Page 1

MAGNUM WINCHESTER

Corn/Biomass/Wood Pellet Stove

Models: WINACP, WINACI, WINDCI, WINDCP

Owner’s Manual

Installation – Operation – Maintenance Instructions

NOTE: THESE INSTRUCTIONS MUST BE SAVED for future reference

PLEASE READ THIS ENTIRE MANUAL BEFORE INSTALLATION AND USE OF THIS PELLET

BURNING STOVE. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN PROPERTY

DAMAGE, BODILY INJURY OR EVEN DEATH.

IMPORTANT: Always contact your local MagnuM dealer/installer with questions before contacting the

factory. When you call, have your serial number, purchase date, who installed the unit and a list of

questions.

9 When installing your MagnuM Winchester (WIN) Corn/Biomass/Wood Pellet stove, particular attention

needs to be made in regards to fire protection. If the unit is not properly installed, a house fire may result.

For your safety, follow the installation and operation instructions provided, and if a question arises contact

local building or fire officials about restrictions and installation requirements in your area.

9 Read the operations and fuel section of this manual before plugging in your unit.

9 Always unplug the unit before attempting any service work.

9 Do not connect the unit to a chimney flue already serving another appliance.

9 When installing the chimney pipe to the unit, it is important to remember that the unit operates on a

negative pressure and the chimney on a positive pressure. All chimney connections, elbows and fittings

must be airtight. (Proper venting practices must be followed. Consult with a venting professional)

9 Ashes must be disposed of in a metal container with a tight fitting lid.

9 All minimum clearances to combustibles must be followed.

9 The MagnuM Corn/Biomass/Wood Pellet Stove is tested for operation with wood pellets, with an ash

content of no more than 2% and Corn with a moisture content from 10-14 percent. It is recommended

that wood pellets with an ash content of 1% or less be used for efficient operation of this unit. Higher

ash content fuels will require additional maintenance and service. Also, for use with wood pellets,

cherry pits, olive pits or other pelletized Biomass fuel. Corn with 11-12 percent moisture is ideal.

9 It is important to use fuel that is clean, dry and consistent. Make sure that your supplier is giving you

the same fuel each time that you purchase. It is recommended that y ou purchase your entire heating season

supply of fuel at one time so that the fuel will be the same.

9 A voltage surge protector or ground fault outlet is required for this unit. The electrical component

warranty will be voided if surge protection is not installed before operating this unit.

9 A grounded outlet must be provided with proper polarity. A constant 115 volt (12volt on DC

models), 60 cycles must be provided for proper operation or the warranty of this appliance will be

forfeited.

9 Special attention needs to be taken to clean out the top heat exchangers of this unit on a regular

basis. The fly ash settles on the heat exchangers and must be cleaned off to keep the unit operating

properly. Check for plugging every two-four weeks or when needed.

9 If unit is not operated for extended periods of time (like summer) unplug the unit and disconnect the

battery to assure long life of electrical components.

AMERICAN ENERGY SYSTEMS, INC. GRANTS NO WARRANTY, IMPLIED OR

STATED, FOR THE INSTALLATION OR MAINTENANCE OF THE STOVE AND

ASSUMES NO RESPONSIBILITY FOR ANY CONSEQUENTIAL DAMAGE(S).

AMERICAN ENERGY SYSTEMS, INC. - 150 Michigan Street SE - HUTCHINSON, MINNESOTA 55350

Web Site: www.MagnuMheat.com

Page 2

date 07/9/07

SECTION PAGE

Introduction/Specifications...…………………………………… 3

Technical Bulletin/Importance of Adequate Fresh Air…………. 4

Safety Steps……………………………………………………… 5

Burning Solid Fuels……………………………………………… 6, 7

Unpacking Your MagnuM Wood Pellet Appliance ……………. 7, 8

Clearances……………………………………………………….. 9

Guidelines for Exhaust Venting Systems Design……………….. 10, 11

Design Guidelines for Outside Combustion Air Connection……. 12

Installation Precautions………………………………………….. 13

Installation Configurations……………………………………….. 14

Vent Termination General Instructions…………………………... 15

Horizontal Installation……………………………………….…… 16

Vertical Installation………………………………………………. 17, 18

AC/DC Control Panel/Thermostat Hook-up…..…………………. 19, 20

MagnuM WIN Insert Installation ………………………………… 21, 22, 23

Installation Instructions…………………………………………… 24, 25, 26

Control Panel/Thermostat Hook-up…………………………….... 27

Optional 12 Volt Battery Back-up……………………………….. 28

Operating Instructions AC/DC/All Models………………………. 29, 30, 31

Cleaning Instructions……………………………………………... 32, 33

Cleaning Instructions for the Winchester Insert………………….. 34, 35

Automatic Features……………………………………………….. 36

Glass Maintenance, Adjustment, Removal and Replacement……. 37

Circuit Board Functions…………………………………………... 38, 39

Setting the Draft…………………………………………………... 40

Wiring Diagram AC/DC.…………………………………………. 41, 42

Draft Slide Gate Adjustment……………………………………… 43

Solar Panel Connections………………………………………….. 43

Igniter Replacement………………………………………………. 44

Trouble Shoot Guide...…………………………………………….. 45, 46, 47, 48

MagnuM Winchester Replacement Parts List……………………. 49

Warranty………………………………………………………….. 50

Service Record……………………………………………………. 51

TESTING/CERTIFICATION INFORMATION

The MagnuM WIN stove (report # 150-S-01b-4) independently tested in accordance with ASTM E1509

The MagnuM WIN Insert (report # 097-S-04-2) independently tested in accordance with ASTM E1509

Tested with OMNI-Test Laboratories, Inc, BEAVERTON, OREGON 97005

per EPA Method 28A, ULC C1482-M1990, CAN/ULC-S627-00, ULC-S628, APFI req.

The pellet fired appliance has been tested and listed for use in manufactured homes in accordance with

Administrative Rules 814-23-900 through 814-23-909 (UM) 84-HUD

SERIAL #______________ DATE PURCHASED_______________

READ THIS MANUAL THOROUGHLY BEFORE INSTALLING THIS UNIT AND KEEP THIS

MANUAL IN A HANDY PLACE FOR FUTURE REFERENCE.

Oregon

2

Page 3

DEAR VALUED MAGNUM PRODUCT OWNER,

We appreciate your decision to help preserve our precious environment by purchasing your MagnuM

Corn/Biomass/Wood Pellet Appliance. With everyone working together, we can have clean air and

renewable heat for our homes.

Please read this Owners Manual carefully before using this appliance and if you have any questions contact

your local MagnuM dealer. We appreciate your business and wish you many warm days and nights with

your new MagnuM Corn/Biomass/Wood Pellet Appliance.

Sincerely,

Mike Haefner, President

American Energy Systems, Inc.

P.S. You are very important to the success of our business and your referral of our products is very much

appreciated. Many of our Resellers have referral rewards available and I encourage you to ask your local

dealer how to get involved in helping make our country energy self-sufficient. GOOD LUCK!

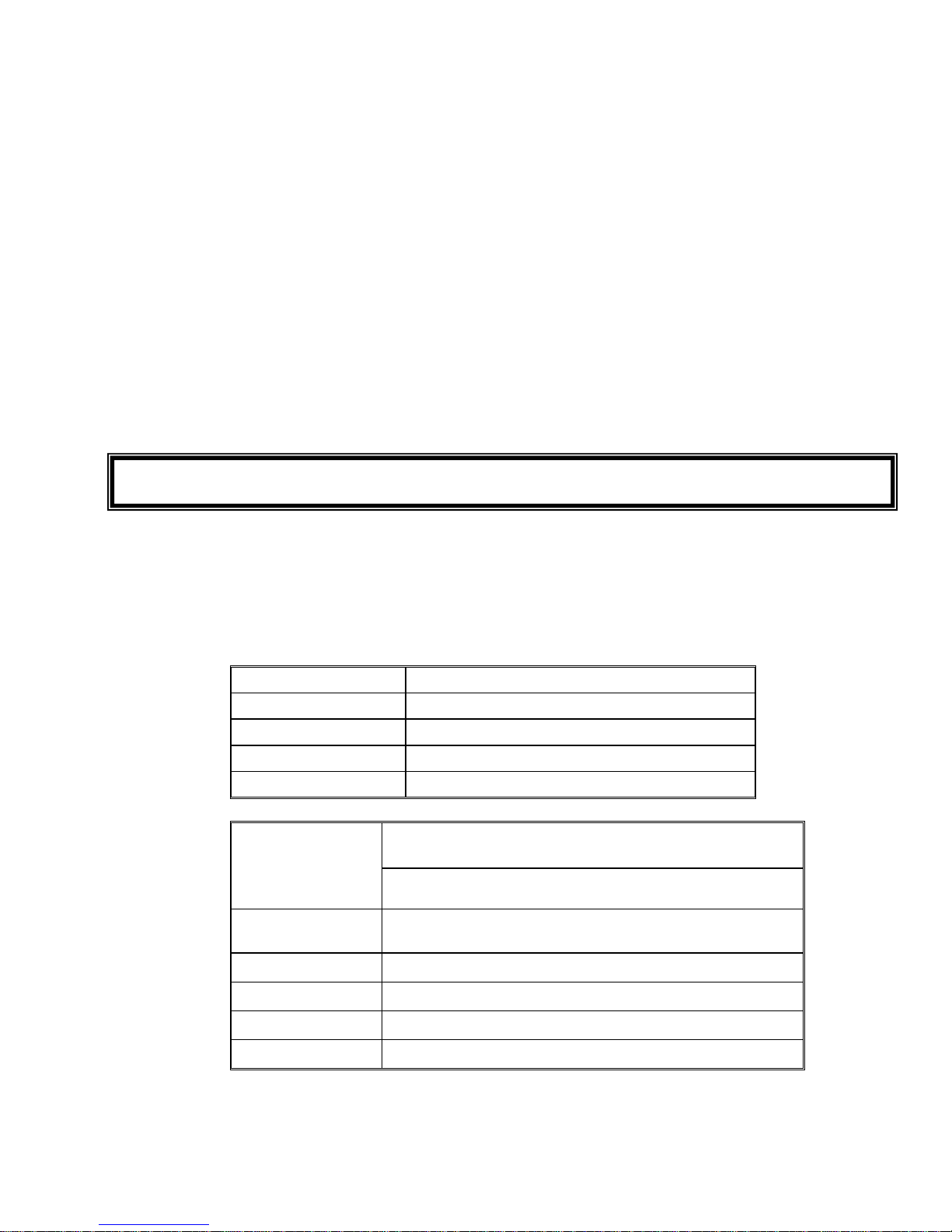

SPECIFICATIONS

American Energy Systems, Inc., manufacturer of the MagnuM Winchester Appliances, reserves the right to

alter its products, their specifications and/or price without notice.

Safety tested and EPA exemption tested by Omni to UL 1482, CAN/ULC-S627, ULC-S628, APFI

requirements, Oregon administrative rules 814-23-900 to 814-23-909 and E.P.A. Method 28A.

