MAGNUM CTV-2920 TXT Schematic

SERVICE MANUAL

TV SET

MODEL:

CTV-2920 TXT

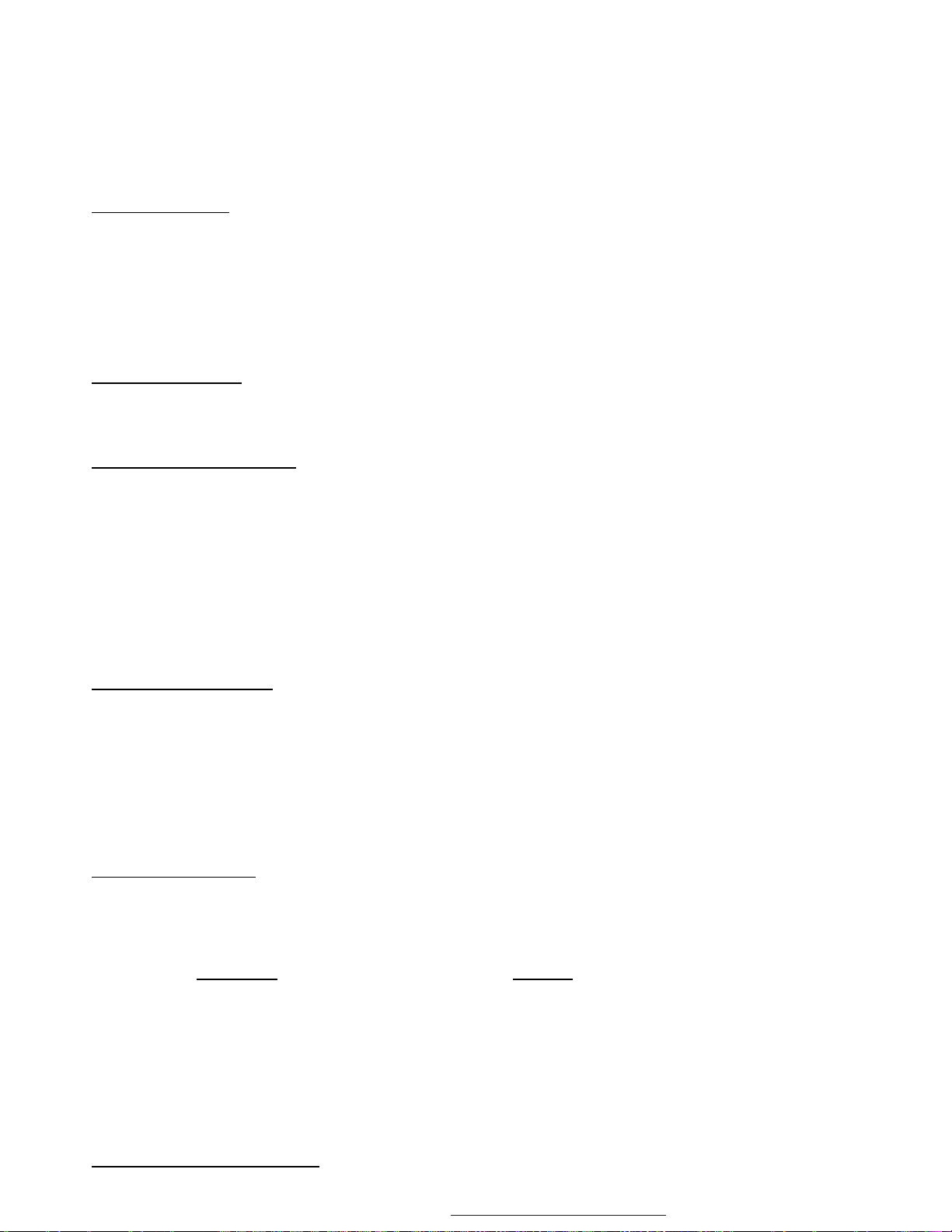

Picture tube high voltage anode cap

SAFETY INSTRUCTIONS

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "X-RAY

RADIATION PRECAUTION", "SAFETY PRECAUTION" AND "PRODUCT SAFETY

NOTICE" DESCRIBED BELOW.

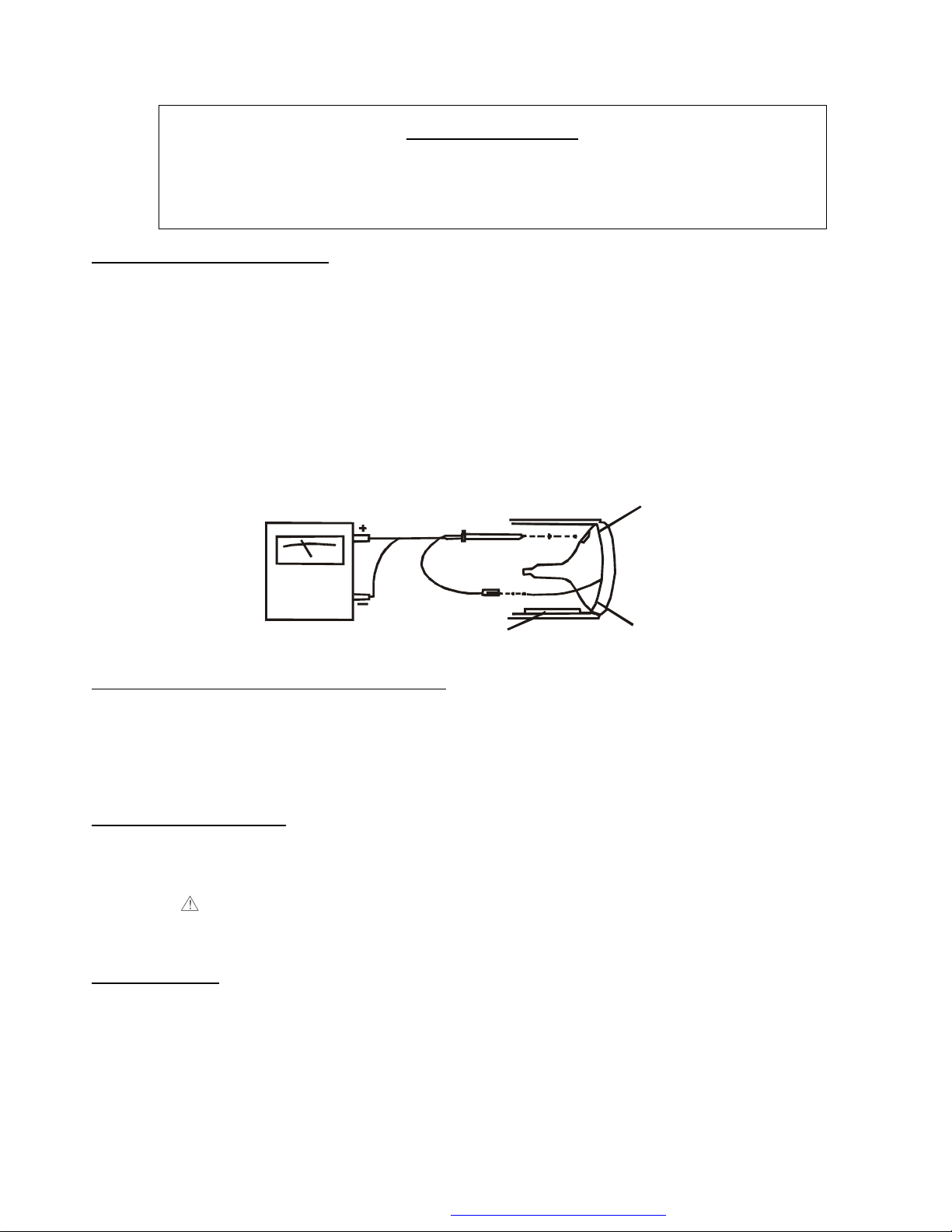

X-RAY RADIATION PRECAUTION

1. Extremely high voltage of the picture tube may result in producing potentially hazardous X-RAY RADIATION. To

avoid such hazards, the high voltage must not be above the specified limit.

The nominal value of the high voltage of this receiver is about 30.4 kV at zero beam current (minimum brightness)

under 175-245V AC power source.

The high voltage must, under any circumstances, not exceed about 36.5kV.

Each time this receiver requires servicing, the high voltage should be checked according to the HIGH VOLTAGE

CHECK procedure at the back of this manual. it is recommended to record the reading of the high voltage in the service

record each time. Using an accurate and reliable high impedance and high voltage meter is quite important.

Connect the NEGATIVE and POSITIVE probe of a high voltage meter to the "ground" and the high voltage anode cap

of the picture tube respectively.

HIGH VOLTAGE CHECK CONNECTION DIAGRAM

2. The only source of X-RAY RADIATION in this receiver is the picture tube. For ensuring the intensity of X-RAY

RADIATION from the picture tube being within the specified safety limit, the replacement picture tube must be exactly

the same type specified in the parts list.

3. Some parts in this receiver have special safety-related characteristics which would affect X-RAY RADIATION

protection. For safety, parts replacement should be carried out only after referring to the "PRODUCT SAFETY

NOTICE" below.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this receiver have special safety-related characteristics (directly relate to high

voltage, high temperature or electric shock) which are not easily seen by visual inspection. Whenever replacing such

components, make sure that the replacement parts can provide effective X-RAY RADIATION protection even though their

high voltage and wattage can meet the specification of the original design. Such parts can be identified by shading and

marking with

Before replacing any of these components, read the parts list in this manual carefully. Using substitute parts which do not

have the same safety characteristics as the ones specified in the parts list may create excessive X-RAY RADIATION.

