Magnifico MR3, MR31, MR4, MR321, MR32 Use And Maintenance Manual

...

USE AND

MAINTENANCE

MANUAL

MR3 - MR31 - MR4 - MR321 - MR32 - MR42

ME423 - ME4232 - ME523 - ME5232.. MME523

ME5 - ME52.. - MME52

ME7 - ME72.. - MME72

ME10 - ME102.. - MME102

MG5 - MG52 - MMG52

MG7 - MG72 - MMG72

MG10 - MG102 - MMG102

Rev. 2013-06.05

3

Use and maintenance manual

2

Index

1. Installation

1.1

General and safety warnings

3

1.2

Connection to gas supply

4

1.3

Checking gas pressure

6

1.4

Replacing nozzles (gas type change)

6

1.5 Electric connection 7

1.6

Fume discharge

8

1.7

Connection to the drain

8

1.8 Switching on oven and testing 9

2. Use instruction

2.1 Preliminary information 10

2.2 Control Panel 11

2.3 Convection cooking 12

2.4 Steaming 13

2.5 Convection/steam combi cooking 14

2.6 Humidity draining valve 15

2.7 Compartment lighting 15

2.8 Stop and oven swich off 15

2.9 Flame control (gas ovens only) 15

2.10 Other versions 16

4. What to do if...

4.1 Most common problems 18

4.2 Safety thermostat of the cooking

compartment

19

3. Maintenance

3.1 Cleaning 17

3.2 Cleaning of the glass 17

Dear Customer,

We thank you for having purchased our product.

This oven is part of a line of appliances specically designed for baking and patisserie, made of gas and electric

ovens with different capacities. The pleasant and modern design of these ovens provides ease of use, ergonomics

and cooking control.

The oven has a 12 month warranty against any manufacturing faults, starting from the date on the sales invoice.

The warranty covers the normal functioning of the oven and does not include the consumption materials (lights,

gaskets, etc.) and faults caused by incorrect installation, wear, maintenance, repair, decalcication & cleaning,

tampering and improper use.

The manufacturer reserves the right at any time to make changes or necessary amendments to the product.

• Carefully read this manual before installing and com-

missioning the oven. The text gives important indications regarding the safe installation, operating and

maintenance of the equipment.

• Keep this manual in a safe and easily accessible place

for further consultation by the operators.

• In case of transferring the oven, always attach the ma-

nual; if necessary, a new copy must be requested from

the authorised dealer or directly from the manufacturing company.

• Once unpacked, ensure the oven is intact and does not

show signs of damage due to transport. A damaged

appliance must never be installed and commissioned; if

in doubt, immediately contact the after-sales technical

assistance or your own dealer.

• The appliance has been designed to cook food in closed

premises and must only be used for this purpose: any

other use must, therefore, be avoided as considered

improper and dangerous.

• The device is intended for professional use only by qua-

lied personnel

• The oven must only be used by staff adequately trained

for its use. To avoid the risk of accidents or damages to

the appliance, it is also fundamental that staff regularly

receive precise instructions regarding safety.

• The oven must not be used by persons with reduced

physical, sensorial or mental capacities or by persons

without experience and knowledge, unless supervised

or educated regarding the operating of the appliance by

a person responsible for their safety.

• Installation, extraordinary maintenance and repair

operations on the equipment must only be carried out

by professionally qualied staff.

• Children must be supervised to assure they do not

play with the appliance or use it.

• Caution! During working conditions, the external sur-

faces of the equipment may exceed 60 C.

• In case of fault or bad functioning, the equipment

must be deactivated; in case of repair, contact only

an after-sales technical assistance centre authorised

by the manufacturer and request original spare parts.

• Do not position other heat sources like, fryers or

hotplates, near the oven.

• Do not deposit or use ammable substances near the

equipment.

• In case of prolonged disuse of the appliance, both the

water and electric energy supply must be shut-off.

• Before commissioning the equipment, ensure to have

removed all packaging, being careful to dispose of it in

compliance with the Standard in force.

• Amendments to the oven wiring are not admitted.

• The non-compliance with the above warnings can je-

opardise the safety of the equipment and may injury

the operator of the oven.