Winchester Insert

Heating range 8,000- 40,000 BTU

Fuel Storage Capacity Up to 68 Lbs. Up to 60 Lbs.

Width 24” 23 1/2”

Height 33”ped, 40”leg, 21 1/2”Insert

Depth 22” 21 ½”

Back Wall

Side 3” (75mm)

Corner 3” (75mm)

Flue to Wall 3” (75mm)

Floor Protection 6” (150mm) out in front of unit 6” to sides

BTU input will vary, depending on the brand of fuel, size of fuel, quality of fuel and moisture content.

Consult your authorized MagnuM reseller for information on the best fuel to use to get the best results.

Fuel feed rates can vary as much as 50 percent depending on fuel quality, size, brand and moisture content.

CLEARANCE TO COMBUSTIBLES, Stoves

Insert clearance to combustibles are on pages 21-24

Vertical Termination

w/3” Pellet Vent

3” (75mm)

3

Page 4

Technical Bulletin

Importance of Adequate Fresh Air

Every home is a slightly different situation and depending on the design of the air movement within

the home, might be easy to distribute heat or very difficult. If you have boiler heat or other nonducted central heating this becomes even more of a challenge as adequate circulation within the

home and proper make up air for combustion is lacking because of the design of your central

heating system.

When a forced-air system is put into a home that is not designed with proper circulatory patterns, it

might be necessary to add return air ducts or at least vents to get the air moving around the home.

Fresh air for the home and fresh air for combustion will have to be added or the stove or furnace

will burn dirty and efficiency will suffer.

Your dealer needs to assess the fresh air requirements for the home. At a minimum, there should be

a 6” or larger (this should be determined by figuring what the home requires) fresh air vent coming

in to a neutral part of the home to make sure that there is adequate fresh air to the home. Then the

3”make up air to the unit is required to be provided.

If the wood pellets are not burning correctly you need to address a few things. Are the wood pellets

wet or dirty? If they are, make sure that your wood pellets are cleaned (we have an excellent “ESIFTER” product that will do a great job) and below 15 percent moisture. 3-4 percent moisture is

ideal.

The most common cause of wood pellets not burning properly is contaminated air or negative

pressure in the home. It can be as simple as the air adjustment not set properly on the side of the

stove or it could be that there is a serious lacking of good quality air in the home caused by negative

pressure. If you have done any remodeling or if this is a newer home, it is a very real possibility

that this is happening. Most basements have negative pressure even if you feel that your home is

drafty. This is called the stack or chimney effect.

If there is a black coating of soot coming into the home it is caused by the reversal of the exhaust

that would normally exit the stove outside being drawn into the home by negative pressure or

improperly installed venting. Depending on your venting configuration this could be aggravated by

back drafts, high wind and cold chimneys.

Sometimes this also occurs if there is an intake for fresh air too close to the exhaust on the outside

of the home or other conditions causing the exhaust to be pulled back into the home.

The first indications of negative pressure affecting the stove occurs app. 3 days after the stove is lit.

The glass gets dirty very easy, the firepot might keep filling up even though you pull the air

adjustment out, and you notice that the venting fills up with soot rapidly. After a few days, the

exhaust can no longer adequately pull out all of the fly ash so it reverses and is pulled into the

home. This might happen through the venting if it is not sealed properly or it might come out when

you open the door for maintenance and also backwards through the air wash system.

This can be easily corrected by adding the fresh air for the home and also for the appliance. It is

imperative that you would have your dealer or installer check the unit out for proper operation to

make sure that there is nothing mechanical wrong with the appliance and then determine your need

for proper fresh air. Your dealer can contact the factory with any questions that he might have.

4

Page 5

SAFETY STEPS

IMPORTANT:

Proper installation of this stove is crucial for proper and safe operation. Installing this

product improperly may result in a house fire and/or personal injury. All applicable building codes for

your location must be followed. In areas where building codes require additional steps to the installation

of this product not included in this manual, the building codes will take precedent and must be followed.

Contact your local building inspector to obtain any necessary permits or inspection guidelines before

installing the product. (This appliance must be installed by a trained professional installer to assure

proper installation and warranty of this product) Warranty labor, parts failing due to improper

installation and shipping will not be covered if the unit is not installed by a trained installer.

9 DISCONNECT THE POWER CORD BEFORE SERVICING THIS STOVE! A power

surge protector is required. The unit must be plugged in to a grounded 110 volt 60 Hz or a 12V

DC sealed battery power source. NEVER use an “unsealed” type battery, nor operate unit on a

battery without a 12 volt 4 ampere in-line fuse on a positive line.

9 Always route the power cord away from the unit. Do not route cord in foot traffic areas. Do not

pinch cord under furniture. Do not add any additional length to the power cord.

9 This product requires simple periodic maintenance for proper operation and long life of the stove.

Read and follow the maintenance schedule closely. Do not operate with the doors or hopper

open.

9 The MagnuM Winchester stove models are designed, approved and tested to burn

corn/wood pellets and other Biomass fuels. The burning of other solid fuels such as cord wood

in this stove is not permitted. If you are burning fuels not approved for this appliance it will void

the warranty and no service/warranty will be allowed.

9 The MagnuM models will burn high ash content fuels but will require additional

maintenance/cleaning.

9 A working smoke detector must be installed in the same room as this product.

9 It is recommended that a fire extinguisher “class a-b-c” be installed close to the appliance.

9 Flammable or explosive liquids such as gasoline, naphtha or engine oil must NEVER be used in or

around this stove. These liquids must be stored well away from this stove as the open flame in the

burn chamber could ignite the fumes of such liquids. Do not burn garbage in this unit.

9 According to HUD requirements, when installed in a mobile home, this stove must be grounded

directly to the steel chassis of the mobile home and bolted to the floor.

9 This stove is not intended for use in commercial installations but can be used.

9 The moving parts of this stove are propelled by high torque electric motors. The auger can cause

severe injury to body parts that may get near them. Keep all body parts away from the auger while

the stove is plugged into an electrical outlet. These moving parts may begin moving at any time

while the stove is plugged in.

9 This unit must be installed on a non-combustible surface. Make sure that the unit is level.

9 Do not attempt internal service to the unit when it is burning and or plugged into power.

9 It is a good idea to burn the unit outside for a couple hours before installation to burn off any paint

or oil fumes. (Most resellers pre-burn the unit before you receive them, do not worry if your unit

looks like it has been burnt.)

IMPORTANT: It is the customer’s responsibility to make sure the MagnuM appliance is installed with the

proper make up air system and the home is checked for adequate fresh air so that the appliance does not

become the fresh air source for the home.

Page 6

BURNING SOLID FUELS (shelled corn and wood pellets)

Unlike petroleum and natural gas products, solid fuels such as wood pellets create ash as the fuel is

burned. Even with the highly efficient flame your MagnuM stove will produce, the solid fuels used will

produce ash. This ash will have to be cleaned out of the stove from time to time. The cleaning procedure

will be discussed later in this manual. You can minimize the amount of cleaning required and maximize

the efficiency of your stove by maintaining the correct draft settings.

The draft setting on your stove may have to be changed from time to time to accommodate your specific

burning conditions. Proper draft setting will be discussed later in this manual. The point we wish to

make here is that your MagnuM stove, due to the nature of solid fuels, will require brief periodic

attention. Please do not expect to light your stove and walk away from it until you want to shut it off in

the spring. A few moments of adjustment and cleaning from time to time is an important part of burning

solid fuels.

The MagnuM stove has been designed to burn wood pellets that meet the Association of Pellet Fuel

Industries standards. Since these fuels vary greatly in quality and consistency, AES cannot be responsible

for damage done to your stove due to fuel problems. The following are guidelines to using and selecting

proper fuels for your stove.

SHELLED CORN (11-12 percent moisture recommended)

9 Store your corn supply in a dry place and keep the bags or containers sealed to prevent your corn from

absorbing excess moisture. Test the moisture content periodically to maintain the proper dryness.

9 Check your corn for foreign objects. Your stove warranty will not cover damage done to your

stove due to foreign objects in the fuel supply.

9 Do not carry your corn supply over into the next heating season if possible unless properly

stored. If you carry over your corn supply make sure to check the corn for proper moisture content.

9 DO NOT BURN “TREATED” SEED CORN IN YOUR STOVE. Seed corn is treated with

chemical pesticides that are harmful or fatal if swallowed; therefore, seed corn is dangerous to have in

the house, especially where children can reach it. Burning treated seed corn in your stove will void

the warranty and will destroy the exhaust system on the unit.

9 Corn must be 14% or less moisture content. Wet corn will cause rapid plugging and deterioration

of the stove and exhaust system, lower the heat output and will void the product warranty.

9 Corn must be cleaned and free from debris. Corn right from the field will often have stalks, sticks,

bolts and cob debris, which can plug the auger and/or cause damage to the auger and motor. Damage

caused by dirty corn and other foreign objects are not covered by the product warranty. Ask for clean

corn when you purchase it from your local corn supplier. Clean corn can be purchased in bulk or

bagged from most elevators, feed stores or even your local farmer.

ALWAYS ASK FOR CORN WITH 11-12% MOISTURE CONTENT.

9 If you are having trouble finding clean Corn, contact your local MagnuM Dealer and ask them

to get you an “Energy Sifter” corn cleaning system. Cleaning your corn with the Energy Sifter

from American Energy Systems will assure clean corn and a more consistent burn rate. It is also

important to vacuum out your hopper once a month to assure trouble free auguring of the corn.

6

Page 7

9 There are many varieties of corn grown around the world. Each variety has unique characteristics

including the shape and size of the kernel. Your stove will burn more consistently with a small to

mid-size kernel corn. If the kernel size of the corn varies greatly or if you switch sources frequently,

you will get a less consistent burn, which will require more attention to the draft setting on your stove.

Therefore, purchasing corn from the same source will help achieve a more consistent burn. DO NOT

USE CORN WITH A HIGH WAX CONTENT!

WOOD PELLETS

9 Be consistent in your wood pellet fuel supplier. Wood pellets will vary in content and burn

characteristics from supplier to supplier. A consistent supply of wood pellets will require fewer

adjustments to the draft of the stove.

9 Check your wood pellets for foreign objects. Your stove warranty will not cover damage done to your

stove due to foreign objects in the fuel supply.

9 Store your wood pellets in a dry place to prevent them from absorbing excess moisture.

9 Vacuum the hopper out after every 6-7 bags to eliminate buildup of sawdust. More often if the wood

pellets are poor quality. If sawdust is a problem you will have to screen each bag of fuel for a

consistent feed.

9 Wood pellets vary from supplier to supplier in ash content from less than 1% to 3% or more. Low ash

content pellets will allow you to burn the stove longer between cleanings. Only wood pellets

manufactured to the Association of Pellet Fuel Industries (A.P.F.I.) standard for residential pellet fuels

are recommended. Look for A.P.F.I. registration number on the back of pellets. Consult your local

MagnuM reseller for more information on approved wood pellet fuel.

