Page 1

Repair and Parts

Project Painter™ 5, Project Painter™ 7,

™

SR

Project Painter 5 and Project Painter 7 ONLY. Use

water based or mineral-spirit type material only. Do

not use materials having flash points lower than 70°F

(21°C). For more information about your material

request MSDS from distributor or retailer.

7, ProX7™ & ProX9™ Airless Sprayers

-

For portable spray applications of architectural paints and coatings -

(See specifications, page 2.)

IMPORTANT SAFETY INSTRUCTIONS.

Read all warnings and instructions in this manual.

Save these instructions. See page 2 for model and

series information including dispense rate, recommended hose length, guns, and maximum working

pressure.

Visit our website;

http://M

AGNUM.Graco.com

312004B

M

AGNUM

Model: 261810

SR7

MAGNUM Project

Painter 5

Model: 261800

ti9195a

M

AGNUM

Model: 261815

ProX7

MAGNUM Project

Painter 7

Model: 261805

ti9194a

MAGNUM ProX9

Model: 261820

ti9193a

Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

Copyright 2007, Graco Inc. is registered to I.S. EN ISO 9001

ti9369a

ti9368a

Page 2

Specifications

Specifications

This equipment is not intended for use with flammable or combustible materials used in places such as cabinet shops

or other “factory”, or fixed locations. If you intend to use this equipment in this type of application, you must comply

with NFPA 33 and OSHA requirements for the use of flammable and combustible materials.

Model Name Series

M

AGNUM Project

Painter 5 A

M

AGNUM Project

Painter 7 A

M

AGNUM SR7 A

M

AGNUM ProX7 A

AGNUM ProX9 A

M

Dispense

Rate gpm

(lpm)

0.24 gpm

(0.91 lpm)

0.31 gpm

(1.17 lpm)

0.31 gpm

(1.17 lpm)

0.34 gpm

(1.28 lpm)

0.38 gpm

(1.44 lpm)

Maximum Working

Pressure

PSI MPa bar

Hose Length and

Diameter

Gun

Model

1/4 in. x 25 ft

(6.4 mm x 7.5 m) SG10 2800 19 193

1/4 in. x 35 ft

6.4 mm x. 11 m) SG10 3000 21 207

1/4 in. X 35 ft

(6.4 mm x 11 m) SG10 3000 21 207

1/4 in. X 50 ft

(6.4 mm x 15 m) SG20 3000 21 207

1/4 in. X 50 ft

(6.4 mm x 15 m) SG20 3000 21 207

2 312004B

Page 3

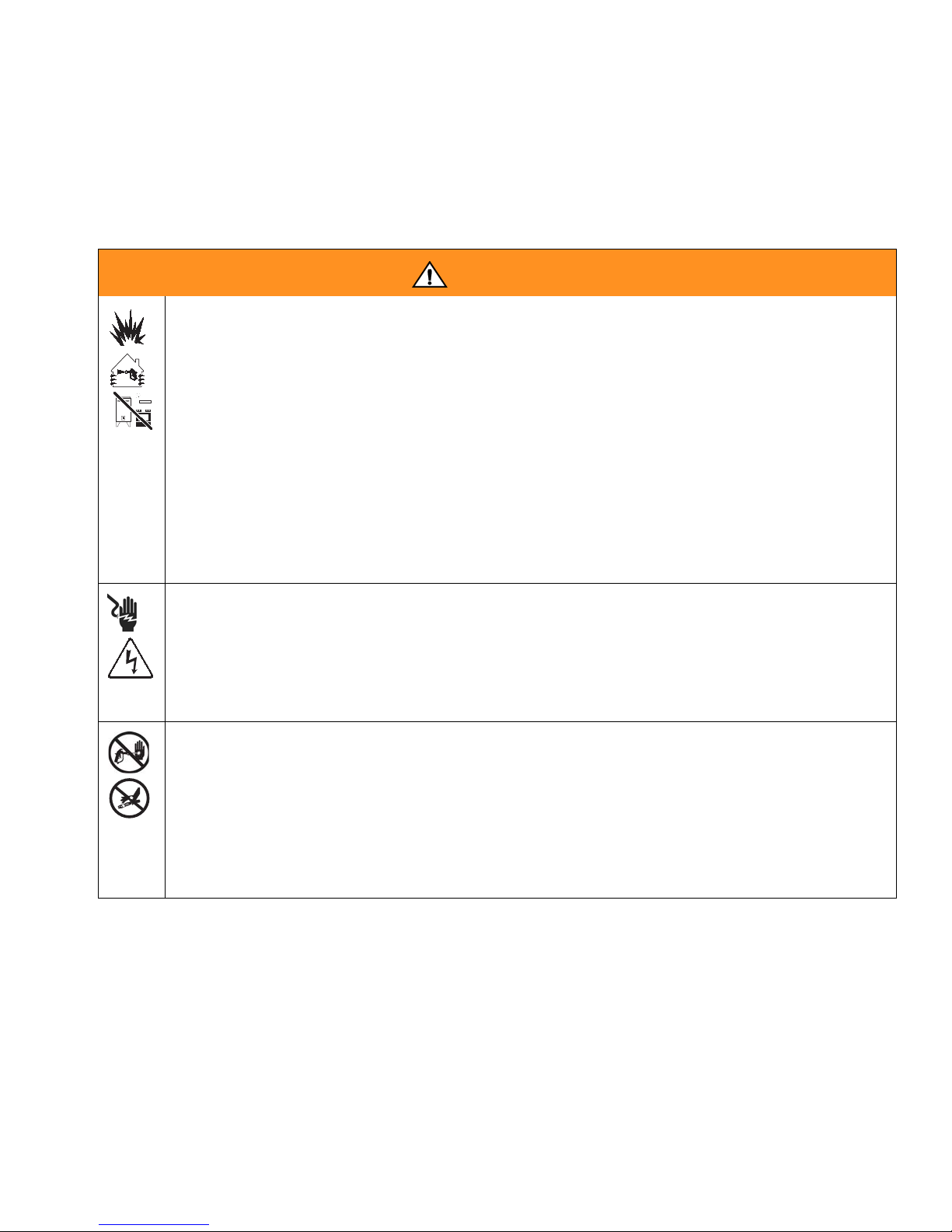

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. Refer

back to these warnings. Additional, product specific warnings may be found throughout the body of this manual

where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Sprayer generates sparks. When flammable liquid is used in or near the sprayer or for flushing or

cleaning, keep sprayer at least 20 feet (6 m) away from explosive vapors.

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground equipment and conductive objects in work area. Read Grounding instructions.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a fire extinguisher in the work area.

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on sprayer and extension cords.

• Do not expose to rain. Store indoors.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

312004B 3

Page 4

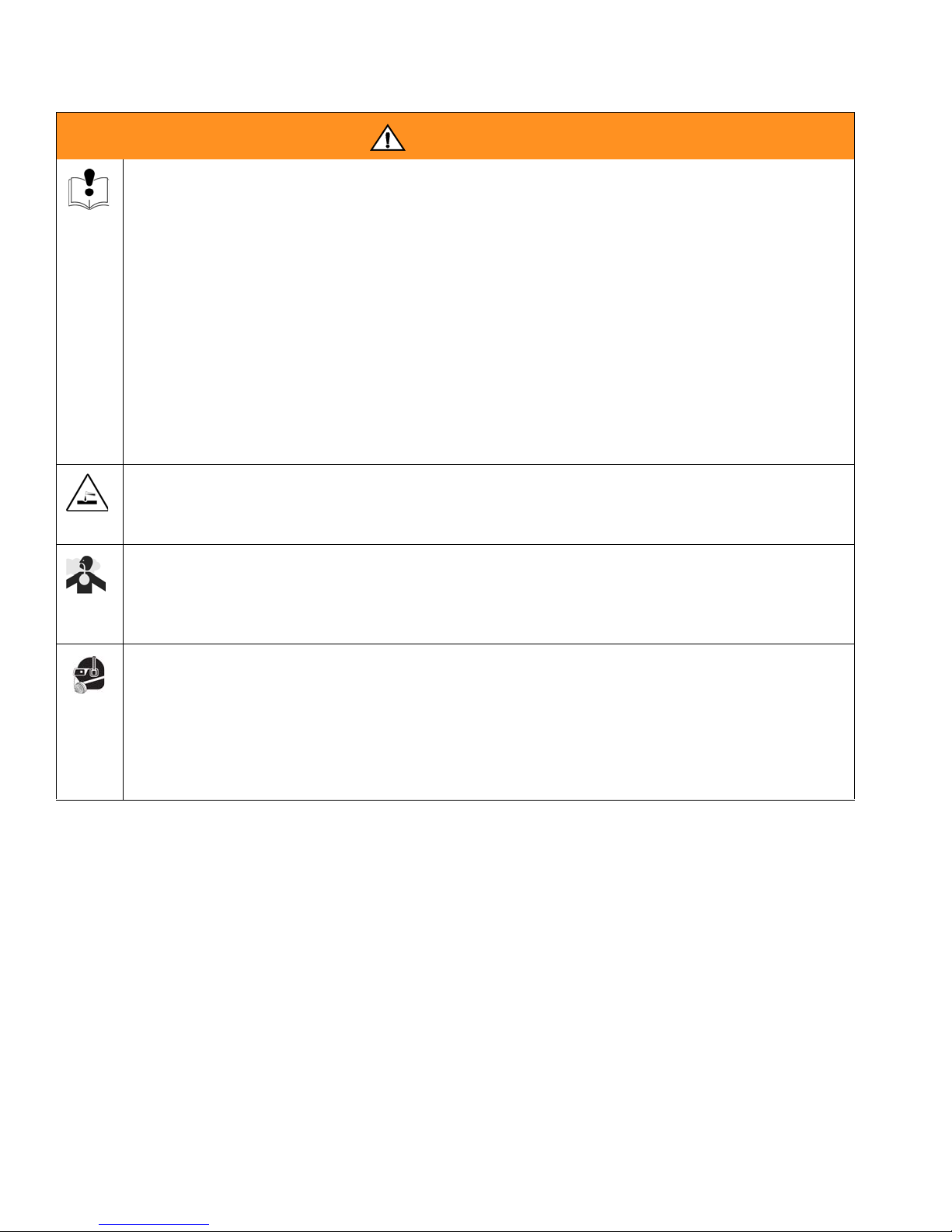

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. Read Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. Read Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine Graco

replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or overbend hoses or use hoses to pull equipment.

• Comply with all applicable safety regulations.

• Keep children and animals away from work area.

• Do not operate the unity when fatigued or under the influence of drugs or alcohol.