The gas ovens comply with the essential requirements of 90/396/EEC Gas Directive and therefore have the EC

conformity certicate issued by an approved body. They satisfy the requirements of the following gas regulations:

• EN 203 + subsequent amendments;

• EN 437 + subsequent amendments.

Installation must be carried out in compliance with safety requirements contained in the following regulations:

• UNI CIG n° 7222-7723-8723 + subsequent amendments.

The appliance complies with the essential requirements of the Low Voltage Directives 2006/95/CEE. It satises the

requirements of the following electrical regulations:

• EN 60335-1 + subsequent amendments;

• EN 60335-2-42 + subsequent amendments;

• EN 60335-2-46 + subsequent amendments;

• EN 60335-2-36 + subsequent amendments;

• EN 55104 / EN 55014 + subsequent amendments;

• EN 61000 + subsequent amendments.

The appliance complies with the essential requirements of the Electromagnetic Compatibility Directive 2004/108/

CEE.

1. Installation

1.1 General and safety warnings

5. Data sheet

5.1 ME523 - ME5232 - MME523 19

5.2 ME5232X - ME5232K1 - ME5232K2 20

5.3 ME5 - ME52 - MME52 - ME52X 21

5.4 ME7 - ME72 - MME72 - ME72X 21

5.5 ME10 - ME102 - MME102 - ME102X 22

5.6 MG5 - MG52 - MMG52 23

5.7 MG7 - MG72 - MMG72 23

5.8 MG10 - MG102 - MMG102 24

5.9 MR3 - MR32 - MR31 - MR312 25

5.10 MR4 - MR42 25

5.11 ME423 - ME4232 26

6. Electrical drawings

Electrical drawings 27-42

5

Use and maintenance manual

4

1. Installation

1.2 Connection to gas supply (for gas ovens only)

The oven is factory set for the type of gas spe-

cied in the order.

The label attached to the appliance indicates

which type of gas the oven has been set for.

During testing, the gas produced through combustion (CO2 and CO) should be

analysed and the nominal heat rating

should be measured to ensure that the

burners have been correctly calibrated

for the type of installation required.

Data collected should be written down and included in the technical documentation of the

appliance.

Installation instructions

The oven should be installed and commissioned by qualied technicians in compliance

with current regulations and legislation.

Gas appliances, electrical connections and rooms where the appliance is to be sited

must comply with current regulations and legislation.

The air requirement of the burners is 2 m3/h per kW of power installed.

Premises open to the public must comply with accident prevention laws and re safety

regulations. A exible metal hose can be used to connect the appliance to the gas supply; make sure you t an approved tap in a point that is easy to reach.

Make sure that the exible hose is not twisted or over-stretched or in contact with parts

of the oven subject to overheating.

Use locking clamps complying with installation regulations.

Checks to be carried out prior to installation.

Check the label on the left-hand panel of the oven to make sure that the appliance has

been set for the type of gas on your premises.

Check the label to make sure that the capacity of the gas pressure reducer is adequate

for the supply of the appliance.

Do not insert section reducers between the reducer and the appliance.

We recommend tting a gas lter between the tap and pressure regulator to ensure

perfect performance.

Connect the oven to the gas supply using a special R 1/2”

hose with an internal section of at least 16 mm.

Connection to gas supply must be carried out using rigid or

exible metal pipes. Use taps or gates with an internal diame-

ter that is greater than that of the hose.

After connecting the appliance to the gas supply make sure

that there are no leaks from joints or connections. You can

test for leaks by using soapy water or foaming agent for leak

detection.

Gas ovens should be inspected in compliance with spe-

cic regulations once a year by an authorised techni-

cian who will analyse combusted gases and check no-

minal heat rating.

The appliance can work correctly only when gas pres-

sure keeps within specic values for each gas type (see

table).

If the pressure falls outside these values, it will not be possible

to achieve optimum functioning of the appliance and for it to

be installed correctly. Should this happen, call a technician to

check your gas mains (ducts, gates and eventually pressure

reducers) then, if necessary, contact your gas provider.

1. Installation

7

Use and maintenance manual

6

1. Installation

1.3

Control of Gas Pressure (for gas ovens only)

Check that the installed nozzles are correct for the type and pressure of supplied gas. If you need to change the

nozzles, read the following paragraph.

