Page 1

PORT ABLE GENERA T OR

MPG 3800 • MPG 3800C

OPERA TING/PARTS MANUAL

Page 2

INTRODUCTION

This manual provides information and procedures to safely operate and maintain the portable generator . For your

own safety and protection from physical injury , carefully read, understand, and observe the safety instructions

described in this manual. The information contained in this manual was based on machines in production at the

time of publication. Magnum Products LLC reserves the right to change any portion of this information without

notice.

DO NOT MODIFY or use this equipment for any application other than which it was designed for .

Magnum Products LLC recommends that a trained and licensed professional perform all electrical wiring and testing

functions. Any wiring should be in compliance with the United S tates National Electric Code (NEC), st ate and local

codes and Occupational Safety and Health Association (OSHA) guidelines.

Keep a copy of this manual with the unit at all times. Additional copies are available from Magnum Product s LLC or

can be found at www.m-p-llc.com. An engine operator’s manual was also supplied with the unit at the time of

shipment from the factory . The manual provides detailed operation and maintenance procedures for the engine.

Additional copies of this manual are available from the engine manufacturer.

MAGNUM PRODUCTS LLC

215 Power Drive • Berlin, WI 54923

U.S.A.

Phone: 920-361-4442

Fax: 920-361-4416

Toll Free: 1-800-926-9768

www.m-p-llc.com

For technical or parts QUESTIONS, please contact Magnum Products’ Customer Support or

Technical Support team at 920-361-4442. Please have your serial number available.

T o ORDER SER VICE PARTS, please contact the dealer from which you purchased the unit,

or call Magnum Products to locate a dealer in your area.

Unit Model Number:

Unit Serial Number:

CALIFORNIA PROPOSITION 65 WARNING:

Engine exhaust and some of its constituents are known to the state

of California to cause cancer, birth defects and other reproductive harm.

2

WARNING

Page 3

TABLE OF CONTENTS

INTRODUCTION ..............................................................................................................................2

T ABLE OF CONTENTS ...................................................................................................................3

SAFETY NOTES.............................................................................................................................4

OPERA TING SAFETY.....................................................................................................................4

ENGINE SAFETY ...........................................................................................................................5

ELECTRICAL SAFETY....................................................................................................................5

UNIT SERIAL NUMBER LOCA TION ................................................................................................6

SAFETY SYMBOL SUMMARY.......................................................................................................6

SPECIFICA TIONS ...........................................................................................................................7

COMPONENT LOCA TIONS.............................................................................................................8

CONTROL P ANEL COMPONENTS.................................................................................................9

GROUNDING THE GENERATOR..................................................................................................10

CONNECTING ELECTRICAL LOADS ............................................................................................10

GFCI TEST INSTRUCTIONS .........................................................................................................10

PREVENTION OF OVERLOAD.....................................................................................................10

WA TT AGE CONSUMPTION OF EQUIPMENT............................................................................... 11

USE OF EXTENSION CORDS ...................................................................................................... 11

EXTENSION CORD SELECTION CHART ......................................................................................12

ADDING ENGINE OIL ...................................................................................................................12

ADDING GASOLINE .....................................................................................................................12

ST ARTING THE ENGINE...............................................................................................................13

POWERING THE LOADS .............................................................................................................13

STOPPING THE ENGINE .............................................................................................................14

MAINTENANCE SCHEDULE ........................................................................................................15

DAIL Y MAINTENANCE CHECKS AND TIPS .................................................................................15

LIFTING THE GENERAT OR ..........................................................................................................15

UNIT DECALS...............................................................................................................................16

CONTROL P ANEL ASSEMBLY.....................................................................................................17

FRAME AND FUEL TANK ASSEMBL Y ....................................................................................18-19

ENGINE AND GENERATOR ASSEMBL Y................................................................................. 20-21

AC WIRING DIAGRAM..................................................................................................................22

DC WIRING DIAGRAM..................................................................................................................23

Page

3

Page 4

SAFETY NOTES

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

This manual contains DANGERS, WARNINGS, CAUTIONS, NOTICES and NOTES which must be

followed to prevent the possibility of personal injury or death, damage to equipment, or improper service.

The following formatting options will apply when calling the readers attention to the DANGERS, WARNINGS, CAUTIONS, NOTICES and NOTES.

Indicates a hazardous situation which, if not avoided, may result in minor or moderate injury.

DANGER

INDICATES A HAZARDOUS SITUATION WHICH, IF NOT AVOIDED,

WILL RESULT IN DEATH OR SERIOUS INJURY.

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

NOTICE

Indicates a hazardous situation which, if not avoided,

may result in property or equipment damage.

Note: Notes contain additional information important to a procedure and will be found within the regular

text body of this manual.

OPERATING SAFETY

Before using the generator be sure you read and understand all of the instructions! This equipment was

designed for specific applications; DO NOT modify or use this equipment for any application other than

which it was designed for. Equipment operated improperly or by untrained personnel can be dangerous!

Read the operating instructions and familiarize yourself with the location and proper use of all instruments

and controls. Inexperienced operators should receive instruction from someone familiar with the equipment before being allowed to operate or set up the generator. The following points should be practiced at

all times:

• The area immediately surrounding the generator should be dry, clean, and free of debris.

• NEVER start a unit in need of repair.

• NEVER operate unit on a combustible surface.

• NEVER operate the generator if any of the following conditions exist during operation:

1. Noticeable change in engine speed.

2. Loss of electrical output.

3. Equipment connected to the generator overheats.

4. Sp arking occurs.

5. Engine misfires or there is excessive engine/generator vibration.

6. Protective covers are loose or missing.

7. If the ambient air temperature is above 1 10° F .

4

Page 5

ENGINE SAFETY

Internal combustion engines present special hazards during operation and fueling! Failure to follow the

safety guidelines described below could result in severe injury or death. Read and follow all safety

warnings described in the engine operator’s manual. A copy of this manual was supplied with unit when it

was shipped from the factory.

