Page 1

MLT 4250

OPERATING/PARTS MANUAL

Page 2

INTRODUCTION

This manual provides information and procedures to safely operate and maintain the light tower and generator . For

your own safety and protection from physical injury , carefully read, understand, and observe the safety instructions

described in this manual. The information contained in this manual was based on machines in production at the

time of publication. Magnum Products LLC reserves the right to change any portion of this information without

notice.

DO NOT MODIFY or use this equipment for any application other than which it was designed for .

Magnum Products LLC recommends that a trained and licensed professional perform all electrical wiring and testing

functions. Any wiring should be in compliance with the United S tates National Electric Code (NEC), st ate and local

codes and Occupational Safety and Health Association (OSHA) guidelines.

Keep a copy of this manual with the unit at all times. Additional copies are available from Magnum Products LLC, or

can be found at www.m-p-llc.com. An engine operators manual was also supplied with the unit at the time of

shipment from the factory . The manual provides detailed operation and maintenance procedures for the engine.

Additional copies of the engine operators manual are available from the engine manufacturer.

MAGNUM PRODUCTS LLC

215 Power Drive • Berlin, WI 54923

U.S.A.

Phone: 920-361-4442

Fax: 920-361-4416

Toll Free: 1-800-926-9768

www.m-p-llc.com

For technical or parts QUESTIONS, please contact Magnum Products’ Customer Support or

Technical Support team at 920-361-4442. Please have your serial number available.

T o ORDER SER VICE PARTS, please contact the dealer from which your purchased the unit,

or call Magnum Products to locate a dealer in your area.

Engine Make:

Engine Serial Number:

Engine Model Number:

Generator Make:

Generator Model Number:

Generator Serial Number:

Unit Model Number:

Unit Serial Number:

Diesel engine exhaust and some of its constituents are known to the state

of California to cause cancer, birth defects and other reproductive harm.

2

WARNING

CALIFORNIA PROPOSITION 65 W ARNING:

Page 3

TABLE OF CONTENTS

INTRODUCTION .................................................................................................................2

T ABLE OF CONTENTS ......................................................................................................3

SAFETY NOTES................................................................................................................4

OPERA TING SAFETY........................................................................................................4

ENGINE SAFETY ..............................................................................................................5

SERVICE SAFETY ............................................................................................................5

TOWING SAFETY..............................................................................................................6

REPORTING TRAILER SAFETY DEFECTS .......................................................................6

UNIT SERIAL NUMBER LOCA TIONS.................................................................................6

SAFETY SYMBOL SUMMARY..........................................................................................7

SPECIFICA TIONS ........................................................................................................ 8 - 9

EXTERIOR LOCA TIONS ...................................................................................................10

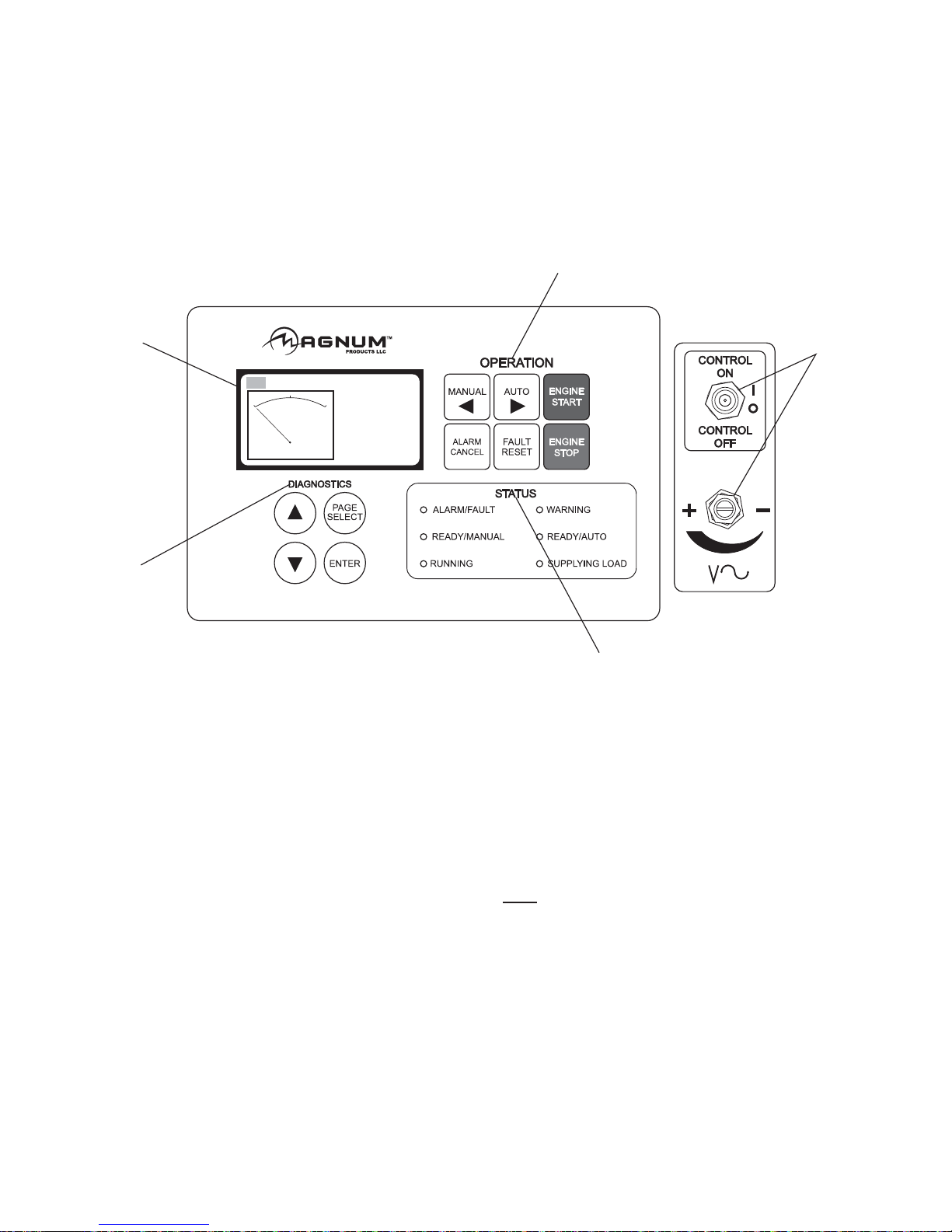

MAIN CONTROL P ANEL COMPONENTS ........................................................................11

MAGNUM DIGIT AL CONTROLLER (MDC)................................................................ 12 - 13

GENERA TOR MONITORING ............................................................................................13

ENGINE MONITORING ............................................................................................ 14 - 15

FINE VOL TAGE ADJUSTMENT ....................................................................................... 15

MDC CONTROLLER INFORMA TION DISPLAYS, FUNCTIONS AND RESET....................16

MDC CONTROLLER - GENERA TOR OPERA TIONAL ST A TUS.........................................16

MDC CONTROLLER - ALARM MANAGEMENT ...............................................................16

MDC CONTROLLER LIST OF POSSIBLE ALARMS WITH DESCRIPTIONS..............17 - 18

MDC CONTROLLER - HISTORY ......................................................................................18

ADJUSTING THE DISPLAY BACKLIGHTING ....................................................................19

RESETTING THE “TIME TO SERVICE” REMINDER.........................................................19

GENERAT OR OUTPUT CONNECTION LUGS ..................................................................20

VOL TAGE SELECT OR SWITCH ...................................................................................... 21

AUXILIARY OUTLETS ......................................................................................................22

VOL TAGE REGULA TION..................................................................................................22

EMERGENCY STOP SWITCH ........................................................................................ 22

MAIN CIRCUIT BREAKER................................................................................................23

REMOTE ST ART TERMINAL BLOCK...............................................................................23

TRANSFER SWITCH ................................................................................................23 - 24

LIGHT TOWER SET-UP ...................................................................................................25

RAISING THE TOWER.....................................................................................................26

RAISING THE TOWER WITH OPTIONAL ELECTRIC WINCH...........................................27

LIGHT TOWER ST ART UP ...............................................................................................28

PRE-ST ART CHECKLIST .................................................................................................28

MANUAL ST ARTING OF THE GENERA T OR .............................................................28 - 30

AUTO (REMOTE) ST ARTING OF THE GENERA TOR .......................................................30

LIGHT OPERA TION..........................................................................................................31

SHUTTING DOWN THE GENERA TOR .............................................................................31

LOWERING THE TOWER ................................................................................................32

LOWERING THE TOWER WITH OPTIONAL ELECTRIC WINCH...................................... 32

REMOVING THE LIGHTS FOR TRANSPOR TA TION.........................................................33

TOWING THE TRAILER ...................................................................................................33

TRAILER WHEEL BEARINGS .........................................................................................33

LIFTING THE TRAILER..................................................................................................... 34

GENERAL MAINTENANCE..............................................................................................34

ENGINE MAINTENANCE .................................................................................................35

OPTIONAL LOWER RADIA TOR HOSE HEA TER USE AND MAINTENANCE ...................35

DERA TING FOR AL TITUDE ..............................................................................................36

TROUBLESHOOTING SHUTDOWN CONDITIONS ...........................................................36

TROUBLESHOOTING THE LIGHTS .................................................................................37

UNIT DECALS...........................................................................................................38 - 41

MANUAL WINCH MAST ASSEMBL Y........................................................................42 - 43

ELECTRIC WINCH MAST ASSEMBLY...................................................................... 44 - 45

FRAME AND COMPONENTS ...................................................................................46 - 48

GENERA TOR ASSEMBLY ...............................................................................................49

MAST JUNCTION BOX ASSEMBL Y - HARD WIRED LIGHTS...........................................50

MAST JUNCTION BOX ASSEMBL Y - QUICK DISCONNECT LIGHTS...............................51

ENCLOSURE ASSEMBL Y ........................................................................................52 - 53

AUXILIARY OUTLET P ANEL ASSEMBL Y..................................................................54 - 55

AUXILIARY OUTLET P ANEL OPTIONS.....................................................................56 - 57

LIGHT ASSEMBL Y ....................................................................................................58 - 59

ENGINE COOLING ASSEMBL Y................................................................................60 - 61

ENGINE ASSEMBL Y ................................................................................................ 62 - 63

CONTROL P ANEL ASSEMBL Y.................................................................................64 - 65

CONTROL BOX ASSEMBL Y .....................................................................................66 - 67

LUG DOOR ASSEMBL Y ..................................................................................................68

WIRING DIAGRAMS .................................................................................................69 - 75

Page

3

Page 4

SAFETY NOTES

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

This manual contains DANGERS, WARNINGS, CAUTIONS, NOTICES and NOTES which must be

followed to prevent the possibility of improper service, damage to the equipment, personal injury or death.

The following formatting options will apply when calling the readers attention to the DANGERS, WARNINGS, CAUTIONS, NOTICES and NOTES.

Indicates a hazardous situation which, if not avoided, may result in minor or moderate injury.

DANGER

INDICATES A HAZARDOUS SITUATION WHICH, IF NOT AVOIDED,

WILL RESULT IN DEATH OR SERIOUS INJURY.

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

NOTICE

Indicates a hazardous situation which, if not avoided,

may result in property or equipment damage.

Note: Notes contain additional information important to a procedure and will be found within the regular

text body of this manual.

OPERATING SAFETY

Before using the light tower be sure you read and understand all of the instructions! This equipment was

designed for specific applications; DO NOT modify or use this equipment for any application other than which

it was designed for. Equipment operated improperly or by untrained personnel can be dangerous! Read the

operating instructions and familiarize yourself with the location and proper use of all instruments and controls.

Inexperienced operators should receive instruction from someone familiar with the equipment before being

allowed to operate or set up the light tower. The following points should be practiced at all times:

• The area immediately surrounding the light tower should be dry, clean, and free of debris.

• Position and operate the light tower on a firm, level surface.

• NEVER start a unit in need of repair.

• Lower tower when not in use, or if high winds or electrical storms are expected in the area.

• Make certain light tower is well grounded and securely fastened to a good earthen ground.

• The tower extends up to 30 ft. (9m). Make sure area above trailer is open and clear of overhead wires

and obstructions.

• Bulbs become extremely hot in use! Allow bulb and light fixture to cool 10-15 minutes before handling.

• Keep area behind trailer clear of people while raising and lowering mast!

• NEVER raise, lower or turn mast while unit is operating!

• Trailer must be leveled and outriggers extended before raising tower. Outriggers must remain ex-

tended while tower is up.

• If for any reason any part of mast hangs up or winch cable develops slack while raising or lowering

tower, STOP immediately! Contact an authorized service representative.

• NEVER remove safety pin or pull mast locking pin while tower is up!

• NEVER use tower if insulation on electrical cord is cut or worn through.

• NEVER operate lights without protective lens cover in place or with a lens cover that is cracked or

damaged!

4

Page 5

ENGINE SAFETY

Internal combustion engines present special hazards during operation and fueling! Failure to follow the

safety guidelines described below could result in severe injury or death. Also read and follow all safety

warnings described in the Engine Operator's Manual. A copy of this manual was supplied with unit when

it was shipped from the factory.

• DO NOT run engine indoors or in an area with poor ventilation unless exhaust hoses are used. Diesel

engine exhaust contains carbon monoxide, a deadly, odorless and colorless gas which, if inhaled,

can cause nausea, fainting or death. Make sure engine exhaust cannot seep into closed rooms or

ventilation equipment.

• DO NOT fill fuel tank near an open flame, while smoking, or while engine is running. DO NOT fill tank

in an enclosed area with poor ventilation.

• DO NOT operate with the fuel tank cap loose or missing.

• DO NOT touch or lean against hot exhaust pipes or engine cylinders.

• DO NOT clean air filter with gasoline or other types of low flash point solvents.

• DO NOT remove engine coolant cap while engine is hot.

• DO NOT operate the unit without a functional exhaust system. Prolonged exposure to sound levels in

excess of 85 DBA can cause permanent hearing loss. Wear hearing protection when working around

a running engine.

• Keep area around exhaust pipes and air ducts free of debris to reduce the chance of an accidental

fire.

• Batteries contain sulfuric acid which can cause severe injury or death. Sulfuric acid can cause eye

damage, burn flesh or eat holes in clothing. Protective eye wear and clothing are necessary when

working on or around the battery. Always disconnect the NEGATIVE (-) battery cable from the

corresponding terminal before performing any service on the engine or other components.

