power Switch – a power switch that turns the ACLD controller on or off.

8

Exhaust Vents

(on right and top sides)

7

ON/OFF

Power

Switch

6

Information

Label

Figure 1-4, ON/OFF Power Switch, Info Label and Exhaust Vents

The left side of the ACLD controller has an access cover that can be removed (Figure 1-5):

Wiring Access Cover – provides access to the internal AC wiring terminal block and

9

ground busbar. This terminal block is used to hardwire all AC wiring connections.

Remove the two #6-32 screws to access the AC wiring terminal block.

8

9

Wiring

Access

Cover

© 2015 Sensata Technologies

Figure 1-5, Wiring Access Cover

Page 7

Page 15

Installation

2.0 Installation

Read the entire Installation section to determine how best to install the ACLD controller. The more

thorough you plan in the beginning, the better the chances are that the installation will go well.

WARNING: Installations should be performed by qualifi ed personnel, such as a

licensed or certifi ed electrician. It is the installer’s responsibility to determine which

safety codes apply and to ensure that all applicable installation requirements are

followed. Applicable installation codes vary depending on the specifi c location and

application of the installation.

WARNING: Review the “Important Product Safety Information” on pages ii-v before

any installation.

CAUTION: The ACLD controller weighs 20 lb (9.1 kg), use proper lifting techniques

during installation to prevent personal injury.

Info: The ACLD controller only controls the renewable energy source connected to the

AC side of the system. Any renewable energy source connected to the DC side of the

system must be controlled separately using a DC controller/diversion load.

2.1 Pre-Installation

The simplifi ed system diagram shown in Figure 2-1 should be reviewed to assist you in planning

and designing your installation. This drawing is not intended to override or restrict any national

or local electrical codes. This drawing should not be the determining factor as to whether the

installation is compliant, that is the responsibility of the electrician and the onsite inspector.

Critical Loads

(Sub-Panel)

Grid-Tie

Inverter (GTI)

PV

Power

Battery

Bank

Mini Magnum

Panel

MS-PAE Series

Battery Based

Inverter (BBI)

Input

(from GTI)

ACLD-40

Load

Controller

Grid

Power

Main Loads

(Main Panel)

MagNet

Comm

-

Input

(from BBI)

Primary

Diversion Load

Output

(to Pri load)

Figure 2-1, Simplifi ed ACLD System

Output

(to Sec load)

© 2015 Sensata TechnologiesPage 8

Secondary

Diversion Load

Page 16

Installation

2.1.1 Considerations when Installing the ACLD System

• The ACLD controller is designed to be connected and powered from the AC output of a batterybased inverter that provides a MagNet communications port and has an output of 230 or 240

VAC (50 or 60 Hz). Normally this would be the MS-PAE Series (MS4024PAE or MS4448PAE),

but can also connect to the MS-E Series and MS-PE Series inverters.

• The continuous power rating of the inverter (MS-PAE Series) must be at least 10% larger than

the maximum power rating of the renewable energy source. Otherwise, the inverter may be

damaged if required to handle current greater than designed.

• During an AC utility outage, some brands of grid-tie inverters are sensitive and disconnect

when powered from battery-based inverters.

• As required by the NEC, a photovoltaic power system (or small wind electric system) employing

a diversion charge controller of regulating the charging of a battery shall be equipped with a

second independent means to prevent overcharging of the battery. The MS-PAE Series inverters

can provide an automatic frequency-shift feature that disconnects the grid-tie inverter when

high voltage is detected on the battery. Note: This frequency-shift feature is enabled by setting

the battery type to ‘custom’ using a remote control, however, this feature should only be used

as a backup—the ACLD-40 should be used as the primary regulation method.

• A diversion load must be connected to the ACLD to prevent over-charge damage to the

inverter’s battery bank. It must be at least 10% larger than the maximum power rating of the

renewable energy source. See Section 2.9 for information on the ACLD load requirements

• As the AC current is being provided by the grid-tie inverter through the sub-panel (i.e., critical

loads panel) into the ACLD, a 30-amp branch rated circuit breaker must be provided from

the sub-panel to the ACLD. Note: The installation can be made easier by using the MMP-30D

Series enclosure. This enclosure provides the required 30-amp overcurrent circuit protection

between the sub-panel and the ACLD controller.

• The ACLD-40 is limited to 4000 watts continuous and is designed to work with a single MSPAE Series pure sinewave inverter that has an output voltage of 240VAC. Note: The ACLD-40

cannot be stacked or combined with another ACLD to handle additional power.

2.1.2 Unpacking and Inspection

Carefully remove the ACLD controller from its shipping container and inspect all contents. Verify

the following items are included:

.

• The ACLD Controller • 6’ yellow communications cable

• ACLD Owner’s Manual • Access panel with hardware

If items appear to be missing or damaged, contact Sensata. If at all possible, keep your shipping

box to help protect your ACLD controller from damage if it ever needs to be returned for service.

