Magnum MI-81350 Operating Manual

MODEL NO.:

MI-81350

OPERATING MANUAL

1

Table of contents

Page

SAFETY INSTRUCTIONS .......................... ............................. .......................... .....................2

Receiving Jointer....................................................................................................................4

Unpacking and cleaning..........................................................................................................5

Placement the 8” jointer.......................................................................................................5

Magnetic Switch......................................................................................................................6

Installation Blade Guard & Removal.......................................................................................6

Grounding Instructions............................................................................................................9

Adjustments..........................................................................................................................10

Fence Adjustments: Tilt .......................................................................................................13

Helical Cutterhead................................................................................................................14

Cutterhead Removal.............................................................................................................15

Replacement.........................................................................................................................16

Jointing Knives......................................................................................................................16

Replacement the Belts..........................................................................................................17

Basic Operations ..................................................................................................................18

Push Blocks..........................................................................................................................21

Wiring Diagrams ...................................................................................................................22

Parts Diagrams.....................................................................................................................23

Parts List...............................................................................................................................26

2

SAFETY INSTRUCTIONS

For Your Safety Read Instruction Manual Before Operating Jointer

As with all machines, there is a certai n amount of hazard involv ed with the use of this joint er. Use the machine with

the respect and caution demanded where safety precautions are concerned. When normal safety precautions

are overlooked or ignored, personal injury to the operator can result.

Wear eye protection.

Always keep cutter head and drive guards in place and in proper operating condition. Do not remove guard

for rabbeting operations.

Never make jointing , planning, or rabbeting cut deeper than 1/8 in.

Always use hold-down/push blocks for jointing material narrower than 3 inches, or planning material thinner

than 3inches.

Never perform jointing. Planning, or rabbeting cuts (with jointers provided with a rabbeting guard) on pieces

shorter than 8 inches (203 mm) in length.

Keep guards in place and in working order.

Remove adjusting keys and wrenches. Form habit of checking to see that keys and adjusting wrenches are

removed from tool before turning it on .

Keep work area clean. Cluttered areas and benches invite accidents.

Don’t use in dangerous environment. Don’t use power tools in damp or wet locations, or expose them to

rain. Keep work area well lighted.

Keep children away. All visitors should be kept safe distance from work area.

Make workshop kid proof with padlocks, master switches, or by removing starter keys.

Don’t force tool. It will do the job better and safer at the rate for which it was designed.

Use right tool. Don’t force tool or attachment to do a job for which it was not designed.

Use proper extension cord. Make sure your extension cord is in good condition. When using an extension

cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord will

cause a drop in line voltage resulting in loss of power and overheating Table (see Figure 9) shows the correct

size to use depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gage.

The smaller the gage number, the heavier the cord.

Wear proper apparel. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other jewelry which

may get caught in moving parts. Nonslip footwear is recommended. Wear protective hair covering to contain

long hair.

Always use safety glasses. Also use face or dust mask if cutting operation is dusty. Everyday eyeglasses

only have impact resistant lenses , they are NOT sa fe t y glas s es .

Secure work. Use clamps or a vise to hold work when practical. It’s safer than using your hand and it frees

both hands to operate tool.

Don’t overreach. Keep proper footing and balance at all times.

Maintain tools with care. Keep tools sharp and clean for best and safest performance. Follow instructions for

lubricating and changing accessories.

Disconnect tools before servicing; when changing accessories, such as blades, bits, cutters, and the like.

3

Reduce the risk of unintentional starting. Make sure switch is in off position before plugging in.

Use recommended accessories. Consult the owner’s manual for recommended accessories. The use of

improper accessories may cause risk of injury to persons.

Never stand on tool. Serious injury could occur if the tool is tipped or if the cutting tool is unintentionally

contacted.

Check damaged parts. Before further use of the tools, a guard or other part that is damage d sh ould be

carefully checked to determine that it will operate properly and perform its intended function – check for

alignment of moving parts, binding of moving parts, breakage of parts, mounting , and any other conditions

that may affect its operation. A guard or other part that is damaged should be properly repaired or replaced.