PRESSURIZED ALUMINUM PARTS HAZARD

Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents in pressurized aluminum equipment. Such use can cause serious chemical

reaction and equipment rupture, and result in death, serious injury, and property damage.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eye wear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

4 312004B

Page 5

Installation

Installation

Grounding and Electric

Requirements

Sprayer must be grounded. Grounding reduces the risk

of static and electric shock by providing an escape wire

for electrical current due to static build up or in the event

of a short circuit.

• This sprayer requires

a 120 Vac, 60 Hz,

15A circuit with a

grounding receptacle.

• Never use an outlet

that is not grounded

or an adapter.

• Do not use the sprayer if the

electrical cord has a damaged

ground prong.

• Only use an extension cord with

an undamaged 3-prong plug.

ti5573a

ti5572a

Fluid supply container

Solvent pails used when flushing

Use only conductive metal pails, placed on a grounded

surface such as concrete. Do not place the pail on a

nonconductive surface, such as paper or cardboard,

which interrupts grounding continuity.

Grounding the metal pail

pail by clamping one end to pail and other end to ground

such as a water pipe.

Maintaining grounding

continuity when flushing or

relieving pressure: hold metal

part of the spray gun firmly to

the side of a grounded metal

pail, then trigger the gun.

: follow local code.

: follow local code.

: connect a ground wire to the

ti9207a

Thermal Overload

Motor has a thermal overload switch to shut itself down

if overheated. If unit overheats, allow approximately 45

minutes for unit to cool. Once cool, switch will close and

unit will restart.

Recommended extension cords

for use with this sprayer:

• 50 ft (15.0 m) 16 AWG (1.0 mm

• 100 ft (30.0 m) 14 AWG (1.5 mm

Spray gun

grounded fluid hose and pump.

: ground through connection to a properly

Smaller gauge or longer extension cords may

reduce sprayer performance.

2

)

2

)

To reduce risk of injury from motor starting unexpectedly when it cools, always turn power switch OFF if

motor shuts down.

312004B 5

Page 6

Component Identification

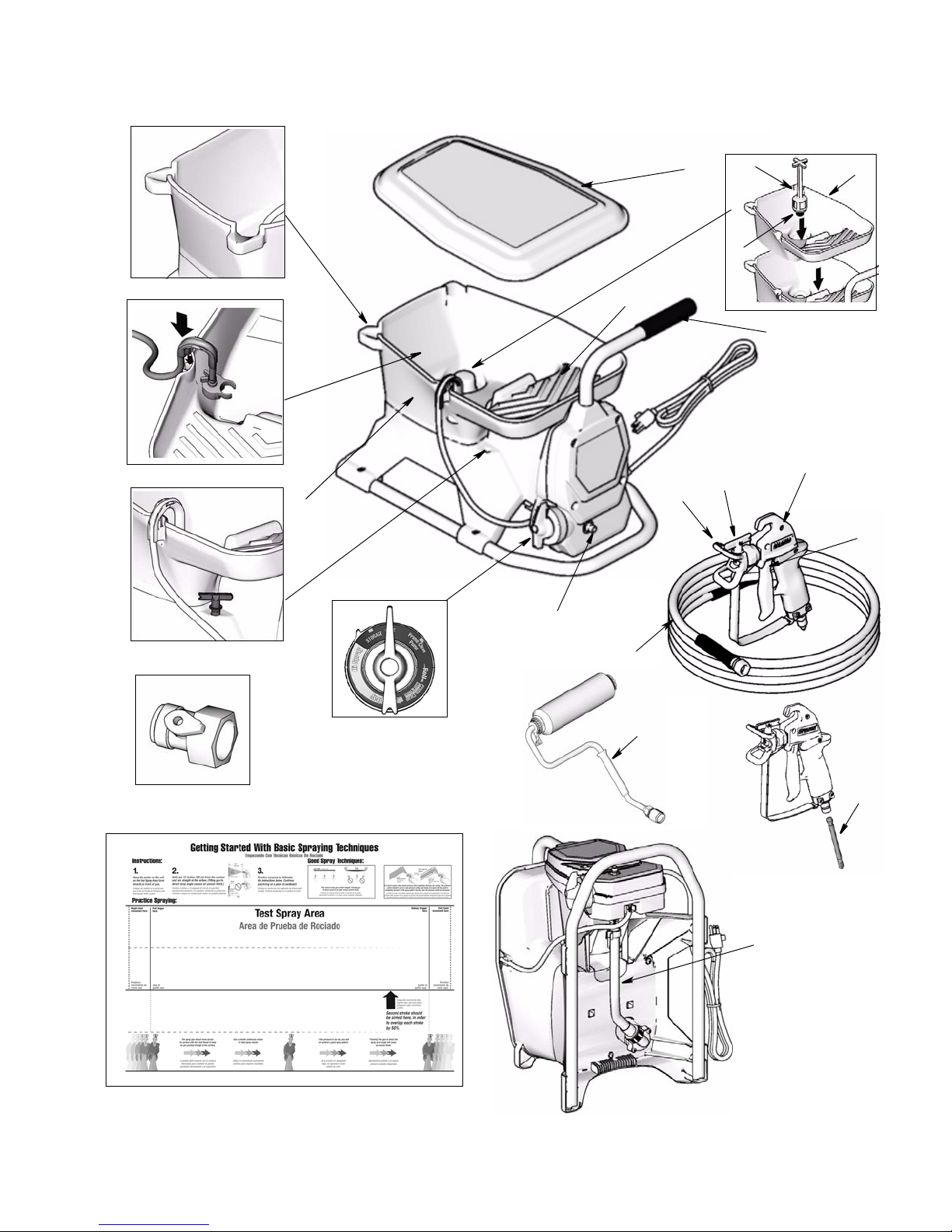

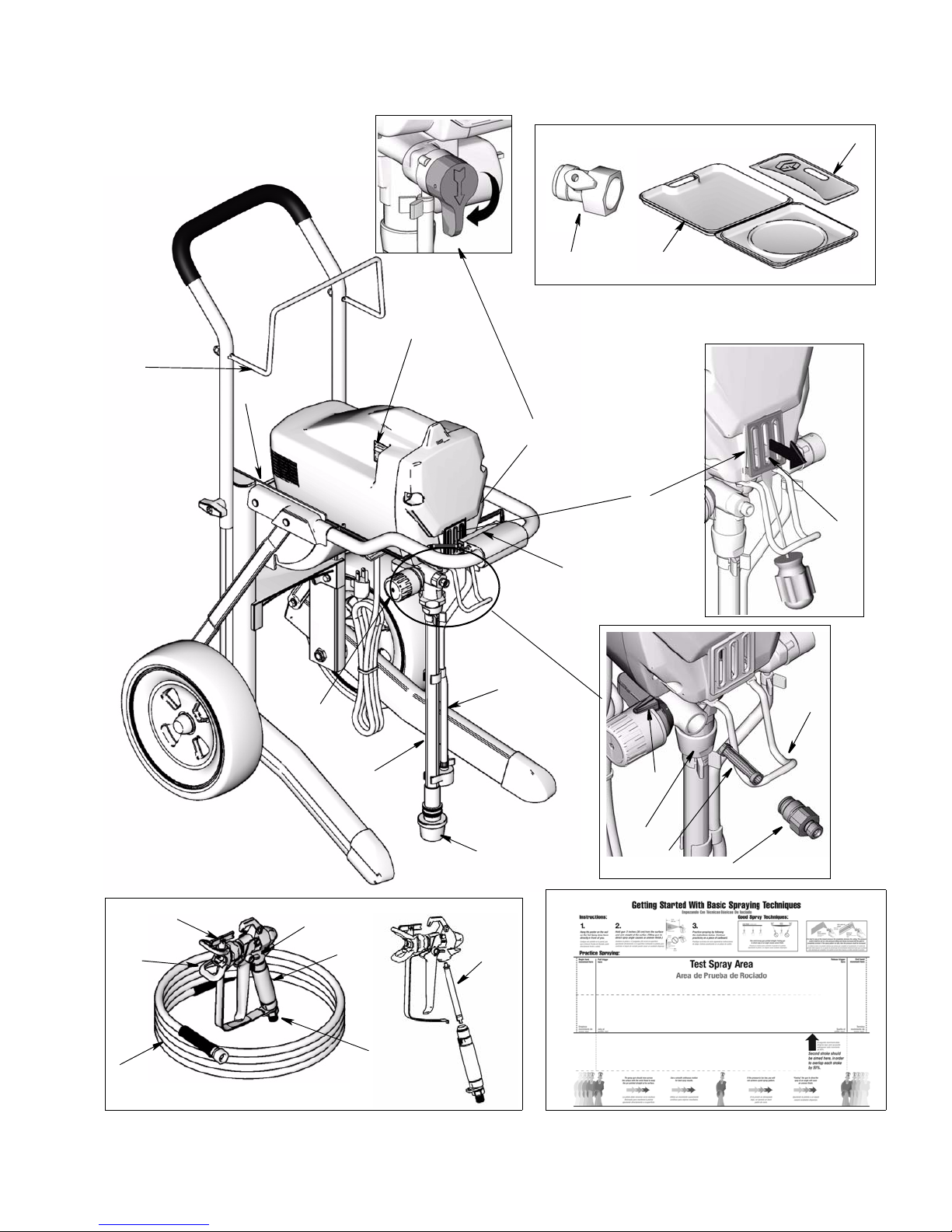

Project Painter 5

Component Identification

A

AllControl

B Pump fluid outlet fitting Threaded connection for paint hose.

C Suction tube Draws fluid from paint pail or hopper into pump.

D Prime tube (with diffuser) Drains fluid in system during priming and pressure relief.

E Inlet screen Prevents debris from entering pump.

E1 Inlet screen handle Aids in the installation and removal of the inlet screen.

F Hopper cover Prevents debris from entering hopper.

G Pour spouts Directs paint out of hopper and back into paint container.

H Hopper 2.5 gal. (9.5 L) capacity hopper that holds paint.

J Tip holder Storage for 2 spray tips.

K Hopper handle Press and turn handle to allow access to hopper and paint

™

• STORAGE: for long term or overnight shutdown and storage.

• OFF: turns motor off for short term shutdown and

relieves system pressure.

• PRIME/CLEAN PUMP: turns on motor and directs fluid

to prime tube.

• ROLL: directs low pressure fluid to roller (when used)

• PRIME/CLEAN GUN & HOSE: directs fluid to gun and

hose.

• LOW SPRAY to HIGH SPRAY: directs fluid to spray gun.

tray.

L Paint tray Built in paint tray to rest roller attachment when not in use.

M Disposable hopper liner Fits directly in hopper and is disposable for simple cleanup.

N Practice Spray Board Instructs user on how to perform basic spraying techniques

and provides surface to practice techniques prior to spraying

surfaces.

P

Power Flush

R Paint hose Transports high-pressure fluid from pump to spray gun.

S Airless spray gun Dispenses fluid.

T Tip guard Reduces risk of fluid injection injury.