9 It is strongly recommended not to keep a supply of wood pellets over the summer months. Moisture

will build up and cause problems in the fall with your appliance operation. Make sure that your

supplier is not selling you left over fuel or fuel that has been out in the rain.

UNPACKING YOUR MAGNUM CORN/BIOMASS/WOOD PELLET UNIT

When you receive your MagnuM Corn/Biomass/Wood Pellet Stove, Pedestal unit, Leg unit or

Fireplace Insert, be careful to inspect all parts and components to make sure that nothing was

damaged or lost in shipment. If there was shipping damage, be sure to report it to your MagnuM

reseller, or the shipping company that delivered your unit. Freight damage claims must be made to

the Freight Company immediately. If parts are missing contact your local MagnuM reseller or

contact the factory right away. Your satisfaction is our top priority.

To uncrate your MagnuM appliance:

1) Cut the banding straps and open the carton lid. The carton is stapled to the wood pallet so it will be

necessary to pull the cardboard loose from the pallet. Remove the crating box carefully lifting up over

the top of the unit. Be careful not to scratch the unit with the staples. Remove the wood blocks and

plastic. We strongly urge you to recycle the packaging materials to help protect the environment.

7

Page 8

The Pedestal unit comes completely assembled, the Insert comes with the shroud packaged separately and

the Leg unit comes with the legs packaged in the hopper.

The installation of the Insert shroud is shown later in the installation manual. Make sure that the shroud is

with the unit when you get it.

The following diagram will show how to install the legs on the Leg Unit. The legs are wrapped up and

packaged in the hopper. Unpack the legs and get the four (4) nuts out of the hardware bag.

Tip the unit back so that you can get the leg onto the bolt that is sticking down in each corner of the

bottom of the base. Be sure to have someone helping hold the unit while you are attaching the leg. The

casting could break if bound or dropped.

NOTE: It is best to attach the legs on one side first and then lift the unit up level to attach the other

side. You can also attach the legs on the back two corners first and then the front.

Place the ¼” nut on the bolt that is located on the base of the unit and attach the leg to the bolt. Swing the

leg so that the foot of the leg is parallel with the 45-deg. angle of the front of the unit. Align the back leg

to match the front leg.

Be careful not to bind the leg when bolting onto the unit so that it does not break. The legs are designed

to face at a 45 degree angle so that they will face in the same direction as the slanted side of the face.

When the legs are bolted on and positioned where you like them, tighten the four (4) nuts. Make sure not

to over tighten the nuts and twist them off.

8

Page 9

CLEARANCES

NOTE: Clearances for the Insert models are shown on pages 21-24

CONVENTIONAL CLEARANCES

A…SIDEWALL 3 In. (75 mm)

B…BACK WALL 3 In. (75 mm)…… (VERTICAL VENTING INSTALLATION REQUIRES A MIN. 3”

CLEARANCE FROM COMBUSTIBLES TO VENT PIPE).

C…CORNER WALL 3 In (75 mm)……. (VERTICAL VENTING INSTALLATION REQUIRES A MIN. 3”

CLEARANCE FROM COMBUSTIBLES TO VENT PIPE).

D…VENT PIPE TO WALL 3 In (75 mm)…….. (MAINTAIN 3” INCH CLEARANCE FOR ALL INSTALLATIONS)

E…FLOOR PROTECTION FRONT 6 In (150 mm)

F…FLOOR PROTECTION SIDES 6 In (150 mm)

Floor protection must be 3/8” inch minimum thickness non-combustible material or equivalent extending beneath heater and to

the front/side/rear as indicated.

CHIMNEY AND CONNECTOR: 3” LISTED PELLET VENT ONLY

NOTE: REGARDLESS OF STOVE CLEARANCE, VENT PIPE MUST ALWAYS HAVE A 3” INCH CLEARANCE.

ALCOVE CLEARANCES

MIN. ALCOVE WIDTH 27 In. (694 mm)

MIN. ALCOVE HEIGHT 47 In. (1194 mm)

MAX. ALCOVE DEPTH 36 In. (914 mm)

WARNING: THE MINIMUM CLEARANCES LISTED ABOVE ARE BASED ON 3” INCH PL LISTED PELLET

VENT PIPE. IF YOUR APPIANCE IS NOT PROPERLY INSTALLED A HOUSE FIRE MAY RESULT. PLEASE

FOLLOW THE PIPE MANUFACTURERS INSTRUCTIONS AND LOCAL BUILDING CODES FOR THE

CLEARANCE TO COMBUSTIBLES REQUIRED FOR THE INSTALLATION OF THE VENT PIPE BEING USED.

9

Page 10

GUIDELINES FOR EXHAUST VENTING SYSTEMS DESIGN

It is recommended that only an authorized MagnuM installer install your wood pellet stove. The following installation

guidelines must be followed to ensure conformity with both the safety listing of this stove and to local building codes.

9 A listed 3” or 4” type “PL” pellet vent exhaust system must be used for FREESTANDING installation and attached to the

pipe connector provided on the back of the stove. Use a 3” to 4” adapter for 4” pipe. A cap must be used at the

termination of type “L” vent chimneys.

9 Do not terminate vent in any enclosed or semi-enclosed area, such as; carports, garage, attic, crawl space, under a sundeck

or porch, narrow walkway or closed area, or any location that can build up a concentration of fumes such as a stairwell,

covered breezeway, etc.

9 Vent surfaces can get hot enough to cause burns if touched by children. Non-combustible shielding or guards may be

required. Do not install a flue damper in the exhaust vent of this unit.

9 Termination must exhaust above air inlet elevation. It is recommended

when the appliance is vented directly through a wall or in a basement. This will create some natural draft to prevent

the possibility of smoke or odor during appliance shutdown and to keep exh aust from causing a nuisance or hazard from

exposing people or shrubs to high temperatures. In any case, the safest and preferred venting method is to extend the vent

through the roof. Do not connect this unit to a chimney flue serving another appliance.

9 Distance from doors and windows, gravity or ventilation air inlet into building:

Not less that 4 ft. / 1.2 m below, 4 ft. / 1.2 m horizontally from, 1 ft. / 305 mm above (This does not apply if the

windows are non-opening or have been fixed so they cannot open.)

that at least 3 ft. of vertical pipe be installed

9 Distance from bottom of termination and grade – 1 ft. / 305 mm minimum. This is conditional upon the plants and nature

of grade surface. The exhaust gases are not hot enough to ignite grass, plants or shrubs located in the vicinity of the

termination. The grade surface must not be a lawn. Distance from bottom of termination and public walkway is 7ft. /2.1m

minimum.

9 Distance to combustible materials – 2 ft. / 610 mm. This includes adjacent building, fences, protruding parts of the

structure, roof overhang, plants and shrubs, etc.

9 It is recommended that a single or double clean-out “tee”, for cleaning the vent in both directions, be installed at every 90-

degree junction

to enable collection of fly ash and to permit periodic cleaning of the exhaust system. 90-degree elbows

accumulate fly ash and soot, thereby reducing exhaust flow and performance of the stove.

9 Total length of horizontal vent must not exceed 10 feet / 3,000 mm. All joints in the vent system must be fastened by at

least three (3) screws, and all joints must be sealed with high temp RTVsilicone sealer to be airtight.

9 A 3” inch single-wall, stainless steel flexible or rigid exhaust pipe should be used for INSERT installations and must be

attached to the stove with a single-wall, stainless steel “tee” with a clean-out cap. The stainless steel “tee” should be

inclined at 45-degrees to enable the vent to be centered on the stove and allow the “tee” to be cleaned without removing

the stove (see diagram 11.1).

9 When venting into an existing masonry or factory built chimney, the ch imney must be cleaned, with all creosote removed.

The chimney must be a type suited for solid fuel. WARNING: The chimney and the chimney connections must be kept

clean and in good condition.

9 The “PL” venting or single wall stainless exhaust system must be installed so as to be GAS TIGHT! The vent

manufacturer’s installation procedures must be followed. In addition, pipe connections, join ts and all pipe seams within

the home should be sealed with high temperature RTV silicone sealer.

9 If an insert is to be installed into an unlined masonry chimney, it is recommended th at a 3” or 4” inch stainless steel pipe

be extended to the top of the existing chimne y. The top of the existing chimney should be sealed with a steel plate (see

diagram 11.2).

