Page 1

SUBMERSIBLE CONTRACTOR PUMP

MSC 2101 • MSC 2202 • MSC 2302

MSC 3202 • MSC 3302

OPERATING/PARTS MANUAL

Page 2

INTRODUCTION

This manual provides information and procedures to safely operate and maintain the pump. For your own safety

and protection from physical injury, carefully read, understand, and observe the safety instructions described in this

manual. Keep a copy of this manual with the unit at all times. Additional copies are available from Magnum Products

LLC, or can be found at www.m-p-llc.com. The information contained in this manual was based on machines in

production at the time of publication. Magnum Products LLC reserves the right to change any portion of this information

without notice.

DO NOT MODIFY or use this equipment for any application other than which it was designed for.

MAGNUM PRODUCTS LLC

215 Power Drive • Berlin, WI 54923

U.S.A.

Phone: 920-361-4442

FAX: 920-361-4416

Toll Free: 1-800-926-9768

www.m-p-llc.com

For technical or parts QUESTIONS, please contact Magnum Products’ Customer Support or

Technical Support team at 920-361-4442 or toll free at 1-800-926-9768. Please have your

serial number available.

To ORDER SERVICE PARTS, please contact the dealer from which you purchased the unit,

or call Magnum Products to locate a dealer in your area.

Unit Model Number:_____________________________________

Unit Serial Number: _____________________________________

2

Page 3

TABLE OF CONTENTS

Page

INTRODUCTION ................................................................................................................................... 2

TABLE OF CONTENTS ......................................................................................................................... 3

SAFETY NOTES .................................................................................................................................... 4

OPERATING SAFETY ........................................................................................................................... 4

UNIT SERIAL NUMBER LOCATION ..................................................................................................... 5

SPECIFICATIONS ............................................................................................................................5 - 6

OPERATING THE PUMP ...................................................................................................................... 7

CLEANING THE PUMP ......................................................................................................................... 7

STORING THE PUMP ........................................................................................................................... 7

COMPONENT LOCATIONS - MSC 2101, MSC 2202 & MSC 3202 ..................................................... 8

COMPONENT LOCATIONS - MSC 2302 & MSC 3302 ........................................................................ 9

UNIT ASSEMBLY AND PARTS - MSC 2101, MSC 2202 & MSC 3202 ........................................ 10 - 11

UNIT ASSEMBLY AND PARTS - MSC 2302 & MSC 3302 ...........................................................12 - 13

WIRING DIAGRAM - MSC 2101 .......................................................................................................... 14

WIRING DIAGRAM - MSC 2202, MSC 2302, MSC 3202 & MSC 3302 .............................................. 15

3

Page 4

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

DANGER

SAFETY NOTES

WARNING

This manual contains DANGERS, WARNINGS, CAUTIONS, NOTICES and NOTES which must be

followed to prevent the possibility of improper service, damage to the equipment, personal injury or death.

The following formatting options will apply when calling the readers attention to the DANGERS, WARNINGS, CAUTIONS, NOTICES and NOTES.

INDICATES A HAZARDOUS SITUATION WHICH, IF NOT AVOIDED,

WILL RESULT IN DEATH OR SERIOUS INJURY.

WARNING

Indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided, may result in minor

or moderate injury.

NOTICE

Indicates a hazardous situation which, if not avoided, may result in

property or equipment damage.

Note: Notes contain additional information important to a procedure and will be found within the regular

text body of this manual.

OPERATING SAFETY

Before using the pump be sure to read and understand all of the instructions! This equipment was designed

for specific applications; DO NOT modify or use this equipment for any application other than which it was

designed for. Equipment operated improperly or by untrained personnel can be dangerous! Read the

operating instructions and familiarize yourself with the location and proper use of all instruments and

controls. Inexperienced operators should receive instruction from someone familiar with the equipment

before being allowed to operate the pump. The following points should be practiced at all times:

• NEVER start a unit in need of repair.

• NEVER operate the pump if any of the following conditions exist during operation:

1. Sparking occurs.

2. Combustible surface is present.

3. Protective covers are loose or missing.

Never pump volatile or corrosive chemicals or solutions with this pump.

These fluids could create serious health and environmental hazards. High

pressure increases the chance of pump explosion which may result in

serious personal injury.