Important: Save your proof-of-purchase as a record of your ownership; it will be required

if the ACLD should require in-warranty repair.

Record the unit’s model and serial number in the front of this manual in case you need to provide

this information in the future. It will probably be much easier to record this information now, rather

than trying to gather it after the unit has been installed.

2.1.3 Required Tools and Materials

Hardware/Materials

• Conduit or strain-reliefs and appropriate fi ttings • Mounting bolts and lock washers

• Electrical tape • Wire ties

Tools

• Miscellaneous screwdrivers • Pliers • Wire strippers

• Drill and drill bits • Pencil or marker • Multimeter

• Level • 1/2” wrench

© 2015 Sensata Technologies

Page 9

Page 17

Installation

2.2 Locating the ACLD Controller

Only install the ACLD controller in a location that meets the following requirements:

Clean and Dry – The controller should not be installed in an area that allows dust, fumes, insects,

or rodents to enter or block the controller’s ventilation openings. This area also must be free from

any risk of condensation, water, or any other liquid that can enter or fall on the controller. Failure

due to any of the above conditions is not covered under warranty.

Info: If the controller is installed in an area where moisture may occur, we recommend

putting silicone dielectric grease compound into the electrical ports (as shown in Figure

1-3, Items 2 and 3). Before installing the cables, or if leaving any ports open, squirt a

liberal amount into each port. Silicone dielectric compound makes an effective moisture

and corrosive barrier to help protect and prevent corrosion to the RJ11 connections.

Cool – The controller should be protected from direct sun exposure or equipment that produces

extreme heat. If the ambient temperature around the controller exceeds 77°F (25°C), the power

specifi cations are reduced.

Ventilation – In order for the controller to provide full output power and to avoid over-temperature

fault conditions, do not cover or block the controller’s ventilation openings or install this controller

in an area with limited airfl ow. The controller uses a fan to provide forced air cooling, this fan pulls

in air through the intake opening (see Figure 1-3, Item 5) and blows out air through the exhaust

vents (see Figure 1-4, Item 7). Allow at the minimum an airspace clearance of 6” (15.2 cm) at

the intake and exhaust vents, and 3” (7.6 cm) everywhere else to provide adequate ventilation.

Safe – Keep any fl ammable/combustible material (i.e., paper, cloth, plastic, etc.) that may be

ignited by heat, sparks, or fl ames at a minimum distance of 2 feet (61 cm) from the controller.

Have access to the MS-PAE Series inverter – The communications control for the ACLD is provided

by the MS-PAE Series inverter, so the ACLD controller must be in an area that allows the network

cable to be connected to the inverter. The network cable provided is 6’ and can be extended up to a

length of 200 feet without data degradation. See Section 2.10.1 for more information on the cable.

Accessible – Do not block access to the controller’s inverter and network ports, as well as the

ON/OFF switch and status indicator. Allow enough room to access the AC wiring terminals and

connections, as they will need to be checked and tightened periodically.

Away from sensitive electronic equipment – High powered devices with PWM circuitry can

generate levels of RFI (Radio Frequency Interference). Locate any electronic equipment susceptible

to radio frequency and electromagnetic interference as far from the controller as possible.

2.2.1 Conduit Knockouts

The ACLD controller comes standard with four dual knockouts (for 1/2” and 3/4” conduits) on each

side (eight total). Figure

knockout that is close to the terminal that the wire will connect to, or whichever one works for the

way your fi eld wiring comes in.

1-3 shows the location of these conduit knockouts. Select the appropriate

Info: The knockouts can be easily removed by tapping the edge with a straight bladed

screwdriver and a hammer, then twist out with pliers. See Figure 2-2.

Before removing any knockouts and mounting the ACLD controller, think about whether you are

going to use

wiring required. See Section 2.4.3 for wire routing requirements to/from the ACLD controller.

cable clamps or conduit (using the optional MPX-CB conduit box), and the different

Figure 2-2, Removing

Knockouts

© 2015 Sensata TechnologiesPage 10

Page 18

Installation

2.3 Mounting the ACLD Controller

When mounting the ACLD controller, the surface and the mounting hardware must be capable of

supporting at least twice the weight of the unit. To meet regulatory requirements, the ACLD must

be mounted in one of the following positions (as shown in Figure 2-3):

• above or under a horizontal surface (shelf or table),

• on a vertical surface (wall) with the intake cooling fan to the right,

• on a vertical surface (wall) with the intake cooling fan toward the bottom, and an optional

MPX-CB (conduit box) installed below the controller.

Info: The four mounting holes on the ACLD have a diameter of 0.280” (7.11 mm), good

for 1/4” bolts/screws (see Figure 2-4 for hole locations).