1.4

Replacing nozzles (gas type change) (for gas ovens only)

Category of appliance: II2H3+ Country: IT- ES -PT- CH-GB -GR - IE

Oven

Nominal

Power

Nozzle for

G30 gas [30 mbar]

Nozzle for

G31 gas [37 mbar]

Nozzle for

G20 gas [20 mbar]

5 GN 1/1 9,5 kW 115 110 161R

7 GN 1/1 16 kW 145 135 195R

10 GN 1/1 19 kW 155 145 225R

Use only original nozzles which must not be tampered with them in any way!

For connection to a type of gas that is different from the

one specied on the rating plate, the burner/s and nozzle/s

must be replaced as follows:

• Unscrew nozzle to be replaced and replace it with the

one that corresponds to the type of gas to be used.

• Ret washer.

• Nozzles are marked in hundredths of a millimetre.

• After replacing the nozzle/s, check gas pressure.

When the appliance is connected, turn it on and check the

gas pressure.

Check gas pressure directly on the valve, as described

below:

• Unscrew screw “P” on the pressure outlet of the valve.

• Apply the pressure gauge to the pressure outlet.

• Regulate gas pressure to the values of table 2 by adju-

sting the pressure reducer outside the oven

• When the pressure is at the correct level, switch off

the oven, remove the pressure gauge and replace

screw “P”.

If the adjustment of the pressure is not sufcient, act as

follows:

• Remove the protective cap A.

• Screw to increase the pressure of the outlet gas acting

on the screw B and unscrew to decrease.

• At the end of the calibration reapply the protective

cap A.

A

P

B

1. Installation

1.5

Electric connection

The electric system, as prescribed and specied by the Standard in force, must be

equipped with an efcient ground. It is possible to guarantee the electric safety of the

appliance only in the presence of Standard electric system.

For direct connection to the mains, it is necessary to interpose a device between the

equipment and the same mains, sized for the load, that ensure its disconnection. The

contacts must have an opening distance enabling the full disconnection, in conditions

of over-voltage category III, per compliance with installation regulations.

This device also must be located in a place and in a manner to be easily accessible at

any moment by the operator.

Bring the main switch, to which the power supply cable plug will be collected, in position

0 (zero).

Have professionally qualied staff check that the plug cables section is adequate to the

power used by the appliance.

Loosen the screws xing the left side of the oven and extract it.

Connect the cable to the terminal board

following the indications on “tab 1”.

Lock the cable with the cable presser.

The power supply voltage with machine

functioning,must not be different from the

nominal voltage value by ±10%.

The equipment must be included in an equipotential system which efciency must be

checked according to that reported in the Standard.

For the connection there is a clamp, located on the frame and marked with the symbol

to which a cable with minimum section of 10 mm² must be connected.

For gas ovens, complete gas connection to the appliance before assembling the

oven side again;

for electric ovens assemble the oven side.

ELECTRIC OVENS GAS OVENS

L1 L2 L3 N N L N X

tab 1

Between phases

and there must be

a potential difference

of 230 V

9

Use and maintenance manual

8

1. Installation 1. Installation

1.6

Fume discharge (for gas ovens only)

Ovens should only be installed in adequately ventilated rooms in compliance with installation regulations.

The oven discharge can be connected by means of a forced evacuation system (e.g. hood tted with an extractor

fan). In this case the gas supply to the appliance must be controlled by the extraction system and will be interrupted

if the extraction capacity drops below the prescribed values. When installing the appliance beneath a hood take

care to ensure that:

a) the extracted volume is greater than the volume of com-

busted gas produced (refer to current regulations);

b) the hood lter is made from a heat-resistant material

(combusted gases may reach 300°C;

c) the nal section of the gas discharge tube must be inser-

ted inside the hood;

d) following interruption of gas supply the gas will be

switched on manually.

1.8 Switching on oven and testing

Before switching on the oven, carefully check that all systems and installation of the appliance are in compliance

with current laws and with the technical and safety guidelines in this manual.

Check the following:

• The oven must be installed in a room where the temperature is over +4° C.

• The oven chamber must be empty.

• All packaging has been completely removed, including the protective lm applied to the walls of the oven.

• Vents and ventilation openings must be open and unobstructed.

