Page 1

Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

Copyright 2002, Graco Inc. is registered to I.S. EN ISO 9001

3Z9478A

Operation/

/

XR9 Airless Sprayer

YS:!

zt[BcBu

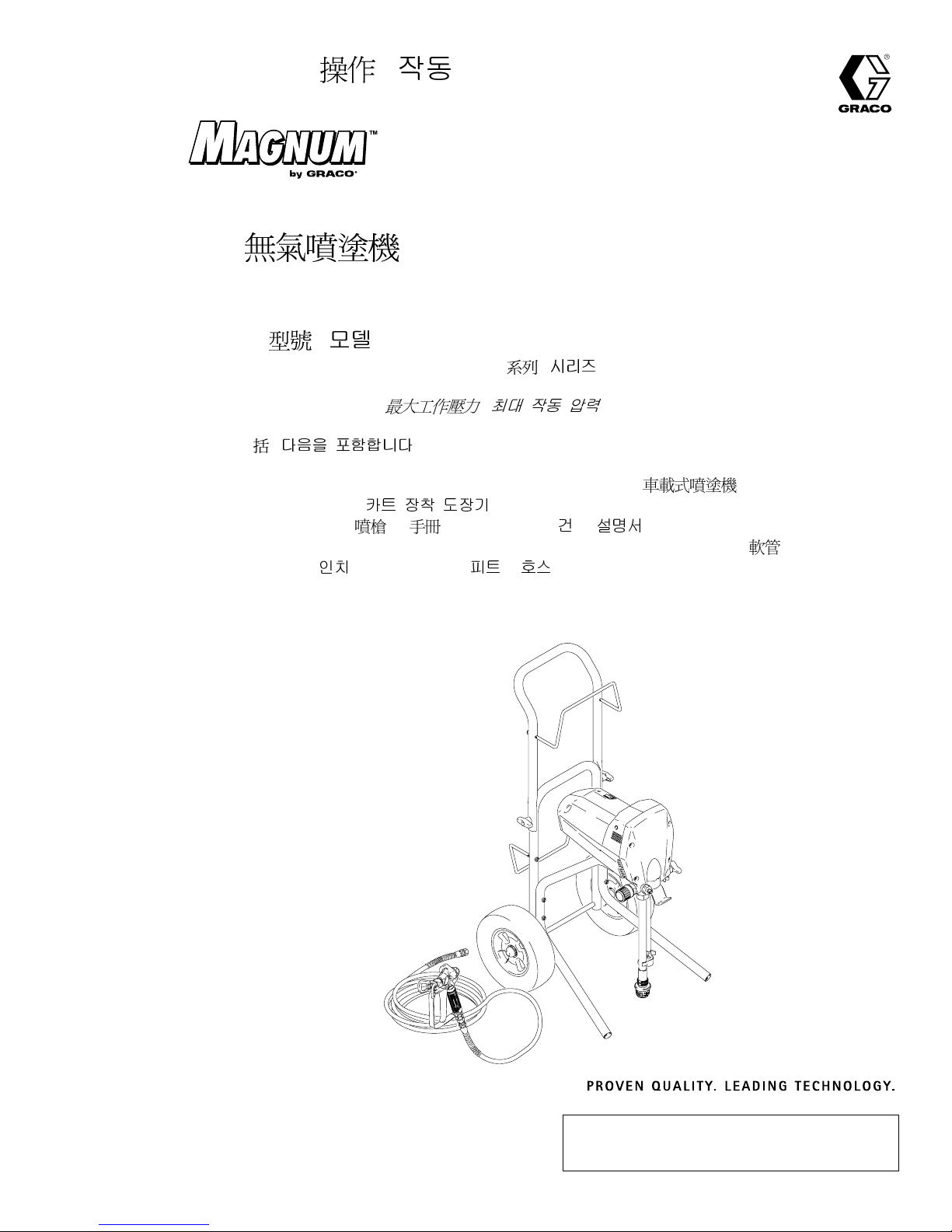

Models/ / :

232751, 232752, 232753 - Series A/B! / Bc

Maximum Working Pressure/ / B B L: 207 bar, 21 MPa (3000 PSI)

Includes/

/ B :

• 1.44 lpm (0.38 gpm) cart-mount sprayer/

2/55!mqn!)1/49!hqn*! /

SPVVBBJRPUZBKB B B

• SG3E/A gun/TH4F0B! !.! 041:1:8/uiUgQcB BOB QUR[R[Y

• 0.635 cm (1/4 in) x 15.2 m (50 ft) hose/1/746!dn!)205!jo*!y!26/3!n!)61!gu*! /

RPXUWBBJSQVB KBBSWPTBBJWRB KB

ti2017a

Page 2

Table of Contents/ /

2 3Z9478A

Table of Contents/ /

Table of Contents/ / B PBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBP T

Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

! /!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/ 4

B PBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBP V

Pressure Relief/ / B B BPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBP [

Grounding and Electrical Requirements/ / B B B BPBPBPBPBPB SR

Component Identification/ / B B PBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPB ST

Setup/ / B PBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPB SV

Priming/ / B BPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPB SW

Spraying Techniques/ / B B PBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPB SY

Cleanup/ / B PBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPB TR

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

! /!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/!/! 49

B B BPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPB VT

Maintenance/ / B PBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPB VX

Technical Data/ / B B BPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPBPB WU

Graco Standard Warranty/Hsbdp! /iB B BBPBPBPBPBPBPBPBPB WX

Page 3

Warning

3Z9478A 3

WARNING

Fire, Explosion and Electrocution

Hazard

Improper grounding, poor air ventilation, open

flames, or sparks can cause a hazardous condition and result in fire, explosion, or electric shock.

To help prevent these hazards:

• Sprayer should be grounded through an elec-

trical outlet as follows:

- Only use grounded electrical outlets.

- Only use 3-wire extension cords.

- Grounded prongs must be intact on sprayer

and extension cords.

• Keep electrical connections and inside of

shroud dry.

• Avoid contact with power lines.

• Use outdoors or in well-ventilated area.

• Sprayer shoul d b e at l e ast 6m (2 0 ft ) fr om gun

when spraying or flushing.

• If there is any static sparking while using

equipment, stop spraying immediately.

Identify and correct the problem.

• Avoid all ignition sources such as pilot lights,

cigarettes and plastic drop cloths (static arc

hazard).

• Do not plug in or unplug power cords or turn

lights on or off i n spray area.

• Only use Graco airless paint hoses.

•

.!

.!

.!

•

•

•

• !

7

31!

•

•

!

•

• !Hsbdp! !