Info: The MPX-CB prevents material from falling out the bottom in the event of an

internal fi re, and also allows suffi cient ventilation to prevent the ACLD controller from

overheating under normal operating conditions.

Info: Sensata provides a backplate that can be used to mount the ACLD (and if required,

the MPX-CB). This backplate part number is BP-S (Back Plate - Single).

After determining the mounting position, refer to the physical dimensions as shown in Figure 2-4

or use the base of the ACLD as a template to mark your mounting screw locations. After marking

the mounting screw locations, mount the controller with appropriate mounting hardware.

SHELF OR TABLE MOUNTED

(Fan facing away from wall)

WALL MOUNTED

(Fan to the right)

Figure 2-3, Approved Mounting Positions

WALL MOUNTED

(Fan facing down and MPX-CB installed)

When the unit is mounted in this position,

either the MPX-CB (MPX conduit box) or

MMP Series Enclosure must be attached

below.

© 2015 Sensata Technologies

Page 11

Page 19

Installation

5 ½"

Fro nt Side

(14 cm)

cm)

6 ½"

(16.5

Right Side

.280

Ø

4 places

(0.71 cm)

Intake Cooling Fan

Vents

Exhaust

Back Side

¾"

&

Dual

½"

6 ¾"

¾"

&

½"

(x4)

Knockouts

(17.1 cm)

(x4)

Dual

Knockouts

12 ¾"

11 ¼"

(32.4 cm)

(28.6 cm)

Top

Side

13 ⅝"

(34.6 cm)

12"

(30.5 cm)

Figure 2-4, ACLD Dimensions and Side Reference

Left Side

© 2015 Sensata TechnologiesPage 12

Page 20

Installation

2.4 General Wiring Requirements

This section describes the requirements and recommendations for wiring the ACLD controller.

Before wiring the controller, carefully read all instructions.

Wiring should meet all local codes and standards and be performed by qualifi ed personnel

such as a licensed electrician.

The NEC (National Electric Code, ANSI/NFPA 70) for the United States and the CEC (Canadian

Electrical Code) for Canada provide the standards for safely wiring residential and commercial

installations. The NEC (or CEC) lists the requirement for wire sizes, overcurrent protection, and

installation methods and requirements.

WARNING: Because the ACLD is wired with an inverter/charger, there is power from

multiple sources (inverter, generator, utility, batteries, solar arrays, etc.) which make

the wiring more hazardous and challenging. Ensure they are all de-energized (i.e.,

breakers opened, fuses removed) before proceeding—to prevent accidental shock.

2.4.1 Protecting Wire – Conduit Box

The AC wires to and from the load controller must be protected as required by code. This can be

done by using jacketed wires or by feeding the wires through conduit. A conduit box (MPX-CB) is

available that allows the AC conduit to be connected to the ACLD controller.

2.4.2 Wiring Requirements

• All conductors that are at risk for physical damage must be protected by conduit, tape, or

placed in a raceway.

• Always check for existing electrical, plumbing, or other areas of potential damage prior to

making cuts in structural surfaces or walls.

• AC overcurrent protection must be provided as part of the installation and be properly sized.

• Use only copper wires with a minimum temperature rating of 75°C (167°F).

• Always use properly rated circuit breakers. If using an electrical sub-panel, circuit breakers

can be moved from the main electrical panel to the sub-panel only if the breakers are also

listed to be installed in the sub-panel.

• Wiring must be no less than #10 AWG (5.3 mm

the application (i.e., residential wiring).

• The wire sizes recommended in this manual are based on the ampacities given in Table

310.16 (in conduit) or Table 310.17 (in free air) of the NEC, ANSI/NFPA 70, for 75°C (167°F)

copper wire based on an ambient temperature of 30°C (86°F).

2.4.3 Wire Routing

Before connecting any wires, determine all wire routes to and from the load controller. Typical

routing scenarios are:

• Network communication cable from the inverter to the load controller.

• AC wiring from the inverter output to the load controller.

• AC wiring from the load controller to circuit protection (if not using the MMP enclosure)

• AC wiring from the circuit protection (or MMP enclosure) to the AC sub-panel (i.e., dedicated

inverter circuits).

• AC output wiring from the load controller to the primary diversion load (which can be

confi gured to turn off).

• AC output wiring from the load controller to the secondary diversion load (which must be

confi gured to always be available and stay on).

• Ground wiring to and from the load controller.

• Remote control cable to the inverter.

2

) gauge copper wire and be approved for

© 2015 Sensata Technologies

Page 13

Page 21

Installation

2.4.4 Wire Size and Overcurrent Protection

The wiring must be approved for the application (i.e., residential wiring) and sized per the local

electrical safety code requirements to ensure the wire’s ability to safely handle the maximum load

current. The wiring must be protected from short circuits and overloads by an overcurrent protection

device. This overcurrent protection device must have a means to disconnect the circuits (e.g., circuit

breaker or a fuse/disconnect), be properly sized, and branch circuit rated for the wire it is protecting.