• Shut the engine down if any of the following conditions exist during operation:

1. Noticeable change in engine speed.

2. Loss of electrical output.

3. Equipment connected to the generator overheats.

4. Sp arking occurs.

5. Engine misfires or there is excessive engine/generator vibration.

6. Operating on a combustible surface.

7. Protective covers are loose or missing.

8. If the ambient air temperature is above 1 10° F .

SERVICE SAFETY

This unit uses high voltage circuits capable of causing serious injury or death. Only a qualified electrician

should troubleshoot or repair electrical problems occurring in this equipment.

• Before servicing light tower, make sure the engine start switch is turned to OFF, circuit breakers are

open (off) and the negative terminal on the battery is disconnected. NEVER perform even routine

service (oil/filter changes, cleaning, etc.) unless all electrical components are shut down.

• NEVER allow water to accumulate around the base of the light tower. If water is present, DO NOT

service!

• NEVER service electrical components if clothing or skin is wet. If the unit is stored outside, check

the engine and generator for any moisture and dry the unit before use.

• NEVER wash the unit with a power washer or high pressure hose.

• Open main circuit breaker before disconnecting battery cables.

• Keep hands, feet, and loose clothing away from moving parts on generator and engine.

• Make sure slings, chains, hooks, ramps, jacks, and other types of lifting devices are attached

securely and have enough weight-bearing capacity to lift or hold the equipment safely. Always

remain aware of the position of other people around you when lifting the equipment.

5

Page 6

TOWING SAFETY

Towing a trailer requires care! Both the trailer and vehicle must be in good condition and securely fastened to each other to reduce the possibility of an accident. Also, some states require that large trailers

be registered and licensed. Contact your local Department of Transportation office to check on license

requirements for your particular unit.

• Check that the hitch and coupling on the towing vehicle are rated equal to, or greater than, the trailer's

"gross vehicle weight rating" (GVWR).

• Check tires on trailer for tread wear, inflation, and condition.

• Inspect the hitch and coupling for wear or damage. DO NOT tow trailer using defective parts!

• Make sure the trailer hitch and the coupling are compatible. Make sure the coupling is securely

fastened to the vehicle.

• Connect safety chains in a crossing pattern under the tongue and attach the breakaway cable TO

THE REAR BUMPER OF THE TOWING VEHICLE. Do not attach the cable to the trailer hitch.

• Make sure directional and brake lights on the trailer are connected and working properly.

• Check that all lug nuts holding wheels on are tight and that none are missing.

• Maximum recommended speed for highway towing is 45 m.p.h. Recommended off-road towing speed

is not to exceed 10 m.p.h. or less depending on terrain.

When towing, maintain extra space between vehicles and avoid soft shoulders, curbs and sudden lane

changes. If you have not pulled a trailer before, practice turning, stopping, and backing up in an area

away from heavy traffic.

A film of grease on the coupler will extend coupler life and eliminate squeaking. Wipe the coupler clean

and apply fresh grease each time the trailer is towed.

REPORTING TRAILER SAFETY DEFECTS

If you believe your trailer has a defect which could cause a crash or could cause injury or death, you should immediately inform the National Highway Traf fic Safety Administration (NHTSA) in addition to notifying Magnum Product s

LLC. If NHTSA receives similar complaints, it may open an investigation; and if it finds that a safety defect exists in

a group of vehicles, it may order a recall and remedy campaign. However, NHTSA cannot become involved in

individual problem between you, your dealer, or Magnum Product s LLC.

T o contact NHTSA, you may either call the Auto Safety Hotline toll-free at 1-888-327-4236 or by fax at: (202)-366-

7882. Additional contact information can be found at: www .nhtsa.dot.gov .

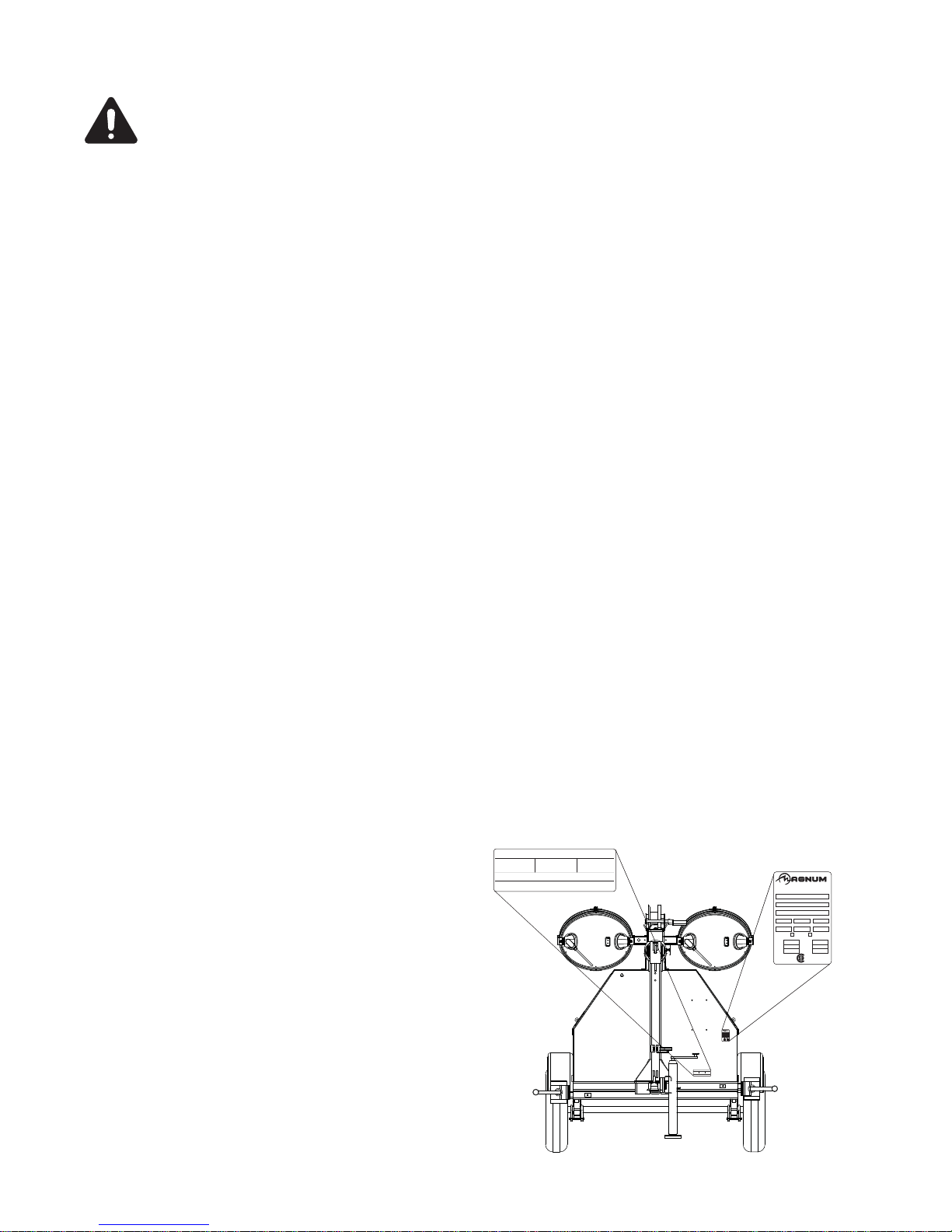

UNIT SERIAL NUMBER LOCATIONS

Refer to the locations illustrated below to find the unit ID

tag, and trailer ID tag on your unit. Important information,

such as the unit serial number, model number and

Vehicle Identification Number (V.I.N.) for your trailer are

found on these tags. Record the information from these

tags, so it is available if the tags are lost or damaged.

When ordering parts or requesting technical service

information, you may be asked to specify this information.

V.I.N. Tag

MANUFACTURED BY/FABRIQUE PAR:

GVWR/PNBV:

GAWR/PNBE TIRE/PNEU RIM/JANTE

THIS VIEHICLE CONFORS TO ALL APPLICABLE STANDARDS PRESCRIBED UNDER THE CANADIAN MOTOR VIEHICLE SAFETY REGULATIONS

IN ECCEFT ON THE DATE OF MANUFACTURE. / CE VEHICULE EST CONFORME A TOUTES LES NORMES QUI LUI SONT APPLICABLES EN

VERTU DU REGLEMENT SUR LA VEHICULES DES AUTOMOBILES DU CANADA EN VIGUEUR A LA DATE SA FABRICATION.

THIS VIEHICLE CONFORMS TO ALL APPLICABLE U.S. FEDERAL MOTOR VEHICLE SAFETY STANDARDS (FMVSS) IN EFFECT ON THE DATE OF

MANUFACTURE SHOWN ABOVE.

V.I.N./N.I.V.: TYPE/TYPE DE VEHICULE:

DATE OF MFG:

COLD INFL. PRESS./PRESS.

DE GONF A FROID

KPA(PSI/LPC)

SGL/DUAL

Located on inside

TM

MADE IN USA

PRODUCTS LLC

215 Power Drive

Berlin, WI 54923

1-800-926-9768

Model

Serial Number

Mfg. Code

kg

lbs

rpm hz amb. temp.

RATING: CONT. STAND BY

1 Phase

3 Phase

KW

KVA

V

V

A

A

FOR ELECTRICAL

EQUIPMENT ONLY.

®

POUR MATERIAL

LR 114630-1

ELECTRIQUE SEULEMENT.

Unit ID Tag

of panel.

TM

MADE IN USA

PRODUCTS LLC

215 Power Drive

Berlin, WI 54923

1-800-926-9768

Model

Serial Number

Mfg. Code

kg

lbs

rpm hz amb. temp.

RATING: CONT. STAND BY

1 Phase

3 Phase

KW

KVA

V

V

A

A

FOR ELECTRICAL

EQUIPMENT ONLY.

®

POUR MATERIAL

LR 114630-1

ELECTRIQUE SEULEMENT.

6

MANUFACTURED BY/FABRIQUE PAR:

GVWR/PNBV:

GAWR/PNBE TIRE/PNEU RIM/JANTE

THIS VIEHICLE CONFORS TO ALL APPLICABLE STANDARDS PRESCRIBED UNDER THE CANADIAN MOTOR VIEHICLE SAFETY REGULATIONS

IN ECCEFT ON THE DATE OF MANUFACTURE. / CE VEHICULE EST CONFORME A TOUTES LES NORMES QUI LUI SONT APPLICABLES EN

VERTU DU REGLEMENT SUR LA VEHICULES DES AUTOMOBILES DU CANADA EN VIGUEUR A LA DATE SA FABRICATION.

THIS VIEHICLE CONFORMS TO ALL APPLICABLE U.S. FEDERAL MOTOR VEHICLE SAFETY STANDARDS (FMVSS) IN EFFECT ON THE DATE OF

MANUFACTURE SHOWN ABOVE.

V.I.N./N.I.V.: TYPE/TYPE DE VEHICULE:

DATE OF MFG:

COLD INFL. PRESS./PRESS.

DE GONF A FROID

KPA(PSI/LPC)

SGL/DUAL

Page 7

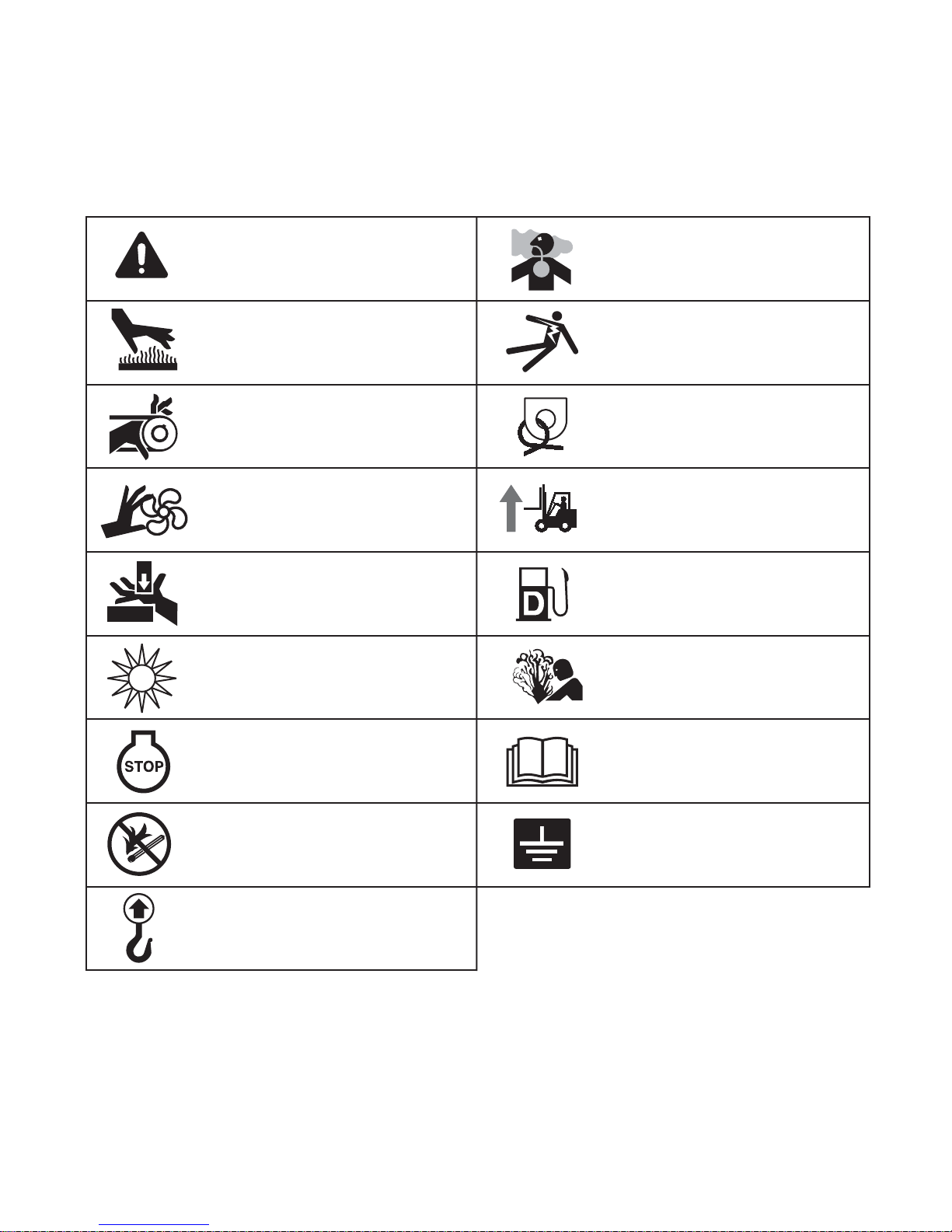

SAFETY SYMBOL SUMMARY

This equipment has been supplied with numerous safety and operating decals. These decals provide important

operating instructions and warn of dangers and hazards. Replace any missing or hard-to-read decals and use care

when washing or cleaning the unit. Decal placement and part numbers can be found in the beginning of the parts

section of this manual. Below is a summary of the intended meanings for the symbols used on the decals.