U Reversible spray tip • Atomizes fluid being sprayed, forms spray pattern and

V Gun fluid filter Filters fluid entering spray gun to reduce tip clogs.

W Roller attachment Attaches to spray gun for pressure rolling directly on

X Gun trigger safety lever (page 14) Prevents accidental triggering of spray gun.

™

attachment

Connects garden hose to suction tube for power flushing

water-base fluids.

controls fluid flow according to hole size.

• When reversed, unclogs plugged tips without disassembly.

surfaces.

6 312004B

Page 7

Component Identification

G

G

E1

F

M

ti9305a

ti9306a

ti9374a

P

D

E

L

ti9533a

K

S

U

T

H

X

ti9301a

J

A

B

R

ti9208a

ti9168a

W

ti9724a

N

312004B 7

V

ti10257a

ti9257a

C

ti9294a

Bottom view and position for direct immersion mode

Page 8

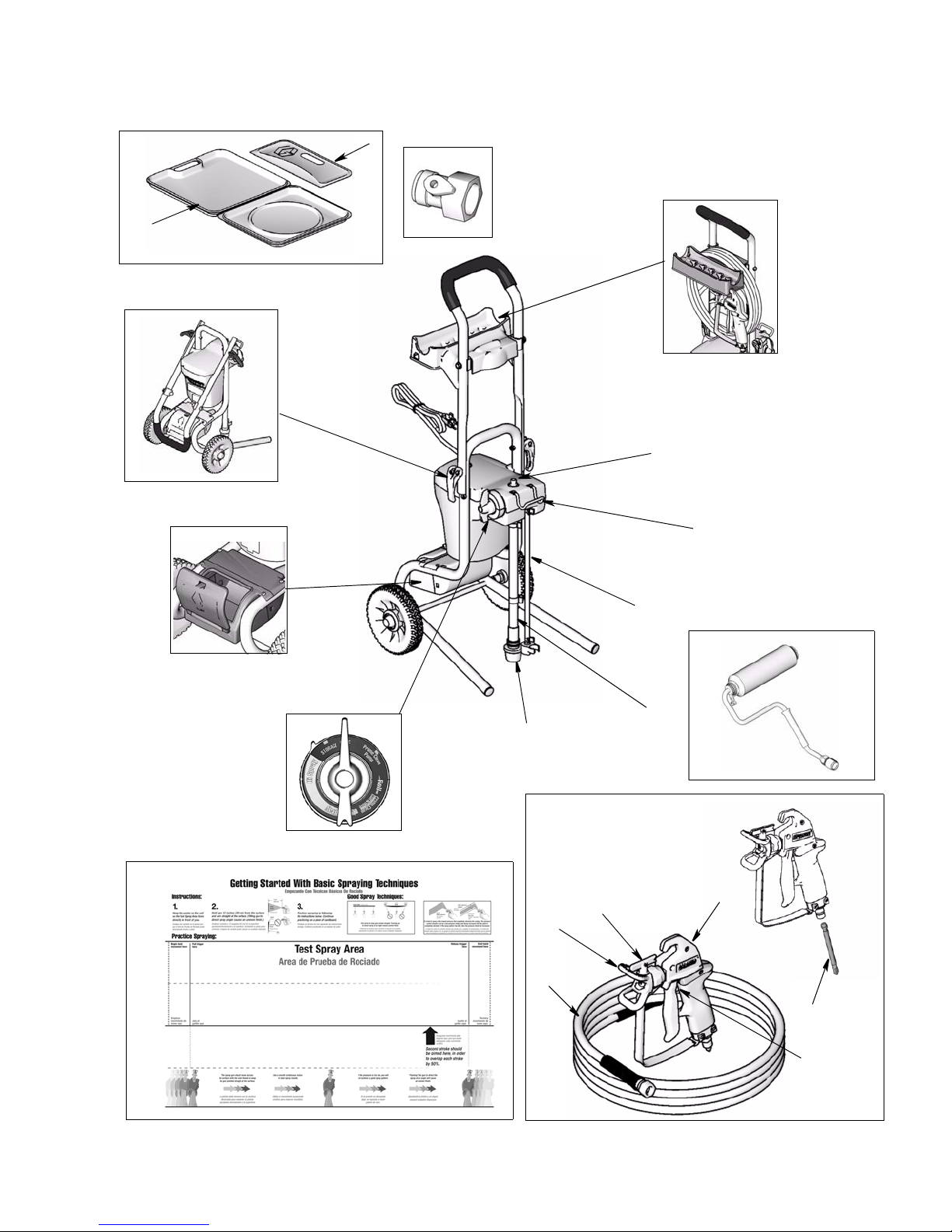

Component Identification

Project Painter 7

Component Identification

A

AllControl

B Pump fluid outlet fitting Threaded connection for paint hose.

C Suction tube Draws fluid from paint pail into pump.

D Prime tube (with diffuser) Drains fluid in system during priming and pressure relief.

E Inlet screen Prevents debris from entering pump.

F Pail hanger For transporting pail by its handle.

G Roller tray/Gun holder/Hose Wrap Removable tray can also be used to clean paint roller.

H Quick Release Latch Collapses handle for compact or hanging storage.

J Storage compartment Provides onboard storage for spray tips and/or tools.

L Sample spray shield Introduces benefits of a spray shield. Blocks paint from surfaces you do

M

SpillGuard

N Practice spray board Instructs user on how to perform basic spraying techniques and provides

P

Power Fl ush™ attachment

R Paint hose Transports high-pressure fluid from pump to spray gun.

S Airless spray gun Dispenses fluid.

T Tip guard Reduces risk of fluid injection injury.

U Reversible spray tip • Atomizes fluid being sprayed, forms spray pattern and controls fluid

V Gun fluid filter Filters fluid entering spray gun to reduce tip clogs.

W Roller attachment Attaches to spray gun for pressure rolling directly on surfaces.

X Gun trigger safety lever (page 14) Prevents accidental triggering of spray gun.

™

™

tray

• STORAGE: for long term and overnight shutdown and storage.

• OFF: turns motor off for short term shutdown and relieves system

pressure.

• PRIME/CLEAN PUMP: turns on motor and directs fluid to prime

tube.

• ROLL: directs low pressure fluid to roller (when used)

• PRIME/CLEAN GUN & HOSE: directs fluid to gun and hose.

• LOW SPRAY to HIGH SPRAY: directs fluid to spray gun.

not want to spray.

Protective tray to set sprayer and paint pail on during operation.

surface to practice techniques prior to spraying surfaces.

Connects garden hose to Suction tube for power flushing water-base

fluids.

flow according to hole size.

• When reversed, unclogs plugged tips without disassembly.

8 312004B

Page 9

Component Identification

M

J

ti9312a

ti9310a

L

ti9724a

P

G

H

ti9307a

B

F

D

ti9309a

W

C

A

ti9168a

E

ti10257a

N

U

S

T

R

ti9257a

V

312004B 9

X

ti9208a

Page 10

Component Identification - SR7

Component Identification - SR7

A Power Switch Turns sprayer ON and OFF.

B Prime/Spray Valve • PRIME position (pointing down) directs fluid to prime tube.

• SPRAY position (pointing forward) directs pressurized fluid to paint

hose.

• Automatically relieves system pressure in overpressure situations.

C Pressure control knob Increases (clockwise) and decreases (counter-clockwise) fluid pressure

in pump, hose and spray gun.

C1 Setting Indicator To select function, align symbol on pressure control knob with setting

indicator, page 15.

D Pump fluid outlet fitting Threaded connection for paint hose.

E

InstaClean

F

Power-Piston

Access door)

G Suction tube Draws fluid from paint pail into pump.

H Prime tube (with diffuser) Drains fluid in system during priming and pressure relief.

J Sample Spray Shield Introduces benefits of a spray shield. Blocks paint from surfaces you do

L Inlet screen Prevents debris from entering pump.

M Storage compartment Provides onboard storage for spray tips and/or tools.

N Quick Release Latch Collapses handle for compact or hanging storage.

P Roller tray/Gun holder/Hose wrap Removable tray can also be used to clean paint roller.

R Paint hose Transports high-pressure fluid from pump to spray gun.

Q Roller attachment Used with spray gun to apply coating directly to surfaces.

S Airless spray gun Dispense fluid through spray tip or roller attachment.

T Tip guard Reduces risk of fluid injection injury.

U Reversible spray tip • Atomizes fluid being sprayed, forms spray pattern and controls fluid

V Gun trigger safety lever (page 14) Prevents accidental triggering of spray gun.

W

SpillGuard

X Practice spray board Instructs user on how to perform basic spraying techniques and provides

Y Power Flush attachment Connects garden hose to suction tube for power flushing water-base

Z Gun fluid filter Filters fluid entering spray gun to reduce tip clogs.

™

fluid filter

™

Pump (behind Easy

™

Tray

• Filters fluid coming out of pump to reduce tip plugging and improve

finish.

• Self cleans only during pressure relief.

Pressurizes fluid and delivers it to paint hose. Easy Access door permits

quick removal of outlet valve.

not want to spray.

flow according to hole size.

• Reverse unclogs plugged tips without disassembly.

Protective tray to set sprayer and paint pail on during operation.

surface to practice techniques prior to spraying surfaces.

fluids.

10 312004B

Page 11

Component Identification - SR7

P

ti9763a

ti9951a

M

ti9950a

J

/.

/&&

A

N

B

B

F

D

E

ti9213a

H

G

L

C

C1

U

S

T

W

ti9312a

X

312004B 11

ti10008a

R

ti9724a

Y

Q

ti10257a

V

ti9257a

Z

ti9208a

Page 12

Component Identification ProX7 & ProX9

Component Identification ProX7 & ProX9

A Airless spray gun Dispenses fluid.

B Power switch Turns sprayer ON and OFF.

C Pressure control knob Increases (clockwise) and decreases (counter-clockwise) fluid pressure

in pump, hose, and spray gun.

C1 Setting Indicator To select function, align symbol on pressure control knob with setting

indicator, page 15.

D Pump fluid outlet fitting Threaded connection for paint hose.

E

InstaClean

F

ProX Power-Piston

Access door, not shown)

F1 Easy Access door Easy Access door permits quick access to outlet valve. To remove door,

G Suction tube Draws fluid from paint pail into pump.

H Prime tube (with diffuser) Drains fluid in system during priming and pressure relief.

J Prime/Spray valve • In PRIME position (pointing down) directs fluid to prime tube.

K Storage compartment Provides onboard storage for spray tips and/or tools.

L Inlet screen Prevents debris from entering pump.

M Paint hose Transports high-pressure fluid from pump to spray gun.

N

Fold-n-Store

P Practice Spray Board Instructs user on how to perform basic spraying techniques and provides

Q Tip guard Reduces risk of fluid injection injury.