As shown in Figure 2-5, the ACLD provides two input circuits, the Battery Based Inverter (BBI)

and Grid-Tie Inverter (GTI) input circuits. As part of the installation, overcurrent protection rated

to handle a maximum 30 amps must be provided from the source to these two input circuits. A

dual-pole, 30 amp, 240-volt branch rated circuit breaker to protect both L1 and L2 circuits for

each input circuit is required. Referring to Figure 2-6, the BBI input to the ACLD (terminals 1 and

2) is protected from a 30A breaker from the main utility panel; and the GTI input to the ACLD

(terminals 5 and 6) is protected using the 30A breaker in the MMP. Note: If the MMP enclosure is

not used, an external panel with a 30A breaker must be provided to protect the GTI input from

the Grid-Tie Inverter.

The ACLD also provides a primary output circuit (terminals 7 and 8) and secondary output circuit

(terminals 9 and 10) that are connected to the diversion loads. An external overcurrent protection

device is not required for these two output circuits as the diversion loads are the only connections

to these two circuits and these circuits are protected by the ACLD’s internal electronic overcurrent

protection circuitry.

CAUTION: The ACLD internal wires are rated for 30 amps, the pass-thru current must

be no greater than 30 amps or damage to the ACLD will occur.

CAUTION: The wiring must be no less than #10 AWG (5.3 mm2) gauge copper wire

and be approved for the application (i.e., residential wiring).

2.5 Torque Requirements

Follow the specifi c torque recommendations below to ensure your fasteners are tightened

suffi ciently. To ensure your connections are correct, you should use an accurate, quality torque

wrench. It is highly recommended to go back over all fasteners and re-torque after fi ve days, and

every six months thereafter.

Table 2-1, Torque Values for Ground Busbar

Note: The ground busbar has different torque values for the small and large screws.

Wire Size

#14 to #10 AWG

(2.1 to 5.3 mm

2

)

10-32 [Small Screw] 5/16-24 [Large Screw]

15 in. lbs. (1.7 N-m) 35 in. lbs. (4.0 N-m)

#8 AWG (8.4 mm2) 20 in. lbs. (2.3 N-m) 40 in. lbs. (4.5 N-m)

#6 AWG

(13.4 mm2)

#4 AWG (21.1 mm

2

) NA 45 in. lbs. (5.1 N-m)

25 in. lbs. (2.8 N-m) 45 in. lbs. (5.1 N-m)

#3 to #1/0 AWG

(26.6 to 53.5 mm2)

Busbar Screw Size Torque Values

NA 50 in. lbs. (5.6 N-m)

Table 2-2, Torque Values for the AC Terminal Blocks

Wire Size Slotted M3.5 Screw Torque Values

#14 to #6 AWG

(2.1 to 13.4 mm2)

16 in. lbs. maximum

(1.8 N-m maximum)

© 2015 Sensata TechnologiesPage 14

Page 22

Installation

2.6 ACLD Terminal Block Connections

The ACLD controller has a ten-pole terminal block and a ground busbar to permanently connect

the BBI/Battery Based Inverter (e.g., MS-PAE Series), the GTI/Grid-Tie Inverter and any primary

or secondary loads (see Figure 2-5). To access and view the terminal block and ground busbar,

remove the two Phillips screws holding the AC wiring access cover plate (see Figure 1-5, Item 9).

Each connection on the terminal block is rated to accept one #14 to #6 AWG (2.1 to 13.4 mm

CU stranded wire, or two #12 AWG (3.3 mm

2

) CU stranded wires. Each connection uses a M3.5

slotted head screw, and the maximum tightening torque is 16 in. lbs. (1.8 N-m).

Info: Both of the ACLD’s NEUTRAL terminals are electrically connected to each other

and either connection can be used to connect the inverter and electrical panel.

The ground busbar has two #14 to #1/0 AWG (2.1 to 53.6 mm

2

) and three #14 to #6 AWG (2.1 to

13.4 mm2) compression terminals with slotted-head screws. See Table 2-1 for torque requirements.

INPUT

INPUT

(GTI)

(BBI)

2

)

From MS-PAE Series

inverter (HOT 2 out)

From MS-PAE Series

Common Neutrals

inverter (HOT 1 out)

(from inverters)

From Sub-Panel /Grid-

OUTPUT

(PRI)

Tie Inverter (LEG 1 out)

From Sub-Panel /Grid-

Tie Inverter (LEG 2 out)

To Primary

Load (LEG 2)

OUTPUT

(SEC)

To Primary

10987654321

To Secondary

Load (LEG 1)

11

To Secondary

Load (LEG 2)

Load (LEG 1)

1110987654321

Ground Busbar

(In & Out)

Figure 2-5, ACLD Terminal Block

2.7 Electrical System Wiring Diagrams

A diagram of the wiring for the ACLD controller is shown in Figure 2-6, and is provided to assist

you or your system installer. Due to the variety of applications and differences in local and national

electrical codes, this wiring diagram should be used as a general guideline only. It is not intended

to override or restrict any national or local electrical codes; and, this diagram should not be the

determining factor as to whether the installation is compliant, that is the responsibility of the

electrician and the onsite inspector.