UV

Safety alert symbol; Used to

alert you to potential personal

injury hazards.

Hot surface(s) nearby.

Belt/entanglement hazard; Keep

body parts clear of this area.

Fan hazard; Keep body parts

clear of this area.

Crush hazard; Keep body parts

clear of this area.

Ultraviolet radiation hazard;

Operate only with lens intact.

Asphyxiation hazard; Operate

in well ventilated area.

Dangerous voltage may be

present.

Anchor/tie down point.

Forklift here only.

Use clean diesel fuel only.

Burn/scald hazard;

pressurized steam.

Stop engine before fueling.

Fire/explosion hazard; Keep

open flames away from unit.

Lift here only.

Read and understand the

supplied operator’s manual

before operating unit.

Unit electrical ground.

7

Page 8

SPECIFICATIONS

Read this manual carefully before attempting to use this light tower. The potential for property damage, personal

injury or death exists if this equipment is misused or installed incorrectly. Read all of the manuals included with this

unit. Each manual details specific information regarding items such as set up, use and service requirements.

Specifications are subject to change without notice.

MAGNUM MODEL MLT 4250

Engine

Make/Brand ........................................................ Isuzu

Model.................................................................. 4LE1-NYGV-01

Type.................................................................... Diesel, liquid cooled, 4-stroke

Horsepower - prime hp (kW) ............................... 31.5 (23.5)

Horsepower - standby hp (kW) ........................... 34.5 (25.7)

Operating Speed rpm ......................................... 1800

Displacement in3 (L) ........................................... 134.25 (2.20)

Cylinders - qty .................................................... 4

Fuel Consumption - 100% prime gph (Lph) ....... 1.80 (6.81)

Battery Type - Group Number ............................. 2 4

Battery Voltage (Quantity per Unit) ..................... 12V (1)

Battery Rating..................................................... 720 CCA

Generator

Make/Brand ........................................................ Marathon Electric

Model.................................................................. 282NSL1505

Type, Insulation ................................................... Brushless, H

Generator Set (Engine/Generator)

3Ø - Standby kW (kV A) ...................................... 20 (25)

Amps - 3Ø St andby - 480 (208V) A..................... 30 (69)

3Ø - Prime kW (kV A).......................................... 18 (23)

Amps - 3Ø Prime - 480 (208V) A ........................ 28 (64)

1Ø - Standby - kW (kVA) .................................... 16.0 (16.0)

Amps - 1Ø St andby - 240V A.............................. 67

1Ø - Prime - kW (kV A)........................................ 15.0 (15.0)

Amps - 1Ø Prime - 240V A ................................. 63

Frequency Hz ..................................................... 60

Power Factor ...................................................... 1 (1Ø), 0.8 (3Ø)

Dimensions

Length w/ mast stowed in (m) ............................ 170 (4.32)

Width in (m) ....................................................... 63 (1.60)

Width w/ outriggers extended in (m) ................... 140 (3.56)

Height w/ mast stowed in (m)............................. 70 (1.78)

Maximum height of tower ft (m) .......................... 30 (9.14)

Weights

Dry Weight lbs (kg)............................................. 2158 (979)

Operating Weight lbs (kg) ................................... 2556 (1159)

Capacities

Fuel T ank V olume gal (L) ................................... 56 (212)

Usable Fuel Volume gal (L)................................ 56 (212)

Coolant (incl. engine) qt (L)................................. 11.6 (11.0)

Oil (incl. filter) qt (L)............................................ 8.6 (8.1)

Maximum Run Time hrs...................................... 31

8

Page 9

SPECIFICATIONS

Read this manual carefully before attempting to use this light tower. The potential for property damage, personal

injury or death exists if this equipment is misused or installed incorrectly. Read all of the manuals included with this

unit. Each manual details specific information regarding items such as set up, use and service requirements.

Specifications are subject to change without notice.

Lighting

Lighting Type....................................................... Metal Halide

Ballast Type........................................................ Coil & Core

Lumens ............................................................... 440,000

Coverage acres (m2)........................................... 5 - 7 (20,234 - 28,328)

AC Distribution

Circuit Breaker Size............................................ 90

Volt age Selection................................................ 3 Position Switch (lockable)

Volt age Regulation .............................................. +/-1%

Volt ages Available 1Ø ......................................... 120, 139, 208, 220, 240, 277

Volt ages Available 3Ø ......................................... 208, 220, 440, 480

Trailer

Number of Axles ................................................. 1

Capacity - Axle Rating lbs (kg) ........................... 3000 (1361)

Tire Size in ......................................................... 15

Hitch - Standard.................................................. 2" Ball

Maximum Tire Pressure psi ................................ 50

9

Page 10

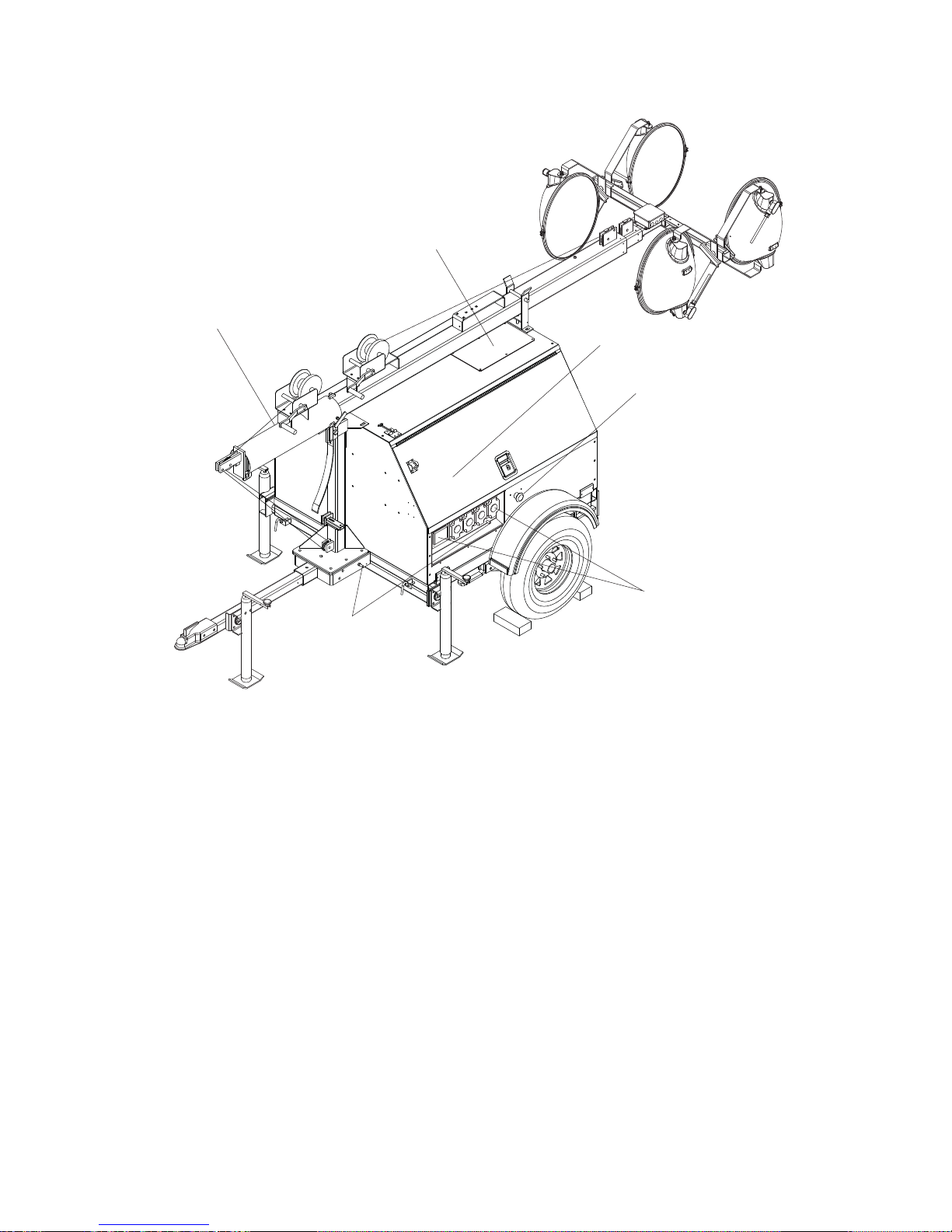

EXTERIOR LOCATIONS

1

2

3

4

5

6

1. FUEL FILLER LOCA TION (under door): Use clean DIESEL FUEL ONL Y .

2. RADIA T OR ACCESS P ANEL: Remove this panel for engine coolant service.

3. CONTROL P ANEL LOCA TION (under door): Engine/generator controls and all circuit breakers.

4. EMERGENCY STOP SWITCH: For emergency shut down; stops engine and trips main circuit breaker .

5. EQUIPMENT OUTLETS: Circuit breaker protected outlets; 20, 30 and/or 50 amp ratings.

6. GROUND STUDS (2): For grounding generator and equipment connected to the equipment outlets.

10

Page 11

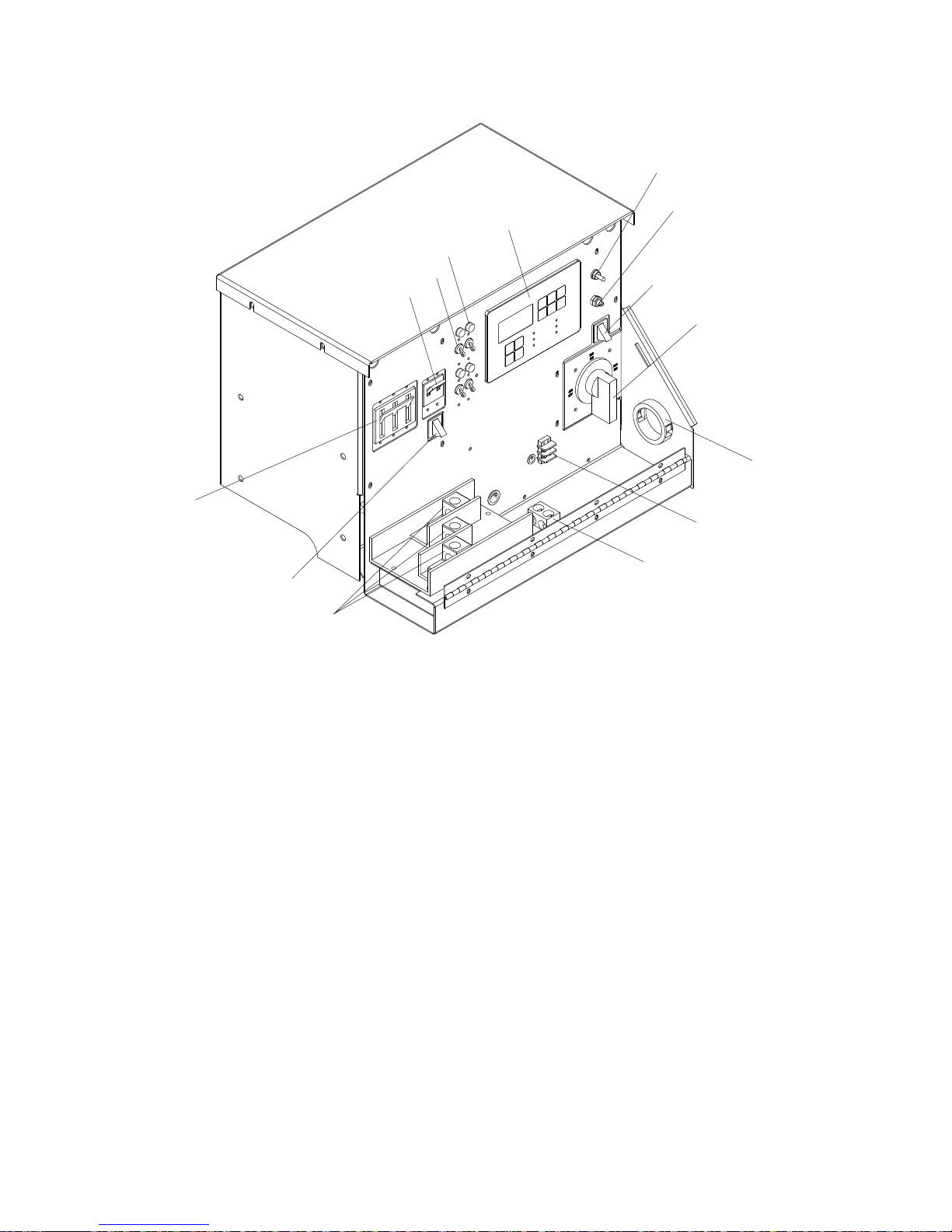

MAIN CONTROL PANEL COMPONENTS

13

1

12

9

8

10

11

2

7

6

5

4

2

3

1. MAIN CIRCUIT BREAKER (90A): This breaker will disconnect power to the connection lugs.

2. LUG DOOR SAFETY SWITCHES: These switches will shut the generator down if the lug door is opened when the

generator is running.

3. GENERAT OR OUTPUT CONNECTION LUGS: These allow appropriate loads to be wired directly to the generator.

4. GENERAT OR GROUND CONNECTION LUG: This lug is for connecting a good earthen ground per any local, state

or National Electric Code (NEC) guidelines before starting the generator .

5. REMOTE START TERMINAL BLOCK: Allows connections for remote st arting of the generator.

6. CABLE ACCESS: Allows for entry of load cables to the connection lugs with the lug box door closed.

7. PHASE SELECTOR SWITCH: This switch will change the generator output between three phase and single phase

power. See the VOL T AGE SELECT OR SWITCH section for more information.

8. VOLT AGE ADJUSTMENT RHEOSTA T : Used to fine tune generator output voltage.

9. CONTROL POWER SWITCH: This is the main power switch for the controller in MANUAL or AUTO mode.

10. ENGINE CONTROL PANEL: See p ages 12 - 13 for additional information.

11. BALLAST INDICA TOR LIGHTS: Indicates power from the ballast to each light.

12. INDIVIDUAL CIRCUIT BREAKERS: One breaker is supplied for each light.

13. AUXILIARY OUTLET MAIN CIRCUIT BREAKER (100A): This breaker disconnects power to the auxiliary equip-

ment outlets.