• DO NOT run engine indoors or in an area with poor ventilation unless exhaust hoses are used.

Engine exhaust contains carbon monoxide, a deadly, odorless and colorless gas which, if inhaled,

can cause nausea, fainting or death. Make sure engine exhaust cannot seep into closed rooms or

ventilation equipment.

• DO NOT fill fuel tank near an open flame, while smoking, or while engine is running. DO NOT fill tank

in an enclosed area with poor ventilation.

• DO NOT operate with the fuel tank cap loose or missing.

• DO NOT touch or lean against hot exhaust or engine parts.

• DO NOT clean air filter with gasoline or other types of low flash point solvents.

• Keep hands, feet and loose clothing away from moving parts on the generator and engine.

• If equipped, batteries contain sulfuric acid which can cause severe injury or death. Sulfuric acid can

cause eye damage, burn flesh or eat holes in clothing. Protective eye wear and clothing are necessary when working on or around the battery. Always disconnect the NEGATIVE (-) battery cable from

the corresponding terminal before performing any service on the engine or other components.

ELECTRICAL SAFETY

While the engine is running, potentially lethal voltages are present at the outlets located on the control

panel. Failure to follow the safety guidelines described below could result in severe injury or death.

• Only a qualified and licensed electrician should make connections to the generator.

• NEVER wash the unit with any high pressure hoses or power washers.

• NEVER allow water to accumulate around the base of the unit. If water is present, DO NOT service!

• NEVER service electrical components if clothing or skin is wet. If the unit is stored outside, check the

engine and generator for any moisture and dry the unit before use.

• NEVER start the engine with any of the circuit breakers switched on or with any loads connected to

the control panel. Serious generator damage will result.

• ALWAYS disconnect the NEGATIVE (-) battery cable from the corresponding terminal before performing any service on the engine, generator or any other components. Remove the NEGATIVE (-) battery

cable from the corresponding terminal if the unit is to be stored or transported.

5

Page 6

UNIT SERIAL NUMBER LOCATION

Refer to the location illustrated at right to find the unit ID

tag. Important information, such as the unit serial

number and model number are found on this tag. Record

the information from this tag, so it is available if the tag is

lost or damaged. When ordering parts or requesting

technical service information, you may be asked to

specify this information.

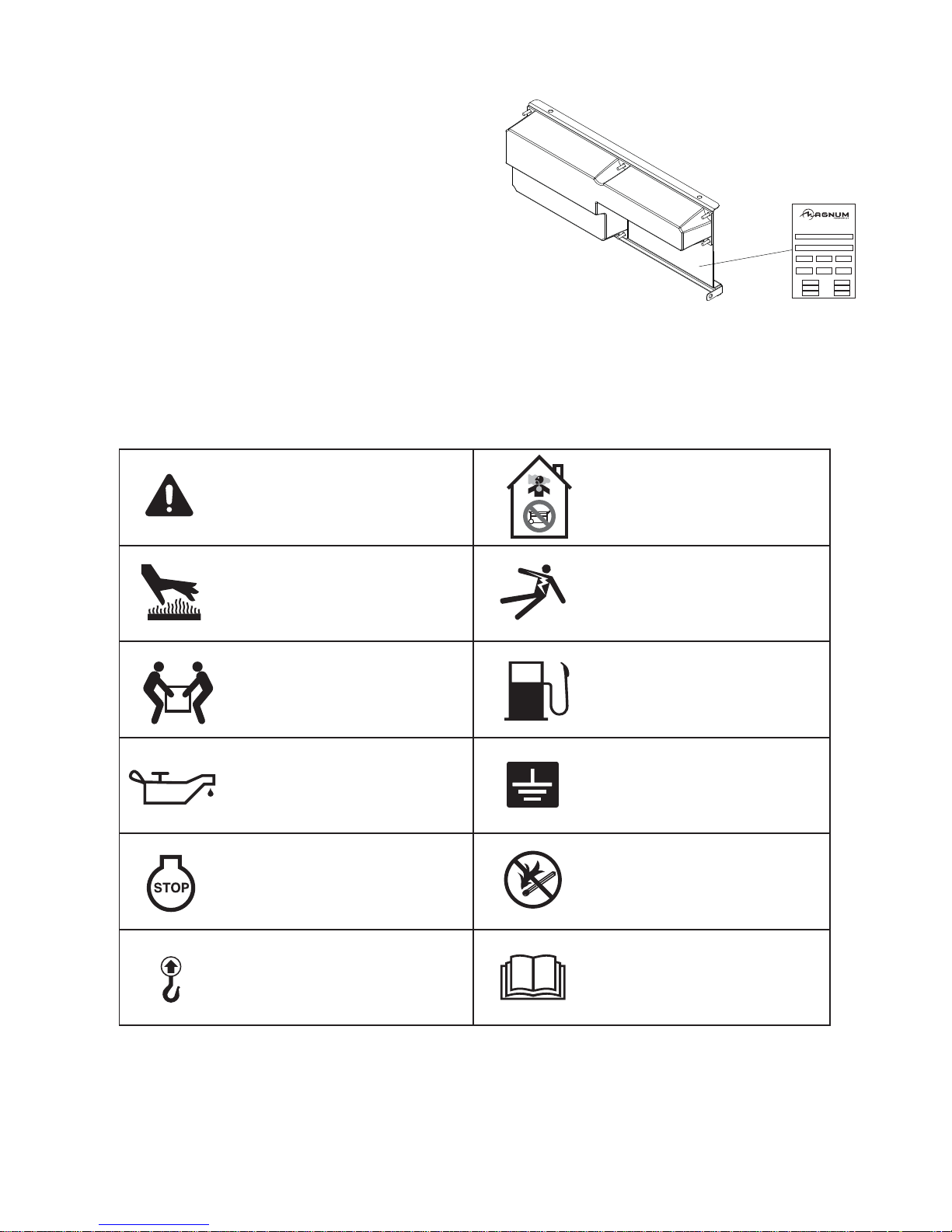

SAFETY SYMBOL SUMMARY

This equipment has been supplied with numerous safety and operating decals. These decals provide important

operating instructions and warn of dangers and hazards. Replace any missing or hard-to-read decals and use care

when washing or cleaning the unit. Decal placement and part numbers can be found in the parts section of this

manual. Below is a summary of the intended meanings for the symbols used on the decals.

