Magnetic Products BD-MD User Manual

Conveyor Metal Detector

for Baked Goods Inspection

Series: BD-MD

Cassel metal detectors protect your product and reputation from harm caused by

metallic foreign body contamination. Committed to the highest standards of

excellence, our goal is to ensure the quality of our customers’ products by providing

the most reliable, sensitive and easy-to-use metal detectors in the world.

Conveyor design and reject system operation:

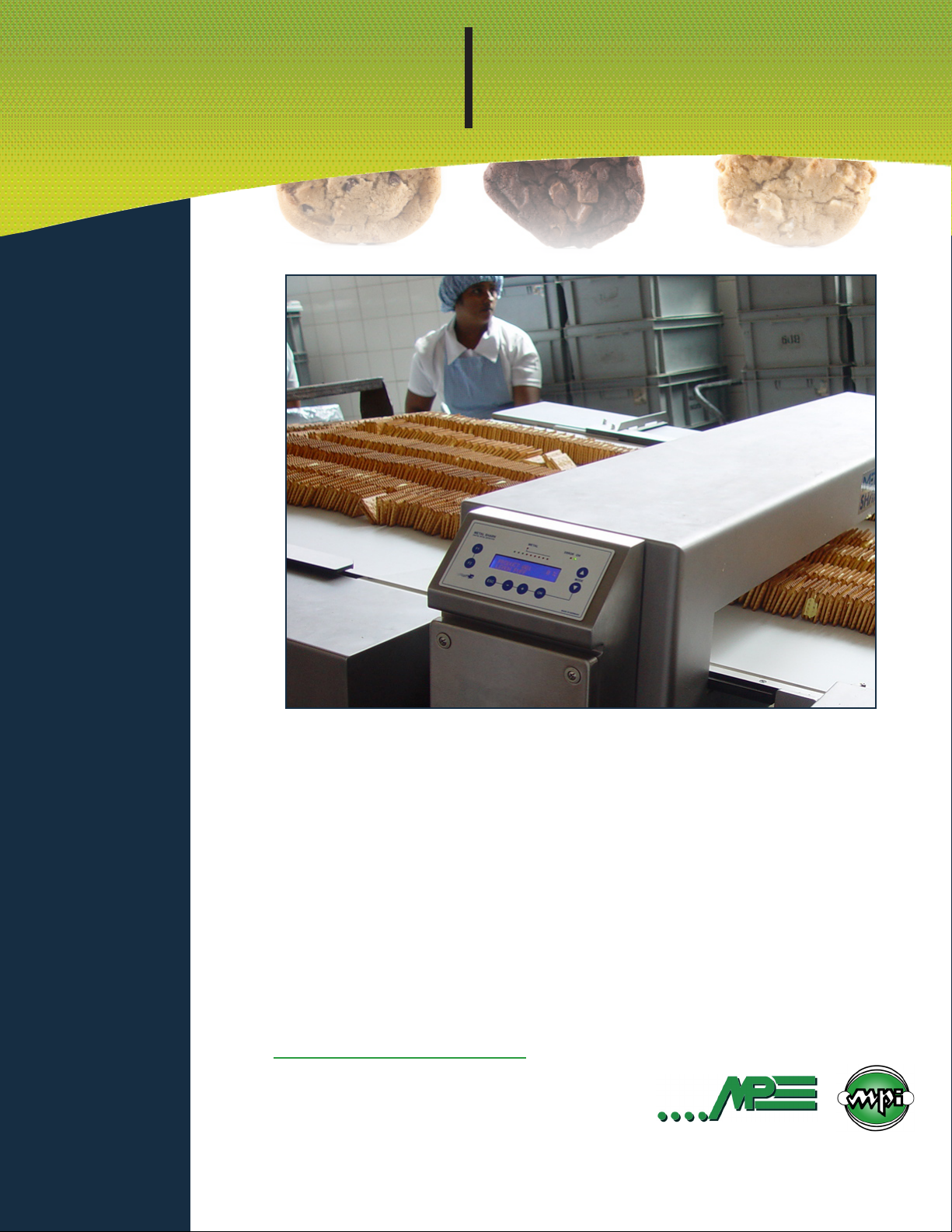

The conveyor metal detector shown above includes a unique reject system fabricated

specically for cookies, crackers and other snack foods. In this application, rejected cookies

fall through an 8” opening at the end of the conveyor and are collected in a bin located

underneath the conveyor. The infeed and outfeed are designed for accurate transfer of

product and awless operation.

An integrated self-tensioning and self-adjusting module keeps the belt stable and

on-center. Any product residue is removed by a scraper located on the return side of the belt.

Simple. Reliable. Solutions.

Magnetic Products, Inc.

Protecting and Moving the World through Innovation

P.O. Box 529 • 683 Town Center Dr. • Highland, MI 48357 USA

P 800.544.5930 • F 248.887.6100 • www.mpimagnet.com • info@mpimagnet.com

Conveyor Metal Detector

for Baked Goods Inspection

Retracting belt end in normal position Retracting belt end in reject position

Because our metal detectors are so user-friendly,

manufacturers can enjoy the benets of the metal detector

immediately after installation. A straight-forward operating

system quickly guides users through the steps needed to

set-up and operate the metal detector. Designed for intuitive

operation, Cassel metal detectors are among the simplest

and easiest to operate. Technical personnel are not required

to operate the metal detector.

Boasting world-class reliability and technological superiority,

our metal detectors employ the latest four-channel

DDS (direct digital synthesizer) and DSP (digital signal

processing) technology. State-of-the-art digital technology

eliminates costly maintenance. Once set, the metal detector

will not require further adjustment from the manufacturer,

cutting the cost of ownership. Exclusive four-quadrant

technology provides extreme sensitivity that far surpasses

the reach of competitive products.

About Magnetic Products, Inc. (MPI)

Magnetic Products Inc. (MPI), based in southeastern

Michigan, is a worldwide provider of both magnetic and

non-magnetic material handling solutions. MPI leads the

industry by continually engineering inventive magnetic

equipment and advancing customer education, through

significant investments in research and development

and proactive product training. For 30 years, MPI

has implemented a business model that combines

technologically superior equipment with industry-leading

customer service. MPI interacts closely with its customers

and expands its offerings to meet the changes of a

dynamic marketplace. Visit www.mpimagnet.com.

MPI is a proud partner of

Material Process Equipment (MPE),

a turn-key solution provider that

specializes in metal control systems, custom fabrication and

electronic controls.

MPI is the exclusive North American distributor for Cassel

metal detectors, X-ray systems and checkweighers for the

food, pharmaceutical, plastics, aggregate, recycling and

mining industries. Over 5,000 metal detectors have been

installed worldwide.

For more information on the equipment featured in this

brochure or any other MPI product or service, please contact

your local sales representative or MPI customer service at

800.544.5930 or info@mpimagnet.com.

DISTRIBUTED BY:

Baked goods application August 2013 © Magnetic Products, Inc.

Loading...

Loading...