R Reversible spray tip • Atomizes fluid being sprayed, forms spray pattern and controls fluid

S Gun trigger safety lever (page 14) Prevents accidental triggering of spray gun.

T Gun fluid inlet fitting Threaded connection for paint hose.

U Power Flush attachment Connects garden hose to suction tube for power flushing water-base

V Gun fluid filter Filters fluid entering spray gun to reduce tip clogs.

W Hose wrap bracket Stows paint hose.

X Pail hanger For transporting pail by its handle.

Y

SpillGuard

Z Sample spray shield Introduces benefits of a spray shield. Blocks paint from surfaces you do

AA

QuickAccess

™

fluid filter

™

Handle

™

tray

™

Inlet

™

Pump (behind Easy

• Filters fluid coming out of pump to reduce tip plugging and improve

finish.

• Self cleans only during pressure relief.

Pumps and pressurizes fluid and delivers it to paint hose.

insert flat blade of screwdriver into slot on the bottom of the door (as

shown on page 13).

• In SPRAY position (pointing forward) directs pressurized fluid to paint

hose.

• Automatically relieves system pressure in overpressure situations.

Used to fold cart frame for hanging on wall.

surface to practice techniques prior to spraying surfaces.

flow according to hole size.

• Reverse unclogs plugged tips without disassembly.

fluids.

Protective tray to set sprayer and paint pail on during operation.

not want to spray.

Permits quick access to inlet valve to clear debris (ProX9 only).

12 312004B

Page 13

Component Identification ProX7 & ProX9

W

K

Z

ti9724a

ti9346a

U

Y

ti9312a

B

J

F

ti9368a

Q

F1

N

ti9670a

H

C

G

C1

AA

L

ti9669a

E

D

P

R

S

A

V

X

M

ti9667a

312004B 13

T

ti9668a

Page 14

General Repair Information

General Repair Information

1. Turn power switch OFF and unplug

power cord.

Trigger L ock

Always engage the trigger lock when you stop spraying

to prevent the gun from being triggered accidentally by

hand or if dropped or bumped.

Trigger Locked

ti8923a

SG10 Gun

ti8908a

SG20 Gun SG20 Gun

Trigger Unlocked

SG10 Gun

ti8922a

ti8909a

2. Turn Prime/Spray valve to

PRIME to relieve pressure.

3. Hold gun firmly to side

of pail. Trigger the gun

to relieve pressure.

4. Engage trigger lock.

ti8908a

Leave Prime/Spray valve in the PRIME position

until you are ready to spray again.

ti2018a

ti9346a

ti9207a

ti8923a

Pressure Relief Procedure

Follow this Pressure Relief Procedure whenever you

stop spraying and before cleaning, checking, servicing,

or transporting equipment.

If you suspect the spray tip or hose is clogged or that

pressure has not been fully relieved after following the

steps above, VERY SLOWLY loosen tip guard retaining

nut or hose end coupling to relieve pressure gradually,

then loosen completely. Clear hose or tip obstruction.

Read Unclogging Spray Tip instructions in the Sprayer

or Gun Operation manual.

14 312004B

Page 15

General Repair Information

AllControl™ Settings

STORAGE - long term and

overnight shutdown and storage

HI SPRAY - uses high pressure

to direct fluid to spray gun

SETTING INDICATOR selects function

OFF - turns motor off for short

term shutdown and relieves

system pressure

PRIME/CLEAN PUMP - turns

motor on and directs fluid to

prime tube

ROLL - directs low pressure

fluid to roller (when used)

LOW SPRAY - uses low pressure

to direct fluid to spray gun

PRIME/CLEAN GUN & HOSE directs fluid to gun and hose

Pressure Control Knob Settings

High Pressure

Spray

To select function, align symbol on pressure control knob with setting indicator on sprayer.

Low Pressure

Spray

Prime/

Clean

Rolling

TIA

312004B 15

Page 16

Flammable materials spilled on hot, bare, motor

could cause fire or explosion. To reduce risk of burns,

fire or explosion, do not operate sprayer with cover

removed.

• Keep all screws, nuts, washers, gaskets, and electrical fittings removed during repair procedures. These

parts usually are not provided with replacement kits.

• Test repairs after problems are corrected.

• If sprayer does not operate properly, review repair

procedure to verify you did it correctly. See Basic

Troubleshooting, page 17 and Advanced Trouble-

shooting, page 21.

• Overspray may build up in the air passages.

Remove any overspray and residue from air passages and openings in the enclosures whenever

you service sprayer.

• Do not operate the sprayer without the cover in

place. Replace if damaged. Covers direct cooling air

around motor to prevent overheating.

General Repair Information

To reduce risk of serious injury, including electric

shock:

• Do not touch moving or electric pars with fingers or

tools while testing repair.

• Unplug sprayer when power is not required for testing.

• Install all covers, gaskets, screws and washers

before you operate sprayer.

CAUTION

• Do not run sprayer dry for more than 30 seconds.

Doing so could damage pump packings.

• Protect the internal drive parts of this sprayer from

water. Openings in the cover allow for air cooling of

the mechanical parts and electronics inside. If

water gets in these openings, the sprayer could

malfunction or be permanently damaged.

• Prevent pump corrosion and damage from freezing.

Never leave water or water-base paint in sprayer

when its not in use in cold weather. Freezing fluids

can seriously damage sprayer. Store sprayer with

Pump Armor to protect sprayer during storage.

16 312004B

Page 17

Basic Troubleshooting

Basic Troubleshooting

Check everything in this Basic Troubleshooting Table before you bring the sprayer to a Graco/MAGNUM authorized

service center.

Problem Cause Solution

Project Painter 5 and Project Painter 7 AllControl is on and sprayer is plugged in,

but motor does not run, and pump does

not cycle, or motor continues to run in

OFF position.

or

SR7, ProX 7 and ProX9 - Power Switch is

on and sprayer is plugged in, but motor

does not run, and pump does not cycle.

Project Painter 5 and Project Painter 7 AllControl is set at zero pressure.

SR7, ProX7 and ProX9 - Pressure is set

at zero pressure.

Motor or control is damaged. Take sprayer to Graco/M

Electric outlet is not providing power. • Try a different outlet or plug in a com-

Extension cord is damaged. Replace extension cord. Read

Sprayer electric cord is damaged. Check for broken insulation or wires.

Paint and/or water is frozen or hardened

in pump.

Turn AllControl clockwise to increase

pressure setting.

Turn Pressure Control Knob clockwise to

increase pressure setting.

AGNUM

authorized service center.

patible working appliance to test outlet.

• Reset building circuit breaker or

replace fuse.

Grounding and Electric Requirements,

page 5.

Replace electric cord if damaged.

Unplug sprayer from outlet. If frozen do

NOT try to start sprayer until it is

completely thawed or you may damage

the motor, control board and/or drivetrain.

Make sure power switch is OFF. Place

sprayer in a warm area for several hours.

Then plug in power cord and turn sprayer

ON. Slowly increase pressure setting to

see if motor will start.

If paint is hardened in sprayer, pump

packings, valves, drivetrain or pressure

switch may need to be replaced. Take

sprayer to Graco/M

service center.

System is already pressurized. Turn AllControl to OFF, pause 2-3 sec-

onds and then turn AllControl to STORAGE to relieve pressure.

Pump does not prime. Project Painter 5 and Project Painter 7 -

AllControl not set to correct function.

SR7, ProX7 and ProX9 - Prime/Spray

Valve is in SPRAY position.

Inlet screen is clogged or suction tube is

not immersed.

312004B 17

Turn AllControl to PRIME/CLEAN PUMP

position.

Turn Prime/Spray Valve to PRIME

position (pointing down).

Clean debris off inlet screen and make

sure suction tube is immersed in fluid.

AGNUM authorized

Page 18

Basic Troubleshooting

Problem Cause Solution

Pump does not prime. Inlet valve check ball is stuck. Remove suction tube and place a pencil

into the inlet section to dislodge the ball,

allowing pump to prime properly. OR

Power Flush sprayer (see Operation

manual).

AutoPrime may need replacement. For

Project Painter 7: plug in unit and listen

for “tap” in pump.

SR7 and ProX7 and 9: turn power switch

ON and listen for “tap” in pump.

If you do not hear “tap”, AutoPrime is

damaged. Take sprayer to

Graco/M

AGNUM authorized service

center.

Inlet valve check ball or seat is dirty. Remove inlet housing. Clean or replace

ball and seat.

Outlet valve check ball is stuck. Insert screw driver in slot and remove

Easy-Access

™

door, page 10, SR7

models or page 12, ProX7 and ProX9

models. Unscrew outlet valve with a 3/4

in. socket. Remove and clean assembly.

Project Painter 5 and Project Painter 7 In immersion mode suction tube is not

Make sure suction tube is immersed in

paint.

immersed

Suction tube is leaking. Tighten suction tube connection. Inspect

for cracks or vacuum leaks.

Pump does not prime with fluid. Remove suction tube from paint. Prime

pump with water or solvent-based

flushing fluid.

AllControl is damaged. Take sprayer to Graco/MAGNUM

authorized service center.

Pump cycles but does not build up

pressure.

Pump is not primed. Prime pump (see Operation manual).

Inlet screen is clogged. Clean debris off inlet screen and make

sure suction tube is immersed in fluid.

All models in Immersion Mode, suction

tube is not immersed in paint.

Project Painter 5 - Hopper mode or all

models in immersion mode, paint pail is

Make sure suction tube is immersed in

paint.

Refill hopper or paint pail. Reprime

sprayer.

empty.

Suction tube is leaking. Project Painter 5 (hopper mode): Inlet

tube fitting improperly or not securely

attached to hopper elbow fitting.

Project Painter 7, SR7, ProX 7 and 9:

Tighten suction tube connection. Inspect

for cracks or vacuum leaks. If cracked or

damaged, replace suction tube.

Project Painter 5 and 7 - AllControl prime

valve is worn or obstructed with debris.

Take sprayer to Graco/M

authorized service center.

AGNUM

SR7, ProX7 and ProX9 - Prime/Spray

Valve is worn or obstructed with debris.

Pump check ball is stuck. Read Pump does not prime section in

Troubleshooting, page 17

18 312004B

Page 19

Basic Troubleshooting

Problem Cause Solution

Pump cycles, but paint only dribbles or

spurts when spray gun is triggered.

Pressure is set too low. Project Painter 5 and Project Painter 7

Sprayers -Slowly turn AllControl to HI

SPRAY to increase pressure setting

or

SR7, ProX 7 and ProX9 - Turn Pressure

Control Knob clockwise to increase

pressure setting which will turn on motor

to build pressure.

Spray tip is clogged. Unclog spray tip (see Operation manual).

SR7, ProX7 and ProX9 - InstaClean fluid

filter is clogged.