Unit ID Tag

215 Power Drive • Berlin, WI 54923

1-800-926-9768

MODEL

MPG 5600

SERIAL NUMBER

000000

kglbs. amb. temp.

rpm hz phase

CONTINUOUS

kW

kW

120/240 120/240

V

A

41.7/20.8

1 Ø

MAXIMUM

V

A

46.7/23.3

Safety alert symbol; Used to

alert you to potential personal

injury hazards.

Hot surface(s) nearby.

Two-person lift only.

Check oil level daily.

Stop engine before fueling.

Asphyxiation hazard; Operate

in well ventilated area.

Dangerous voltage may be

present. Disconnect battery

before servicing.

Use unleaded gasoline only.

G

Unit electrical ground.

Fire/explosion hazard; Keep

open flames away from unit.

Lift here only.

6

Read and understand the

supplied operator’s manual

before operating unit.

Page 7

SPECIFICATIONS

Read this manual carefully before attempting to use this generator. The potential for property damage, personal

injury or death exists if this equipment is misused or installed incorrectly. Read all of the manuals included with this

unit. Each manual details specific information regarding items such as set-up, use and service requirements.

MAGNUM MODEL MPG 3800 MPG 3800C

Engine

Engine Make....................................................... Honda .............................................. Honda

Engine Model ...................................................... GX240 .............................................. GX240

Power-net prime*................................................. 7.1 hp (5.3 kW)................................ 7.1 hp (5.3 kW)

Fuel Consumption - net prime ............................. 0.68 gph (2.57 Lph).......................... 0.68 gph (2.57 Lph)

Displacement ...................................................... 15 in3 (242 cm3)................................ 15 in3 (242 cm3)

Recoil Start ......................................................... Yes .................................................. Yes

Generator

Generator Frequency .......................................... 60 Hz ............................................... 60 Hz

Maximum Output Watts ...................................... 3800 ................................................ 3800

Continuous Output Watts.................................... 3400 ................................................ 3400

Maximum Amps.................................................. 32A.................................................. 3 2A

Electrical

Main Circuit Breaker............................................ 16 Amp-2 pole.................................. 16 Amp-2 pole

Volt age (Receptacles) ......................................... 120/240V ......................................... 120/240V

120V , 20A Duplex - qty........................................ 2...................................................... 2

120/240, 20A T wist Lock - qty ............................. 1 ...................................................... 1

120/240, 30A T wist Lock - qty ............................. 1 ...................................................... 1

Capacities

Fuel T ank ............................................................ 6.6 gal. (25 L)................................... 6.6 gal. (25 L)

Approximate Run time......................................... 9.7 hours.......................................... 9.7 hours

Weights and Dimensions

Dry Weight.......................................................... 185 lbs. (84 kg)................................ 185 lbs. (84 kg)

Operating Weight ................................................ 226 lbs. (103 kg) .............................. 226 lbs. (103 kg)

Dry Weight, w/Wheel Kit Option.......................... 212 lbs. (96 kg) ................................ 212 lbs. (96 kg)

Operating Weight, w/Wheel Kit Option ................ 253 lbs. (115 kg) .............................. 253 lbs. (115 kg)

Dimensions (L x W x H) ...................................... 36.8 x 21.4 x 21.5 in. ....................... 36.8 x 21.4 x 21.5 in.

934.7 x 543.6 x 546.1 mm ............... 934.7 x 543.6 x 546.1 mm

Dimensions, Wheel Kit Option (L x W x H) ......... 36.8 x 27.0 x 27.0 in. ....................... 36.8 x 27.0 x 27.0 in.

934.7 x 686.0 x 686.0 mm ............... 934.7 x 686.0 x 686.0 mm

* The power rating of the engine indicated in this document is the net power output tested on a production engine for

the engine model and measured in accordance with SAE J1349 at 3600 rpm. Mass production engines may vary

from this value. Actual power output for the engine inst alled in the final machine will vary depending on numerous

factors, including the operating speed of the engine in application, environmental conditions, maintenance, and other

variables.

