Magnum X5, X7 Repair Manual

Repair

Magnum X5 and X7 Airless Sprayers

- For Portable Spray Applications Architectural Paints and Coatings -

- Not for use in explosive atmospheres -

Models:

Magnum X5 (16J750) - Series A

Maximum Working Pressure: 207 bar, 21 MPa (3000 PSI)

Includes:

•

0.91 lpm (0.24 gpm) stand-mount sprayer

• SG2 gun - Manual 312830

• 0.635 cm (1/4 in) x 7.5 m (25 ft) hose

Magnum X7 (16J751) - Series A

Maximum Working Pressure: 207 bar, 21 MPa (3000 PSI)

Includes:

•

1.17 lpm (0.31 gpm) cart-mount sprayer

• SG3 gun - Manual 312830

• 0.635 cm (1/4 in.) x 15 m (50 ft) hose

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

Use water based or mineral-spirit type material only.

Do not use materials having flash points lower than

70°F (21°C). For more information about your material request MSDS from distributor or retailer.

3A1943B

EN

Magnum X5

(16J750)

Magnum X7

(16J751)

ti17678a

Specifications

Specifications

This equipment is not intended for use with flammable or combustible materials used in places such as cabinet shops

or other “factory”, or fixed locations. If you intend to use this equipment in this type of application, you must comply

with NFPA 33 and OSHA requirements for the use of flammable and combustible materials.