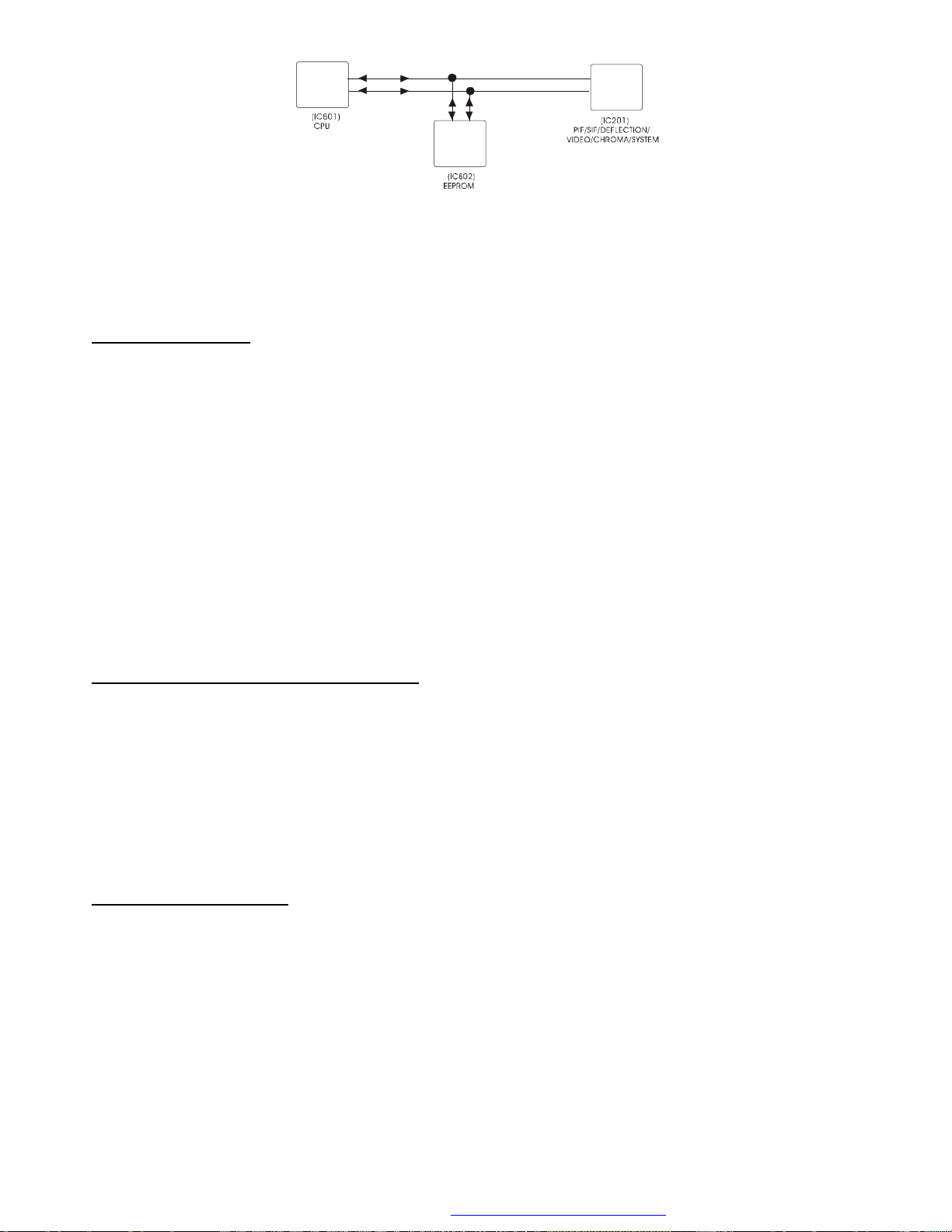

I2C BUS CONCEPT

(1). Characteristics

1.1 I2C Bus consists of clock (SCL) and data (SDA) lines.

1.2 It transmits data among integrated circuits in full duplex mode.

1.3 It is composed of a main IC chip (CPU) and one or more sub-IC chips.

l The CPU mainly operates data transmissions and also generates clock signal.

l The CPU also controls all sub-IC chips, making them work.

(2). I2C Bus Application in this TV unit

High impedance and high voltagh meter Chassis

in the schematic diagram and the parts list.

Picture tube ground

2

SDA

SCL

SDA

SCL

SDA

SCL

In this TV unit, IC801 is the main chip while IC802, IC201 and other chips are regarded as sub-chips.

2.1 IC801 (CPU) controls the functions of IC201 via the I2C bus between them.

2.2 The data of channel positions, BT voltage, band, AFT, clear, volume, power on/off, timer, color, etc. are written into,

stored in and read out from IC802 via the I2C bus.

SAFETY PRECAUTION

1. High voltage of 27-32kV is always present inside this receiver when it is operating, so be cautious of electric shock hazard

while removing the back cabinet to process adjustment.

(A) Servicing should not be attempted by any person who is not very familiar with the required re-cautions when

working on this high-voltage equipment.

(B) Before removing the anode cap of the picture tube, discharge the high voltage potential from the picture tube anode

several times by short-circuiting the anode together with its ground to keep off electric shock hazard.

(C) Perfectly discharge the high voltage potential of the picture tube before handling the picture tube which is highly

evacuated. When it is broken, danger may be caused because of the violent burst of its glass fragments.

2. If the fuse in this receiver is blown, replace it with the type specified in the chassis parts list or with the same

specifications (never use other types).

3. Whenever replacing with new components, twist the lead wires of the component together with the concerned residual

leads before soldering.

4. Whenever replacing with a new high wattage resistor (such as oxide metal film resistor) on any of the circuit boards,

keep the body of the resistor 10 mm above the circuit board.

5. Keep all connecting wires away from the components of high voltage or high temperature.

6. This receiver is designed to operate at AC 175-245V~50/60Hz, NEVER connect to DC supply or any other power sources.

7. The main chassis of this receiver is perfectly isolated.

INSTALLATION AND SERVICE ADJUSTMENTS

GENERAL INFORMATION:

Normally, this receiver have been thoroughly checked and adjusted before leaving the factory; therefore it should operate

normally and produce perfect color and B/W pictures upon installation. However, several minor adjustments may be

required according to the practical situation.

This receiver is packed in a cardboard carton during transportation. Carefully draw it out from the carton and remove all

packing materials.

Plug the receiver's power cord into a convenient 175-245V 50/60Hz AC two pins or three pins power outlet.

Check and adjust all the customer controls such as BRIGHTNESS, CONTRAST and COLOUR to obtain natural color or

B/W picture.

AUTOMATIC DEGAUSSING :

A degaussing coil is mounted around the picture tube so that external degaussing after moving the receiver is normally

unnecessary, providing the receiver is properly degaussed upon installation. The degaussing coil operates for about 1 second

after the power to the receiver is switched ON. If the set is moved or faced in a different direction, the power switch must be

switched off at least one hour in order that the automatic degaussing circuit operates properly. And then the receiver turned it

again.

Should the chassis or parts of the cabinet become magnetized to cause poor colour purity, use an external degaussing

coil. Slowly move the degaussing coil around the faceplate of the picture tube, the sides and front of the receiver and slowly

withdraw the coil to a distance of about 2 meters before disconnecting it from AC source. If colour shading still persists,

perform the “COLOUR PURITY ADJUSTMENT” and “CONVERGENCE ADJUSTMENTS” procedures as mentioned

later.

3

m

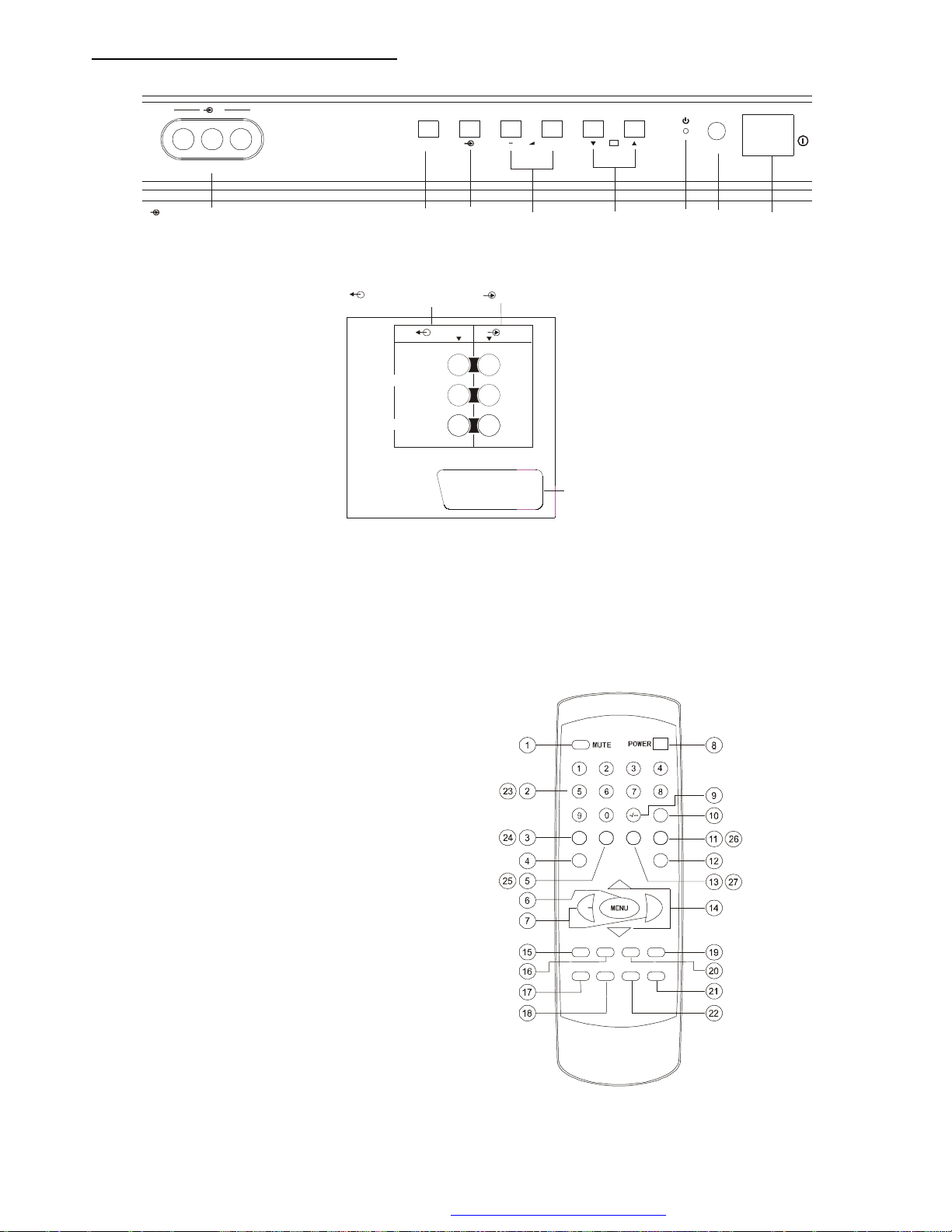

LOCATION OF CONTROLS AND SWITCHES

+

TV/ Video

Select Button

Terminals (Video), (Audio), (L/Mono).