Page 4

4 3Z9478A

NB B B B

B NB B NB B B B

B NB NB B B B B

B P

B B \

• B B B B B

B P

OB

B B B P

OBU

B B B P

OB

B B B B B

B B P

• B B B B B B

B P

• B B P

• B B B B B

P

• B B B B

BXBJTRB KB B B

P

• B B B B B B

B B B B B B

B B P

• NB NB B J B B KB

B B B B B B B

P

• B B B B B

B NB B B B P

• iB B B B

PB

Page 5

3Z9478A 5

WARNING

Pressurized Equipment Hazard

To avoid component rupture and injury, do not

operate sprayer with components rated less than

pressure of sprayer.

Sprayer is equipped with a pressure drain that

automatically relieves overpressure in the event of

a fault condition. This automatic pressure relief

may cause splashing fluid. Correct fault before

you resume sprayi ng.

Inadequate flushing and/or dried paint in drain

system may prevent proper overpressure relief.

Toxic Fluid Hazard

Hazardous flui ds or toxic fume s can cause serio us

injury or death if splashed in eyes or on skin, swallowed, or inhaled.

• Know specific hazards of fluid being used.

Read fluid manufac turer’s warnings.

• Wear appropriate protective clothing, gloves,

eyewear, and respirator.

•

•

Fluid Injection Hazard

If high-pressure fluid pierces skin, the injury might

look like “just a cut” but it is a serious wound. Get

immediate medical attention. To help prevent

injection:

• Always engage trigger safety when not spray-

ing.

• Always shut off power and relieve pressure

when you stop spraying, before you service or

clean sprayer, remove parts or repair leaks.

See Pressure Relief Procedure, page 9.

• Do not allow children to use this equipment.

• Keep clear of tip. Never point at yourself or

anyone else.

•

•

!:!

•

• .

Fluid Splashback Hazard

To avoid splashing fluid when spraying into pail,

always aim at inside wall of pail. Make sure gun is

assembled with correct gasket for fluid being

sprayed.

Page 6

6 3Z9478A

B B

B B B B NB

B B B B B B

B B P

B B B B B B B

B B B B B PB

B B B B B B

PB B B B B B B

P

B B B B B B

B B B B B B

B P

B B B

B B B B B B B

B B B B B B

B B P

• B B B B

B B P

• B NB B NB B B

B P

B B B

B B B B B B

B B B B B B

PB B B B B B

PB B B \

• B B B B B

B PB

• B B B B

B B B B B

B B B B B B

B PB[ B B

B P

• B B B B P

• B B B B B

B B P

B B

B B B B B B B

B B B PB B

B B B B B

B P

Page 7

3Z9478A 7

WARNING

Recoil Hazard

Due to the high pressure fluid emitted, a strong

recoil action may occur when you trigger the

gun. If you are unprepared, your hand could be

forced back toward your body or you could lose

your balance and fall, resulting in serious injury.

Equipment Misuse Hazard

Equipment misuse can cause equipment to rupture, malfunction, or start unexpectedly and

cause serious injury.

• Read all manuals, tags, and labels before

operating equipment.

• Only use equipment for its intended pur-

pose.

• Do not alter or modify equipment.

• Do not exceed maximum working pressure

of lowest rated system component .

• Do not modify extension tube or roller frame

or use parts not designed for this equipment

• Do not use 1,1,1-trichloroethane, methylene

chloride, other halogenated hydrocarbon

solvents or fluids containing such solvents in

this or any other pressurized aluminum

equipment. Such use could result in a chemical reaction, with the possibility of explosion.

•

•

•

•

!

•

•

2-2-2.

Startup Hazard After Thermal

Overload

Motor has thermal overload switch to shut itself

down if overheated. To reduce risk of injury from

motor restarting unexpectedly when it cools,

always turn power switch OFF if motor shuts

down.

Page 8

8 3Z9478A

B

B B B B B B B

B B B B PB B B

B B B B B B

B B B B B P

B B

B B B B B

B B B B B B B

B P

• B B B B NB B

B B P

• B B B P

• B B B P

• B B B B B B B

B B B B B

P

•

B B B B B B

B B B B

B P

• B B B B B B

BSPSPSO NB B NB B

B B B B B

B B B B PB

B B B B B

B B B B B P

B B B B

B B B B B B B

B B B PB B

B B B B B

B B B B B B

B B P

Page 9

Pressure Relief/ / B

3Z9478A 9

Pressure Relief/ / B

WARNING/ /

Page/ ! / 5.

1. Turn OFF power switch.

B P

2. Place prime tube in waste pail.

B B B B P

3. Turn Prime/Spray valve to PRIME.

0 QSJNF

Q B Brtkog B P

4. Turn pressure control knob left (minimum pressure).

B B J B K B P

5. Trigger gun into bucket to relieve pressure in hose.

B B B B B B P

ti2018a

ti2034a

ti2019a

ti2020a

ti2033a

Page 10

Grounding and Electrical Requirements/ / B B B

10 3Z9478A

Grounding and Electrical Requirements/ / B B B

A. This sprayer requires 220-240 VAC, 50/60 Hz 10A circuit with

a grounding receptacle. Never use an outlet that is not

grounded.

!331.351!W-!61071!I{!

21B!

B B B B TTROTVRBxceNB

WRQXR j

BSRcB B PB B B

B B P

B. Do not use sprayer if electrical cord has damaged ground

prong.

B B B B B B B

B P

ti10-a

t10-*b

Page 11

Grounding and Electrical Requirements/ / B B B

3Z9478A 11

C. Do not use an extension cord with damaged ground plug.

Recommended extension cords:

• 15 m (49.2 ft) 1.0 mm

2

• 30 m (88.4 ft) 1.5 mm

2

• 50 m (164.0 ft) 2.5 mm

2

• 26!n!)5:/3! *!2/1!nn

3

• 41!n!)99/5! *!2/6!nn

3

• 61!n!)275/1! *!3/6!nn

3

B B B B B B P

B B \

• SWBBJV[PTBKBSPRB

T

• URBBJZZPVBKBSPWB

T

• WRBBJSXVPRBKBTPWB

T

Smaller gauge or longer extension cords may reduce sprayer performance.

