Magnescale SR138-015R, SR138-020R, SR138-030R, SR138-035R, SR138-040R Instruction Manual

...

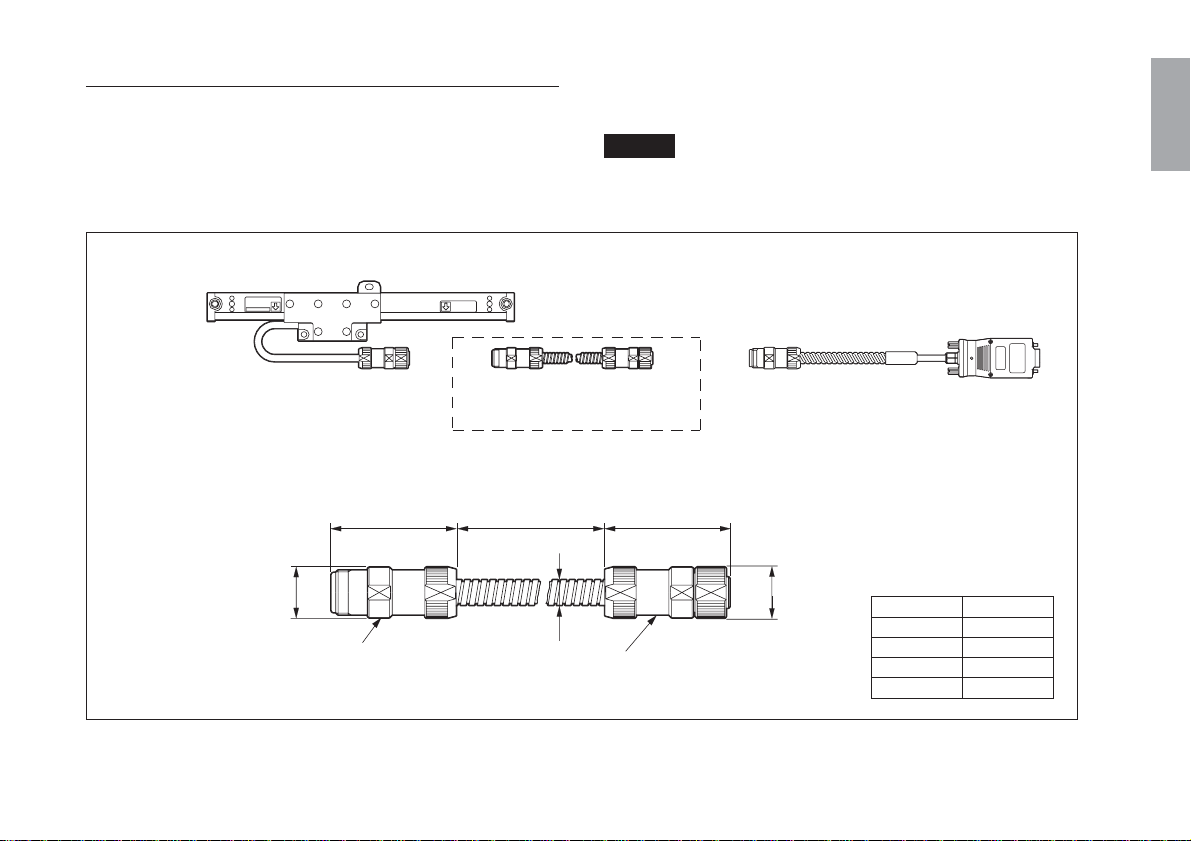

スケールセット/ Scale Set / Maßstab-Satz / 直线标尺组件

GB-ER/SR138R Series

スケールセット/ Scale Set / Maßstab-Satz / 直线标尺组件

GB-005ER~220ER

スケールユニット/ Scale Unit / Maßstabseinheit / 直线标尺器

SR138-005R~220R

お買い上げいただき、ありがとうございます。

ご使用の前に、この取扱説明書を必ずお読みください。

ご使用に際しては、この取扱説明書どおりお使いください。

お読みになった後は、後日お役に立つこともございますので、必ず保管してください。

Read all the instructions in the manual carefully before use and strictly follow them.

Keep the manual for future references.

Lesen Sie die ganze Anleitung vor dem Betrieb aufmerksam durch und folgen Sie beim Betrieb des Geräts den

Anweisungen. Bewahren Sie diese Bedienungsanleitung zum späteren Nachlesen griffbereit auf.

感谢您惠购本产品。

使用之前请务必认真阅读本手册,并且严格按照手册中的规定操作。将此手册留作以后的参考。

/

取扱説明書/ Instruction Manual / Bedienungsanleitung / 使用说明书

[For U.S.A. and Canada]

THIS CLASS A DIGITAL DEVICE COMPLIES WITH

PART15 OF THE FCC RULES AND THE CANADIAN

ICES-003. OPERATION IS SUBJECT TO THE

FOLLOWING TWO CONDITIONS.

(1) THIS DEVICE MAY NOT CAUSE HARMFUL

INTERFERENCE, AND

(2) THIS DEVICE MUST ACCEPT ANY

INTERFERENCE RECEIVED, INCLUDING

INTERFERENCE THAT MAY CAUSE

UNDERSIGNED OPERATION.

CET APPAREIL NUMÉRIQUE DE LA CLASSE A

EST CONFORME À LA NORME NMB-003 DU

CANADA.

■ 一般的な注意事項

■ 次の環境下で、ご使用になる場合の注意事項

以下は当社製品を正しくお使いいただくための一般的な注意事項で

す。個々の詳細な取扱上の注意は、本取扱説明書に記述された諸事

項および注意をうながしている説明事項に従ってください。

• 始業または操作時には、当社製品の機能および性能が正常に作動

していることを確認してからご使用ください。

• 当社製品が万一故障した場合、各種の損害を防止するための十分

な保全対策を施してご使用ください。

• 仕様に示された規格以外でのご使用、または改造を施された製品

については、機能および性能の保証はできませんのでご留意くだ

さい。

• 当社製品をほかの機器と組み合わせてご使用になる場合は、使用

条件、環境などにより、その機能および性能が満足されない場合

がありますので、十分ご検討の上ご使用ください。

1 水溶性切削液を使用する場合あるいは、金属微粉末が発生する

加工やセラミック•グラスファイバー等の加工物を加工する場

合。

• 水溶性切削液や切屑が直接スケールユニットに掛からない場

所へ取付けてください。

• 内部に水溶性切削液のミストや粉塵が侵入しないようスケー

ルカバーを付けてください。

2 ホーニングマシーンのような、長時間特定区間を高速摺動する

機械に装着する場合。

• 定期的にオイルまたはスプレー式潤滑油(CRC·WD40等)の

塗布をお願いします。

1または2の環境でご使用になる場合は必ず上記対策をしてくださ

い。行なわない場合は品質保証しかねます。

(J

) i

安全のために

当社の製品は安全に十分配慮して設計されています。しかし、操作や設置時にまちがった取

扱いをすると、火災や感電などにより死亡や大ケガなど人身事故につながることがあり、危

険です。また、機械の性能を落としてしまうこともあります。

これらの事故を未然に防ぐために、安全のための注意事項は必ず守ってください。操作や設

置、保守、点検、修理などを行なう前に、この「安全のために」を必ずお読みください。

警告表示の意味

このマニュアルでは、次のような表示をしています。表示内容を

よく理解してから本文をお読みください。

警告

この表示の注意事項を守らないと、火災や感電などにより死亡や

大ケガなど人身事故につながることがあります。

注意

この表示の注意事項を守らないと、感電やその他事故によりケガ

をしたり周辺の物品に損害を与えることがあります。

注意を促す記号

注意

感電注意

行為を禁止する記号

分解禁止

行為を指示する記号

ご注意

機器の正しい取扱のために、注意していただきたい事項です。

ii

(J)

プラグの取外し

警告

注意

• 表示された電源電圧以外での電圧で使用しないでください。火災や感電の原因となる

恐れがあります。

• 濡れた手での取付作業はおやめください。感電の原因となります。

• 本体を分解や改造したりしないでください。ケガの恐れや、内部回路が破損すること

があります。

• 作業を行なう前には、機械や装置の状況をよく確かめて作業の安全を確保してくださ

い。

• 電源やエアーなどの駆動源は必ず切って作業をしてください。火災や事故の原因とな

ります。

• 電源などを入れて動かす場合は、周辺機械や装置などに指を挟まれないように十分注

意してください。

(J

) iii

取付上の注意

設置上のご注意

本機を設置されるときは、他の機器からのノイズ、電磁波障害などを防止するため、以

下の点に注意してください。

1. リードケーブルおよび接続ケーブルは、動力線と同じダクトには通さないでくださ

い。

2. 高電圧源、大電流源および大電力リレーからは必ず0.5m以上離して設置してくださ

い。

3. 各種マグネットや電磁波発生源を絶対に近づけないでください。

ご注意

• マグネットチャックなど6×10–2[T]程度の磁力源を近づける場合は、スケールユ

ニットのスチール製筐体側面より10 mm 以上、ダストリップ面より

50mm以上離してください。

• もし近づけなければならない場合は、磁気シールド対策を十分に施しご使用願い

ます。

4. ノイズによるトラブルを防ぐために、スケール部とスライダ部をグランドに落ちる

ように取付けてください。

iv

(J)

取付場所についてのご注意

1. スケールユニットは機械の加工物、測定物のできるだけ近くに取付けてください。

(スケールユニット取付位置が加工物より離れるほど、機械系の誤差が拡大されて表

示されます。)

2. 本製品は、周囲温度0〜40℃の範囲内でご使用ください。直射日光の当る場所や近く

にモーターなど、熱源のある場所への取付けは避けてください。

3. 取付けられたスケールユニットの上に物を置いたり、作業者がひじや足を掛けるな

ど、無理な力をかけることは絶対に避けてください。

(J

) v

vi

(J)

目次

1. 概要 .............................................................................. 2

1-1. はじめに ...................................................................... 2

1-1-1. SR138Rシリーズ ................................................. 2

1-1-2. CH04シリーズ .................................................... 2

1-1-3. GB-ERシリーズ .................................................. 2

1-1-4. CE10シリーズ ..................................................... 2

1-2. 主な特徴 ...................................................................... 2

1-3. 部品構成 ...................................................................... 3

1-4. システム構成 .............................................................. 3

2. 各部の名称と働き ........................................................ 5

2-1. スケールユニット...................................................... 5

2-2. 接続ケーブル .............................................................. 7

3. 取付方法 ....................................................................... 8

3-1. 取付け前の注意事項.................................................. 8

3-2. 取付け時の注意.......................................................... 9

3-2-1. 取付方向の確認 .................................................. 9

3-2-2. 可動範囲の設定 ................................................ 10

3-2-3. ヘッドケーブルの保護 .................................... 10

3-2-4. スケールカバーの取付け ................................ 10

3-3. 取付けに必要なもの................................................ 11

3-4. 取付方法 .................................................................... 12

〈1〉 スケール部取付面の平行度•平面度が

事前に出ている場合 ............................. 12

〈2〉 スケール部取付面が鋳肌面の場合 .............. 13

〈3〉 スライダ部の取付け .................................... 15

〈4〉 スライダホルダの取外し ............................. 18

〈5〉 可動範囲の確認 ........................................... 18

〈6〉 ヘッドケーブルの取付け ............................. 18

〈7〉 ケーブルの接続 ........................................... 19

〈8〉 コンジットケーブルの取付け ...................... 21

〈9〉 丸型コネクタの取付け ................................ 22

〈10〉インターフェースユニットを表示装置に

接続する場合 ............................................... 23

〈11〉インターフェースユニットを

コントローラに接続する場合...................... 24

〈12〉スケールユニットを取外す場合 .................. 24

4. 接続ケーブル回路の電気調整について ...................... 25

〈1〉 アッパーケースの取外し ............................. 25

〈2〉 SIN/COS信号確認 ...................................... 26

〈3〉 原点信号確認 ............................................... 28

〈4〉 原点位置確認 ............................................... 30

5. 主な仕様 ..................................................................... 33

5-1. 一般仕様 .................................................................... 33

5-2. 外形寸法図 ................................................................ 34

6. トラブルインフォメーション .................................... 37

日本語

(J

) 1

1. 概要

日本語

1-1. はじめに

1-1-1. SR138Rシリーズ

SR138Rシリーズは原点内蔵型直線スケールです。

スケール部とスライダ部の相対位置関係がスライダホルダ

にて位置調整され、固定されています。

必ず別売りの接続ケーブルCH04とセットでご使用くださ

い。

ご注意

SR138RシリーズとCH04を別々に購入された場合は、使用

する前にCH04の電気調整が必要となります。ご購入時に電

気調整を依頼された場合は、調整は必要ありません。

1-1-2. CH04シリーズ

SR138Rシリーズの信号を汎用のA/B相出力に変換する回路

を内蔵した専用ケーブルです。SR138Rシリーズと組み合わ

せることで、当社の表示ユニット(LH71等)やコントローラ

などの外部機器に接続することができます。

1-1-3. GB-ERシリーズ

GB-ERシリーズは、SR138Rシリーズと電気調整済みの接続

ケーブルCH04-03Cが同梱されている製品です。

ご注意

SR138RシリーズのSerialNo.とCH04-03Cのコンビネーショ

ンNo.が必ず同一の物同士を組み合わせてご使用ください。

1-1-4. CE10シリーズ

ケーブルを延長する場合の別売りの延長ケーブルです。

CH04との組み合わせで最大30mまで延長可能です。

1-2. 主な特徴

• 小型• 軽量• 原点内蔵

• 取付けが簡単

• 機械と同じ温度膨張係数

• 高精度な位置検出

• 油• 汚れに強い

2

(J)

1-3. 部品構成

1-4. システム構成

スケールユニット ............................................................. 1

接続ケーブル(CH04:GB-ERシリーズにのみ同梱) ........ 1

付属品

クランプ ........................................ 1

配線止め ............................. 小2,大4

スペーサ ........................................ 5

目隠しラベル ................................. 1

平ワッシャ(S) .............................. 2

平ワッシャ(M) .............................. 3

+B4×10 .......................................... 2

+P4×5 ............................................ 4

+P4×10 .......................................... 4

+K3×5 ............................................ 2

HSBM4×8 ..................................... 2

HSBM4×10 ................................... 3

HSBM4×12 ................................... 2

HSBM5×25 ................................... 2

ナット(M5) ................................... 2

固定板 ............................................ 1

システム接続構成

• SR138Rシリーズ

スケールユニット

延長ケーブル

(別売)

• GB-ERシリーズ

スケールユニット(SR138R) 接続ケーブル

(CH04-03C)

接続ケーブル

(別売)

表示ユニット

(別売)

CH01-**C

COMBINATION No.

******

MADE IN JAPAN

表示ユニット

LH71シリーズ等、

コントローラ

(別売)

(J

日本語

) 3

日本語

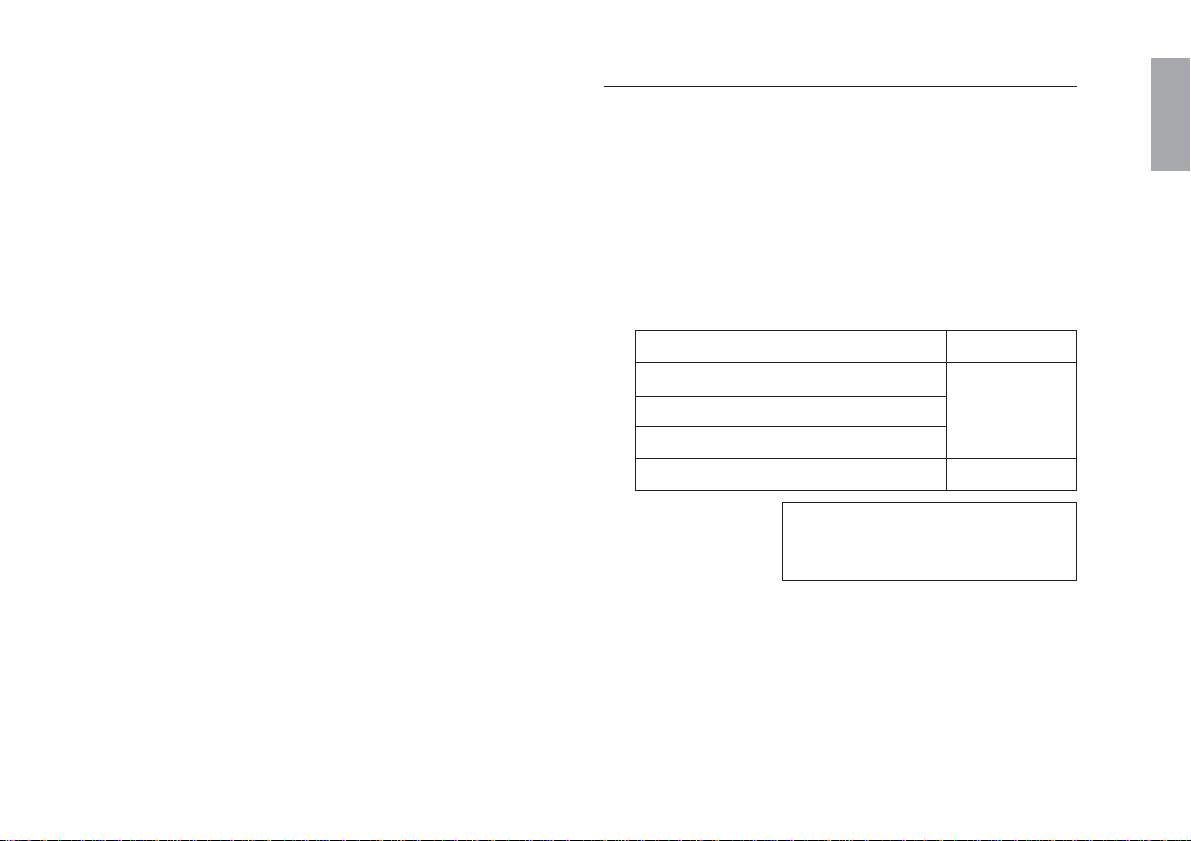

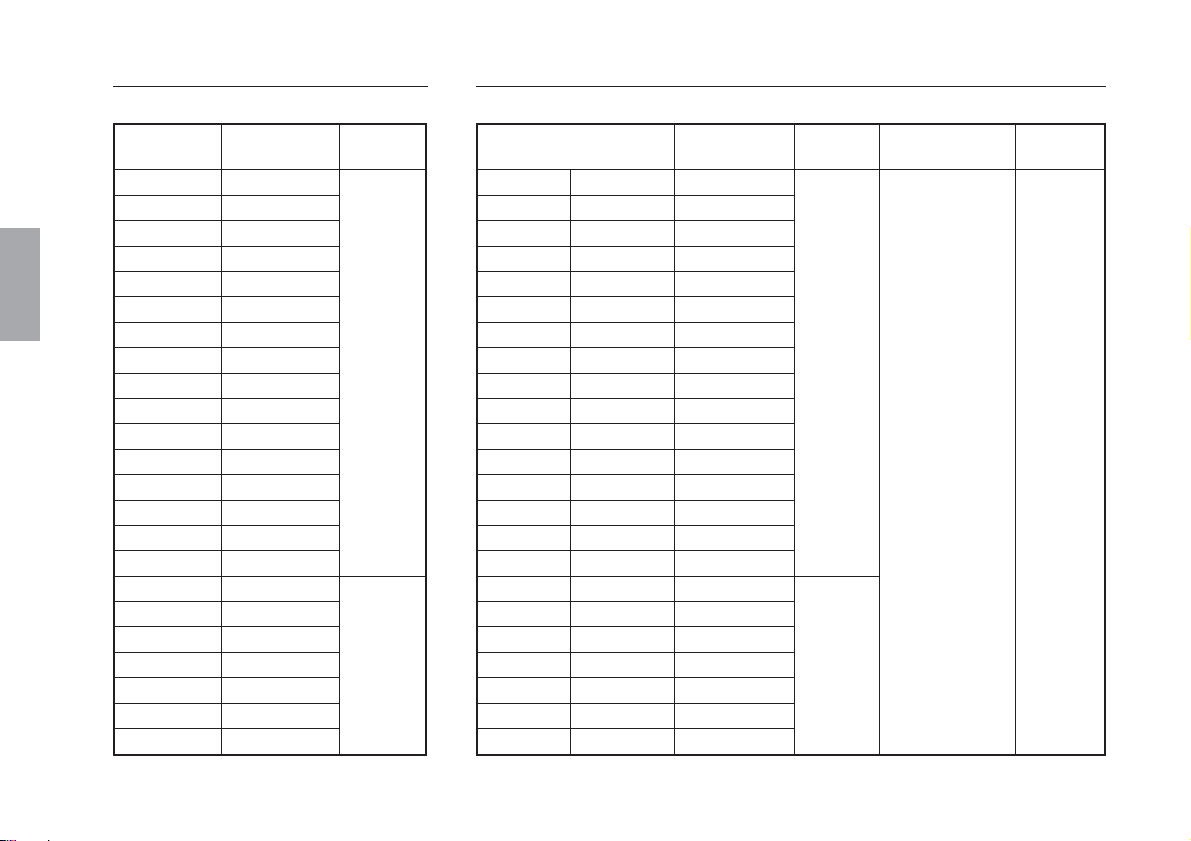

機種構成(SR138Rシリーズ)

型名

SR138-005R

SR138-010R

SR138-015R

SR138-020R

SR138-025R

SR138-030R

SR138-035R

SR138-040R

SR138-045R

SR138-050R

SR138-055R

SR138-060R

SR138-065R

SR138-075R

SR138-085R

SR138-095R

SR138-105R

SR138-125R

SR138-140R

SR138-160R

SR138-185R

SR138-205R

SR138-220R

有効長(L)

50mm

100mm

150mm

200mm

250mm

300mm

350mm

400mm

450mm

500mm

550mm

600mm

650mm

750mm

850mm

950mm

1050mm

1250mm

1400mm

1600mm

1850mm

2050mm

2200mm

中央フット

無し

有り

機種構成(GB-ERシリーズ)

有効長(L)

1050mm

1250mm

1400mm

1600mm

1850mm

2050mm

2200mm

GB-005ER

GB-010ER

GB-015ER

GB-020ER

GB-025ER

GB-030ER

GB-035ER

GB-040ER

GB-045ER

GB-050ER

GB-055ER

GB-060ER

GB-065ER

GB-075ER

GB-085ER

GB-095ER

GB-105ER

GB-125ER

GB-140ER

GB-160ER

GB-185ER

GB-205ER

GB-220ER

型名 中央フット

SR138-005R

SR138-010R

SR138-015R

SR138-020R

SR138-025R

SR138-030R

SR138-035R

SR138-040R

SR138-045R

SR138-050R

SR138-055R

SR138-060R

SR138-065R

SR138-075R

SR138-085R

SR138-095R

SR138-105R

SR138-125R

SR138-140R

SR138-160R

SR138-185R

SR138-205R

SR138-220R

50mm

100mm

150mm

200mm

250mm

300mm

350mm

400mm

450mm

500mm

550mm

600mm

650mm

750mm

850mm

950mm

無し

有り

接続ケーブル型名

CH04-03C

ケーブル長

3m

4

(J)

2. 各部の名称と働き

2-1. スケールユニット

サイドカバーL

型名

6

スケール部

スライダ部

SR138−***R

スライダ

スライダホルダ

5

3

1

中央フットプレート固定穴

アライメントマーク

有効長マーク(左)

原点マーク

4

2

スライダ取付穴

スライダ取付穴

スライダ中心

中央フットプレート

7

スケール本体

有効長マーク(右)

3

Serial No.

******

SerialNo./原点位置表示

8

スケール

取付穴

(両端2箇所)

サイド

カバーR

日本語

ヘッドケーブル

1 スライダ

検出ヘッドを保持しています。出荷時にはスライダホ

ルダで固定されています。

丸型コネクタ(オス)

2 スライダ中心

スライダのメカニカルセンタを表わします。有効長

マークとの位置関係を見る目安となります。

(J

) 5

日本語

3 有効長マーク

スライダ中心に対して、精度を保証する有効可動範囲

の目安を指示するマークです。有効長とは、有効可動

範囲の長さを表します。

ご注意

取付け、およびご使用の際に、この範囲内で可動させ

てください。有効可動範囲を超えて使用すると、本製

品を破損させる原因となります。

4 原点マーク

スライダ中心に対して、原点信号が出力される位置の

目安を指示するマークです。

標準仕様では、有効長の中央に1箇所の原点が存在しま

す。

5 スライダホルダ

スケール部とスライダ部を固定します。取外した後は

保管してください。

6 型名

本製品の型名を明記してあります。

7 中央フットプレート

有効長1050mm以上の場合に取付けられています。ス

ケールユニット取付けの際は、この部分も固定しま

す。

8 SerialNo./原点位置表示

本製品のSerialNo.とスケール本体の原点位置を明記し

てあります。

GB-ERシリーズの場合、組み合わせる接続ケーブルの

コンビネーションNo.と同一になっています。

ご注意

本スケールシステムは、スケールユニットのSerialNo.

と接続ケーブル(CH04シリーズ)のコンビネーション

No.が必ず同一の物同士を組み合わせてご使用くださ

い。

6

(J)

1

2-2. 接続ケーブル

CH04:GB-ERシリーズのみに同梱されています。

ご注意

別途購入された場合は、電気調整が必要となります。

日本語

インターフェースユニット

出入力コネクタ

5

6

型名

3

ステータスランプ

7

CH04-03C

コンビネーションNo.

1 インターフェースユニット

表示ユニットの背面に接続します。

最適に電気調整された回路が組み込まれています。

2 コンジットケーブル

内部のケーブルを保護しています。

3 型名

本製品の型名を明記してあります。

4 丸型コネクタ(メス)

スケールユニット側の丸型コネクタ(オス)と接続します。

5 入力コネクタ

電源としてDC+5[V]を供給することにより、スケール

信号と原点信号が出力されます。

丸型コネクタ(メス)コンジットケーブル

2

インターフェ−スユニット固定用タップ

8

4

6 コンビネーションNo.