Direction of feed. Feed work into a blade or cutter against the direction of rotation of the blade or cutter only.

Never leave tool running unattended. Turn power off. Don’t leave tool until it comes to a complete stop.

Do not perform jointing operation on material shorter than 8 in , narrower than 3/4 in, or less than 1/4 in thick.

Do not perform planning operation on material shorter than 8 in , narrower than 3/4 in, or wider than 8” in or

thinner than 1/2 in.

Maintain the proper relationships of infeed and outfeed table surfaces and cutter head knife path.

Support the work piece adequately at all times during operation; mqintain control of the work at all times.

Do not back the work toword the infeed table.

Do not attempt to perform an abnormal or a little-used operation without study and the use of adequate hold-

down/push blocks, jigs, fixtures, stops and the like.

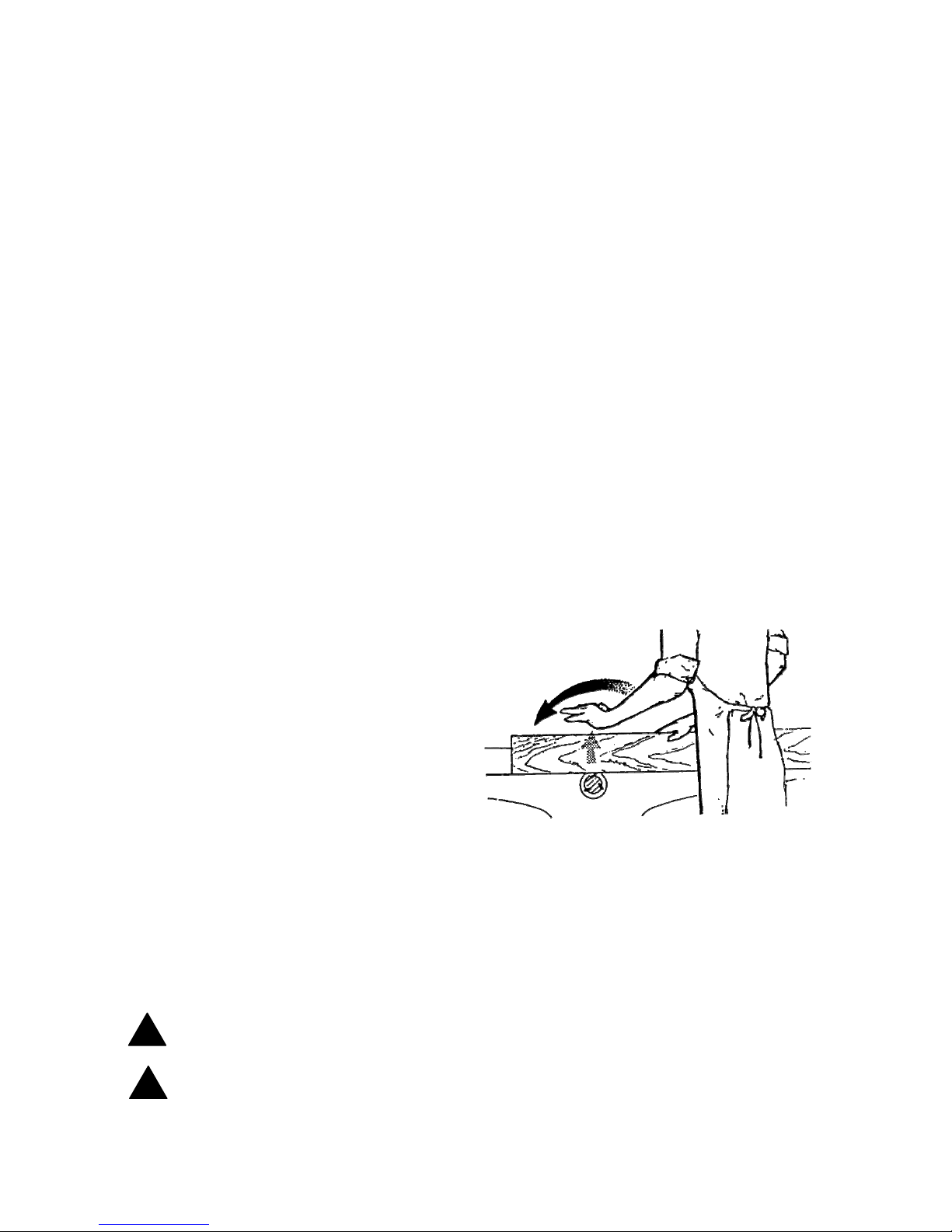

Hand safety. It is good practice to move the hands

in an alternate motion from back to front as the work

continues through the cut. Never pass the hands

directly over the cutter knife. As one hand approaches

the knives remove it from the stock in an arc motion

and place it back on the stock in a position beyond

the cutterknife.

Three inch rule. When working a piece of wood on

the jointer, follow the 3 inch radius rule. The hands

must never be closer than 3 inches to the cutter head.

Health hazards. Some dust created by power

sanding, sawing, grinding, drilling and other construction activities contains chemicals known to cause cancer,

birth defects or other reproductive harm. Some examples of these chemicals are:

*

Lead from lead-based paint.

*

Crystalline silica from bricks and cement and other masonry products.

*

Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area, and work with approved safety equipment, such

as those dust masks that are specifica lly designed to filter out microscopic particles.

Familiarize yourself with the following safety notices used in this manual:

CAUTION: (This means that if precautions are not heeded, it may result in minor or moderate injury

and/or possible machine damage)

WARNING: (This means that if precautions are not heeded, it could result in serious injury or

possibly even death).

!

!