B B B B B B B B B B P

Page 12

Component Identification/ / B

12 3Z9478A

Component Identification/ / B

B

J

W

A

X

H

L

G

K

F

E

D

C

P

M

U

T

V

S

R

Q

ti2023a

Page 13

Component Identification/ / B

3Z9478A 13

Component/ /

A

Electric motor (inside enclosure)/

/ B J K

B

Power switch/

/ B

C

Pressure control knob/

/ B

D

Pump fluid outlet fitting/

/ B B B

E

InstaClean™ fluid filter/

JotubDmfbo™! /ke B B B

F

Power-Piston™ pump (behind Easy Access door)/

Qpxfs.Qjtupo™! /

rOr B BJ B B B K

G

Suction tube/

/ B

H

Prime tube (with diffuser)/

/ B J B K

J

Prime/Spray valve control/

0 0 / Q Q B B

K

Fluid inlet connection and inlet valve/

/ B B B B B

L

Inlet screen/

/ B

M

Paint hose/

/ B

P

SG3E/A airless spray gun/

TH4F0B! /uiUgQcB B B

Q

Tip guard/

/ B

R

Reversible spray tip/

/ B B

S

Trigger safety lever/

/ B B

T

Gun fluid inlet fitting/

/ B B B

U

Smooth Glide™ swivel/

Tnppui!Hmjef™! /uBi B B

V

Gun fluid filter (in handle)/

) */ B B J B K

W

Hose/cord wrap bracket/

0 / Q B B

X

Pail hanger/

/ B

Y

Power Flush attachment (included)/

/ B B J K

Page 14

Setup/ /

14 3Z9478A

Setup/ /

1. Turn OFF power switch.

B P

2. Connect one end of grounded fluid hose to SG3E/A spray

gun. Use a wrench to tighten.

!TH4F0B!

B B B B BuiUgQcB B

B B NB B B P

3. Connect other end of hose to sprayer fluid outlet fitting. Use

wrench to tighten.

Connect other end of hose to sprayer fluid outlet fitting. Use

wrench to tighten.

B B B B B B B B NB

B B P

4. Turn pressure control knob left (minimum pressure).

B B J B K B P

ti2018a

ti2024a

ti2025a

ti2020a

Page 15

Priming/ /

3Z9478A 15

For flushing storage fluid and loading pump and hose with paint.

B B B B B B B \

Priming/ /

Before priming sprayer, follow Pail Flushing procedure, Steps 1-6, page 24.

!24! !2.7!

B B B B B J24 BSOXB K B P

1. Turn OFF power switch.

B P

2. Submerge suction tube in paint.

B B B P

3. Turn Prime/Spray valve to PRIME.

0 QSJNF

Q B Brtkog B P

4. Point gun into waste pail.

B B B B P

ti2018a

ti2026a

ti2019a

ti2027a

Page 16

Priming/ /

16 3Z9478A

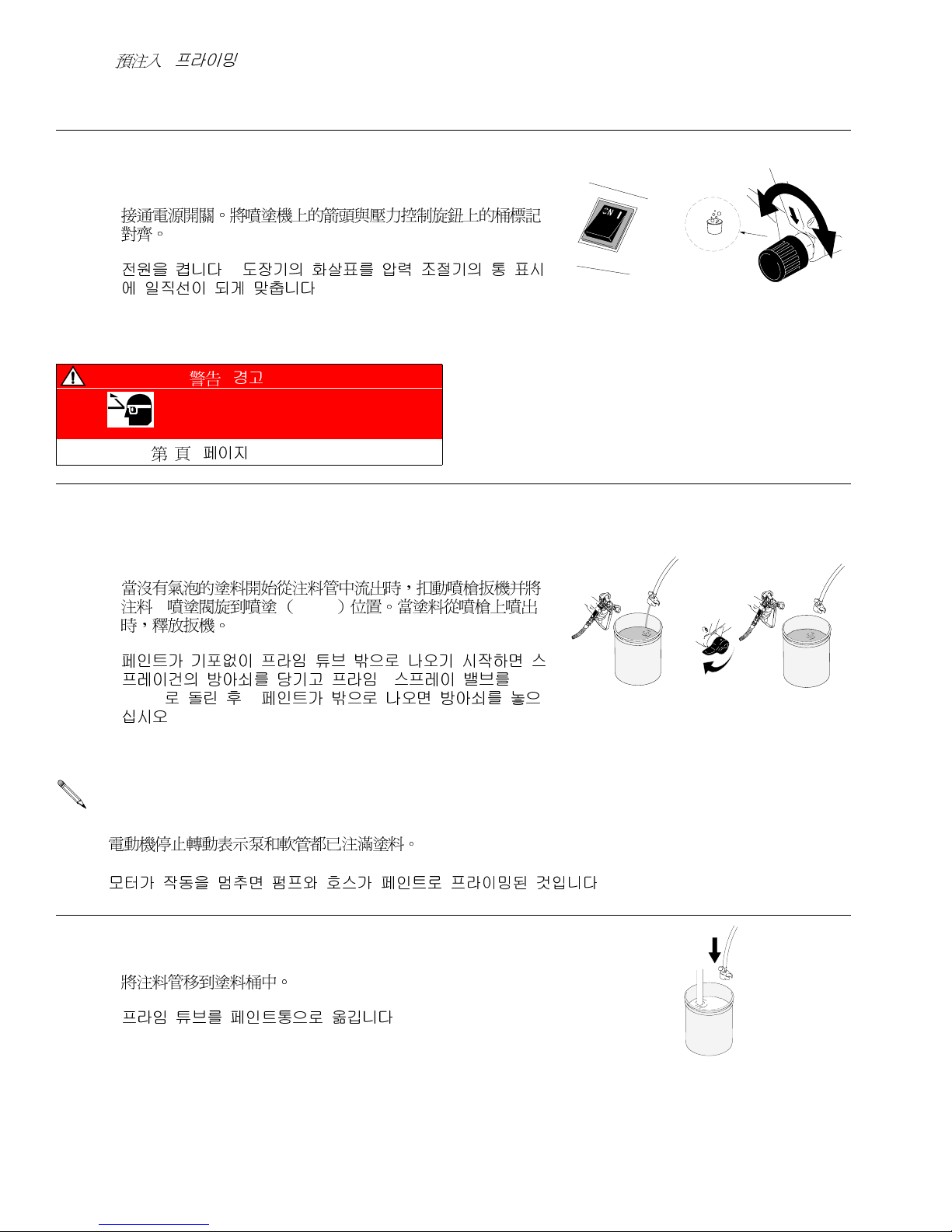

5. Turn ON power switch. Align arrow on sprayer and bucket

symbol on pressure control knob.

B PB B B B B B

B B B P

WARNING/ /

Page/ ! / 5.

6. When paint, without bubbles, starts to come out of prime tube,

trigger gun and turn Prime/Spray valve to SPRAY. When paint

comes out of gun, release trigger.

0 TQSBZ

B B B B B B B

B B B Q B B

urtc{

B B NB B B B B

P

The motor stopping indicates the pump and hose are primed with paint.

B B B B B B B P

7. Transfer prime tube to paint pail.

B B B P

ti2028a

ti2029a

ti2030a

Page 17

Spraying Techniques/ / B

3Z9478A 17

Pressure Adjustment/ / B

Spraying Techniques/ / B

WARNING/ /

Page/ ! / 3, 5.