SPECIFICA TIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

7

Page 8

A

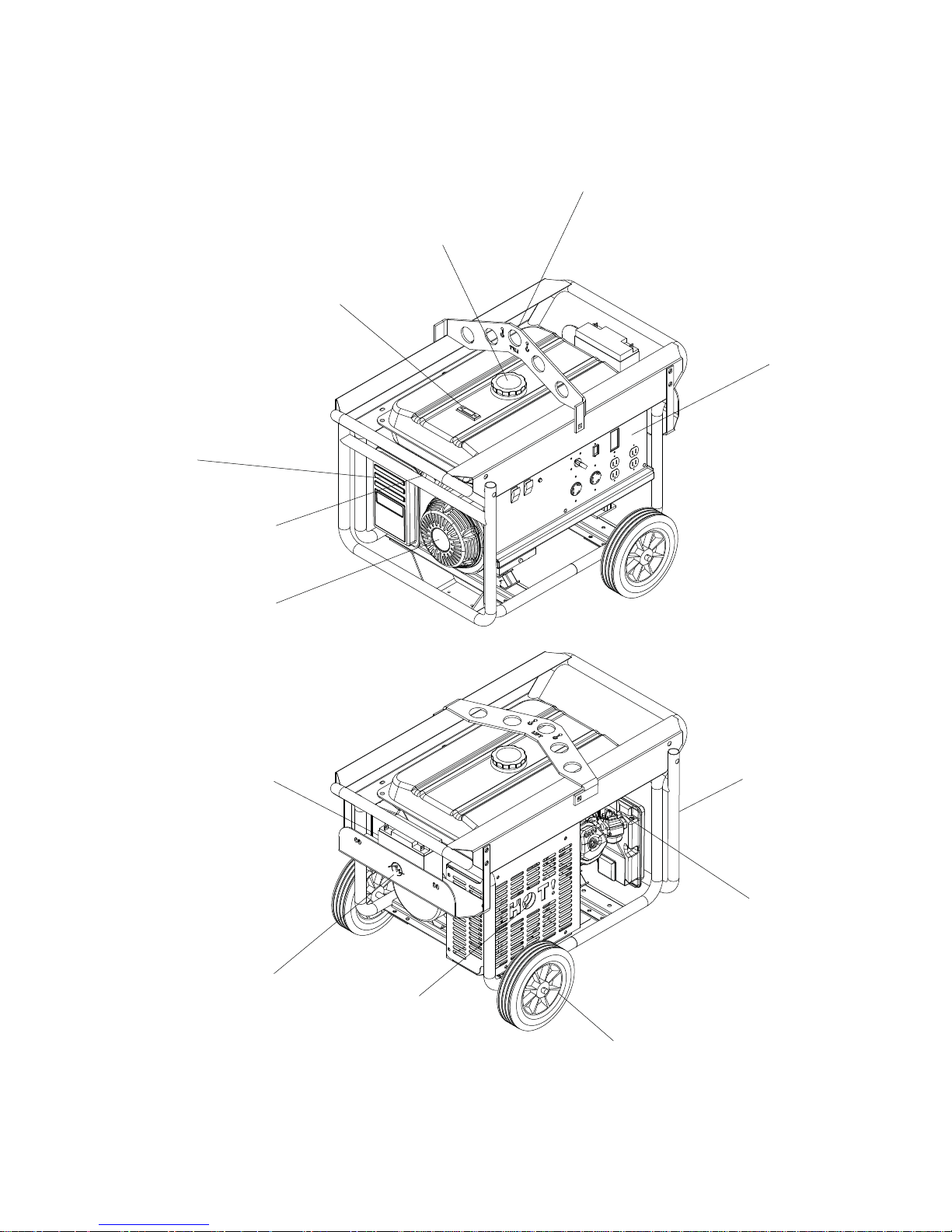

COMPONENT LOCATIONS

FUEL LEVEL

GAUGE

IR FILTER

HOUSING

CENTRAL

LIFTING EYE

FUEL TANK

CAP

CONTROL

PANEL

FUEL SHUT

OFF VALVE

(UNDER TANK)

RECOIL

STARTER

ENGINE

STARTING

BATTERY

HANDLE -

WHEEL KIT

(OPTIONAL)

ENGINE CHOKE

(UNDER TANK)

BATTERY

TRAY

(OPTIONAL)

8

ENGINE

EXHAUST

WHEEL KIT

(OPTIONAL)

Page 9

CONTROL PANEL COMPONENTS

A

B

C

D

GROUND FAULT

SENSING MODULE

P

O

W

E

R

RESET

WARNING

TEST BEFORE EACH USE

SEE INSTRUCTIONS

RESET

E

F

A

U

L

T

MPG 3800

FG H

A. ENGINE START SWITCH: This switch must be in the ON position to start the engine. To stop the engine,

place switch in OFF position.

B. AUTO IDLE SWITCH: When this switch is engaged, the engine speed will return to idle whenever the

generator is not under load.

C. VOL T AGE SWITCH: This switch changes voltage on the L14-30R outlet from 120V to 240V .

D. MAIN CIRCUIT BREAKER: This unit contains a 16A circuit breaker .

E. GFCI TEST MODULE: This module is the ground fault circuit interrupter to protect all electrical outlets.

F. 120/240V TWIST-LOCK CONVENIENCE OUTLET : This L14-30R outlet is used to connect additional loads or

equipment to the generator.

G. 120V TWIST-LOCK CONVENIENCE OUTLET : This L5-30R outlet is used to connect additional loads or

equipment to the generator.

H. 120V DUPLEX CONVENIENCE OUTLETS: These 120V outlets are used to connect additional loads or

equipment to the generator.

9

Page 10

GROUNDING THE GENERATOR

The National Electrical Code (NEC) requires that the

generator be properly connected to an approved ground

source. The ground connection for this unit is located on

the generator support leg.

CONNECTING ELECTRICAL LOADS

Allow the engine to warm-up before connecting any

devices to the unit. Connect the desired 120 or 240 volt

AC, single phase, 60 Hz electrical loads.

GFCI TEST INSTRUCTIONS

NOTICE:

ALWA YS test GFCI outlet s before connecting any loads to the generator .

The device green LED is “ON” and circuit breaker is at “ON” position.

GROUND SOURCE

LOCATION

1. Press the “TEST” button. The green LED should go out and red LED should come on. The circuit breaker

should trigger to the off position.

2. If the LED does not change state, or the breaker does not trip, DO NOT USE! Consult an electrician for

assistance.

3. Press the “RESET” button. The red LED should turn off and green LED should turn on.

4. Manually reset the circuit breaker to the on position to restore circuit power.

PREVENTION OF OVERLOAD

Exceeding wattage capacity can result in damage to the generator and to the connected electrical devices. Adhere

to the following to prevent exceeding wattage capacities:

• Calculate the total wattage of all electrical devices to be connected at one time to the generator.