4

Page 5

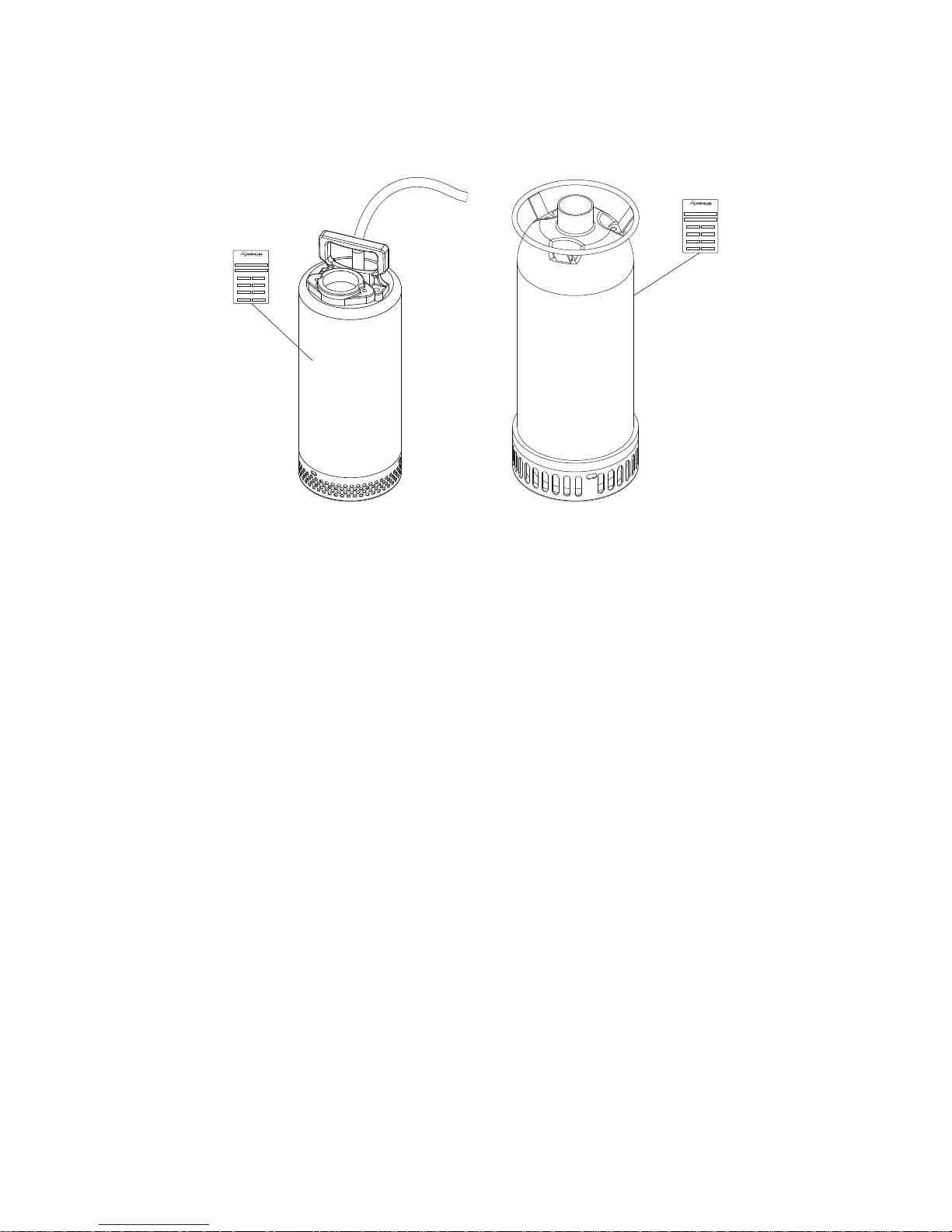

UNIT SERIAL NUMBER LOCATION

Refer to the location illustrated below to find the unit ID tag. Important information, such as the unit serial number

and model number are found on this tag. Record the information from this tag, so it is available if the tag is lost or

damaged. When ordering parts or requesting technical service information, you may be asked to specify this

information.

Unit ID Tag

215 Power Drive • Berlin, WI 54923

1-800-926-9768

MODEL

MSC 3302

SERIAL NUMBER

000000

WEIGHT

kglbs.

FLOW

Lpmgpm

POWER

kWhp

Unit ID Tag

215 Power Drive • Berlin, WI 54923

1-800-926-9768

MODEL

MSS 2101

SERIAL NUMBER

000000

WEIGHT

kglbs.

FLOW

Lpmgpm

POWER

kWhp

TOTAL HEAD

mft.

DO NOT RUN PUMP DRY!

TOTAL HEAD

mft.

DO NOT RUN PUMP DRY!

SPECIFICATIONS

Read this manual carefully before attempting to use this pump. The potential for property damage, personal injury

or death exists if this equipment is misused or installed incorrectly.