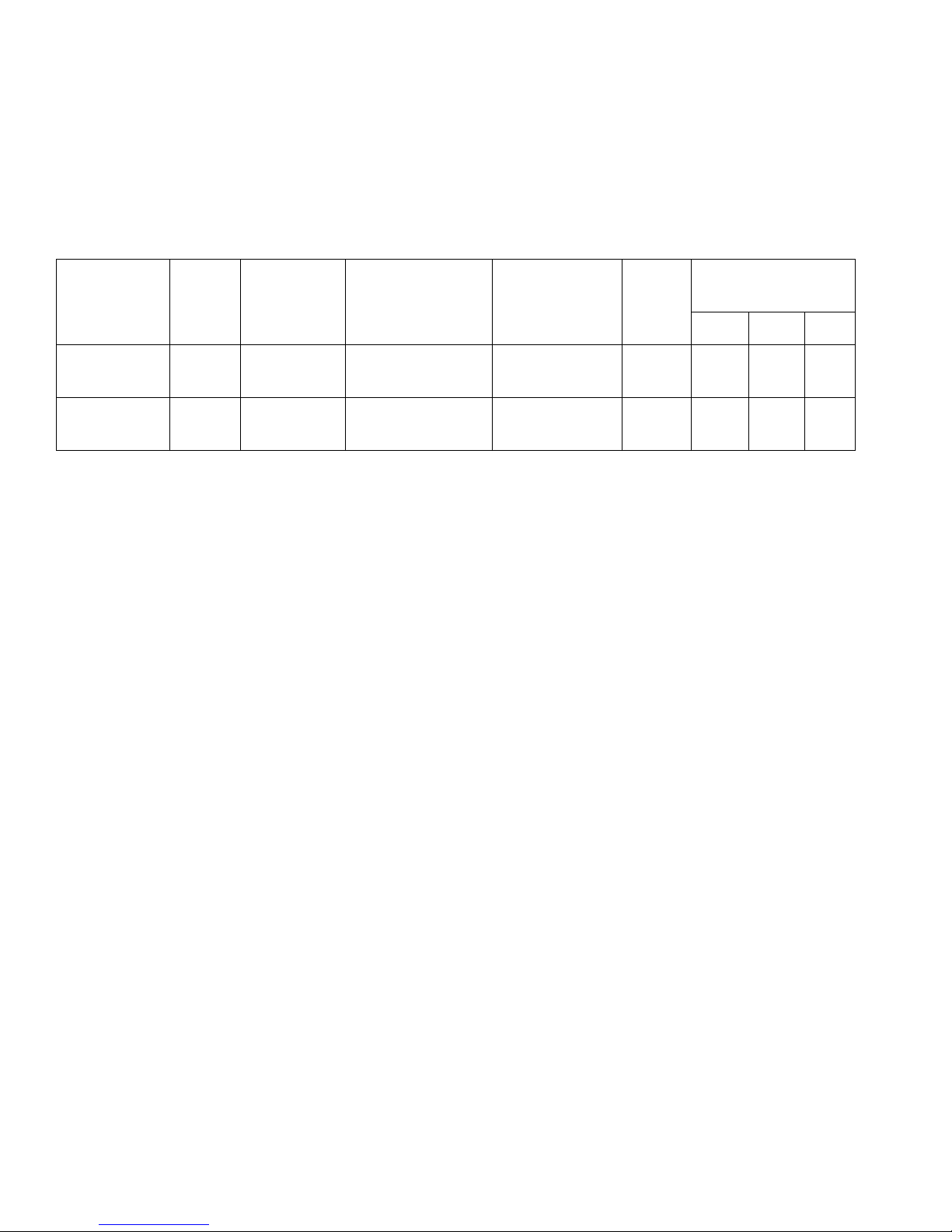

Model

Name

Series

Magnum X5 A

Magnum X7 A

Dispense

Rate gpm

(lpm)

0.24 gpm

(0.91 lpm)

0.31 gpm

(1.17 lpm)

Hose Length

and Diameter

1/4 in. x 25 ft

(6.4 mm x 7.5 m)

1/4 in. x 50 ft

(6.4 mm x 15 m)

Maximum

Maximum

Hose Length

Gun

Model

Working Pressure

PSI MPa bar

75 ft (23 m) SG2 3000 21 207

100 ft (30 m) SG3 3000 21 207

2 3A1943B

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance and repair of this equipment. The exclamation

point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risks. Refer back to

these warnings. Additional, product-specific warnings may be found throughout the body of this manual where applicable.