• The total should NOT be greater than the generator’s wattage capacity .

• The wattage from various devices can be found on the device’s data plate or decal. See the Wattage

Consumption of Equipment section on page 1 1 for a listing of devices and their running watts.

• If you cannot locate the running wattage for a device, multiply volts times ampere rating.

10

Page 11

WATTAGE CONSUMPTION OF EQUIPMENT

DEVICE APPROXIMATE RUNNING WATTS

Air Conditioner (12,000 BTU)** ........................................................................................................................... 1700

Air Conditioner (24,000 BTU)** ........................................................................................................................... 3800

Air Conditioner (40,000 BTU)** ........................................................................................................................... 6000

Battery Charger (20 Amp).....................................................................................................................................500

Belt Sander (3”).................................................................................................................................................. 1000

Chain Saw.......................................................................................................................................................... 1200

Circular Saw (6-1/2”)................................................................................................................................ 800 to 1000

Compressor (1 hp)**........................................................................................................................................... 2000

Compressor (3/4 hp)**........................................................................................................................................ 1800

Compressor (1/2 hp)**........................................................................................................................................ 1400

Disc Sander (9”) ................................................................................................................................................. 1200

Edge Trimmer ......................................................................................................................................................500

Electric Nail Gun................................................................................................................................................ 1200

Electric Range (per element) .............................................................................................................................. 1500

Furnace Fan (3/5 hp)** .........................................................................................................................................875

Garage Door Opener**............................................................................................................................... 500 to 750

Hand Drill .................................................................................................................................................250 to 1 100

Hedge Trimmer..................................................................................................................................................... 450

Impact Wrench.....................................................................................................................................................500

Jet Pump**........................................................................................................................................................... 800

Lawn Mower ....................................................................................................................................................... 1200

Light Bulb.............................................................................................................................................................100

Oil Burner on Furnace ..........................................................................................................................................300

Oil Fired Space Heater (140,000 BTU)..................................................................................................................400

Oil Fired Space Heater (85,000 BTU)....................................................................................................................225

Oil Fired Space Heater (30,000 BTU)....................................................................................................................150

Paint Sprayer , Airless (1/3 hp)** ........................................................................................................................... 600

Paint Sprayer , Airless (handheld).......................................................................................................................... 150

Radio ..........................................................................................................................................................50 to 200

Submersible Pump (1-1/2 hp)** .......................................................................................................................... 2800

Submersible Pump (1 hp)** ................................................................................................................................ 2000

Submersible Pump (1/2 hp)** ............................................................................................................................. 1500

Sump Pump** ......................................................................................................................................... 800 to 1050

T able Saw (10”)**................................................................................................................................... 1750 to 2000

Weed Trimmer ..................................................................................................................................................... 500

**Allow three times the listed watts for starting these devices.

USE OF EXTENSION CORDS

Long extension cords used to connect devices to the generator result in a loss of voltage. The longer the extension

cord, the greater the voltage loss. Refer to the chart on page 12 to help select proper cable size when using extension cords.

Damaged extension cords can cause electrical shock, resulting in serious injury or death.

• DO NOT use split, frayed or worn cords.

• AL WA YS replace damaged cords immediately.

WARNING

11

Page 12

EXTENSION CORD SELECTION CHART

CURRENT

(AMPS)

5

10

15

20

Keep extension cords as short as possible, preferably less than 15 feet long, to prevent voltage drop and possible

overheating of wires. Use only high quality , well-insulated, three-wire, grounded cord sets to connect equipment to

the generator.

LOAD IN

WATTS

600

1200

1800

2400

VOLTS

120

240

120

240

120

240

120

240

MAXIMUM CABLE LENGTH (FT)

#10 #12 #14 #16

225

115

75

57

140

455

70

225

47

151

36

110

285

140

95

70

90

180

45

90

30

60

-

-

60

120

-

-

-

-

-

-

OPERATING THE GENERATOR

Before operating the generator, the engine oil level will need to be checked and gasoline will need to be added to the

unit.

ADDING ENGINE OIL

1. Place the generator on a firm, level surface.

2. Remove the oil fill cap/dipstick. Clean the area

around the oil fill cap and wipe the dipstick

clean.

3. Insert the dipstick in oil filler neck. Do not thread

into filler neck. Remove the dipstick, and check

the oil level.

3. If oil is needed, carefully add oil to the bottom of

the oil filler neck, below the threads. While

filling, stop to check oil level. DO NOT overfill.

4. Insert oil fill cap/dipstick and secure tightly.

5. Check engine oil level before each use of the generator.

UPPER

LIMIT

LOWER

LIMIT

ADDING GASOLINE

1. Remove the gasoline cap.

2. Carefully fill the fuel tank with UNLEADED gasoline. DO NOT use premium gasoline. DO NOT overfill. Allow

approximately 1/2” tank space for fuel expansion.

WARNING

DO NOT fill fuel tank near an open flame, while smoking, or while engine is running. DO NOT fill tank

in an enclosed area with poor ventilation, doing so may result in serious personal injury or death.

3. Tighten gasoline cap after filling the fuel tank.

12

Page 13

STARTING THE ENGINE

WARNING

Never start or stop engine with electrical devices plugged into the receptacles OR with

devices turned on, doing so may result in property damage, serious personal injury, or death.

1. Unplug all electrical loads from the unit’s receptacles before starting the engine.

2. Make sure the generator is on a firm, level surface, away from any overhangs, open windows, vents or doors.

3. Check the fuel and engine oil levels.

4. Turn the main circuit breaker off.

5. Open the fuel shut-off valve.

6. Turn the engine start switch on.

7. If the engine is cold or has not been run recently , locate the choke lever , just above the air cleaner housing on

the left side of the generator . Pull the choke lever toward you to engage.