GB-ERシリーズの場合、組み合わせるスケールユニッ

トのSerialNo.と同一になっています。

7 ステータスランプ

信号確認用のランプです。

緑色点灯:正常

赤色点灯:エラー(速度超過、ケーブル断線、信号不良)

8 インターフェースユニット固定用タップ

インターフェースユニットを固定する場合、付属の固

定板とねじを用いて固定できます。(M3深さ3mm)

(J

) 7

3. 取付方法

日本語

3-1. 取付け前の注意事項

取付前に、必ず「取付け時の注意」をご確認ください。

分解禁止

<スケールユニット>

• スケールユニットは分解しないでください。精度が保証

できなくなります。スライダホルダのみ取外し可能で

す。

<接続ケーブル>

• 接続ケーブルは調整されていますので分解しないでくだ

さい。精度が保証できなくなります。

• SR138Rで別途購入された接続ケーブルは、電気調整のた

めのケース取外しが必要ですが、それ以外の分解は行な

わないでください。

無理な力をかけない

• 作業時に、スケールユニットに無理な力をかけないでく

ださい。スケールユニットは精密機構部品および電磁気

部品で構成されています。無理な力を加えると性能や寿

命に大きな影響を与えます。

• 作業時に、接続ケーブルのインターフェースユニットに

無理な力をかけないでください。インターフェースユ

ニット内部には精密電気部品が実装、調整されていま

す。無理な力を加えると性能や寿命に大きな影響を与え

ます。

• 持ち運びの際は、スケール部とスライダ部を共に支えて

ください。ヘッドケーブルや丸型コネクタなどを持って

運ばないでください。

8

(J)

3-2. 取付け時の注意

上下軸に取付ける場合は、スケールユニットのスライダ部

が加工物(刃物)と反対側を向くように取付けてください。

ご注意

ノイズによるトラブルを防ぐために、スケール部とスライ

ダ部をグランドに落ちるように取付けてください。

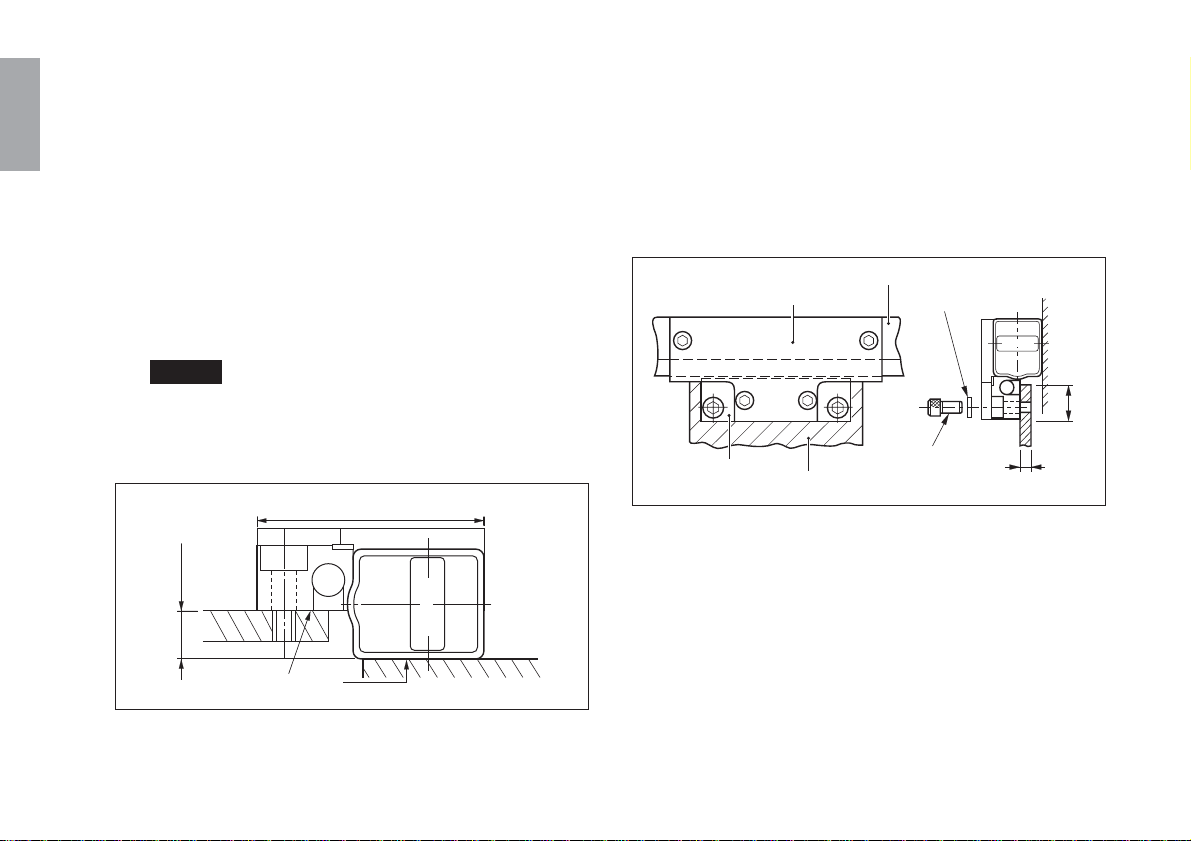

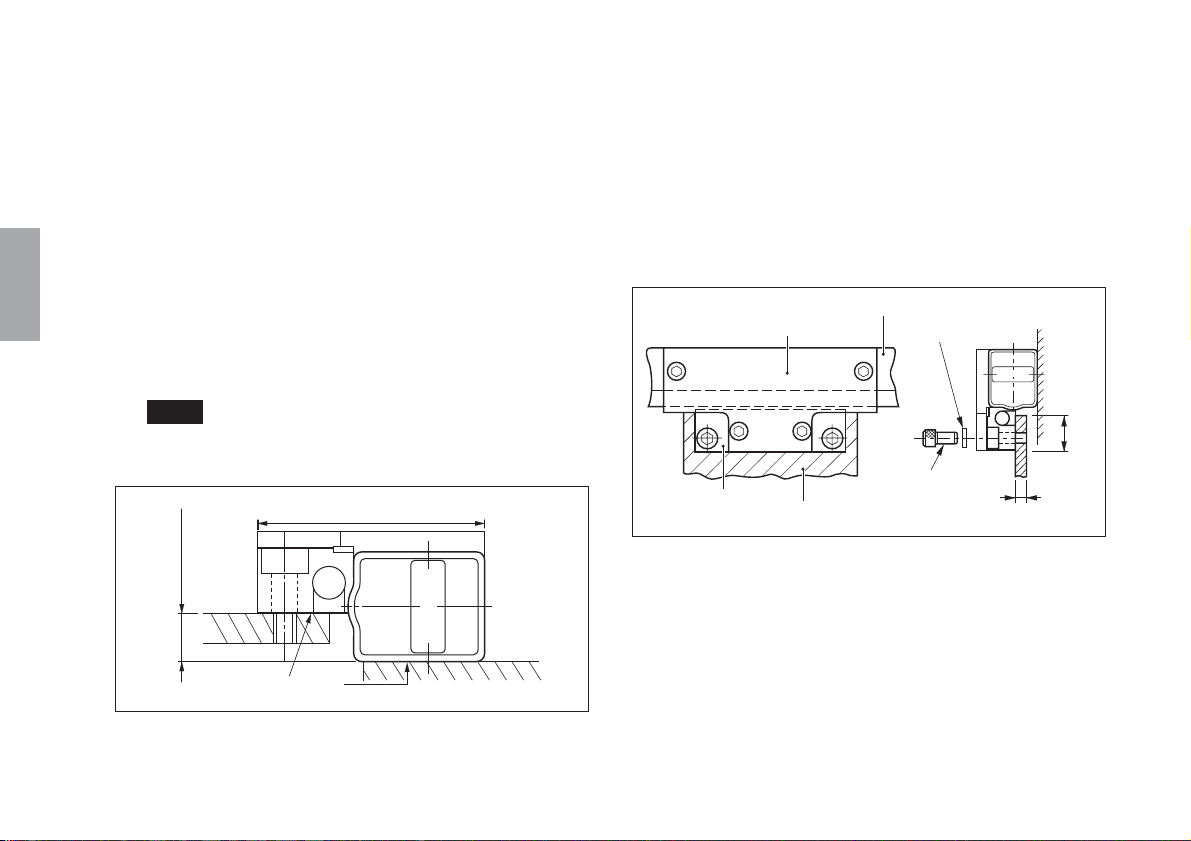

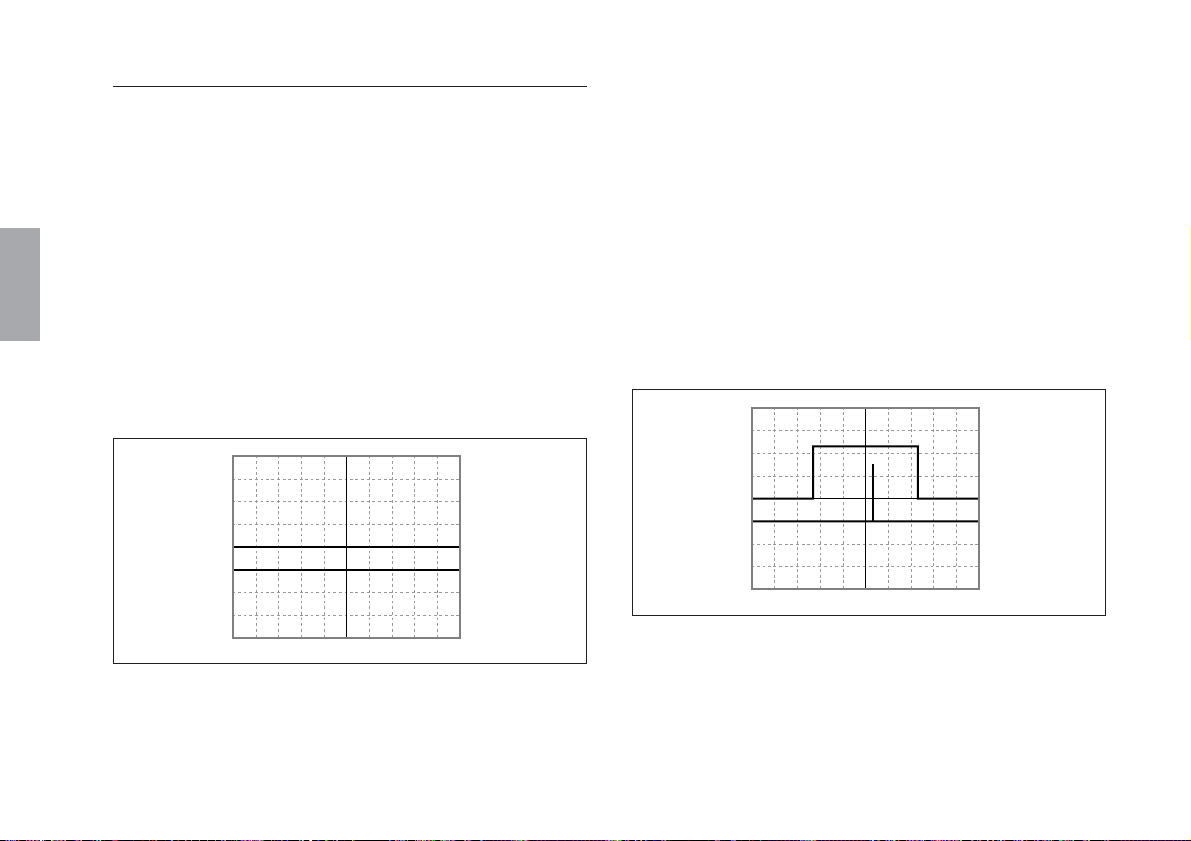

3-2-1. 取付方向の確認

本スケールユニットが、図3-1のような位置関係に取付くこ

とを確認してください。

*

その他の向きはサービス、メンテナンスに不都合なため使

用しないでください。

(切削液や切粉の侵入を防ぐため、Aの取付けを特におす

すめします。)

(B方向取付けは、切削液や切粉の進入がない場合のみ取

付可能です。)

推奨

A

B

日本語

スライダ部

スケール部

加工刃物

図3-2.上下軸スケールユニットの取付位置と方向

図3-1.スケールユニット取付方向

(J

) 9

3-2-2. 可動範囲の設定

3-2-3. ヘッドケーブルの保護

日本語

スケールユニット取付時は図3-3の可動範囲で取付けてくだ

さい。

• スケールユニットには可動余裕(有効長200mmまで左右

7mm,有効長250mm以上左右15mm)がありますが、そ

れ以上にスライダ部を移動させますとスケール部が破損

しますのでご注意ください。

• スケールユニットの有効可動範囲を超える工作機械に

は、機械的な制限機構(ストッパなど)が必要です。

必ず、このような処置を施してからスケールユニットを

取付けてください。

有効長マーク

スライダ中心

この範囲内にスライダ中心がくるように取付けてください。

(有効可動範囲)

図3-3.可動範囲

有効長マーク

ヘッドケーブルはスケールユニットと一体構造になっています

のでケーブルに負荷がかからないように取付けてください。

ヘッドケーブルを強く引張ったり繰返し折り曲げたりしま

すと、断線する恐れがあります。ご注意ください。

3-2-4. スケールカバーの取付け

ご使用中、スケールユニットに直接切粉や切削液などが降

りかかる場合には、スケールユニットの性能維持のために

も図3-4のような外部からスケールユニットを覆うカバーを

取付けてください。

10

図3-4.スケールカバーの取付け例

(J)

3-3. 取付けに必要なもの

付属品一式

六角穴付ボルト M4×10 スケール部取付用 ................. 3

(有効長1000mm未満は2本)

六角穴付ボルト M4×8 スライダ部取付用................. 2

M4×12 スライダ部取付用 ................. 2

小ねじ M4×5 配線止め用(小) .................... 2

M4×10 配線止め用(大) .................... 4

M4×5

M3×5 固定板取付用 ......................... 2

平ワッシャ(M) みがき丸呼び4スケール部取付用..... 3

(有効長1000mm未満は2個)

平ワッシャ(S) 小型丸 呼び4 スライダ部取付用 ... 2

配線止め(大) コンジットケーブル取付用 ................. 4

目隠しラベル スライダホルダ取外し後

ねじ穴隠し用 ......................................... 1

六角穴付ボルト M5×25 スライダ部取付用 ................. 2

六角ナット M5 スライダ部取付用................. 2

スペーサ t=0.1 スライダ部取付用 ................. 5

クランプ 丸型コネクタ取付用 ............................. 1

バインド小ねじ M4×10 クランプ取付用 ..................... 2

配線止め(小) ヘッドケーブル固定用 ......................... 2

固定板 インターフェースユニット固定用 ..... 1

インターフェースユニット

取付用 ....

付属品以外に下記のものをご用意ください。

スケール部取付用ブラケット(A,B面相当部品) .......... 1〜2

スライダ部取付用ブラケット(C面相当部品) ..................... 1

0.01mmピックテスター(またはダイヤルゲージ) ....... 1〜2

Lレンチ M2.6用(対辺2mm) ............................................... 1

Lレンチ M4用(対辺3mm) .................................................. 1

Lレンチ M5用(対辺4mm) .................................................. 1

タップ M4 ............................................................................ 1

2

ドリル ø3.2 ........................................................................... 1

電気ドリル ................................................................................. 1

ライナ•スペーサ(0.05〜0.2t) ........................................... 少々

ドライバ2号(+) ........................................................................ 1

モンキスパナ(小)..................................................................... 2

(J

日本語

) 11

日本語

3-4. 取付方法

0.1 MG

0.1

25 12 25 25

0.1 MG

0.1

0.1 MG

図3-5.取付方法

〈1〉 スケール部取付面の平行度•平面度が事前に出

ている場合

取付面が機械加工面で、事前に下表の平行度、平面度が出

ていれば、そのままスケール部を取付けることができま

す。

有効長1050mm未満(中央フットプレート無し)のスケール

ユニットの場合

使用ねじ / 締め付けトルク:六角穴付ボルトM4× 10

(2本)、平ワッシャ(M)2個使用/350N·cm

8 以上

A

B

D

C

有効長1050mm以上(中央フットプレート有り)のスケール

ユニットの場合

使用ねじ / 締め付けトルク:六角穴付ボルトM4× 10

(3本)、平ワッシャ(M)3個使用/350N·cm

A面,B面平面度

A面,B面機械の走り 0.1mm以内

に対する平行度

A面:スケール部突き当て

B面:スケール部取付面

面

A面は図3-5で示す範囲としてください。ただし、上記許容

値は平面内に急激な変化がないことと、左右取付面の間に

スケール部を取付けるのに障害がないことが条件となりま

す。

12

(J)

〈2〉 スケール部取付面が鋳肌面の場合

取付ブラケットによる取付け

(1) 取付面が鋳肌面などで平行度が出ていない面のとき

スケール部設置位置に取付ブラケットを取付けて〈1〉

項の値になるように調整してください。

取付ブラケットはスケール部の左右フット部分にあれ

ば、スケール部全長に渡ってある必要はありません。

取付機械の可動長により左右フットの平行度が測定で

きない場合には、測定できる範囲まで取付ブラケット

を長く作ってください。

機械との温度追従性が問題となる場合は、スケールユ

ニット全長に渡り取付ブラケットを配置するようにし

てください。

A面の平行度測定

日本語

取付ブラケット

ピックテスター

B面の平行度測定

図3-6.取付ブラケットの平行度測定

取付ブラケットの形状として突き当て面があれば、こ

の面精度を〈1〉項の値になるように調整してくださ

い。突き当て面が無い場合には(4)に示す方法で調整し

てください。また、取付面の精度が得られないとき

も、(4)に示す方法で調整してください。

(J

) 13

日本語

(2) 取付位置の確認とねじ穴加工

スケール部の取付平行度が出たら、外形寸法図(P34)に

したがって取付穴の位置にそれぞれM4深さ10のタップ

穴を作ってください。

(3) スケール部の取付け

スケール部は平ワッシャ(大)を付けた六角穴付ボルト

M4×10で仮止めし、30分以上放置して温度をよく機械

になじませてから取付けを行なってください。

(4) スケール部と機械の走りとの平行度測定

スケール部側面のアライメントマーク位置(図3-7、1)

に直接ピックテスターまたはダイヤルゲージを当て、機

械の走りに対してスケール部の平行を出してください。

2

1

平行度はアライメントマークの2点間が0.08mm以内に入る

ように調整して、取付ねじを固定してください。

有効長1050mm以上の場合は、中央フットプレート付近と

左右のアライメントマークの3点間が0.08mm以内に入るよ

うにして取付ねじを固定してください。

ご注意

有効長150mm以下のスケール部にはアライメントマークが

付いていませんので、スケール部にピックテスターを当

て、機械の可動長の両端が0.08mm以内に入るようにして

ください。

フット

行度0.08mm以内

平

中央フットプレート

14

(J)

アライメントマーク

図3-7.スケール部と機械の走り測定

フット

平ワッシャ(M)

アライメントマーク

アライメントマーク

アライメントマーク

M4×10

図3-8.アライメントマークによる平行出し

(5) スケール取付ブラケットの平行度が出せないとき

図3-7の2の位置にピックテスターまたはダイヤルゲー

ジを当てて各アライメントマークを計り、0.08mm以内

の平行度になるようにフットの下部にスペーサなどを

入れて取付けてください。

中央フットプレート付のスケールユニット(有効長

1050〜2200mm)については、中央フットプレート付

近の位置も0.08mm以内の平行度に入れてください。

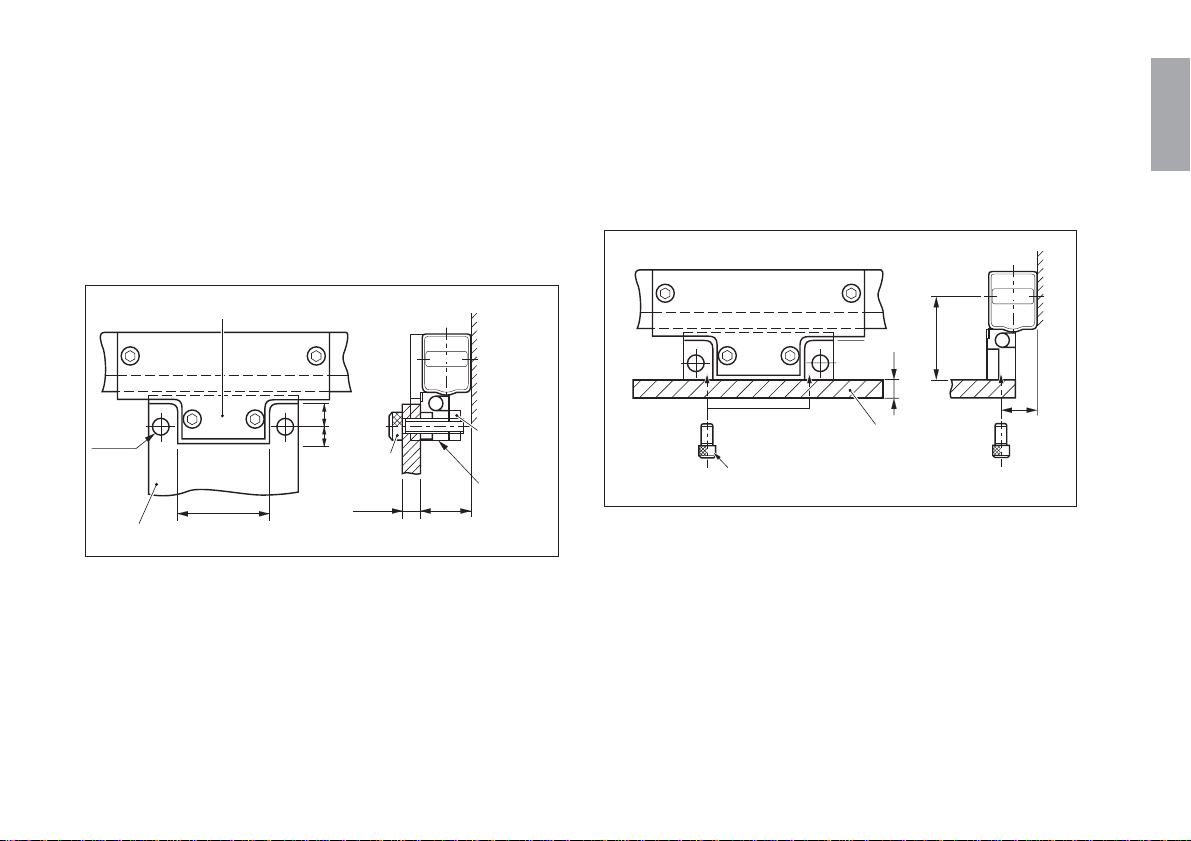

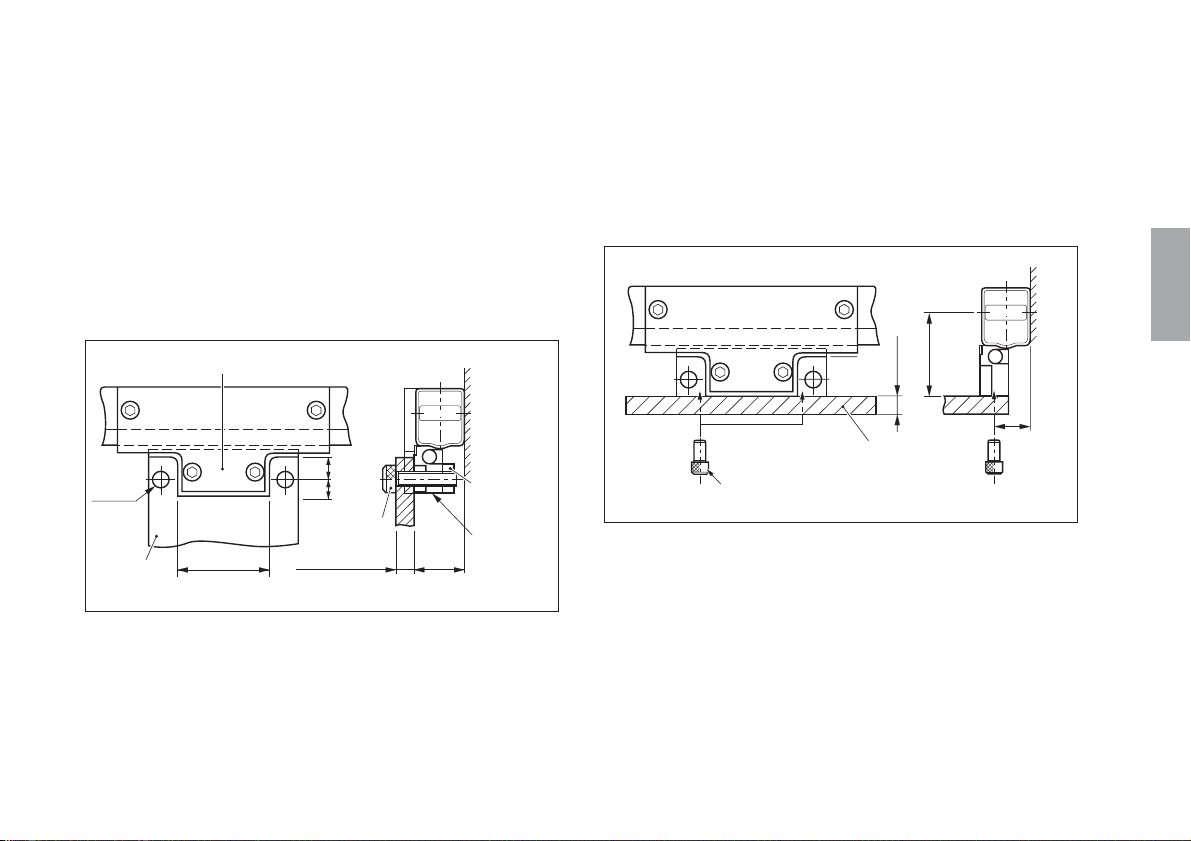

〈3〉スライダ部の取付け

(1) 取付面の平行度、平面度が事前に出ているとき

取付面が機械加工面で、事前に下の平行度、平面度が

出ていれば、そのままスライダ部を取付面に取付ける

ことができます。

使用ねじ / 使用ワッシャ:六角穴付ボルトM4× 12

(2本)、平ワッシャ(S)2個使用

締め付けトルク:350N·cm

日本語

C、D面平面度

0.05mm以内

C、D面機械の走りに対する平行度

B面〜C面間の平行度

0.05mm/

60mm以内

B面〜D面間の平行度

B面〜C面の間隔

8.7〜8.8mm

A面:スケール部突き当て面

B面:スケール部取付面

C、D面:スライダ部取付面

取付面がスライダ部の下にくるように機械を動かしま

す。

付属のスペーサで取付面とスライダ部の隙間を埋めて

から、スライダ部を固定してください。その後スライ

ダホルダを止めているねじを外してください。このと

き、スライダ部とブラケットが当らないように注意し

て機械を動かしてください。

(J

) 15

日本語

【付属のスペーサt=0.1mm(5枚)でスライダ部の隙間を

埋められなかった場合】

その状態で、スライダホルダのスライダ部を止めてい

るねじを緩め、スライダ部をスケール部に押し当てな

がらボルトで固定してください。

(2) B-C面の間隔を9mmに設定した場合

スライダホルダを止めているねじを緩め、スライダ部を

手で動かしブラケットに合わせ、図3-9の42±0.2mm寸法

の位置で止めてください。スペーサは必要ありません。

ご注意

スライダホルダを止めたまま、ブラケット側を動かす

と、スライダ部に当たる恐れがありますので、この方

法では行なわないでください。

42±0.2

8.7〜8.8

(3) スライダ部取付面が精度出しされていない場合

機械本体の取付面が鋳肌面の場合は、取付ブラケット

を使用します。

スライダホルダを固定しているねじを緩めずに、スラ

イダ部下面と取付ブラケットを合わせ、ブラケットの

高さを調整しながらボルト固定してください。

スケール部

図3-10.