© 2015 Sensata Technologies

Page 15

Page 23

Installation

Disconnect

Utility Power

Panel

Main Utility

Power

Utility/Grid

Utility Meter

Bi-Directional

ON

OFF

Photovoltaic Array

@60Hz

120/240VAC

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

O

N

O

N

O

N

O

N

O

N

O

N

O

N

O

ON

O

N

O

N

O

OFF

OFF

OFF

OFF

N

O

N

N

O

N

O

N

O

N

O

N

OFF

OFF

OFF

OFF

OFF

Bank

Battery

Inverter

PV Array

Disconnect

REMOTE

Control

Remote

Inverter

Utility-Interactive

MMP

MS-PAE

Enclosure

Inverter on

@60Hz

240VAC

OFF

OFF

OFF

OFF

O

N

O

N

O

N

O

N

O

N

O

N

O

N

O

ON

= INVERTER HOT OUT (L2)

= INVERTER HOT OUT (L1)

= COMMON NEUTRAL

= COMMON NEUTRAL

= ELECTRICAL SUB-PANEL (L1)

= ELECTRICAL SUB-PANEL (L2)

= PRIMARY LOAD (L2)

= PRIMARY LOAD (L1)

= SECONDARY LOAD (L2)

= SECONDARY LOAD (L1)

9

8

7

6

5

4

3

2

1

10

INVERTE

R

TO

N

OFF

OFF

OFF

OFF

OFF

Sub-Panel

Critical Loads

Load

Primary

(thermostat

PV

Meter

Performance

Figure 2-6, ACLD System Wiring

controlled -

can turn off)

ACLD-40

Diversion

Controller

987654321

10

4kW Load

Secondary

(must

always

Battery Management

remain on)

© 2015 Sensata TechnologiesPage 16

Page 24

Inverter AC Terminal Block

(Input and Output Wiring)

Installation

AC LEG 1 IN

(from Main Panel)

AC LEG 2 IN

(from Main Panel)

INV HOT 1 OUT

(to Sub-Panel via ACLD)

AC NEUTRAL

(from Main Panel)

AC NEUTRAL

(to Sub-Panel via ACLD)

INV HOT 2 OUT

(to Sub-Panel via ACLD)

ACLD-40

Diversion

Controller

1

MS-PAE Inverter/Charger

(on MMPxxx- 30D Encl osu re

2

3

B

with hood and backplate)

4

C

5

A

6

AC GROUNDS

(to Sub Panel)

INV OUT (HOT 2)

(from inverter H2 Out)

(from inverter H1 Out)

(from inverter Neutral)

(to Sub-Panel Neutral)

SUB-PANEL (LEG 1)

(to Sub-Panel/AC Loads)

SUB-PANEL (LEG 2)

(to Sub-Panel/AC Loads)

PRIMARY LOAD (L2)

(to Diversion Load)

PRIMARY LOAD (L1)

(to Diversion Load)

SECONDARY LOAD (L2)

(to Diversion Load)

SECONDARY LOAD (L1)

(to Diversion Load)

INV OUT (HOT 1)

AC NEUTRAL

AC NEUTRAL

ACLD Terminal Block

(Input and Output Wiring)

1

2

3

A

B

C

MMPxxx-30D AC Te rm inal Block

(Input and Output Wiring)

4

5

6

7

8

9

D

E

F

E

F

D

G

6 5 4 3 2 1

G

INV HOT 2 OUT

INV HOT 1 OUT

(from ACLD to Sub-Panel)

(from ACLD to Sub-Panel)

INV HOT 2 IN

(from Main Panel)

INV NE UTRAL OUT

(from ACLD to Sub-Panel)

Figure 2-7, AC Wiring from Inverter to ACLD

INV HOT 1 IN

INV NE UTRAL IN

(from Main Panel)

(from Main Panel)

© 2015 Sensata Technologies

Page 17

Page 25

Installation

2.8 Wiring the ACLD

The following steps are basic guidelines for installing and connecting wiring to and from the ACLD

controller. Refer to Figure 2-7 for visual guidance.

Note: The instructions below refer to the ACLD’s terminals using the attached label terminology.

Wiring the Inverter AC Output to the ACLD

1. Route wires from the inverter’s AC output (HOT 1 OUT, HOT 2 OUT and NEUTRAL) thru the

unused strain relief clamp on the inverter and into the ACLD (using an appropriate knockout).