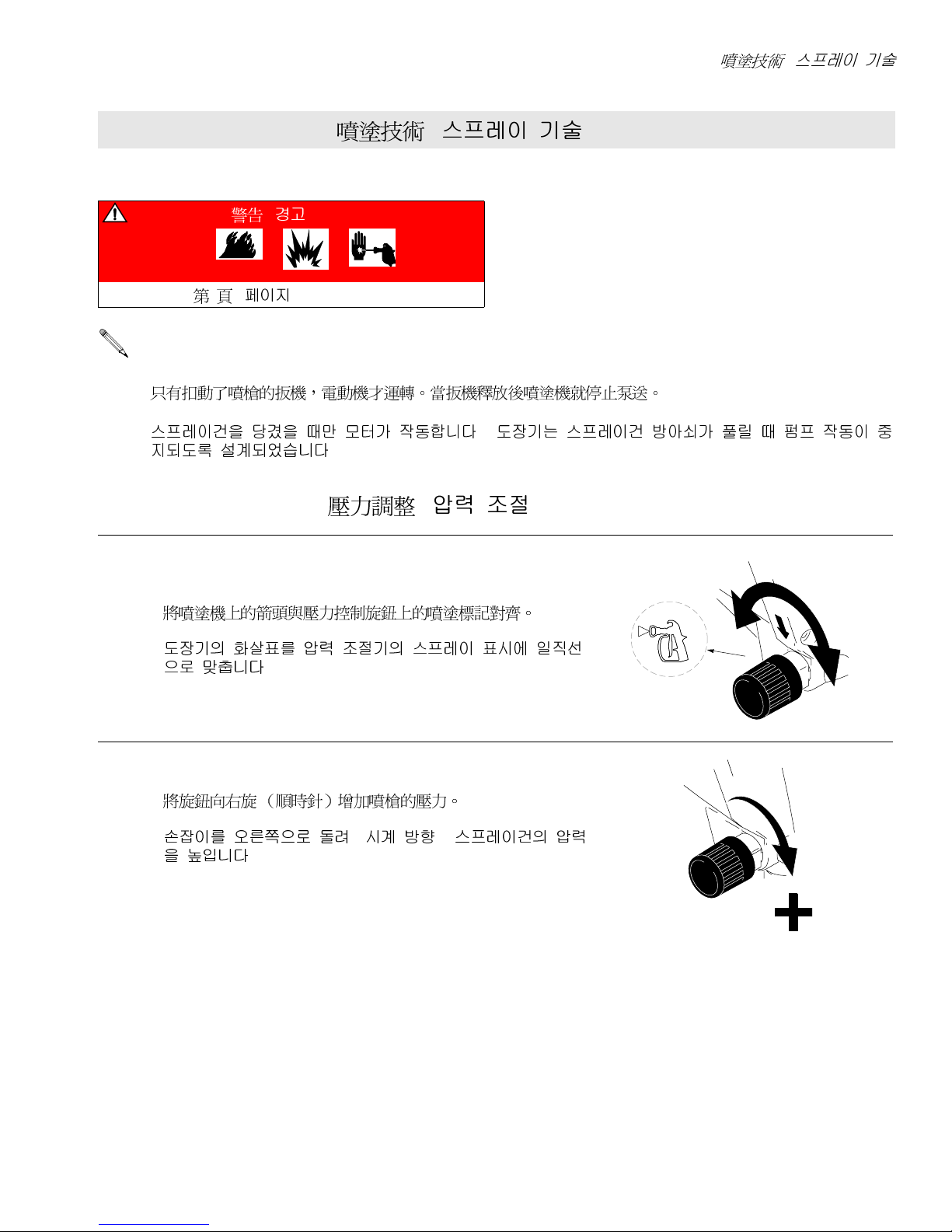

Motor runs only when gun is triggered. Sprayer is designed to stop pumping when gun trigger is released.

B B B B PB B B B B B B B

B P

. Align arrow on sprayer with spray symbol on pressure control

knob.

B B B B B B

B P

. Turning knob right (clockwise) increases pressure at gun.

B B J B KB B

B P

ti2031a

ti2032a

Page 18

Spraying Techniques/ / B

18 3Z9478A

Getting Started with Basic Techniques/

/

B B B

. Turning knob left (counterclockwise) decreases pressure at

gun.

B B J B B KB B

B P

. Hold gun 30 cm (12 in.) from surface and aim straight at sur-

face. Tilting gun to direct spray angle causes an uneven finish.

!41!dn!)23! *

URJSTB KB B B B B

B PB B B B B

B B B B P

. Flex wrist to keep gun pointed straight. Fanning gun to direct

spray angle causes uneven finish.

B B B B B B

PB B B B B

B B B B B P

ti2020a

ti2035a

ti2036a

Page 19

Spraying Techniques/ / B

3Z9478A 19

Triggering Gun/ / B B

Aiming Gun/ / B

. Pull trigger after starting stroke, release trigger before end of

stroke. Gun must be moving when trigger is pulled and

released.

B B B B NB B

B B B PB B B B

B B B B B P

. Aim tip of gun at edge of previous stroke to overlap each

stroke by half.

B B B B B B

B B B B B B P

ti2037a

ti2038a

Page 20

Cleanup/ /

20 3Z9478A

Power Flush - Quick Cleaning/ !.! /

B B-B B

For flushing water-based fluids only.

B B

Cleanup/ /

1. Turn Prime/Spray valve to PRIME.

0 QSJNF

Q B Brtkog B P

2. Separate prime tube from suction tube.

B B B B P

3. Unscrew inlet screen from suction tube.

B B B B B P

4. Place prime tube in waste pail.

B B B B P

ti2019a

ti2039a

ti2040a

ti2034a

Page 21

Cleanup/ /

3Z9478A 21

5. Screw Power Flush attachment (included with sprayer) onto

garden hose. Close Power Flush valve.

B B J B K B B B B

B B B B

6. Connect garden hose and Power Flush attachment onto suc-

tion tube. Turn on garden hose.

B B B B B B B B

B B B P

7. Turn ON power switch. Ali gn arrow on sprayer to bucket sym-

bol on pressure control knob.

B P B B B B B

B B P

8. Open Power Flush valve.

B B B P

ti2041a

ti2042a

ti2028a

ti2043a

Page 22

Cleanup/ /

22 3Z9478A

9. Aim gun in waste pail. Trigger gun.

0

B B B B B B PB

B Q B P

WARNING/ /

Page/ ! / 5.

10. Turn Prime/Spray valve to SPRAY.

0 TQSBZ

rQuB Burtc{ B P

11. Trigger gun for 2-3 minutes, until somewhat clear water flows

out of roller frame.

!3.4!

B B B B B B

BTOU B P

12. Turn Prime/Spray valve to PRIME.

0 QSJNF

Q B Brtkog B P

ti2027a

ti2044a

ti20 33a

ti2019a

Page 23

Cleanup/ /

3Z9478A 23

13. Let water flow through sprayer, into waste pail, for 30 seconds.

!41!