(1)

Groups 1 of Audio/ Video Input

Termainals (Audio), (Video), (L/Mono)

REVEAL

++-

Front View (Front Configuration)

(2)

CH

Channel Position

Up/Down Button

(Channel Select)

Standby

(RED)

Infra-red

Sensor

Power On/Off

Button

R

(2)

Groups 2 of Audio/ Video Input

VIDEOL/MONO

MENU

MENU

Button

Volume Up/Down

Button

Rear View (Back Configuration)

TV/ VideoOut Termainals

(Video), (Audio), (Video), (L/Mono),

MONITOR

L/MONO

AUDIO

VIDEO

R

PERI-TELEVISION CONNECTOR

(1)

Peri-Television Connector

Remote Handset Operation

Top View of Remote Control

HOW TO OPERATE REMOTE CONTROL

There are 27 buttons on the remote control. It operates with infra-red beam which is not affected by noise or other

interferences. Make sure strong light never strikes on the infra-red receiver; otherwise, it would obstruct the remote

control working normally with the TV unit.

Do not drop or expose it to high temperature.

*4 (FOR NICAM/ GERMAN STEREO ONLY) *15-27 (FOR TELETEXT ONLY)

1. SOUND MUTING BUTTON

2. NUMBER (0-9) BUTTONS

3. STATUS (RED) BUTTON

4. NICAM BUTTON

5. PERSONAL PREFERENCE (GREEN) BUTTON (PP)

6. MENU BUTTON

7. VOLUME (UP/DOWN) BUTTONS

8. STANDBY BUTTON

9. DIGIT SELECT BUTTONS

10. TV/AV BUTTON

11. PREVIOUS (YELLOW) BUTTON

12. ANALOG BUTTON

13. SLEEP (BLUE) BUTTON

14. PROGRAM (UP/DOWN) BUTTONS

15. CANCEL BUTTON

16. SUBCODE BUTTON

17. STOP BUTTON

18. REVEAL BUTTON

19. TV/TXT. BUTTON

20. INDEX BUTTON

21. MIX. BUTTON

22. SIZE BUTTON

23. DIGIT ENTRY (0-9) BUTTONS

24-27. COLOUR BUTTON

STATUS

NIACM

CANCEL

STOP

PP

VOL

SUBCODE

AV

SLEEP

RECALL

ANALOG

P

VOL

P

INDEX

TV/TXT

SIZE

MIX

4

HOW TO DISASSEMBLE REMOTE CONTROL HAND UNIT (see Fig. 1)

Screws(B)

High-volotage anode cap

1. Remove the battery cover and loosen the screws.

2. Open one side of the back cabinet to take it away from the front cabinet.

Fig. 1

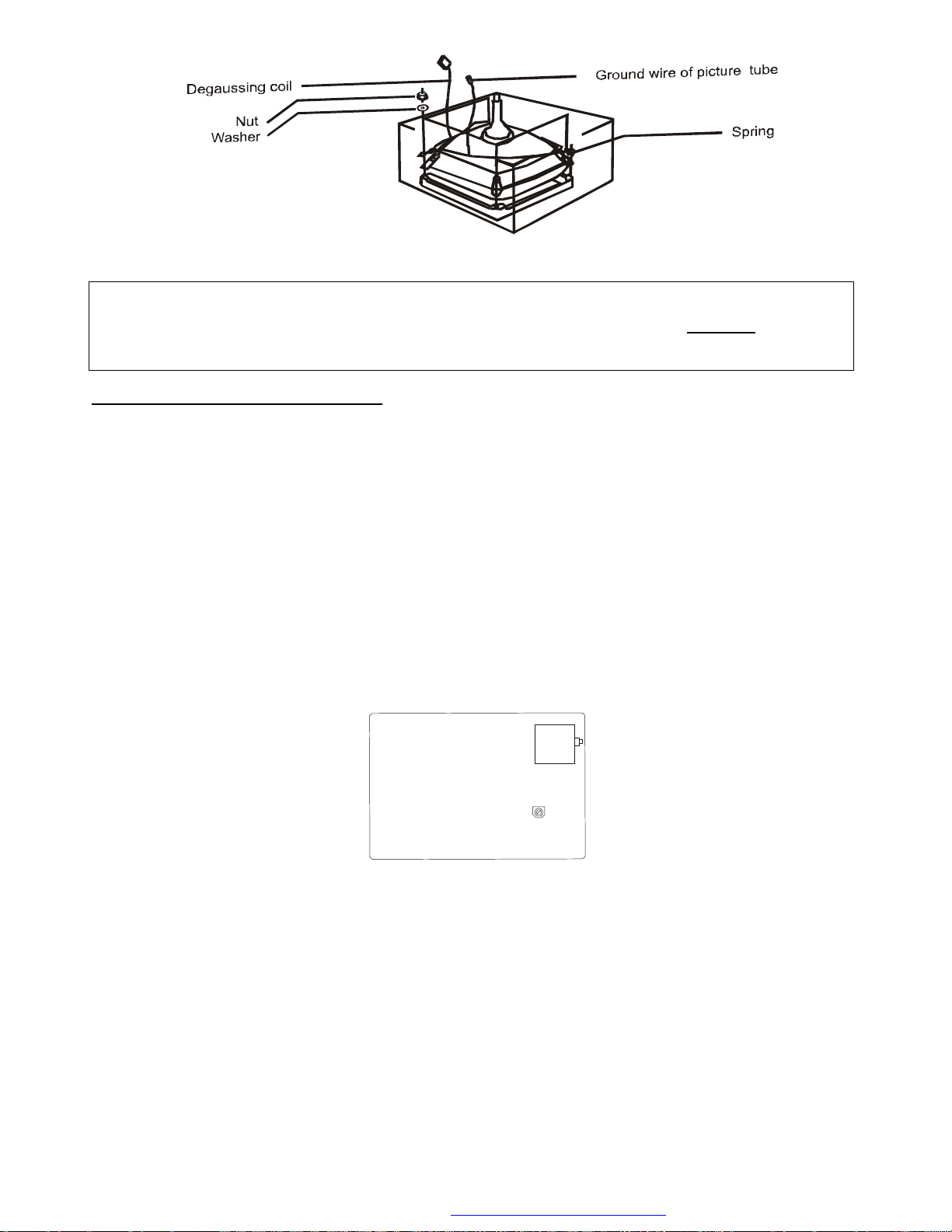

METHOD OF REMOVING BACK CABINET

(see Fig. 2)

Attn.: Before disassembling the back cabinet, first draw the power cord plug of the receiver from AC outlet.

1. Disconnect the antenna cable from the antenna terminal.

2. Loosen the 5 pieces of screw (A) used in fixing the antenna jack plate on the back cabinet.

3. Loosen the 9 pieces of screw (B) used in fixing the back cabinet to the front cabinet; then remove the back cabinet.

Screws(B)

Screws(A)

Fig.2

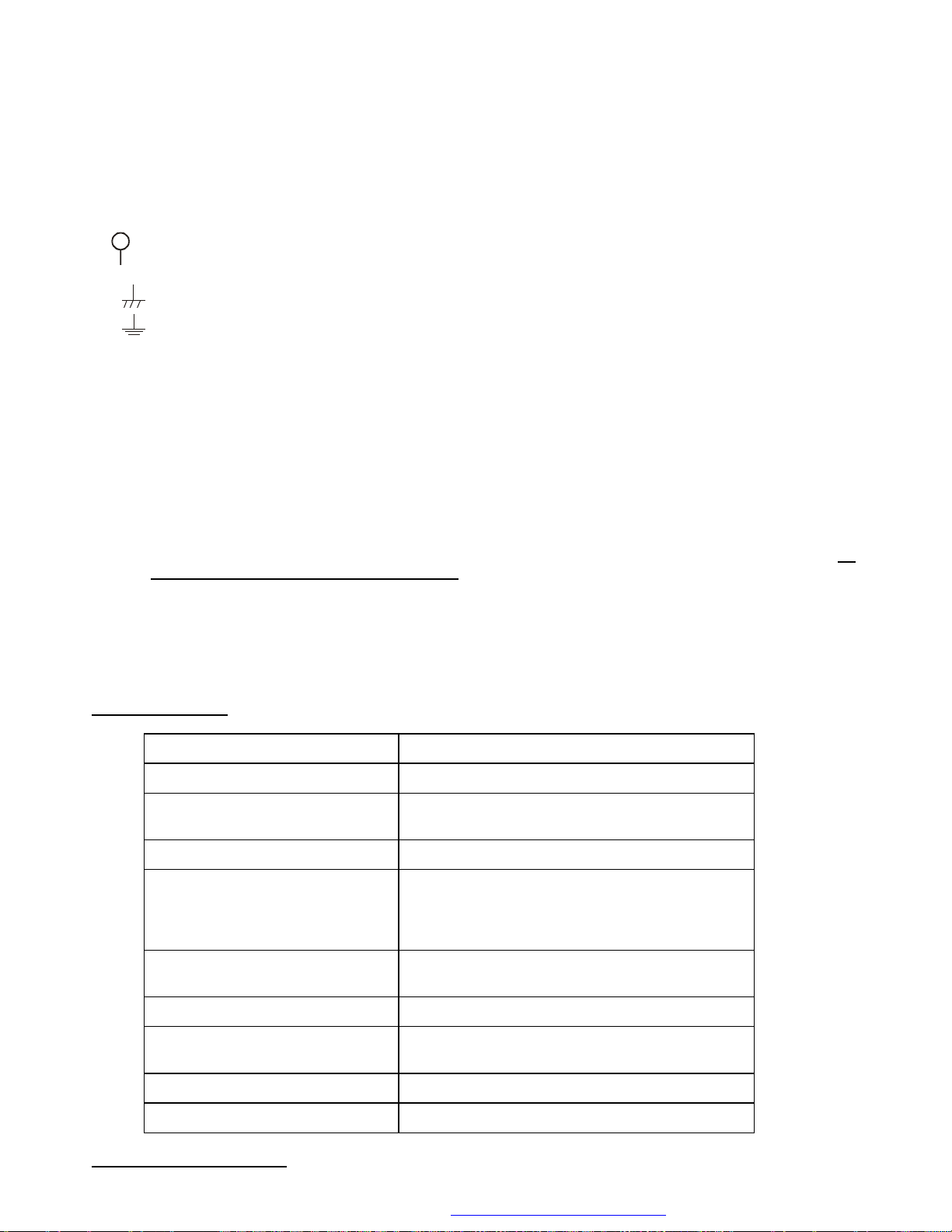

METHOD OF REMOVING MAIN CHASSIS

(see Fig. 3 & 4)

After removing the back cabinet, proceed the following procedures accordingly.