2-平ワッシャ(小)

2-M4×12

(付属品)

4〜6t

スライダ部

スライダホルダ

取付ブラケット

17以下

16

BC

図3-9.

(J)

(4) スライダ部の上側にブラケットを取付ける場合

スライダ部上面と取付ブラケットを合わせて、スケー

ル部取付面からの高さが21±0.1mmになるように取付ブ

ラケットを調整してください。取付ブラケットはスラ

イダホルダ凸部を逃げた形状にしてください。図3-11の

ようにスライダ部をボルト(六角穴付ボルト)M5×25

(2本)とナットM5(2個)で固定します。

スライダ凸部

(5) スライダ部の背面にブラケットを取付ける場合

スライダホルダを固定しているねじを緩めずに、スラ

イダ部背面と取付ブラケットを合わせ、ブラケットの

高さを調整しながら付属ねじM4×8(2本)で固定してく

ださい。

42±0.2

4t

日本語

2-ø5.5

取付用ブラケット

9

7

2-M5×25

(付属品)

37

6~8t

21±0.1

2-M5ナット

(付属品)

スライダ部

取付ブラケット

2-M4×8(付属品)

15

図3-12.

図3-11.

* スライダ部の有効ねじ深さは4.5mmです。

取付ブラケットが4mmより薄い場合は、ワッシャで

厚さを調整してください。

(J

) 17

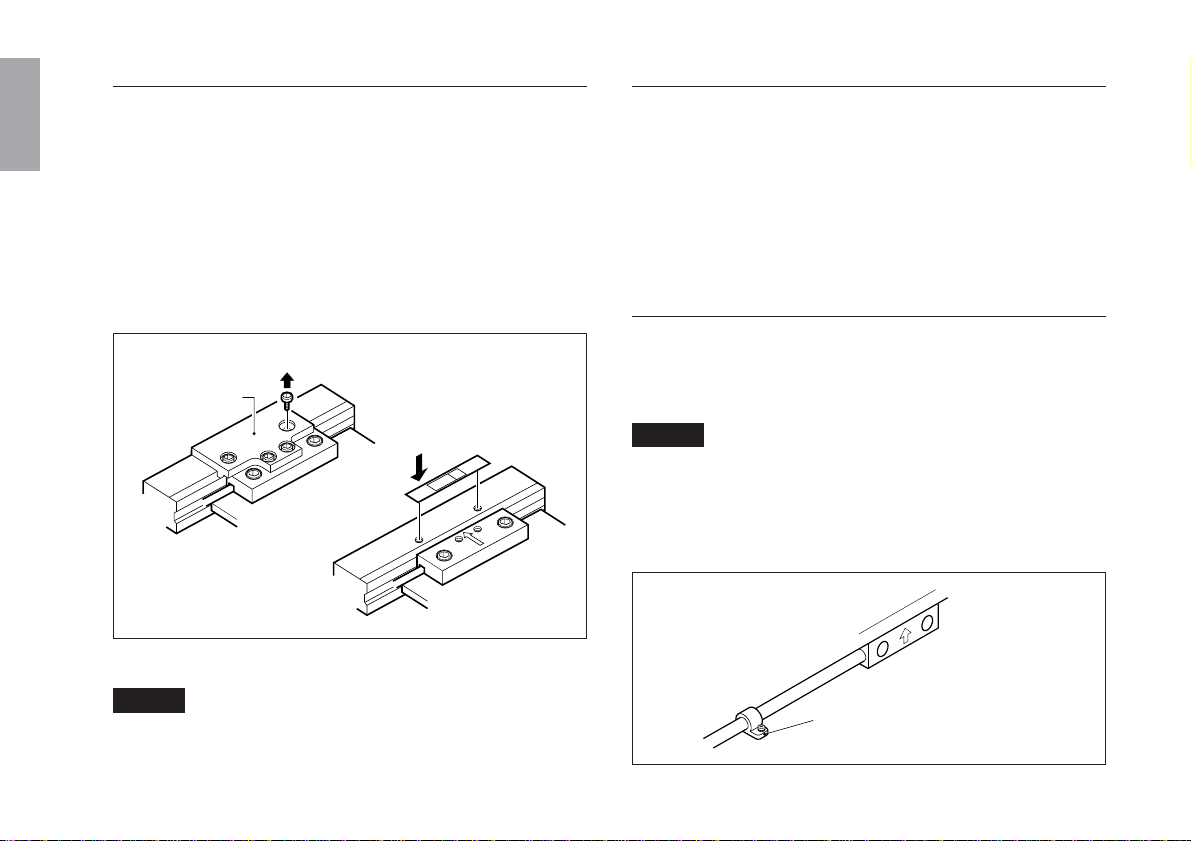

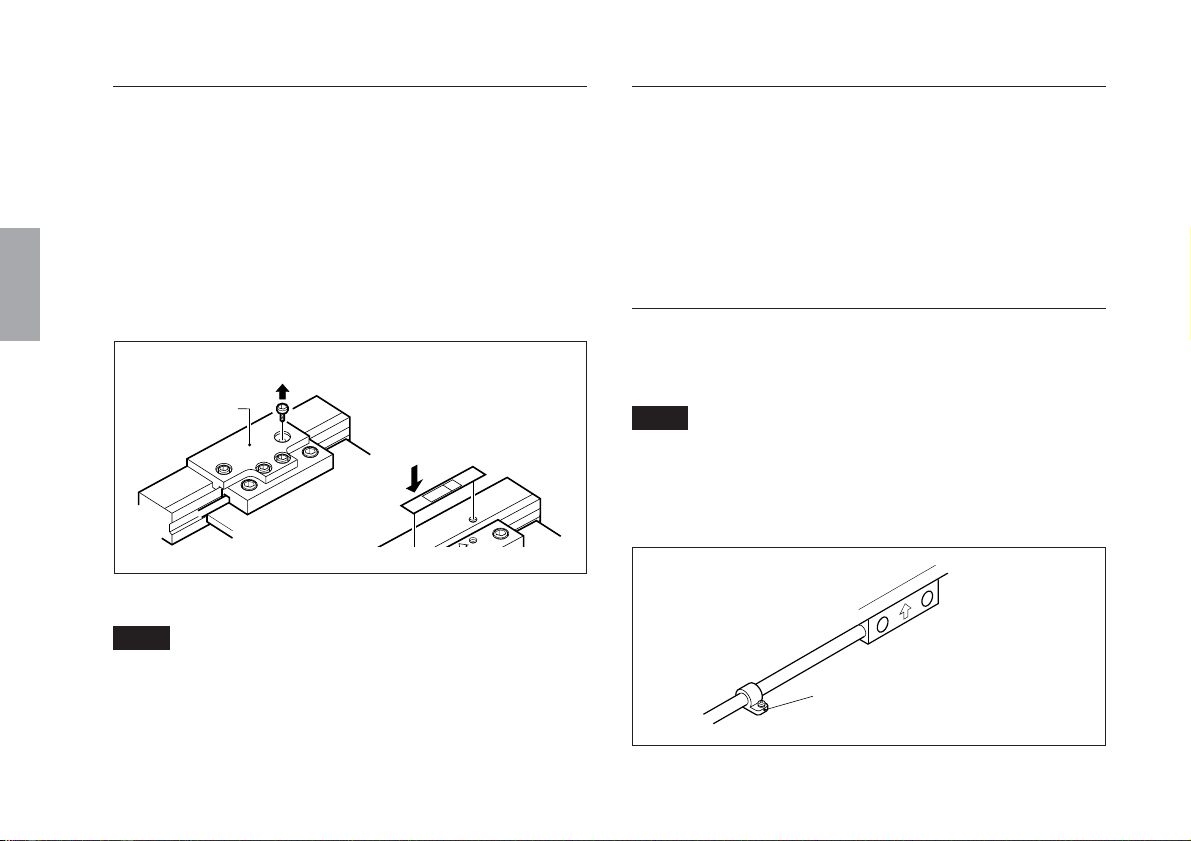

〈4〉スライダホルダの取外し

〈5〉可動範囲の確認

日本語

18

スライダホルダの取付ボルトM2.6(4本)を外し、スライダ

ホルダを取外します。

• 取外し後のねじ穴は必ず目隠しラベル(付属品)を貼って

ふさいでください。目隠しをしないと切削油、切粉、塵

埃が入って中のスケール精度に支障をきたす恐れがあり

ます。ラベルには取付年月日と担当者の名前をボールペ

ンで記入してください。

M2.6ボルト4本を外します。

スライダホルダ

目隠しラベル

(付属品)を貼ります。

図3-13.スライダホルダの取外し方

ご注意

取外したスライダホルダと残りのM2.6ボルト(4本)は保管

しておいてください。

(J)

スケール部とスライダ部取付後は必ず機械を全長にわたっ

て移動させて、スケール有効長と機械の移動量が有効長以

内であることを確認してください。

機械の移動量がスケールユニットの有効長+可動余裕量を超

えると、スケールユニットを破損させてしまいますのでご

注意ください。

〈6〉ヘッドケーブルの取付け

ヘッドケーブルは、邪魔にならないように配線止めで固定

します。

ご注意

ヘッドケーブルはスケールユニットと一体構造になっています

のでケーブルに負荷がかからないように取付けてください。

ヘッドケーブルを強く引張ったり繰返し折り曲げたりしま

すと、断線する恐れがあります。ご注意ください。

配線止め

小ねじM4×5で固定します(付属品)。

図3-14.

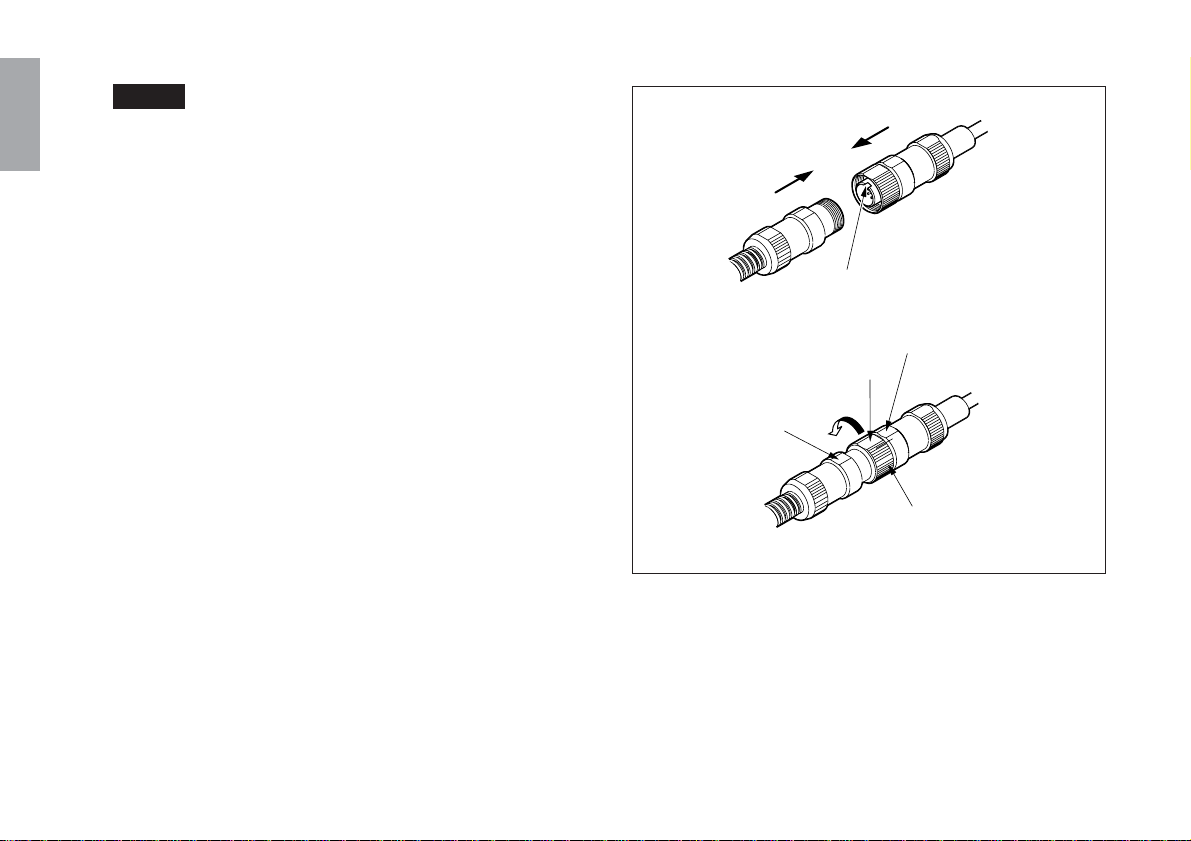

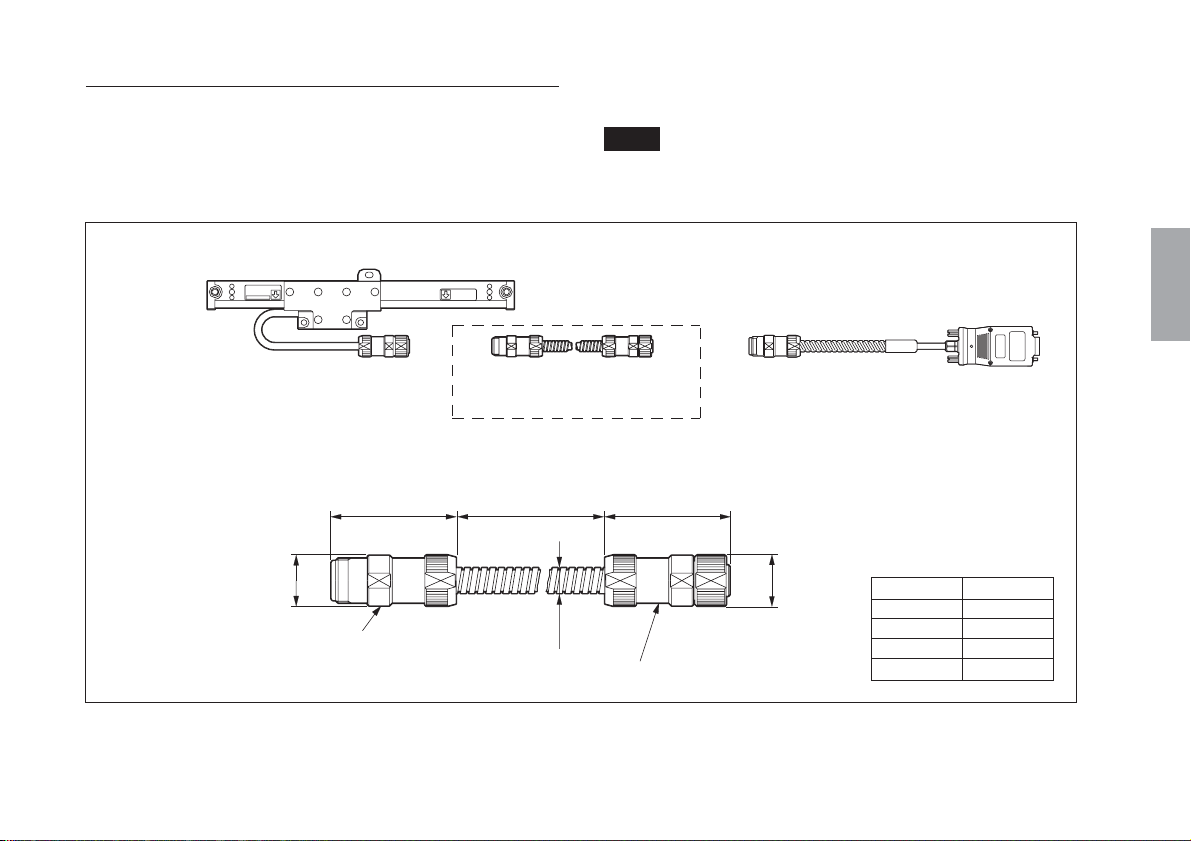

〈7〉ケーブルの接続

別売の延長ケーブル (CE10シリーズ) を使用すると、

SR138RおよびGB-ERシリーズと接続ケーブルの間を延長す

ることができます。

スケールユニット

延長ケーブル(CE10-**C)

ケーブル長

CE10-**C

44 44

ø18

丸型コネクタ(メス)

ご注意

ケーブルを延長した場合の最大総ケーブル長は、30mまで

となっています。

接続ケーブル(CH04-03C)

**

ø18

ø9

丸型コネクタ(オス)

単位:mm

型名

CE10-01C

CE10-03C

CE10-05C

CE10-10C

日本語

ケーブル長

1m

3m

5m

10m

図3-15.

(J

) 19

日本語

ご注意

• GB-ERシリーズは、必ずスケールユニットのSerialNo.と

接続ケーブルのコンビネーションNo.が同じ組合わせで接

続してください。

• SR138Rシリーズと、別売の接続ケーブル(CH04シリー

ズ)を、電気調整をご依頼されてお求めになられた場合

は、GB-ERシリーズと同様にスケールユニットのSerial

No.と接続ケーブルのコンビネーションNo.が同じ組合わ

せで接続してください。

• 別売の接続ケーブル(CH04シリーズ)を単品でお求めの場

合、必ず電気調整が必要となります。

1

2

メス側

B部

メス側

切り欠き部を合わせる

C部

A部

手でまわす

カップリングナット

図3-16.

オス側

オス側

20

(J)

3 A部とB部にスパナを

かけて矢印方向に回す

メス側

3/4回転

B部

図3-17.

A部

C部

オス側

ご注意

• スパナ等の工具を用い、締付トルク150〜250N·cmで接続

してください。規定トルクで締付けないと防水性能が保

証されません。

• A部とC部にスパナをかけて締めることは行なわないでく

ださい。

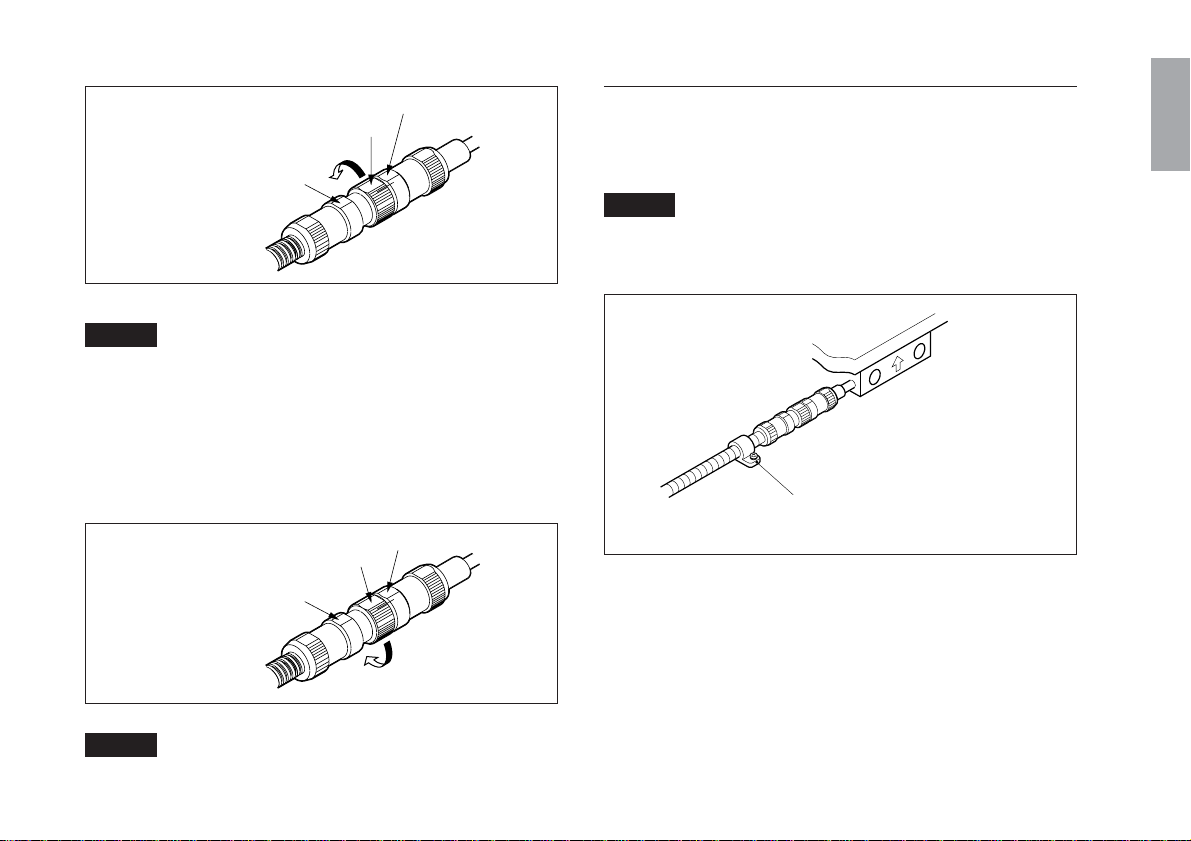

〈8〉コンジットケーブルの取付け

コンジットケーブルは、邪魔にならないように配線止めで

固定します。

ご注意

このとき、機械の動作に対して、余裕をもたせて配線する

必要があるので、ご注意願います。

日本語

外す場合

A部とC部にスパナを

かけて矢印方向に回す

メス側

C部

A部

B部

図3-18.

オス側

ご注意

• A部とB部にスパナをかけて緩めることは行なわないでく

ださい。

配線止め

小ねじM4×10で固定します(付属品)。

図3-19.

(J

) 21

日本語

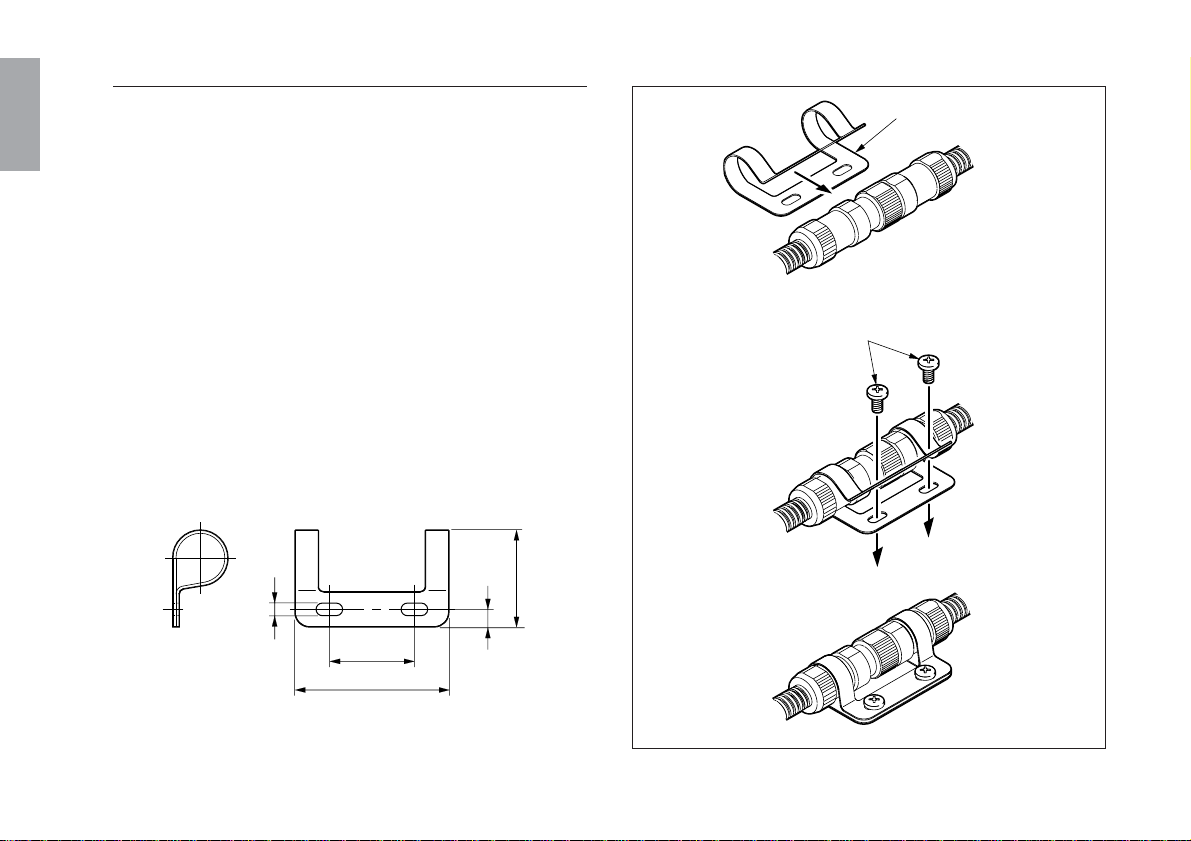

〈9〉 丸型コネクタの取付け

接続されたオス―メスの丸型コネクタを、付属品のクラン

プで固定します。

コネクタは、固定されていないと危険ですので、必ず固定

してください。

1 クランプの開口部側からコネクタにはめ込みます。

2 +BM4×10(2本,付属品)でクランプの上下を共締めす

るように押付けます。

3 クランプの上下が突き当たるまで、しっかりとねじを

締付けます。

コネクタが固定されていることを確認します。

クランプ取付寸法および外形寸法

34

4.4

30

54

6

クランプ

+B(バインド小ねじ)

M4×10で締付けます。

22

取付後の高さ寸法は、コネクタ外形と同じとなります。

(J)

突き当たるまで締付けます。

図3-20.