8. On recoil start engines, grasp the t-handle of the pull rope and pull the rope in a rapid, steady motion to start

the engine. On electric start models, push the engine start push-button located on the control panel to start the

engine.

9. If the choke was used, allow the engine to run with it on for a few moments before pushing the lever back in.

POWERING THE LOADS

CAUTION

Never connect any equipment in need of repair to the generator. DO NOT use extension cords that

are worn, cut or damaged. Doing so may result in property damage or personal injury.

1. Connect any equipment directly to the generator outlets or extension cords. For the 120/240V NEMA L4-30A

outlet, select the proper output voltage for the outlet and the equipment that will be connected to it.

NOTICE

DO NOT connect 240 volt loads to 120 volt receptacles. DO NOT connect 3-phase loads or 50 Hz loads

to the generator, doing so may result in equipment damage and property damage.

2. Switch the main circuit breaker on. The equipment connected to the generator is now ready to use.

3. If the main circuit breaker is overloaded, it will “trip” or switch off. V erify that the loads connected to the

generator are within the generator’s output range. Refer to the unit specifications on page 7 for maximum and

continuous output watts.

4. Reset the breaker by switching it on. If the breaker trips again, reduce the load to the generator and reset the

circuit breaker.

13

Page 14

STOPPING THE ENGINE

1. Shut off all loads and unplug electrical loads from the control panel receptacles.

CAUTION

NEVER start or stop the engine while electrical devices are plugged in and turned on,

doing so may result in property damage or personal injury.

2. Turn the idle control switch off.

3. Switch the main circuit breaker to the off position.

3. Let the unit run for 3-5 minutes with no load to allow stabilization of the internal temperatures of the engine and

generator.

4. Turn the unit off.

5. Close the fuel shut-off valve.

14

Page 15

MAINTENANCE SCHEDULE

The following maintenance schedule should be followed to ensure proper performance of the unit.

ITEM DAILY

Visual walk around inspection

Check engine oil level

Check air filter

Change engine oil

Clean air filter

Check and adjust spark plug

Clean muffler/spark arrester

Replace spark plug

Check and adjust idle speed

Check and adjust valve clearance

Replace air filter

Clean combustion chamber

Clean fuel tank and filter

Check fuel tube

* After initial break-in, change the engine oil and filter. Oil change interval can then be extended to 100 hours.

DAILY MAINTENANCE CHECKS AND TIPS

20

HRS.

*

50

HRS.

Every 500 hours

Every 1 year

Every 2 years

100

HRS.

300

HRS.

WARNING

DO NOT service the generator unless you have the proper tools and are mechanically proficient.

Improper repairs may result in equipment damage or serious personal injury!

• Check the engine oil level daily before starting engine.

• DO NOT start the generator if the oil level is low! The normal operating level for the engine oil is when oil is

present on the crosshatch pattern of the dipstick. Add oil to the engine if it does not st art or if oil is not

present on the dipstick when tested.

• DO NOT overfill the crankcase.

• Consult the engine OPERA TION AND MAINTENANCE MANUAL for the proper grade of oil, including special operating conditions such as a change in season or climate.

• Service the generator more frequently when used in dusty areas.

LIFTING THE GENERATOR

A large central lifting eye is located on the top of the generator and

the eye is connected to the frame of the unit. Attach a sling or hook

directly to the lifting eye only if the devices are in good condition and

the equipment being used to raise the unit has sufficient capacity .

Approximate weights can be found on page 7. Always remain aware

of others around you when moving or lifting the generator .

15

Page 16

UNIT DECALS

2 3 4 5 1 2 3

1

G

ON

ENGINE SWITCH

OFF

CHECK FUEL

ON

ON

MAIN

MAIN

TURN FUEL

BREAKER

CHECK OIL

BREAKER

ON

WARNING

ADVERTENCIA

AVERTISSEMENT

ON

OFF

ON

MAIN

ENGINE

TURN FUEL

BREAKER

SWITCH

OFF

OFF

OFF

OFF

PN: 26298

Decal, Patent Pending

GFCI TESTING INSTRUCTIONS TEST BEFORE EACH USE!

GROUND FAULT

SENSING MODULE

Normal operating state - sensing device green led is “on”

and circuit breaker is at “on” position.

Step 1: press “test” button. Green led should go “out” and

red led should come “on” and circuit breaker should trigger

P

F

to “off” position.

O

A

W

U

E

L

Step 2: if sensing device led or breaker does not trip or

R

T

change state, “do not use”. Consult an electrician for

assistance.

RESET

RESET

Step 3: press “reset” button. Red led should turn “off” and

green led should turn “on”.

WARNING

TEST BEFORE EACH USE

Step 4: manually reset (switch) circuit breaker to “on”

SEE INSTRUCTIONS

position to restore circuit power.

OFF

GFCI QUE PRUEBA INSTRUCTIONSTEST

ANTES DE QUE CADA ESTADO DE FUNCIONAMIENTO DE USE!

Normal - el dispositivo de detección led verde es "on" y el

interruptor está en "on" position.

Step 1: presione el botón de la "prueba". El led verde debe ir

"fuera de" y el led rojo debe venir "on" y el interruptor debe

accionar a "off" position.

Step 2: si el dispositivo de detección led o el triturador no

dispara ni cambia el estado, "no utilice". Consulte a electricista

para assistance.

Step 3: presione el botón del "reset". El led rojo debe dar vuelta

a "off" y el led verde debe dar vuelta a "on".

Step 4: reajuste manualmente el interruptor (del interruptor) a la

posición de "on" para restaurar energía del circuito.

GFCI EXAMINANT INSTRUCTIONS

TEST AVANT QUE CHAQUE ÉTAT DE FONCTIONNEMENT D'USE!

Normal - le dispositif de sensation led verte est "on" et le

disjoncteur est à "on" position.