• Any parts that have been removed for installation purposes must be replaced.

• The main switch must be switched on and the water and gas taps must be open.

Testing

The oven should be tested by carrying out a trial cooking session to check that the appliance is working properly and

that there are no problems or malfunctioning.

Switch on the oven by turning the cooking mode knob to the preferred position (convection, steam, combi) and by

turning the timer knob to a time position or on the innite symbol.

Carry out a trial cooking session setting the temperature to 150° C, the timer to 10 min. and humidity (if present).

Check every item in the list below:

• The light in the oven chamber switches on.

• The oven switches off if the door is opened and starts up again after the door has been closed.

• The temperature controller regulating the oven temperature is activated, causing the heating elements to

switch off temporarily.

• Every 2 minutes the fan motor automatically reverses direction of rotation followed by a 20-second rest.

• During the 20-second motor rest the S1 “°C” lighting indicator will temporarily switch xed-on showing that

the oven chamber heating elements have been temporarily switched off.

• For 7-tray and 10-tray ovens: the two fans in the oven chamber rotate in the same direction.

• Check that water is being discharged to the fan/s from the humidity inlet duct in the oven chamber (models

with humidier only).

• At the end of the cooking session the oven alarm sounds for about 15 seconds.

1.7

Connection to the drain

The oven must be connected to an open drain (funnel).

There is a sleeve (A) present in the lower part of the cooking

chamber (in the centre)to which the bendand and the rigid pipe

supplied (p) must be connected. Couple the bend in the rigid pipe

and connect it to the oven. Now, take the rigid pipe into the funnel

(not provided).

Another exible hose is present, which connects the front basin.

This hose must also be made to ow into the funnel.

A

B

p

11

Use and maintenance manual

10

2. Use instructions (combi-ovens)

2.1 Preliminary information

The appliance has been designed to cook food in

closed premises and must only be used for this pur-

pose: any other use must, be avoided and conside-

red improper & dangerous.

Survey the equipment during functioning.

Before cooking, we recommend pre-heating the

oven at a temperature of about 20/25% higher

than that required. Once the pre-heating tempera-

ture is reached, insert the food in the oven cavity,

and lower the temperature to the one desired for

cooking.