B B B B BUR B B B

P

14. Turn OFF power switch.

B P

15. Close Power Flush valve. Turn off garden hose.

B B B B B P

16. Unscrew Power Flush attachment from suction hose.

B B B B B B P

ti2045a

ti2018a

ti2046a

ti2047a

Page 24

Cleanup/ /

24 3Z9478A

Pail Flushing/ / B

For flushing non-waterbased fluids or if garden hose is not accessible.

B B B B B B B B B P

1. Engage gun trigger safety.

B B B P

2. Turn OFF power switch. Turn Prime/Spray valve to PRIME.

0 QSJNF

B PBrQuB Brtkog B P

3. Place prime tube in waste pail. Submerge suction tube in

water or compatible solvent for non-water based material.

B B B B B PB B B B

J KB B B B P

4. Turn ON power switch. Align arrow on sprayer and bucket

symbol on pressure control knob.

B PB B B B B B

B B B P

WARNING/ /

Page/ ! / 5.

ti2048a

ti2018a

ti2019a

ti2050a

ti2028a

Page 25

Cleanup/ /

3Z9478A 25

5. While pump continues to stroke, remove trigger safety. T rigger

gun into paint pail. Turn Prime/Spray valve to SPRAY. Continue to trigger gun until flushing fluid comes out of gun.

Release trigger.

0 TQSBZ

B B B B B B B

PB B B B PB

rQuB

Burtc{ B PB B

B B B B B B PB

B P

To minimize splashing, aim gun at inside wall of empty waste pail.

B B B B B B B B B P

6. Move gun to waste pail. Trigger gun until remaining flushing

fluid is gone from flushing pail. Release gun trigger.

!

B B B PB B B

B B B B B B B

B P

7. Fill unit with Pump Armor or mineral spirits. Cleanup, page 20.

!Qvnq!Bsnps!

!! 20 .

rBcB B B J20 B B KP

ti2051a

ti2052a

Page 26

Cleanup/ /

26 3Z9478A

Cleaning SG3E/A gun filter/ !TH4F0B! /

uiUgQcB B B

1. Relieve pressure, page 9.

!9!

B J9 B KPB

2. Engage gun trigger safety.

B B B P

3. Unscrew hose.

B B P

4. Remove filter and clean it in compa tibl e sol v ent.

B B B B P

Do not soak entire gun in solvent. Prolonged exposure to solvent can ruin packings.

B B B B B PB B B B B B B P

5. Insert filter.

!

B PB

ti2053

ti2048a

ti2007

ti2055a

ti2009a

Page 27

Cleanup/ /

3Z9478A 27

Filling sprayer with storage fluid/ / B B B

WARNING/ /

Page/ ! / 3, 5.

Always pump storage fluid through pump system after cleaning. Water left in sprayer will corrode sprayer and

damage pump.

B B B B B B B PB B B B B B

B B P

1. Remove inlet strainer. Place suction tube in storage fluid bottle

and prime tube in waste pail.

B B B B B B B B B B

B P

2. Turn Prime/Spray valve to PRIME.

0 QSJNF

Q B Brtkog B PB

ti2057a

ti2019a

Page 28

Cleanup/ /

28 3Z9478A

3. Turn pressure control knob all the way left (counterclockwise)

to minimum pressure.

B B B B B B

J B B K B P

4. Turn ON power switch.

B P

5. Align arrow on sprayer with roller symbol on pressure control

knob.

B B B B B B B

B P

ti2020a

ti2028a1

ti2058a

Page 29

Cleanup/ /

3Z9478A 29

6. When storage fluid comes out of prime tube (5-10 seconds)

turn OFF power switch.

6.21!

B B B B B BWOSR B B

B P

7. Turn Prime/Spray valve to SPRAY to keep storage fluid in

sprayer during storag e.

0 TQSBZ

rQuB Burtc{ B B B B B B

B P

ti2059a

ti2044a

Page 30

Cleanup/ /

30 3Z9478A

Selecting the Right Tip/ / B B

Tip Hole Size/ / B B

. Spray should be atomized (evenly distributed, no gaps or

edges). Start at a low pressure setting, increase pressure a little at a time until paint atomizes.

B B B B B B B B

B B PB B B B

B B B B B B P

. Fluid flow rate is controlled by tip hole size.

B B B B P

. The best tip hole size for fluid you are spraying is determined

by type of coating and type of surface you are spraying.

B B B B B B B B B

B B B B P

. Use large tip hole size when spraying thicker coatings.

B B B B B B B P

Page 31

Cleanup/ /

3Z9478A 31

If maximum pressure of sprayer is not enough for good spray pattern, tip is too large or worn. See Reversible Tip

Selection Table, page 33.

!33!

B B B B B B B B B B B B B B

P 33 B B B B B P

. Use small tip hole size when spraying thinner coatings.

B B B B B B B P

. Tips wear and enlarge when you spray. Starting with a tip hole

size smaller than the maximum will allow you to spray within

rated flow capacity. To prevent excessive wear, spray at lowest pressure that atomizes paint.

B B B PB B B

B B B B B B B B

B PB B B B B B

P

Page 32

Cleanup/ /

32 3Z9478A

Fan Width/ / B

Fan Width is the size of the spray pattern.

B B B B P

Narrow Fan/ / B

- Thicker coat/ / B B

- Better control/ / B B B B

- Small, confined surfaces/ !, B B B

Wide Fan/ / B B

- Thin coat/ / B

- Fast coverage/ / B

- Broad, open surfaces/ , B B

COATINGS/ /

Tip Hole Size

B B

(diameter based on area of elliptical orifice)

J B B B K

lacquers

and stains

enamels

oil-based

primers and

paints

interior latex

paint

exterior

latex paint

acrylics

B B

B

B B

B B B B

0.011 in. (0.28 mm) X

0.013 in. (0.33 mm) X X X X

0.015 in. (0.38 mm) XXXX

0.017 in. (0.43 mm) XXXX

0.019 in. (0.48 mm) X X

Page 33

Cleanup/ /

3Z9478A 33

Tip Number/ / B

The last three digits of tip number (example 286413) contain information about hole size and fan width when gun is

held 30.5 cm (12 in.) from surface being sprayed.

!397524 !41/6!dn!)23! *

!

B B B B J \BTZXVSUK B B B BURPWBBJSTB KB

B B B B B B B B B P

Reversible Tip Selection Table/ / B B B

Example: For an 203-254 mm (8-10 in.) fan width and a 0.33 mm (0.013 in.) hole size, order part no. 286413.

!9.21! )314.365!nn* !1/124! )1/44!nn* !