〈10〉 インターフェースユニットを表示装置に接続

する場合

SR138Rシリーズで接続ケーブルとの電気調整が必要な場

合、「4.接続ケーブル回路の電気調整について」に進んで

ください。

1 表示ユニットの電源がOFFになっていることを確認

し、接続ケーブルのインターフェースユニットを表示

ユニット背面の1〜3のコネクタに接続します。

ご注意

スケールユニット取付軸と表示ユニット差込みを確認して

ください。

2 インターフェースユニットのねじを用いて固定しま

す。(締付けトルク:60N·cm)

日本語

インターフェース

ユニット

表示ユニット背面

図3-21.

(J

) 23

日本語

〈11〉 インターフェースユニットをコントローラに

接続する場合

1 付属の固定板を小ねじ(M3×5)でインターフェースユ

ニットに取付けます。

21を付属の小ねじ(M4×5)で取付面に固定します。

ご注意

取付面にはM4タップ2箇所を準備してください。

20

〈12〉 スケールユニットを取外す場合

一度機械に取付けられたスケールユニットを取外す場合は

スライダホルダを必ず使用し、スライダ部をスケール部に

固定します。

番号順に行なってください。

2 ボルトM2.6(4本)で固定します。

1 目隠しラベルを剥がします。

3 ねじを緩め機械から

外します。

図3-23.スケールユニットの取外し方

24

(J)

図3-22.

このように固定することにより、スケール部とスライダ部

は取付時と同じ状態に再現されますので、再度取付ける場

合は容易に取付けられます。

4.

接続ケーブル回路の電気調整について

(SR138Rシリーズのみ)

* この項目は、最適調整されて組み合わせ出荷されている

GB-ERシリーズには必要ありません。

SR138Rシリーズを表示ユニットと接続する場合、接続ケー

ブルとしてCH04シリーズ(別売)をご使用ください。

接続ケーブルは、使用するスケールユニットと必ず一体で

電気調整する必要がありますので、以下の手順に従い調整

してください。

電気調整は、スケールユニットからのA/B相信号を最適化

するために行ないます。したがって、規定通りに調整され

ない場合、スケール精度仕様が満足されません。

ご注意

ただし、スケールユニットと表示ユニット接続ケーブル

(CH04シリーズ)を一体で注文された場合は、調整して出荷

されますので調整の必要はありません。スケールユニット

のSerialNo.と接続ケーブル側のコンビネーションNo.が同

じ組合わせで接続してください。

準備するもの

• オシロスコープ

(感度0.01V以上,周波数帯域 1MHz以上のもの)

入力感度 : DC0.1V/div(10:1プローブ使用)

水平軸掃引 : 50ms/div〜0.5ms/div

トリガソース : INT

トリガモード : AUTO

• マイナスドライバ(トリマ回転用)

• プラスドライバ(アッパーケース取付・取外し用)

〈1〉アッパーケースの取外し

インターフェースユニットのアッパーケースを取付けている

M2×8(2本)ねじを取外し、アッパーケースを外します。

M2×8

アッパーケース

日本語

図4-1.

(J

) 25

日本語

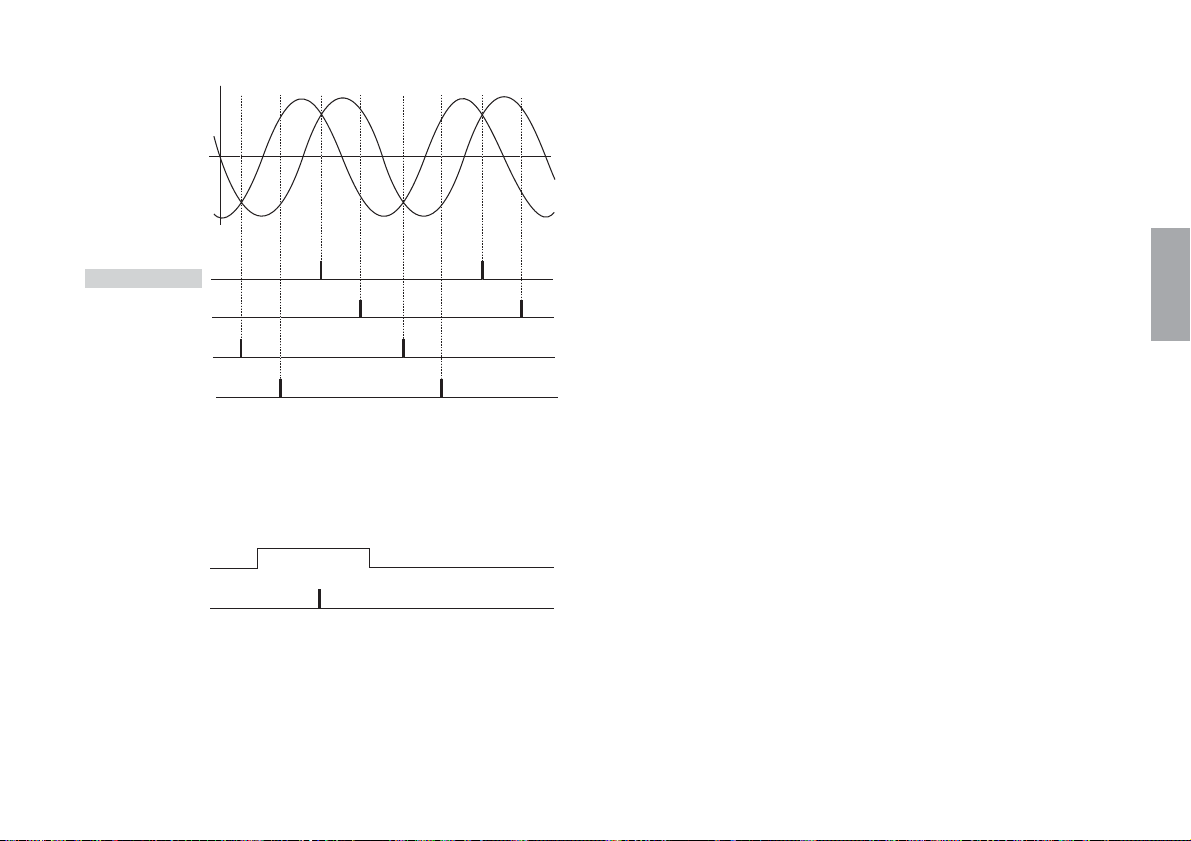

〈2〉SIN/COS信号確認

ご注意

• オシロスコープのプローブの取付け、取外しは、イン

ターフェースユニットの電源がOFFの状態のときに行

なってください。

• インターフェースユニットのチェック端子は、小さく物

理的強度がないため、ICクリップ等を用いて接続してく

ださい。(推奨ICクリップ:テクトロニクス製 グラバ•

クリップSMG50等)

オシロスコープ

CH1CH2

プローブ

インターフェースユニット

CN2-5pin (Z)

26

• インターフェースユニットの電源がOFFになっているこ

とを確認してください。

• インターフェースユニットカバーの取外し、取付けは、

「アッパーケースの取外し」を参照してください。

1 インターフェースユニットのチェック端子のTP1(SIN)

とTP4(GND)に、オシロスコープのCH1プローブを接

続します。

2 インターフェースユニットのチェック端子のTP2(COS)

とTP4(GND)に、オシロスコープのCH2プローブを接

続します。

(J)

スイッチ1

(原点POS1sw)

スイッチ2

(原点POS2sw)

RV5 (REF DC)

RV6 (REF振幅)

RV3 (COS DC)

RV4 (COS振幅)

RV1 (SIN DC)

RV2 (SIN振幅)

TP4 (GND)

CL1 (ZG)

TP3 (REF)

TP2 (COS)

TP1 (SIN)

シグナル調整部詳細図

図4-2.

3 オシロスコープのTIME/DIVスイッチをX-YMODEに

します。

4 オシロスコープのCH1、CH2の偏向感度(VOLTS/DIV)

を0.2V/DIVにします。

5 オシロスコープのCH1、CH2のINPUTCOUPLINGス

イッチをGNDに合わせ、信号がスクリーン左下にくる

ようにオシロスコープのPOSITIONを調整します。

(図4-3参照)

8 SIN/COS信号DCレベルの確認と調整

スケール部またはスライダ部を移動させて全長に渡り

リサージュの中心(図4-4参照)が規定値に入っているこ

とを確認します。

規定値に入っていない場合は、リサージュの中心が規

定値となるようにDCレベルを調整してください。

規定値 リサージュの中心=0.9V±0.02V

DCレベル調整トリマ RV1(SIN) : a方向

RV3(COS) : b方向

a

b

日本語

図4-3.

6 オシロスコープのCH1およびCH2のINPUTCOUPLING

スイッチをDCにします。

7 インターフェースユニットの電源をONにします。

図4-4.

(J

) 27

日本語

9 SIN/COS信号振幅の確認と調整

スケール部またはスライダ部を移動させて全長に渡り

リサージュの振幅A・B(図4-5参照)が規定値に入ってい

ることを確認します。

規定値に入っていない場合は、リサージュの振幅A•B

が規定値となるように振幅を調整してください。

規定値 リサージュの振幅=1.0Vp-p±0.06V

振幅調整トリマ RV2(SIN) : A方向

RV4(COS) : B方向

A

B

図4-5

! インターフェースユニットの電源をOFFにします。

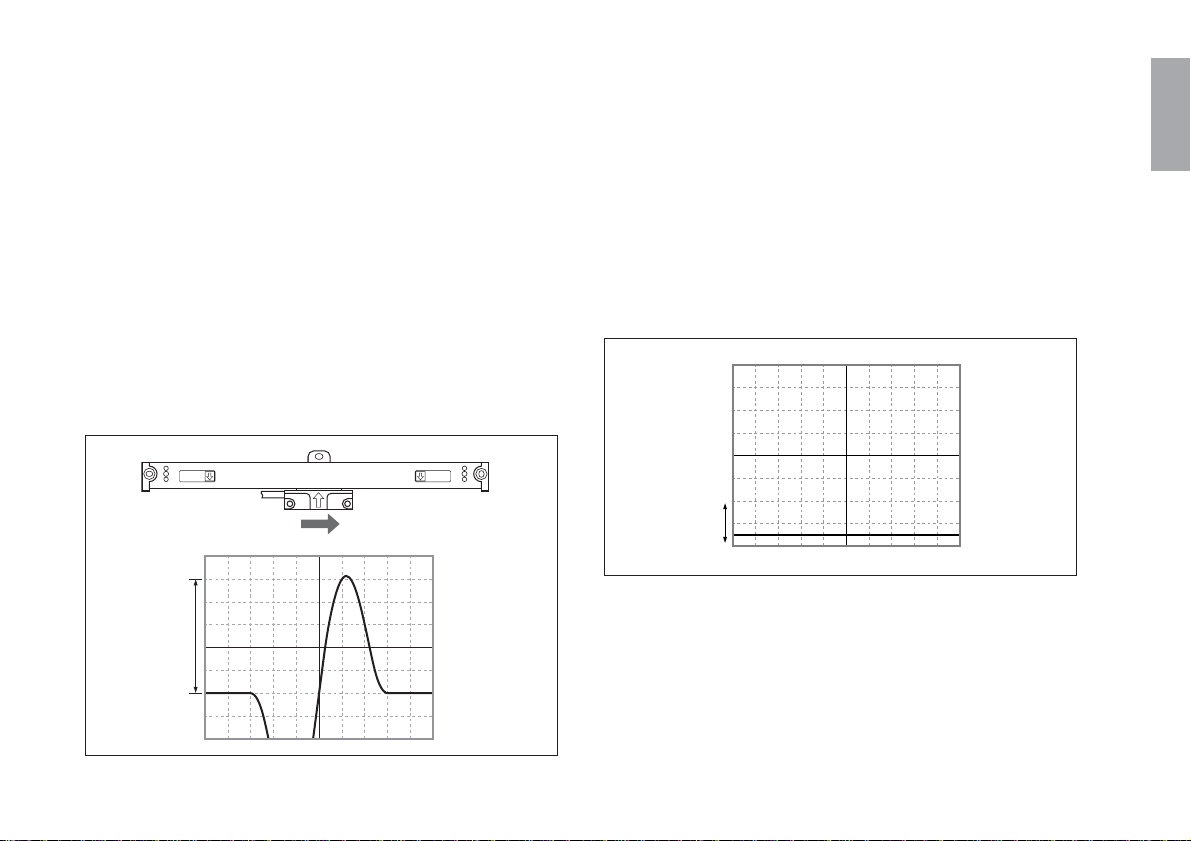

〈3〉原点信号確認

オシロスコープのCH1プローブをインターフェースユニッ

トのチェック端子のTP3とTP4に接続します。

1 オシロスコープのTIME/DIVスイッチを200msにしま

す。

2 オシロスコープのCH1の偏向感度(VOLTS/DIV)を0.2V/

DIVにします。

3 オシロスコープのCH1のINPUTCOUPLINGスイッチを

GNDに合わせ、信号がスクリーン下端にくるようにオ

シロスコープのPOSITIONを調整します。(図4-6参照)

28

図4-6.

(J)

4 オシロスコープのCH1のINPUTCOUPLINGスイッチを

DCにします。

5 インターフェースユニットの電源をONにします。

6 原点信号片振幅の確認と調整

スケール部に対してスライダ部を右方向に移動させて

原点を通過させます。

このとき、原点上側の片振幅C(図4-7参照)が規定値に

入っていることを確認します。

規定値に入っていない場合は、原点上側の片振幅Cが規

定値となるように振幅を調整してください。

規定値 原点の片振幅=1.0V±0.04V

原点振幅調整トリマ RV6

7 原点信号DCレベルの確認と調整

原点のない位置にスケール部またはスライダ部を移動

させます。

このとき、原点信号のDCレベルc(図4-8参照)が規定値

に入っていることを確認します。

規定値に入っていない場合は、原点信号のDCレベルc

が規定値となるようにDCレベルを調整してください。

規定値 原点信号のDCレベル=0.2V±0.02V

原点振幅調整トリマ RV5

日本語

原点検出確認方向

C

図4-7.

c

図4-8.

(J

) 29

日本語

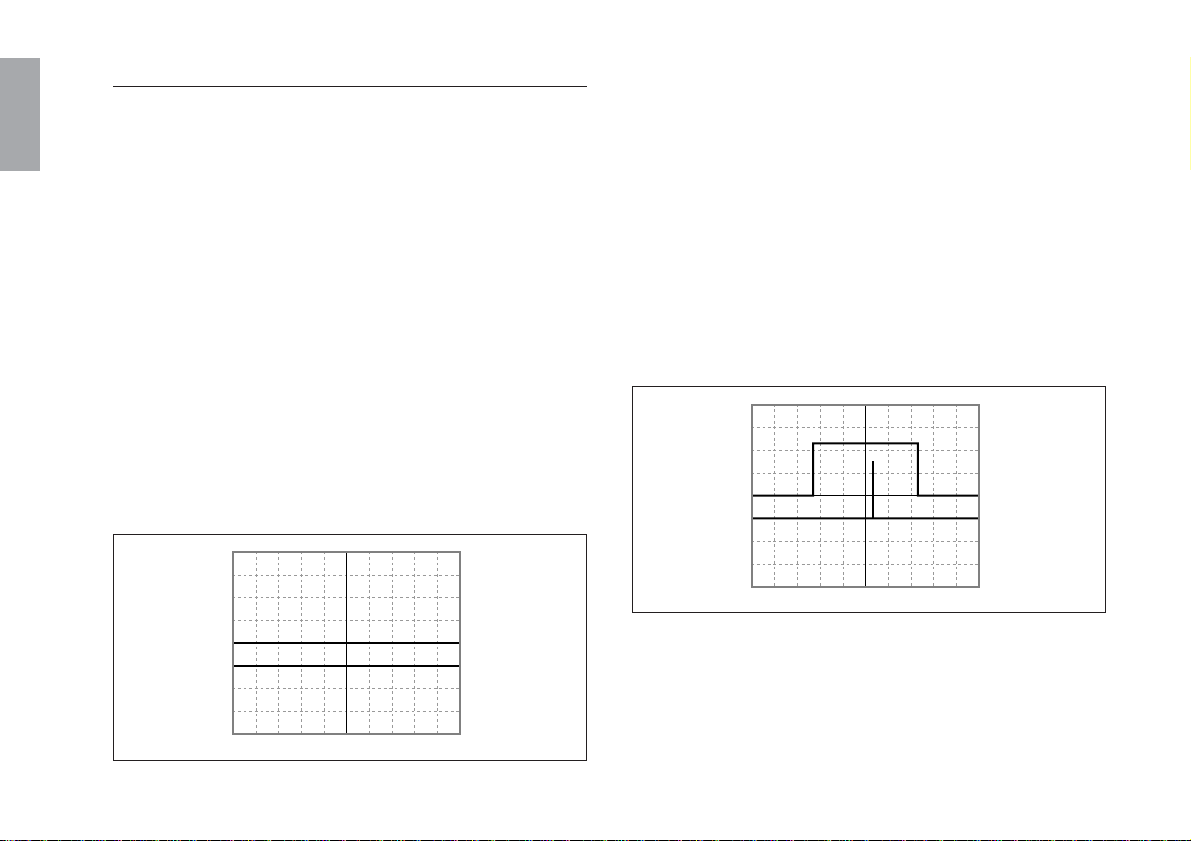

〈4〉原点位置確認

1 インターフェースユニットのチェックランドCL1(ZG)

とチェック端子TP4(GND)に、オシロスコープのCH1

プローブを接続します。

2 インターフェースユニットのコネクタCN2-5ピン(Z)と

チェック端子TP4(GND)に、オシロスコープのCH2プ

ローブを接続します。

3 オシロスコープのTIME/DIVスイッチを200msにしま

す。

4 オシロスコープのCH1、CH2の偏向感度(VOLTS/DIV)

を2V/DIVにします。

5 オシロスコープのCH2のINPUTCOUPLINGスイッチを

GNDに合わせ、CH1はスクリーンセンターにくるよう

にオシロスコープのPOSITIONを調整します。

CH2は、1マス下にくるようにオシロスコープの

POSITIONを調整します。(図4-9参照)

6 オシロスコープのCH1およびCH2のINPUTCOUPLING

スイッチをDCにします。

7 インターフェースユニットの電源をONにします。

8 原点ゲート信号(CL1)と原点出力信号(CN2-5pin)の位

置設定

スケール部またはスライダ部を移動させて原点を通過

させます。

このとき、原点ゲート信号のセンターに一番近い位置

に原点出力信号が出力されるように、スイッチ1·2(原点

POS1·2sw)を設定してください。(図4-10参照)

CH1 (ZG)

CH2 (Z)

30

(J)

図4-9.

CH1 (ZG)

CH2 (Z)

図4-10.

SIN信号

COS信号

MODE1 MODE2

ON ON

約45°

OFF ON

約135°

ON OFF

約225°

OFF OFF

約315°

原点出力信号は、スイッチ設定で選択した1周期基

準点4つの内1つと原点ゲートの論理積となります。

原点ゲート信号

原点出力

MODEスイッチ1•2共にON時

日本語

(J

) 31

日本語

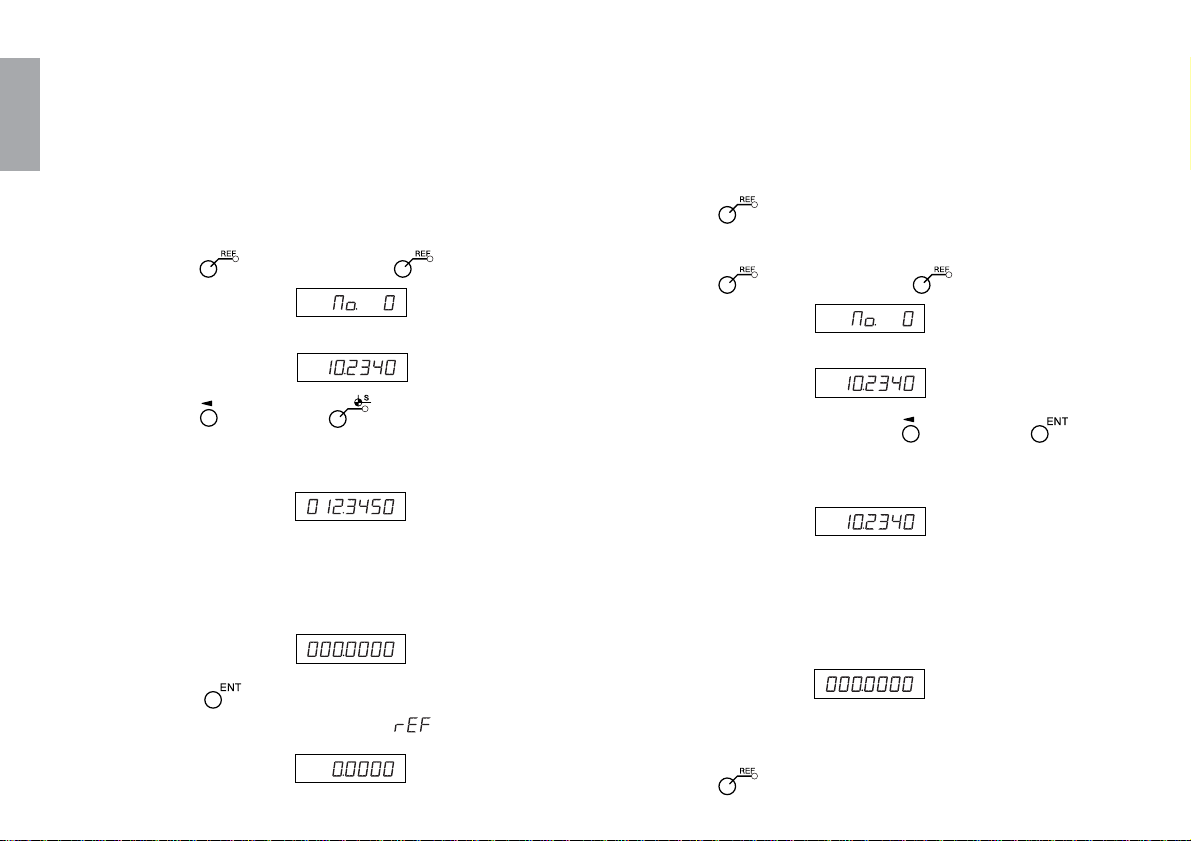

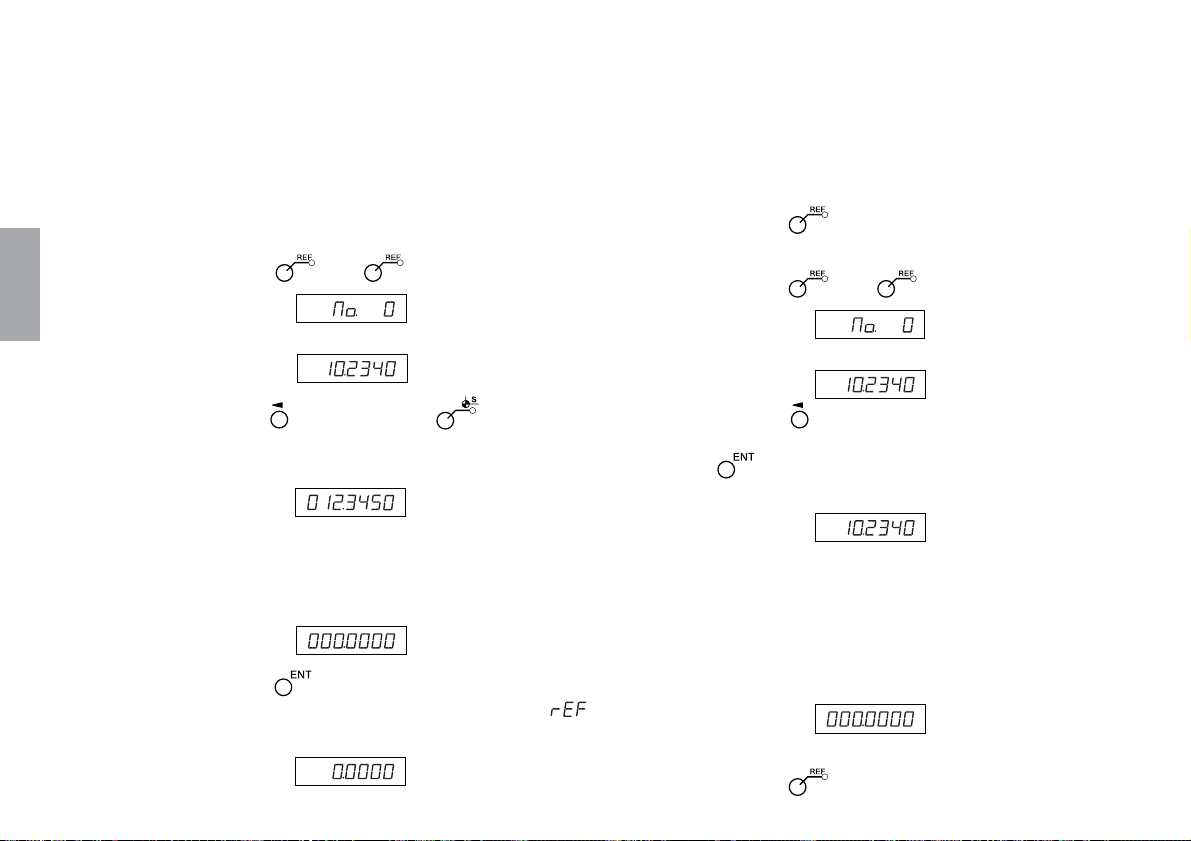

9 原点動作の確認(LH71を用いて確認する場合)

原点ロードと原点ホールドを用いて、両方向原点の確

認をします。

1. インターフェースユニットを表示ユニットLH71に接

続して電源をONします。

2. 原点オフセット量「000.0000」入力

1)

キーを押します。( ランプ点灯)

5) スケール部またはスライダ部を移動し、原点を通

過させます。

原点を検出したときに「ピッ」と鳴ります。

* 原点を検出すると、カウントが開始されます。

6) キーを押してモードから抜けます。

3. 両方向原点の確認

1)

キーを押します。( ランプ点灯)

32

(J)

表示 ↓

(現在値表示(ABS))

2) キーを押して キーを押します。

保存されているオフセット量(原点ロード時の表

示値)が表示されます。

表示 (例:原点から基準点

までの距離)

3) テンキーでオフセット量(000.0000)を入力しま

す。

表示 (000.0000)

4) キーを押します。

原点待ちになります。(

表示 (点滅)

値点滅)

表示 ↓

(現在値表示(ABS))

2) 原点ホールドする軸の キーを押して キー

を押します。

原点待ちになります。(現在値表示)

表示 (点灯)

3) 2)で原点を通過させた反対方向から原点を通過

すると、原点位置でカウントがホールドしま

す。(軸ラベル点滅)

* 原点を検出したときに「ピッ」と鳴ります。

表示

4) ホールドされた値が「0」であることを確認しま

す。

5) キーを押してモードから抜けます。

5. 主な仕様

5-1. 一般仕様

スケールユニット

有効長 : 50,100,150,200,250,300,350,400,

450,500,550,600,650,750,850,950,

1050,1250,1400,1600,1850,2050,

2200mm

全長 : 有効長+104mm(有効長200mm以下)

有効長+120mm(有効長250mm以上)

最大可動長 : 有効長+14mm

(有効長200mm以下,左右各7mm)

有効長+30mm

(有効長250mm以上,左右各15mm)

スケール精度 :(5+L)µm(SR138Rシリーズ)

(20℃にて)

Lは有効長(mm)

入出力信号

出力信号 : A/B/Z相

電源 : DC5V±5%

コネクタ : D-sub9ピン

コネクタピン配置 : 外形寸法図参照

分解能 : 0.5µm

5

1000

応答速度

スケール信号 : 60m/min

原点信号 : 60m/min

原点位置 : 有効長の中央1箇所

ケーブル長 :最大30m

許容取付平行度 : 0.1mm

消費電流 :最大200mA

–6

温度膨張係数 : (11±1)×10

使用温度範囲 :0〜40℃

保存温度範囲 : –10〜+50℃

/℃

接続ケーブル

ケーブル長 :3m

製品は一部改良のため、予告なく外観•仕様を変更すること

があります。

日本語

(J

) 33

44

6.5

9.5

6.5

20

10.5

5

25

15

6

21

12 9

25

42

36.5

50

36

60

75

85

(C)

D

(C)

Serial No.