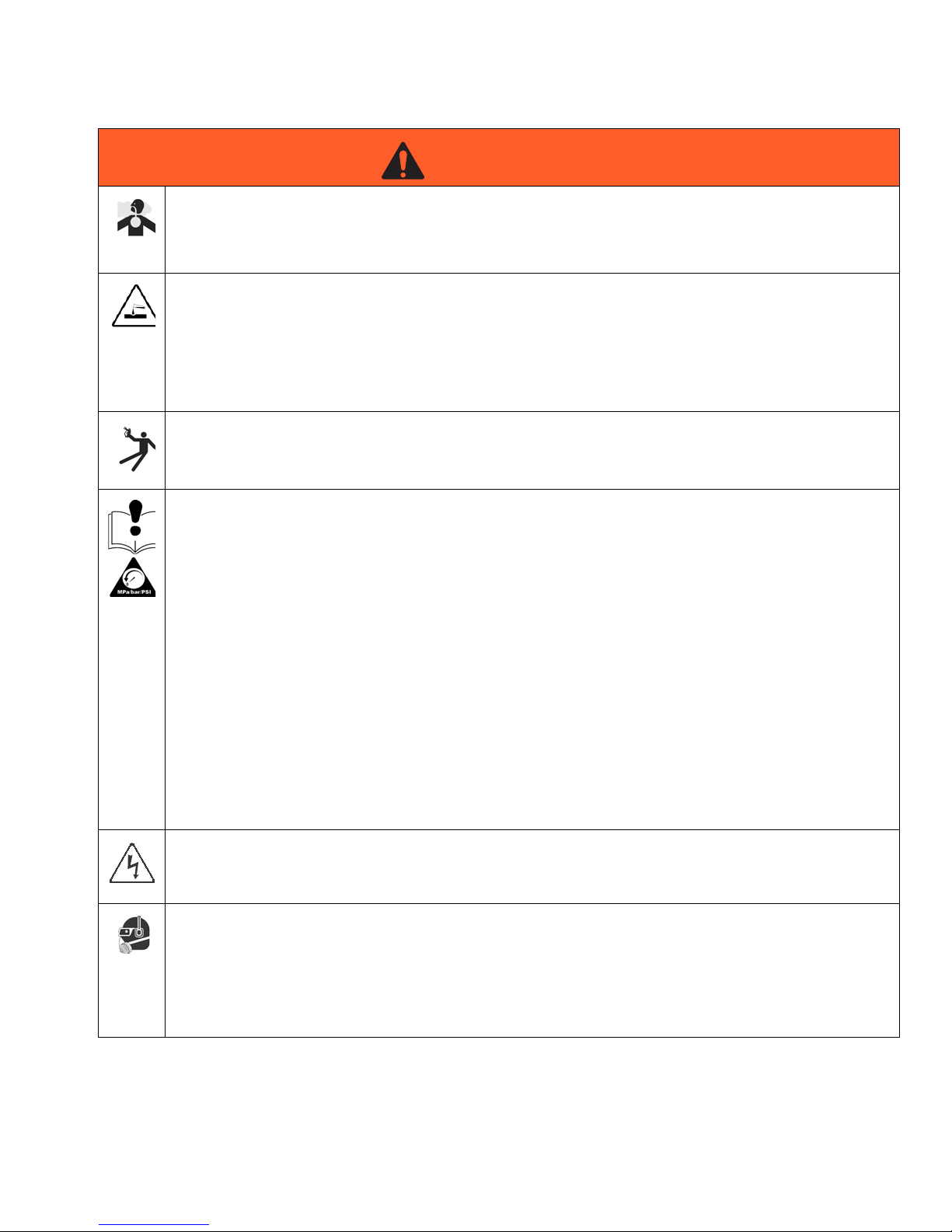

WARNING

WARNINGWARNINGWARNING

GROUNDING

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the electric current. This product is equipped with a cord

having a grounding wire with an appropriate grounding plug. The plug must be plugged into an outlet that

is properly installed and grounded in accordance with all local codes and ordinances.

• Improper installation of the grounding plug is able to result in a risk of electric shock.

• Check with a qualified electrician or serviceman when the grounding instructions are not completely

understood, or when in doubt as to whether the product is properly grounded.

• Do not modify the plug provided; if it does not fit the outlet, have the proper outlet installed by a qualified electrician.

• This product is for use on a nominal 240V circuit and has a grounding plug similar to the plug illustrated in the figure below.

• Only connect the product to an outlet having the same configuration as the plug.

• Do not use an adapter with this product.

Extension Cords:

• Use only a 3-wire extension cord that has a 3-blade grounding plug and a 3-slot receptacle that

accepts the plug on the product.

• Make sure your extension cord is not damaged. If an extension cord is necessary, use 15m (49.2 ft)

1.0 mm

product draws. An undersized cord results in a drop in line voltage and loss of power and overheating.

2

, 30m (98.4 ft) 1.5 mm2, or 50m (164.0 ft) 2.5 mm2 minimum to carry the current that the

3A1943B 3

Warnings

WARNING

WARNINGWARNINGWARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and

explosion:

• Do not spray flammable or combustible materials near an open flame or sources of ignition such as cigarettes,

motors, and electrical equipment.

• Only use water-based or mineral spirit-type materials with a flash point greater than 70° F (21° C).

• Paint or solvent flowing through the equipment is able to result in static electricity. Static electricity creates a risk

of fire or explosion in the presence of paint or solvent fumes. All parts of the spray system, including the pump,

hose assembly, spray gun, and objects in and around the spray area shall be properly grounded to protect

against static discharge and sparks. Use Graco conductive or grounded high-pressure airless paint sprayer

hoses.

• Verify that all containers and collection systems are grounded to prevent static discharge.

• Connect to a grounded outlet and use grounded extensions cords. Do not use a 3-to-2 adapter.

• Do not use a paint or a solvent containing halogenated hydrocarbons.

• Keep spray area well-ventilated. Keep a good supply of fresh air moving through the area. Keep pump assembly

in a well ventilated area. Do not spray pump assembly.

• Do not smoke in the spray area.

• Do not operate light switches, engines, or similar spark producing products in the spray area.