10

Page 11

GUIDELINES FOR EXHAUST VENTING SYSTEMS DESIGN, CONT……

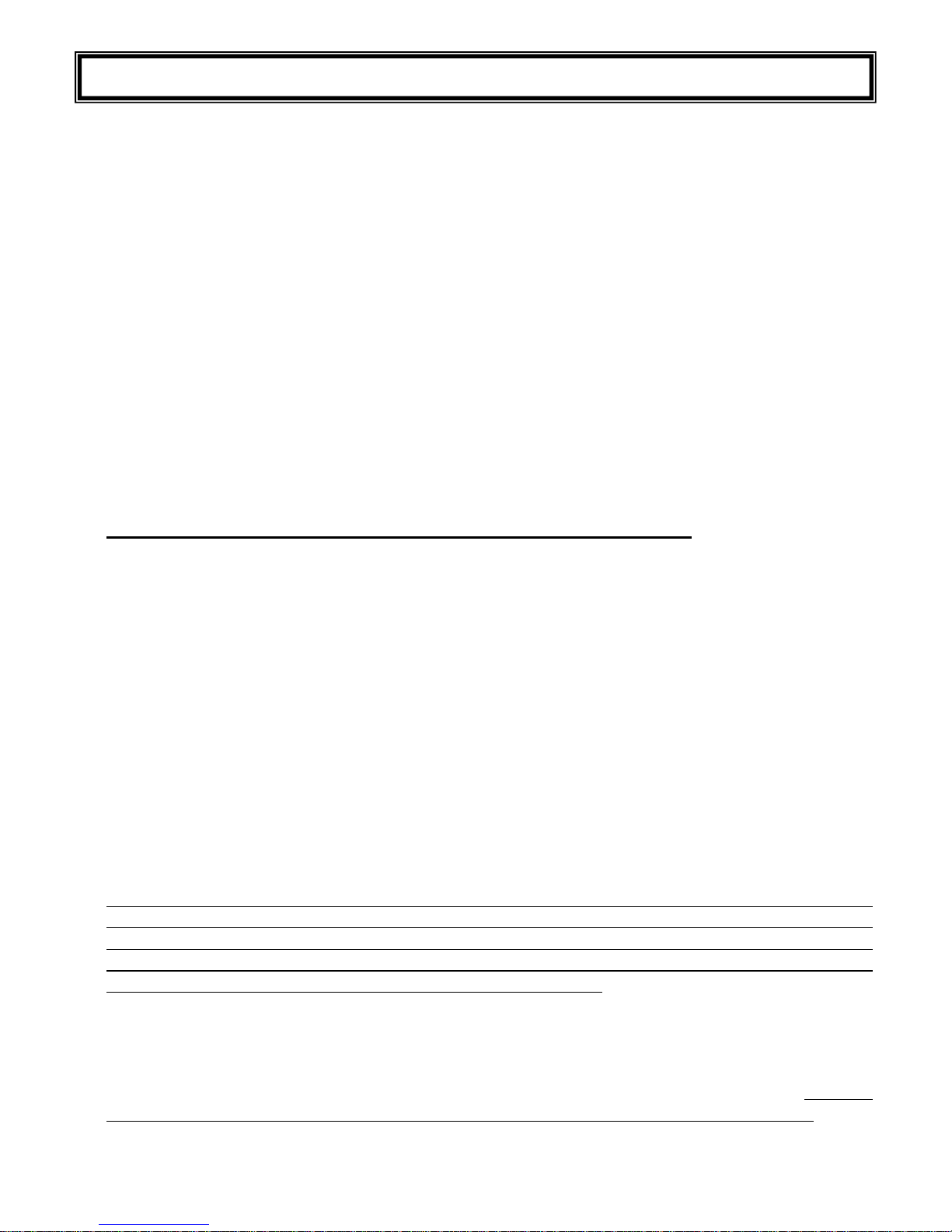

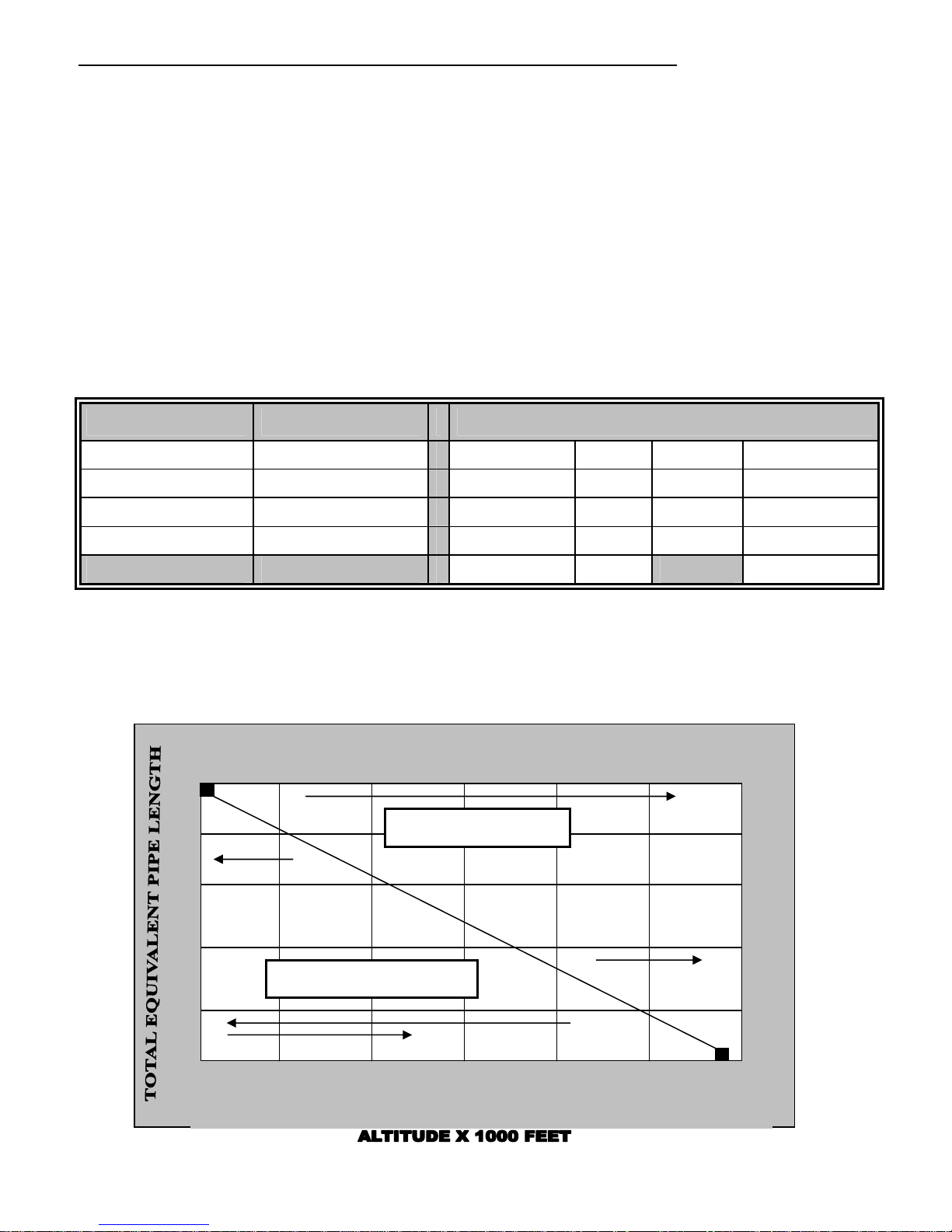

To determine whether a 3” or 4” inch exhaust system should be used, follow the guidelines below:

1) Determine the “equivalent pipe length” for each component used according to the comparison chart

below. Add the “equivalent pipe length” of all components to get the “total equivalent pipe length”.

2) Determine the altitude at which you are installing the stove.

3) Cross-reference the “total equivalent pipe length” and the altitude using the graph below.

NOTE: The “total equivalent pipe length” should not exceed 30’ feet.

Diagram 11.1

Component Equivalent Length Equivalent Pipe Length

Horizontal Straight Pipe Actual Length in ft. x 1.0 Horizontal Pipe = 1 x (2+1) = 3 ft.

Vertical Straight Pipe Actual Length in ft. x 0.5 Vertical Pipe = 0.5 x 8 = 4 ft.

900 Elbow or Tee 5.0 feet 90 Degree Tee = 2 x 5 = 10 ft.

450 Elbow 3.0 feet 45 Degree Tee = 1 x 3 = 3 ft.

TOTAL

=

20 ft.

NOTE: These are guidelines only. Proper venting is accomplished by design and common sense. In most

installations 3” inch diameter venting is adequate. If it does not vent properly you will have to change it to

4” inch.

Diagram 11.2

25

20

15

10

5

0

0 2 4 6 8 10 12

0 2 4 6 8 10 12

CRITERIA FOR SELECTING PIPE DIAMETER

MAXIMUM

4” DIAMETER ONLY

3” OR 4” DIAMETER

ALTITUDE X 1,000 FEET

11

Page 12

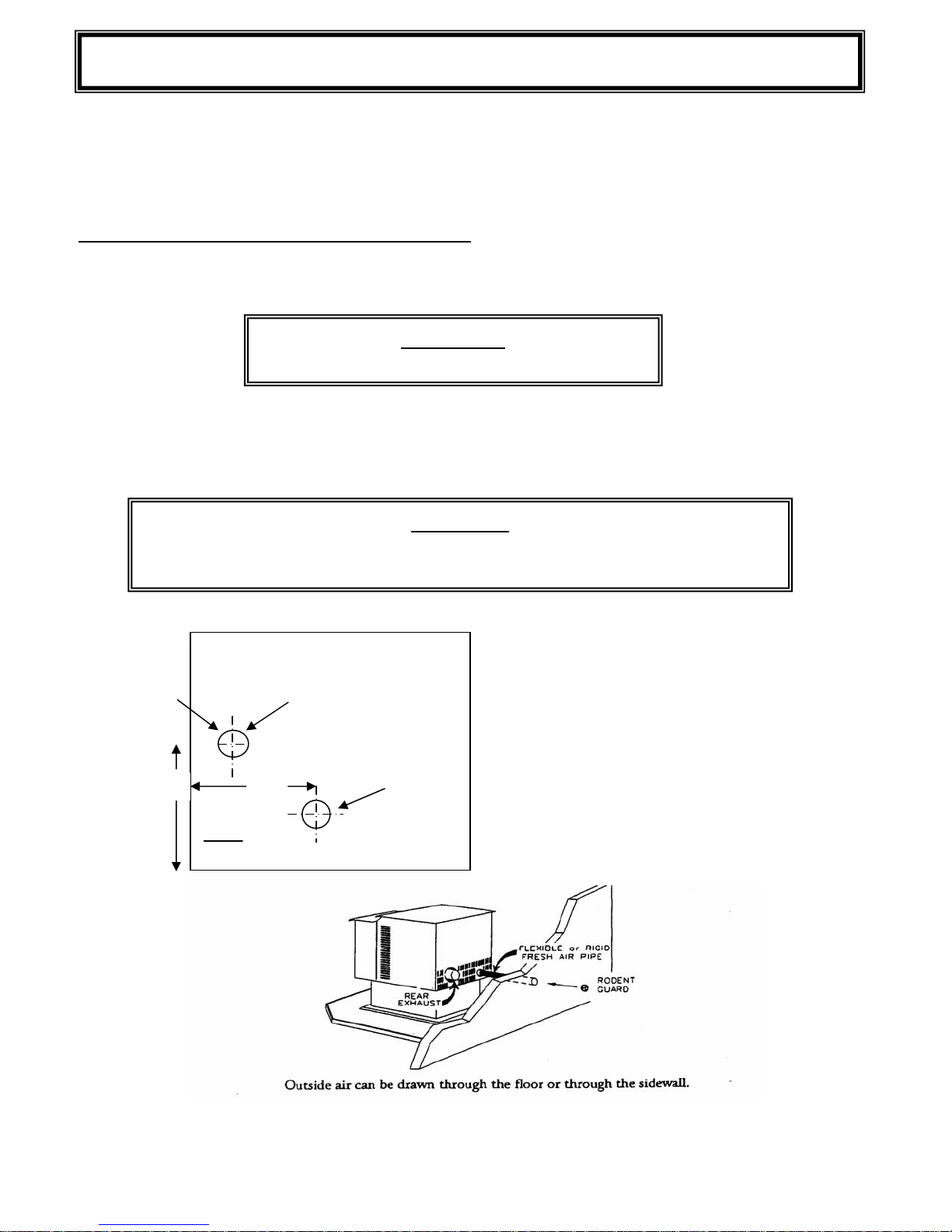

DESIGN GUIDELINES FOR OUTSIDE COMBUSTION AIR CONNECTION

OUTSIDE MAKE-UP AIR FOR COMBUSTION IS REQUIRED ON ALL INSTALL ATIONS

1) For FREESTANDING installations with horizontal through-the-wall exhaust, it is REQUIRED that the stove

combustion air intake be connected to a fresh air intake outside. If the home is newer or has been tightly

insulated it is imperative to the operation of the unit to install outside combustion air. If you do not, then an

additional 6” inch intake into the furnace room in the basement is required.

2) For INSERT installations into an existing fireplace, or FREESTANDING installations with a vertical exhaust,

outside air connection is required. It is not recommended to exit the fresh air intake out the top of the chimney.

3) Connection to outside the house is REQUIRED for all installations.

IMPORTANT: It is the customer’s responsibility to make sure that there is adequate fresh air to the home

so that the MagnuM appliance does not become the fresh air source.