SR138—

* * *

R

* * * * * *

日本語

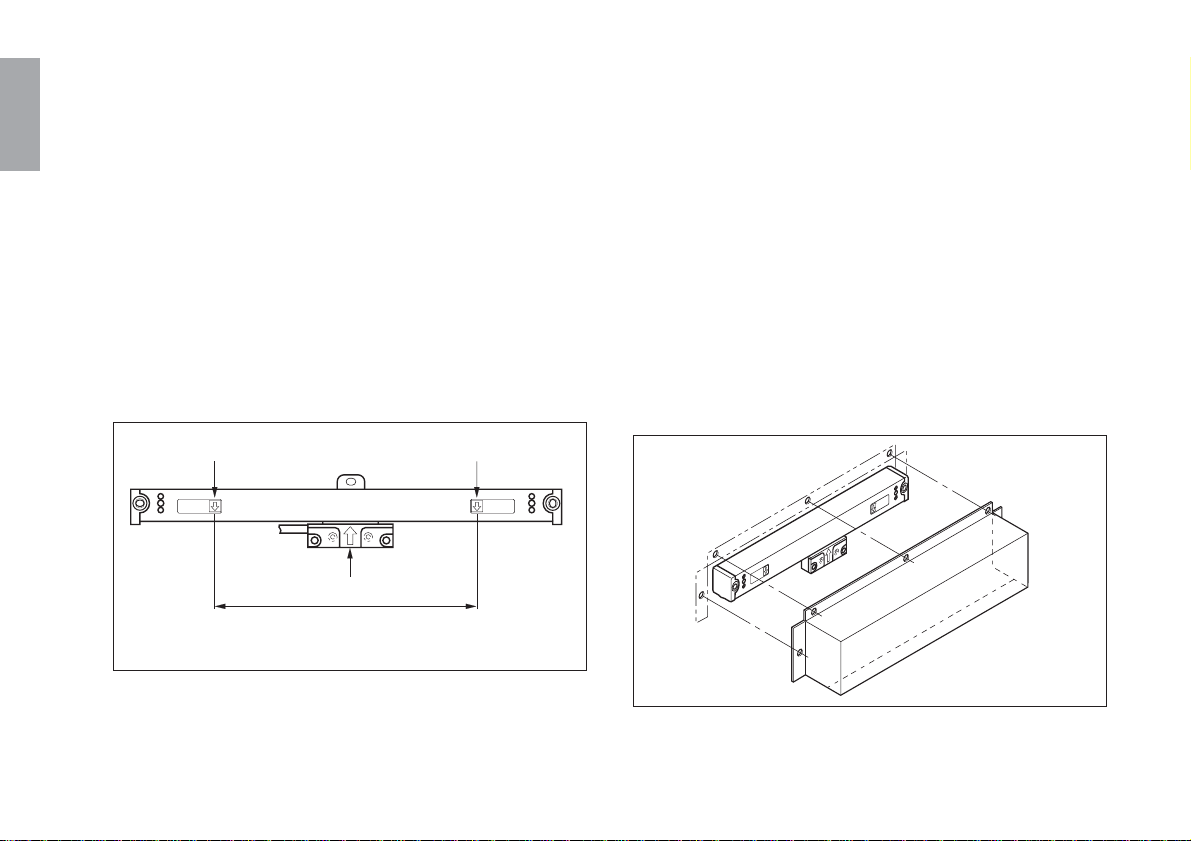

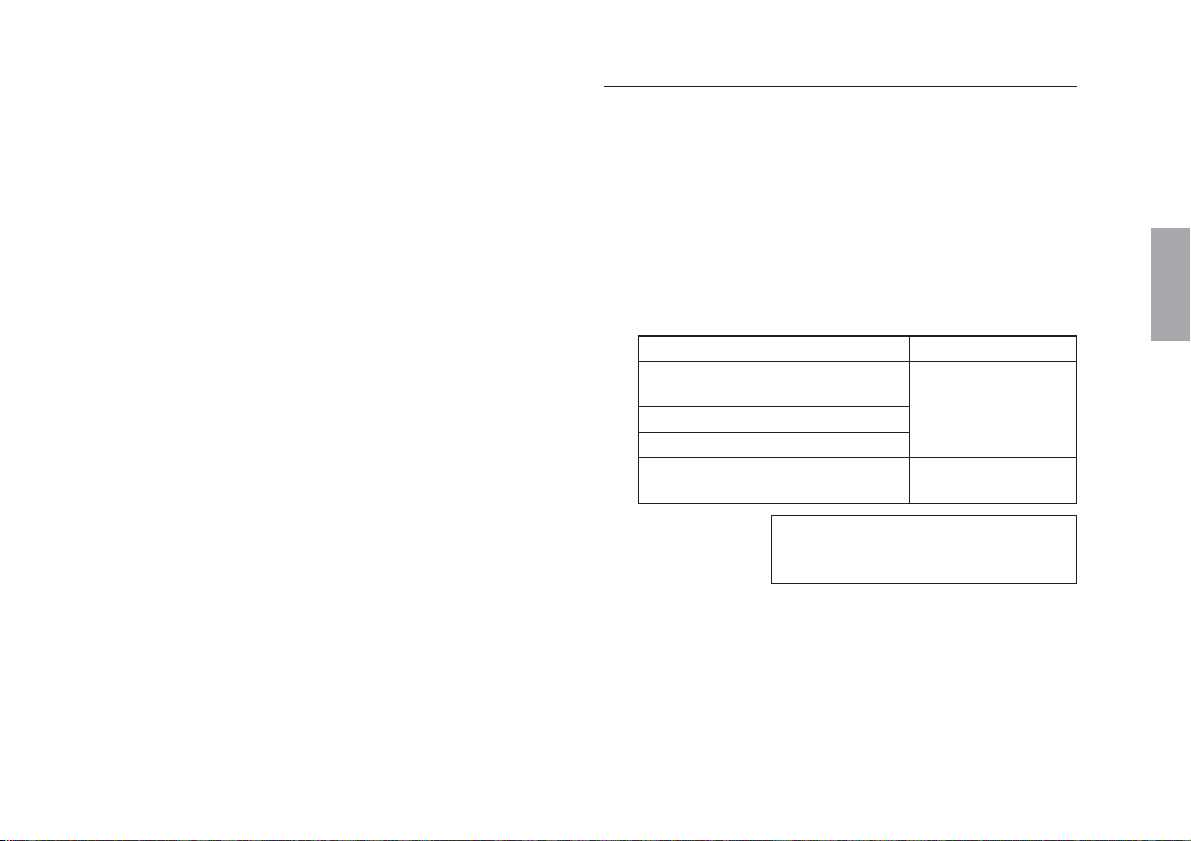

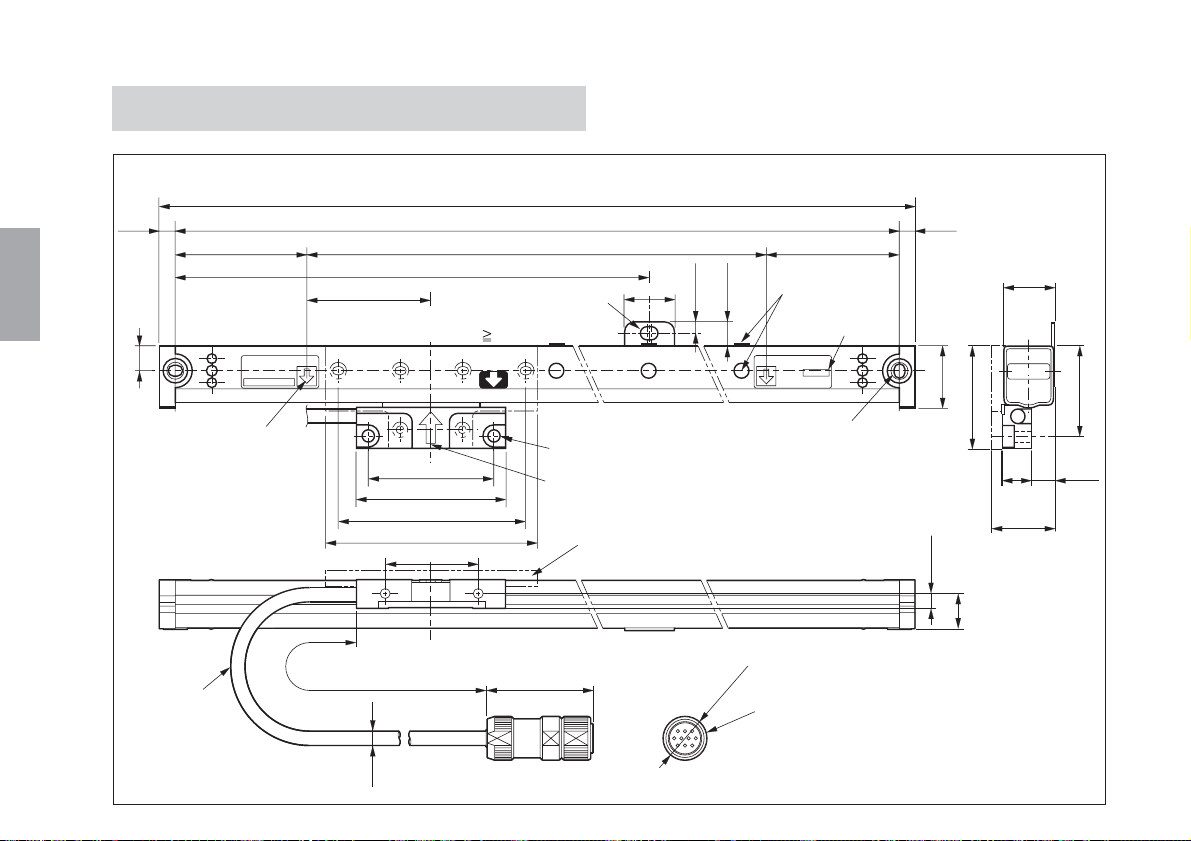

5-2. 外形寸法図

スケールユニット

取付穴ピッチ×1/2

(有効長L=1050mm以上)

全長=A

取付穴ピッチ=B

有効長=L

中央フットプレート

5×7長穴(取付穴)

アライメントマーク

SerialNo.

34

(J)

有効長マーク

ヘッドケーブル

ケーブル長=300

2-ø5穴,ø9座ぐり

スライダ中心

スライダホルダ

2-4.5×5.5長穴

(取付穴)

丸型コネクタ(オス)

単位:mm

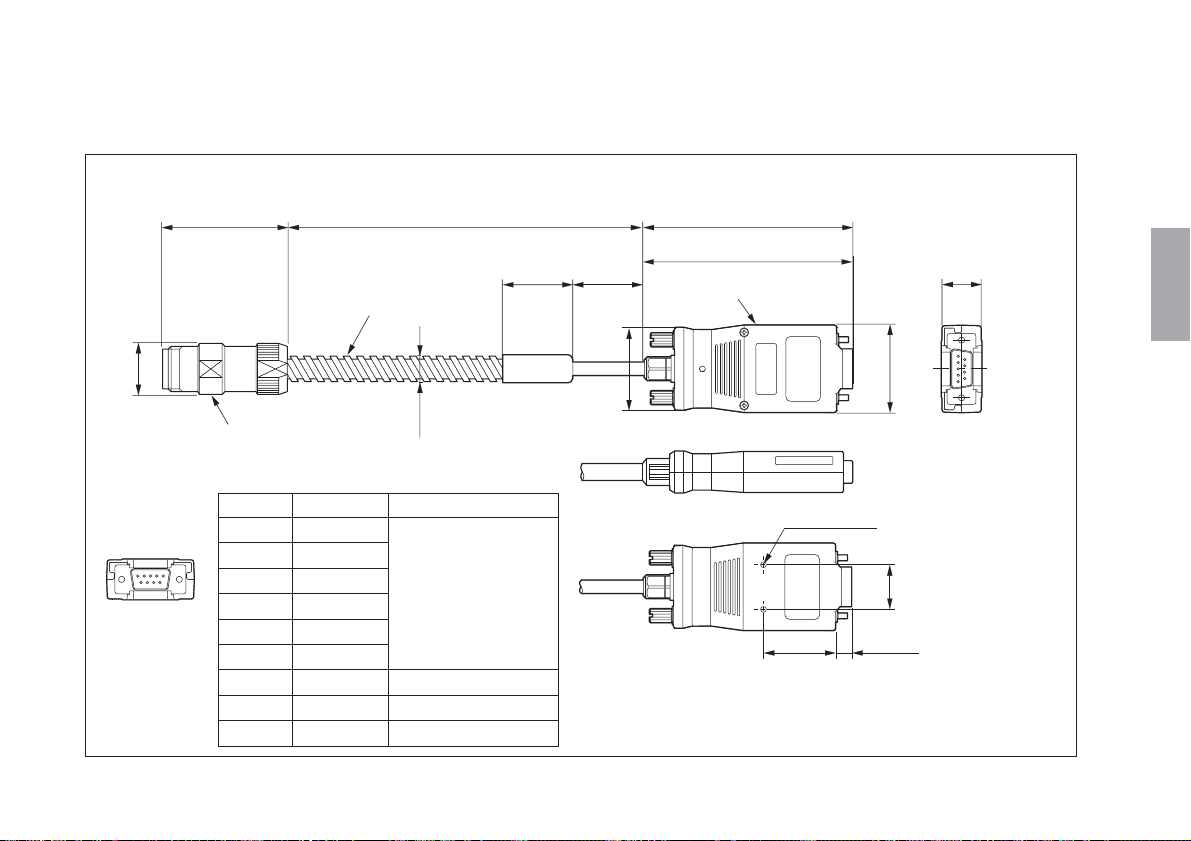

接続ケーブル(CH04:GB-ERシリーズのみに同梱)

44 (91)

ケーブル長

日本語

コンジットケーブル

丸型コネクタ(メス)

インターフェースコネクタ(D-sub9ピンオス)ピン配置

15

69

番号 信号名 備考

1A

2 *A

3B

4 *B

5Z

差動出力

(EIA-422準拠)

最小位相差200ns

6 *Z

70V

8 +5V入力 DC+5V±5%

90V

(86.5)

30

30

インターフェースユニット

**

36

2-M3深さ3

(31) (7)

(17.7)

3820

単位:mm

(J

) 35

日本語

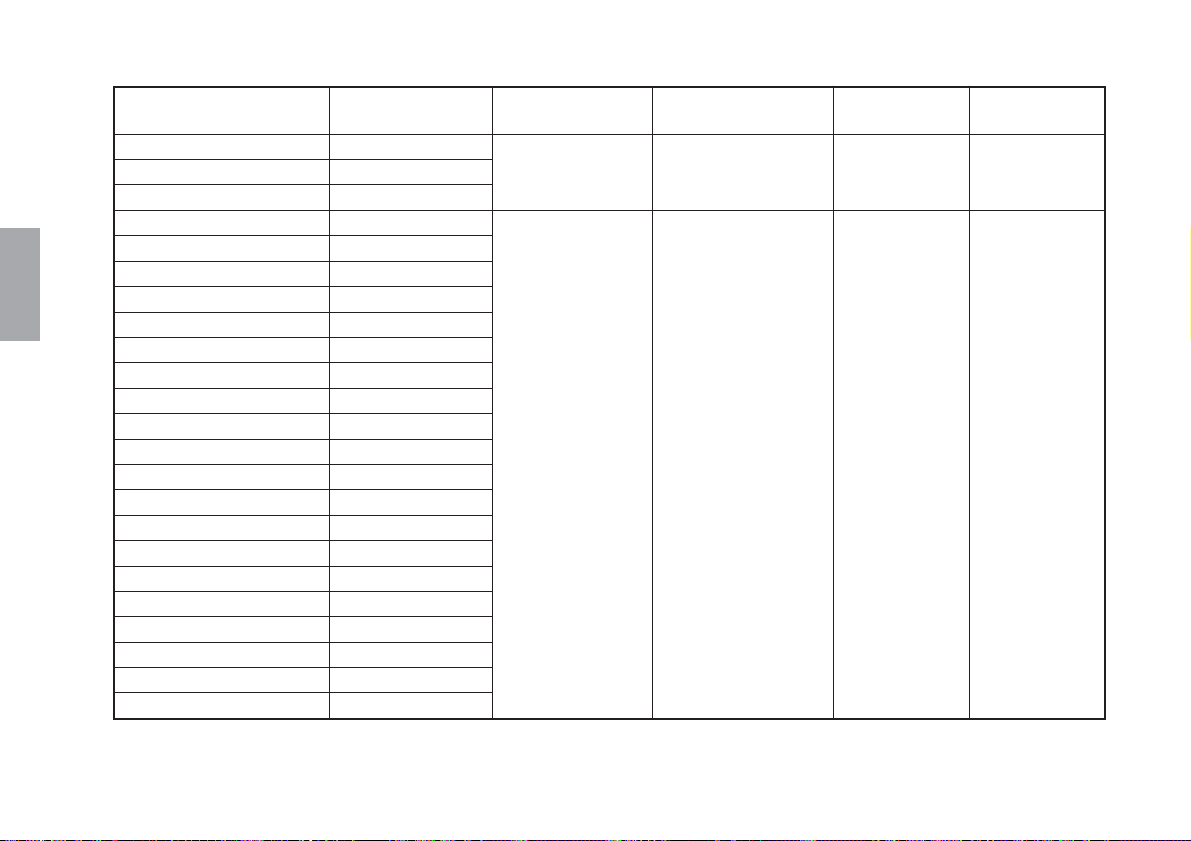

型名

GB-005ER/SR138-005R

GB-010ER/SR138-010R

GB-015ER/SR138-015R

GB-020ER/SR138-020R

GB-025ER/SR138-025R

GB-030ER/SR138-030R

GB-035ER/SR138-035R

GB-040ER/SR138-040R

GB-045ER/SR138-045R

GB-050ER/SR138-050R

GB-055ER/SR138-055R

GB-060ER/SR138-060R

GB-065ER/SR138-065R

GB-075ER/SR138-075R

GB-085ER/SR138-085R

GB-095ER/SR138-095R

GB-105ER/SR138-105R

GB-125ER/SR138-125R

GB-140ER/SR138-140R

GB-160ER/SR138-160R

GB-185ER/SR138-185R

GB-205ER/SR138-205R

GB-220ER/SR138-220R

有効長(L)

50mm

100mm

150mm

200mm

250mm

300mm

350mm

400mm

450mm

500mm

550mm

600mm

650mm

750mm

850mm

950mm

1050mm

1250mm

1400mm

1600mm

1850mm

2050mm

2200mm

全長(A)

有効長+104mm

有効長+120mm

取付穴ピッチ(B)

有効長+91mm

有効長+107mm

C

45.5mm

53.5mm

D

有効長×1/2

50mm

36

(J)

6. トラブルインフォメーション

■ オーバーラン•ケーブル破損•スケールユニットの変形な

どスケールとしての機能に影響を与えるような状況が発

生した場合、修理が必要となります。

• すぐに機械を停止し、ご連絡ください。

■ 損傷の程度によっては、修理不能となります。

このようなトラブル発生を防ぐために、清掃の励行をお願

いします。

• スケールユニットの周りに切粉が溜まらないよう、毎

日始業時と終業時に切粉の清掃をするように心掛けて

ください。

• 切粉が溜まるとスケールユニットの摺動を妨げ、障害

の原因となることがあります。

• 切粉の清掃にはエアーガン等の使用はお避けくださ

い。スケールユニットの走行部分はシールされていま

すが、構造上完全密閉にはなっておりません。エアー

ガン等を使用すると、切粉等がスケールユニットの

シール部分から侵入し、故障の原因となることがあり

ます。

日本語

(J

) 37

38

(J)

■ General precautions

When using Magnescale Co., Ltd. products, observe the following

general precautions along with those given specifically in this

manual to ensure proper use of the products.

• Before and during operations, be sure to check that our products

function properly.

• Provide adequate safety measures to prevent damage in case

our products should develop a malfunction.

• Use outside indicated specifications or purposes and

modification of our products will void any warranty of the

functions and performance as specified for our products.

• When using our products in combination with other equipment,

the functions and performance as noted in this manual may not

be attained, depending upon the operating environmental

conditions. Make a thorough study of the compatibility in

advance.

■ Precautions for use under the following

environments

1 When using water-miscible cutting fluid or when cutting metal or

non-metal (ceramic, glass fiber, etc.) objects.

• Mount the scale unit so that it is not directly exposed to

water-miscible cutting fluid or cutting scraps.

• Attach a scale cover to prevent water-miscible cutting fluid

mist or powder from entering the inside of the scale unit.

2 When mounted on a honing machine or other machine that

slides at high speed for long periods within a specific area.

• Regularly apply oil or spray lubricant (CRC•WD40, etc.).

If using in the environments in 1 or 2, be sure to always implement

the measures above. Quality cannot be guaranteed unless these

measures are implemented.

(E

) i

Safety Precautions

Magnescale Co., Ltd. products are designed in full consideration of safety. However, improper

handling during operation or installation is dangerous and may lead to fire, electric shock or other

accidents resulting in serious injury or death. In addition, these actions may also worsen machine

performance.

Therefore, be sure to observe the following safety precautions in order to prevent these types of

accidents, and to read these “Safety Precautions” before operating, installing, maintaining,

inspecting, repairing or otherwise working on this unit.

Warning indication meanings

The following indications are used throughout this manual, and their

contents should be understood before reading the text.

Warning

Failure to observe these precautions may lead to fire, electric shock

or other accidents resulting in serious injury or death.

Symbols requiring attention

CAUTION ELECTRICAL

SHOCK

Symbols prohibiting actions

Caution

Failure to observe these precautions may lead to electric shock or

other accidents resulting in injury or damage to surrounding objects.

DO NOT

DISASSEMBLE

Symbols specifying actions

Note

This indicates precautions which should be observed to ensure

ii

(E)

proper handling of the equipment.

UNPLUGGING

Warning

Caution

• Do not use this unit with voltages other than the specified supply voltage as this may

result in fire or electric shock.

• Do not perform installation work with wet hands as this may result in electric shock.

• Do not disassemble or modify the unit as this may result in injury or damage the

internal circuits.

• Be sure to check the machine and device conditions to ensure work safety before

working on the machine.

• Be sure to cut off the power supply, air and other sources of drive power before

working on the machine. Failure to do so may result in fire or accidents.

• When turning on the power supply, etc. to operate the machine, take care not to catch

your fingers in peripheral machines and devices.

(E

) iii

Handling Precautions

Installation precautions

When installing this unit, care should be given to the following points to prevent noise

and electromagnetic wave interference from other equipment.

1. Do not pass lead and connection cables through the same ducts as power lines.

2. Be sure to install the unit at least 0.5 m/19.6" or more away from high voltage or

large current sources or high-power relays.

3. Absolutely do not bring the unit near magnets or sources of electromagnetic waves.

Note

• Magnet chucks and other sources of magnetic force of approx. 6 × 10–2 [T] should

be kept at least 50 mm/19.6" or more away from the side surfaces and 10 mm/

0.39" or more away from the opening surfaces of the steel chassis on the scale

unit.

• If the unit must be installed close to sources of magnetic force, be sure to

implement adequate electromagnetic shielding countermeasures.

4. Be sure to ground the scale part and the slider part to prevent trouble to noise.

iv

(E)

Installation place precautions

1. Mount the scale unit for more precise positioning as closely as possible to the

workpiece or to the object being measured.

(The farther the scale unit is mounted from workpiece, the greater the mechanical

errors grow.)

2. The scale unit should be used within an ambient temperature range of 0 to 40°C

(32 to 104°F). Avoid locations where the scale unit is exposed to direct sunlight and

heat sources such as motors.

3. Do not place anything on the mounted scale unit, or step on it: excessive force to the

scale unit causes trouble.