• Keep area clean and free of paint or solvent containers, rags, and other flammable materials.

• Fire extinguisher equipment shall be present and working.

• Sprayer generates sparks. When flammable liquid is used in or near the sprayer or for flushing or cleaning, keep

sprayer at least 20 feet (6 m) away from explosive vapors.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and cause

serious injury.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or servicing

equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just a cut, but

it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or servicing

equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

4 3A1943B

Warnings

WARNING

WARNINGWARNINGWARNING

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical reaction

and equipment rupture. Failure to follow this warning can result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for

compatibility.

RECOIL HAZARD

Gun may recoil when triggered. If you are not standing securely, you could fall and be seriously injured.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component.

See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all equipment

manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your material,

request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment and follow

the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s

replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

STARTUP HAZARD AFTER THERMAL OVERLOAD

Motor has thermal overload switch to shut itself down if overheated. To reduce risk of injury from motor restarting

unexpectedly when it cools, always turn power switch OFF if motor shuts down.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area of the

equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of toxic fumes, and

burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

3A1943B 5

Grounding Instructions

Grounding Instructions

Sprayer must be grounded. Grounding reduces the

risk of static and electric shock by providing an escape

wire for electrical current due to static build up or in the

event of a short circuit.

3. Do not use an extension cord with damaged ground

plug.

Recommended extension cords:

• 15 m (49.2 ft) 1.0 mm

• 30 m (98.4 ft) 1.5 mm

• 50 m (164.0 ft) 2.5 mm

2

2

2

1. This sprayer requires 220-240 VAC, 50/60 Hz 10A

circuit with a grounding receptacle. Never use an

outlet that is not grounded.

2. Do not use sprayer if electrical cord has damaged

ground prong.

4. Smaller gauge or longer extension cords may

reduce sprayer performance.

Thermal Overload

Motor has a thermal overload switch to shut itself down

if overheated. If unit overheats, allow approximately 45

minutes for unit to cool. Once cool, switch will close and

unit will restart.

To reduce risk of injury from motor starting unexpectedly when it cools, always turn power switch OFF if

motor shuts down.

ti7528a

6 3A1943B

Component Identification (16J750)

Component Identification (16J750)

B

A

Z

C

Q

S

V

P

R

T

A Electric motor (inside enclosure)

B Power switch

C Pressure control knob

D Pump fluid outlet fitting

G Suction Tube

H Prime tube (with diffuser)

J Prime/Spray valve control

K Fluid inlet connection and inlet valve

L Inlet screen

J

G

L

M

H

M Paint hose

P SG2 airless spray gun

Q Tip guard

R Reversible spray tip

S Trigger safety lever

T Gun fluid inlet fitting

V Gun fluid filter (in handle)

Z Pump Priming Button

K

D

ti17679a

3A1943B 7

Component Identification (16J751)

Component Identification (16J751)

Z

C

B

W

A

J

Q

S

V

R

U

T

A Electric motor (inside enclosure)

B Power switch

C Pressure control knob

D Pump fluid outlet fitting

G Suction Tube

H Prime tube (with diffuser)

J Prime/Spray valve control

K Fluid inlet connection and inlet valve

L Inlet screen

M Paint hose

X

D

H

K

P

G

L

M

P SG3 airless spray gun

Q Tip guard

R Reversible spray tip

S Trigger safety lever

T Gun fluid inlet fitting

U Smooth Glide™ swivel

V Gun fluid filter (in handle)