11

Page 12

MAGNUM DIGIT AL CONTROLLER (MDC)

The Magnum Digital Controller (MDC) is an enhanced digital generator controller used to start, stop and monitor the

operation of the generator and the engine. The controller constantly monitors vital generator and engine functions

for a number of pre-programmed alarm and fault conditions. When a fault condition occurs, the engine will shut

down automatically and the Liquid Crystal Display (LCD) window will display the fault that caused the shutdown; to

resume operation the fault condition must be resolved. The controller has the ability to provide the display readout

in English and Sp anish; other languages are available. A screen print out of the display screen is also available.

This controller also records a “History” of the unit’s performance which may be viewed at any time and will not be

removed or lost when the controller is powered down.

2

3

MAN AUT

0

kW

Ready

PF 0.00

RPM 0

0

1

4

5

The MDC panel consists of five sections, including: the “CONTROL ON” / “CONTROL OFF” Toggle Switch and Fine

Volt age Adjustment Screw; the “OPERA TION” keyp ad; the LCD window; the “DIAGNOSTICS” keypad; and the

“ST A TUS” Light Emitting Diodes (LED’s). The following is a brief summary of the operation of each section of the

control panel:

1. The “CONTROL ON” / “CONTROL OFF” Toggle Switch and Fine Voltage Adjustment Screw

• Control On/Off T oggle Switch

This toggle switch powers-up the control panel and the controller.

• Fine Volt age Adjustment Screw

This screw may be adjusted to set the generator output voltage after the voltage selector switch has been

changed from one phase to another. This adjustment must be accomplished within 45 seconds of start-up

so that the unit does not experience a shut down alarm for “SENSING”.

2. The “OPERA TION” Keypad

• “ENGINE STAR T” Button

The Power Screen Display must be in the “MAN” mode in the upper left corner of the LCD window and the

“Ready/Manual” LED lit in the “Status” portion of the controller . Press the green “ENGINE ST AR T” button to

start the unit.

• “ENGINE STOP” Button

Press the red “ENGINE STOP” button to shut down the unit and start the “S top V alue” timer.

• “MANUAL W” Button

Press this button to change from the Automatic (Remote) starting mode to Manual st arting mode.

• “AUTO

XX

X” Button

XX

Press this button to change from Manual starting mode to Automatic (remote) st arting mode.

12

Page 13

• “ALARM CANCEL” Button

When an alarm is activated, either visually or audibly , press this button to silence or cancel the alarm.

• “FAUL T RESET” Button

Press this button to clear the fault from the LCD window after the fault has been corrected.

Press “FAUL T RESET” and “ENTER” to clear the John Deere ECU Alarm List Codes.

3. The Liquid Crystal Display (LCD)

• This window will toggle between the Generator Display Screen and the Engine Display Screen upon start-

up of the unit. By viewing these screens, the operator will be able to monitor both the engine and generator

status while the unit is running.

4. The “DIAGNOSTICS” Keypad

•“S” Scroll-Up Button

Press this button to scroll-up within the LCD window.

•“T” Scroll-Down Button

Press this button to scroll-down within the LCD window.

• “P AGE SELECT” Button

Pressing this button will select the next display screen.

• “ENTER” Button

Pressing this button will place you inside the particular display to review the generators preprogrammed

setpoints or parameters.

5. The “ST A TUS” Light Emitting Diodes (LED’ s)

• These 6 LED’s will illuminate to display the current operational status of the generator;

- Alarm/Fault: Indicates active or inactive alarms, but not reset shutdown alarms.

- Warning: Indicates an active or inactive alarm, or a warning alarm that has not been reset

- Ready/Manual: Indicates the controller is ready to start and in the manual mode.

- Ready/Auto: Indicates the unit is in the “AUTO” mode ready for the remote start signal.

- Running: Indicates the unit is running.

- Supplying Load: Indicates a load is being applied to the generator.

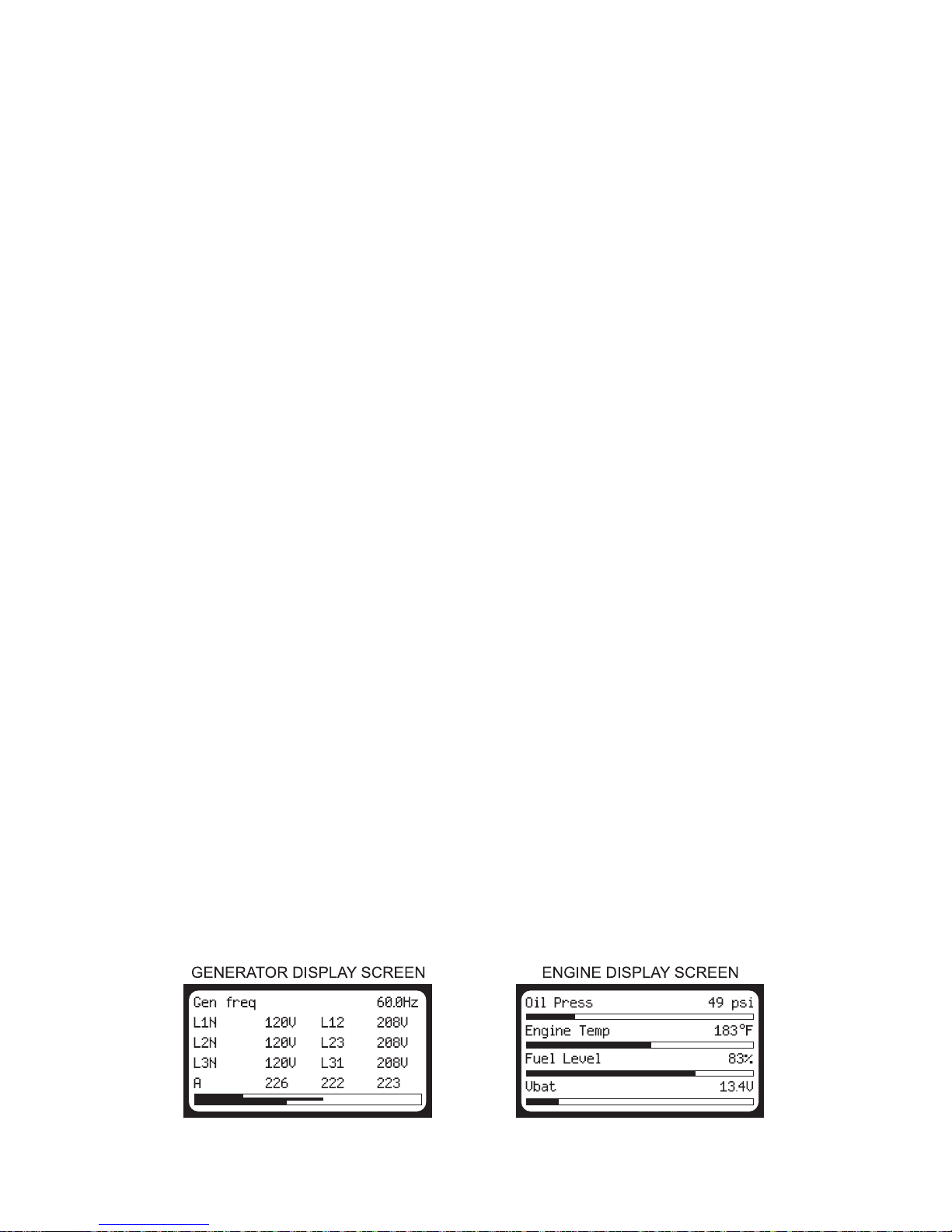

GENERATOR MONITORING

Generator information is shown on the Liquid Crystal Display (LCD) window in a toggling manner with the Engine

information after the first 60 seconds of operation, then every five seconds thereafter . The generator display screen

will show frequency , line to neutral voltage, line to line voltage and amperage.

Note: When loading the generator , it is import ant to observe the amperage to determine the load balance on each

line of the generator. Minor load unbalances, usually 5% or less, will not cause any particular problems. Every

effort should be made to distribute the load equally between all lines.

• Hertz: Displays output frequency .

• Generator Output V olt age: Line to Neutral display, single phase (1Ø).

• Generator Output V olt age: Line to Line display, 3 phase (3Ø).

• Amps: Displays the AC output amperage produced by the generator .

13

Page 14

ENGINE MONITORING

Engine information is shown on the Liquid Crystal Display (LCD) window in a toggling manner with the Generator

information after the first 60 seconds of operation and then every 5 seconds thereafter . The engine display screen

will show oil pressure, engine coolant temperature, fuel level and battery voltage.

• Oil Press: Displays engine oil pressure. The display registers oil pressure between 0-100 psi.

Normal operating pressure is between 35-80 psi.

• Eng T emp: Displays the temperature of the engine’s coolant. If the coolant temperature exceeds the

Maximum Water Temperature of 230° F the engine will automatically shut down. Zero “0”

will be displayed until a minimum temperature of 100° F is reached.

• Fuel Level: Displays the relative fuel level in the fuel tank in percent (50% = 1/2 tank, 75% = 3/4

tank, etc.). If the fuel level drops below a programmed low fuel point – usually at 15%, a

low fuel warning and optional audio alarm will be activated. If the fuel level drops below

the programmed low fuel limit, usually at 5%, the engine will automatically shut down.

(Note: The MLG 25 does not display fuel level).

• Vbat: Displays the engine battery voltage. A normal reading is 13-14V on 12 volt systems and

24-26 on 24 volt systems, (with the engine running).

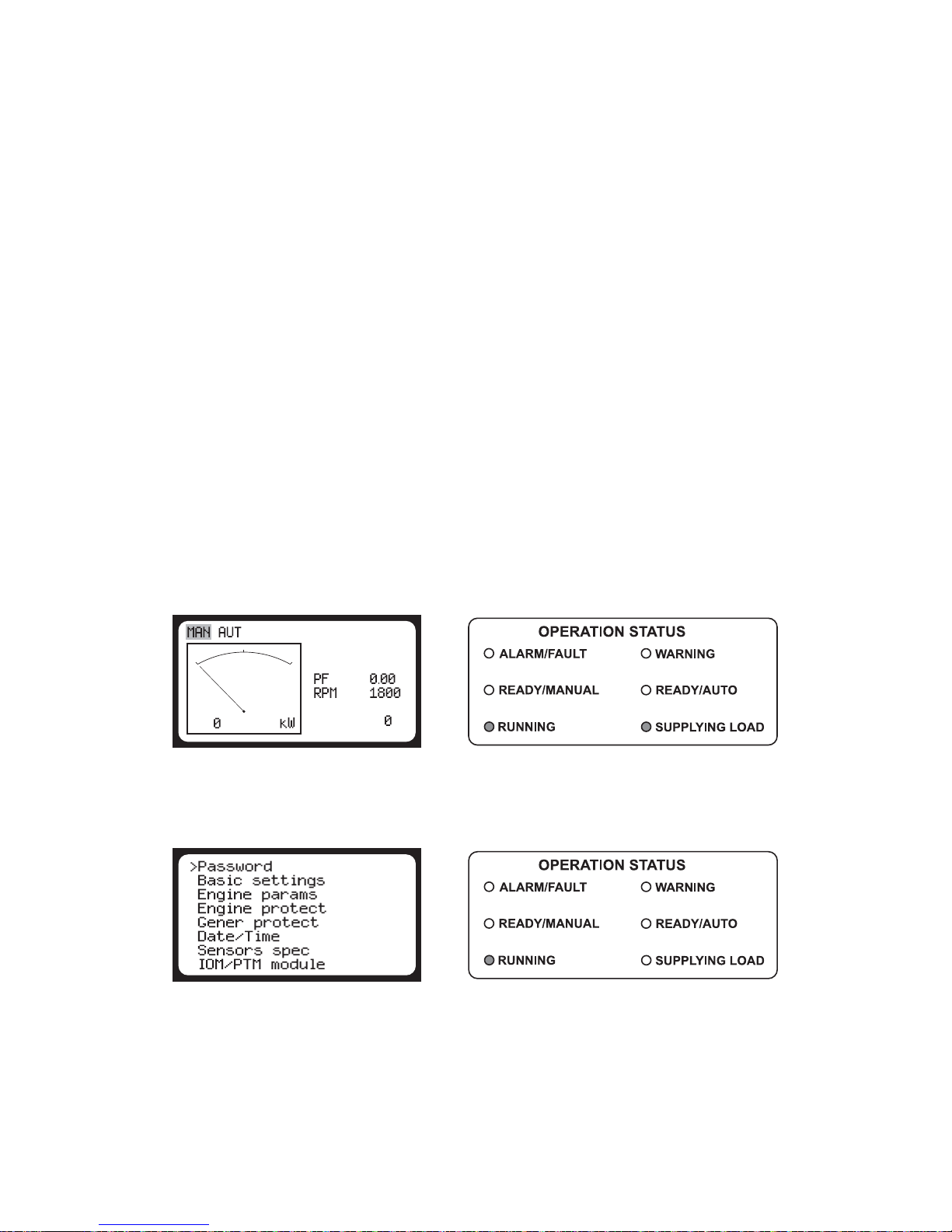

Additional information may be viewed while the unit is in “MANUAL” or “AUTO” mode. By pressing the “Page

Select” button, the operator will select one of the following screens; “Running” screen, “Password” screen, or

“History” screen. In each of these page selections the operator may press the “S” or “T” buttons on the “DIAGNOSTICS” keypad to display additional information as follows:

• “Running” screen:

The operator may press the “S” or “T” buttons on the “DIAGNOSTICS” keypad to

display the “Alarm List” screen, “ECU Alarm List” screen, “Run Hours” screen, “ECU

V alues” screen, Engine display screen and Generator display screen.

• “Password” screen:

The operator may press the “S” or “T” buttons on the “DIAGNOSTICS” keypad to move

the “>” cursor up or down a list of text.