(E

) v

vi

(E)

Contents

1. Outline ......................................................................... 2

1-1. Introduction .................................................................. 2

1-1-1. SR138R series ...................................................... 2

1-1-2. CH04 series .......................................................... 2

1-1-3. GB-ER series ........................................................ 2

1-1-4. CE10 series ........................................................... 2

1-2. Major Features ............................................................. 2

1-3. Parts Configuration ...................................................... 3

1-4. System Configuration .................................................. 3

2. Name and Function of Each Part ............................. 5

2-1. Scale Unit ..................................................................... 5

2-2. Connection Cable ......................................................... 7

3. Mounting Method .......................................................8

3-1. Precautions before Mounting ...................................... 8

3-2. Mounting Precautions .................................................. 9

3-2-1. Checking the mounting method ........................... 9

3-2-2. Setting the movement range............................... 10

3-2-3. Protection of the head cable ............................... 10

3-2-4. Mounting a protective cover .............................. 10

3-3. Required Items for Mounting .................................... 11

3-4. Mounting Dimensions ............................................... 12

<1> When the mounting surface already meets

parallelism and flatness requirements ...... 12

<2> When the scale mounting surface

is a casting surface ................................... 13

<3> Mounting the slider part ................................. 15

<4> Removal of the slider holder ......................... 18

<5> Checking the movement range ..................... 18

<6> Mounting the headcable ................................ 18

<7> Connecting cables .........................................19

<8> Mounting the conduit cable ........................... 21

<9> Mounting the round connectors ..................... 22

<10> Connecting the interface unit to a

counter unit ............................................... 23

<11> Connecting the interface unit to a controller .... 24

<12> Removal of the scale unit ..............................24

4. Electrical Adjustment of the Connection

Cable Circuit ............................................................. 25

<1> Removing the upper case ............................. 25

<2> SIN/COS signal check ...................................26

<3> Reference point signal check ........................ 28

<4> Reference point position check ..................... 30

5. Specifications........................................................... 33

5-1. General Specifications ............................................... 33

5-2. Dimensions ................................................................. 34

6. Trouble Information ................................................. 37

(E

English

) 1

1. Outline

English

1-1. Introduction

1-1-1. SR138R series

The SR138R series is a linear scale with a built-in reference

point.

The relative positional relationship between the scale part and

slider part is adjusted and secured using a slider holder.

Be sure to always use together with the CH04 connection cable

(optional).

Note

If the SR138R series and CH04 are ordered separately, electrical

adjustment needs to be made for the CH04 before usage. No

adjustment is necessary if electrical adjustment was requested

when ordering.

1-1-2. CH04 series

This is a dedicated cable incorporating a built-in circuit for

converting SR138R series signals to general-purpose A/B

quadrature output. Combining with the SR138R series enables

connection of Magnescale Co., Ltd. counter units (such as the

LH70 and LH71), controllers, and other external equipment.

1-1-3. GB-ER series

The GB-ER series is a product that includes the SR138R series

and a CH04-03C connection cable which has already been

electrically adjusted.

Note

Be sure that the serial No. of the SR138R series and the

combination No. of the CH04-03C match when using in

combination together.

1-1-4. CE10 series

This is an extension cable (optional) for extending the cable

length.

Combining with the CH04 enables extension up to a maximum of

30 m/98.4 ft.

1-2. Major Features

• Compact size and light weight, built-in reference point

• Easy to install

• Same coefficient of expansion as that of machine tools

• Highly accurate position detection

• Highly resistant to oils and dirt

2

(E)

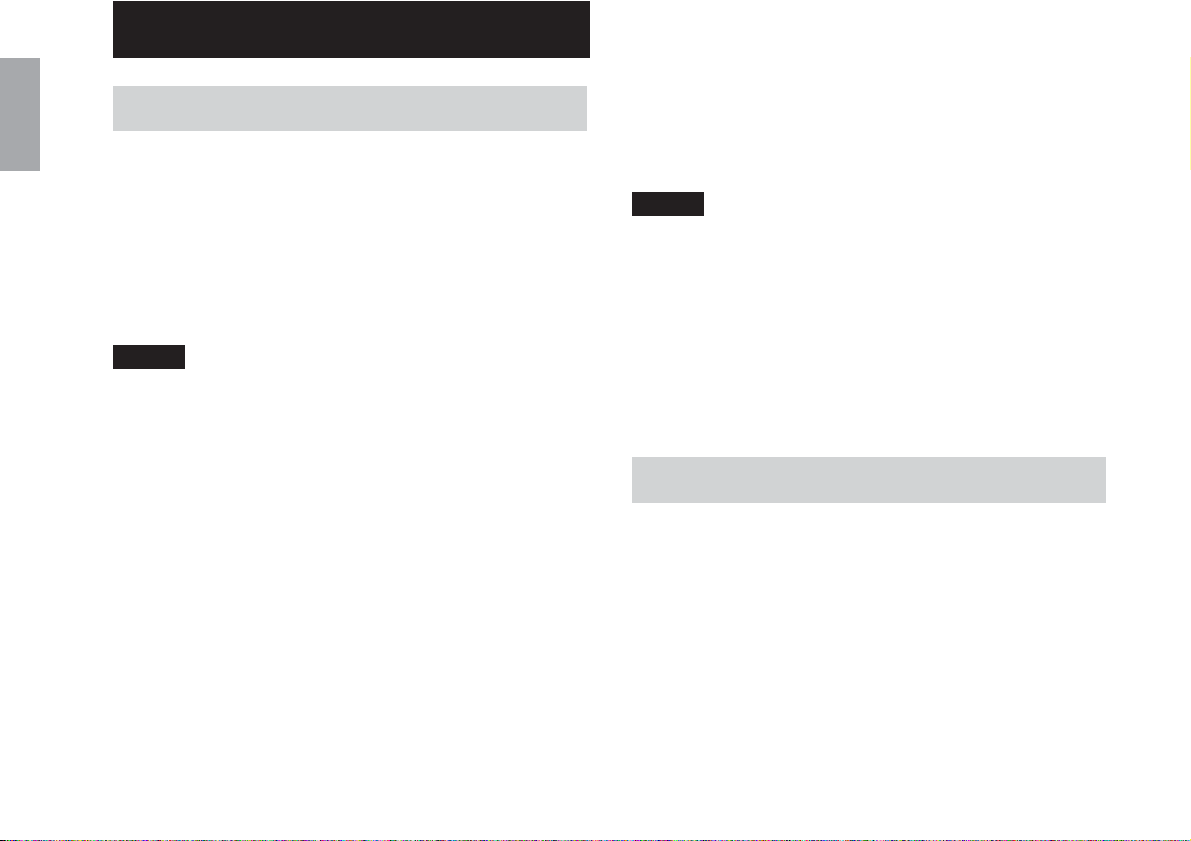

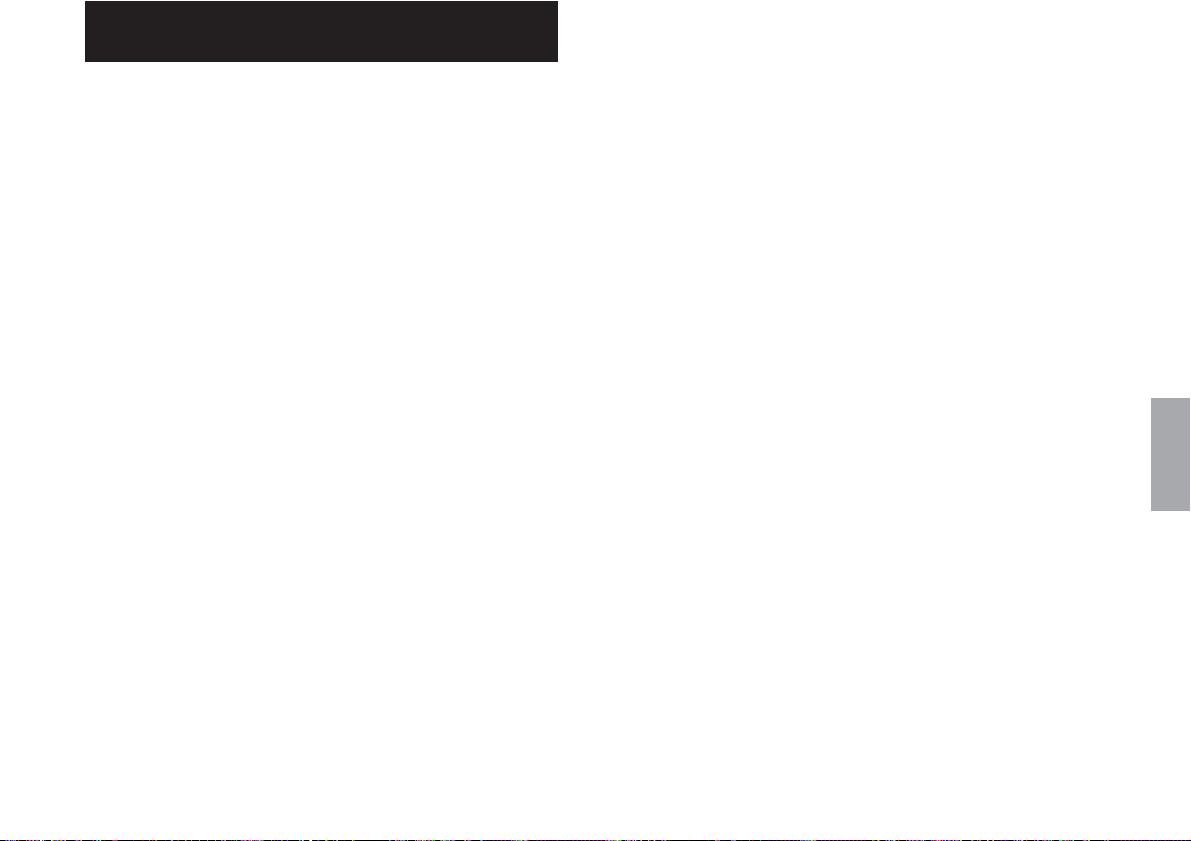

1-3. Parts Configuration

1-4. System Configuration

Scale unit.......................................................................... 1

Connection cable (CH04: included only with the GB-ER series) ....

Accessories

Clamp ............................................ 1

Cable clamps ....... (small 2, large 4)

Spacers ......................................... 5

Screening label ............................. 1

Plain washers (S) .......................... 2

Plain washers (M) ......................... 3

+B4×10 .......................................... 2

+P4×5 ............................................ 4

+P4×10 .......................................... 4

+K3×5 ............................................ 2

HSB M4×8 ..................................... 2

HSB M4×10 ................................... 3

HSB M4×12 ................................... 2

HSB M5×25 ................................... 2

Nuts (M5) ...................................... 2

Fixing plate .................................... 1

System connections

• SR138R series

Scale unit

1

• GB-ER Series

Scale unit (SR138R)

Extension cable

(optional)

Connection cable

(CH04-03C)

Connection cable

(optional)

Counter unit

(optional)

CH01-**C

COMBINATION No.

******

MADE IN JAPAN

Counter unit

LH70/71 series etc.,

Controller

(optional)

(E

English

) 3

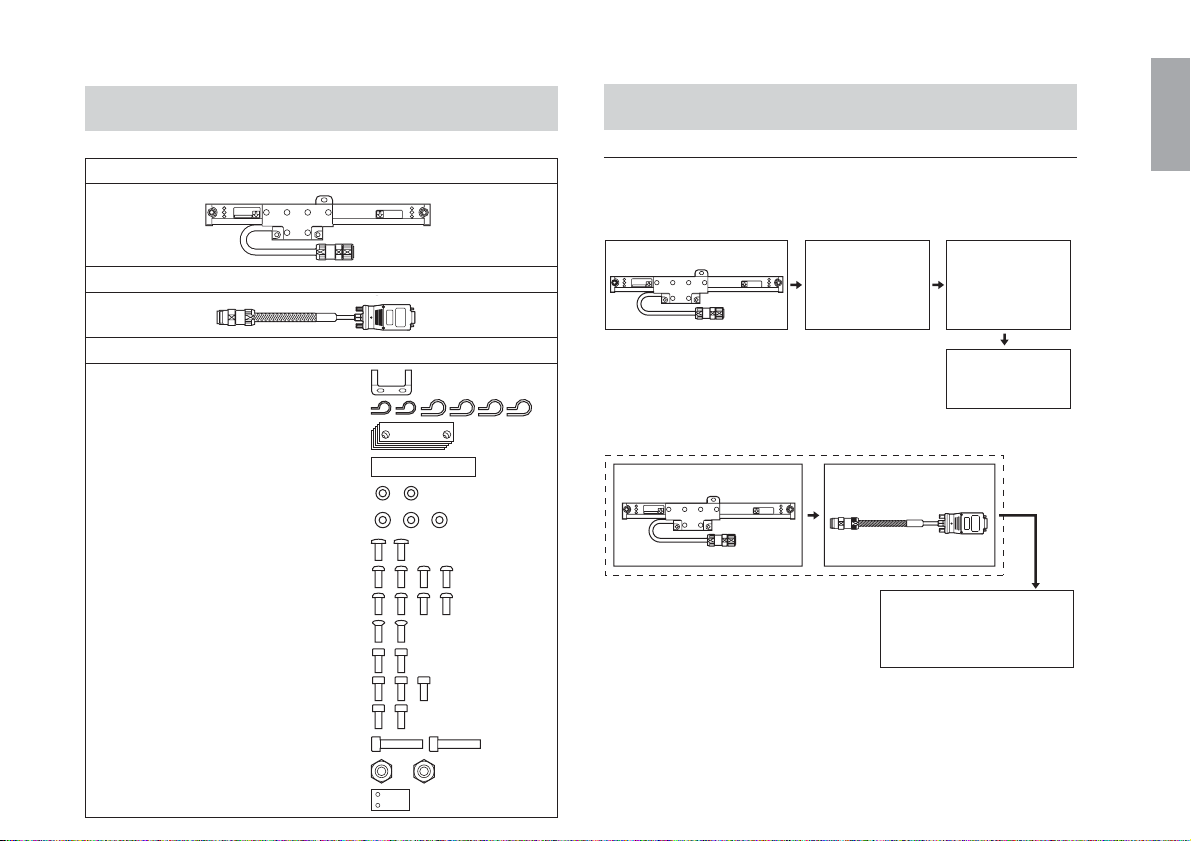

Model lineup (SR138R series) Model lineup (GB-ER series)

English

Model name

SR138-005R

SR138-010R

SR138-015R

SR138-020R

SR138-025R

SR138-030R

SR138-035R

SR138-040R

SR138-045R

SR138-050R

SR138-055R

SR138-060R

SR138-065R

SR138-075R

SR138-085R

SR138-095R

SR138-105R

SR138-125R

SR138-140R

SR138-160R

SR138-185R

SR138-205R

SR138-220R

Measureing

length (L)

50 mm/1.9"

100 mm/3.9"

150 mm/5.9"

200 mm/7.8"

250 mm/9.8"

300 mm/11.8"

350 mm/13.7"

400 mm/15.7"

450 mm/17.7"

500 mm/19.6"

550 mm/21.6"

600 mm/23.6"

650 mm/25.5"

750 mm/29.5"

850 mm/33.4"

950 mm/37.4"

1050 mm/41.3"

1250 mm/49.2"

1400 mm/55.1"

1600 mm/62.9"

1850 mm/72.8"

2050 mm/80.7"

2200 mm/88.6"

Center

foot

None

Included

Model name Center

GB-005ER

GB-010ER

GB-015ER

GB-020ER

GB-025ER

GB-030ER

GB-035ER

GB-040ER

GB-045ER

GB-050ER

GB-055ER

GB-060ER

GB-065ER

GB-075ER

GB-085ER

GB-095ER

GB-105ER

GB-125ER

GB-140ER

GB-160ER

GB-185ER

GB-205ER

GB-220ER

SR138-005R

SR138-010R

SR138-015R

SR138-020R

SR138-025R

SR138-030R

SR138-035R

SR138-040R

SR138-045R

SR138-050R

SR138-055R

SR138-060R

SR138-065R

SR138-075R

SR138-085R

SR138-095R

SR138-105R

SR138-125R

SR138-140R

SR138-160R

SR138-185R

SR138-205R

SR138-220R

Measureing

length (L)

50 mm/1.9"

100 mm/3.9"

150 mm/5.9"

200 mm/7.8"

250 mm/9.8"

300 mm/11.8"

350 mm/13.7"

400 mm/15.7"

450 mm/17.7"

500 mm/19.6"

550 mm/21.6"

600 mm/23.6"

650 mm/25.5"

750 mm/29.5"

850 mm/33.4"

950 mm/37.4"

1050 mm/41.3"

1250 mm/49.2"

1400 mm/55.1"

1600 mm/62.9"

1850 mm/72.8"

2050 mm/80.7"

2200 mm/88.6"

foot

None

Included

Connection cable

length model

CH04-03C

Cable

length

3 m/9.8 ft

4

(E)

7

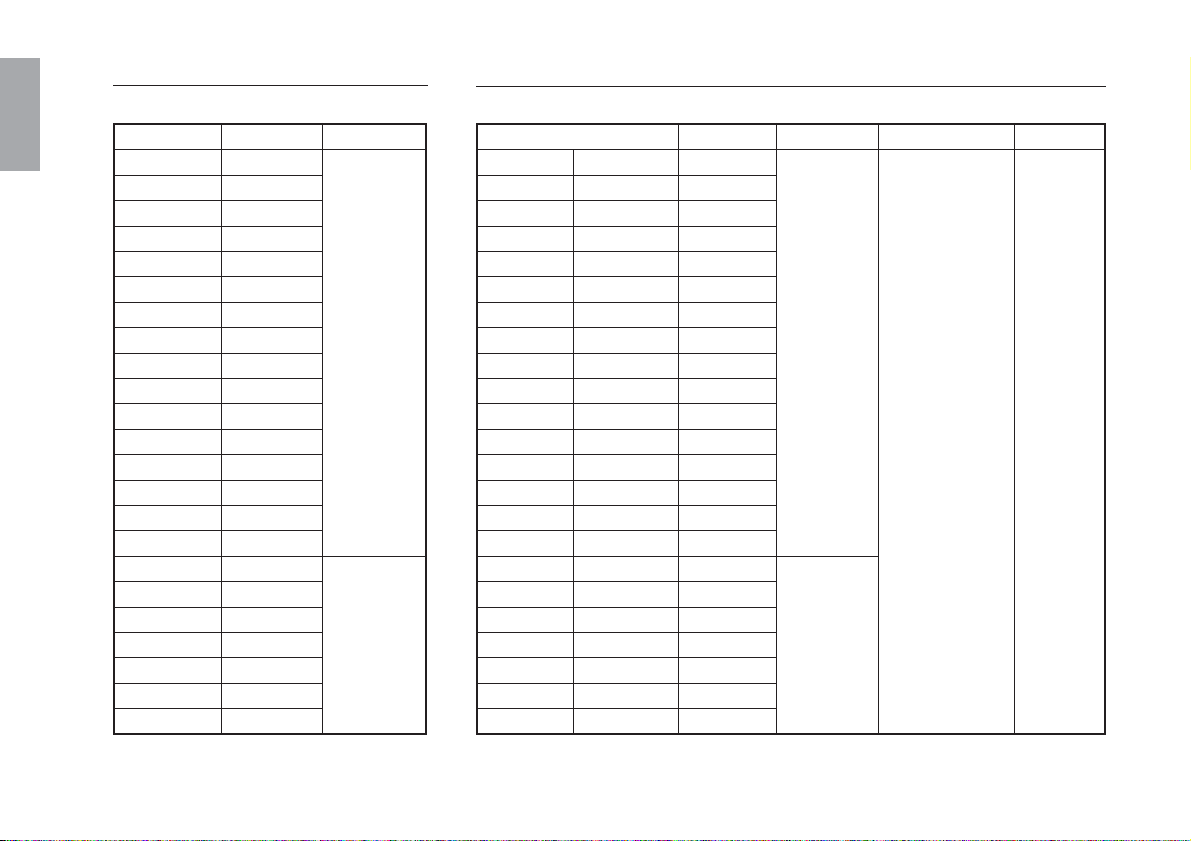

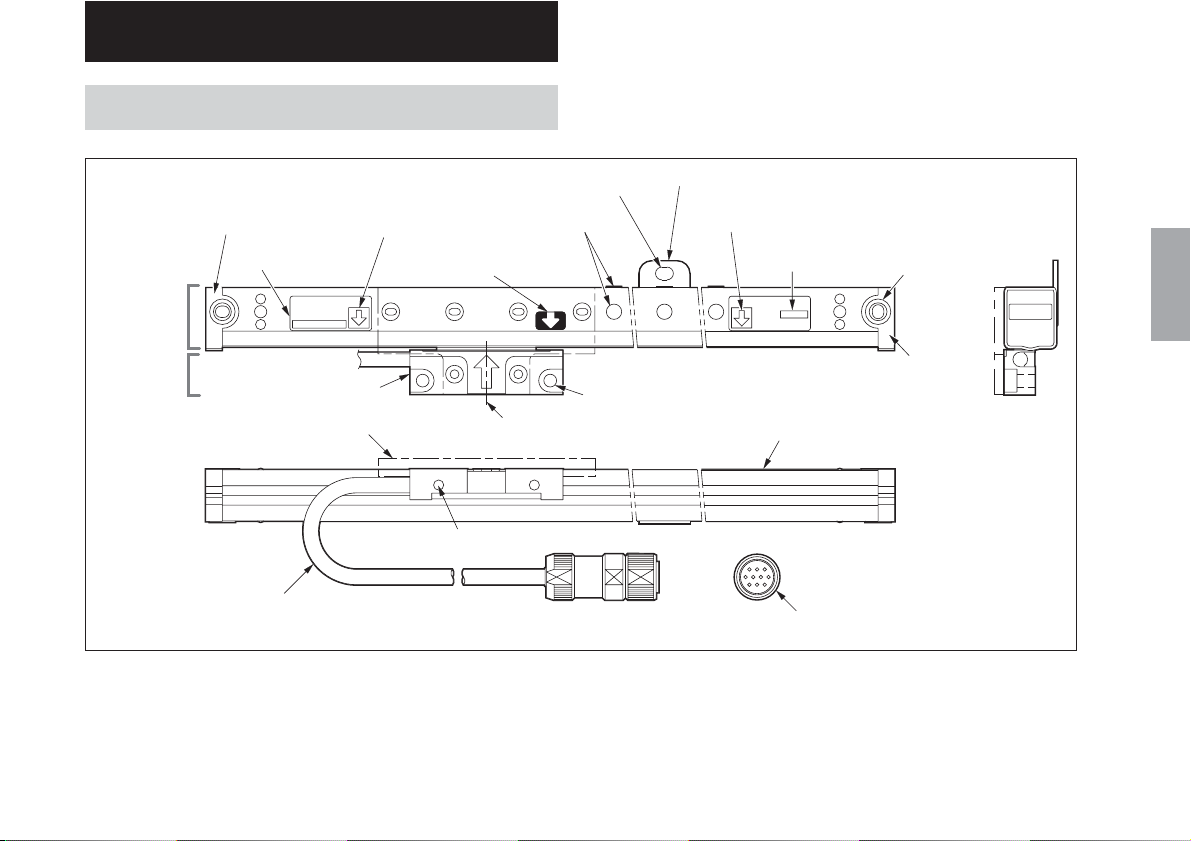

2. Name and Function of Each Part

2-1. Scale Unit

Center foot plate securing hole

Side cover L

Scale part

Slider part

Measuring length mark (left)

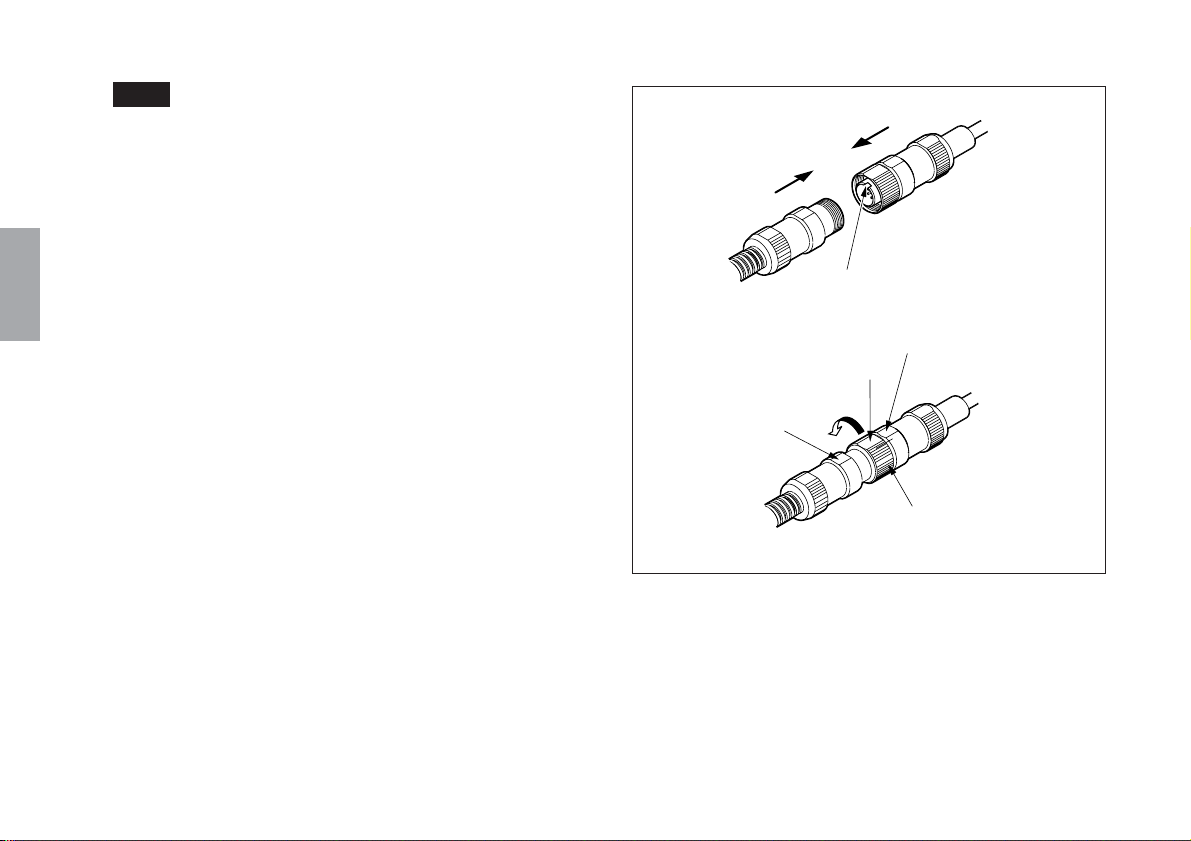

Model name

6

SR138−***R

Slider

1

Slider holder

Head cable

5

3

Reference point mark

Slider mounting hole (two holes)

1 Slider

This holds the detection head. When shipped, it is secured by

the slider holder.