4) Only non-combustible piping 3” inches in diameter is approved to use for outside air connections (straight or

flexible). PVC pipe is NOT approved and should NEVER be used.

5) If the air inlet is connected to the outside, it MUST be terminated with a vertical 90-degree bend (down) or with

a wind hood. Failure to do so could result in a burn back during high winds blowing directly up the air inlet

during a simultaneous power failure (see diagram above).

6) It is important not to terminate the inlet of the fresh air intake too close to the venting outlet for the exhaust. It

is recommended that the inlet for the fresh air is a minimum of 3’ to 5’ feet away from the venting outlet and at

least 1’-2’ feet below.

7) Blockage, excessive length, or bends in the air intake pipe will starve the stove of combustion air. A 90-degree

bend is equivalent in restriction to approximately 30” inches of straight inlet pipe.

12

Page 13

INSTALLATION PRECAUTIONS

CAUTION: Do not install this appliance in any manner other than as described in this manual. If you

have any questions about properly venting or installing your MagnuM corn/biomass/wood pellet stove,

please contact your dealer or American Energy Systems, Inc. for information.

NOTE: THIS STOVE MUST BE BURN TESTED OUTSIDE IN A WELL VENTILATED AREA

FOR AT LEAST FOUR (4) HOURS. THIS WILL CURE THE PAINT AND SEASON THE

STOVE METAL. SMOKING AND STEAMING IS NORMAL DURING THE CURING

PROCESS, AND MAY CONTINUE DURING THE FIRST FEW TIMES THE STOVE IS USED.

The ONLY authorized exhaust vent pipe for this appliance is 3” or 4” inch listed Type PL pellet vent

pipe, designed for use with pellet stoves. This stove may be connected to an existing factory-built

chimney using pellet vent pipe as a connector, and a 3”-4”, 3”-6”, or 3”-8” PELLET VENT to

CHIMNEY ADAPTER. Follow the pellet vent pipe manufacture’s instructions for the installation of the

vent pipe being used. (See “Existing Vertical Installation”).

As you plan your installation, consider the following:

- The stove should be placed as central in the home as possible. Consider safety, convenience,

traffic flow and the fact that the stove will need a venting system and fresh air to the outside of the

home.

- Before drilling or cutting holes, select the location of the appliance. Determine where the ceiling

rafters, wall studs or floor joists are located before making any large holes as the appliance may

have to be moved.

- Care must be taken to maintain minimum clearances to combustibles as per local building codes,

fire codes, and the safety listing tag on the inside hopper lid.

- An outside air source must be connected to the stove and can be brought in through the sidewall

or vented crawl space. Flexible or rigid pipe should be used and will connect to the adaptor on the

back of the stove. (See air inlet location under the CLEARANCE section of this manual)

- Place the stove where you will enjoy watching the fire along with getting the best heat distribution

possible. Locating the stove in a closed room will not allow the unit to perform properly.

Installing the stove in an un-insulated area will also not allow the stove to heat the home properly.

- If the home was not designed with proper heat circulation, the stove will not perform properly.

Make sure that the installer looks at the entire home as a unit when installing your MagnuM

appliance. Make sure that there is adequate cold air returns to pull the heat to adjoining rooms.

DO NOT CONNECT THIS STOVE TO A CHIMNEY FLUE SERVING ANOTHER

APPLIANCE.

DO NOT USE SINGLE WALL PIPE FOR ANY INSTALLATION.

DO NOT INSTALL A FLUE DAMPER IN THE EXHAUST VENTING SYSTEM OF THIS UNIT.

THIS EXHAUST SYSTEM IS PRESSURIZED.

Electrical power is 115volt-60 Hz. The stove is provided with a six foot grounded electrical cord, and

should be connected to a standard 3 prong 115volt, 60 Hz electrical outlet. (Make sure you have a surge

protector installed.) Do not route the cord in front of, or under the stove.

NOTE: A MAJOR CAUSE OF VENT RELATED FIRES IS FAILURE TO MAINTAIN

REQUIRED CLEARANCES (AIR SPACES) TO COMBUSTIBLE MATERIAL. PLEASE

FOLLOW THE VENT PIPE MANUFACTURERS INSTRUCTIONS AND LOCAL BUILDING

CODES FOR THE PROPER CLEARANCES TO COMBUSTIBLES REQUIRED FOR THE

INSTALLATION OF THE VENT PIPE BEING USED.

13

Page 14

INSTALLATION CONFIGURATIONS

The MagnuM Corn/Biomass/Wood Pellet Appliances may be installed as follows:

1) A freestanding unit (with a pedestal only).

2) A hearth mounted fireplace insert into a masonry or factory built fireplace.

3) A built-in heater mounted in an alcove with a pedestal.

4) A built-in heater mounted on a non-combustible floor without a pedestal.

MOBILE HOME INSTALLATION REQUIREMENTS

IN ADDITION TO THE STANDARD INSTALLATION INSTRUCTION, THE FOLLOWING

REQUIREMENTS ARE MANDATORY FOR INSTALLATION IN A M OBILE HOME:

DO NOT INSTALL IN SLEEPING ROOM

WARNING

1) Stove must be permanently bolted to the floor.

2) Stove must have permanent outside air source.

3) Stove must be permanently, electrically ground to the steel chassis of the mobile home. (12 ga. or larger wire)

4) All vertical chimney vent must have wall supports every five (5’) feet.

5) All exhaust systems must have a spark arrestor.

The structural integrity of the mobile home floor, wall and ceiling must be maintained.

Check with your local building official as other codes may apply.

CAUTION

4.25”

12.50”

3” Exhaust vent

12”

3” fresh air

intake

4.25”

14

Page 15

VENT TERMINATION GENERAL INSTRUCTIONS

NOTE: The following are general instructions for installing this appliance.

THE PELLET VENT MANUFACTURER’S INSTRUCTIONS SHOULD BE

FOLLOWED FOR THE VENT PIPE BEING USED. USE ONLY 3” or 4” INCH

LISTED TYPE PL PELLET VENT PIPE.

WARNING: Shut off all electrical power to the wall or room where the appliance is going to be installed

before cutting any holes. Be careful not to drill or cut into any water lines or electrical wiring as water

damage or electrical fire may result.

Upon determining the best location for your new appliance, maintain at least the minimum allowable clearances.

Line up a plumb bob to the flue collar on the stove with the location for the hole in the wall or ceiling before

drilling or cutting any holes. (See rear exhaust and air inlet locations under the CLEARANCE section of this

manual.) Be sure to allow for any stove pad that you will be placing underneath the unit.

Prepare the vent pipe for painting (if you are painting the venting) by wiping down with straight vinegar. Rinse

vinegar off with clean water and allow the pipe to dry. Use high temperature paint as directed by the manufacturer

(the standard paint is Stove Bright Metallic Black). Let the paint dry for a couple hours before assembling.

Drill and enlarge the hole as required for installation of the wall thimble, vent pipe and components per the pellet

vent manufacturer’s instructions.

Connect the pipe and lock the joints as directed by the pellet vent manufacturer, and secure the vent pipe to the flue

collar on the back of the stove. Add a small bead of RTV high temperature silicone around the outside edge of the

flue collar prior to securing the vent pipe. Drill and attach the vent pipe to the flue collar with sheet metal screws.

Alternate (preferred) method: Attach the approved PL pipe adaptor on the back of the exhaust pipe located on the

rear of the appliance, secure with a 3” hose clamp and then attach all venting to the pipe adaptor.

Do not terminate the vent in any enclosed or semi-enclosed area, such as a carport, garage, attic, crawl space, under

a sun deck or porch, in a narrow walkway or closely fenced area, stairway, covered breezeway, or any other

location which can build up a concentration of flue gases.

Vent surfaces can become hot enough to cause burns if touched. Non-combustible shielding or guards may be

required.

Note: Make sure that you leave adequate clearance between the back of the unit and the wall to allow for proper

cleaning, servicing, and for when you open the hopper lid, that it does not hit the wall. It is recommended that you

leave 4”-6” inches of clearance between the appliance and the back wall of the home.

NOTE: THE VENT PIPE SHOULD BE INSPECTED FREQUENTLY TO VERIFY THE INTEGRITY OF

THE VENTING SYSTEM AND TO INSURE THAT NO OBSTRUCTI ONS OR BUILD-UP EXIST

WITHIN THE VENT PIPE. FAILURE TO INSPECT THE VENT PIPE CAN CAUSE A MALFUNCTION

OR HAZARDOUS OPERATION OF THE STOVE.

15

Page 16

(

HORIZONTAL INSTALLATION

EXHAUST VENT TERMINATION SHALL BE AS FOLLOWS:

A MINIMUM OF 4’ FEET/122Omm BELOW, BESIDE AND 1’ FOOT ABOVE ANY DO OR OR WI ND O W THA T

OPENS, OR ANY OPENING INTO A BUILDING.

A MINIMUM OF 2’ FEET/610mm FROM ANY ADJACENT BUILDING OR OVERHANG.

A MINIMUM OF 7’ FEET/2130mm ABOVE GRADE, WHEN LOCATED ADJACENT TO PUBLIC WALKWAYS.

A MINIMUM OF 2’ FEET/610mm ABOVE GRASS, PLANTS OR OTHER COMBUSTIBLES.

Note: The pipe lengths shown are for reference only.

Your actual pipe length requirements may differ.

SINGLE WALL PIPE SHALL NOT BE

USED FOR ANY INSTALLATION.

HORIZONTAL INSTALLATION SHALL

BE A MAXIMUM O F 5’ FEET.

MINIMUM 6"

(152mm)

304 mm)

CLEARANCE

12”

E

V

O

T

S

Wall Thimble

WARNING:

Vent surfaces can become hot enough to cause burns

if touched. Non-combustible shielding may be required.

PLEASE FOLLOW THE PELLET VENT MANUFACTURER’S INSTRUCTIONS AND LOCAL BUILDING CODES

FOR THE CLEARANCES TO COMBUSIBLES REQUIRED FOR INSTALLATION OF THE VENT PIPE BEING

USED.

R

E

T

P

A

D

A

STOVE ADAPTER

MIN. 12"

CLEARANCE

RAIN CAP

WALL THIMBLE

16

Page 17

Storm Collar

VERTICAL INSTALLATION

GUIDELINES FOR CONNECTING TO AN EXISTING FACTORY-BUILT CHIMNEY:

1. Inspect the chimney for the presence of creosote, soot or other combustible deposits, and blockage or

obstructions. Thoroughly clean the chimney and remove any obstructions.

2. Thoroughly inspect the chimney for soundness, proper clearances and presence of all necessary parts, including a

chimney cap, prior to making the connection.

3. This stove may be connected to an existing ceiling-mounted factory-built chimney with a diameter of 4”, 6”, or 8”

inches.

4. Use a 3”-4”, 3”-6” or 3”-8” inch pellet vent to chimney adapter provided by the pellet vent manufacturer.

5. Use only listed 3” inch Type PL pellet vent pipe between the stove and the chimney.

6. Follow the pellet vent manufacturer’s instructions to assemble the vent pipe and make the connection to the

chimney.