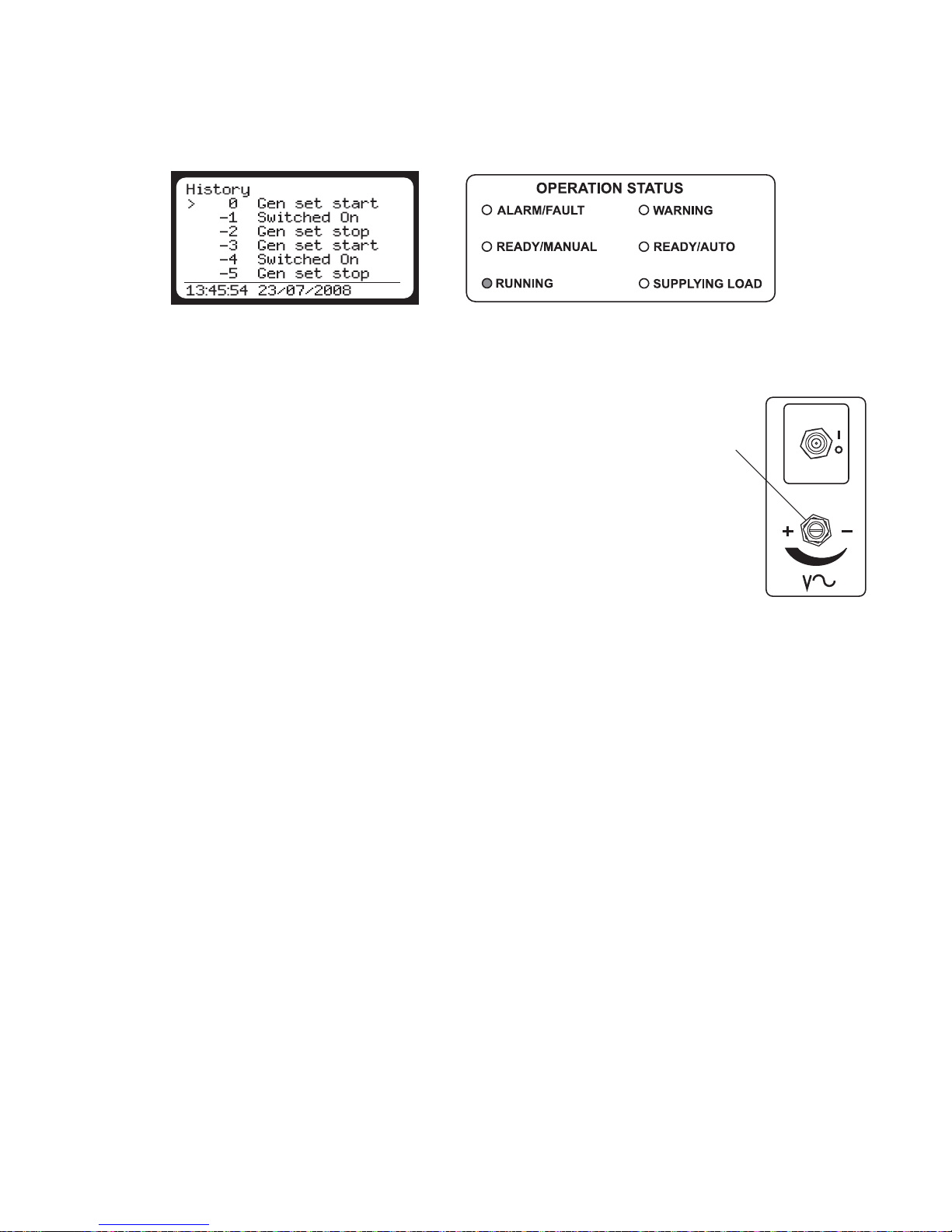

• “History” screen:

The operator may press the “S” or “T” buttons on the “DIAGNOSTICS” keypad to move

the “>” cursor up or down a list of the latest alarm or shutdown codes. Pressing the

“Enter” button at a particular selection will allow the operator to scroll to the right in the

LCD window to view the generator operating parameters at the time of the alarm or

shutdown.

14

Page 15

The history of alarms or codes of the unit are saved in the digital controller. The most

A

recent alarm or code is the first to be listed, with the time/date of the alarm or code at

the bottom of the screen. The controller stores up to 1 18 codes. When full, the controller

will automatically remove the oldest file. These codes will not be lost when the control

power toggle switch is powered off.

FINE VOLTAGE ADJUSTMENT

Upon start-up of the generator , the “Running” screen of the Magnum Digital

Controller (MDC) will display “SENSING” and will countdown from 45 seconds

to “0” Zero. This is a safety feature of the controller to protect the generator

from over or under voltage upon start-up.

VOLTAGE

DJUSTMENT

RHEOSTAT

CONTROL

ON

CONTROL

OFF

“SENSING” is a 45 second time delay and count down process before the

MDC records the generator nominal output voltage. This nominal generator

voltage is then compared to the current set point voltage of the voltage selector switch. If the nominal voltage recorded by the controller is greater than or

lower than the current set point voltage of the voltage selector switch setting

by 10% or more, the controller will shut the generator down automatically . The

display will read: Wrn VG1 or 2 or 3 Under/Over and/or Sd Vg1 or 2 or 3

Under/Over. This means the controller warned (“Wrn”) or even shut down (“Sd”) the unit due to an output voltage

irregularity .

The output voltage of the generator may be adjusted after the generator is running by use of the fine voltage adjustment screw. The adjusting screw is located directly below the control On/Off toggle switch on the control panel.

This screw turns a rheostat that will provide an increase (“+”) or a decrease (“-”) in the generator output voltage as

displayed on the Power Display Screen on the control panel. When making this adjustment, if the voltage is

increased or decreased too fast or too slow, the unit will automatically shut down. This adjustment needs to be

made within the 45 second delay and countdown to “0” Zero period.

T o adjust the output voltage, check the output voltage on the Liquid Cryst al Display (LCD) window labeled Gen freq

& Hz. Look at the L1N voltage or the L12 voltage on the display . The generator nominal output voltage should be

within 10% of the voltage rating on the voltage selector switch.

To adjust the output voltage loosen the lock nut at the base of the screw and turn the screw in the desired direction

until the required voltage shown on the LCD window matches the stated voltage on the voltage selector switch.

For Example: With the voltage selector switch set to “208/120V” 3 Phase position, the voltage displayed on

the Gen freq & Hz screen must be within ± 10 % of the 208/120 position (188-228 V Line to

Line / 108-132 V Line to Neutral).

If the voltage is not set within 10% of the applied voltage or the voltage is not reset within the

45 second delay period, the generator will shut down automatically and the display will read

Wn VG1 or 2 or 3 Under/Over and/or Sd Vg1 or 2 or 3 Under/Over.

Note: Each time the voltage selector switch is changed from one setting to another, an adjustment will need to be

made to the fine voltage using this adjustment screw.

15

Page 16

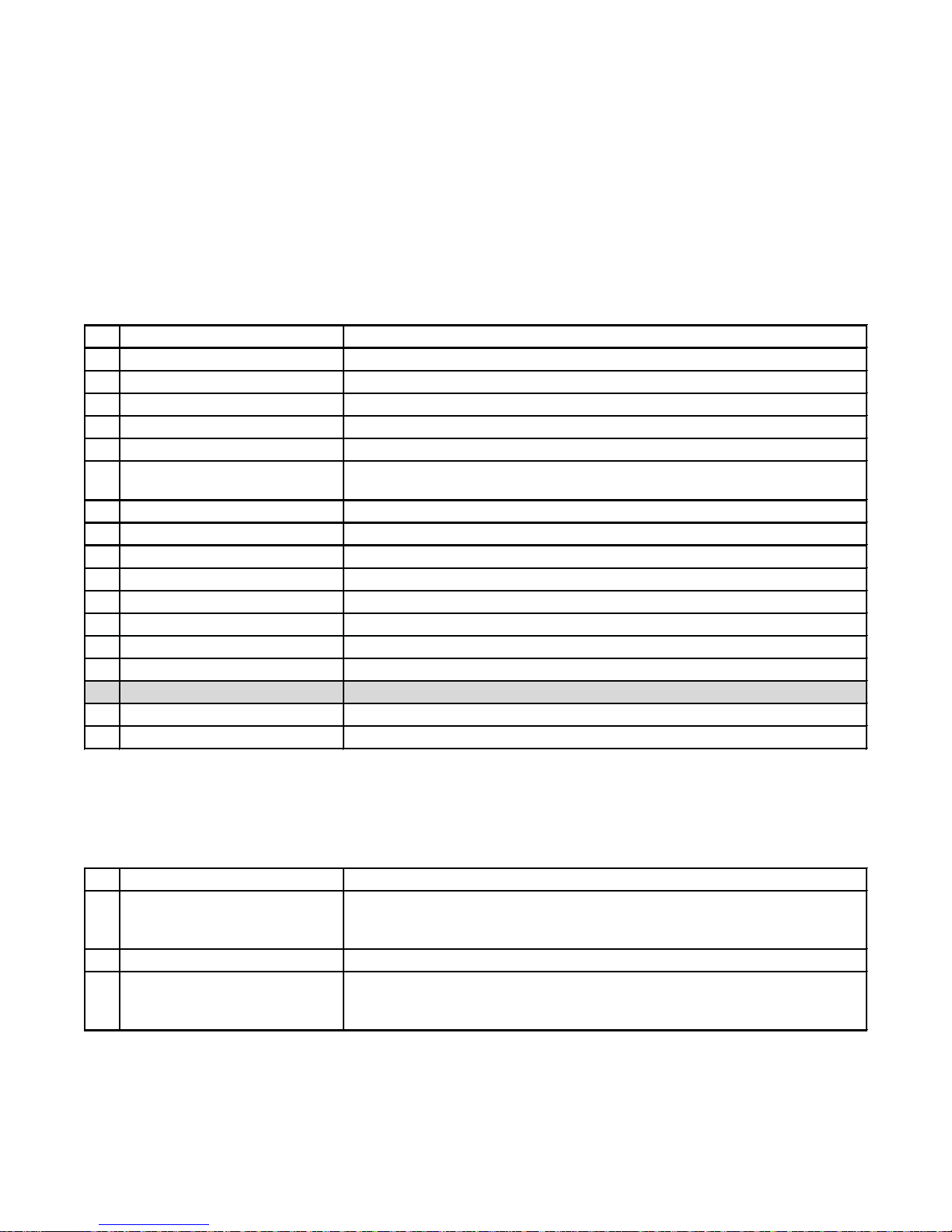

MAGNUM DIGITAL CONTROLLER (MDC) INFORMATION DISPLAYS, FUNCTIONS AND

No. Engine State Machine Description

1 AfterCool Engine aftercooling, Cooling Pump output is closed.

2 Cooling The generator is cooling before stop.

3 Cranking Engine is cranking.

4 EmergMan Emergency Manual gen-set operation.

5 Init Autotest during controller power on.

6 Loaded

The generator is running at nominal speed and GCB OPEN/CLOSE is

closed.

7 Not Ready The generator is not ready to start.

8 Pause Pause between start attempts.

9 Prestart Prestart sequence in process, Prestart output is closed.

10 Ready The generator is ready to run.

11 Running The generator is running at nominal speed.

12 Shutdown Shut-down alarm is activated.

13 Starting Starting speed is reached and the

Idle timer

is running.

14 Stop Stop

No. Electrical State Machine Description

1 StabilTO Stabilization Timeout

No. Type Description

1 Sensor fail (FLS)

Sensor fail is detected when measured value is 6% out of the selected

characteristic. Sensor fail indicated by ##### symbol instead measured

value.

2 Warning (WRN) When warning comes up, see list of possible alarms.

3 Shut down (SD)

When the shut-down alarm comes up the Magnum Digital Controller opens

outputs GCB CLOSE/OPEN, FUEL, SOLENOID, STARTER AND

PRESTART to stop the engine immediately.

RESET

The Magnum Digital Controller (MDC) constantly monitors vital generator and engine functions for a number of

operation, alarm and fault conditions. When a fault condition occurs, the engine will shut down automatically and

the Liquid Crystal Display (LCD) window will show the fault that has caused the shut down. To resume operation,

the fault condition must be resolved. T o reset the controller and resume operation, press the “F AUL T RESET”

button.

MAGNUM DIGITAL CONTROLLER (MDC) – GENERATOR OPERATIONAL STATUS

The Magnum Digital Controller (MDC) displays the operational status of the generator using the following codes:

MAGNUM DIGIT AL CONTROLLER (MDC) - ALARM MANAGEMENT

The Magnum Digital Controller (MDC) is capable of displaying the following alarms:

16

Page 17

MAGNUM DIGITAL CONTROLLER (MDC) - LIST OF POSSIBLE ALARMS/DESCRIPTIONS

No.

Events

Specification

Protection

Type

Information

on Binary

Output

Available

Description

1 AnInIOM Sd SD YES

Shutdown alarm configurable on the input of IG-IOM/IGS-PTM.

2 AnInIOM Wrn WRN YES

Warning alarm configurable on the input of IG-IOM/IGS-PTM.

3 Battery Flat SD YES

If the controller switches off during starting sequence due to

bad battery condition it doesn't try to start again and activates

this protection.

4 Binary Input Configurable YES

Configurable Warning/Shutdown alarms on the inputs of IL-NT.

5 ChrgAlternFail WRN YES

Failure of the alternator for charging the battery.

6 EmergencyStop SD NO

If the input

Emergency stop

is opened shutdown is immediately

activated.

7 Engine Temp Sd SD NO

Water temperature is greater than

Sd Water temp

setpoint.

8 Engine Temp Wrn WRN YES

Water temperature is greater than

Wrn Water temp

setpoint.

9 Fgen <, > SD YES

The generator frequency is out of limits given by

Gen >f

and

Gen <f

setpoints.

10 Fuel Level Sd SD YES

Fuel level is less than

Sd Fuel Level

setpoint.

11 Fuel Level Wrn WRN YES

Fuel level is less than

Wrn Fuel Leve

l setpoint.

12 GCB fail SD NO

Failure of the generator circuit breaker.

13 Igen unbl SD NO

The generator current is unbalanced.

14 Low BackupBatt WRN NO

RTC backup battery is flat.

15 Oil Press Sd SD NO

Oil pressure is less than

Sd Oil press

setpoint.

16 Oil Press Wrn WRN YES

Oil pressure is less than

Wrn Oil press

setpoint.

17 Overload SD YES

The load is greater than the value given by

Overload

setpoint.

18 Overspeed SD YES

The protection comes active if the speed is greater than

Overspeed

setpoint.

19 ParamFail NONE NO

Wrong checksum of parameters. Happens typically after

downloading new firmware or changing of the parameter. The

controller stays in INIT mode. Check all parameters write at

least one new parameter.

20 PickupFault SD NO

Failure of the magnetic pick-up sensor for speed measurement.

21 Sd IOM fail SD NO

Shutdown alarm in case of lost connection to IG-IOM/IGS-PTM

module.

22 SprinklActive WRN NO

The protection is active if the output

Sprinkler

is closed.

23 Start failed SD YES

Gen-set start failed

24 Stop fail SD YES

Gen-set stop failed.