MAGNUM MODEL MSC 2101 MSC 2202 MSC 2302

Motor Type................................................. 1 Ø, 60 hz .........................1 Ø, 60 hz.........................1 Ø, 60 hz

Amperage Range (Min. - Max.)* ................ 9.7 - 12.6A ........................7.7 - 11.8A........................10.4 - 16.2A

Voltage ....................................................... 120V .................................240V.................................240V

Pump Output

Discharge Diameter ................................... 2 in. (50 mm)..................... 2 in. (50 mm)....................2 in. (50 mm)

Maximum Head.......................................... 59.1 ft. (18 m) ...................72 ft. (22 m)......................89 ft. (27 m)

Maximum Discharge .................................. 79.3 gpm (300.09 Lpm) ....119 gpm (450.33 Lpm) .....132 gpm (499.53 Lpm)

Power......................................................... 1 hp (746 W) ..................... 2 hp (1491 W) ..................3 hp (2237 W)

Solids Handling Capacity ........................... .2 in. (6 mm)...................... .4x1.4 in. (10x35 mm) .......4x1.4 in. (10x35 mm)

Weights and Dimensions

Dry Weight ................................................. 46 lbs. (21 kg)...................81 lbs. (37 kg) ..................110 lbs. (50 kg)

Shipping Weight......................................... 52 lbs. (24 kg) ...................83 lbs. (38 kg) ..................112 lbs. (51 kg)

Maximum Diameter.................................... 7 in. (180 mm)................... 9 in. (228 mm) ..................9 in. (228 mm)

Maximum Height ........................................ 18 in. (457 mm)................. 26 in. (650 mm)................26 in. (670 mm)

Cable Length.............................................. 20 ft. (6 m) ........................33 ft. (10 m)......................33 ft. (10 m)

Other Specifications

Cable Diameter .......................................... 14AWG ............................. 12AWG.............................12AWG

Impeller Material ........................................ HCr ...................................HCr...................................HCr

Impeller Type ............................................. Semi-open ........................ Semi-open ........................Semi-open

Strainer Material......................................... HCr ...................................HCr...................................HCr

Seal............................................................ Silicone Carbide Mech. .....Silicone Carbide Mech. ....Silicone Carbide Mech.

Electric Plug Included ................................ Yes.................................... No.....................................No

*Amperage varies upon head and flow.

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

5

Page 6

SPECIFICATIONS

Read this manual carefully before attempting to use this pump. The potential for property damage, personal injury

or death exists if this equipment is misused or installed incorrectly.

MAGNUM MODEL MSC 3202 MSC 3302

Motor Type................................................. 1 Ø, 60 hz .........................1 Ø, 60 hz

Amperage Range (Min. - Max.)* ................ 8.1 - 10.7A ........................13.4 - 16.6A

Voltage ....................................................... 240V .................................240V

Pump Output

Discharge Diameter ................................... 3 in. (76 mm)..................... 3 in. (76 mm)

Maximum Head.......................................... 52 ft. (16 m) ......................66 ft. (20 m)

Maximum Discharge .................................. 172 gpm (650.9 Lpm) .......211 gpm (798.49 Lpm)

Power......................................................... 2 hp (1491 W) ................... 3 hp (2237 W)

Solids Handling Capacity ........................... .4x1.4 in. (10x35 mm) ........4x1.4 in. (10x35 mm)

Weights and Dimensions

Dry Weight ................................................. 91 lbs. (41 kg)...................111 lbs. (50 kg)

Shipping Weight......................................... 94 lbs. (42 lbs.) ................. 114 lbs. (52 kg)

Maximum Diameter.................................... 9 in. (228 mm)................... 9 in. (228 mm)

Maximum Height ........................................ 26 in. (650 mm)................. 26 in. (670 mm)

Cable Length.............................................. 33 ft. (10 m) ......................33 ft. (10 m)

Other Specifications

Cable Diameter .......................................... 12AWG ............................. 12AWG

Impeller Material ........................................ HCr ...................................HCr

Impeller Type ............................................. Semi-open ........................ Semi-open

Strainer Material......................................... HCr ...................................HCr

Seal............................................................ Silicone Carbide Mech. .....Silicone Carbide Mech.

Electric Plug Included ................................ No .....................................No

*Amperage varies upon head and flow.

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

6

Page 7

OPERATING THE PUMP

WARNING

1. Connect the discharge hose with the proper fittings.

2. Place the pump in the water. Lower by attaching a strong rope to the handle. The pump should be placed on a

flat, hard surface in at least 2 inches of water.

WARNING

Never lower or move the pump with the electrical cord. Damage to the cord or cord

seal could result in equipment damage and/or electrocution.

NOTICE

Do not install the pump on clay, dirt, or sand surfaces. Small stones, gravel, sand, and mud can clog the pump and

reduce the performance or cause malfunction of the pump. If necessary, place the pump on a concrete block or slab

to prevent the pump from sinking.

3. Connect the grounding-type plug to an outlet.

4. The pump should begin to cycle. To ensure proper operation, observe the pump to make sure it has enough

water to avoid cavitation.