397524

\B B BTRUOTWVBJZOSRB K B B BRPUUBJRPRSUB K B B B B

TZXVSU

P

Tip Part Number

B B

Fan Width ( 305 mm (12 in.) from surface

!23! !)416!nn*

B B B JURWBNBSTB K

Hole Size

B

286411 203-254 mm (8-10 in. ) 0.28 mm (0.011 in. )

286511 254-305 mm (10-12 in.) 0.28 mm (0.011 in. )

286313 152-203 mm (6-8 in.) 0.33 mm (0.013 in.)

286413 203-254 mm (8-10 in.) 0.33 mm (0.013 in.)

286415 203-254 mm (8-10 in.) 0.38 mm (0.015 in. )

286515 254-305 mm 10-12 in.) 0.38 mm (0.015 in.)

286417 203-254 mm (8-10 in.) 0.43 mm (0.017 in.)

286517 254-305 mm (10-12 in.) 0.43 mm (0.017 in.)

286519 254-305 mm (10-12 in. ) 0.48 mm (0.019 in.)

286619 305-356 mm (12-14 in. ) 0.48mm (0.019 in. )

See manual 309097 for SG3E/A gun

operating instructions and spray

techniques.

!TH4F0B!

!41:1:8

uiUgQcB B B B B B

B B BUR[R[Y B

P

Page 34

Troubleshooting

34 3Z9478A

Troubleshooting

Problem Cause Solution

Pump will not prime

HINT:

• Attempt to free chec k bal ls by

tapping side of inlet valve as

sprayer is stroking.

• Strain paint before spraying.

Keep sand and debris out.

• Thoroughly flush after every

paint job.

• Do not store in water. Use

Pump Armor or mineral spirits.

Prime/Spray valve set at SPRAY. Turn Prime/Spray valve to PRIME.

Inlet screen clogged. Clean debris off inlet screen.

Suction tube is not immersed. Reposition suction tube in bottom of paint pail.

Inlet valve check ball stuck. Remove tube. Insert end of pencil into inlet section to

dislodge ball. OR Power Flush unit, page 20.

Outlet valve check ball stuck. Use screw driver to open Easy-Access door. Unscrew

outlet valve. Remove and clean assembly.

Suction tube is leaking. Tighten suction tube connection. Inspect for cracks or

vacuum leaks.

Prime/Spray valve clogged. Clean/replace drain tube as necessary. Return sprayer

to Graco/M

AGNUM authorized service center if drain

valve is clogged.

Power switch is on and sprayer is

plugged in but pump does not

cycle.

Pressure set at minimum. Turn pressure control knob right to increase pressure.

Electrical outlet is not providin g

power .

• Try a different outlet OR test outlet by plugging

something in that you know is working.

• Reset buildin g circuit breaker or repl ace fuse.

Damaged extension cord. Replace extension cord. See Grounding and Electrical

Requirements, page 10.

Damaged sprayer electrical cord . Check f or b roken insu lation or wires. Rep lace damag ed

electrical cord.

Motor or control damaged. Return sprayer to authorized Graco service center.

Paint frozen or hardened in pump. Unplug sprayer from electrical outlet.

If paint if frozen in sprayer:

Do NOT try to start frozen sprayer. Thaw completely or

you may damage motor, control board and/or drivetrain.

1 Turn OFF power switch.

2 Place sprayer in warm area for several hours.

3 Plug in and turn on sprayer.

4 Slowly increase pressure until motor starts.

If paint hardened in sprayer:

1 Replace pump packings.

2 Remove all residue from valves and passages.

Page 35

Troubleshooting

3Z9478A 35

Problem Cause Solution

Pump cycles but pressure does

not build up.

Pump not primed. Prime pump, page 15.

Inlet screen clogged. Clean debris off inlet screen

Suction tube not immersed. Reposition suction tube in bottom of paint pail.

Paint pail empty. Refill paint pail and reprime sprayer.

Suction tube has vacuum air leak. Tighten suction tube connection. Inspect for cracks or

vacuum leaks. If cracked or damaged, replace.

Pump check valves are dirty or

damaged.

Return sprayer to Graco/M

AGNUM authorized service

center.

Prime/Spray valve worn or

obstructed with debris.

Pump check ball stuck. See “Pump will not prime” section of Troubleshooting

table, page 34.

Cannot pull gun trigger. Gun trigger safety engaged. Remove gun trigger safety

Gun stops spraying. Spray tip clogged. 1 Turn arrow-shaped handle to unclog position.

2 Aim gun into waste pail.

3 Squeeze trigger.

4 Return arrow-shaped handle to spray position

and begin spraying.

Pump cycles but paint only

dribbles or spurts when trigger is

pulled.

Pressure is set too low. Turn pressure control knob right to increase pressure.

Spray tip clogged. Clean tip. See “Gun stops spraying” section of

Troubleshooting table, page 34.

Spray tip too large or worn. Replace tip.

Gun filter clogged. Clean or replace gun filter, page 48.

InstaClean fluid filter is clogged. Clean or replace InstaClean fluid filter, page 47.

Pump check ball stuck. See “Pump will not prime” section of Troubleshooting

table, page 34.

Pressure set at maximum, but

cannot achieve good spray

pattern.

Tip is too large for sprayer. Select smaller tip, Tip Hole Size, page 30.

Tip is worn beyond capability of

sprayer.

Replace tip.

Gun filter clogged. Clean or replace gun filter, page 48.

Inlet screen clogged. Clean debris off inlet screen.

Pump valves worn. Check for worn pump valves:

1 Prime sprayer with paint.

2 Trigger gun momentarily. When trigger is

released, pump should cycle and stop.

3 If pump continues to cycle, pump valves may be

worn.

4 Return sprayer to Graco/M

AGNUM authorized

service center.

InstaClean fluid filter clogged. Clean or replace InstaClean fluid filter, page 47.

Extension cord too long or not

heavy enough gauge.

Replace cord, Grounding and Electrical Requirements,

page 10.

Page 36

Troubleshooting

36 3Z9478A

Problem Cause Solution

Sprayed paint runs down wall or

sags.

Going on too thick. Move gun faster.

Use tip with smaller hole size.

Use tip with wider fan.

Move gun away from surface.

Sprayed paint is not covering. Going on too thin. Move gun slower.

Use tip with larger hole size.

Use tip with narrower fan.

Move gun closer to surface.

Pattern is inconsistent or leaving

stripes.

HINT:

Thin paint slightly with

water/solvent.

Pressure set too low. Turn pressure control knob right to increase pressure.

Spray tip worn beyond capability of

sprayer.

Replace tip.

Motor is hot and runs

intermittently.

This is a Thermal Overload

condition. Motor will automatically

shut off due to excessive heat.

Damage can occur if caus e is not

corrected. Startup Hazard After

Thermal Overload, Warnings,

page 7.