1. To avoid electric shock hazard, discharge the high Fig.3

voltage potential from the picture tube anode

several times by short-circuiting the positive anode

of the picture tube with its ground before detaching

the high-voltage anode cap.

2. Unsolder and detach the ground wire of the picture

tube from the picture tube socket board.

3. Detach the picture tube socket board.

4. Detach the high-voltage anode cap.

5. Unplug Socket KP, KK, SV, SC, T, K or X and P.

Picture tube socket board

6. Take out the chassis from the chassis holder.

METHOD OF REMOVING PICTURE TUBE

(see Fig. 4)

After taking out the chassis holder (main chassis), proceed the following procedures accordingly:

1. Turn the receiver down and let the screen of the picture tube face downward, and put it on a soft cushion.

2. Loosen the 4 pieces of nut used in fixing the picture tube on the front cabinet, remove the degaussing coil; then use two

hands to hold the edges of the picture tube tightly and draw it out.

3. Detach the ground wire of the picture tube which is attached to the lugs of the picture tube with springs.

5

MAIN CHASSIS PC BOARD

T901

Fig.4

SUGGESTION: Before servicing the chassis, please read through “X -RAY RADIATION PRECAUTION",

"SAFETY PRECAUTION" and "PRODUCT SAFETY NOTICE" at Page 2 & 3

of this manual.

GENERAL ADJUSTMENT INSTRUCTIONS

This receiver is transistorized and special care should be taken when servicing. If not necessary, do not attempt any

adjustments because the requirements of the procedures are very stringent. Read the following matters before attempting

any adjustments.

An isolation transformer should be used during any dynamic service to avoid possible electric shock hazard.

The test equipment specified or their equivalent is required in having proper alignment. Using unsuitable equipment, which

do not meet these requirements, may result in improper alignment.

Correct matching of the equipment is essential. Failure of using proper matching will result in responses which cannot show

the true operation of the receiver.

Excessive signal by using a sweep generator can cause the receiver circuit overloaded. Overloading should be avoided to

obtain a true response curve. Insertion of markers by using the marker generator should not cause the response curve

distorted.

The AC power line voltage should be accurately kept during alignment.

During the process of alignment, the AC voltage should be kept in the range from 215V to 225V (50Hz).

Do not attempt to connect or disconnect any wire while the receiver is in operation. Make sure the power cord is unplugged

before replacing any parts in the receiver.

Unless specified, start adjustments after the receiver is turned on for at least 30 seconds.

CHASSIS'S TOP VIEW

VR 501

NOTICE:

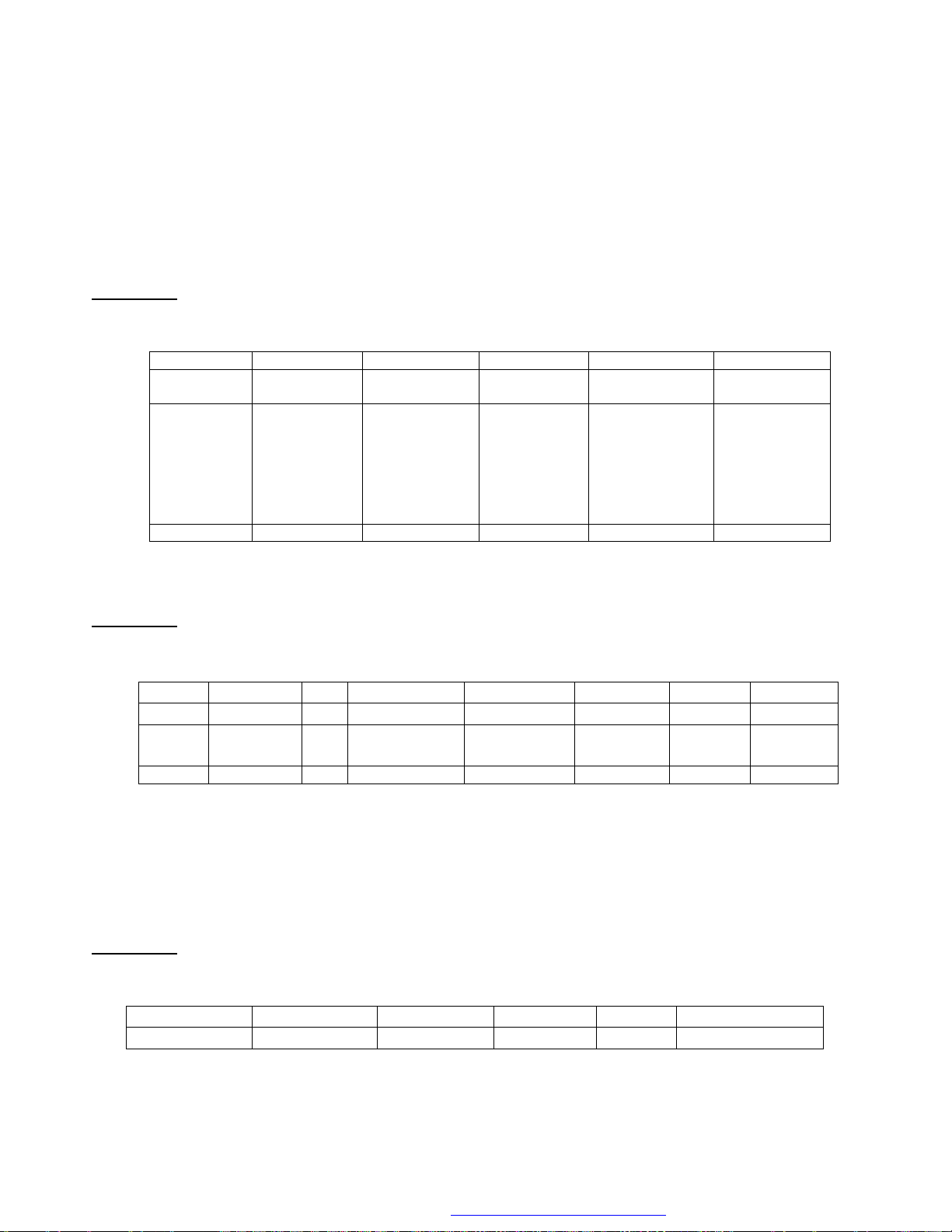

1. Resistor

All resistors are of 1/8W Carbon Film type except those listed below. The unit of measure for resistor is OHM

(K = 1,000 ohm, M = 1,000,000 ohm).

CARBON FILM RESISTOR

CARBON COMPOSITION RESISTOR

METAL OXIDE RESISTOR +5%

METAL OXIDE RESISTOR +2%

FUSIBLE RESISTOR

NON-INFLAMMABLE RESISTOR

PTC THERMISTOR

VARIABLE RESISTOR

2. Capacitor

6

All capacitors are of 50V Ceramic type except those listed below. The unit of measure for capacitor is

FARAD (F) (UF = 0.000001 F, PF = UUF = 0.000001 UF)

CERAMIC CAPACITOR

TANTALUM CAPACITOR

POLYESTER FILM CAPACITOR

POLYPROPYLENE FILM CAPACITOR

ELECTROLYTIC CAPACITOR

TRIMMER CAPACITOR

METAL POLYESTER FILM CAPACITOR

3. Unit of Measure: UH

4. Test Point

5. Marking of Ground Wire

: Ground wire of chassis (COLD)

: Ground wire of external wire (HOT)

6. Voltage Measurement

The voltages at all points should be measured with a digital multi-meter, and the measuring conditions are as follows:

Power Source: AC220V 50Hz

Receiving Signal: Color Bar Signal

All Control Buttons: in Normal Position

7. Waveform

The numeral in the small circle represents the number of waveform, refer to the waveform table.

8. It is easy to locate a connection point in the direction as indicated by arrow (↗).

9. The schematic diagram in this manual is drawn according to the original design. It may be slightly different from the

actual circuit of the receiver because of any change in the circuit subject to no prior notice.

Notice: This circuit has a transformer to isolate the power supply circuit from the majority of the other circuit, and they

can be identified in the schematic diagram by marking with "HOT" and "COLD”. Please note the followings .All

circuits are "COLD" except power supply circuit

.

(1) To avoid electric shock hazard, never touch the "HOT" and "COLD" circuit simultaneously.

(2) Never short-circuit the "HOT" and "COLD" circuit to prevent the fuse or other components from burning.

(3) Never connect any measuring equipment such as oscilloscope to both the "HOT" and "COLD" circuit at the same time

to prevent the fuse from burning. Also, connect the ground of the measuring equipment to the ground of the circuit

being tested.

(4) Never fail to unplug the power cord of the receiver before taking out the chassis.