2. Connect the HOT 1 OUT (black) wire from the inverter’s INV HOT 1 OUT terminal to the INV

OUT (HOT 1) terminal on the ACLD.

3. Connect the HOT 2 OUT (red) wire from the inverter’s INV HOT 2 OUT terminal to the INV OUT

(HOT 2) terminal on the ACLD.

4. Connect a NEUTRAL (white) from one of the inverter’s AC NEUTRAL terminals to one of the

NEUTRAL terminals on the ACLD.

Wiring from the ACLD to the Critical Loads Sub-panel (thru circuit protection)

1. On the ACLD terminal block, connect a black wire to the ELECTRIC PANEL (L1) terminal, a red

wire to ELECTRIC PANEL (L2) terminal, and a white wire to the unused NEUTRAL terminal.

2. Connect a wire (green or bare copper) to the GROUND busbar on the ACLD.

3. Route the ELECTRIC PANEL (L1) and ELECTRIC PANEL (L2), NEUTRAL, and GROUND wires

through an appropriate knockout on the ACLD to an enclosure with a dual-pole 30A branchrated circuit breaker (using minimum #10 AWG/5.3 mm

4. Connect the ELECTRIC PANEL (L1) and ELECTRIC PANEL (L2) wires to the line side of the dualpole 30A circuit breaker (one wire for each pole). See Section 2.4.4 for breaker information.

Info: Figures 2-6 and 2-7 show the ACLD wired through a MMP-30D Series enclosure.

The MMP-30D Series enclosures provide the required branch-rated 30-amp circuit

breaker. These enclosures also provide a full system Inverter Bypass Switch. This

simple item provides a convenient way to isolate the ACLD and inverter from the AC

loads without any re-wiring, which could save you hours of downtime—if you ever

need to service your load controller or inverter.

5. From the load side of the dual-pole 30A circuit breaker, connect the ELECTRIC PANEL (L1)

and ELECTRIC PANEL (L2) wires and route (along with the NEUTRAL and GROUND wire on the

ACLD) to the AC electrical sub-panel.

Wiring to the Diversion Load

1. On the ACLD terminal block, connect a black wire to the PRIMARY LOAD (L1) terminal and a

red wire to PRIMARY LOAD (L2) terminal.

2. Connect a wire (green or bare copper) to the GROUND busbar on the ACLD.

3. Route the wires [PRIMARY LOAD (L1), PRIMARY LOAD (L2) and GROUND] through an appropriate

knockout on the ACLD to a diversion load. See Section 2.4.4 for diversion load information.

Info: If connecting a secondary diversion load, use the same three steps listed above,

except connect a black wire to the SECONDARY LOAD (L1) terminal, a red wire to

SECONDARY LOAD (L2) terminal, and connect an additional GROUND wire.

2

wire).

Wiring Inspection

1. Verify all wire runs are secured. If using strain relief clamps on the knockouts, tighten the

strain relief clamp securely on the wires. Always leave a little extra slack in the wiring.

2. Verify that all connections are correct and secure, all the ACLD terminal screws are torqued to

a maximum tightening torque of 16 lbf-in (2.0 N-m), and the ground screws are torqued based

on Table 2-1.

3. Replace the ACLD wiring access cover and any other cover you removed to access wiring

terminals during this installation (i.e., on the electrical/distribution sub-panel, etc.).

© 2015 Sensata TechnologiesPage 18

Page 26

Installation

2.9 ACLD Load Requirements

A diversion load is required to be connected to the ACLD. When the ACLD is activated during a

power outage, current from the renewable energy source is used to charge the battery. As the

battery becomes charged, the ACLD connects the diversion load to consume any excess power

—preventing the battery from being overcharged and damaged.

The diversion load connected to the ACLD must:

• handle 240VRMS,

• be pure resistive,

• sized a minimum of 110% of the renewable energy source,

• rated no less than 2500 watts and no greater than 5000 watts.

CAUTION: Do not use light bulbs, motors, or other electrical devices for diversion

loads. They are not stable and may be damaged or fail—causing the battery to be

overcharged. Only purely resistive heating elements (such as “Wire-wound” resistors or

electric heating elements) rated for 240-volts RMS should be used.

CAUTION: Ensure the diversion load is sized correctly. If the diversion load is sized too

low or too high, the ACLD could fault and disconnect—possibly resulting in damage to

the system battery or other system components.

2.9.1 Selecting and Sizing the Diversion Load

To size the diversion load, you should fi rst consider the MS-PAE Series inverter that will be used

with the ACLD controller. The power output of the renewable energy source must be sized 10%

lower than the continuous power rating of the chosen inverter. This is to ensure the inverter will

not be damaged when handling the maximum current from the renewable energy source.