Vent holes in shroud are clogged

or sprayer is covered.

Clear vent holes.

Extension cord too long or not

heavy enough gauge.

Replace cord, Grounding and Electrical Requirements,

page 10.

Unregulated electrical generator

being used has excessive voltage.

Use electrical generator with proper voltage regulator.

Sprayer requires 220-240, VAC 50/60 Hz.

Sprayer was operated at high

pressure with small tip, causing

frequent motor starts and

excessive heat build up.

Decrease pressure setting or increase tip size.

Move sprayer to cooler location.

Building circuit b reaker opens after

sprayer operates for 5-10 minutes.

OR

Building circuit breaker opens as

soon as sprayer is plugged into

outlet and sprayer is turned on.

Too many appliances plugged in

on same circuit.

Unplug some appliances or use a less busy circuit.

Extension cord is damaged, too

long, or not a heavy enough

gauge.

Plug in something that you know is working to test

extension cord. Rep lace extens ion cord. Gro unding and

Electrical Requirements, page 10.

Damaged sprayer electrical cord. Check for brok en in sulat ion o r wire s. R eplac e da maged

electrical cord.

Damaged motor or control. Return sprayer to Graco/M

AGNUM authorized service

center.

Fan pattern varies dramatically

while spraying.

Pressure cont rol switch is worn

and causing excessive pressure

variation.

Return sprayer to Graco/M

AGNUM authorized service

center.

Sprayer does not turn on promptly

when resuming spraying.

Spray comes out of gun in two

thick streams.

Reversible tip is in UNCLOG

position.

Rotate arrow-shaped handle on tip to SPRAY position.

Page 37

Troubleshooting

3Z9478A 37

Problem Cause Solution

Paint leaks down outside of pump. Worn pump packings. Replace pump packings, page 51.

Paint comes out of pressure

control knob.

Worn pressure control knob. Return sprayer to Graco/M

AGNUM authorized service

center.

Pressure drain actuates

automatically, relieving pressure

through prime tube.

System is overpressuring.

Page 38

38 3Z9478A

•

•

•

.

•

!Qvnq!

Bsnps!

0 TQSBZ 0 QSJNF

!

!20!

0

!Hsbdp0N

BHOVN

!

!

•

•

!10!

!

!Hsbdp!

0

2!

3!

4!

5!

2!

3!

Page 39

3Z9478A 39

!15!

!Hsbdp0N

BHOVN

!

0

!38!

2!

3!

4!

5!

!38!

!48!

JotubDmfbo!

!JotubDmfbo!

!47!

!38!

!30!

!48!

2!

3!

4!

5! !Hsbdp0N

BHOVN

!

JotubDmfbo! !JotubDmfbo!

!47!

!10!

Page 40

40 3Z9478A

0

!!

!10!

!

331.351!W

!61071!I{!

!6.21!

!10!

!Hsbdp0N

BHOVN

!

!Hsbdp0N

BHOVN

!

Page 41

3Z9478A 41

!51!

!Hsbdp0N

BHOVN

!

Page 42

B

42 3Z9478A

B

B

B B P

\

•

B B B B

B B B B

B P

• B B B

PB B B

B P

• B B B B

B P

• B B PBrB

cB B P

rQuB

Burtc{ B

P

Q B Brtkog B PB

B B P B B B PB

B B B P B B P

B B B B B

P

B PB B B B B B

B B J B B B20 B

KP

B B B B B

P

B B B B B PB

B B B B B B P

B B P B B B B PB B B

B B P

rQuB

B PB B B B Q PB B

B BiQo

cipwo

B B B B B

P

B B B B

B B B

P

B B P B B B B B

P

B B B B

PB

•

B B B B B B

B B B P

•

B B B B B

P

B B P B B J10 B B B B

B KP

B B B

PB

B B B B PB

B B B P

B B B

P

BiB B B B P

B B B B

P

B B B P

B B B \

B B B B PB B

B B NB B Q B

B B B P

SB

B P

TB

B B B B B B P

UB

B B B B P

VB

B B B B B

P

B B B \

SB

B B P

TB

B B B P

Page 43

B

3Z9478A 43

B

B B B

B P

B B P B J15 B KP

B B P B B B P

B B B P B B P

B B P B B B B P

B B B B

P

B B B PB B B B B

B PB B B B

P

B B B B

B P

iQo

cipwo

B B B B B

P

B BrQuB

B B P

B B B B

P

B B B B B

B 42P

B B B B

P

B B B

B P

B B B P

B B

P

B B PSBB B B B B B

P

TB

B B B P

UB

B P

VB

B B B B

B B B B B P

B B B B

B B B B

B B B P

B B B B

P

B B B B B

P

B B P B PB B B B

B B B P

B B B B

P

B P

B B P B B B 48P

keB

B B

P

keB

B B B J47

B KP

B B B B

P

B B B B B

B 42P

B B B

B B B B B

P

B B B P B B B J30 B B B

B KP

B B B B

P

B P

B B P B B B 48P

B B P B B B P

B B P B B B P

SB

B B P

TB

B B PB B

B B B B P

UB

B B B B B B B

P

VBiQo

cipwo

B B B B B

P

keB

B B

P

keB

B B B

J47 B KP

B B B B

B B P

B J10 B B B B

B KP

Page 44

B

44 3Z9478A

B

B B B B

B P

B B P B B P

B B B B P

B B B P

B B B P

B B B

B P

B B PB B B P

B B B B P

B B B P

B B B P

B B B B

P

\

Q B B B

B B P

B B B P

B B B B B

P

B B B B

B P

B P

B B B

B P

B B B PB

B B B B

B PB B B

B B B PB

B BY B B B B

B P

B B B

B B P

B P

B B B B

B B P

B J10 B B B B

B KP

B B B B

B B P

B B B B B PB

BTTROTVRNBxceBWRQXRBj B P

B B B B

B B B B

B B B B

PB

B B B B P

B B B P

WOSR B B B B B

B B

B B NB

B B B B B

B B PB

B B B B B

B B P

B B B B B NB B

B B B B PB

B B B B

B B B B

B P

B B B B B B B B

B B B B PB B B

J10 B B B B B

KP

B B

P

B B B B PB

B B B P

B B B

P

iQo

cipwo

B B B B B

P

B B B B

B B P

B B B

NB B B B B

PB

iQo

cipwo

B B B B B

P

B B B B

B B B P

B B B B B

B B P

wpenqiB B P

B B B B B P

Page 45

B

3Z9478A 45

B

B B B

P

B B P B B J51 B KP

B B B B

P

B B P iQo

cipwo

B B B B B

P

B B B

B B B B B

P

B B B P

Page 46

Maintenance/ /

46 3Z9478A

Caring for Sprayer/ / B

Maintenance/ /

CAUTION/ / :

Openings in shroud provide air for cooling mechanical parts and electronics inside. If water gets in these

openings sprayer could malfunction or be permanently damaged.