Clean or replace InstaClean fluid filter

(see Operation manual).

Spray gun fluid filter is clogged. Clean or replace gun fluid filter (see

Operation manual).

Spray tip is too large or worn. Replace spray tip.

Pressure is set at maximum but cannot

achieve a good spray pattern.

Reversible spray tip is in UNCLOG

position.

Rotate arrow-shaped handle on spray tip

so it points forward in SPRAY position

(see Operation manual).

Spray tip is too large for sprayer. Select smaller spray tip.

Spray tip is worn beyond capability of

Replace spray tip.

sprayer.

Extension cord is too long or not heavy

enough gauge.

Replace extension cord. Grounding and

Electrical Requirements, page 5.

Spray gun fluid filter is clogged. Clean or replace spray gun fluid filter (see

Operation manual).

SR7, ProX7 and ProX9 - InstaClean fluid

filter is clogged.

Clean or replace InstaClean fluid filter

(see Operation manual).

Inlet screen is clogged. Clean debris off inlet screen.

Pump valves are worn. Check for worn pump valves.

a. Prime sprayer with paint

b. Trigger gun momentarily. When

trigger is released, pump should

cycle momentarily and stop. If

pump continues to cycle, pump

valves may be worn. Take

sprayer to Graco/M

AGNUM

authorized service center.

Material too thick. Thin material.

Hose too long (if extra section is added). Remove section of hose.

Spray gun stopped spraying. Pump was not primed with flushing fluid. Remove suction tube from paint. Prime

pump with water or flushing

solvent-based flushing fluid.

Suction tube is leaking. Tighten suction tube connection. Inspect

for cracks or vacuum leaks.

SR7, ProX7 and ProX9 - Prime/Spray

Valve is plugged.

Clean/replace prime tube as necessary.

Take sprayer to Graco/M

AGNUM

authorized service center if valve is

plugged.

Spray tip is clogged. Unclog spray tip (see Operation manual).

312004B 19

Page 20

Basic Troubleshooting

Problem Cause Solution

When paint is sprayed, it runs down the

wall or sags.

Coat is going on too thick. Move gun faster.

Choose a tip with smaller hole size.

Choose tip with wider fan.

Make sure gun is far enough from

surface.

When paint is sprayed, coverage is

inadequate.

Paint coating is going on too thin. Move gun slower.

Choose tip with larger hole size.

Choose tip with narrower fan.

Make sure gun is close enough to

surface.

Fan pattern varies dramatically while

spraying.

SR7, ProX7 and ProX9 - Pressure control

switch is worn and causing excessive

Take sprayer to Graco/M

authorized service center.

AGNUM

pressure variation.

OR

Sprayer does not turn on promptly when

resuming spraying.

Cannot trigger spray gun. Spray gun trigger lock is locked. Rotate trigger safety lever to unlock

trigger lock, page 14.

Paint is coming out of pressure control

switch.

Prime/Spray valve actuates automatically

relieving pressure through prime tube.

SR7, ProX7 and ProX9 - Pressure control

switch is worn.

Take sprayer to Graco/MAGNUM

authorized service center.

System is over pressurizing. Take sprayer to Graco/MAGNUM

authorized service center.

Paint leaks down outside of pump. Pump packings are worn. Replace pump packings.

Motor is hot and runs intermittently.

Motor automatically shuts off due to

excessive heat. Damage can occur if

cause is not corrected.

Thermal Overload, page 5.

Vent holes in enclosure are plugged or

sprayer is covered.

Extension cord is too long or not a heavy

enough gauge.

Unregulated electrical generator being

used has excessive voltage.

Keep vent holes clear of obstructions and

overspray and keep sprayer open to air.

Replace extension cord. Read

Grounding and Electrical

Requirements, page 5.

Use electrical generator with a proper

voltage regulator. Sprayer requires

120VAC, 60 Hz, 1500-Watt generator.

Sprayer was operated at high pressure

with very small tip which causes frequent

Decrease pressure setting or increase tip

size.

motor starts and excessive heat build up.

Building circuit breaker opens after

sprayer operates for 5 to 10 minutes.

Too many appliances are plugged in on

same circuit.

Free up circuit (unplug things), or use a

less busy circuit.

Sprayer electrical cord is damaged. Check broken insulation or wires.

Replace electrical cord if damaged.

Extension cord is damaged or too long or

not a heavy enough gauge.

• Plug in something that you know is

working to test extension cord.

Prox7 and ProX9 - Fold ‘n Store handle

does not actuate

20 312004B

• Replace extension cord.

Dirty or dried paint Clean handle parts.

Page 21

Advanced Troubleshooting

Advanced Troubleshooting

See Basic Troubleshooting first, page 17 for problems that are more easily remedied.

General Problem: Motor Does Not Operate

Specific Problem Cause Solution

Power switch is on and sprayer is

plugged in; pump does not cycle.

Basic mechanical problems. Paint is frozen or hardened in

See Basic Troubleshooting,

page 17.

Unplug sprayer from electrical outlet.

pump.

If paint is frozen in sprayer:

Do NOT try to start sprayer until completely thawed or

you may damage the motor, control board, and/or

drivetrain.

1. Project Painter 5 and Project Painter 7 - Turn AllControl to OFF or STORAGE.

SR7, ProX7 or ProX9 - Turn OFF power switch.

2. Place sprayer in warm area for several hours.

3. Plug sprayer in.

4. Project Painter 5 and Project Painter 7 - Turn

AllControl to Prime/Clean Pump

SR7, ProX7 and ProX9 a. Turn on sprayer.

b. Turn prime valve to PRIME position.

If paint hardened in sprayer:

Replace pump packings.

Remove all residue from valves.

Pump Service, page 31.

Motor is damaged. Remove gear and try to rotate motor shaft by hand. See

Motor Diagnostics, page 30. If shaft will not turn,

replace motor using Motor Kit, page 28.

SR7, ProX7 and ProX9 - Yoke is

broken because pump is locked up

due to dried paint or worn

packings

Repair or replace using Gear/Yoke Kit, page 28.

Repair pump. See Pump Service, page 31.

312004B 21

Page 22

Advanced Troubleshooting

Specific Problem Cause Solution

Basic electrical problems. Motor overheated. Allow motor to cool for 45 minutes. Retry.

Electrical outlet is damaged. Reset building circuit breaker or replace fuse. Try

another outlet.

Check electric supply with volt meter. Meter must read

85 to 130V AC. If voltage is too high, do not plug sprayer

in until outlet is corrected.

Control board leads are improperly

fastened or improperly mated.

Replace any loose terminals. Make sure all leads and

harnesses are firmly connected.

Check pressure control harness connection on front

side of drive housing.

Clean control board terminals. Securely reconnect

leads.

Motor brushes are worn. Check length of BOTH brushes (brushes do not wear

evenly on both sides of the motor). Brush length must

be 0.25 in. (6.4mm). If brushes are worn replace motor

using Motor Kit, page 28.

Motor armature commutator

damaged.

Check for burn spots, gouges and extreme roughness.

Have motor shop resurface commutator if possible, or

replace motor using Motor Kit, page 28.

Fuse is blown. Replace fuse using Fuse Kit, page 28.

Motor armature shorting. Check for shorts using armature tester (growler) or

perform spin test, Motor Diagnostic, page 30. If shorts

are evident, replace motor using Motor Kit, page 28.

Control board damaged.

See Control Board Diagnostics, page 31. Replace

control board if damaged using Control Board Kit,

CAUTION: Do not perform control

page 28.

board diagnostics until you have

determined the armature is good.

A damaged armature can burn out

a good control board.

22 312004B

Page 23

Advanced Troubleshooting

Specific Problem Cause Solution

Sprayer Wiring Problems

Sprayer electrical cord damaged. Unplug sprayer electrical cord.

NOTE: Remove enclosure

mounting screws and pull

enclosure away from drive

housing. Take care not to pull on

leads from electrical cord and

power switch.

Disconnect black electrical cord wire at power switch.

Unplug in-line connection white cord wire.

Plug in electrical cord.

Test voltage between black and white wires. Meter must

read 85 to 130V AC.

Replace electrical cord if no voltage.

SR7, ProX7 and ProX9 - Sprayer

power switch damaged.

1. Unplug sprayer electrical cord.

2. Disconnect black control board wire at power

switch.

3. Unplug in-line connection white cord wire.

4. Plug in electrical cord.

5. Turn power switch ON.

6. Test voltage between open terminal of power

switch and white electrical cord wire. Meter must

read 85 to 130V AC.

7. Replace power switch if no voltage.

Motor thermal overload cutoff

switch damaged.

1. Unplug sprayer electrical cord.

2. Remove motor harness from control card.

3. Check for continuity between yellow leads or motor

Startup Hazard After Thermal

Overload, page 5.

harness.

4. If thermal relief switch is open (no continuity) allow

motor to cool.

5. If switch remains open after motor cools, replace

motor using Motor Kit, page 28.

6. If thermal relief switch closes after motor cools, find

correct cause of overheating.

Terminals are damaged or loose. Replace any damaged terminals. Make sure all terminal

connections are tight.

312004B 23

Page 24

General Problem: Circuit Breaker is Tripping

Specific Problem Cause Solution

Building circuit breaker opens as

soon as sprayer is turned on.

Building circuit breaker opens as

soon as sprayer is plugged into

outlet and sprayer is NOT turned

on.

NOTE: Remove enclosure

mounting screws and pull

enclosure away from drive

housing. Take care not to pull on

leads from electrical cord and

power switch.

Sprayer electrical wiring is pinched

or insulation is damaged.

Wires between pressure control

switch and control board are

pinched.

Motor armature is shorting. Check for shorts using armature tester (growler) or

Control board is damaged.

CAUTION: Do not perform control

board diagnostics until you have

determined the armature is good.

A bad motor armature can burn

out a good motor control board.

Sprayer electrical cord is

damaged.

SR7, ProX7 and ProX9 - Sprayer

power switch damaged.

Also see Basic Electrical Problems, and Sprayer Wiring Problems, page 22.

Repair or replace any damaged wiring or terminals.

Securely reconnect wires.

perform spin test, Motor Diagnostics, page 30. If

shorts are evident, replace motor using Motor Kit, page

28.

See Control Board Diagnostics, page 31. Replace

control board if damaged using Control Board Kit,

page 28.

1. Unplug sprayer electrical cord.

2. Disconnect black electrical cord wire at power

switch.

3. Unplug in-line connection white cord wire.

4. Plug in electrical cord.

5. Test voltage between black and white wires. Meter

must read 85 to 130V AC.

6. Replace electrical cord if no voltage.

1. Unplug sprayer electrical cord.

2. Disconnect black control board wire at power

switch.