The load must have a total power rating at least 10% greater than the renewable energy source’s

maximum output to ensure all the excess current can be diverted from the batteries to prevent

overcharging. Also, each load (primary or secondary) must be no less than 2500 watts or greater

than 5000 watts to prevent the controller’s overload protection from activating; if this happens, the

diversion load would disconnect allowing all the excess current to go into the battery—causing an

overcharge condition.

Note: If using the MS4024PAE, the renewable energy source must be no greater than 3600 watts

and the load should be at least 4000 watts. For the MS4448PAE, the renewable energy source

must be no greater than 4000 watts and the diversion load should be at least 4400.

CAUTION: To prevent the battery from being overcharged and damaged, it is critical

that one of the diversion loads connected to the ACLD must always be available (must

not be thermostat controlled or be able to be turned off) and be correctly sized to

handle the full power produced by the renewable energy source (wind, hydro, etc).

If only one load is wired to the ACLD, it must be sized correctly and always be on and available—it

cannot be allowed to turn off. However, if there is both a primary and secondary load wired to

the ACLD, then the primary load does not need to stay on, nor is it required to be sized to handle

the full output current of the renewable energy source. However, if the primary load is allowed to

turn off (i.e., water heater with thermostat control) or not large enough to handle the full output

current, then the secondary load is used as a back-up to the primary load and must always be on

and available if needed—and correctly sized to handle the full power produced by the renewable

energy source (wind, hydro, etc.).

Note: If the primary load is not sized large enough to consume the excess power, the ACLD will

activate an internal relay to connect the secondary load in parallel with the primary load. Once

the secondary load connects, the benefi t of the primary load will not be utilized because the

current to the primary load will be decreased. For example, if the primary load is a small water

heater, and the renewable energy is greater than the small water heater can handle, the ACLD

will connect the secondary load. Once the secondary has connected, the water heater element is

no longer able to stay hot because it is receiving less current now that the secondary load is in

parallel with the water heater (primary load).

© 2015 Sensata Technologies

Page 19

Page 27

Installation

2.9.2 Compatible Diversion Loads

Below is a list of compatible loads that may be used with the ACLD.

Info: The diversion load must be sized at 110% or larger than the RE source (4800

watts max), and the RE source must be limited to 10% below the continuous power

of the battery-based inverter used. For MS-PAE Series inverters, the MS4024PAE is

limited to ≤3600 watts and the MS4448PAE is limited to ≤4000 watts.

Power Resistors:

Ohms Watts Part Number Manufacturer

15 3840 PR4410-13A PowerOhm

15 3150 PR15R3K15 PowerOhm

14 3150 PR14R3K15 PowerOhm

14 2657 222-8 IPC

13 3328 PR13R3K32 PowerOhm

13 2800 PF13R2K80 PowerOhm

12 3888 PR5505-16A PowerOhm

12 3888 PR4405-14 PowerOhm

12 3072 PR12R3K07 PowerOhm

Resistor assemblies listed above are manufactured by IPC Power Resistors Inc. (www.ipcresistors.

com) and Powerohm Resistors Inc. (www.powerohm.com). Available resistor assembly options

from these companies include an overtemperature switch, auxiliary terminal blocks, and custom

enclosures.

Water Heaters:

Size Watts Part Number Manufacturer

28-Gallon 3500 E2F30LD035V Whirlpool

30-Gallon 3500 E2F30HD035V Whirlpool

Air Heaters/Resistor Boxes:

Watts Part Number Manufacturer

2160 L2000W48V Coleman Air (www.colemanair.us)

3000 W3024

4000 WD4024

4000 W4024 Infratech (www.infratech-usa.com)

4800 BRU-4.8KW/12R-J EAGTOP (www.eagtop.com)

Baseboard Heaters:

Infratech (www.infratech-usa.com)

Infratech (www.infratech-usa.com)

Watts Part Number Manufacturer

2500 8F2025 Cadet

2500 LC6025W31 Dimplex

© 2015 Sensata TechnologiesPage 20

Page 28

Installation

2.10 Connecting the ACLD to a MS-PAE Series Inverter

One end of the ACLD/NETWORK cable plugs into the port labeled TO INVERTER (orange) on the ACLD,

and the other end plugs into the NETWORK (green) port on the MS-PAE Series inverter (see Figure 2-8).

Note: Do not connect the ACLD/NETWORK cable from the inverter into the TO NETWORK (green)

port on the ACLD, it will not be damaged, but will not operate correctly.