Alignment mark

4

2

Slider mounting hole (two holes)

Slider center

Center foot plate

Measuring length mark (right)

3

Serial No./Reference

point indication

8

Serial No.

******

Scale unit

Round connector (male)

Scale

mounting hole

(two holes,

both ends)

Side cover R

2 Slider center

This indicates the mechanical center of the slider. It serves as

a reference when viewing the relative position with the

measuring length marks.

(E

English

) 5

English

3 Measuring length marks

These indicate the effective movement range over which

accuracy is assured with respect to the slider center. The

measuring length represents the length of the effective

movement range.

Note

When mounting and using the scale unit, be sure to operate

the unit within this range. Using the scale unit in excess of

the effective movement range may damage the unit.

4 Reference point mark

This mark indicates the position where the reference point

signal is output with respect to the slider center.

In the standard specifications, one reference point exists in

the center of the measuring length.

5 Slider holder

This secures the scale part and slider part, and should be

stored after removal.

6 Model name

This indicates the scale unit model name.

7 Center foot plate

This is mounted when the measuring length is 1050 mm/

41.3" or more, and should be secured when mounting the

scale unit.

8 Serial No./Reference point indication

This indicates the scale unit serial No. and the reference

point of the scale unit.

For the GB-ER series, it is the same as the combination No.

of the matching connection cable.

Note

In this scale system, the serial No. of the scale unit and the

combination No. of the connection cable (CH04 series) must

match when used in combination together.

6

(E)

1

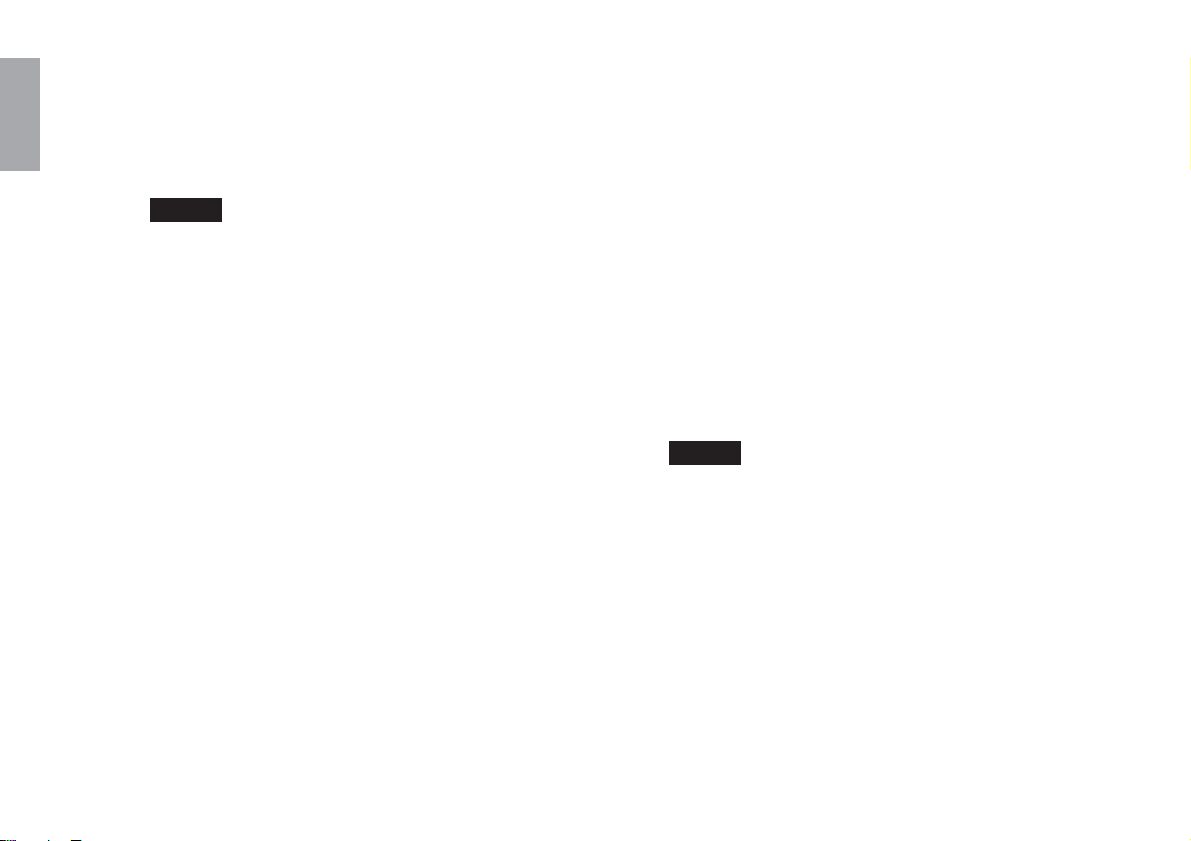

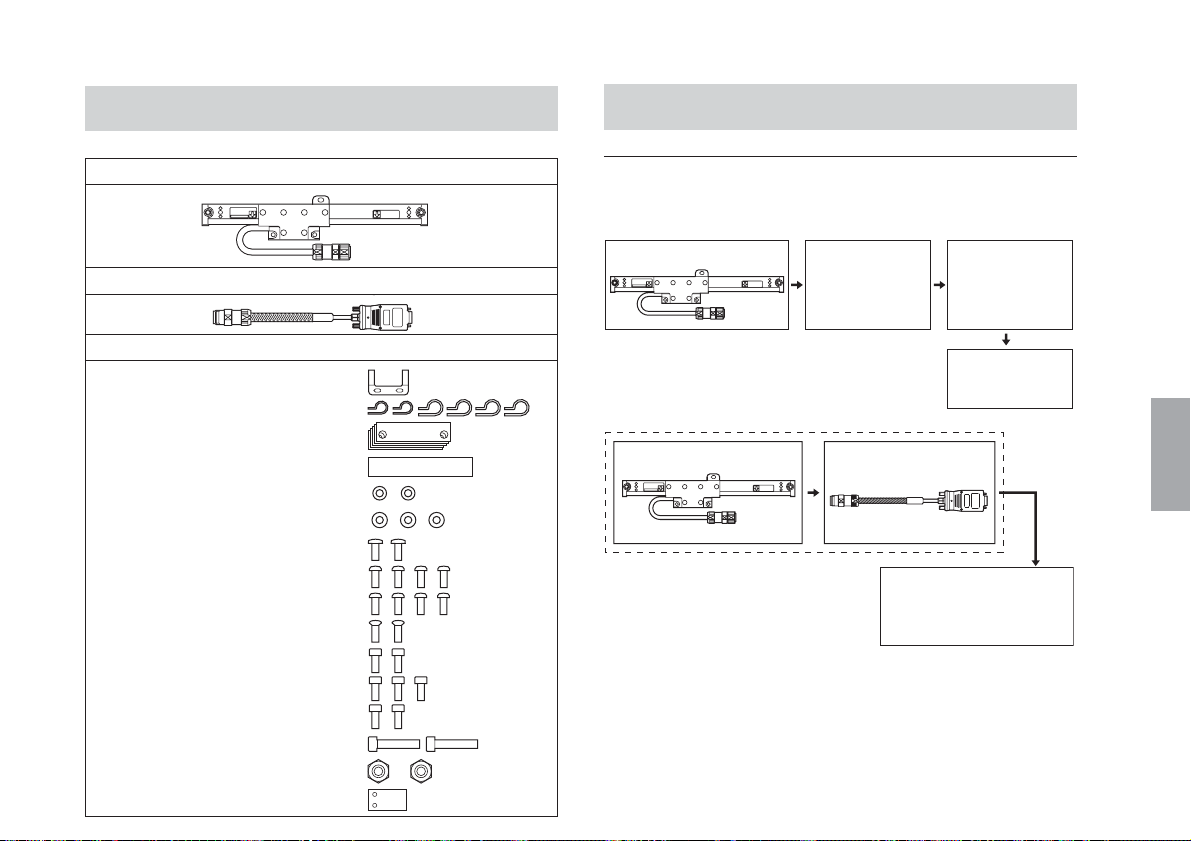

2-2. Connection Cable

CH04 : included only with the GB-ER series

Note

When procured separately, electrical adjustment is necessary.

Input/output connector

Interface unit

5

6

Model name

3

7

CH04-03C

Combination No.

Status lamp

1 Interface unit

This is connected to the rear panel of the counter unit.

The interface unit incorporates circuits that have been

electrically adjusted to the optical setting.

2 Conduit cable

This protects the internal cables.

3 Model name

This indicates the cable model name.

4 Round connector (female)

This connects with the round connector (male) on the scale

unit.

5 Input/output connector

Scale signals and reference point signals are output when

DC +5 V is supplied as the power source.

Conduit cable

2

8

Interface unit tap for fixing

Round connector

4

(female)

6 Combination No.

For the GB-ER series, this is the same as the serial No. of the

matching scale unit.

7 Status lamp

This is a lamp for checking the signals.

Lit green : Normal

Lit red : Error (Overspeed, cable disconnection, invalid

signal)

8 Interface unit tap for fixing

The interface unit can be secured in place using the supplied

fixing plate and screw. (M3 depth 3 mm)

(E

English

) 7

3. Mounting Method

English

3-1. Precautions before Mounting

Before mounting, be sure to always check “Mounting

Precautions”.

Disassembly prohibited

<Scale unit>

• Do not disassemble the scale unit. The accuracy cannot be

guaranteed if disassembled. The slider holder only can be

removed.

<Connection cable>

• The connection cable is already adjusted, and so do not

disassemble it. The accuracy cannot be guaranteed if

disassembled.

• The connection cable that is sold separately for the SR138R

must have its case removed for electrical adjustment. It should

not be disassembled for any other reason.

Do not apply excessive force.

• During operation, do not apply excessive force to the scale

unit. The scale unit is comprised of precision mechanical parts

and electromagnetic parts. Applying excessive force can

significantly reduce the performance and lifespan.

• During operation, do not apply excessive force to the interface

unit of the connection cable. Precision electrical parts are

installed and adjusted inside the interface unit. Applying

excessive force can significantly reduce the performance and

lifespan.

• When carrying, support both the scale part and slider part

together. Do not carry by holding the head cable, round

connectors, or other parts.

8

(E)

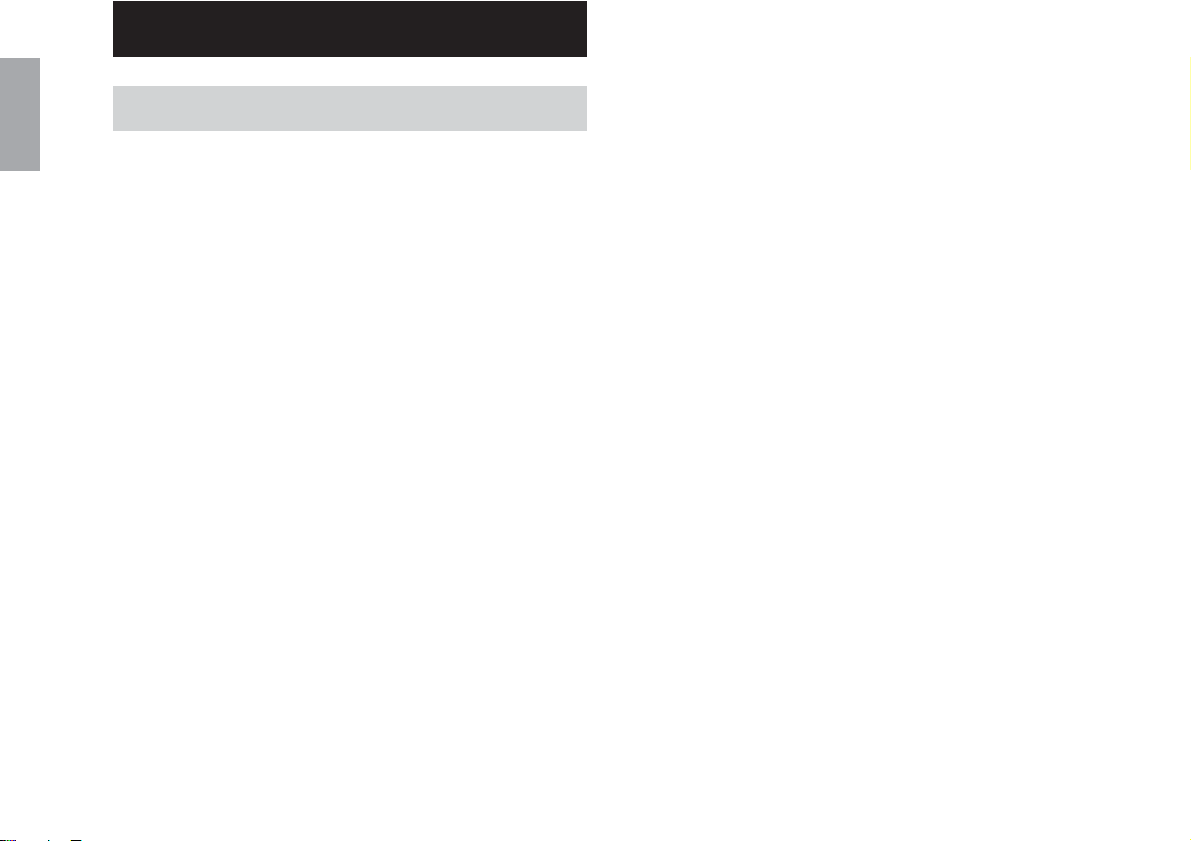

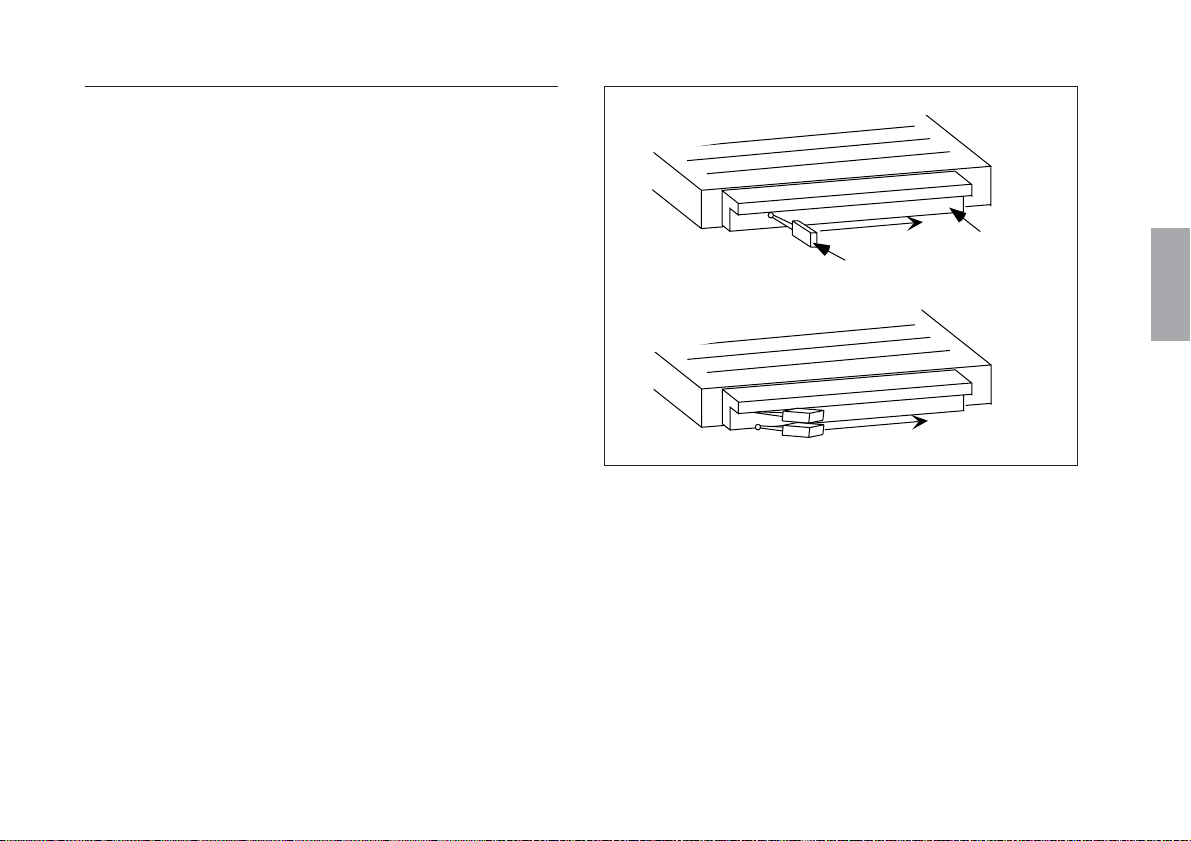

3-2. Mounting Precautions

Note

Be sure to ground the scale unit and the slider part to prevent

trouble to noise.

When mounting the scale unit vertically, be sure to mount the

slider part of the scale unit on the opposite side of a workpiece or

cutting tool.

3-2-1. Checking the mounting method

Check that the scale unit can be mounted in the relative position

shown in the Fig. 3-1.

* Do not mount the scale in any other direction since difficulties

with servicing and maintenance may arise.

(The mounting position A in particular is recommended:

cutting fluid and chips may be effectively kept out.)

(The mounting position B is possible only when cutting fluid

and chips will not get inside the scale.)

Recommended

A

Fig. 3-1 Scale unit mounting direction

B

Cutting tool

Fig. 3-2 Mounting the scale unit vertically

Slider part

Scale part

(E

English

) 9

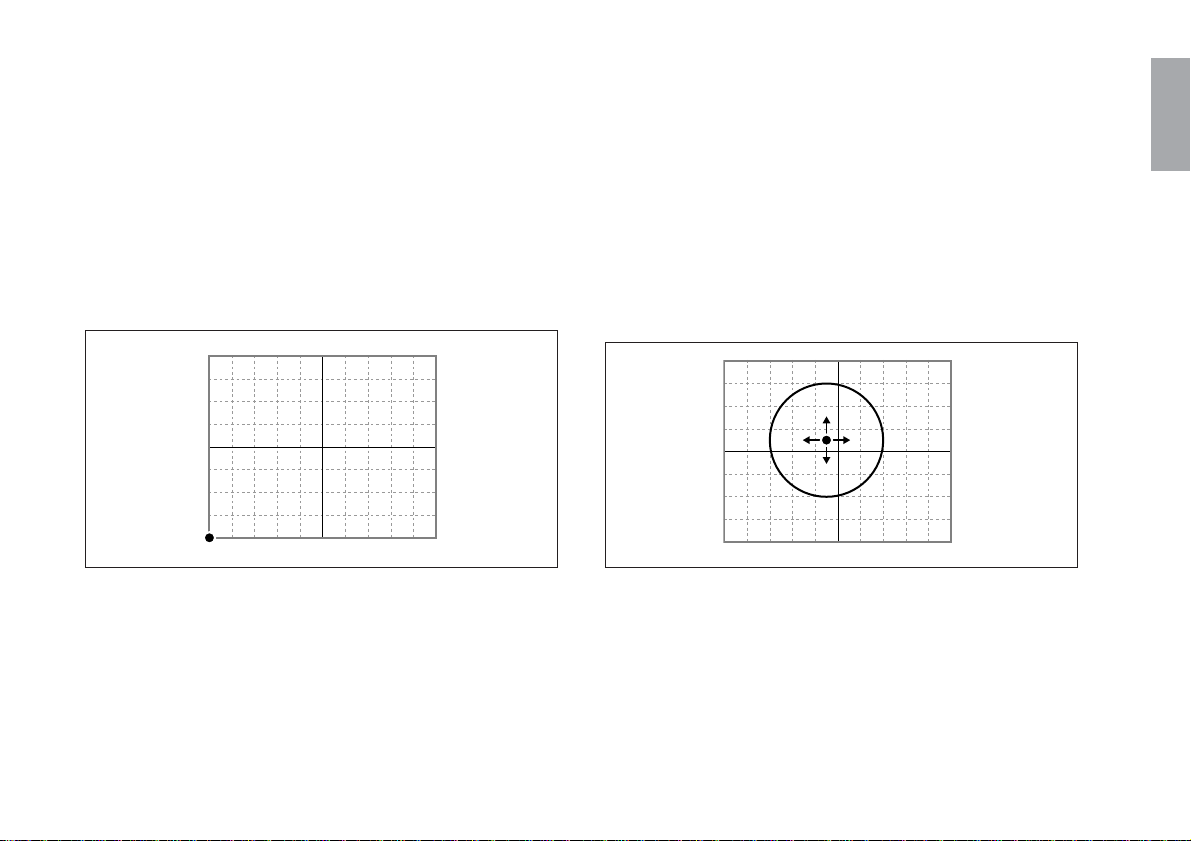

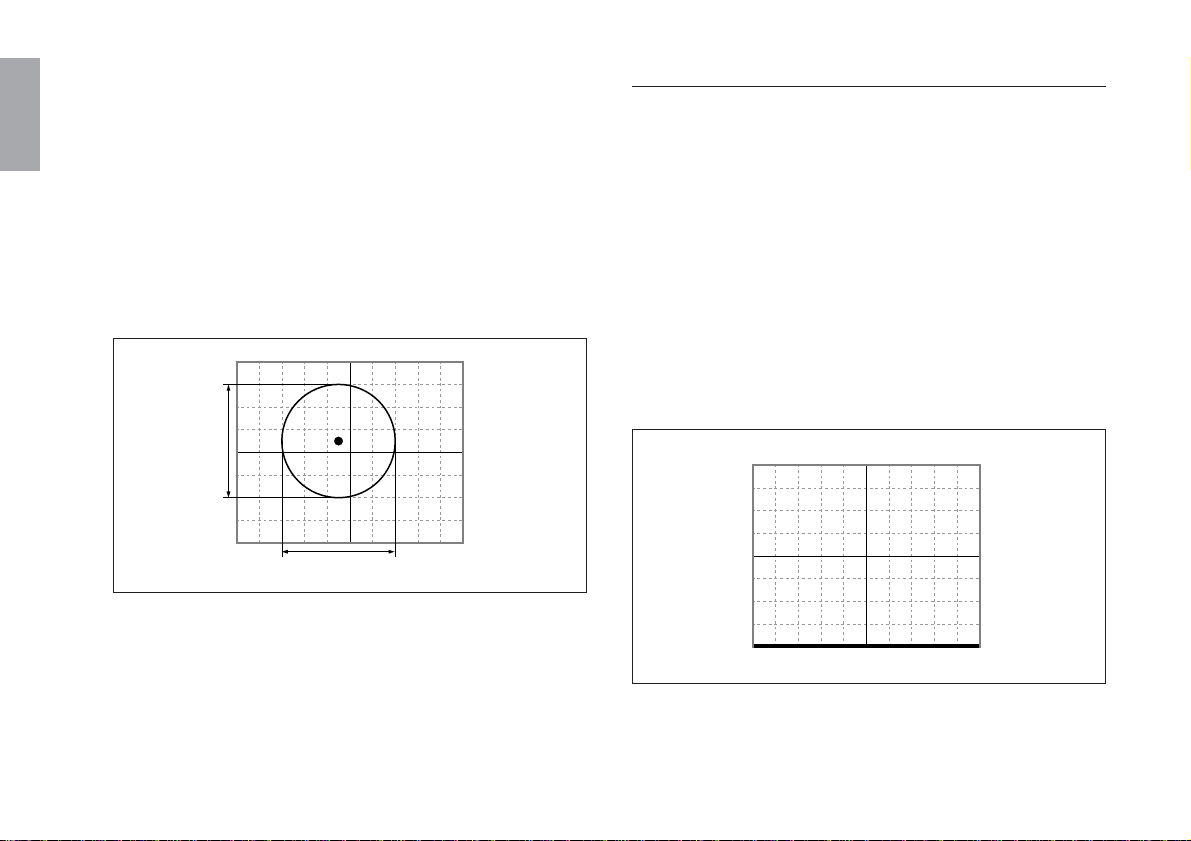

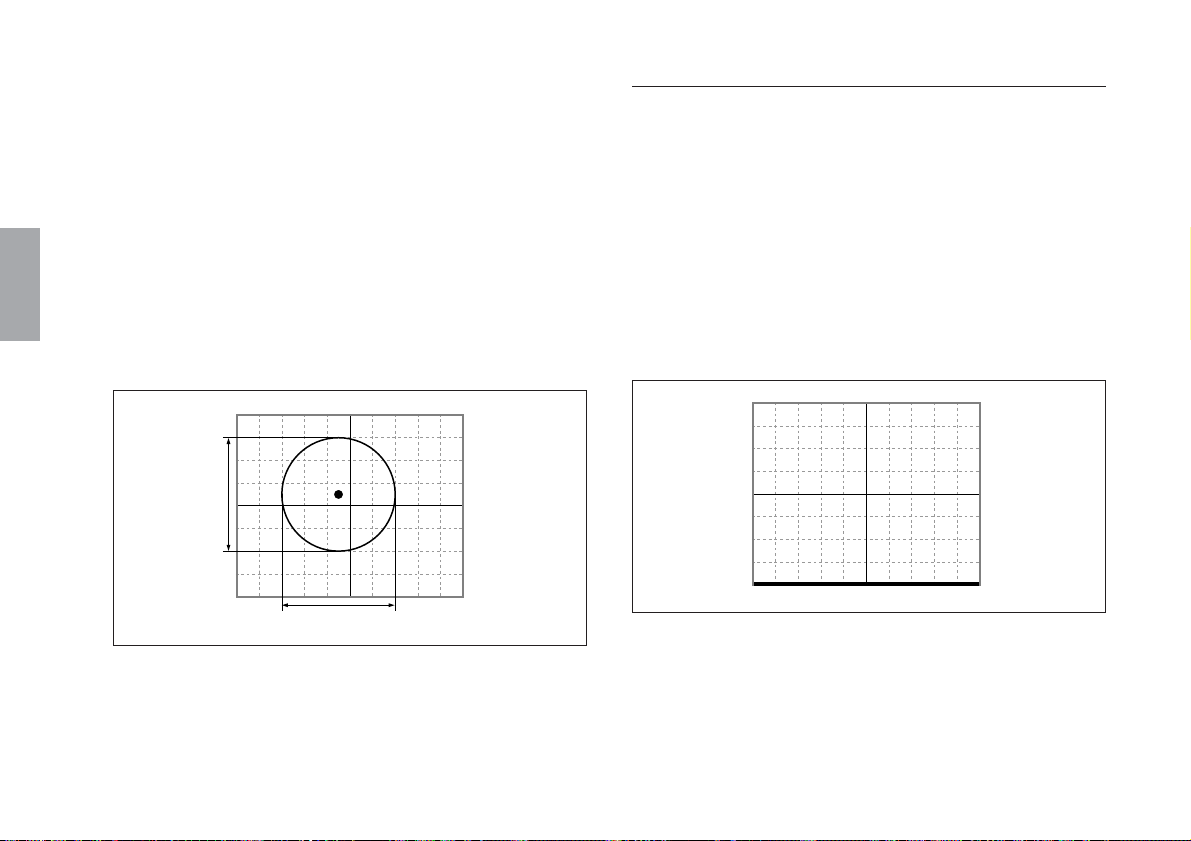

3-2-2. Setting the movement range

3-2-3. Protection of the head cable

English

Mount the scale unit in the operating range shown in Fig. 3-3.