TEST EQUIPMENT :

EQUIPMENT SPECIFICATION

High Impedance Voltmeter Having an impedance of at least 100 Kohm.

Oscilloscope Volt sensitivity over 10mV input impedance over 1

Sweep/Marker Generator Output adjustable to at least 0.1 volts rms.

Colour Bar Generator With functions: BAR/DOT/SQUARE/SYSTEM

Power Supply

AC/DC Voltmeter High sensitive (better use digital voltmeter)

Isolation Transformer

Probe Low-capacitance / High impedance.

FM/AM Signal Generator National ; MODEL : VP8177A

B+ VOLTAGE ADJUSTMENT

Mohm, below 10PF.

SELECT/VIDEO OUTPUT TERMINAL/CROSS-

HATCH/S-VIDEO OUTPUT TERMINAL functions

and green or red purity signal.

Source such as a battery or a well regulated and

isolated DC bias supply. (Adjust 0-20V)

Voltage adjustable type having capacity of more than

200 watts.

7

Notice: (A) B+ voltage closely relates to the picture tube's positive high voltage.

(B) To prevent it from producing excessive hazardous X- RAY RADIATION, ensure that B+ voltage must be

adjusted to at the 130V (CE-6422)/ 125V (CE-7422)/ 140V (CE-7429)/ 145V (CE-8628) POSITIONS.

1. Check the AC line voltage supplied is AC220V +-5% 50 Hz.

2. Turn in an active channel, adjust BRIGHTNESS and CONTRAST controls to obtain a normal picture.

3. Connect test point (C506) on the MAIN CHASSIS PCB with high impedance DC voltmeter.

4. Adjust VR501 (on the MAIN PCB) for B+ 130V +/-0.3V (CE-6422)/ 125V(CE-7422)/ 140V +/-0.3V(CE-7428, CE7429, CE-7431 and CE-7498)/ 145V +/-0.3V(CE-8627 and CE-8628) voltage reading.

Note:

(1)

'FORTUNE' 29" CRT -73SX731Y22-DC01 (69-01118-40) ---- B+ =138V

(2)

"SAMSUNG" 29" INFINITE FLAT CRT (TYPE: A68QCP891X005) (69-01118-45) ---- B+ = 125V

(3) 'THOMSON' 29" SUPERFLAT CRT - A68EEH038X890 (69-01118-16) ---- B+ = 125V

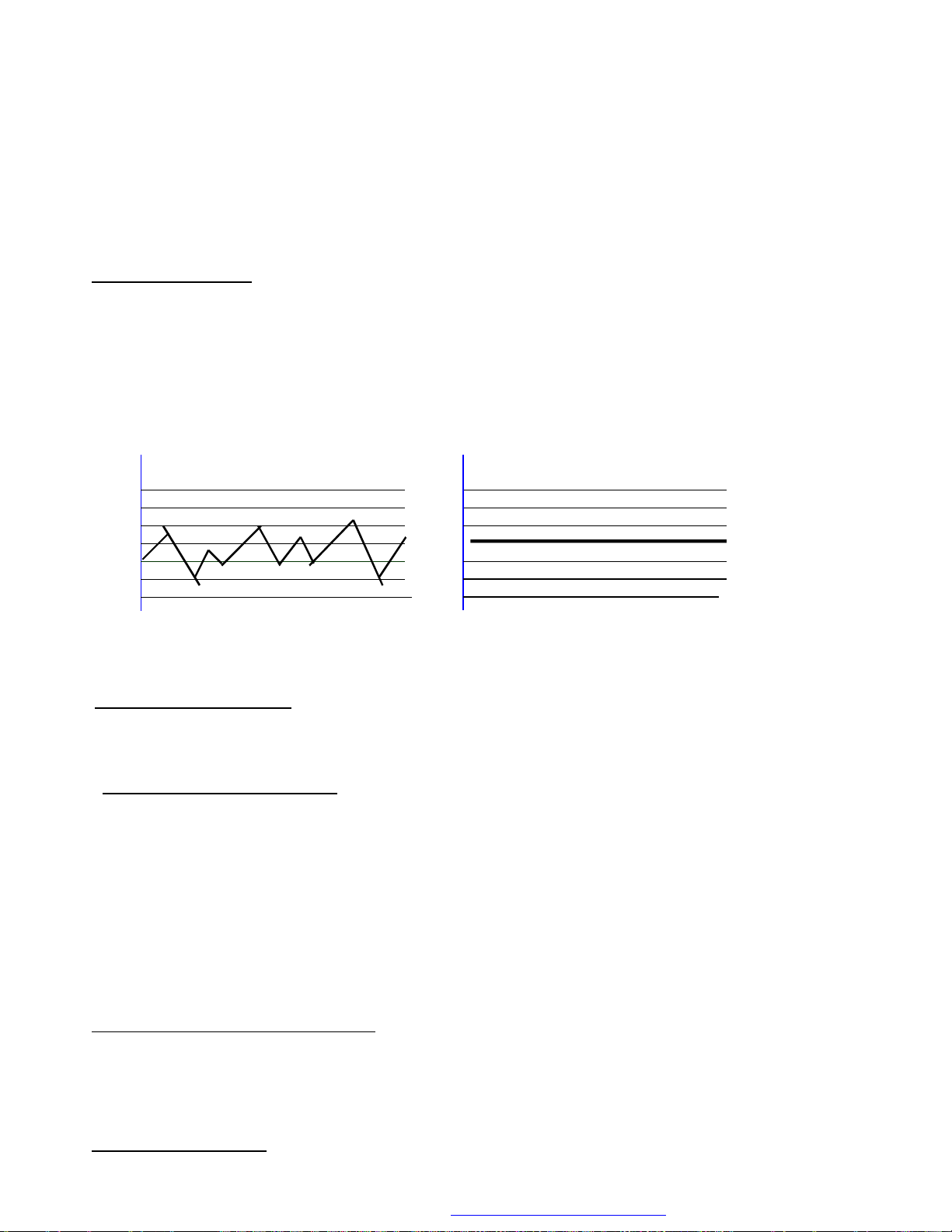

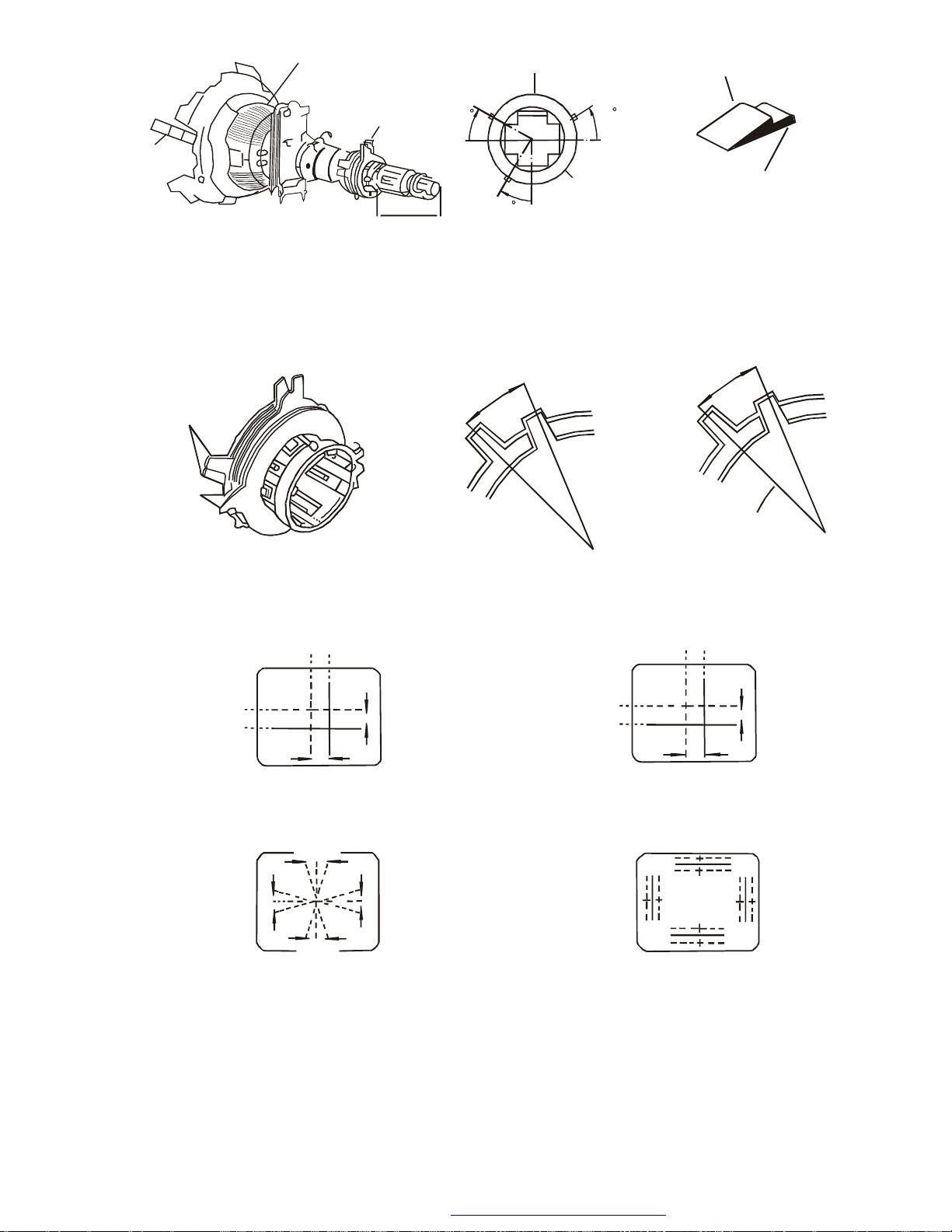

VCO IF ADJUSTMENT:

(1) In AV mode, disconnect the solder link( P1 ) on main chassis board.

(2) Connect an Oscilloscope Measure pin 1 of IC201.

(3) Does not apply signal to Tuner & Power on TV.