4

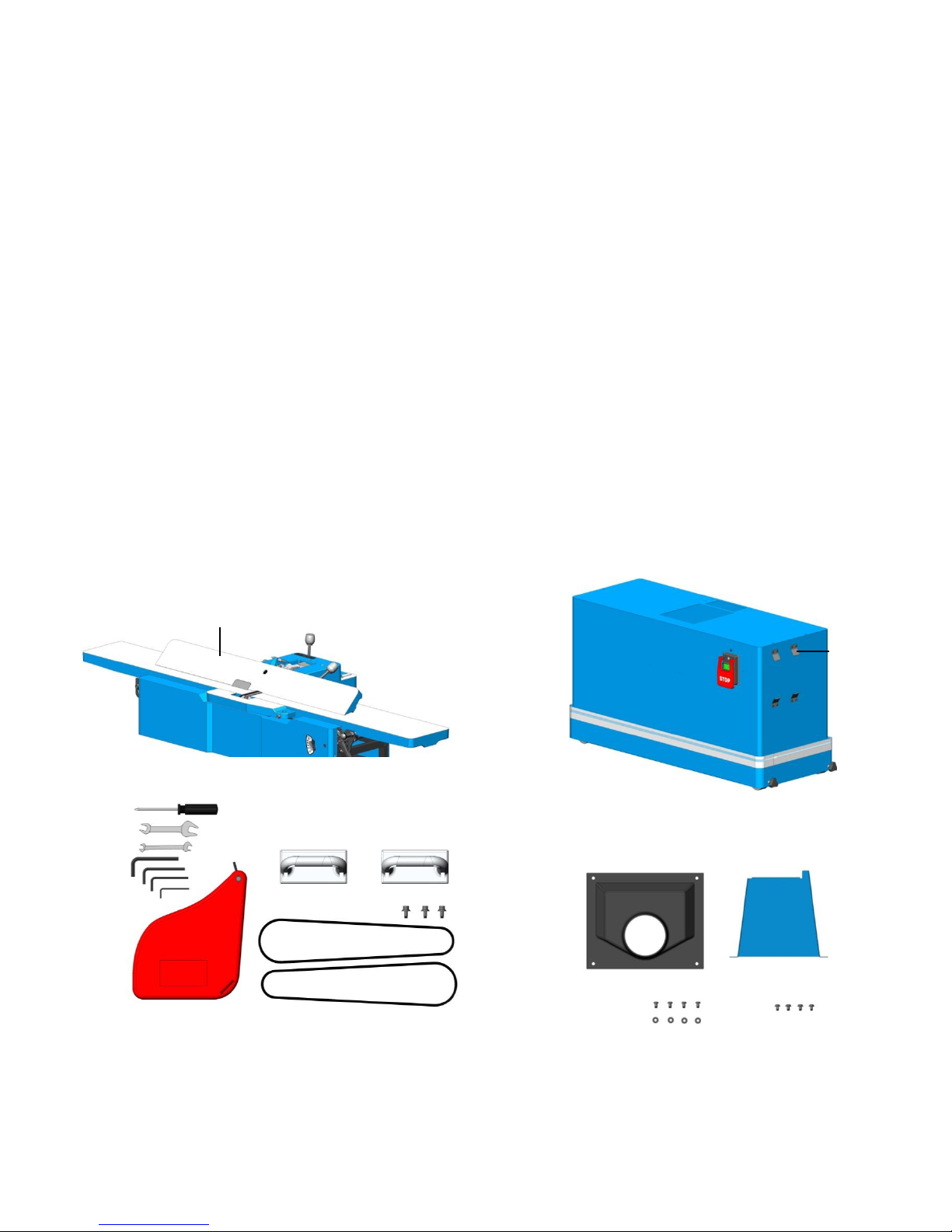

Receiving Jointer

Upon deliv e ry , o pen shippin g co nta iner s and che ck

that all parts are in good condition. Any damage

should be reported to your distributor and

shipping agent immediately. Before proceeding

further, read your manual and familiarize yourself

thoroughly with assembly, maintenance and

safety procedures.

Contents of box 1:

A. Jointer Body with F enc e Assembly..... 1

B. Blade Guard .......................................... 1

C. Push Block ............................................2

D. CAP Screw W/Spring Washer

& Flat Washer ......................................3

E. V-Belt .....................................................2

F. Screw D river.......................................... 1

G. Open Wrench 11*13..............................1

H. Open Wrench 8*10................................1

I. HEX. Wrench 8mm ...............................1

J. HEX. Wrench 6mm ...............................1

K. HE X. Wrenc h 5mm ..................................1

L. HEX. Wrench 3mm..................................1

Contents of box 2:

M. Stand................................... ...................1

N. Pulley Cover ..........................................1

O. Dust Chute.............................................1

P. Round Head Phillips Screw

W/WASHER...........................................4

Q. Round Head Phillips Screw...................4

R. Flat Washer ...........................................4

A

F

G

H

I

K

J

L

C

D

B

E

M

ON

Q

R

P

5

Unpacking and cleaning

To ensure maximum performance from your 8"

jointer, clean it properly; and install it accurately

before use. As soon as you receive the jointer,

we recommend you follow these procedures:

1. Finish removing the contents of the shipping

carton and compare with the contents list.

2. Report damage, if any to your local distributor.

3. Clean all rust protected surfaces with a mild

solvent or kerosene. Do not use lacquer

thinner; paint thinner, or gasoline. These will

damage painted surfaces.

4. To prevent rust, apply a light coating of paste

wax to surface.

Although some users prefer a wax coating for

the table surfaces, white talcum powder rubbed

in vigorously once a week with a blackboard

eraser will fill any casting pores and form a

moisture barrier. Talcum powder will not stain

wood or mar finishes.