3. Check resistance of switch with ohmmeter.

4. Reading must be infinity with power switch OFF.

5. Reading must be zero with power switch ON.

6. Replace power switch if damaged.

Advanced Troubleshooting

General Problem: Erratic Motor Operation

Specific Problem Cause Solution

Sprayer quits after running for 5 to

10 minutes

Motor is hot and runs

intermittently.

24 312004B

Electrical outlet is damaged Reset building circuit breaker or replace building fuse.

Electrical outlet supplying wrong

voltage

Also see Basic Electrical Problems and Sprayer Wiring Problems, page 22.

Motor is overheating See Motor is hot and runs intermittently in Basic

See Motor is hot and runs intermittently in Basic Troubleshooting, page 20.

Try another outlet. Check electric supply with volt meter.

Meter must read 85 to 130V AC. If voltage is too high,

do not use outlet until corrected.

Troubleshooting, page 20.

Page 25

Advanced Troubleshooting

General Problem: Low or Fluctuating Output

Specific Problem Cause Solution

Pump cycles, but output is low or

surging.

See Basic Troubleshooting,

page 17.

Worn or obstructed pump valves. Check for worn pump valves as follows:

Prime sprayer with paint.

Trigger spray gun momentarily.

When spray gun trigger is released pump should cycle

momentarily and stop.

If pump continues to cycle, pump valves may be worn or

obstructed.

Pump Service, page 31.

SR7, ProX7 and ProX9 Prime/Spray valve is leaking.

Voltage from electrical outlet is too

low. Low voltages reduce sprayer

performance.

Check Prime/Spray valve for debris trapped on seat and

for worn parts. Torque to 130-180 in-lb (15.8-18.1 N•m).

Replace if parts are worn using AllControl

Prime/Spray Valve Kit, page 28.

Check voltage of outlet. Meter must read 85 to 130V

AC.

Reset building circuit breaker or replace building fuse.

Repair electrical outlet or try another outlet.

Extension cord is too long or not

heavy enough gauge.

Leads from motor or pressure

switch to control board are

damaged, loose, pinched, or

overheated.

Motor brushes are worn. Check length of BOTH brushes (brushes do not wear

Motor brush springs are broken. If springs are broken replace motor using Motor Kit,

Motor brushes are binding in brush

holders.

Motor stops before sprayer

reaches correct pressure (stall

pressure is too low).

Motor armature shorted. Check for shorts using armature tester (growler) or

Replace extension cord.

Grounding and Electrical Requirements, page 5.

Be sure terminals are centered and firmly connected.

Inspect for pinched wiring and wiring insulation and

terminals for signs of overheating. Replace any loose

terminals or damaged wiring. Securely reconnect

terminals.

evenly on both sides of the motor). Brush length must

be 0.25 in. (6.4mm). If brushes are worn replace motor

using Motor Kit, page 28.

page 28.

Clean brush holders. Remove carbon dust with small

cleaning brush.

Replace pressure control using Pressure Control

Switch Kit, page 28.

perform spin test, Motor Diagnostics, page 30. If

shorts are evident, replace motor using Motor Kit, page

28.

312004B 25

Page 26

Specific Problem Cause Solution

Motor runs and pump cycles, but

pressure does not build up.

Spray pattern has variations,

pressure fluctuates excessively, or

motor runs very slowly.

Control board is damaged.

CAUTION: Do not perform control

board diagnostics until you have

determined the armature is good.

A damaged armature can burn out

a good control board.

Intake valve ball or outlet valve ball

is not seating properly.

Pump packings are worn or

damaged.

Project Painter 5 and Project

Painter 7 - AllControl leaking.

SR7, ProX7 and ProX9 Prime/Spray Valve leaking.

All models - leads from motor

or SR7, ProX7 and ProX9 Pressure switch to control board is

damaged, loose or overheated

SR7, ProX7 and ProX9 - Pressure

switch leads are pinched between

pump and drive housing or

between front cover and drive

housing.

Control board is damaged.

CAUTION: Do not perform control

board diagnostics until you have

determined the armature is good.

A bad armature can burn out a

good control board.

Project Painter 5 and Project

Painter 7 - AllControl is damaged

or worn out.

SR7, ProX7 and ProX9 - Pressure

control switch is damaged or worn

out.

See Control Board Diagnostics, page 31. If damaged

replace control board using Control Board Kit, page

28.

Remove and clean valves and check balls and seats for

nicks; replace if necessary. Strain paint before spraying

to remove particles that could clog pump. Pump

Service, page 31.

Check for leaking around throat packing nut. Replace

pump packings if there are leaks. Pump Service, page

31.

Check Drain Valve for debris trapped on seat and for

worn parts. Torque to 130-180 in-lb (14.6-20.3 N•m). If

parts are worn, replace using Drain Valve Kit, page 28.

Check Prime/Spray Valve for debris trapped on seat

and for worn parts. Torque to 130-180 in-lb (14.6-20.3

N•m). If parts are worn, replace valve using

Prime/Spray Valve Kit, page 28.

Be sure terminals are centered and firmly connected.

Inspect wiring insulation and terminals for signs of

overheating. Replace any loose terminals or damaged

wiring. Securely reconnect terminals.

Make sure pressure control harness is routed behind

pump, through retention clip and connected to control

board connector on control board (connect with tab to

right).

See Control Board Diagnostics, page 31. If damaged,

replace control board using Control Board Kit, page

28.

Check AllControl for debris trapped on seat and for

worn parts. Torque to 140-160 in-lb (15.8-18.1 N•m). If

parts are worn, replace AllControl using AllControl Kit,

page 28.

Replace pressure control switch using Pressure

Control Switch Kit, page 28.

Advanced Troubleshooting

26 312004B

Page 27

Advanced Troubleshooting

Specific Problem Cause Solution

General Problem: No Output

Project Painter 5 and Project

Painter 7 - AllControl is ON

or

SR7, ProX7 and ProX9 - Power

switch is on and sprayer is

plugged in but pump does not

cycle

Motor runs but pump does not

cycle.

Motor does not run. Water or paint entered

See Basic Troubleshooting,

page 17.

Gear and/or yoke are damaged Replace gear and yoke using Gear/Yoke Repair

pressure control switch or

shorted control board.

General Problem: Excessive Pressure Build Up

Specific Problem Cause Solution

SR7, ProX7 and ProX 9 Prime/Spray Valve actuates

automatically, relieving

pressure through drain tube.

Pressure control switch is

worn.

Water or paint entered

pressure control switch or

shorted control board.

Control board failed. See Control Board Diagnostics, page 31.

Kit, page 28.

Clean out and/or dry out and retry. Replace if

necessary using Pressure Control Switch Kit,

page 28.

Replace pressure control switch using Pressure

Control Switch Kit, page 28.

Clean out and/or dry out and retry. Replace if

necessary using Pressure Control Switch Kit,

page 28.

Replace damaged control board using Control

Board Kit, page 28.

312004B 27

Page 28

List of Kits

Kit Number Models Kit Description

289210 Project Painter 5 AllControl

288711 Project Painter 7 AllControl

289107 Project Painter 7, SR7,

ProX7 and ProX9

288707 Project Painter 5 Control Board

288706 Project Painter 7 Control Board

288705 SR7 and ProX7 Control Board

288900 ProX9 Control Board

244035 All Drain Tube Diffuser

288712 Project Painter 5 and

Project Painter 7

289122 Project Painter 5 Elbow

287772 SR7 Enclosure (Includes Both Sides, Labels and Screws)

288697 Project Painter 7 Enclosure (Includes Labels and Screws)

288695 ProX7 and ProX9 Enclosure (Includes Labels and Screws)

287770 SR7, ProX7 and ProX9 Fan Replacement

288747 SR7, ProX7 and ProX9 Filter Kit

288694 Project Painter 5 Front Cover

288693 Project Painter 7 Front Cover

288692 ProX7 and ProX9 Front Cover

287708 SR7 Front Cover

119276 SR7 and ProX7 Fuse, 12.5 Amp

119277 ProX 9 Fuse, 16 Amp

289209 Project Painter 5 Gear and Rod

245149 Project Painter 7 Gear and Rod

289102 SR7, ProX7 and ProX9 Gear and Yoke

289119 Project Painter 7 and

SR7

289123 Project Painter 5 Hopper Cover

288730 Project Painter 5 Hopper Liner

288716 Project Painter 5 Inlet Strainer

243082 Project Painter 7, SR7,

ProX7 and ProX9

289103 SR7 Motor (includes drive housing)

245080 Project Painter 5 and

Project Painter 7

289104 ProX7 and ProX9

244267 SR7, ProX7 and ProX9 Pressure Control Switch

235014 SR7, ProX7 and ProX9 Prime/Spray Valve

289116 Project Painter 5 Pump Inlet Module

288701 Project Painter 7 and

SR7

288700 ProX7 Pump Inlet Module

288699 ProX9 Pump Inlet Module

AutoPrime

Drain Valve

Handle Cam

Inlet Strainer

Motor

Motor (includes drive housing)

Pump Inlet Module

List of Kits

28 312004B

Page 29

List of Kits

Kit Number Models Kit Description

289120 Project Painter 5 and

Pump Outlet Valve

Project Painter 7

243094 SR7, ProX7 and ProX9 Pump Outlet Valve

288818 SR7, ProX7 and ProX9 Pump Packing Repair

289121 Project Painter 5 Pump Repair (complete)

288698 Project Painter 7 Pump Repair (complete)

288704 SR7 Pump Repair (complete)

288703 ProX7 Pump Repair (complete)

288702 ProX9 Pump Repair (complete)

289129 Project Painter 5, Project

Roller Core

Painter 7 and SR7

289126 Project Painter 5, Project

Roller Frame

Painter 7 and SR7

289124 Project Painter 7and SR7 Spray Shield

289125 ProX7 and ProX9 Spray Shield

15K214 Project Painter 5 Suction Tube

15K449 Project Painter 7 Suction Tube

15D671 SR7 Suction Tube

15K617 ProX 7 and ProX9 Suction Tube

288710 Project Painter 7 and

Tool Box

SR7

288709 ProX7 and ProX9 Tool Box

312004B 29

Page 30

Motor Diagnostics

Motor Diagnostics

Check for electrical continuity in motor armature, windings and brush as follows:

If Motor Diagnostics reveal a damaged motor or if motor brushes are shorter than 1/4 in. (6.4 mm) or if the motor

shaft cannot turn, replace the motor using Motor Kit, page 28.

Armature Short Circuit Spin Test

Setup

1. Relieve pressure, page 14.

2. Unplug electric cord.

3. Remove enclosure and disconnect motor leads from

control card.

4. Remove fan brace (if equipped).

5. Remove four screws and front cover.

Quickly turn motor fan by hand. There should not be

electrical shorts and fan should coast two or three

revolutions before stopping. If fan does not spin freely,

armature is shorted. Replace motor using Motor Kit,

page 28.