(4) Access service mode, then selects PIF VCO item adiustment setting date = 80

(5) Adjust the VCO coil (L204) so that the pin 1 of IC201 voltage is DC 2.5V and the waveform

(see Fig. 6)

(6) Press Factory handset [PP] key to finish.

(7) Turn off TV set and connect the solder link( P1 ) on main chassis board.

(1) Press Factory handset [ PP] key to finish.

5V 5V

2.5V 2.5V

0 Incorrect Waveform

0 Correct Waveform

(Fig. 5) (Fig. 6)

AGC DELAY ADJUSTMENT:

(1) Tune the strongest station in your area.

(2) Access service mode, then selects RF AGC item adiustment setting is about = 25 in the range (00 TO 3F).

(3) The snow just disappears from the screen.

WHITE BALANCE ADJUSTMENT:

(1) Tune in a active channel and warm up the set for 15 minutes.

(2) Rotate the screen control fully counter clockwise .

(3) Access service mode, and press 'MUTE' button.

(4) Rotate the screen control gradually clockwise until the first horizontal line appears on the

screen.

(5) Set the [ CUT OFF --- R,G, B, ] items. Component level to get a white horizontal line .

(6) Press [MUTE] key against, Set the Brightness and Contrast controls at normal position,

Colour control to the minimum level.

(7) Set the [ Green Gain & Blue Gain ] items to maintain a good white balance at the brightest part of the screen. Set

the brightness and contrast controls to maximum and minimum. Observe the screen white balance , if it is not proper

in high brightness or low brightness condition , Set the [CUT OFF --- R,G, B] items or [Green Gain & Red Gain ] items,

in order to maintain a good white balance in both low and high luminance conditions.

B-Y, R-Y ADJUSTMENT (SECAM) ONLY :

(1) Set colour System [AUTO ] or [SECAM].

(2) Receive SECAM colour bar signal.

(3) Set the Brightness and Contrast controls at normal position, Colour control to the minimum.

(4) Set the[ Secam B-Y & Secam R-Y ] items to maintain a good white balance at the brightest part of the screen.

HIGH VOLTAGE CHECK:

8

CAUTION : There is no HIGH VOLTAGE ADJUSTMENT on this chassis.

a. Connect an accurate high voltage meter to the second anode of the picture tube.

b. Turn on the receiver and set the BRIGHTNESS, COLOUR and CONTRAST Controls to the minimum (zero beam

current).

c. High voltage will be measured below 35KV.

d. Adjust the BRIGHTNESS Control to both extremes to ensure the high voltage does not

exceed the limit of 34KV under any circumstances.

FS CIRCUIT CHECK

:

a. Push the Power Switch on and adjust all controls for normal operation.

b. Temporarily connect a 18Kohm resistor across R919 on the Main Chassis PC Board. Raster and sound will

disappear.

c. The receiver must remain in this state even after removing the resistor. This is the evidence that the Fail Safe

circuit is functioning properly.

d. To obtain a picture again, temporarily push the power switch off and allow the Fail Safe circuit move than 30

seconds to reset. Then push the power switch on to produce a normal.

FOCUS ALIGNMENT :

Tune in an active channel or Phillips Pattern. Adjust the Focus control on the FLYBACK

TRANSFORMER (T901) for well defined scanning lines in the center area on the screen.

HORIZONTAL ADJUSTMENT

a. Receive the Phillips Pattern. Apply a crosshatch signal.

b. Set the contrast and colour to their minimum, and the brightness to its maximum.

c. Adjust (CORNER) to obtain a corner correction picture.

Adjust (PARABOLA 50/60) to obtain a parabola correction picture.

Adjust (TRAPEZIUM 50/60) to obtain a trapezium correction picture.

Adjust (H-POSITION 50/60) to move the picture at the center.

Adjust (H-SIZE 50/60) to move rightful high picture.

ATTN.: These settings should be done with separate test signals with a 50 Hz and a 60 Hz field frequency. These parameters

are stored in separate groups for 50 Hz and 60 Hz and are recalled or set, depending on the field frequency of the

currently received program.

VERTICAL ADJUSTMENT

Apply a crosshatch signal.

Adjust (V-S CORRECTION) to obtain a s-correction picture.

Adjust (V-LINEARITY 50/60) to obtain a linear picture.

Adjust (V-POSITION 50/60) to move the picture at the center.

Adjust (V-SIZE 50/60) to obtain rightful high picture.

ATTN.: These settings should be done with separate test signals with a 50 Hz and a 60 Hz field frequency. These parameters

are stored in separate groups for 50 Hz and 60 Hz and are recalled or set, depending on the field frequency of the

currently received program.

SAFETY PRECAUTION :

Dielectric voltage withstand test :

The following accessible parts should be stressed for a period of one second on each complete appliance before it leaves the

factory.

The test potential voltage not less than 3500V, 50Hz should be applied for 1 second between both blades of the attachment

plug cap. and the following parts :

Name of part

Locations

1. Antenna Terminal Back Cabinet

2. AV input Terminals Front / Back Cabinet

3. AV output Terminals Back Cabinet

3. Enclosure Screws Back Cabinet

4. S-Video Sockets Front Cabinet

5. Ext. Speaker Terminals Back Cabinet

COLOUR PURITY ADJUSTMENT

9

Note: Before attempting any color purity adjustments, the receiver should be turned on for at least 30 minutes. (see

Figure 8). A few rubber wedges should be available for use whenever necessary during the process of

color purity adjustment.

a. Demagnetize the picture tube and cabinet using an external degaussing coil.

b. Turn the CONTRAST and BRIGHTNESS controls to maximum.

c. Adjust RED and BULE bias controls (R-CUT OFF) and (B-CUT OFF) to provide only a green raster.

Advance the GREEN bias control (G-CUT OFF) is necessary.

d. Loosen the clamp screw holding the yoke and slide the yoke and slide the yoke backward to provide vertical

green belt (zone) in the picture screen.

e. Remove the rubber wedges.

f. Rotate and spread the tabs of the purity magnet (See Fig. 9 around the neck of the picture tube until the

green belt is in the center of the screen. At the same time center the raster vertically.

g. Move the yoke slowly forward or backward until a uniform green screen is obtained. Tighten the clamp

screw of the yoke temporarily.

h. Check the purity of the red and blue raster by adjusting the (CUT OFF) bias controls.

i. Obtain a white raster, referring to "CRT GREY SCALE ADJUSTMENT (White Balance Adjustment).

j. Proceed with convergence adjustment.

CENTER CONVERGENCE ADJUSTMENT :

Note : Before attempting any convergence adjustments, the receiver should have operated for at least fifteen minutes.

a. Receive crosshatch pattern with a colour bar signal generator.

b. Adjust the BRIGHTNESS and CONTRAST controls for a well defined pattern.

c. Adjust two tabs of the 4-Pole magnets to change the angle between them (See Fig.9) and superimpose red and blue

vertical lines in the center area of the picture screen (See Fig. 10).

d. Turn both tabs at the same time , keeping their angles constant to superimpose red and blue horizontal lines at the

center of the screen (See Fig. 10).

e. Adjust two tabs of 6-Pole magnets to superimpose red and blue line with green one. Adjusting the angle affects the

vertical lines and rotating both magnets affects the horizontal lines.

f. Repeat adjustments c,d,e, keeping in mind red, green and blue movements because 4-Pole magnets and 6-Pole magnets

mutual affection and make dot movement complex.

CIRCUMFERENCE CONVERGENCE ADJUSTMENT :

a. Loosen the clamping screw of the deflection yoke to allow the yoke to tilt.

b. Put a wedge as shown in Fig.8 temporarily. (Do not remove the cover paper on the adhesive part of the wedge).

c. Tilt front of the deflection yoke up or down to obtain better convergence in circumference. (See Fig.10).

Push the mounted wedge into the space between the picture tube and the yoke to hold the yoke temporarily.

d. Put another wedge into bottom space and remove the cover paper to stick.

e. Tilt front of the yoke right or left to obtain better convergence in circumference. (See Fig. 10).

f. Keep the yoke position and put another wedge in either upper space. Remove the cover paper and stick the wedge on

picture tube to hold the yoke.

g. Detach the temporarily mounted wedge and put it in another upper space. Stick it on the picture tube to fix the yoke.

After fixing three wedges, recheck overall convergence.

h. Tighten the screw firmly to hold the yoke tightly in place. Stick 3 adhesive tapes on wedges as shown in Fig. 8.