25 Ubat WRN YES

Battery voltage is out of limits given by

Batt overvolt

and

Batt

undervolt

setpoints.

26 Underspeed SD YES

During starting of the engine when the RPM reaches the value

of

Starting RPM

setpoint the starter is switched off and the

speed of the engine can drop under

Start RPM

again. Then the

Underspeed protection becomes active. Protection evaluation

starts 5 sec

27 Vgen <, > SD YES

The generator voltage is out of limits given by

Gen <V

and

Gen >V

setpoints.

Shut down and warning fault conditions and the displayed message are described in the following table:

17

Page 18

28 Vgen unbal SD NO

The generator voltage is unbalanced more than the value of

Volt unbal

setpoint.

29 Wrn ECU Alarm WRN NO

ECU alarm list is not empty.

30 Wrn RA15 fail WRN NO

Warning alarm in case of lost connection to IGL-RA15 module.

31 WrnServiceTime WRN NO

The period for servicing is set by the

NextServTime

setpoint.

The protection comes active if the running hours of the engine

reach this value.

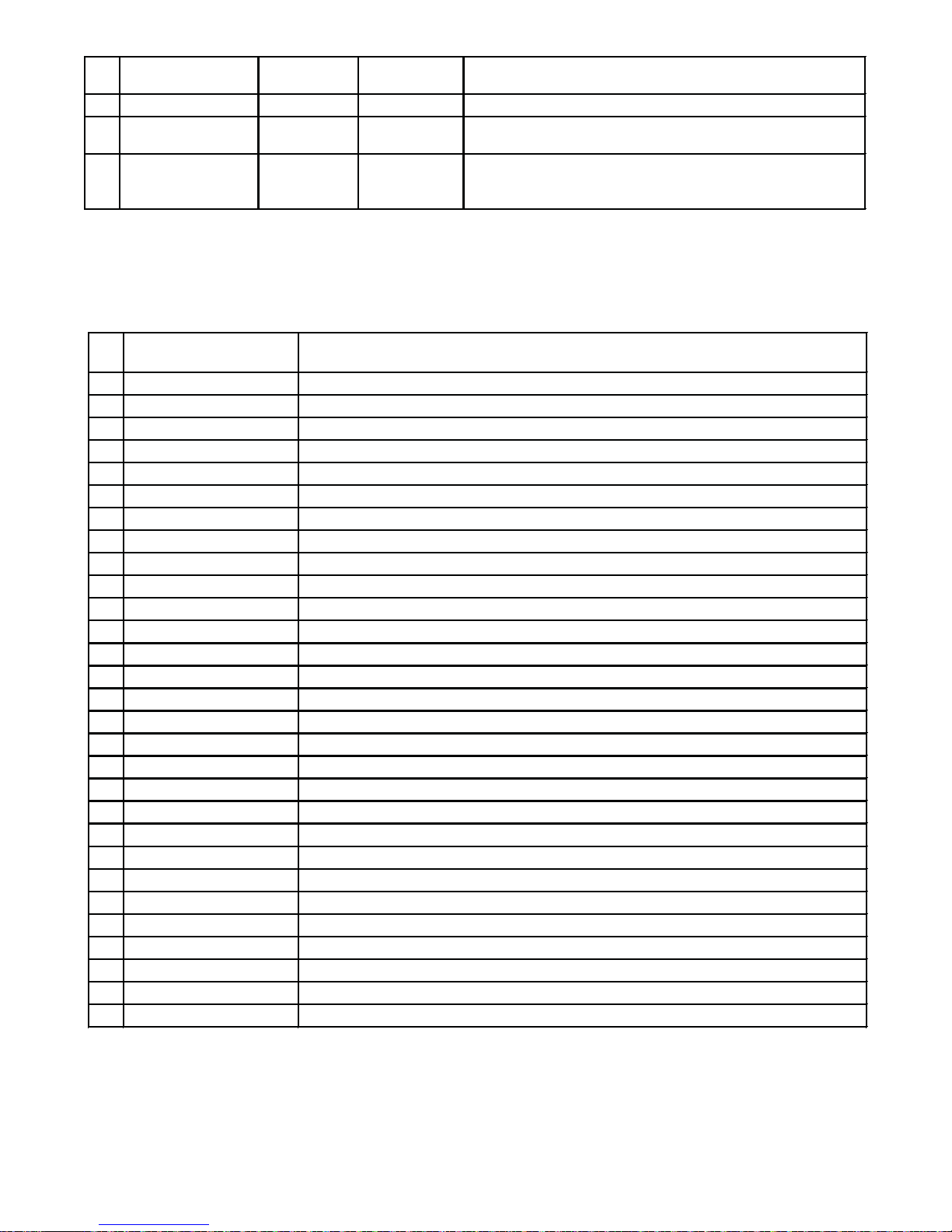

MAGNUM DIGIT AL CONTROLLER (MDC) – HIST OR Y

No.

Record Structure

Abbreviation

Historical value

1 AIM1 IG-IOM, IGS-PTM Analog input 1 value (when configured IG-IOM, IGS-PTM)

2 AIM2 IG-IOM, IGS-PTM Analog input 2 value (when configured IG-IOM, IGS-PTM)

3 AIM3 IG-IOM, IGS-PTM Analog input 3 value (when configured IG-IOM, IGS-PTM)

4 AIM4 IG-IOM, IGS-PTM Analog input 4 value (when configured IG-IOM, IGS-PTM)

5 BIM IG-IOM, IGS-PTM Binary inputs (when configured IG-IOM, IGS-PTM)

6 BIN Binary inputs IL-NT

7 BOM IG-IOM, IGS-PTM Binary outputs (when configured IG-IOM, IGS-PTM)

8 BOUT Binary inputs IL-NT

9 Date Date of historical event in format DD/MM/YY

10 EngT IL-NT Analog input 2 value (default Water temperature)

11 FC ECU alarm FailureCode

12 FLvl IL-NT Analog input 3 value (default Fuel level)

13 FMI ECUalarm Failure Mode Identifier

14 Gfrg Generator frequency

15 Ig1 Generator current L1

16 Ig2 Generator current L2

17 Ig3 Generator current L3

18 LChr Character of the load

19 Num Number of historical event

20 OilP IL-NT Analog input 1 value (default Oil pressure)

21 PF Generator PF

22 Pwr Generator active power

23 Reason Event specification

24 RPM Engine Speed

25 Time Time of historical event in format HH:MM:SS

26 Ubat Battery voltage

27 Vg1 Generator voltage L1

28 Vg2 Generator voltage L2

29 Vg3 Generator voltage L3

The Magnum Digital Controller (MDC) controller stores a record of each important event into the history file of the

controller. The history file seat s 1 18 records. When the history file is full, the oldest records are removed.

18

Page 19

ADJUSTING THE DISPLAY BACK LIGHTING

The backlighting on the Liquid Crystal Display (LCD) window may be adjusted brighter or darker by the operator

whenever the Magnum Digital Controller (MDC) is powered up.

1. Press and hold “Enter” and press “S” or “T” on the Diagnostics keypad to increase or decrease the

display contrast as needed.

2. Release the “Enter” button and the “S” or “T”buttons when the desired backlighting is attained.

Note: Anytime an “*” is displayed on the LCD, the text or set point cannot be changed with out the use of a pass-

word. Contact Magnum Products Technical Support for assistance.

RESETTING OF THE “TIME TO SERVICE” REMINDER

The Magnum Digital Controller (MDC) will display the message “ WrnServiceTime” when the unit is due for maintenance or service. The maintenance or service interval is set at 250 hours of engine running time. Once the unit has

been serviced, the “ServiceTime” reminder needs to be reset to the 250 hour interval. The following procedure

demonstrates how to reset the running hours to 250:

1. With the unit shut down, power up the controller with the “Control On/Off” T oggle Switch. The initialization

screen will be displayed. The controller will toggle automatically to the “Ready” Display screen.

2. Press the “S” button. The “Alarm List” display screen will appear. The next screen will display lines of text;

starting with the word “Password”, then “Basic Settings”, “Engine Params”, “Engine Protect” etc. The top

line has a “> “ cursor before the word ‘Password”.

3. Press the “T” button to move the “> “cursor down to the “Engine Protect” line of text.

4. Press Enter. “NextServTime” will appear at the top of the display screen on the left side, with the current

service time hour setting (250) one line below on the right side

5. Press Enter. The current run time in hours will now appear on the left side of the display screen, directly

under “NextServTime”

6. Press the “S” button and reset the current run time hour setting to 250. If you overshoot the 250 time

interval use the “T” button to get back to the 250 time interval.

7. Press “Enter” to save the current run time hour setting.

8. Move the “CONTROL ON / I” toggle switch to the “CONTROL OFF / O” position.

19

Page 20

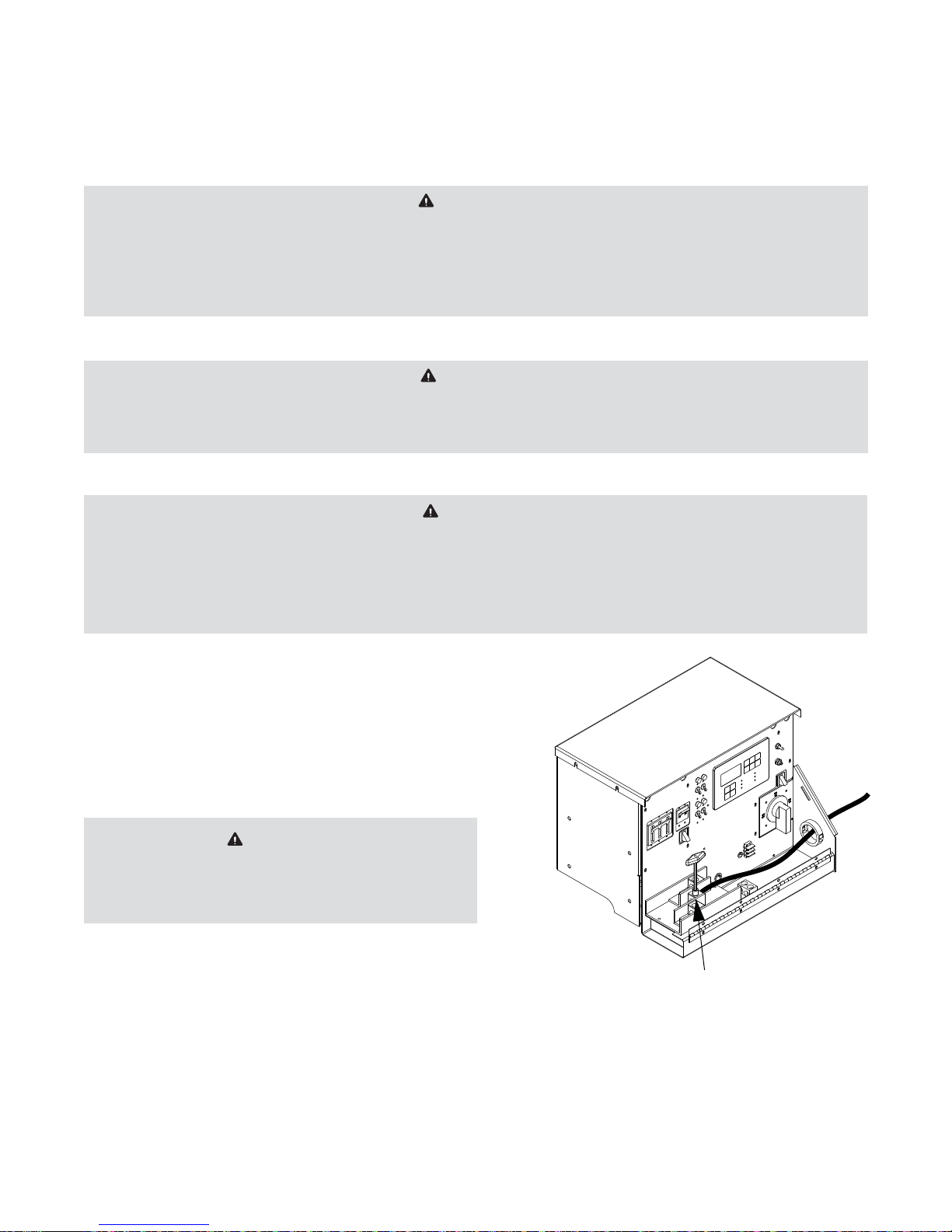

TIGHTEN CONNECTION

LUGS WITH A HEX WRENCH

GENERATOR OUTPUT CONNECTION LUGS

The generator is equipped with connection lugs behind a door below the controller face. The lugs provide connection

points for attachment of external loads to the generator . A large decal on the inside of the connection lug door

details the proper connections for selected voltages.

WARNING

It is HIGHLY RECOMMENDED that only a trained and licensed electrician perform any wiring and

related connections to the generator. Installation should be in compliance with the National

Electric Code (NEC) as well as any local or state guidelines as required by law. Failure to follow

proper installation requirements may result in equipment or property damage, personal injury

or death.

WARNING

Before any connections are made to the generator, make sure that the main circuit breaker and

the control power switch are in the OFF “O” position. Potentially lethal voltages may be present

at the generator connection lugs.

DANGER

IMPROPER OR INCORRECT CONNECTIONS TO A BUILDINGS ELECTRICAL SYSTEM CAN CAUSE

POTENTIALL Y LETHAL VOL T AGE T O BACKFEED ONTO UTILITY LINES. THIS MA Y RESUL T IN

INJURY OR ELECTROCUTION T O UTILITY WORKERS NEARBY . MAKE SURE THE GENERA TOR IS

SUPPL YING POWER TO AN ISOLA TED OBJECT OR BUILDING THA T IS NOT CONNECTED T O ANY

UTILITY LINES.