Armature, Brushes and Motor Wiring Open Circuit

Test

1. Connect red and black motor leads together with

test lead.

6. Remove yoke and guide rods.

7. Remove gear.

2. Turn motor fan by hand, about two revolutions per

second.

3. If there is an uneven resistance or no resistance,

replace motor using Motor Kit, page 28.

30 312004B

Page 31

Control Board Diagnostics

Control Board Diagnostics

Check for motor problems before replacing control board. A damaged motor may burn out a good

control card.

Check for a damaged control board or pressure control switch as follows:

7. Attach harness from a pressure control switch you

know is functioning correctly to control board.

Pressure control switch does not have to be

1. Relieve pressure, page 14.

installed in pump.

2. Unplug electrical cord.

3. Remove cover screws and front cover.

4. Project Painter 5 and Project Painter 7, go to step 6.

SR7, Prox7 and Prox9: Remove yoke and guide

rods.

5. Remove gear.

6. Remove pressure control harness from control

board. Using tip of small, flat blade screwdriver,

press tab on right side connector to release.

Pump Diagnostics

CAUTION

When repairing or cleaning the pump, never submerge

pump in water or allow fluid to enter pressure control.

8. Turn pressure control adjustment knob clockwise to

maximum pressure setting.

9. Plug electrical cord into 120VAC receptacle.

10. Turn power switch ON.

• If motor runs, replace pressure switch.

Pressure Control Switch Kit, page 28.

• If motor does not run, replace control board

repeat test. Control Board Kit, page 28.

When pump packings wear, paint begins to leak down

outside of pump. Replace pump packings at the first

sign of leaking or additional damage to drive train could

occur. Use Pump Repair Kit, page 30.

CAUTION

When repairing or cleaning pump, never submerge

pump in water or allow fluid to enter pressure control.

312004B 31

Pump Service

If sprayer continues to cycle (motor and pump run) when

the spray gun trigger is released, or if performance is

poor even with new spray tips and clean filters, the

pump inlet or outlet valve may be obstructed or worn. If

a pump is worn, replace it. List of Kits, beginning on

page 28.

Page 32

Parts

Project Painter 5, Model 261800

Ref Part Description Qty

1 15J960 FRAME

2 288716 KIT, Strainer

3 244035 DEFLECTOR

4 195400 SPRING CLIP

5 15K214 SUCTION TUBE

6 289116 KIT, Inlet Valve

11 15K215 DRAIN TUBE

12 115489 DRAIN TUBE CLAMP

14 255105 KIT, Roller, includes 14a, 14b, 14c

14a 289126 KIT, Roller frame

14b 289129 KIt, Roller core

14c 289130 Kit, Roller seal

15 288730 LINER

16 288712 KIT, Drain Valve

18 289120 KIT, Outlet Valve

23 289121 KIT, Pump, includes 25

24 288694 KIT, Cover, includes 24a, 24b, 24c, 24d

24a▲

24b▲

24c▲

24d 120724 SCREW, tapping, torx, pan head

24e HANDLE

24f 15J879 GRIP

24g

25 289209 KIT, Gear, w/connecting rod

29 245080 KIT, Motor

30 288707 KIT, Control Board, includes 30a

30a 115477 SCREW, mach, torx, pan hd

31 15K316 POWER CORD

32 115498 SCREW, mach, grounding

34 15J957 BASE

35 115477 SCREW, mach, torx pan hd

36 15J958 HOPPER

37 289123 KIT, Cover, includes 37a, 37b

37a▲

15K489 LABEL

15K450 LABEL

15K451 LABEL, control

15K502 LABEL

▲

15K545 QUICK GUIDE, English

Ref Part Description Qty

15K548 QUICK GUIDE, Spanish

37b▲

1

1

38 SERIAL LABEL

1

42 289122 KIT, Elbow, includes 139

1

45▲

1

46 244168 PUMP ARMOR, 8 oz (not shown)

1

47 115648 POWERSFLUSH VALVE

1

48 255107 SPRAY GUN, SG10

2

49 247339 HOSE, cpld,1/4 in. X 25

1

56 179960 SIGN, warning (not shown)

1

59 338506 OPERATION DVD (not shown)

1

60 116295 TUBE CLAMP

1

67 198547 HANG TAG, instructional (not shown)

1

70 15C295 LOOSE LEAF RING, (not shown)

1

77 15J967 TUBE, 1/2 in. O.D. Bayonet

1

79 111630 SCREW, mach, pnh

1

103 15K024 BRACKET

1

108 117630 SCREW, torx, tri lob

1

111 15K132 COTTER PIN

1

116 15K220 ACTUATOR

1

117 289210 KIT, AllControl

4

118 15K630 PRACTICE SPRAY BOARD, page 6

124▲

125▲

128 15K732 VENT FILTER

1

131 116073 THRUST WASHER

1

132 15K777 HOSE GUIDE

1

134 15K829 TUBE EXTENSION

2

135 15K898 STRAINER CROSS-HANDLE

1

139 115099 GARDEN HOSE WASHER

1

15K818 LABEL, cover, English

15K819 LABEL, cover, Spanish

15K475 LABEL, warning

15K502 LABEL (not shown)

195810 LABEL, instruction

1

6

1

1

1

Replacement Danger and Warning labels, tags, and

▲

cards are available at no cost.

Parts

1

1

1

2

1

1

1

1

1

'1

1

1

1

1

1

2

3

1

4

1

2

1

1

1

1

1

1

1

1

1

1

32 312004B

Page 33

Parts

Parts

Project Painter 5, 261800

134

47

135

45

34

37a

49

37

2

36

132

37b

15

14c

125

38

31

14a

14c

24f

48

14

14b

24g

24e

3

ti9198a

12

11

108

38

5

42

139

79

131

79

4

60

12

77

1

24c

24b

24d

24a

24

312004B 33

Page 34

Parts

Project Painter 5, 261800

Parts

29

11

5

4

30

32

128

116

117

12

30a

60

6

35

23

131

103

25

16

111

18

34 312004B

ti9231a

Page 35

Notes

Notes

312004B 35

Page 36

Parts

Project Painter 7, Model 261805

Ref Part Description Qty

1 15J648 FRAME

2 15J649 CART HANDLE

3 15J720 AXLE

4 289119 KIT, Quick Release Handle

8 288697 KIT, Enclosure, includes 8a, 8b, 8c, 8d

15K450 LABEL

8a▲

15K451 LABEL, control

8b▲

15G179 LABEL, warning, fire & shock

8c▲

15G180 LABEL, warning, skin injection

8d▲

9 288693 KIT, Cover, includes 9a, 9b

15K491 LABEL

9a▲

15K490 LABEL

9b▲

10 288710 KIT, Tool Box, includes 10a, 10b

10a 198904 SCREW, Plastite #8

10b 120833 WASHER, plain, #8

11 15K026 PAIL HOOK

12 288698 KIT, Pump, includes 53

13 288711 KIT, AllControl

14 289107 KIT, Solenoid

15 255107 SPRAY GUN, SG10

16 277445 HOSE, clpd, 1/4 in. X 35 ft

17 255105 KIT, Roller, includes 17a, 17b, 17c

17a 289126 KIT, Roller Frame

17b 289129 KIT, Roller Core

17c 289130 KIT, Roller Seal

18 15J686 ROLLER TRAY

19 15K140 POWER CORD, lighted

20 120654 WHEEL, 7 in.

21 289124

15K639 LABEL, spray shield instructions

21a▲

15G180 LABEL, warning, skin injection

21b▲

22 288706 KIT, Control Board

22a 117501 SCREW, mach, slot hex wash hd (not

25 15K223 ROLLER TRAY HANGER

26 105521 TUBING PLUG

27 15K132 COTTER PIN

28 15C753 SCREW, mach, hex wash hd

29 15K220 ACTUATOR

KIT,

Spray Shield Tray, page 8 1

shown)

Ref Part Description Qty

30 289120 KIT, Outlet Fitting

35 243082 KIT, Strainer

1

36 244035 DEFLECTOR

1

37 195400 SPRING CLIP

1

38 15K449 KIT, Suction Tube, includes 39

2

39 115099 WASHER

1

42 195108 DRAIN TUBE

1

43 115489 DRAIN TUBE CLAMP

1

45 288712 KIT, Drain Valve

1

46 15K024 BRACKET

2

48 288701 KIT, Inlet Housing Assy

1

53 245149 KIT, Gear, w/connecting rod

1

57 245080 KIT, Motor

1

58 115498 GROUNDING SCREW

1

60 115477 SCREW, mach, torx pan hd

4

61 115478 SCREW, mach, torx/slt pan hd

4

64 SERIAL LABEL

1

68 244168 PUMP ARMOR, 8 oz (not shown)

1

69 115648 POWERFLUSH VALVE (not shown)

1

74 116295 TUBE CLAMP

1

77▲

1

79 198547 HANG TAG, instructional (not shown)

1

82 15C295 LOOSE LEAF RING, (not shown)

1

94 112612 HUB CAP

1

95 195367 SPACER

1

100 15C292 TAG, accessory (not shown)

1

101 15D781 TAG, instructions (not shown)

1

102 15D782 TAG, instructions (not shown)

1

103▲

2

107 15K549 QUICK GUIDE, English (not shown)

1

109 338506 OPERATION DVD (not shown)

1

118 15K630 PRACTIC SPRAY BOARD, page 8

1

119 15K744 PUMP DRAIN FOAM

2

120 15K706 FOAM

121 109570 WASHER, plain

2

195810 LABEL, instruction

179960 SIGN, warning (not shown)

15K550 QUICK GUIDE, Spanish (not shown)

2

1

2

2

Replacement Danger and Warning labels, tags, and

▲

cards are available at no cost.