17

Page 18

3” min.

Storm Collar

Note: This type of installation

is not recommended in cold

climates unless closed in and

insulated properly.

required

Warning: Unless the venting is enclosed and insulated, this installation will cause poor venting,

excess ash buildup, premature failure of exhaust system, staining of the house siding and serious

creosote buildup. This installation should not be used in a cold climate area.

18

Page 19

AC CONTROL PANEL/THERMOSTAT HOOK-UP

WARNING: ALWAYS DISCONNECT POWER CORD DURING ANY ELECTRICAL

OPERATION

1. Remove control panel from protective packaging.

2. Connect the one way molex plug to the control panel; do not pull on the wire harness inside

the stove.

NOTE: Use only a low voltage mercury or bi-metal thermostat switch. (No power required on

thermostat)

NOTE: If you are not going to use the thermostat function then skip steps #4 - #8 and go to Step #9.

3. Locate the thermostat on a wall six (6’) to (10’) feet away.

4. Route the wires into the stove near where the AC power cord enters.

5. Pull the thermostat wire through to the control panel cut-out.

6. Move the factory installed jumper from the upper position to the lower position. (see details

below)

7. Connect the thermostat wires to the two terminals on the back of the control panel.

When the room temperature drops below the thermostat setting, the thermostat switch will

close, allowing the stove to operate at the medium or higher settings. When the room

temperature matches the thermostat setting, the thermostat switch will open, allowing the stove

to operate at the low setting.

8. Locate the control panel into the side panel cut-out and secure with four (4) #7 X ½ Phillips

screws (supplied). Do not over tighten. Set control board to thermostat operation.

9. The stove is now ready for operation. Refer to the OPERATING INSTRUCTIONS.

Note: The thermostat function of the stove will cycle with the room temperature when the “Fuel

Feed Control” is set at a medium or higher setting.

THERMOSTAT JUMPER

MUST BE MOVED TO

Must be in this

THIS POSITION

position

.250 TERMINAL SPADE

MOLEX PLUG

CONTROL PANEL

MOLEX PLUG

AC POWER CORD

QTY.- 4

#7 x 1/2"

SCREWS

19

.250

TERMINAL

THERMOSTAT WIRE

CONNECTION

MERCURY SWITCH

LOW VOLTAGE

THERMOSTAT

MOLEX

PLUG

Page 20

DC CONTROL PANEL/THERMOSTAT HOOK-UP

WARNING: ALWAYS DISCONNECT POWER CORD DURING ANY ELECTRICAL

OPERATION

10. Remove control panel from protective packaging.

11. Connect the one way molex plug to the control panel; do not pull on the wire harness inside

the stove.

NOTE: Use only a low voltage mercury or bi-metal thermostat switch. (No power required on

thermostat)

NOTE: If you are not going to use the thermostat function then skip steps #4 - #8 and go to Step #9.

12. Locate the thermostat on a wall six (6’) to (10’) feet away.

13. Route the wires into the stove near where the AC power cord enters.

14. Pull the thermostat wire through to the control panel cut-out.

15. Move the factory installed jumper from the upper position to the lower position. (see details

below)

16. Connect the thermostat wires to the two terminals on the back of the control panel.

When the room temperature drops below the thermostat setting, the thermostat switch will

close, allowing the stove to operate at the medium or higher settings. When the room

temperature matches the thermostat setting, the thermostat switch will open, allowing the stove

to operate at the low setting.

17. Locate the control panel into the side panel cut-out and secure with four (4) #7 X ½ Phillips

screws (supplied). Do not over tighten. Set to Thermostat operation on the top front of the

board.

18. The stove is now ready for operation. Refer to the OPERATING INSTRUCTIONS.

Note: The thermostat function of the stove will cycle with the room temperature when the

“Fuel Feed Control” is set at a medium or higher setting.

The Thermostat wire connection is located on the back of the board

just above the white molex connector.

To operate t

switch in th

he unit in the thermostatic operation mode, place the selector

e T-Stat position. (Center position)

20

Page 21

MAGNUM WIN INSERT INSTALLATION

21

Page 22

WIN INSERT INSTALLATION cont.

pip

Chimney cap

Storm Collar

Seal Plate

3”(75mm

Minimum

Clearance

Around

6” (150mm) min.

Use only rigid Pellet

Vent

Siding

Framing

e

6” (150mm)

minimum

16” (375mm)

minimum

22

Page 23

WIN INSERT INSTALLATION cont.

For a raised Hearth, you can have

a decorative skirting made by your

installer to finish off the front of

the unit. The skirting must be

made out of non-combustible

materials and must support the

weight of the unit.

23

When extending the

unit beyond a raised

hearth, you must use

some type of supp

bolt to hold and lev

the unit.

(not provided)

ort

el

Page 24

It is not recommended to

run the fresh air to the

top of the chimney

Your installer will determine what type of

leveling bolts or other means that will level

the unit properly.

It is best to route the fresh air intake either

out the back of the fireplace cavity or down

and out to an outside air source. Running

the fresh air up and out the top of the

chimney can cause excessive draft issues.

24

Page 25

25

Page 26

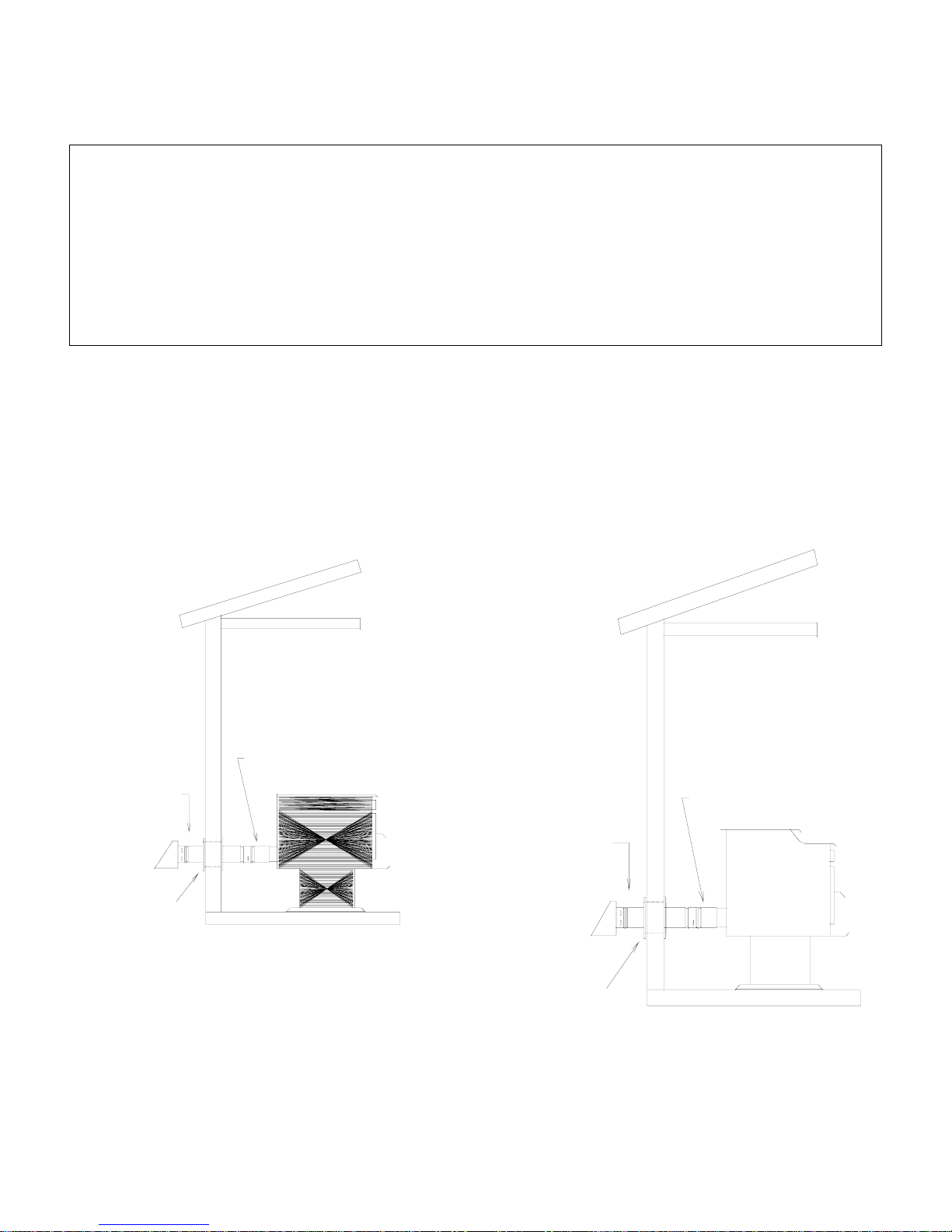

Fireplace Insert Shroud Installation Diagram:

26

Page 27

Molex Plug

p

Thermostat wire

connection

24 volt thermostat

hooku

Low voltage thermostat

27

Page 28

OPTIONAL 12 VOLT BATTERY BACK-UP

WARNING: ALWAYS DISCONNECT POWER CORD DURING ANY ELECTRICAL OPERATION

Note: Never use an unsealed battery.

1. Disconnect the 110 volt AC power before connecting the 12 volt battery.

2. Determine the location for the 12 volt battery and obtain the proper length and type of wire (Use 18

gauge stranded wire)

3. Drill and install 1/2” conduit where passing through a wall or floor.

4. Connect a red 18 gauge wire to red positive (+) battery terminal on the stove.

5. Install a 4 amp inline fuse on the red positive wire near the stove.

6. Connect a black 18 gauge wire to black negative (-) battery terminal on the stove.

7. Pass wire through the conduit to battery location. Allow enough wire length between battery box and

exterior wall for a drip loop to prevent moisture from reaching terminals. (see diagram)

8. Connect the red positive (+) lead to the positive (+) battery terminal.

9. Connect the black negative (-) lead to the negative (-) battery terminal.

10. Reconnect the 110 volt AC power. The stove is now ready for 12 volt back-up and will switch

automatically to 12 volt operation when AC power is lost. When AC power is restored, the stove will

automatically switch back to AC power and recharge the battery.

NOTE: THE SELF IGNITER WILL NOT START THE STOVE IN THE DC POWER MODE.

(12v Battery Back-up)

STARTING THE STOVE IN DC POWER MODE (12v Battery Back-up)

1. See normal start up.

ELECTRICAL CONDUIT

WHERE PASSING

THROUGH A WALL

VENTED

BATTERY

BOX

12 V

DRIP LOOP

4 AMP FUSE ON

POSITIVE LEAD

FRESHAIR

N

E

G.

P

O

BATTERY

CONNECTIONS

S.

POWER

CORD

Models before April 2006 have exterior

connections for 12V, newer models have the

connection on the interior. Open the left pane

to access the connections.