10

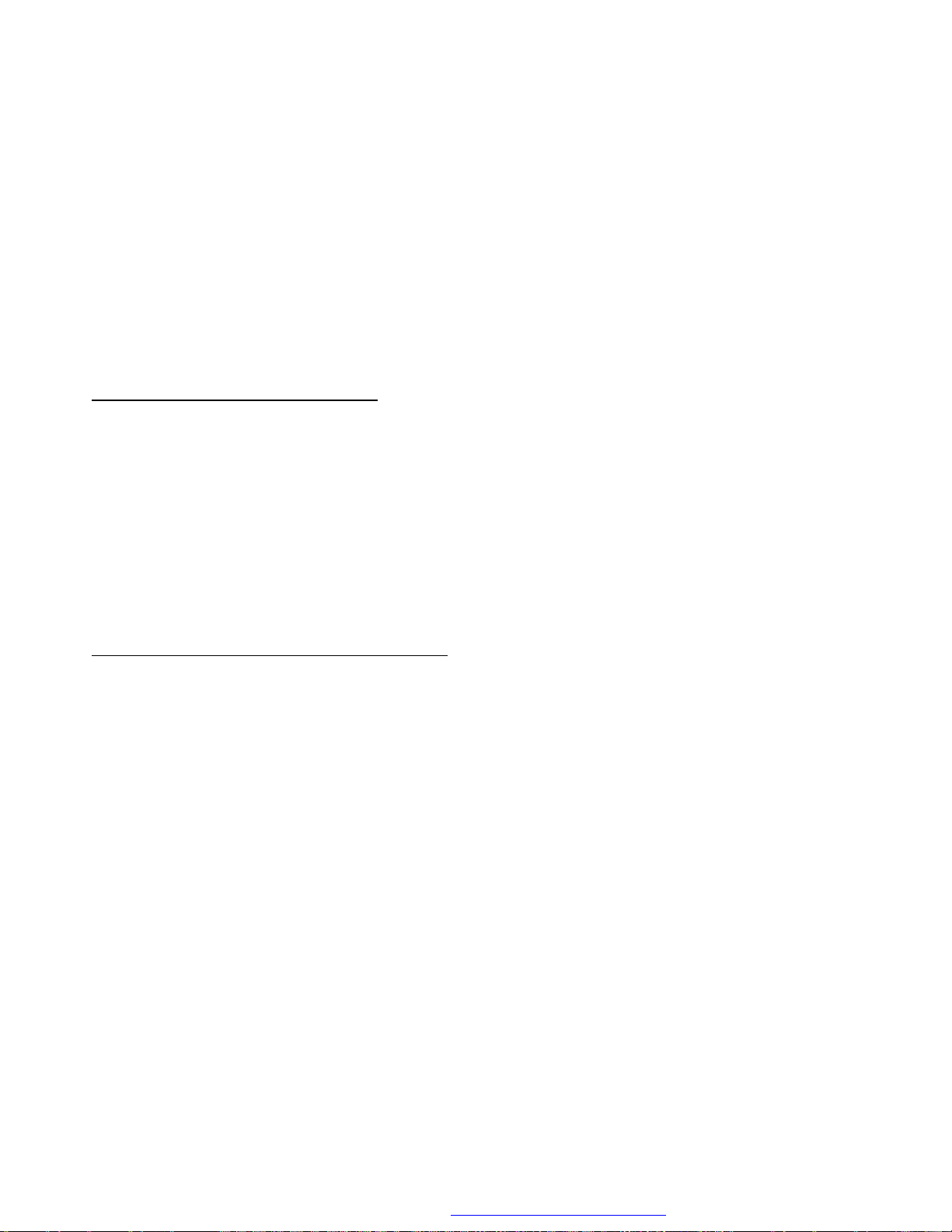

DEFLECTION YOKE

RUBBER

Incline the Yoke right (or left)

Center Convergence by Convergence Magnets

Figure 8

WEDGES

PURIIY AND

CONVERGENCE

MAGNET ASS Y

33 mm

(1-5/16 )

TEMPORARY

MOUNTING

30

30

RUBBER WEDGES

LOCATION

30

DEF.YOKE

RUBBER WEDGE

ADHESIVE

4-POLE MAGNETS

PURITY MAGNETS

6-POLE

MAGNETS

CONVERGE MAGNET ASSEMBLY

BLU RED

BLU

RED

4-Pole Magnets Movement

ADJUST THE ANGLE

(VERTICAL LINES)

ADJUSTMENT OF MAGNETS

Figure 9

ROTATE TWO TABS

AT THE SAME TIME

(HORIZONTAL LINES)

RED

BLU

/

RED

BLU

/

6-Pole Magnets Movement

FIXED

GRN

R

G

B

Incline the Yoke up (or down)

R

G

B

Circumference Convergence by DEF Yoke

Fig .10 Dot movement Pattern

11

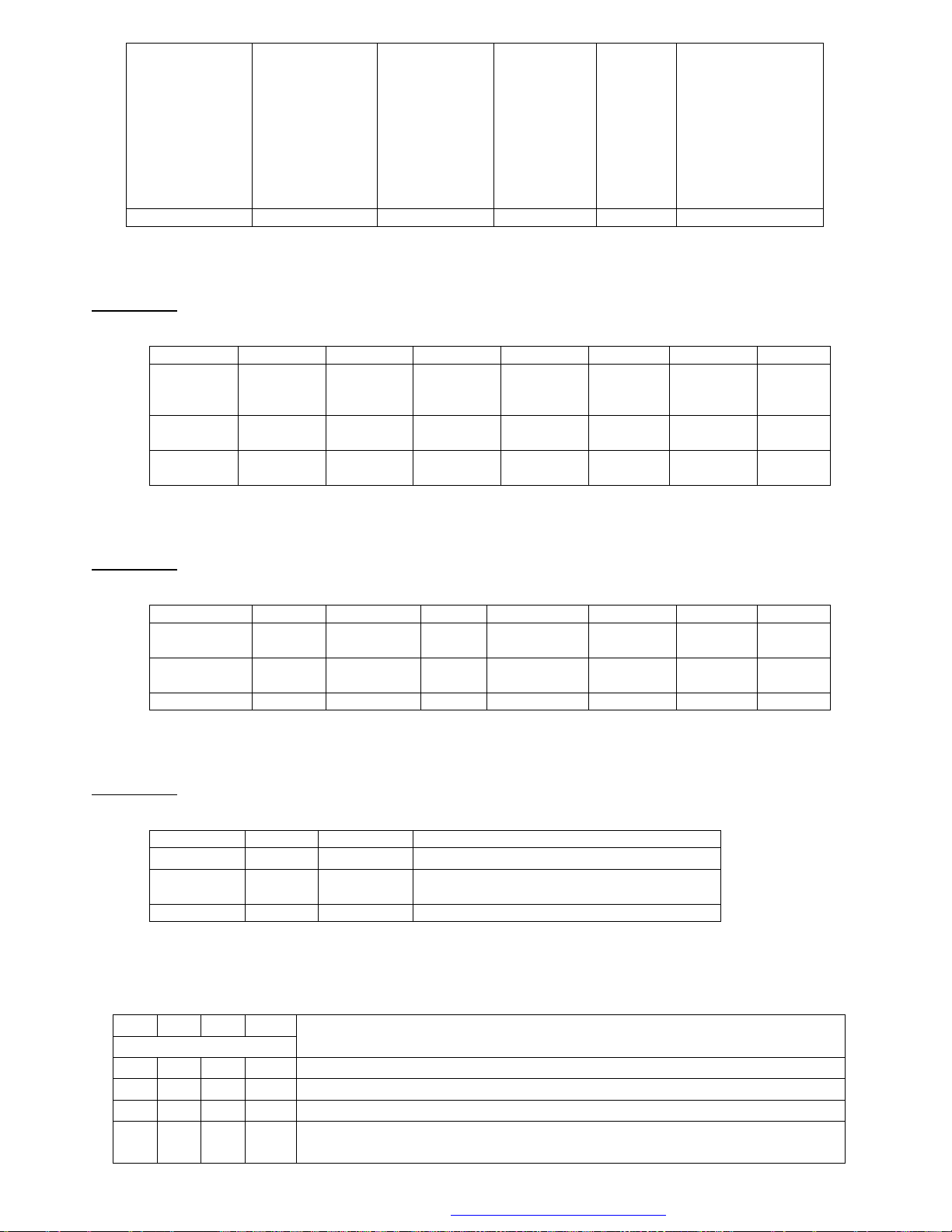

FACTORY ADJUSTMENT MODE:

HOW TO ACCESS THE SERVICE MODE

1. First press the VOLUME "-" button in the TV set until the volume turn to zero.

2. Keep pressing this button, then press the "status" button on the remote contol,then you can access the service mode. Use

the [MENU], [CH UP], [CH DOWN], [VOL UP] or [VOL DOWN] button to highlight the item to set ,which i s displayed in red.

Other items are displayed in white.

3. Finally, press the 'PP' button to log out of the service mode.

Attention:

(1) In case the user should forget the password that has been entered, there is a “built-in” password,

that will always work:

512

.

(2) The data marked with “#” are not allowed to change.

n

Press [MENU] to display the Service 1 MENU.

Service 1

RF AGC 25

V SC 07

H Position 50 14

V Position 50 03

V Size 50 19

V Linearity 50 08

H Position 60 19

V Position 60 04

V Size 60 1B

V Linearity 60 0B

Bright Max 58

Bright Min 26

Sub Tint 50

PIF VCO # 80

n

Press [CHANNEL UP OR DOWN] to select the highlighted item, then [VOL DOWN],or

[VOL UP] to increase or decrease the setting, The data is written to EEPROM.

n TB1240BN Adjustment Items

Rf AGC: Selects RF AGC adjustment setting is 25 in the range 00 to 3F.

V SC: Selects vertical s-correction adjustment setting is about 07 in the range 00 to 0F.

H Position50: Selects horiztion position 50 adjustment setting is 14 range 00 to 1F.

V POS 50: Selects vertical position 50 adjustment setting is 03 in the range 00 to 07.

V Size 50 : Selects vertical size 50 adjustment setting is 19 in the range 00 to 3F.

V Linearity50: Selects vertical linearity 50 adjustment. Setting is 08 in the range 00 or 0F.

H Position60: Selects horiztion position 60 adjustment setting is 19 range 00 to 1F.

V POS 60: Selects vertical position 60 adjustment setting is 04 in the range 00 to 07.

V Size 60 : Selects vertical size 60 adjustment setting is 1B in the range 00 to 3F.

V Linearity60: Selects vertical linearity 60 adjustment. Setting is 0B in the range 00 or 0F.

Brightn Max: Selects brightness maximum adjustment . Setting is 58 in the range from 00 to 7F.

Bright Min: Selects brightness minimum adjustment. Setting is 26 in the from 00 to 58.

Sub Tint: Selects sub tint adjustment setting is 50 in the from 00 to 7F.

PIF VCO: Selects PIF VCO adjustment setting is 80 in the from 00 to FF.

n

Press [MENU] to display the Service 2 MENU.

Service 2

Logo 6CONTEC

RGB Contrast 30

Sub Contrast 06

Secam B-Y 08

Secam R-Y 07

Time #0B

PREFM #15

PRE NICAM #19

PRE LINE IN #06

DRAG MULTIPE #0C

DRAG BASE #04

Hi Voltage #A5

Bus Off #00

VCO Coarse #00

VCO Fine L1 #00

n Press [CHANNEL UP OR DOWN] to select the highlighted item, then [VOL DOWN],or [VOL UP] to increase or

decrease the setting, The data is written to EEPROM.

n

TB1240BN Adjustment Items

12

How to set the Logo

Sync Value #55

1. Press [CHANNEL UP OR DOWN] to select the “Logo” item, and then the Volume Up or Down Button to

move the pointer to the position where the logo character to be set or changed.