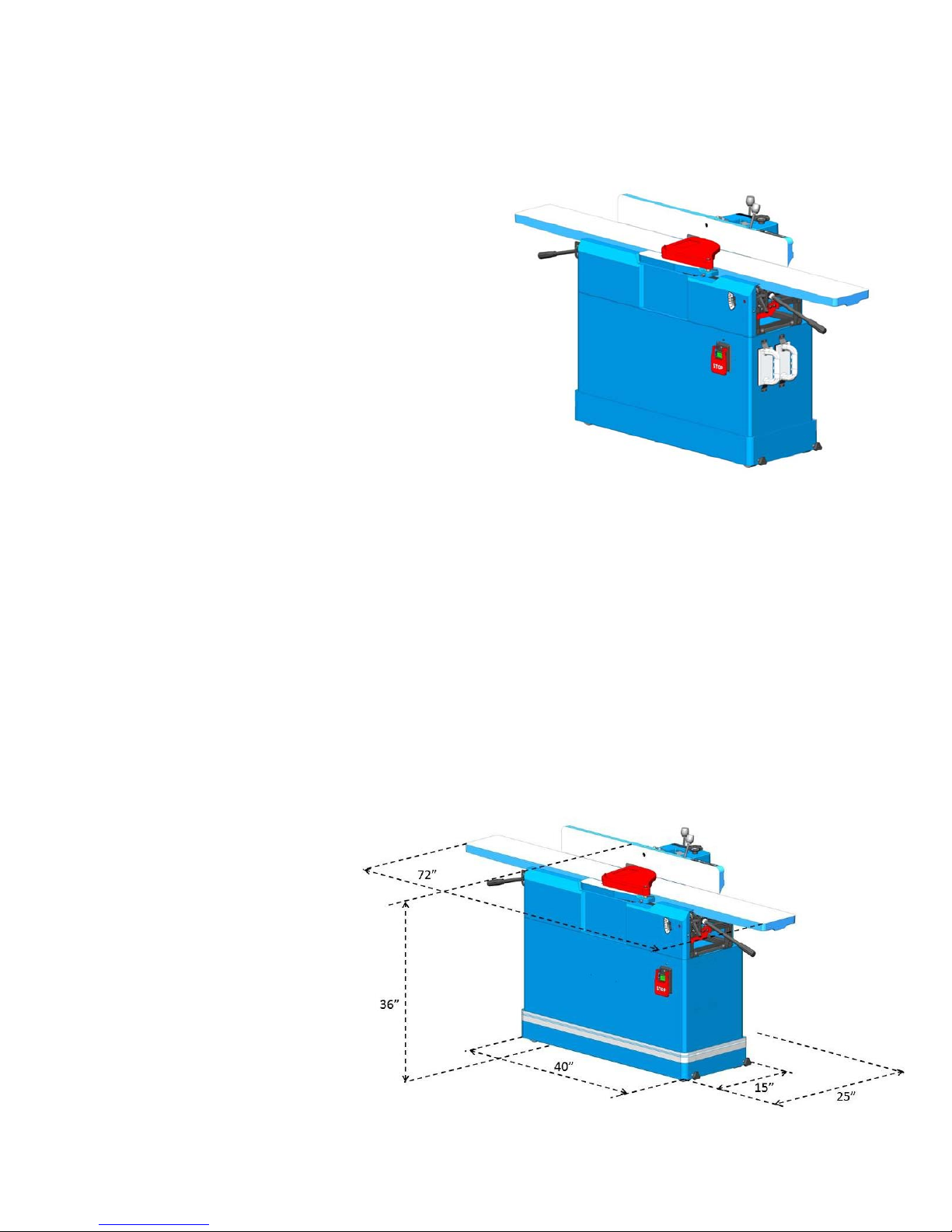

Placement the 8” jointer

This machine should be installed and operated

only on a solid, flat and stable floor that is able to

support the weight of the Jointer (366 lbs-166kgs)

and the operator.

Using the dimensions shown as below (L 66”x

W15”x H 36”), plan for placement within your

shop that will allow the operator to work

unencumbered and

unobstructed by foot traffic or

other tools or machinery.