B B NB B B B B PB B B B B B

B B B B B P

Clean sprayer and accessories thoroughly after each use.

B B B B B B

P

Do not cover vent holes or shroud while spraying.

B B B B B P

ent Holes

Page 47

Maintenance/ /

3Z9478A 47

InstaClean Fluid Filter/JotubDmfbo! /keB B

The InstaClean fluid filter (E) self-cleans during pressure

relief. Embedded particl es may req uire man ual clea nin g.

JotubDmfbo! F

keB B JgK B B B B

PB B B B B B P

Remove pump fluid outlet fitting (D) to remove and check

InstaClean filter. Replace if damaged.

E !JotubDmfbo!

B B JfK B BkeB B

B B PB B P

To activate InstaClean fluid filter system sprayer must be under pressure. If sprayer is not under pressure, it

needs to be primed. Priming, page 15.

!JotubDmfbo!

!15!

keB B B B B B B B PB B B B B

B B B J15 B B KP

Page 48

Maintenance/ /

48 3Z9478A

Gun Fluid Filter/ / B B

Paint Hoses/ / B

Clean gun fluid filter with compatible solvent and brush every

time you flush system. Replace when damaged.

B B B B B B

B B B B B P

Check hose for damage every time you spray. Do not attempt

to clean or repair hose if hose jacket or fittings are damaged.

Do not use hoses shorter than 7.6 m (25 ft).

!

8/7!n

36!

B B B B PB

B B B B B B B

PB BYPXBBJTWBKB B B B

P

Page 49

Maintenance/ /

3Z9478A 49

Drive Train Lubrication/ / B B

Tips/ /

Regrease gear every time pump packings are replaced or

every 100 hours of operation.

!211!

!

B B BSRR B B B B

B B P

Always clean tips with compatible solvent and brush after

spraying.

B B B B B B B

P

Tip life: 57 liters (15 gallons) - 227 liters (60 gallons)*

68! 26! !.!338! 71! +

B \BWYB BJSWB KBOBTTYB BJXRB KL

*Depends on abrasiveness of paint/

+ /

L B B B B

Do not spray with worn tip.

B B B P

Page 50

Maintenance/ /

50 3Z9478A

Pump Check Valves/ / B B

Storing in water, inadequate flushing or ingested debris can

cause either of the two check valves to malfunction.

B B B B B B B

B B B B B B B B P

If pump does not prime after 30 seconds, try to loosen check

balls by tapping inlet valve with small wrench as the sprayer

is stroking.

Excessive shock will fracture or cause other damage to pump.

!41!

UR B B B B B B B

B B B B B B B B

B P

B B B B B B P

inlet valve

Page 51

Maintenance/ /

3Z9478A 51

HINT: T o verify inlet valve ball is sticking, unscrew valves from

pump and check them.

If sprayer continues to cycle (motor and pump run) after you

release gun trigger, pump valves may be obstructed or worn.

V alve repair kits are available from Graco/M

AGNUM authorized

service centers.

!Hsbdp0N

BHOVN

!

\B B B B B B

B B B P

B B B B B B

J B B KB B B B B B B

PB B BiQo

cipwo

B B B

B B B B P

Page 52

Maintenance/ /

52 3Z9478A

Pump Packings/ / B

When pump packings wear, paint will begin to leak down

outside of pump. Replace pump packings at first sign of

leaking or additional damage could occur.

B B B B B B B

PB B B B B B B

PB B B B B P

Pump repair kits are available from Graco/MAGNUM authorized

service centers.

!Hsbdp0N

BHOVN

!

iQo

cipwo

B B B B B B B

B B P

Page 53

Technical Data/ / B

3Z9478A 53

Technical Data/ / B

Maximum fluid working pressure - sprayer

!.!

B B B B-

207 bar, 21 MPa (3000 psi)

Sprayer inle t si ze

B B

3/4 in. internal thread (standard garden hose)

405!

UQVB B B J B B K

Sprayer outl e t size

B B

1/4 npsm external thread

205!OQTN!

SQVBB B

Roller valve fluid inlet size/ /

B B B B

1/4 npsm

Electric motor

B

7/8 hp 6.5 Amp, permanent magnet, open frame motor

809! !7/6!

YQZBBXPWBcNB B NB B B

Sprayer weig h t o nl y/ /

B

16.5 kg (36 lb)

27/6!lh!)47! *

Dimensions/ /

Length/ /

49.5 cm (19.5 in.)

Width/

/

48.3 cm (19.0 in.)

Height/ /

101.6 cm (40.0 in.)

Wetted parts sprayer

B B B

Stainless steel, brass, ultra-high molecular weight

polyethylene (UHMWPE) leather carbide, nylon,

aluminum, PVC, polypropylene, fluroelastomer

uuvNB NB B JwjoyrgKB B

NB NB NBrxeNB NB

Page 54

Technical Data/ / B

54 3Z9478A

*Measured while spraying water-based paint - specific gravity 1.36 through a 517 tip at 207 bar, 21 MPA (3000 psi)

per ISO 3744. Actual sound levels may vary with length of extension used.

+ !JTP!4855! !318! 32!NQb! !4111!qtj !628! !

2/47!

L B B B B B B BOBTRYB BWSYB B B B

SPUXPBTSBorBJURRRBK

BkuqBUYVVPB B B B B B B B B B P

Inlet Screen on Suction Tube

B B

450 micron (35 mesh)

561! !)46! *

Maximum material temperature

B B

50°C (120°F)

Electrical power requirement

B

220-240V AC 50/60 Hz, 1 phase, 10A

!331.351W 61071!I{-! -!21B

TTROTVRxBceBWRQXRBjNB

NBSRBc

Sound data* SG3E/A spray gun

TH4F0B! +

B LBuiUgQcB B

Sound pressure leve/ /

J B KB

78 dB(A)

Sound power level/

/

B

87 dB(A)

Page 55

Technical Data/ / B

3Z9478A 55

Page 56

Graco Standard Warranty/Hsbdp! /iB B

56 3Z9478A

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any

special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any

part of the equipment determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained

in accordance with Graco’s written recommendations.

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any

special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any

part of the equipment determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained

in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CHINESE/KOREAN CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English.

!HSBDP! 0

Q BitceqB B

B B B B B B B B B B NB B B B NB B B B B B

B B B P

TO PLACE AN ORDER OR FOR SERVICE, contact your Graco distributor,

or call 1-888-541-9788 to identify the nearest distributor.

!Hsbdp!

2.999.652.:899!

B B B B B P

B B B BRTOWYWOZR[S B B B B P

Graco Standard Warranty/Hsbdp! /iB B

Loading...

Loading...