+ DENOTES POSITIVE

- DENOTES NEGATIVE

l

28

Page 29

OPERATING INSTRUCTIONS (DC Models)

NOTE: Each time the stove is started, the firepot should be checked for debris and clear air holes. Some fuels will

cause the firepot to build up more frequently making it necessary to stir and clean the firepot more often. Do not allow

ash to build up underneath the firepot. Take the firepot out at least weekly to vacuum ou t any ash in the bottom.

PRIMING THE AUGER:

Place Thermostat switch in manual position or turn up wall thermostat to call for heat. Never leave the stove

unattended during priming or start-up. Priming the auger is required when the unit is new or when the hopper has

completely run out of fuel. Be sure to vacuum out the hopper every 4-6 bags of fuel.

TO PRIME THE AUGER:

A. Load the hopper with Fuel.

B. Push the “On/Off” switch to the “On” position. Wait about 1 minute.

C. Press the “auger” switch button until fuel begins to drop into the firepot.

When fuel begins to drop regularly, the auger is primed.

STARTING YOUR STOVE: Place Thermostat switch in manual position or

turn up wall thermostat to call for heat.

Note: The viewing door, ash pan door and hopper door must be closed

and/or latched during operation.

A. Turn the air intake butterfly damper to approximately ¼ open. (located on back of unit)

B. If using a DC battery, make sure that all connections are secure. If the unit

will not start, the battery (not supplied with unit) may need charging.

C. Clean out the firepot; make sure nothing is plugging the igniter.

D. Press the “On/Off” switch to the “On” position.

This stove is equipped with a self igniter (optional) that will start Wood Pellets

without the use of fire starter. NOTE: The igniter will not operate if the unit

is on DC battery power. You must manually light the unit.

Fuel will drop into the firepot and ignite in 3-5 minutes. The igniter will

continue to run for approximately 10 min until a fire is established. If a fire is

not started within the minimum cycle time, the auger will stop feeding and you

will need to start the cycle over again.

Pushing and holding the auger switch allows you to prime the auger and add

fuel to the firepot automatically. This can be done app. 1 minute after pushing

the on/off start button. The unit starts automatically on the low heat setting.

When you have started the unit (app. 10 minutes) you can press and hold the

heat level button and it will advance one heat setting. Press the button until you

have reached the desired heat setting. It is recommended to burn the unit on the

number 3 heat setting for the first 30-45 minutes.

The convection blower speed varies directly with the feed rate. The “High Fan” switch will override the variable fan

function (# 1 heat setting only). Setting 2-5 is full fan speed.

NOTE: In case of a power outage or interruption lasting longer than 5 seconds, the “Start” button must be pushed to

re-engage the auger. The self-igniter will not operate if the unit is on battery power. Manually light the unit.

IMPORTANT: The circuit board will not function properly if the outlet is not a constant 115 volt, 60 cycle power

source. The outlet must be grounded properly and have the correct polarity. A polarity and ground tester can be

picked up at any hardware store to assure proper operation. If you are using a power generator, solar power or wind

generation make sure that you have a constant correct power source.

The unit’s electrical warranty would become void if a constant power source is not available. Also, make sure that a

proper surge protector is between the unit and the power source. The circuit board will not be warranted if there is not

a surge protector installed to the unit.

It is strongly recommended that you unplug the power source during times when the unit is not being operated to

protect the unit from power surges, power spikes and drops in power. It is very common for a circuit board to work

when the unit is shut off in the spring and then won’t work in the fall. Unplugging the unit will prevent this from

happening.

29

Page 30

OPERATING INSTRUCTIONS (AC models)

NOTE: Each time the stove is started, the firepot should be checked for debris and clear air holes. Some fuels will

cause the firepot to build up more frequently making it necessary to stir and clean the firepot more often. Do not allow

ash to build up underneath the firepot.

PRIMING THE AUGER:

Never leave the stove unattended during priming or start-up. Priming the auger is required when the unit is new or when

the hopper has completely run out of fuel. Be sure to vacuum out the hopper every 4-6 bags of fuel.

TO PRIME THE AUGER:

A. Load the hopper with fuel.

B. Push the “On/Off” switch to the “On” position.

C. Press the auger override switch until fuel begins to drop into the firepot.

When fuel begins to drop regularly, the auger is primed. You may need to prime the auger a couple times if the fuel

has been completely run out. This may take 2 or 3 cycles to light properly.

STARTING YOUR STOVE

Note: The viewing door, ash pan door and hopper door must be closed and/or latched during operation.

A. Pull the air damper control rod out to approximately 1/4.

B. Clean out and dump the firepot. Place a small amount of fuel in firepot.

C. Press the “On/Off” button to initiate the start up sequence.

D. Set the heat level on #3. (Press the advance button.)

This stove maybe equipped with a self igniter that will start

the pellets without the use of fire starter. Fuel will

drop into the firepot and ignite in 3-5 minutes. The

igniter will continue to run for approximately 10 min

until a fire is established. If a fire is not started

within the minimum cycle, the auger will stop feeding.

The auger button allows you to prime the

auger and add fuel to the firepot automatically. Press and

hold the button until you have the right fuel load.

Do not continue to hold the a uger button under

normal operation, as it could overload the firepot,

smother the fire and lead to a dangerous condition.

The convection blower speed varies directly with the feed rate. The “Fan le fan

function when pressed. It will set the convection blower to high at any feed rate setting.

NOTE: In case of a power outage, the pressure switch has tripped, the door has been opened, the hopper door has been

left open or any power interruption lasting longer than 5 seconds, the “On/Off” button must be pushed and held for

app. 7 seconds (or until you here a click) to re-engage the auger system.

IMPORTANT: The circuit board will not function properly if the outlet is not a constant 115 volt, 60 cycle power

source. The outlet must be grounded properly and have the correct polarity. A polarity and ground tester can be

picked up at any hardware store to assure proper operation. If you are using a power generator, solar power or wind

generation make sure that you have a constant correct power source.

The unit’s electrical warranty would become void if a constant power source is not available. Also make sure that a

proper surge protector is between the unit and the power source. The circuit board will not be warranted if there is not

a surge protector installed to the unit.

It is strongly recommended that you unplug the power source during times when the unit is not being operated to

protect the unit from power surges, power spikes and drops in power. It is very common for a circuit board to work

when the unit is shut off in the spring and then won’t work in the fall. Unplugging the unit will prevent this from

happening.

” button will override the variab

30

Page 31

OPERATING INSTRUCTIONS…continued (ALL MODELS)

PROPER FUEL

This stove is designed and approved to burn approved Biomass fuel only. Do not use any other type of

fuel. Clean corn with moisture content less than 15% must be used. Factory approved pellets are those ¼”

in diameter and not over 1” in total length. Larger pellets will cause the auger to jam or bridge in the

pellet hopper. The use of unapproved fuel will void all warranties. Do not burn damp or wet pellets. The

stove’s performance depends greatly on the quality of your pellet fuel.

Clean fuel means a consistent and trouble-free operation. Do not use corn/wood pellets that have:

1. Excess fines-loose material that looks like sawdust or sand. Loading this material into the

hopper may eventually slow down or jam the auger and prevent the flow of fuel in the hopper

compartment. Dirty Corn (corn cobs, cockle burrs, etc. will plug the auger)

2. Binders-material used to hold the pellet together. Wax content corn cannot be used.

3. High ash content-avoid pellet brands that immediately smoke up the viewing window and

leave a residue in the burn pot. You will be required to clean the ash boxes and vent pipe more

frequently. It may be necessary to sample several brands until you find a brand of pellets that

will burn properly. Corn supply must be clean, consistent and preferred 11-12% m o isture.

RUNNING YOUR STOVE

A. After starting the stove, leave it burning on the #3 setting for at least 20-30 minutes to allow

the stove to heat to operating temperatures. You may then set the desired burn rate by moving

the control switch to the desired operating position.

B. Select the most efficient burn by adjusting the air damper control rod in or out. An air damper

closed too much will produce a lazy and slow flame. Adjusted properly, the flames should be

bright and lively. Altitude and fuel types greatly affect the amount of air required. Opening

the damper approximately ¼-1/2 will be sufficient for most installations and fuels. The

operating temperatures of this unit may vary with the different types or grades of fuel

used.

TURNING THE STOVE OFF

A. Move the power switch to the “Off” position. (push the On/Off button on the AC & DC

models) The fan will continue to run for approximately 45 minutes to let the stove cool down,

and then automatically shut itself off.

NOTE: IF THIS UNIT RUNS OUT OF FUEL AND COOLS DOWN, THE AUGER WILL STOP

FEEDING. IT WILL BE NECESSARY TO PRIME THE AUGER ANY TIME THE HOPPER

RUNS OUT OF FUEL. THE BLOWERS WILL CONTINUE TO RUN UNTIL THE POWER

SWITCH IS MOVED TO THE “OFF” POSITION.

WARNING: DO NOT USE ADDITIONAL GRATES TO SUPPORT THE FUEL.

WARNING: Auger jams are the leading cause of stove malfunctions. Jams occur due to foreign objects

in the fuel, or more commonly, failure to follow the operating instructions. Most auger jams are

preventable by properly priming the auger as required before starting the stove. Keeping the hopper from

running out of fuel will help prevent auger jams.

IMPORTANT: Selecting the proper combustion air is done by moving the air damper control rod in or

out to decrease or increase the air flow (in = closed = decrease, out = open = increase). High altitude or

high ash fuel may require more air for efficient fuel combustion. The stove should be started with the

damper control rod out in the 1/4 open position.

31

Page 32

CLEANING INSTRUCTIONS

NOTE: BE SURE THE STOVE IS TURNED OFF, THE POWER CORD IS UNPLUGGED, AND

THE UNIT IS COLD BEFORE CLEANING OR SERVICING.

RECOMMENDED CLEANING PERIODS:

A. The heat exchange tubes in the stove should be cleaned daily.

B. The firebox should be cleaned every 3 to 7 days or when needed.

C. The interior ash chambers should be inspected and cleaned as needed.

D. The chimney pipe and cap should be checked monthly for soot buildup.

E. Combustion blower should be cleaned as needed. Check at least semi-annually.

DISPOSAL OF ASHES:

Ashes should be placed in a metal container with a tight fitting lid. The closed container of ashes should

be placed on a noncombustible floor or on the ground, well away from all combustible materials, pending

final disposal. If the ashes are disposed by burial in soil or otherwise locally dispersed, they should be

retained in the closed container until all cinders have been thoroughly cooled.

WARNING: MANY HOME VACUUM CLEANERS ALLOW ASH TO ESCAPE INTO THE

ROOM AIR; HOWEVER, VACUUMING (Use an approved Ash vacuum system.) IS

RECOMMENDED OCCASIONALLY TO AID IN SEASONAL CLEANING AND KEEP THE

UNIT FREE OF EXCESS ASH. DISCARD THE VACUUM BAG AFTER EACH USE ON THE

STOVE.

FIREBOX: This needs to be done every 3-7 days depending on fuel quality, heat settings.