Parts

1

1

1

1

1

1

1

2

1

1

1

1

1

1

10

2

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

2

36 312004B

Page 37

Parts

Parts

Project Painter 7, 261805

18

25

2

17

28

17a

17c

17b

17c

15

16

4

20

10a/10b

95

10

ti10218

312004B 37

61

3

1

26

94

121

Page 38

Parts

Project Painter 7, 261805

Parts

13

64

12

29

53

9a

57

60

22

58

48

119

30

120

45

60

11

9

9b

27

46

14

19

8d

77

8a

8b

8c

43

74

8

38

37

39

35

42

43

36

ti10219

38 312004B

Page 39

Notes

Notes

312004B 39

Page 40

Parts

SR7 Sprayer, Model 261810

Parts

Ref Part Description Qty

1 288704 KIT, Pump, complete, includes 1a,1b,

1c, 1d, 3, 4, 5, 81

1a 288747 KIT, filter

1b 288701 KIT, pump inlet

1c 288818 KIT, packing repair

1d 243094 KIT, pump outlet

2 244267 KIT, Pressure Control, includes 2a, 2b,

15A464 LABEL, control

2a▲

2b▲ 15K530 LABEL

197233 LABEL, instruction

2c▲

3 224807 VALVE BASE

4 187625 VALVE DRAIN HANDLE

5 111600 PIN, grooved

6 119275 WIRE CLIP (not shown)

7 287773 KIT, Motor, includes 7a

7a 287770 KIT, Fan

8 116295 TUBE CLAMP

9 288705 KIT, Control Board

10 115477 SCREW, mach, torx pan hd, 8-16 x 5/8

11 289102 KIT, Gear And Yoke

15 194507 DOWEL PIN, 5/16

16 288708 KIT, Drive Cover, includes 16a, 16b,

15K494 LABEL, front

16a▲

16b 197211 PUMP OUTLET COVER

16c 115478 SCREW, mach, torx/slt pan hd, 1/4-20 x

17 15K153 POWER CORD, lighted

18 115498 SCREW, ground 8-32 x.375 in. taptite

19 115478 SCREW, mach, torx, 1/4-20 x 1-3/8

20 118899 ROCKER SWITCH

21 15J726 LEG, right

22 15J728 LEG, left,

23 15J724 CART FRAME

24 15J727 CART HANDLE

26 116630 SCREW, carriage, 1/4-20 x 2-1/4 in.

27 289119 KIT, Lever, Handle, cam

28 15J725 AXLE

29 195367 SPACER

30 115095 WHEEL, 9-inch

31 112612 HUB CAP

32 102040 NUT, lock, hex, 1/4 - 20

33 15D658 PAIL HOOK

34 15D671 KIT, Suction Tube, includes 39

35 243082 KIT, Strainer

2c

plastite

16c

1-3/8 in.

Ref Part Description Qty

36 195108 DRAIN TUBE

1

37 115489 DRAIN TUBE CLAMP

38 195400 SPRING CLIP

1

39 115099 WASHER

1

41 277445 HOSE, clpd, 1/4 in. X 35 ft

1

42 255107 SPRAY GUN, SG10

1

43 244035 DEFLECTOR

1

50 179960 SIGN, warning (not shown)

1

52▲

54 115648 POWERFLUSH VALVE, (not shown)

1

55 SERIAL LABEL

1

57 287772 KIT, Enclosure, includes 57a, 57b, 57c,

1

1

57a 115477 SCREW, 8-16 x 5/8 plastite

1

57b▲

2

57c▲

1

57d▲

58 196001 WASHER

1

61 15C295 LOOSE LEAF RING, (not shown)

1

63 244168 FLUID, Pump Armor, 8 Oz (not shown)

2

66▲

73 288710 KIT, Tool Box, includes 73a, 73b, 73c

1

73a 15K226 TOOL BOX ADAPTER

2

73b 15C753 SCREW, 5/16-18 x 1-1/4 taptite

1

73c 198904 SCREW, plastite #8

1

74 15C753 SCREW, 5/16-18 x 1-1/4 taptite

1

75 15J686 ROLLER TRAY

4

76 15J816 ROLLER TRAY ADAPTER

78 289124 KIT, Spray Shield Tray, page 10,

1

1

78a▲

4

78b▲

1

81 235014 KIT, Drain Valve

1

83 255105 KIT, Roller, includes 83a, 83b, 83c

1

83a 289126 KIT, Roller Frame

1

83b 289129 KIT, Roller Core

1

83c 289130 KIT, Roller Seal

4

86 15J874 SOLENOID COVER

2

92▲

1

2

98 289107 KIT, Solenoid

2

99 15K630 PRACTICE SPRAY BOARD, page 10

195811 LABEL, instruction

57d

15G187 LABEL, warning skin inject right side

15G188 LABEL, warning fire & expl left side

15E072 LABEL, identification

198547 HANG TAG, instructional (not shown)

includes 78a,78b

15K639 LABEL, spray shield instructions

15G180 LABEL, warning, skin injection

15K551 QUICK GUIDE, English (not shown)

15K552 QUICK GUIDE, Spanish (not shown)

2

6

1

1

Replacement Danger and Warning labels, tags, and

▲

cards are available at no cost.

1

1

2

1

1

1

1

1

1

1

1

2

1

8

1

1

1

2

1

1

1

1

1

2

4

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

40 312004B

Page 41

Parts

Parts

SR7 Sprayer, Model 261810

75

27

31

74

30

24

73

73b

26

76

29

57a

57b

57

23

28

73c

7a

73a

18

7

17

19

55

86

9

98

2a

15

58

2b

42

57

34

20

57d

16

1c

2c

1

2

1a

8

1d

1b

38

10

81

55

57c

11

16a

16c

52

16b

33

5

4

3

37

36

83

83a

83c

ti9196a

312004B 41

83c

83b

32

22

21

41

39

37

43

35

Page 42

Parts

ProX7 and ProX9 Sprayers, Model 261815, 261820

Parts

Ref Part Description Qty

1 15J632 LEG

2 15J633 SUPPORT, frame

3 15J641 PULL ROD

4 15J675 SPACER, frame

5 15J678 BRACKET

6 15J940 AXLE PIN, ProX7

15J691 AXLE PIN, ProX9

7 15J695 TUBE CAP

8 15J699 TUBE CAP

9 247313 ACTUATOR

10 119547 NUT, hex, lock, nylon, 1/2-13 in.

12 247314 COVER, side

15 15J941 PIN

16 15J949 HOSE RACK

17 15J950 CART HANDLE

18 15J984 SPACER, linkage

19 15J985 BRACE, center

20 288458 BRACKET, frame

21 112612 HUB CAP

22 15J681 BAR, linkage

23 115477 SCREW, mach, 8-16 x 5/8 in. plastite

25 117630 SCREW, torx, 1/4-20 x .50 in. taptite

27 120688 SPRING, compression

28 120689 NUT, hex, acorn, 5/16-18

29 15K617 SUCTION TUBE, includes 35

30 243082 KIT, Strainer

31 116295 TUBE CLAMP

32 195108 DRAIN TUBE

33 244035 DEFLECTOR

34 115489 DRAIN TUBE CLAMP

35 115099 WASHER

37 235014 KIT, Drain Valve

38 115648 SHUTOFF VALVE (not shown)

39 187625 DRAIN VALVE HANDLE

40 224807 BASE, valve

41 247340 HOSE, cpld,1/4 in. x 50 ft

42 289102 KIT, Gear And Yoke

43 244168 FLUID, Pump Armor, 8 oz (not shown)

44 118899 ROCKER SWITCH

45 288695 KIT, Motor Shield, includes 45a, 45b,

45c, 45d

15K521 LABEL, warning skin injection

45a▲

15K522 LABEL, warning fire explosion

45b▲

15K520 LABEL, warning elec shock

45c▲

45d 118444 SCREW, mach, hwhd 10-24 x .5 in.

46 15J802 SOLENOID COVER

47 15J803 SWITCH BRACKET

49 194507 DOWEL PIN, 5/16

50 196001 WASHER

51 111600 PIN, grooved

52 115498 SCREW, ground, 8-32 x .375 in. taptite

53 195400 SPRING CLIP

Ref Part Description Qty

55 289107 KIT, solenoid

2

56 119275 WIRE CLIP

2

57 15J790 PAIL HOOK

1

58 15J952 POWER CORD, lighted

4

59 288705 KIT, Control, ProX7

2

2

59a 115477 SCREW

2

62 244267 KIT, Pressure Control, includes 62a,

2

4

62a▲

1

62b▲

2

63 288703 KIT, Pump, (complete) ProX7, includes

1

4

1

1

63a 288747 KIT, Filter

2

63b 288700 KIT, Pump Inlet Module, ProX7

1

1

63c 288818 KIT, Packing Repair

2

63d 243094 KIT, Pump Outlet Valve

2

66 288709 KIT, Tool Box

8

67 288692 KIT, Housing Cover, includes 67a, 67b,

4

67a 15J809 COVER, Pump Outlet

2

67b 115478 SCREW, mach, 1/4 x 20 x 1.375 in.

2

1

67c▲

1

1

68 289104 KIT, Motor, includes 68a

1

68a 287770 KIT, fan

1

75 101005 RING, retaining, ext.

2

76 120729 WHEEL,10 inch, ProX7

1

1

77 15K315 SPACER, ProX7

1

80 289125 KIT, Paint Shield Tray, page 12,

1

1

80a▲

'1

80b▲

1

81 260212 SCREW, hw hd, thd form 1/4-20 x .75

1

1

82 120788 SCREW, carriage, 1/4-20 x 3 in.

1

83 115480 T-HANDLE KNOB

85▲

1

88▲

1

92▲

1

93▲

2

1

97 15C295 LOOSE LEAF RING, (not shown)

1

110 255108 SPRAY GUN, SG20

2

114 15K630 PRACTICE SPRAY BOARD, page 12

2

288900 KIT, Control, ProX9

62b

15K530 LABEL

15A464 LABEl

37, 39, 40, 51, 63a, 63b, 63c, 63d

288702 KIT, Pump (complete) ProX9, includes

37, 39, 40, 51, 63a, 63b, 63c, 63d

288699 KIT, Pump Inlet Module, ProX9

67c

taptite

15K492 LABEL, front,ProX7

15K493 LABEL, front, ProX9

115094 WHEEL,10 inch, ProX9

includes 80a, 80b

15K639 LABEL, paint shield tray instructions

15G180 LABEL, warning, skin injection

in.

SERIAL LABEL

198547 HANG TAG, instructional (not shown)

179960 SIGN, Warning (not shown)

15K551 QUICK GUIDE, English (not shown)

15K552 QUICK GUIDE, Spanish (not shown)

1

▲ Replacement Danger and Warning labels, tags, and cards

1

1

are available at no cost.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

1

1

1

1

6

2

2

2

1

1

1

10

2

2

2

1

1

1

1

1

1

1

42 312004B

Page 43

Parts

Parts

ProX7 and ProX9 Sprayers, Models 261815, 261820

45b

45

67b

67c

85

67

62b

62a

63c

62

45c

63d

46

45a

45d

49

42

50

56

44

68

47

66

85

23

68a

59

52

59a

58

63a

37

63

67a

57

312004B 43

23

110

63b

31

53

29

35

41

40

34

32

34

33

30

55

51

39

81

Page 44

Parts

ProX7 and ProX9 Sprayers, Models 261810, 261820

9

17

3

27

15

16

Parts

28

21

12

23

75

20

83

9

18

22

81

76

77

8

5

25

8

6

2

4

82

75

19

7

44 312004B

4

1

10

81

Page 45

Notes

Notes

312004B 45

Page 46

Parts

Wiring Diagrams

Project Painter 5, Model 261800

Notes

ALL CONTROL

CHASSIS

GROUND

POWERCORD

BLACK WIRE

32 REF

POWERCORD

GREEN WIRE