2. Press the Volume Up or Down Button to move the pointer to first word is setting Logo number. (change the

number from 0 to 9 and A to C)

3. Press the Channel Position Up or Down Button to change the character from 0 to 9, A to Z to space forward

or backward.

Attn.: The maximum logo characters are twelve. (From A to Z to space character)

Character available for change is in H

ighlighted item

.

Logo -----: Selects logo adjustment setting is twelve characters.

RGB Contrast: Selects RGB contrast adjustment setting is 30 in the range 00 to 3F.

Sub Contrast: Selects sub contrast adjustment setting is about 06 in the range 00 to 0F.

SECAM B Y: Selects secam B-Y adjustment setting is 08 range 00 to 0F.

SECAM R Y: Selects secam R-Y adjustment setting is 07 in the range 00 to 0F.

Time: Selects time of station tuning adjustment setting is 0B in the range 00 to 1F.

PRE FM: Selects pre-FM adjustment. Setting is 15 in the range 00 or 1F.

PRE NICAM: Selects pre-NICAM adjustment . Setting is 19 in the range from 00 to 1F.

PRE LINE IN: Selects pre-line in adjustment. Setting is 06 in the from 00 to 0F.

DRAG MULTIPE: Selects drag multipe of AFT adjustment setting is 0C in the from 00 to 0F.

DRAG BASE: Selects drag base of AFT adjustment setting is 04 in the from 00 to 0F.

Hi Voltage: Selects X-RAY protection level adjustment. Setting is A5 in the from 00 to FF.

Bus Off: Selects I2C bus control adjustment setting is 00 in the from 00 to 01.

VCO Coarse L1: Selects VCO coarse L1 adjustment setting is 00.

VCO Fine L1: Selects VCO fine L1 adjustment setting is 00.

n Press [MENU] to display the Service 3 MENU.

n Press [CHANNEL UP OR DOWN] to select the highlighted item, then [VOL DOWN],or [VOL UP] to increase or

decrease the setting, The data is written to EEPROM.

n

TB1240BN Adjustment Items

H Size 50: Selects horizontal size 50 adjustment setting is 26 in the range 00 to 3F.

Parabola 50: Selects horizontal parabola 50 adjustment setting is about 30 in the range 00 to 3F.

Trapezium 50: Selects horizontal trapezium 50 adjustment setting is 0F range 00 to 3F.

H Size 60: Selects horizontal size 60 adjustment setting is 25 in the range 00 to 3F.

Parabola 60: Selects horizontal parabola 60 adjustment setting is 2E in the range 00 to 3F.

Trapezium 60: Selects horizontal trapezium 60 adjustment. Setting is 10 in the range 00 or 3F.

Corner: Selects horizontal corner adjustment . Setting is 07 in the range from 00 to 0F.

H EHT: Selects horizontal EHT adjustment. Setting is 01 in the from 00 to 07.

V EHT: Selects vertical EHT adjustment setting is 01 in the from 00 to 07.

n Press [MENU] to display the Service4 MENU.

Service 3

H Size 50 26

Parabola 50 30

Trapezium 50 0F

H Size 60 25

Parabola 60 2E

Trapezium 60 10

Corner 07

H EHT #01

V EHT #01

Service 4

option 0 #90

Option 1 #98

Option 2 #98

Option 3 #46

Option 4 #23

option 5 #94

option 6 #1C

HPOS OSD 14

VPOS OSD 02

HPOS TXT 4C

VPOS TXT 0B

TXT CONTRAST 2A

G2 Adjust 00

Mix Value 3C

13

HPOS OSD: Selects OSD horizontal position adjustment setting is 14 in the range 00 to FF.

NTSC Comb

& low RGB

1 = Killer on

(This function

t work on

Auto1 & Auto2

(This function

works on only for

VPOS OSD: Selects OSD vertical position adjustment setting is about 02 in the range 00 to 3F.

HPOS TXT: Selects teletext horizontal position adjustment setting is 4C range 00 to FF.

VPOS TXT: Selects teletext vertical position adjustment setting is 0B in the range 00 to 3F.

TXT CONTRAST: Selects screen adjustment setting is 2A in the range 00 to 3F.

Mix Value: Selects sharpness maximum adjustment. Setting is 3C in the range 00 or FF.

Sync Value: Selects synchrours timing value adjustment. Setting is 55 in the from 00 to FF.

Option byte 0

Option byte 1

The following options are available in option byte 1:

Option byte 2

n

Press [CHANNEL UP OR DOWN] to select the highlighted item, then [VOL DOWN],or [VOL UP] to increase or

decrease the setting, The data is written to EEPROM.

n

TB1240BN Adjustment Items

G2 Adjust: Selects screen adjustment setting is 00 in the range 00 to 01.

The following options are available in option byte 0:

bit 7 bit 6 bit 5 bit 4 bit3 bit 2 bit1 bit 0

SW (N-com)

0 = ON

1 = OFF

H-out stop

(H-STP)

0 = Normal

1 = H-out stop

output

Forced ID ON

(FID)

0 = Normal

Fixed System

doesn’

ABL Gain ID sensitivity

switching(id sw)

00: -0.74V

01: -0.64V

0:normal mode

1:low mode

10: -0.37V

11: -0.12V

NTSC mode.)

ABL start point

00: -0.01V

01: -0.11V

10: -0.3V

11: -0.45V

mode.)

Preset: OFF Preset: Normal Preset: Normal Preset: -0.37V Preset: Normal Preset: -0.01V

Table 0 Option byte 0 definitions

Option Byte 0 adjustment setting are 90hex.

bit 7 bit 6 bit 5

bit 4 bit 3 bit 2 bit 1 bit 0

S-Video RF NTSC - Stereo (Balance) Secam function Super Sense STV8203 Custom Logo

0 = AV1

1 = AV2

0 = OFF

1 = ON

0 = OFF

1 = ON

0 = OFF

1 = ON

0 = OFF

1 = ON

0 = OFF

1 = ON

0 = OFF

1 = ON

Preset: OFF - Preset: OFF Preset: ON Preset: OFF Preset: ON Preset: ON

Table 1 Option byte 1 definitions

The setmaker’s logo can only be displayed if memory bank 1 is present. If this bank is present, displaying the logo

can disabled by setting bit 0 high. If the memory bank is present and bit 1 is set, then the logo will be displayed for

15 seconds, after a cold start only.

NOTE: If no text is defined for the logo in memory bank 1, this option should always be 1

Option Byte 1 adjustment setting are 98hex.

The following options are available in option byte 2:

bit7 bit6 bit5 bit4 bit3 bit2 bit1 bit0

PIF overmod Secam adj IF freq AFT ON BGP P Ym enb

14

(white Peak

Blanking SW

ish &

0 = OFF

1 = ON

Preset: ON Preset: Normal Preset: 100 Preset: Normal Preset: 0 Preset: 0

Option Byte 2 adjustment setting are 98hex.

Option byte 3

The following options are available in option byte 3:

bit 7 bit 6 bit 5 bit 4 bit3 bit 2 bit1 bit 0

1238 setting WPS

0: OFF

1: ON

Option byte 4

Option Byte 4 adjustment setting are 23hex.

Option byte 5

Option Byte 5 adjustment setting are 94hex.

Preset: OFF Preset: ON Preset: OFF Preset: Auto Preset: OFF Preset: ON Preset: ON Preset:

Table 3 Option byte 3 definitions

Option Byte 3 adjustment setting are 46hex.

The following options are available in option byte 4.

bit 7 bit 6 bit 5 bit 4 bit3 bit 2 bit1 bit 0

Woofer precess Audio

0: Off

1: On

Preset: Off Preset: Off Preset: On Preset: 0 Preset: 0 Preset: 0 Preset: 1 Preset: 1

Table 4 Option byte 4 definitions

The following options are available in option byte 5.

bit 7 bit6 bit 5 bit 4 bit3 bit2 bit1 bit 0

- Nicam EHT protect

- 0: Off

- Preset: 1 Preset: 1

Table 5 Option byte 5 definitions

0: Normal

1: Secam black

level alignment

mode

Table 2 Option byte 2 definitions

(BLK)

Suppressor)

0: ON

1: OFF

processor

0: Off

1: On

1: On

0:BLK ON

1:BLK OFF

Volume L_R Zwelton

0: Off

1: On

0: Off

1: On

000: 58.75MHz

001: 45.75MHz

010: 39.5MHz

011: 38.9MHz

100: 38MHz

101: 34.47MHz

110: 33.95MHz

111: 33.9MHz

CW SW Market

0:Auto

1:4.43MHz

Selected

0: Off

1: On

0: Normal

1: AFT Mute

off

France

set

0: OFF

1: ON

RGB S-Video AV2 AV1

0: Off

1: On

Option

Language Treat

Language Treat

0: Normal

1: 1.5us

S-Video in

0: OFF

1: ON

0: Off

1: On

Table

Table

0: 0~0.8V TV

more than 0.8V OSD

1: 0~0.8V TV

0. 8~2.4V Half Tone

more than 2.4V OSD

Mute Logic Surround

0: OFF

1: ON

0: Off

1: On

In option byte 5, the bits 0, 1 and 2 form a number between 0 and 7.

bit 3 bit 2 bit 1 bit 0

Op

Language Treat

0 0 0 0 English, French, Swedish, Turkish, German, Portuguese, Italian & Rumanian

Table

0 0 1 0 Polish, French, Estonian, Czech, German, Serbain, Lettish & Rumanian

Option teletext character

0 1 0 0 English, French, Swedish, Czech, German, Portuguese, Lettish & Rumanian

0 1 1 0 English, French, Swedish, Turkish, German, Portuguese, Lett

Rumanian

15

process

0: OFF

1: ON

OFF

0: Off

1: On

Loading...

Loading...