Shut off unit and let cool, open the door,

sweep or vacuum out the ash buildup.

Remove the firepot and empty,

inspect all air holes and clean if blocked.

Inspect under the firepot for buildup of

ash. Replace the firepot in the stove.

Periodically inspect the ash chambers

“A”, “B”, and “C” by removing the

inspection doors. If the heat exchangers

become plugged remove the three (3) wing

nuts, bracket and brick panels. The ash

chambers can be removed from the firewall for a

more thorough cleaning.

BACK ASH CHAMBER AREA: Every 2-4 weeks

Periodically inspect the back ash chambers to make

sure that they have not plugged. Contact your local

dealer for the proper cleaning tools. Clean out any

obstruction that would cause the ash to not drop out

of the chamber. There is a clean out plug behind the

ash pan that needs to be inspected once a month.

32

Page 33

ASH PAN: Empty as needed.

Empty the ash pan before it overflows with ash. Clean out the area that the ash pan sits in so that the ash

pan can go back to its original location.

NOTE: The ash pan door must be latched for the unit to operate.

WARNING: Failure to clean the stove is a leading and preventable cause of stove malfunctions.

Fuel types and installations may dramatically affect the cleaning intervals required for your stove.

Sampling different brands of fuel to find the cleanest burning fuel available in your area can

greatly reduce the amount of maintenance required.

HEAT EXCHANGER:

This stove is designed with a built-in heat exchange

rake. The rake handle is located on the front of the stove

and is moved backwards and forwards several times

to remove the buildup of ash. After cleaning, push the

rake handle in until it stops.

COMBUSTION BLOWER:

Over the course of the heating season dust and ash may

collect on the blades of the combustion blower.

Periodically they should be inspected, vacuumed, and

clean. The combustion blower is accessed by opening

the stove’s right side panel and then removing the

inspection caps or the exhaust manifold cover (See

figure to the right). Never

operate the stove without

the inspection cap or

manifold cover in place.

The convection (room air fan) blower will accumulate dust, pet hair, etc. on

the blades during the heating season. This must be vacuumed and clean as

needed. If you have pets, the convection blower will need to be cleaned

regularly as the pet hair will clog up the blades and motor windings and

cause premature wear, overheating and failure of the blower system.

Ash Rake Handle

g

200 Manual Reset

High Temp Shut Off

Au

er Thermodisk

Inspection Cap

Auto Reset

110 deg Normally open

Cool Down

33

Page 34

N

N

CLEANING INSTRUCTIONS FOR THE WIN INSERT

ESSEX model shown but all DC & AC models

have the same items

110

Auto reset 110 deg.

ormally open proof of fire

thermodisk

Auto reset 110 deg.

ormally open cool down

thermodisk

The convection (room air fan) blowe on the blades during the heating

season. This must be vacuum e convection blower will need to

ed and clean as needed. If you have pets, th

be cleaned regularly as the pet ha dings and cause premature wear,

overheating and failure of the blower system

r will accumulate dust, pet hair, etc.

ir will clog up the blades and motor win

.

34

Page 35

INSERT CLEANING INSTRUCTIONS…continued

WARNING: DISCONNECT POWER CORD BEFORE CLEANING OR SERVICING.

NOTE: CLEANING INTERVALS MAY VARY GREATLY WITH DIFFERENT

TYPES/BRANDS OF FUEL DUE TO THE ASH CONTENT, MOISTURE, AND MATERIAL

COMPOSITION OF DIFFERENT FUELS.

INSPECT AND CLEAN EXHAUST SYSTEM FREQUENTLY

DAILY WEEKLY MONTHLY ANNUALLY

FIREPOT

FIREBOX (BURN

CHAMBER)

ASH CHAMBERS

EXCHANGER

TUBES

COMBUSTION

FAN

VENTING

SYSTEM

GASKETS

DOOR GLASS

V. CHIMNEY CLEANING:

A. Creosote Formation - Any time wood or a wood product is burned slowly, tar and other

bi-products of combustion are produced. These products can condense in a cooled chimney

flue and will accumulate over a period of time. It is important to remove these products

periodically to eliminate the possibility that they will be ignited in the chimney and produce

damage to the chimney or even possibly destroy the home. Clean the chimney as often as

needed and never go more than one (1) year without a flue cleaning.

B. Soot and Fly Ash - Formation and Need for Removal - The products of combustion will

contain small particles of fly ash. The fly ash will collect in the exhaust venting system and

restrict the flow of the flue gases. Incomplete combustion, such as it occurs during startup,

shutdown, or incorrect operation of the stove will lead to some soot formation which will

collect in the exhaust venting system. The exhaust venting system should be inspected at least

once every year to determine if cleaning is necessary.

C. Inspection and Removal - The chimney connector and the chimney should be inspected to

eliminate the risk of a chimney fire. Check the chimney from both the top and bottom. The

creosote should be removed with a brush designed for your chimney. A chimney sweep can

perform this service. It is recommended that before each heating season the entire system be

professionally inspected, cleaned, and repaired if necessary.

Stirred

Emptied

CHECKED CLEANED

CHECKED CLEANED EXTRA

CLEANED EXTRA

INSPECTED CLEANED

CHECKED CLEANED

INSPECTED

CLEANED INSPECTED

SCRAPPED &

CLEANED

CLEANING

CLEANING

35

Page 36

AUTOMATIC FEATURES

A. THERMOSTAT OPTION (Optional):

When using a thermostat, set the unit to one of the medium or higher settings. The unit will

burn at the rate selected on demand by the thermostat (medium to high). When the room

temperature drops below the thermostat setting, the thermostat switch will close, allowing the

unit to operate at the medium or higher settings. When the room temperature matches the

thermostat setting, the thermostat switch will open, allowing the stove to operate at the low

setting.

B. THERMOSTAT EQUIPMENT REQUIRED (is optional): A low voltage millivolt

thermostat that will automatically switch between settings previously selected.

Type CL2 thermostat wire-20 AWG, 2 conductors.

C. VACUUM PRESSURE SWITCH/STOVE PRESSURE SENSOR:

A blocked flue, a down draft, open door, open hopper lid, negative or positive pressure in the

home, drafty location of the appliance, not hooking up the outside air, improper venting or

maintenance of the 3” inch exhaust venting from the stove will cause the pressure switch to

shut off the auger. To resume operation, it is necessary to locate the cause and correct it.

Restart the unit following the instructions in this manual.

D. HIGH TEMP THERMODISK/SNAP DISK:

If the unit overheats, it will shut itself down safely. The unit may not be restarted until it has

cooled and the reset button is depressed. (See Thermodisk location section) If the auger does

not turn after cleaning the back of the unit, you might have tripped this disk. To reset high

temp push in on the center button until it clicks into place.

E. SELF-IGNITER (Optional):

Automatically ignites the pellets within 3-5 minutes, without the use of fire starter. The igniter

will continue to run for approximately 10 minutes until a fire is established. If the fuel is wet,

poor quality or the hopper has not been primed, it might take 2 or 3 cycles for the unit to

properly light. Using a small amount of fire starter will help with this.

F. PROOF OF FIRE THERMODISK/SWITCH/SNAP DISK:

If the temperature required by the PROOF OF FIRE thermodisk is not high enough within the

10 (15 minutes on the AC models) minute cycle, the auger will stop feeding fuel.

G. COOL DOWN SENSOR/SWITCH/LOW LIMIT: (Same as Proof of Fire Thermodisk)

After the power switch has been moved to the “OFF” position, the blowers will continue to run

for approximately 45 minutes. The cool down sensor will allow the stove to cool down and

then automatically shut itself off. If the hopper runs out of fuel and the stove cools off, the

auger will stop feeding. However, the blowers will continue to run until the POF switch has

cooled down to initiate the shut down cycle

36

Page 37

GLASS MAINTENANCE, ADJUSTMENT, REMOVAL AND REPLACEMENT

Your MagnuM Biomass Pellet Stove comes to you with the glass door installed in place, ready for use.

The glass is surrounded on the edges with a gasket and seated in a glass channel. It is held in place with

two (2) clips on the top and two (2) clips on the bottom and two (2) clips on each side.

REMOVAL OF BROKEN OR DAMAGED GLASS

Open the door and lift it off of hinges. If the door is tight, tap gently on the bottom of the door with your

hand or rubber hammer. Lay door on newspaper with glass clips facing you. Using a #2 Phillips

screwdriver, loosen the screws and take the glass clips off. Remove the broken glass carefully and

discard. Check to insure that the gasket material under the glass is in working order. You can obtain this

material from the factory or from an authorized MagnuM reseller if it is in need of replacement.

Reverse the above procedure for replacing the new glass. When installing the new glass insure that the

glass is not sitting on top of any obstructions. The glass will break when tightening the screws if the

glass is on the gasket. Hold the glass toward the top of the door glass channel when tightening.

Do no operate unit with broken glass.

Do not substitute original factory glass.

You must use only factory authorized glass:

Do not use abrasive cleaners.

Do not clean when glass is hot.

WARNING

Do not slam door shut.

Do not strike glass.

CLEANING THE GLASS

When the fire is first started, it will produce some smoke. The smoke might accumulate on the glass

surface. Before the fire gets hot, open the door and wipe the glass surface off with a damp rag. Do not

touch the surface with your hands. If after constant use, the glass is dirty; you must clean the glass so that

it will not become etched with the fly-ash. When the glass has cooled off, take a damp rag, put a little fly

ash from the unit on it and clean the glass. If this does not clean the glass use a special glass cleaner

provided by your MagnuM reseller. We have found that Amway’s Crème Glass & Chrome Cleaner

works very well.

GLASS CLIPS

37

Page 38

p

CIRCUIT BOARD/CONTROL BOARD FUNCTIONS (How does the circuit

board o

erate?)

Startup/Normal Operation

When the circuit board is energized (the On/Off button is pushed), the start up cycle is initiated. This

starts a timed 8-15 minute cycle which allows the unit to light. If the unit is on AC power, the automatic

ignition system will energize. The igniter (optional f eature) will glow red in the firepot for 10 minutes

and then shut off to protect the igniter. If the unit is on DC back up power the automatic ignition system

will not work and the unit will have to be lit manually. If the proof of fire thermodisk has not reac hed

operating temperature, the unit will go into the shut down mode. The circuit board is programmed to start

at a specified feed rate regardless of where the heat level setting is set. The unit should be set to the # 2 or

#3 heat level setting for the first 45 minutes. To restart the system if it does not light, push the ON/OFF

button and the startup sequence will start over again. If you open the door, it will stop the startup

sequence.

The circuit board is programmed to start on the # 2 heat setting regardless of what the advance heat

setting is on.

NOTE: Make sure that the wall thermostat is turned up so the unit will start. (When using T-STAT or

AUTO settings.)

Once the unit is operating at the proper temperature (usually after 10-15 minutes), the circuit board

switches from the start up cycle to normal operation. Then the manual draft slide can be set for the right

fuel load in the firepot.

The unit is not designed to be operated for long periods of time on the highest heat level setting.