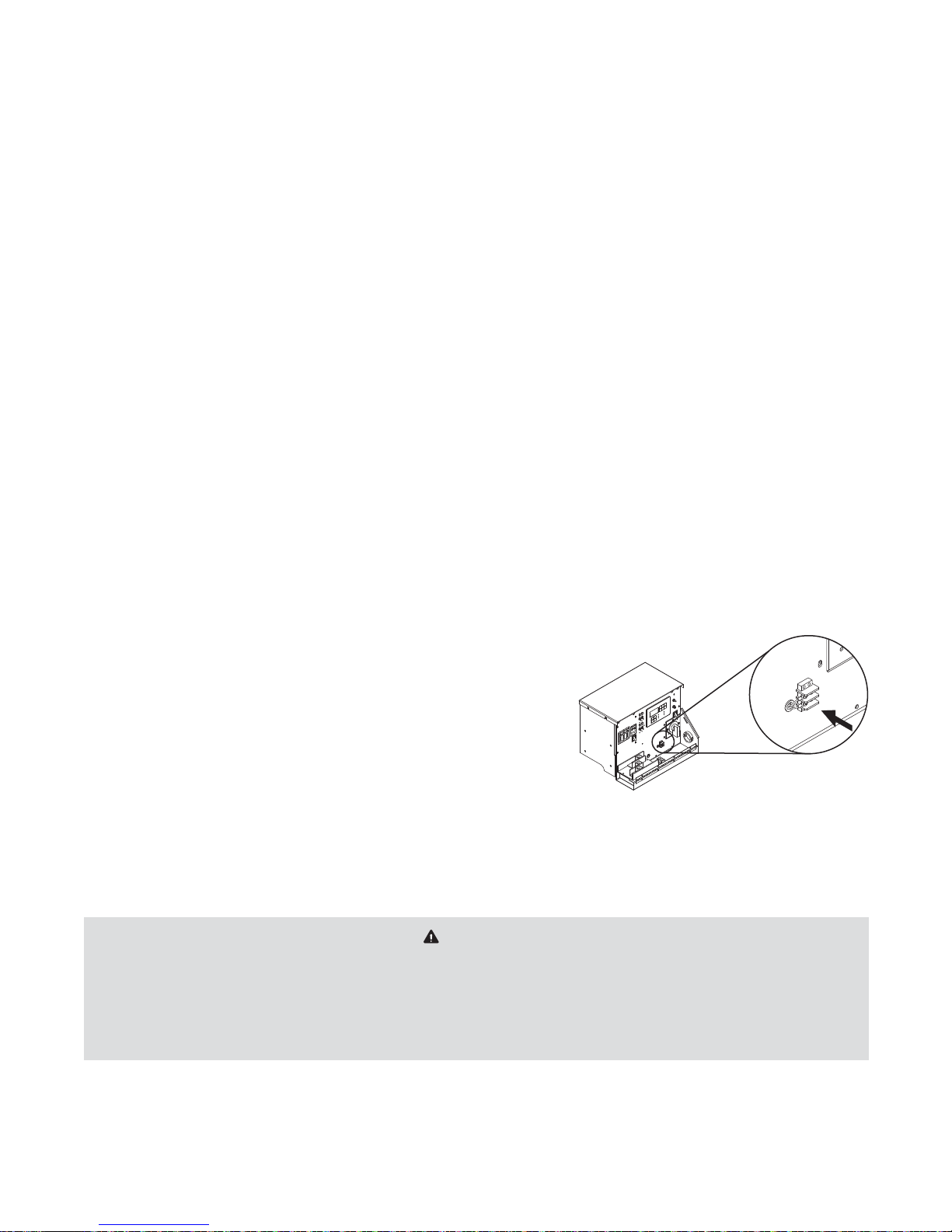

Connections to the lugs should be made by running the power

cables through the circular plastic bushing on the lower right side

of the control box. DO NOT make any connections directly to the

lugs without routing the cables through this bushing. The lug door

is equipped with safety interlock switches that will automatically

trip the main circuit breaker and disable the voltage regulator when

the lug door is opened. Use a hex-wrench to tighten the cable

connections.

WARNING

Never attempt to disable or modify the lug door

safety switches. Equipment damage, personal

injury or death may result.

A ground connection is located next to the connection lugs. The

unit MUST HAVE this ground lug connected to a good earthen

ground for proper operating safety . The ground connection should

be in compliance with the National Electric Code (NEC) as well as

any state or local guidelines or codes.

20

Page 21

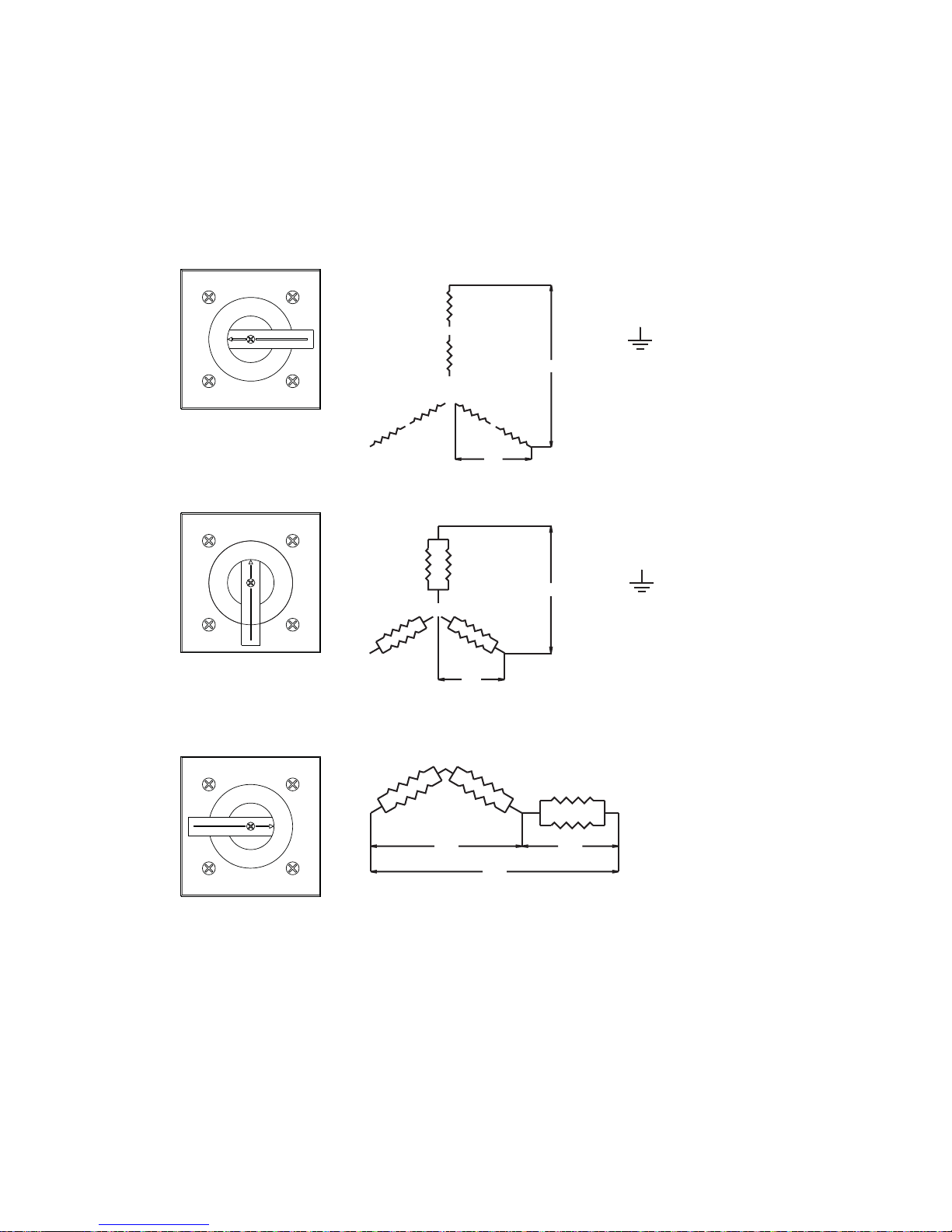

VOLTAGE SELECTOR SWITCH

The voltage selector switch is located behind the lug door , underneath the engine controller panel. The selector

switch is a three position switch that mechanically changes the connections between the generator output leads and

the connection lugs. Voltage ranges are selected by rot ating the handle on the switch to the desired voltage.

NOTICE

Never change the voltage selector switch while the engine is running!

This will cause sever arcing and damage to the switch and generator windings.

480/277V

3-PHASE

208/120V

3-PHASE

208

120

480

277

T6

T3

L3

208

120

L1

T1

T4

T7

T10

N

T11

T12

T9

L1

T7

T8

L-N

T1

L-L

T5

T2

L2

L1 - L2 = 480V L1 - N = 277V

L2 - L3 = 480V L2 - N = 277V

L3 - L1 = 480V L3 - N = 277V

N =

L1 - L2 = 208V L1 - N = 120V

L2 - L3 = 208V L2 - N = 120V

L3 - L1 = 208V L3 - N = 120V

480

277

240

120

T12

T9

T3

L3

T4

T10

T5

N

T6

T11

T8

L-N

L-L

T2

L2

N =

T6

240/120V

1-PHASE

208

120

240

120

T3

T9

L3

T8

T2

T12

240V

T11

T10

N

T5

T4 T1

120V120V

L1 - L3 = 240V L2 - N = ------L1 - N = 120V L3 - N = 120V

T7

L1

The voltage switch is equipped with a locking mechanism. Once the proper voltage has been selected, push the red

latch on the inside of the phase switch handle up and insert a padlock through the handle. By locking the handle in

place you will prevent unauthorized personnel from changing the switch settings.

Note: When the voltage selector switch is in position for 480/277V 3Ø, voltage at the two GFCI duplex convenience

outlets is 139 Volts and the voltage at the three twist-lock outlets is 240/139 Volts. When the voltage selector

switch is in position for 208/120V 3Ø, voltage at the three twist-lock outlets and the two GFCI outlets is 208/120

Volts.

21

Page 22

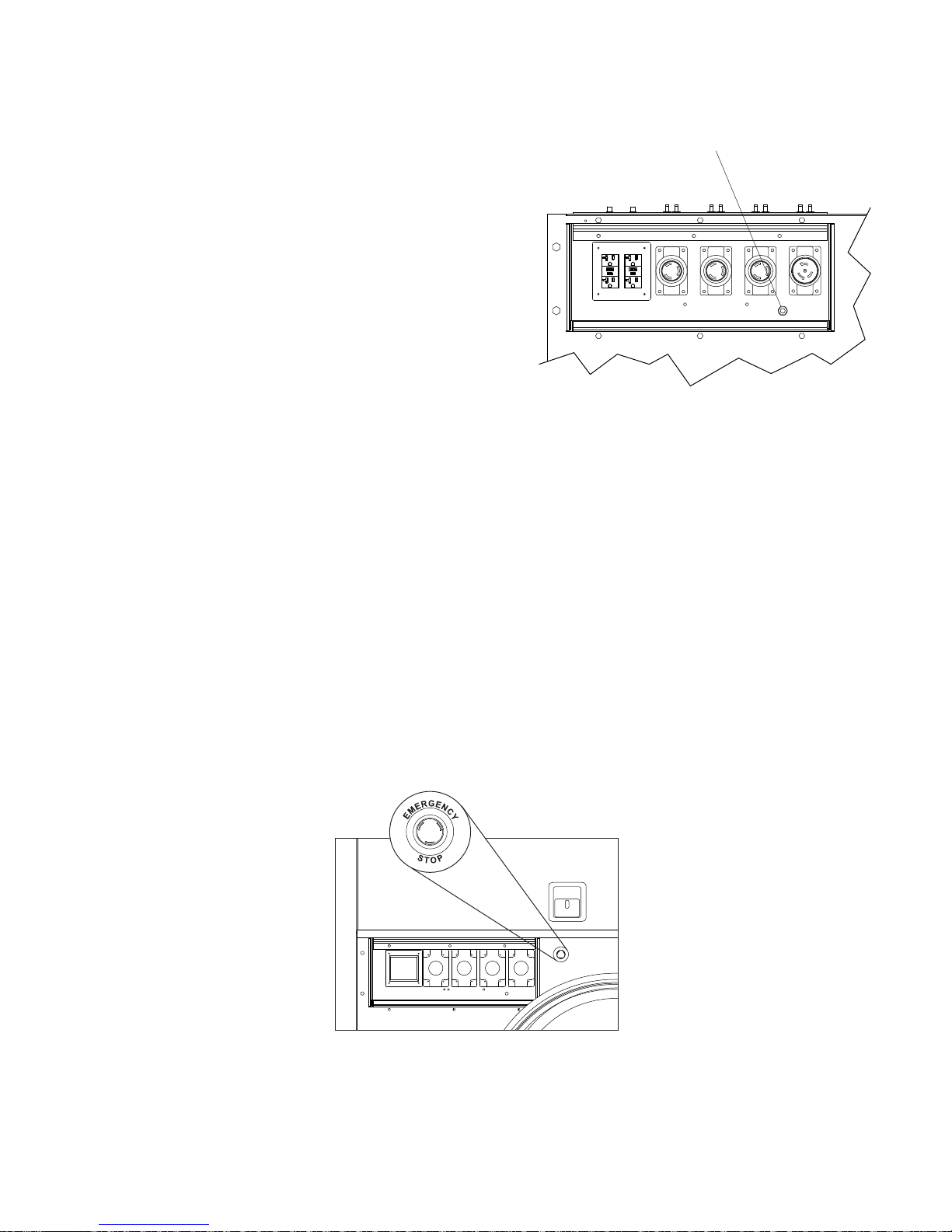

AUXILIARY OUTLETS

The control panel is equipped with six outlets for running accessories or tools from the generator. Power is supplied to the

outlets any time the engine is running and the main circuit

breaker and the auxiliary outlet main circuit breaker are switched

in the ON “I” position.

Should the main breaker trip, or the auxiliary outlet main circuit

breaker trip, remove some of the load to the outlets before

turning them back on.

Note: To ensure proper grounding, anytime the generator is

providing power to any equipment or load panels that do not have

a grounded plug, a ground wire must be added between the

equipment and the grounding stud on the outlet panel per any

local, state or NEC codes and guidelines.

AUXILIARY OUTLET

GROUNDING STUD

VOLTAGE REGULATION

The electronic voltage regulator controls the output of the generator by regulating the current into the exciter field.

The regulator has three screwdriver adjustable potentiometers that may be adjusted for voltage, stability and under

frequency (U/F). The voltage regulator on your unit is adjusted before shipment from the factory . Contact Magnum

Products LLC for additional information before attempting to adjust the voltage regulator .

EMERGENCY STOP SWITCH

The generator is equipped with one emergency stop switch, located on the side panel next to the auxiliary outlet

panel. The switch is clearly labeled with “EMERGENCY ST OP” and is red in color . The switch can be accessed

and activated with all doors closed and locked.

Activate the emergency stop switch by pushing the red button in until it locks down. This will trip the main circuit

breaker which will open the contact disconnecting the load to the connection lugs. This will also open the fuel

circuit, shutting down the engine and the Emergency Stop fault will be displayed on the LCD. The switch will remain

closed until it is pulled out. Note: Use the EMERGENCY STOP only when the generator must be shut down

immediately . For any other shut down, follow the detailed shut down procedure.