6

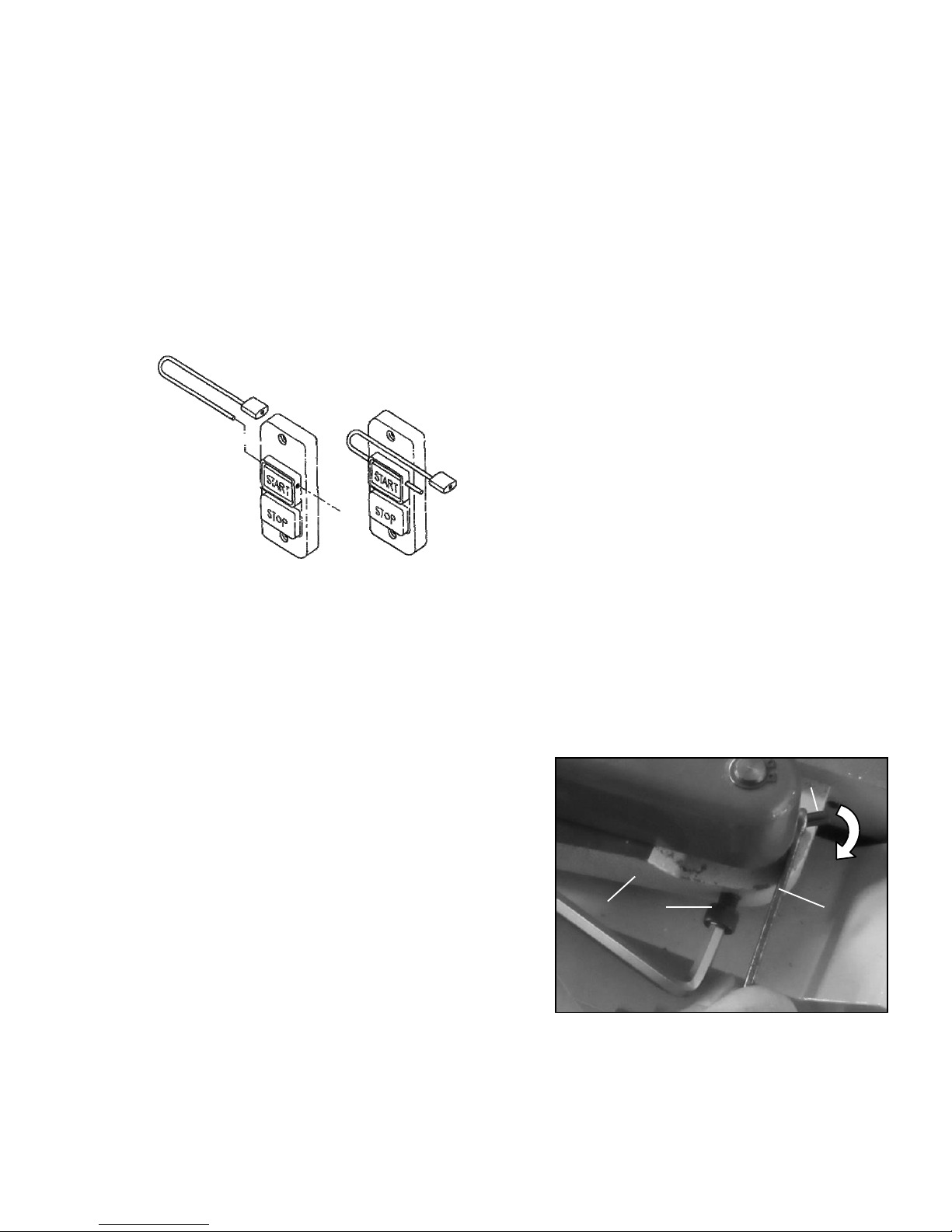

Magnetic Switch

The jointer is equipped with a magnetic switch that will accept a safety padlock (not included).

To safeguard your machine from unauthorized operation and accidental starting by young children, the use

of a padlock is required.

When you have finished using the machine be sure to re-install the lock-out pin and unplug the jointer from

the power source.

WARNING: Always be sure the switch is in the “OFF” position before connecting the jointer to the power

source.

Installation Blade Guard & Removal

WARNING: The Jointer knives are extremely

sharp. Use caution when working with or around

the cutterhead. Use the jointer guard for all

operations. Do not connect the plug to power

source

1. Loosen the CAP screw (Q) on the rabbet arm

(R), Fig. 11

2. Insert a spanner or similar object to hole the

pin (S).

3. Twist the pin (T) by spanner go to the end by

clockwise and hold it there.

4. Put the blade guard post into the hole on the

appropriated position, tighten the CAP screw

then remove the spanner.

5. Note: the blade guard could not touch the

rabbet arm surface for smooth move.

6. Check the guard for proper tension. If guard

does not swing back to contact the fence.

Repeating steps 1-4 until correct tension is

achieved. NEVER run the jointer without the

guard being in place and in perfect working

order.