W Hose/cord wrap bracket

X Pail hanger

Z Pump Priming Button

ti17680a

8 3A1943B

General Repair Information

General Repair Information

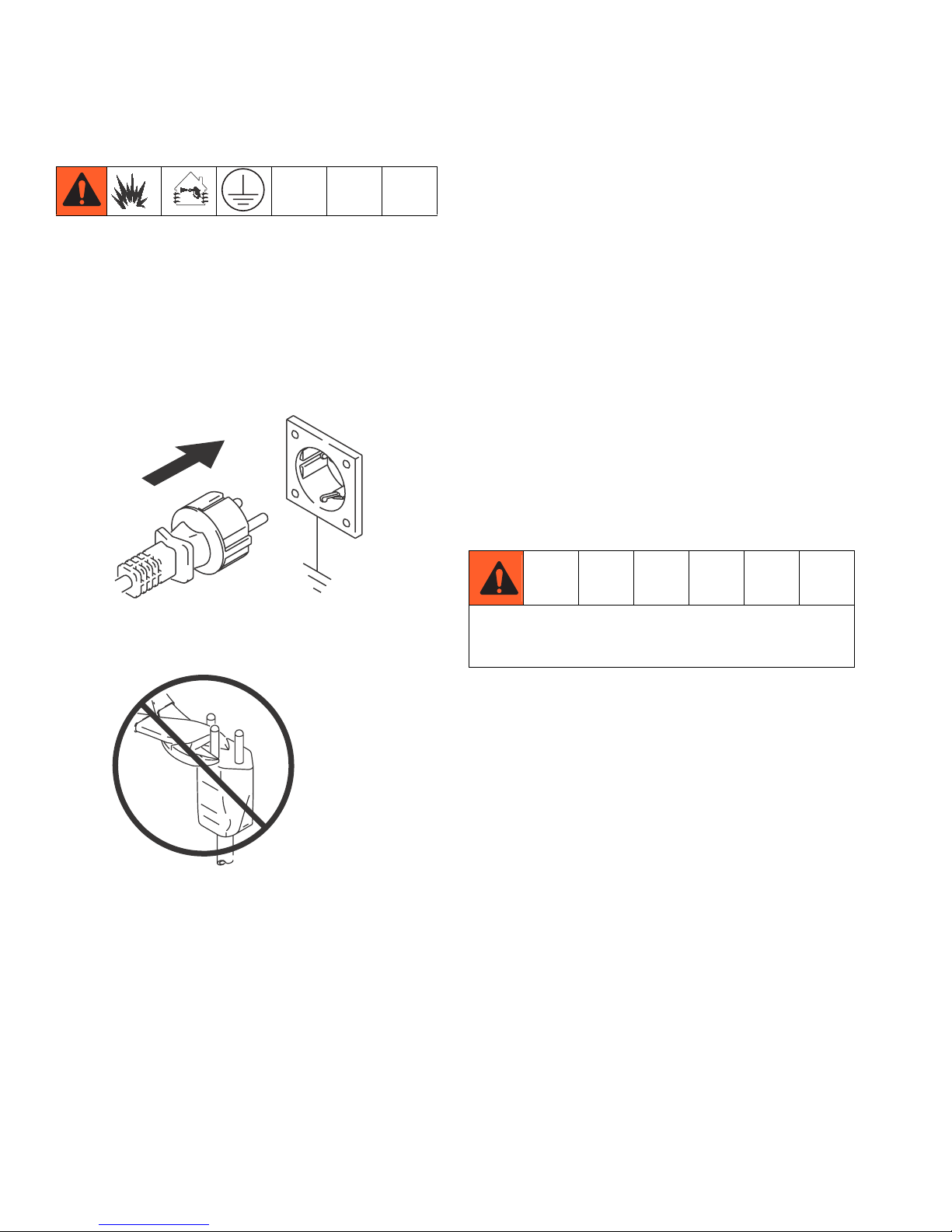

Trigger Lock

Always engage the trigger lock when you stop spraying

to prevent the gun from being triggered accidentally by

hand or if dropped or bumped.

Trigger Locked

ti8908a

Pressure Relief Procedure

Trigger Unlocked

ti8909a

2. Place prime tube in waste pail.

ti2034a

3. Turn Prime/Spray valve to PRIME.

ti2019a

4. Turn pressure control knob left (minimum pressure).

Follow this Pressure Relief Procedure whenever you

stop spraying and before cleaning, checking, servicing,

or transporting equipment.