Step 1 : appuyez sur le bouton d'"essai". La led verte devrait

aller "hors de" et la led rouge devrait venir "on" et le disjoncteur

devrait déclencher à "off" position.

Step 2 : si le dispositif de sensation led ou le briseur ne se

déclenche pas ou ne change pas l'état, "n'employez pas".

Consultez un électricien pour assistance.

Step 3 : appuyez sur le bouton de "reset". La led rouge devrait

tourner "off" et la led verte devrait tourner "on".

Step 4 : remettez à zéro manuellement le disjoncteur (de

commutateur) dans la position de "on" pour reconstituer la

puissance de circuit.

PN: 26560

Magnum Red Stripe - PG

MPG 3800

PN: 26334

Decal, control panel MPG3800

MPG 3800C

PN: 27084

Decal, control panel MPG3800C

WARNING

ADVERTENCIA

AVERTISSEMENT

PN: 26298

Decal, Patent Pending

Use only in well ventilated area!

Do not use in any enclosed space or near open

doors, windows or ducting. Fumes can cause

death!

¡Cutilice solamente en área bien ventilada!

o utilice en ningún espacio incluido ni cerque a las

puertas abiertas, a windows al ducting.

¡Clos humos pueden causar muerte!

Employez seulement dans le secteur bien aéré!

N'employez dans aucun espace inclus ou ne vous

approchez pas des portes ouvertes, du windows

ou de la canalisation. Les vapeurs peuvent causer

la mort!

Improper connection of generator to a building’s electrical system can allow electrical current from the generator to

backfeed into utility lines. This may result in electrocution of utility workers, fire or explosion. Connections to a

building’s electrical system must be made by a qualified electrician and comply with all applicable laws and

electrical codes.

La conexion incorrecta de un generador al sistema electrico de un edificio puede conducir a un retorno de la

corriente electrica desde el generador al sistema de distribuicion electrico publico. Esto puede conducir a la

electrocucion de los obreros del servicio publico, incendios o explosiones. Solo un tecnico electricista

capacitadopodra efectuar la conexion al sistema electrico del edificio. La conexion electrica a debera cumplir con

las leyes y codigos electricos pertinentes.

Le branchement non conforme du generateur au reseau de distribution electrique d’un immeuble peut provoquer la

reinjection du courant electrique du generateur dans les lignes du reseau public. Ceci peut provoquer une

electrocution des employes du service public, un incendie ou une explosion. Les branchements au reseau

electrique. Immeuble doivent etre effectues par un electricien qualifie et doivent etre conformes a toutes les lois ou

tous les codes electriques applicables.

WARNING

ADVERTENCIA

AVERTISSEMENT

PULL TO

CHOKE

ENGINE

G

Note: All safety and operating decals shown above are located on decal sheet 26332, unless otherwise noted.

16

Page 17

CONTROL PANEL ASSEMBLY

17

1

TO

FRAME

16

13

9

8

7

20

6

15

12

5

20

18

9

14

11

4

19

11

3

10

18

2

ITEM NO. PART NO. QTY DESCRIPTION

1 26213 1 Panel, control - rear housing

2 24986R 1 Panel, control

3 65888 2 Receptacle, 120V/20A duplex-black

4 65878 1 Module, auto idle

5 65487 1 Receptacle, 120V/30A twist (L5-30R)

6 65488 1 Receptacle, 240V/30A twist (L14-30R)

7 65886 1 Module, GFI sensing

8 65941 1 Breaker, 16A, 240V

9 26233 1 Switch, 120V/240V

10 60398 4 Screw, 10-32X.500 pan phil 316 SS

11 60181 4 Screw, M3-0.50X5 pan phil

12 60091 4 Screw, M4-0.70X12 pan phil G4.8

13 60051 4 Nut, M4-.70 nylock G8.8

14 65874 1 Switch, rocker - idle select

15 65873 1 Switch, rocker - on/off

16 19211 1 Tether, cable - 10.50 long

17 60161 7 Nut, .250-20 sflg G5

18 60046 5 Screw, 6-32X.750 pan phil G2

19 60290 5 Nut, 6-32 nylk 18-8 SS

20 60061 4 Nut, 10-32 nylk G5

17

Page 18

FRAME AND FUEL TANK ASSEMBLY

27

19

26

37

17

16

20

15

18

13

21

19

28

29

10

20

22

12

1

23

24

2

22

19

28

6

3

4

5

6

7

6

8

29

33

14

30

27

13

34

36

35

25

11

10

9

31

8

32

27

13

18

Page 19

ITEM NO. PART NO. QTY DESCRIPTION

1 26123 1 Valve, fuel tank

2 26122 1 Gauge, fuel tank

3 28495 1 Cap, fuel tank

4 28494 1 Tank, fuel

5 60393 4 Screw, .250-20X1.000 hx hd

6 60243 9 Washer, flat .250 USS

7 24916B 1 Weldment, frame

8 60144 6 Nut, .250-20 nylock

9 60690 2 Screw, .375-16X1.000 hx hd SS

10 60698 4 Washer, flat .375 SS

11 61120 2 Spacer, shoulder-.375 ID .500 OD .750 SH

12 61088 2 Washer, .500 nylon .750/.062

13 60358 18 Nut, .375-16 nylock

14 26115 1 Assembly, control panel

15 60028 2 Screw, .312-18X1.000 hx hd

16 60271 2 Washer, split lock .312

17 60119 2 Washer, flat .312

18 61142 2 Screw, .500-13X1.500 carriage square

19 60309 6 Washer, flat .500 SAE

20 61152 4 Washer, .500 flat .03TH nylon

21 24920B 1 Bracket, lift eye

22 60307 4 Nut, .500-13 nylock

23 61147 2 Nut, .312-18 U-clip G5 ZY long type

24 60168 1 Screw, .312-18X.750 hx hd G5

25 60095 1 Nut, .312-18 ser flg G5 case hardened

- 50380 .521 ft. Hose, fuel - .250 ID MPG carb certified (not shown)

- 14216 2 Clamp, hose - SAE (.21-.62) miniature (not shown)

OPTIONAL FEATURES:

26 26088B 1 Weldment, lifting handle

27 60328 2 Screw, .500-13X2.500 hx hd G5

28 60205 16 Screw, .375-16X1.000 hx hd G5

29 60386 32 Washer, flat .375

30 26085B 1 Bracket, leg - wheel kit

31 26084B 1 Weldment, bracket - wheel kit

32 60321 2 Pin, cotter - .156X1.75

33 24998 2 Wheel, 10 in.