Fig.11

S

R

Q

T

7

Grounding Instructions

WARNING: If the machine does not come

wired to run, the electricals and motor

wiring must be done by a qualified

electrician. The machine must be properly

grounded to help avoid electrical shock and

possible death. Follow the recommendations

made by the National Electrical Code for

grounding.

1. All grounded, cord connected tools:

In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

electric current to reduce the risk of electric shock.

This tool is equipped with an electric cord having

an equipment-grounding conductor and a

grounding plug. The plug must be plugged into a

matching outlet that is properly installed and

grounded in accordance with all local codes and

ordinances. Do not modify the plug provided - if it

will not fit the outlet, have the proper outlet

installed by a qualified electrician.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock.

The conductor with insulation having an outer

surface that is green, with or without yellow

stripes, is the equipment-grounding conductor. If

repair or replacement of the electric cord or plug

is necessary, do not connect the equipmentgrounding conductor to a live terminal. Check

with a qualified electrician or service personnel if

the grounding instructions are not completely

understood, or if in doubt as to whether the tool is

properly grounded.

Use only 3-wire extension cords that have 3-

prong grounding plugs and 3-pole receptacles

that accept the tool’s plug.

Repair or replace damaged or worn cord

immediately.

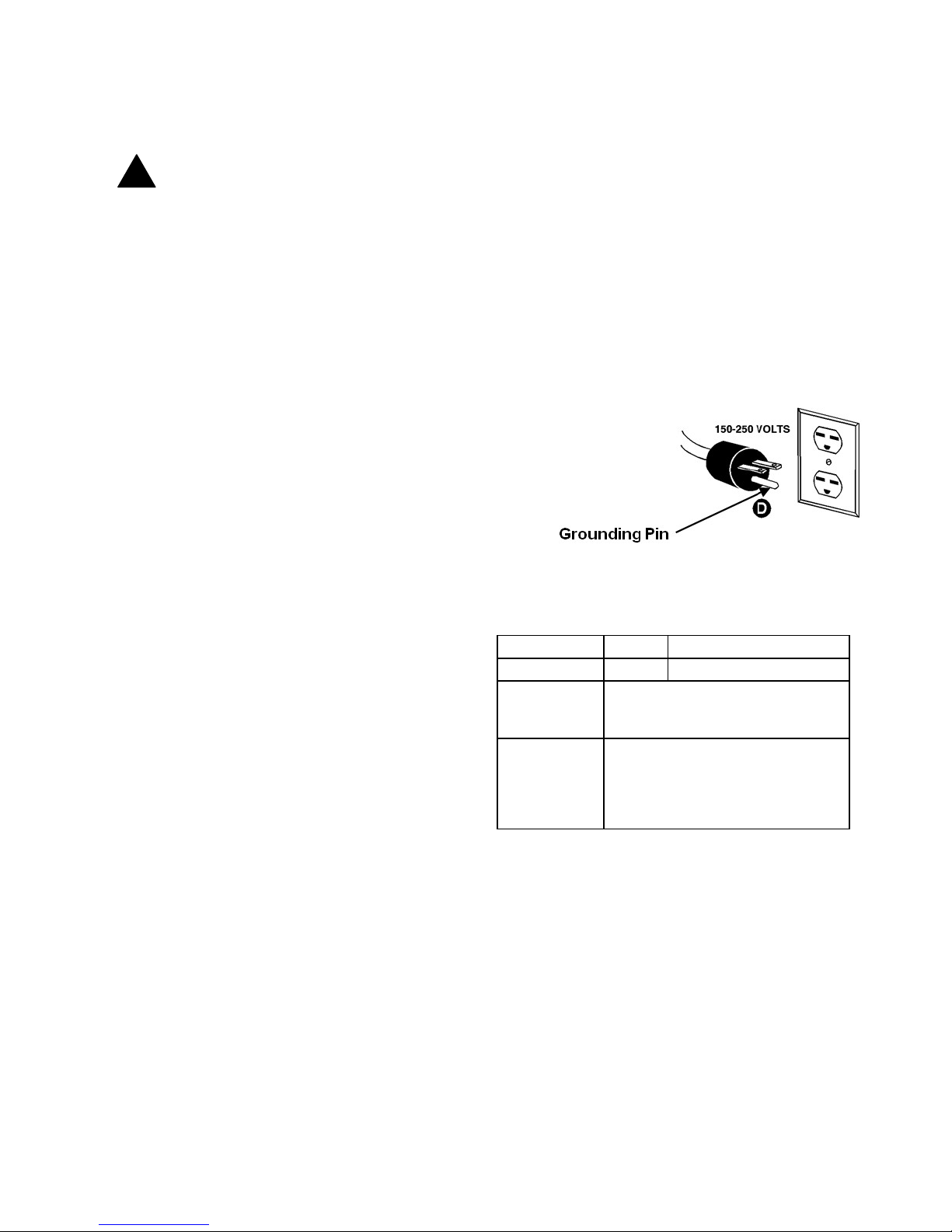

2. Grounded, cord-connected tools intended for

use on a supply circuit having a nominal rating

between 150-250 volts, inclusive:

This tool is intended for use on a circuit that has

an outlet that looks like the one illustrated in

Sketch D Fig. 12. The tool has a grounding plug

that looks like the plug illustrated in Sketch D.

Make sure the tool is connected to an outlet

having the same configuration as the plug. No

adapter is available or should be used with this

tool. If the tool must be reconnected for use on a

different type of electric circuit, the reconnection

should be made by qualified service personnel

and after reconnection, the tool should comply

with all local codes and ordinances.

Extension Cords

Use proper extension cord. Make sure your

extension cord is in good condition. When using

an extension cord, be sure to use one heavy