Never operate a pump or pump motor with wet hands. Never stand on a wet or damp

surface when operating the pump. Doing so could result in equipment damage or

personal injury.

WARNING

To prevent overheating, always keep the pump completely submerged when running

continuously. Running the pump continuously while not submerged could result in

equipment damage.

CLEANING THE PUMP

After running the pump, wash the pump in clean water. Keep inlet screens clean at all times, and always check the

screens before each use.

STORING THE PUMP

Please take the following actions in preparing the unit for storage.

1. Remove pump impeller cover and clean inside of pump housing. Coat inside of pump with a light film of oil to

reduce corrosion.

2. Tape up ports to prevent anything from falling into pump.

3. Store in a clean, dry area.

7

Page 8

HANDLE

DISCHARGE

INLET

IMPELLER

(UNDER INLET)

HOUSING

CORD

COMPONENT LOCATIONS - MSC 2101, MSC 2202 & MSC 3202

8

Page 9

COMPONENT LOCATIONS - MSC 2302 & MSC 3302

DISCHARGE

HANDLE

HOUSING

IMPELLER

(UNDER INLET)

INLET

9

Page 10

UNIT ASSEMBLY AND PARTS - MSC 2101, MSC 2202 & MSC 3202

1

2

3

14

12

11

4

10

6

5

9

13

16

7

8

15

10

17

18

Page 11

ITEM NO. PART NO. QTY DESCRIPTION NOTES

1 41618 1 Handle

2 41612 1 Power cord For MSC 2202 & 3202

2 41611 1 Power cord For MSC 2101

3 41770 1 Rubber gasket For MSC 2202 & 3202

3 41769 1 Rubber gasket For MSC 2101

4 41720 1 Base-capacitor

5 41636 1 Upper bearing For MSC 2202 & 3202

5 41635 1 Upper bearing For MSC 2101

6 41626 1 Capacitor - run For MSC 2202 & 3202

6 41625 1 Capacitor - run For MSC 2101

7 41667 1 Capacitor - start For MSC 2202 & 3202

7 41616 1 Capacitor - start For MSC 2101

8 41732 1 Impeller key For MSC 2202 & 3202

8 41731 1 Impeller key For MSC 2101

9 41642 1 Lower bearing

10 41651 1 Mechanical seal For MSC 2202 & 3202

10 41650 1 Mechanical seal For MSC 2101

11 41661 1 Seal plate For MSC 2202 & 3202

11 41660 1 Seal plate For MSC 2101

12 41691 1 Impeller For MSC 2101

12 41692 1 Impeller For MSC 2202

12 41693 1 Impeller For MSC 3202

13 41783 1 Nut - M12-1.25 For MSC 2202 & 3202

13 41782 1 Nut - M10-1.25 For MSC 2101

14 41764 1 Square ring For MSC 2202 & 3202

14 41763 1 Square ring For MSC 2101

15 41686 1 Pump casing For MSC 2202 & 3202

15 41685 1 Pump casing For MSC 2101

16 41758 1 O-ring - 4”

17 41701 1 Suction cover For MSC 2101

17 41706 1 Suction cover For MSC 2202

17 41703 1 Suction cover For MSC 3202

18 41711 1 Strainer For MSC 2202 & 3202

18 41710 1 Strainer For MSC 2101

- 41630 1 Centrifugal switch Not shown

- 41745 1 O-ring - .375” Not Shown

11

Page 12

UNIT ASSEMBLY AND PARTS - MSC 2302 & MSC 3302

1

4

5

10

11

2

3

6

7

8

9

14

12

13

15

16

17

18

12

Page 13

ITEM NO. PART NO. QTY DESCRIPTION NOTES

1 41620 1 Handle

2 41613 1 Power cord

3 41770 1 Rubber gasket

4 41720 1 Base-capacitor

5 41637 1 Upper bearing

6 41626 1 Capacitor - run

7 41667 1 Capacitor - start

8 41732 1 Impeller key

9 41644 1 Lower bearing

10 41652 1 Mechanical seal

11 41661 1 Seal plate

12 41694 1 Impeller For MSC 3302

12 41695 1 Impeller For MSC 2302

13 41783 1 Nut - M!@-1.25

14 41764 1 Square ring

15 41686 1 Pump casing

16 41758 1 O-ring - 4”

17 41704 1 Suction cover For MSC 3302

17 41706 1 Suction cover For MSC 2302

18 41712 1 Strainer

- 41630 1 Centrifugal switch Not shown

- 41745 1 O-ring - .375” Not shown

13

Page 14

WIRING DIAGRAM - MSC 2101

14

Page 15

WIRING DIAGRAM - MSC 2202, MSC 2302, MSC 3202 & MSC 3302

15

Page 16

REV: A

PART NO: 41866

01.28.09

Loading...

Loading...