TO NETWORK port

[used to connect

additional network

accessories]

ACLD-40 Diversion Controller

[Connects from (orange) port to

inverter NETWORK (green) port]

ACLD / NETWORK cable

ME-ARC Advanced Remote

[connects to REMOTE (blue)

port on Inverter]

REMOTE cable

MS-PAE Series Inverter/Charger

[Connects to remote from REMOTE (blue) port,

connects to ACLD from NETWORK (green) port]

Figure 2-8, ACLD to Inverter Communications Cable Connection

2.10.1 ACLD/NETWORK Communication Cable

4-conductor telephone-type

opposite colors from top to

4

3

TAB

12

same

color

sam e co lor

4

3

TAB

12

Figure 2-9, ACLD/NETWORK

Communication Cable

bottom (tabs facing toward you)

The ACLD/NETWORK communications cable is

a 6-foot (1.83m), 4-conductor, twisted-pair,

telephone-type with RJ14 (m) connectors on both

ends; with a orange colored label on one end and

a green NETWORK label on the other end.

Note: This 6’ communications cable can be

extended up to a length of 200 feet without data

degradation.

© 2015 Sensata Technologies

Page 21

Page 29

Installation

2.11 Using a Remote Control with the ACLD Controller

A remote control display (ME-ARC, ME-RC11, or ME-RTR1) is used to confi gure the MS-PAE Series

inverter to ensure the ACLD controller operates correctly. During the Standby and Active modes,

the ACLD controller is in charge of monitoring and regulating the battery voltage and determining

the absorption charge time. The following settings in the remote display should be adjusted to

operate with the ACLD:

• Set the Battery Type to “Custom” - this setting is used to determine the battery voltage

regulation level and also enables the frequency shift feature. Once the battery type is set to

“Custom”, the battery voltage settings (i.e., bulk and fl oat) must be set to the correct regulation

values for your battery type.

Info: The frequency shift feature causes the MS-PAE Series inverter to automatically

increase it’s output frequency when high voltage is detected on the battery. This

frequency shift is enough to cause the utility-interactive inverter to disconnect and

stop charging the battery bank. However, this feature does not guarantee protection

against overcharging the batteries. Therefore, it should only be used as a backup, the

ACLD-40 should be used as the primary regulation method to protect the battery bank

from being overcharged during utility power failures.

The frequency shift feature is enabled when the Battery Type is set to “Custom” (using an

optional remote that allows Battery Type to be set to Custom). This feature automatically

activates when the battery voltage increases 2-volts (24v units) or 4-volts (for 48v

units) above the Absorb Voltage setting. When activated, the output frequency of the

MS-PAE Series inverter increases to 60.6Hz, causing the utility-interactive inverter to

disconnect. When the battery voltage falls 2-volts (24v units) or 4-volts (for 48v units)

below the Absorb Voltage setting, the frequency returns to 60.0Hz, allowing the utilityinteractive inverter to reconnect.

• Set the Absorb Time - this setting is used to determine the time that the ACLD will regulate

the battery at the absorption voltage.

• Defeat the Search Watts feature - when the MS-PAE Series inverter is fi rst turned on, its

automatic search feature is enabled. This feature must be disabled for the ACLD to operate

correctly. To disable the Search Watts feature, turn the Search Watts setting to “OFF”.

• Set the Final Charge Stage to Float - change the fi nal charge stage setting (if available

on your remote control) from “Multi” to “Float”. This ensures that the battery is ready and

maintained if a power outage occurs and the RE source is not available (i.e., night-time).

Note: The ACLD requires a ME-ARC remote display (version 4.0 or higher) to monitor the ACLD.

This remote provides displays for the ACLD that indicates: ACLD Status, Power Diverted, ACLD

Temperature, Target Volts, Model, and Software Version.

Info: When utility power is connected and the ACLD is in the Inactive mode, the MSPAE Series inverter is in charge of maintaining the battery bank—using the Absorb and

Float voltage settings in your remote. During the Standby and Active operating modes

of the ACLD—when utility power is lost—the same absorb and fl oat voltage settings

in your remote are used to regulate the current to the battery. Therefore, these two

settings (absorb and fl oat voltage settings) should already be adjusted correctly and

do not need to be changed when installing the ACLD.

Info: If the ACLD is used without a remote, the Battery Type will be defaulted to

“Flooded” and the Absorb Time will be set at 2.0 hours. Also, a load greater than 5

watts must always be connected to the inverter’s output to ensure the Search mode is

defeated (i.e., search turned off).

1 The ME-RC and ME-RTR can be used with and confi gure the ACLD, however, only the ME-

ARC remote (version 4.0 or higher) provides displays for the ACLD that indicates: ACLD Status,

Power Diverted, ACLD Temperature, Target Volts, Model, and Software Version.

© 2015 Sensata TechnologiesPage 22

Page 30

Operation

3.0 Operation

3.1 ACLD Operation

Normally, when utility power is available, the grid-tie inverter in the system converts the renewable

energy to AC that works in parallel with the utility to: power the load panels (main panel and subpanel for critical loads) in the home, charge the battery system, and feed any power—from the

renewable energy source—that is not used in the home back into the utility grid.