1. Turn OFF power switch.

ti2018a

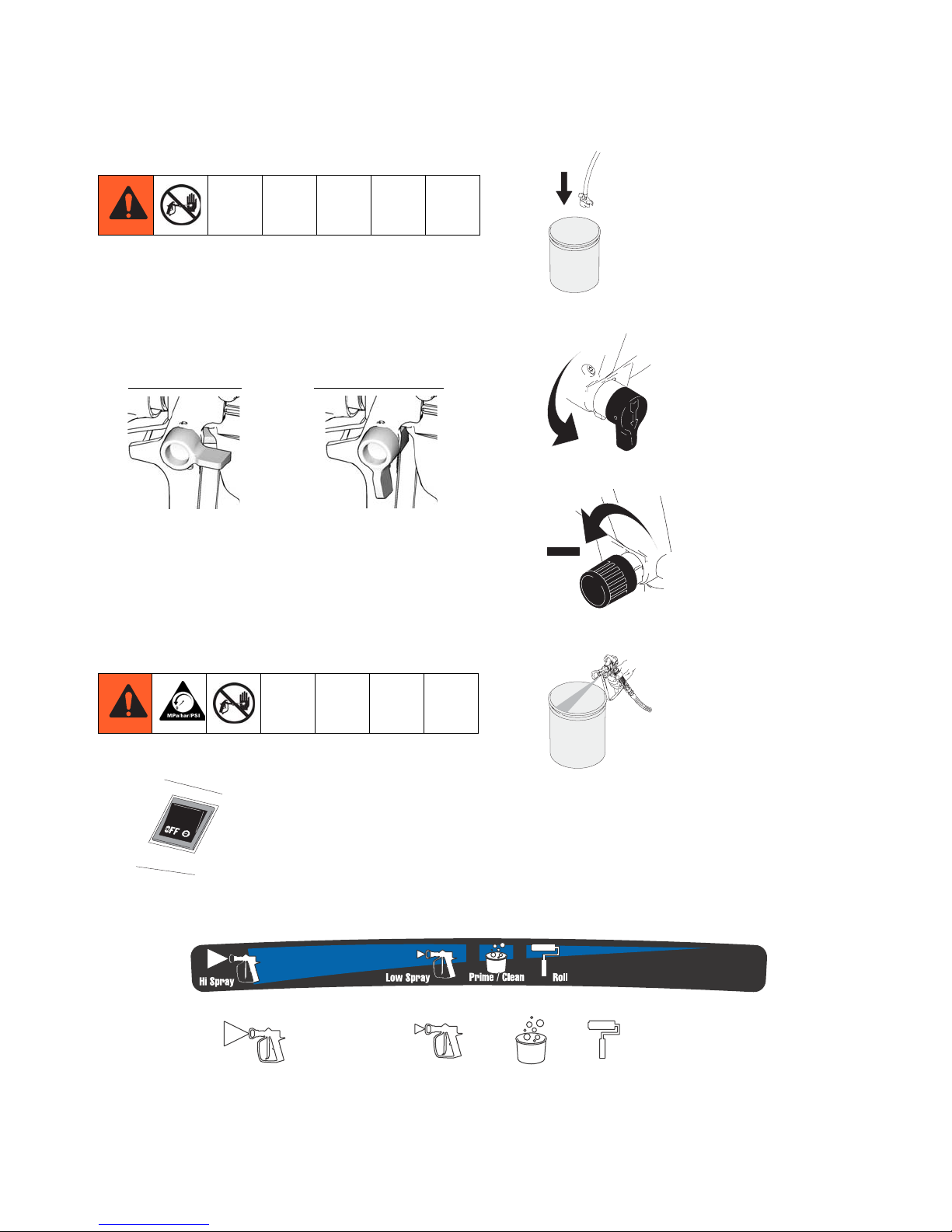

Pressure Control Knob Settings

High Pressure

Spray

Low Pressure

Spray

ti2020a

5. Trigger gun into bucket to relieve pressure in hose.

ti2033a

ti5597b

Prime/

Clean

Rolling

To select function, align symbol on pressure control knob with setting indicator on sprayer.

3A1943B 9

Loading...

Loading...