enough to carry the current your product will

draw. An undersized cord will cause a drop in

line voltage resulting in loss of power and

overheating. Fig. 13 shows the correct size to

use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier

gauge. The smaller the gauge number, the

heavier the cord

FIG. 12

Ampere Rating

Volts Total length of cord in feet

Ampere Rating

230 25' 50' 100'

150'

More Not

Than

More

Than

AWG

0 6

6 10

10 12

12 16

18 16 16 14

18 16 14 12

16 16 14 12

14 12

Not recommended

FIG. 13

Note: The reconnection shall be made by qualified

service personnel.

!

8

Adjustments

Warning: Always disconnect the machine from

the power source before making any

adjustments.

Failure to heed this warning can lead to serious

personal injury.

To adjust outfeed table

The outfeed table should be set level with the

highest point of the knives, Fig. 14. The height

of the outfeed table should be verified and

adjusted prior to first use. It should also be

verified and readjusted periodically to

compensate for knife wear and also upon knife

replacement.

The Jointer table is adjusted at manufactory and

should no further adjustment required. To align

the tip of knife & outfeed table as below if

necessary.

1. Make sure that the machine is

disconnected from the power source.

2. To give yourself unimpeded access to the

cutterhead and upper pulley, remove the

blade guard.

3. Set a straightedge (A, Fig. 14 & 15) onto

the outfeed table so that it sits over the

cutterhead but does not completely cross

the gap between the tables and do not

touch the infeed table.

4. Turn the upper pulley by hand, until any

one of the knives is at its highest point.

5. Loosen the C AP screw (B, Fig. 16) by

8mm Hex. wrenc h .

6. Push up or down the height adjustment

handle (C, Fig. 16) to adjust the outfeed

table height so th at the knife tip barely

touches the straight-edge

.

7. Re-tighten t he CA P scre w (B) to secure the

outfeed table in positio n.

8. If the outfeed table couldn’t low to correct

position release the Hex. nut (D) then loosen

the Hex. bolt (E), Fig. 17.

9. Lower the outfeed table to the location of the

appropriate by height adjustment h andle (C)

then tighten the CAP screw (B).

10. Re-tighten the Hex. nut (D)

11. Re-tighten the Hex. bolt (E).

FIG. 14

FIG. 15

FIG. 16

FIG. 17

A

OUTFEED

TABLE

INFEED

TABLE

(

RIGHT

)

A

B

C

B

D

E

Loading...

Loading...