22

Page 23

MAIN CIRCUIT BREAKER

The main circuit breaker is located on the main control panel. When the breaker is in the OFF “O” position, power is

interrupted between the customer connection lugs and the generator. Once the connections have been made to the

connection lugs and the generator has been started and allowed to reach normal operating temperature, the breaker

may be switched to the ON “I” position.

The main circuit breaker will be tripped, disconnecting power to the connection lugs, if any of the following items

occur while the unit is running:

1. Overload of the generator circuits to the connection lugs.

2. The lug box door covering the customer connection lugs is opened.

3. If the emergency stop switch is activated.

Make sure that any problems that caused the main circuit breaker to trip are corrected before returning the switch to

the ON “I” position.

NOTICE

The main circuit breaker interrupts power to the customer connection lugs only . The customer convenience outlets

have power even if the main circuit breaker is in the OFF “O” position. The auxiliary outlet main circuit breaker ,

located next to the main circuit breaker, will disconnect all power to the auxiliary outlet panel.

REMOTE START TERMINAL BLOCK

The remote start terminal block is located under the lug box door just below the voltage selector switch. It provides

a connection for installation of a remote start switch which will allow the generator to be started by a remote drycontact closure switch.

Before pressing the AUT O button, verify that the contacts on any

remote switch linked to the generator are OPEN. If the contacts on

a remote switch are closed, the generator will crank and start when

AUTO is selected on the controller . Attach the switch leads to the

two unused terminals on the generators remote start block. For

additional information on starting the generator , see the GENERATOR ST ART UP section of this manual.

TRANSFER SWITCH

When the generator is used as a standby power supply , it must be

equipped with a transfer switch which isolates it from the utility’s distribution system. A transfer switch is designed

to transfer electrical loads from the normal power source (utility) to the emergency power source (generator) when

normal voltage falls below a prescribed level. The transfer switch automatically returns the load back to the normal

source when power is restored back to operating levels.

DANGER

FAILURE TO ISOLA TE THE GENERA TOR FROM THE NORMAL POWER UTILITY CAN CAUSE

POTENTIALL Y LETHAL VOL T AGE TO BACKFEED INT O THE UTILITY LINES. THIS MA Y RESUL T IN

INJURY OR ELECTROCUTION OF UTILITY WORKERS NEARBY . MAKE SURE THA T THE GENERA TOR IS

ISOLA TED BY A TRANSFER SWITCH FROM ANY LOCAL UTILITY LINES. THIS ALSO APPLIES IF THE

GENERA TOR IS BEING USED AS A BACK UP TO SOME OTHER TYPE OF POWER SUPPL Y.

23

Page 24

Installation of a transfer switch or other type of remote starting device is the responsibility of the generator user.

Installation of such devices must be performed by following all directions supplied by the manufacturer of the switch. If

attaching generator to a power supply normally serviced by a utility company , notify the utility company and check local

and state regulations. Familiarize yourself with all instructions and warning labels supplied with the switch.

WARNING

It is strongly recommended that ONLY a licensed electrician perform any wiring and any related

connections to the generator. Installation should be in compliance of the National Electric Code as

well as any state or local codes or regulations. Failure to follow these procedures could result in

property damage, personal injury or death. Before any connections are attempted, make sure the

main circuit breaker and the engine start switch are in the OFF “O” position and that the negative (-)

battery cable has been disconnected from the engine starting battery.

NOTICE

When using the generator as a stand by or substitute power supply , make sure the output voltage and phase

rotation of the generator match those of the local power utility . Improper voltage or phase rotation may

cause equipment damage or malfunction.

INCOMING

UTILITY

POWER

UTILITY

METER

POWER FROM

GENERATOR

WHITE = INCOMING UTILITY POWER

EMERGENCY

DISTRIBUTION PANEL

(GENERATOR POWER)

MAIN DISTRIBUTION

PANEL

(UTILITY POWER)

TRANSFER

SWITCH

GRAY = NORMAL UTILITY POWER CIRCUIT

BLACK = EMERGENCY GENERATOR POWER CIRCUIT

24

Page 25

LIGHT TOWER SET-UP

1. For maximum light coverage locate tower at ground level or in a spot higher than the area being illuminated

by the lamps.

WARNING

Check for any overhead obstructions such as utility lines or vegetation as the tower extends up

to 30 ft. (9.14 m). Do not set up the tower if high winds or storms capable of producing lightening

are expected in the area!

H

DETAIL C

DETAIL D

F

E

D

B

C

D

E

2. Place the trailer on firm ground that is relatively flat. This will make it easier to level the tower.

Block the wheels on the trailer to keep it from moving (A).

3. Pull the locking pin on the tongue jack and rotate it 90º until the spring loaded pin snaps back into place

(B). Turn the jack handle clockwise to raise the trailer tongue off of the towing vehicle.

4. Connect a good earthen ground to the grounding stud on the frame of the trailer near the trailer tongue (C).

5. Pull the locking pins (D) on the outriggers (E) and pull the outriggers out until the spring loaded locking pin snaps

back into place. Pull the locking pin on the outrigger jacks and rotate them 90º until the spring loaded pin snaps back

into place.

G

A

DETAIL G

DETAIL H

6. Pull the locking pin on the rear jack (F) and rotate it 90º until the spring loaded pin snaps back into place. Turn the

jack handle clockwise to start leveling the trailer. Adjust all four jacks by turning their handles clockwise until they

are firmly in contact with the ground and the trailer is as level as possible (G).

7. Before raising the tower it may be necessary to adjust the lamps. The lamps may be adjusted up, down, left or right

by loosening the wing bolts on the lamp fixture (H) and aiming them in the desired direction. Tighten the hardware

completely and make sure the lamps are connected to the junction box.

25

Page 26

RAISING THE TOWER

WARNING

The trailer must be leveled with the outriggers extended before raising the tower. The outriggers

must remain extended while the tower is up. Failure to level the trailer or extend the outriggers

will severely reduce the stability of the unit and could allow the tower to tip and fall.

1. Remove the mast cradle locking pin from the mast cradle (I).

2. Check both sets of mast cables for excessive wear or damage. Make sure the cables are properly centered in

each pulley (J). Check the electrical cord for damage.

WARNING

Do not start the unit if the insulation on the electrical cord is cut or worn through.

Bare wires in contact with the mast or frame may energize the trailer and cause electrocution.

Repair or replace cord.

3. Make sure the area behind the unit is clear before

raising the mast to the vertical position.

4. Remove the safety pin (K) from the mast lock bar

(L). Using the handle for the lower mast winch (M),

raise the mast until it is vertical and the tab on the

mast is positioned into the mast lock. The mast lock

bar should snap into place automatically. Secure

the lock with the safety pin (N).

DETAIL I DETAIL K

DETAIL N

STOP

5. After the mast is up and locked into place, use

the upper mast winch (O) to telescope the

tower to the desired height. Extend the mast slowly,

making sure that the electrical cord is extending

at the top sections of the mast. If, for any reason,

the winch cable begins to develop slack or any of

the tower sections get stuck, STOP IMMEDIATELY

and contact an authorized service center.

CAUTION

Do not extend the mast beyond the colored mark

on the middle mast tube (P).

6. The mast can be rotated by loosening the locking

knob at the bottom of the mast (Q). Turn the mast

until the lights face in the desired direction and

then tighten the knob.

WARNING

Never raise or lower the mast while the unit is

operating! Never remove the safety pin or mast

lock while the tower is up. Releasing the lock

will cause the mast to fall.

DETAIL P

J

I

Q

O

M

K, L, N

J

26

Page 27

RAISING THE TOWER WITH THE OPTIONAL ELECTRIC WINCH

1. Set up and level the trailer as described on page 25, and follow steps 1-3 on page 26.

2. Remove the safety pin from the mast lock bar (R).

3. Press the lower winch control toggle switch upward to

raise mast into the vertical position (S). Hold switch until

the mast lock is engaged. The mast lock bar should snap

into place automatically . Note: On light towers equipped

with the electric winch option, a limit switch on the mast

tube will disconnect power to the lower electric winch to

prevent deadheading the winch.

4. Secure the lock with the safety pin (T).

DETAIL R

5. Press and hold the upper winch control toggle switch

upward to telescope the mast to desired height (U).

Extend the mast slowly , making sure that the coiled

electrical cord is extending at the top sections of the

mast. If, for any reason, the winch cable begins to

develop slack or any of the tower sections get stuck,

STOP IMMEDIA TEL Y and cont act an authorized service

center.

CAUTION

Do not extend the mast beyond the colored mark

on top of the lower mast section (V). On light

towers equipped with the electric winch option, a

limit switch on the main mast section will disconnect power to the upper electric winch to prevent

over extending the mast.

6. The mast can be rotated by loosening the locking

knob at the bottom of the mast (W). Turn the mast

until the lights face in the desired direction and

then tighten the knob.

DETAIL S

DETAIL T

V

DETAIL U

U

STOP

DETAIL V DETAIL W

WARNING

Never raise or lower the mast while the

unit is operating! Never remove the safety

pin or mast lock while the tower is up.

Releasing the lock will cause the mast to fall.

S

R,T W

27

Page 28

LIGHT TOWER START UP

Before starting the light tower, carefully read the pre-st art check list. Make sure that all of the items are checked

before trying to start the light tower. This check list applies for both manual and remote starting.

PRE- START CHECK LIST

Make sure the control ON/OFF toggle switch is in the OFF “O” position.

Make sure that the circuit breakers (main and convenience) are switched OFF “O”.

Check that the light tower is properly grounded to a good earthen ground per any local and NEC

regulations.

Check all electrical connections at the connection lugs. Are they wired correctly?

Are the connection lugs tight?

Check that the voltage selector switch is set to the desired voltage.

Is the voltage selector switch locked?

Is the light tower sitting level?

Check for any water inside, on, or near the unit. Dry the unit before starting.

Check oil, coolant and fuel levels and engine battery connections.

Check engine fan belt tension and condition.

Check engine fan belt guard.

Check engine exhaust system for loose or rusted components.

Check radiator and surrounding shroud for debris.

Are any of the generator covers loose or missing?

Are all preventative maintenance procedures up to date?

Check that the battery disconnect switch is on, if equipped.

MANUAL STARTING OF THE LIGHT TOWER

1. Move the control ON/OFF toggle switch to the “CONTROL ON / I” position.

2. The Liquid Crystal Display (LCD) window will quickly display system information, all Light Emitting

Diodes (LED’s) will flash.

3. The LCD window will indicate MANUAL mode and Ready . The Ready/Manual LED will be lit. Note: The

unit must be in the “MAN” Mode with the Ready/Manual LED lit to start the unit.

28

Page 29

4. Press the green “ENGINE ST ART” button. The Prestart (Preheat) screen will be displayed (if equipped)

and a countdown will begin from 20 seconds to 0.

5. The S tarting screen will be displayed. The engine will crank and start running.

6. The Running screen will display . Note: It may take a few seconds for the engine to run smoothly and

reach its governed operating speed. The 45 second “SENSING” time delay will start to count down.

7. The LCD window will then toggle from the Running screen to the Generator Display Screen and then to

the Engine Display Screen.

8. If the engine does not start after the first cranking attempt, the engine will pause for 15 seconds to

allow the starter to cool. The LCD window will show “P AUSE”. The engine will make two more attempts

to start for a total of three crank cycles.

9. Should the engine not start and run within 3 starting cycles, the LCD window will show “SD Start fail”.

The starting sequence may be repeated after the starter has had a minimum of two minutes to cool.

Press the “FAULT RESET” button to clear the controller. To start the unit, press the green “ENGINE

ST ART” button. Note: The engine controller may skip the preheat engine steps on some of the larger

models.

29

Page 30

10. Once the engine starts it will immediately begin speeding up to a constant 1800 rpm. On units with

isochronous engine governing, the engine may hunt or change speeds until operating temperature is

reached. Af ter a few minutes of operation, the engine will be warmed up and the LCD window will show

engine and generator operating parameters. Temperature will be shown as “0” until the engine temperature is approximately 100° F.

1 1. Once the generator is at normal operating temperature, check the generator for excessive noise or

vibration and any coolant, oil or fuel leaks before applying any loads.

12. Check that the AC output voltage is correct. The output voltage can be fine adjusted by using the fine

voltage adjustment screw (rheostat), as described on page 15.

13. Check that the frequency (Hz) is correct. With no loads connected to the generator , the frequency

should read approximately 60-62 Hz, depending on the type of engine governing used.

14. If all wiring connections have been made correctly, switch the main circuit breaker to the “ON / I”

position and then add any loads attached to the convenience outlets by switching the respective circuit

breaker to the “ON / I” position. Y ou will notice a slight change in engine sound when a load is applied

to the unit.

“AUTO” (REMOTE) STARTING OF THE LIGHT TOWER

The “AUTO” button is used when the generator is started from a location other than the control panel and by using

a dry-contact closure remote start switch (transfer switch). “AUTO” (remote start) is the normal setting when the

generator is being used as a standby power supply . Before putting the generator in the “AUTO” mode, review the

Pre-Start Check List and Manual S tarting of the Generator sections beginning on p age 28. Also follow all safety

warnings and information on isolating the generator with a transfer switch if the unit is to be used as a standby

power supply , as described on pages 23 and 24. Then continue with the steps described below:

1. Perform a manual start of the generator at least once to verify that the engine is operating correctly.

2. If a check of the remote start circuit is desired, remove the wires from the remote start terminal block.

Press the “AUTO” button, the Liquid Crystal Display (LCD) window should highlight “AUTO” in the

upper left corner . Att ach a jumper wire (minimum 16 gauge) across the two terminals on the remote

start terminal block. This applies a ground to the Magnum Digital Controller (MDC) to close the starting

circuit contacts. The engine should crank, start and run.

3. Remove the jumper wire from the remote start terminal block and the engine will stop. Reconnect any

necessary wires from the remote start switch (transfer switch) to the remote start terminal block.

4. Confirm unit is in “AUTO” mode. The LCD window should have “AUT” highlighted in the upper left

corner.

5. Close (set to “ON / I”) the main circuit breaker.

6. Secure the generator by closing and locking all access doors.

7. The generator is now ready for remote starting.

30

Page 31

LIGHT OPERA TION

1. Once the engine is up to temperature and running smoothly , switch main circuit breaker to the ON “I” position.

2. With main circuit breaker on, switch each individual circuit breaker for the lights to ON “I”, one at a time.

3. The green ballast indicator lights will come on momentarily as the lights strike. As the lights warm up, the