34 60696 2 Washer, .250 flat .625/.050 SS

35 26274 2 Isolator, rubber

36 61025 2 Screw, .250-20X1.500 hx hd SS

37 26271 2 Fitting, plug-1.000 tapered polyethylene

19

Page 20

ENGINE AND GENERATOR ASSEMBLY

36

35

34

33

32

31

39

37

28

18

TO

FRAME

19

33

MUFFLER

18

18

29

TO

27

25

6

17

19

24

38

39

30

17

3

26

TO

FRAME

20

22

23

17

18

21

24

40

19

8

1

2

2

1

3

4

5

9

2

7

1

10

TO

FRAME

2

3

11

12

14

13

15

16

20

Page 21

ITEM NO. PART NO. QTY DESCRIPTION

1 60028 8 Screw, .312-18X1.000 hx hd

2 60271 10 Washer, split lock .312

3 61147 8 Nut, .312-18 U-clip G5 ZY long type

4 24922R 1 Muffler guard front

5 24954 1 Muffler

6 60119 2 Washer, .312 flat .875/.070

7 60080 2 Nut, M20-2.50 hex G10.9

8 60358 2 Nut, .375-16 nylock G5

9 26114BH 1 Bracket, muffler

10 60168 2 Screw, .312-18X.750 hx hd

11 61131 4 Screw, M6 X 120

12 26416 1 Cover, rear - gen end

13 26463 1 Coupler assembly

14 26417 1 Brush holder assembly, generator

15 26418 1 Diode assembly

16 26419 1 Voltage regulator assembly

17 60140 4 Nut, .375-16 hx

18 60206 8 Washer, split lock .375

19 60386 6 Washer, flat .375

20 15241 1 Compression mount

21 60309 1 Washer, flat .500 SAE

22 60276 1 Washer, split lock .500

23 60275 1 Screw, .500-13X1.000 hx hd

24 60478 2 Screw, .375-16X2.000 hx hd G5

25 24923B 1 Bracket, mount

26 60205 2 Screw, .375-16X1.000 hx hd

27 - Terminal, ground

28 12927 1 Nut, .375-16 wing 316 SS

29 60352 4 Screw, .375-16X1.250 hx hd

30 28492 1 Generator (MPG3800)

27083 1 Generator (MPG3800C)

31 26411 1 Housing, front

32 60972 2 Screw, .312-18X1.500 hx hd

33 60020 6 Nut, M8 ser flg lock

34 28483 2 Isolator, engine

35 60095 2 Nut, .312-18 ser flg

36 28482 1 Engine, 8 hp

37 24956BH 1 Weldment, muffler pipe

38 24921B 1 Weldment, muffler guard rear

39 24988 2 Honda, gasket - exhaust GX240-390

40 61134 1 Screw, rotor 170mm

- 26601 1 Honda, air cleaner element ( not shown)

- 26602 1 Honda, air cleaner seal (not shown)

- 26603 1 Honda, solenoid valve assembly (not shown)

- 26604 1 Honda, carb gasket set (not shown)

- 26605 1 Honda, spark plug (not shown)

- 26606 1 Honda, starter return spring (not shown)

- 26607 1 Honda, recoil starter rope (not shown)

21

Page 22

AC WIRING DIAGRAM

GRN/YEL

BLU

GRN

PRINT

SEE DC

RD/WT

BLK

WHT/BLK

RED

WHT

BLK

BLU

WIRES MUST BE TWISTED

TOGETHER GOING THRU CT

BLU

BLU

BLK

BLK

RED

RED

WHT

WHT

WHT

BLK

YEL

1

(Y)

2

(R)

3

(B)

4

(G)

WHT

WHT

W

120

RECP #2

120

RECP #1

X

RED

WHT

W

X

X

X

120

TWIST

TWIST

120/240

Y

BLK

W

X

RED

BLK

WHT

W

G

BLK

RED

WHT

WHT

WHT

RED

Y

G

GRN/YEL

BLK

BLK

BLK

LINE

LOAD

COM

N/O

13

ORN

YEL

RED

24

BLK

BLK

BLK

RED

2,6,10,14

120 ONLY

BLK

WHT

BLU

BLK

8

4

3

7

2

6

BLK

BLU

BLU

3,7,11,15

COMMONS

BLK

12

11

10

16

15

14

120/240

4,8,12,16

RD/WT

GRN

BLU

22

Page 23

DC WIRING DIAGRAM

STARTER

+ -

GENERATOR

OIL ALERT

CHARGE COIL

UNIT

WHT/BLK

BLK

RECTIFIER

ORN

BLU

RED

GRN

START SWITCH

IDLE/RUN MODULE

OIL LEVEL SWITCH

COIL

SHUTDOWN

SOLENOID

IDLE/RUN

SOLENOID

GRY

ORN

RED

GRN

GRY

BLK

1

2

IDLE/RUN SWITCH

WHT/BLK

3

4

1

2

ON/OFF SWITCH

23

Page 24

REV: B

P ART NO: 26126

02.04.09

Loading...

Loading...