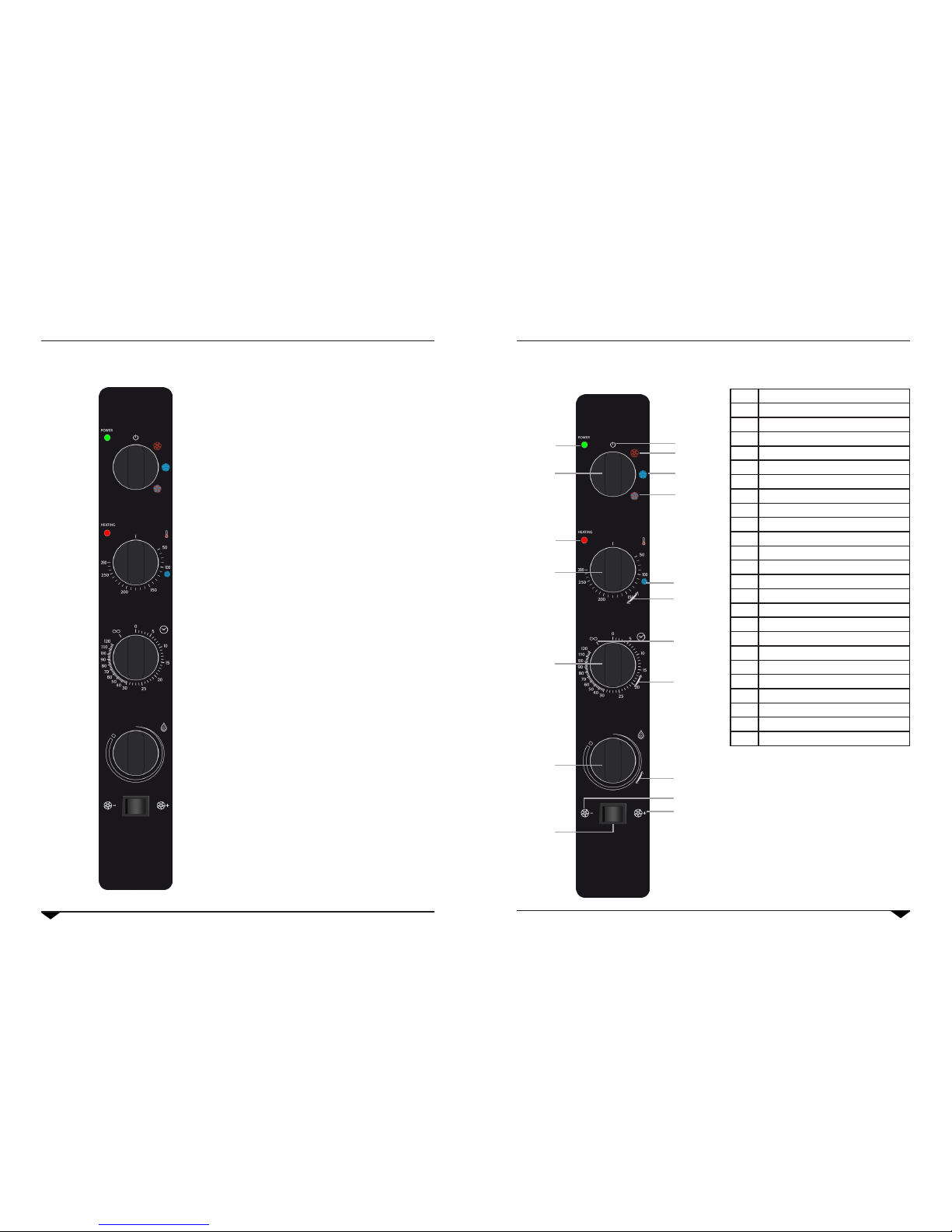

2.2 Control panel

M 1 Cooking mode / OFF knob

I 1 OFF position

I 2 Convection position

I 3 Steaming position

I 4 Mix (steam / convection) position

M 2 Temperature knob

I 5 Steaming treshold position

S 1 Temperature scale in °C

M 3 Timer knob

I 6 Innite time position

S 2 Timer scale in minutes

M 4 Humidity knob

S 3 Humidity scale

T 1 TIME / PROBE selector

I 8 TIME position

I 9 PROBE position

T 2 Fan speed selector

I 7 FAST fan position

I 10 SLOW fan position

D 1 Core probe temperature display

T 3 Core probe DOWN temperature

T 4 Core probe UP temperature

T 5 SET button

led 1 Oven status: ON / OFF

led 2 Heating element /s status: ON / OFF

2. Use instruction (combi-ovens)

I 1

I 2

I 3

I 4

I 5

S 1

S 2

S 3

I 7

I 8

M 1

M 2

M 3

M 4

I 6

led 1

led 2

T 1

13

Use and maintenance manual

12

2.3.1 Convection cooking with moisture.

To add moisture to the convection cooking turn the

M4 knob to the desired moisture grade. Turn the M4

knob to left to reduce the moisture production.

When the M4 knob in in up-vertical position the hu-

midier is off.

2.3 Convection cooking

Choose the convection cooking mode by turning the

M1 knob clockwise to position I2.

Then choose the cooking temperature by turning the

M2 knob to the desired temperature.

Set the cooking time by turning the M3 knob. Place

the knob indicator on the I6 symbol to avoid the

timer. When the timer set will be over the oven will

buzz and turn off itself.

Set the fan speed using the button T1.

2. Use instruction (combi-ovens)

I 1

I 2

S 1

S 2

S 3

M 1

M 2

M 3

M 4

I 6

T 1

Choose steaming mode by turning the M1 knob to

clockwise to position I3.

Then choose the cooking temperature by turning the

M2 knob to the desired temperature. It is suggested

to set the steaming temperature at 110°C as indica-

ted on the I5 symbol.

Set the cooking time by turning the M3 knob. Place

the knob indicator on the I6 symbol to avoid the

timer. When the timer set will be over the oven will

buzz and turn off itself.

Set the fan spped using the button T1.

2.4 Steaming

2. Use instruction (combi-ovens)

I 1

I 3

I 5

S 1

S 2

M 1

M 2

M 3

I 6

T 1

Loading...

Loading...