• A leeway (equivalent to 7 mm/0.28" at the left and right ends of

the scale unit for a measuring length of up to 200 mm/7.8" and

15 mm/0.59" for a measuring length of up to 250 mm/9.8") is

provided for the slider movement. Be sure not to move the

slider part beyond this limit or the scale part may be damaged.

• Mechanical limiting devices (stoppers, etc.) are required for

sliders which move in excess of the effective movement range

of the scale unit. In these cases, be sure to take the appropriate

measures before mounting the scale unit.

Measuring

length mark

Slider center

Mount the scale so that the slider center moves within this range.

(Effective movement range)

Fig. 3-3 Movement range

Measuring

length mark

The head cable has an integrated design with the scale unit, and

so mount the scale unit while being careful not to put pressure on

the cable. Take care not to pull the head cable forcefully or bend

it repeatedly or the cable may break.

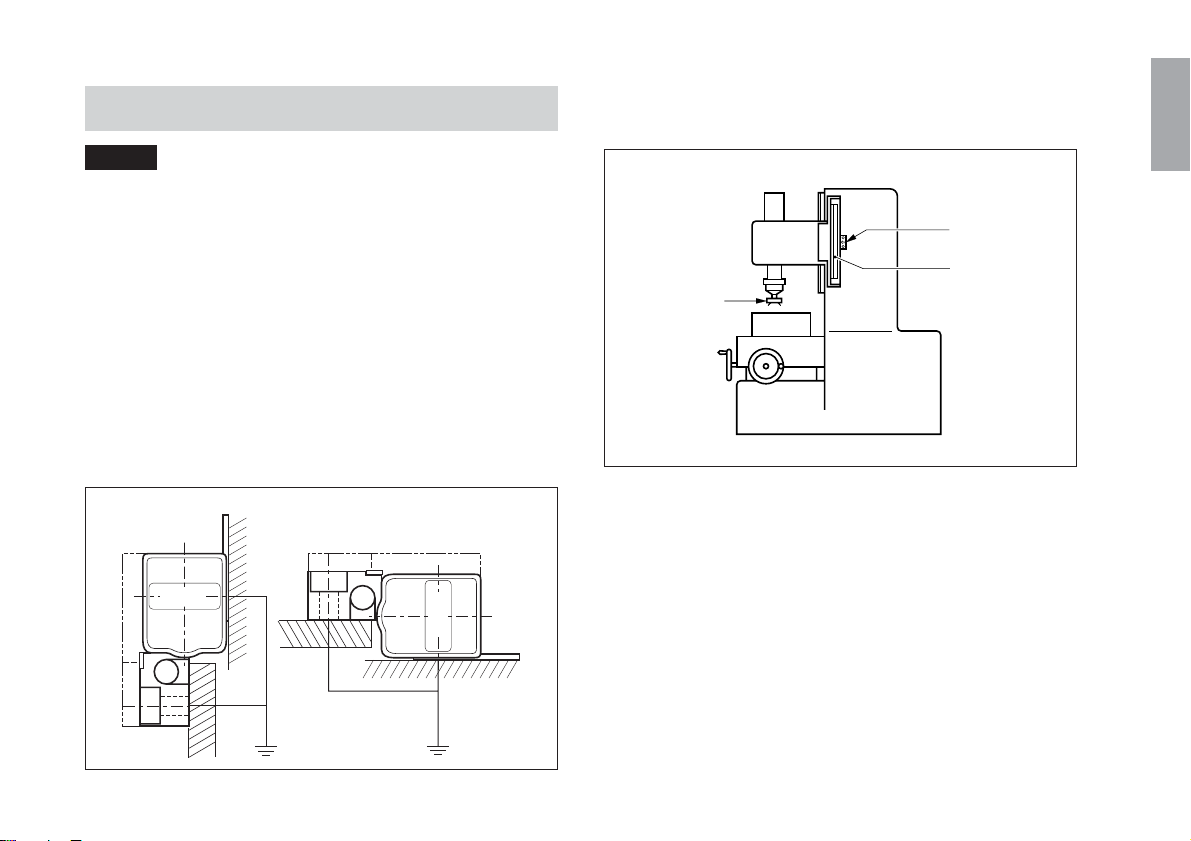

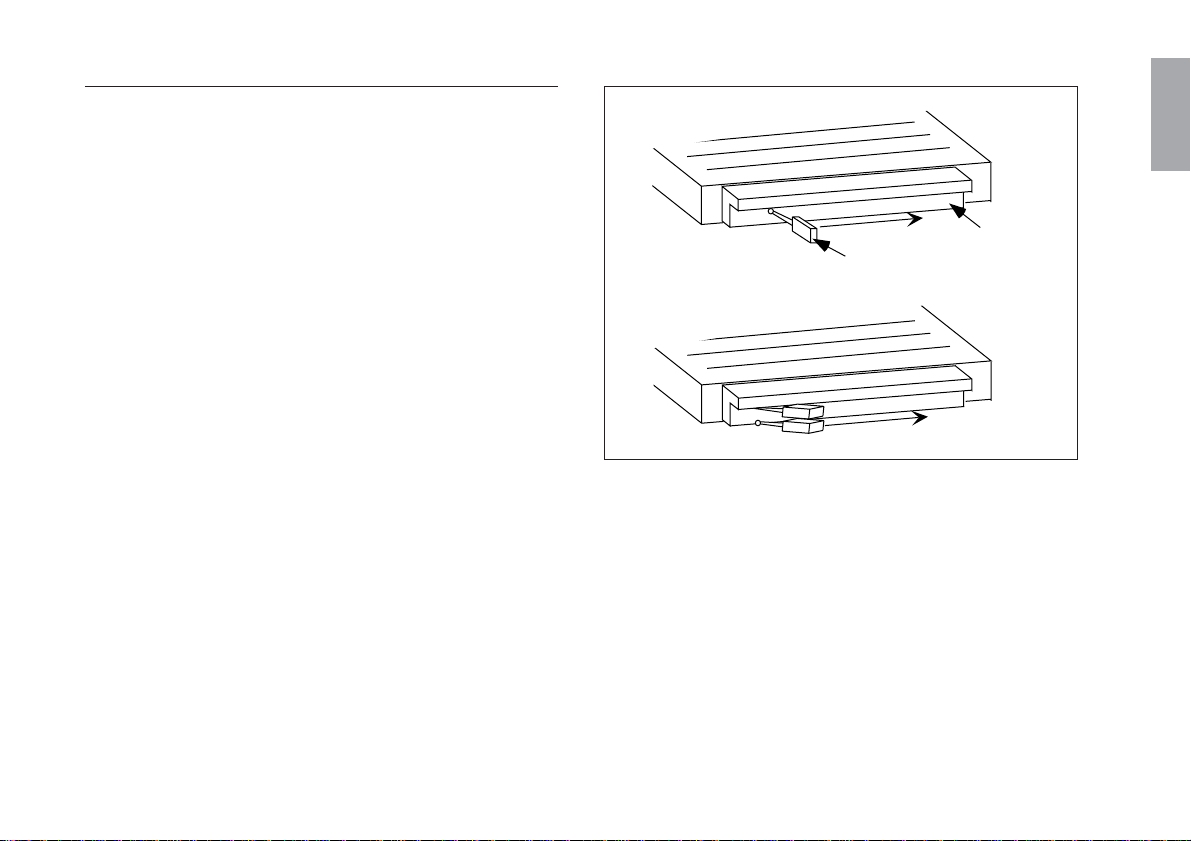

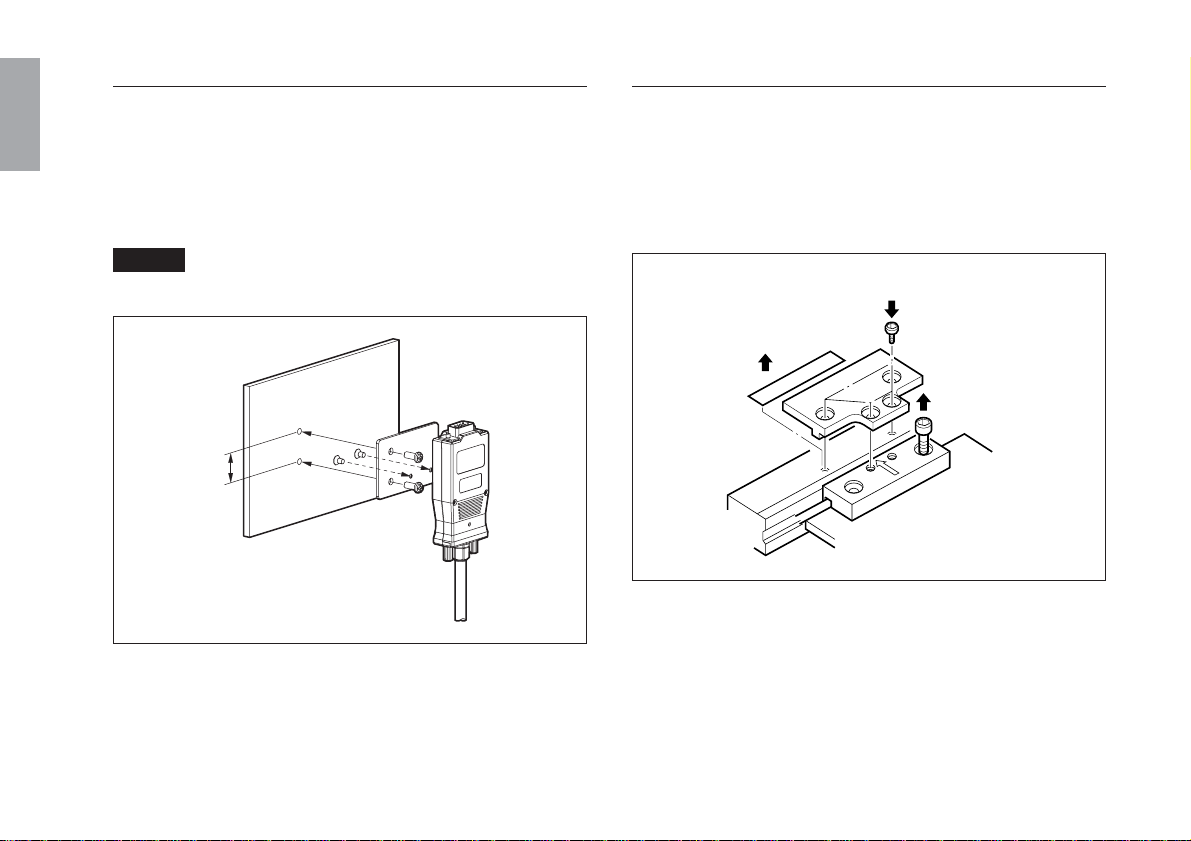

3-2-4. Mounting a protective cover

Where the scale unit is exposed to chips and cutting fluid, provide

a protective cover shown in Fig. 3-4 to maintain high

performance of the scale unit.

Fig. 3-4 Example of protective cover

10

(E)

3-3. Required Items for Mounting

Accessories (supplied)

Hexagonal socket head cap screw ............................................ 3

M4×10 for mounting scale part

(2 pcs. for scale of L<1000 mm/39")

Hexagonal socket head cap screw

M4×8 for mounting slider part ...................................... 2

M4×12 for mounting slider part .................................... 2

Pan head screw

M4×5 for cable clamp (small) ....................................... 2

M4×10 for cable clamp (large) ...................................... 4

M4×5 for mounting interface unit ................................. 2

M3×5 for mounting fixing plate .................................... 2

Plain washer (M) ...................................................................... 3

with 4 mm dia. hole for mounting scale part

(2 pcs. for scale of L<1000 mm/39")

Plain washer (S) ........................................................................ 2

with 4 mm dia. hole for mounting slider part

Cable clamp for mounting conduit cable (large) ..................... 4

Screening label ......................................................................... 1

for concealing the screw holes after the slider holder

has been removed

Hexagonal socket head cap screw ............................................ 2

M5×25 for mounting slider part

Hexagonal nut ........................................................................... 2

M5 for mounting slider part

Spacer ....................................................................................... 5

t=0.1 for mounting slider part

Clamp for mounting round connectors .................................... 1

Binding pan head screw

M4×10 for mounting clamp........................................... 2

Cable clamp for securing head cable (small)........................... 2

Fixing plate for securing interface unit .................................... 1

Tools you need other than the supplied accessories.

Bracket for mounting scale part (for A, B surfaces) ........... 1 to 2

Bracket for mounting slider part (for C surface) ....................... 1

0.01 mm/0.0005" pick tester (or dial gauge) ....................... 1 to 2

Allen wrench for M2.6 (2 mm/0.07") type ................................ 1

Allen wrench for M4 (3 mm/0.11") type.................................... 1

Allen wrench for M5 (4 mm/0.15") type.................................... 1

Tap M4 ........................................................................................ 1

Drill ø3.2/0.126" dia ................................................................... 1

Electrical drill.............................................................................. 1

Liner, spacer t=0.05 to 0.2 mm/0.002 to 0.008" ................. Some

Phillips head screwdriver for M2.6 ............................................ 1

Adjustable spanner (small) ......................................................... 2

Note: L= measuring length

t= thickness

(E

English

) 11

English

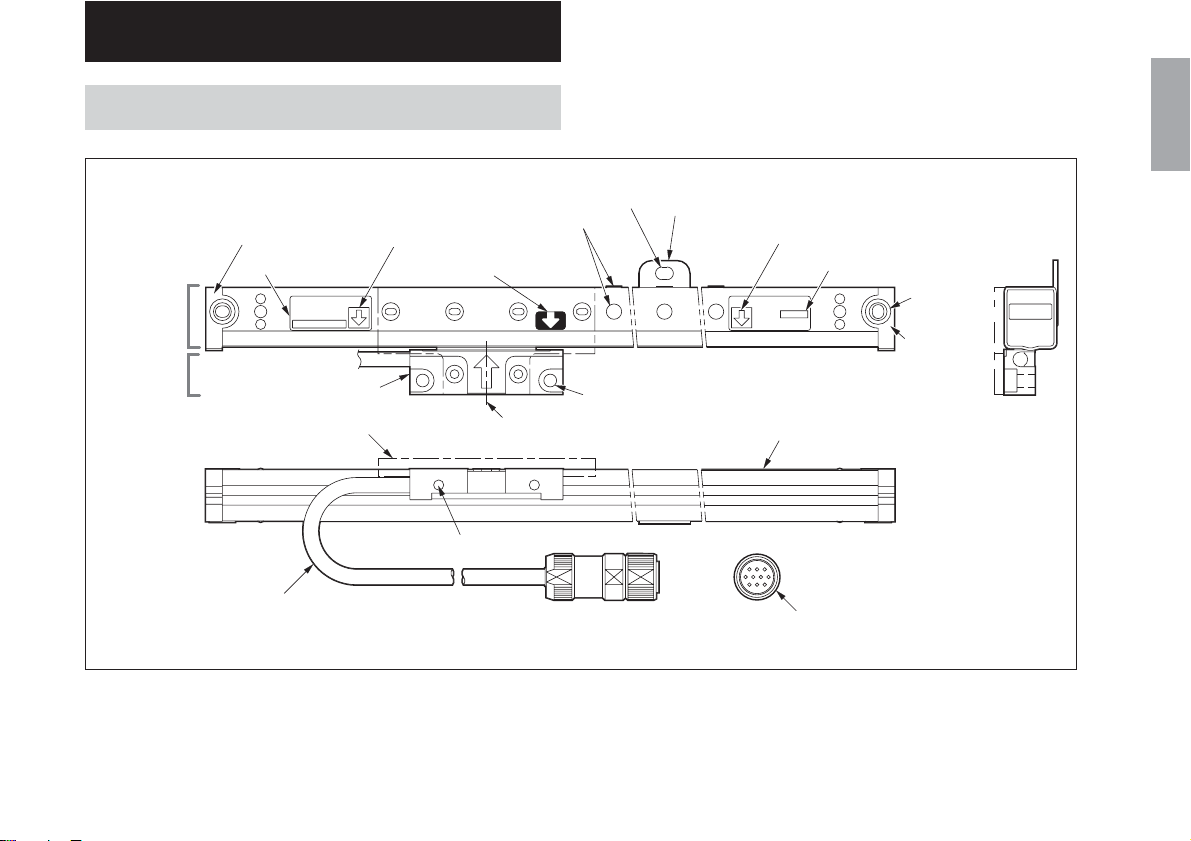

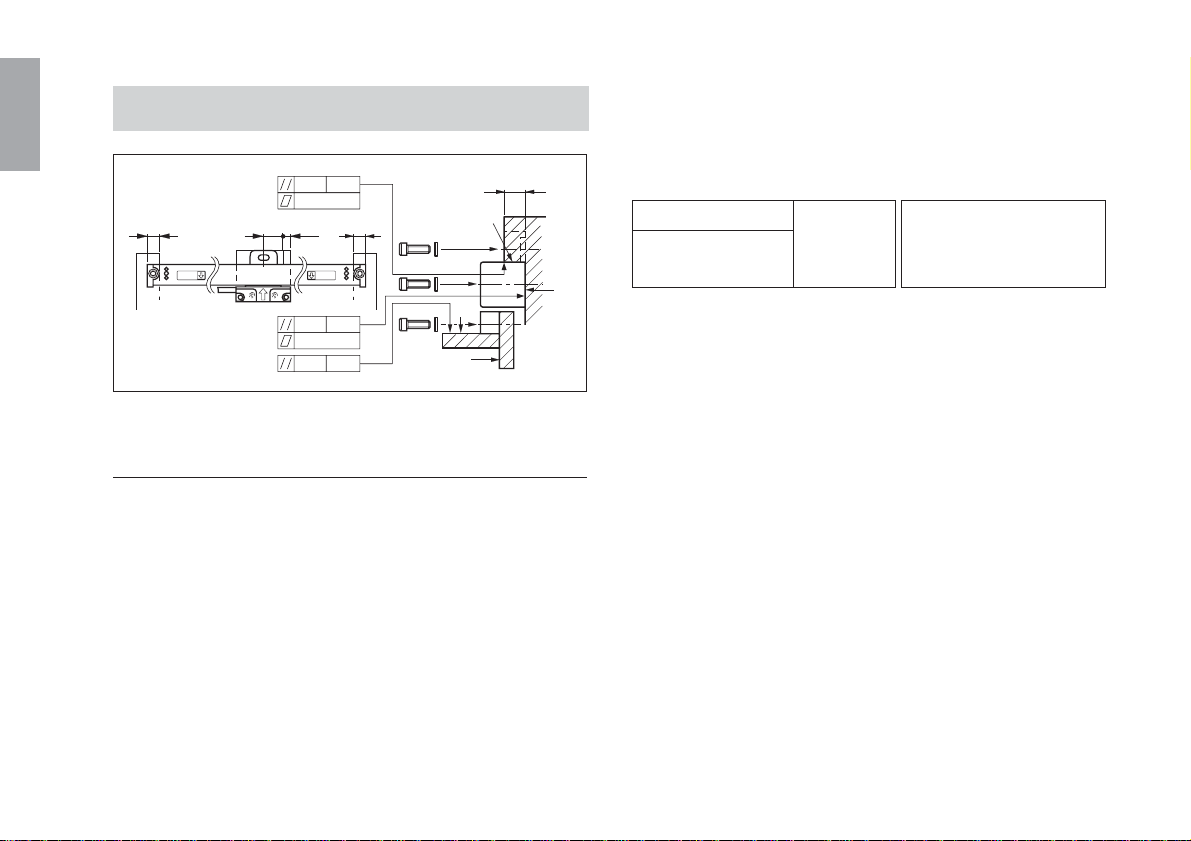

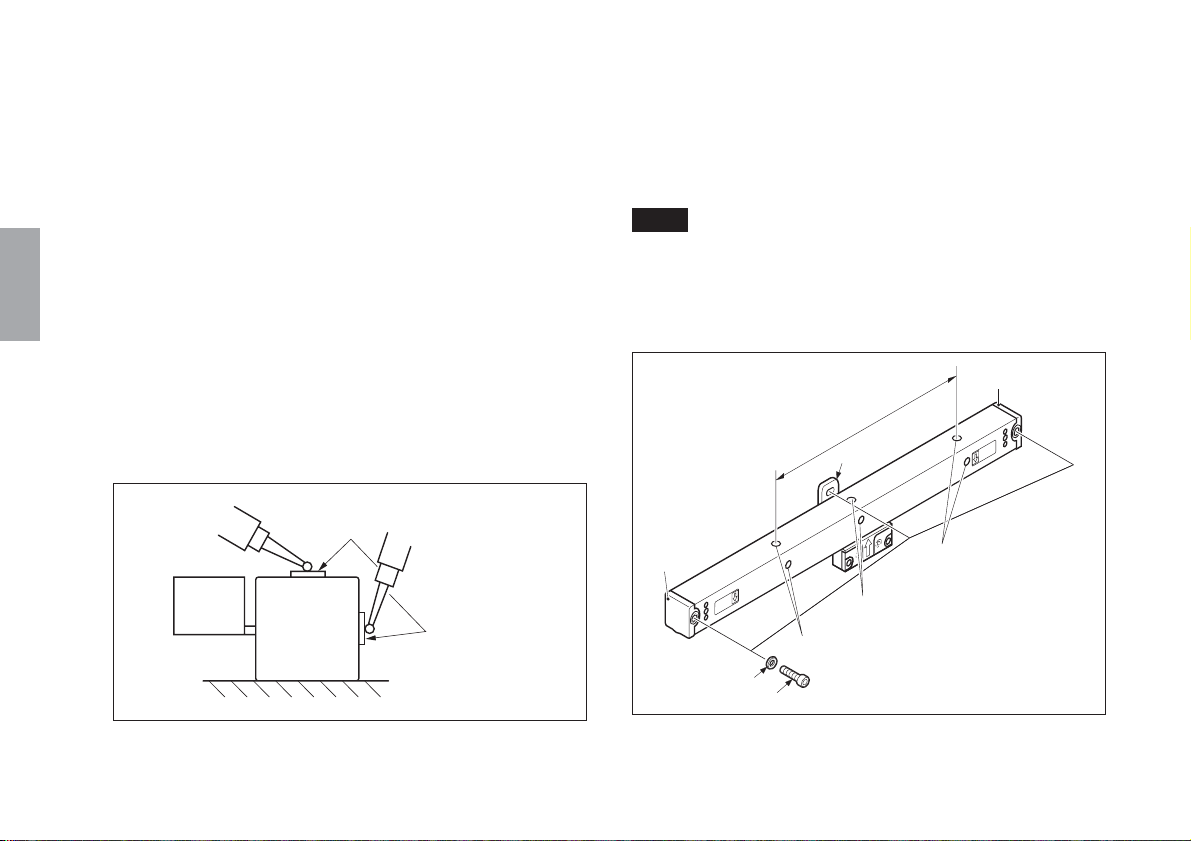

3-4. Mounting Dimensions

0.1 MG

0.1

25/0.98"

12/0.47" 25/0.98" 25/0.98"

0.1 MG

0.1

0.1 MG

Fig. 3-5 Mounting dimensions

<1> When the mounting surface already meets

parallelism and flatness requirements

When the scale mounting surface is finished and meets the

parallelism and flatness specifications below, just mount the

scale part.

Scale unit with measuring length of less than 1050 mm/

41.3" (no center foot plate)

Screws used / Tightening torque: Hexagonal socket head cap

screws M4×10 (2 pcs.), 2 plain washers (M) / 350 N·cm

8/0.31" or more

A

B

D

C

Scale unit with measuring length of 1050 mm/41.3" or

more (with center foot plate)

Screws used / Tightening torque: Hexagonal socket head cap

screws M4×10 (3 pcs.), 3 plain washers (M) / 350 N·cm

Flatness of A, B surfaces

Parallelism of A, B surfaces to

machine table movement

Side A: Scale part abutment side

Side B: Scale part installation side

within 0.1 mm/0.004"

Provide the range shown in Fig. 3-5 for surface A. The above

tolerances suppose no quick change in the surfaces and no

obstacle in the way between the right and left mounting surfaces.

12

(E)

<2> When the scale mounting surface is a

casting surface

Mount the scale part using mounting brackets

(1) When the scale mounting surface is a casting

surface and parallelism is not satisfied

Use mounting brackets and adjust so that the parallelism

specified in <1> may be satisfied.

The mounting brackets need only cover the length of at least

the feet of the scale part. However, the brackets must be long

enough for the parallelism of the right and left feet of the

scale part to be measurable.

If a problem occurs in the temperature tracking performance

with the machine, try to place the mounting brackets over the

entire length of the scale unit.

Parallelism measurement of side A

Mounting bracket

Pick tester

Parallelism measurement of side B

English

Fig. 3-6 Parallelism measurement of the mounting brackets

If the mounting bracket shape has an abutment surface,

adjust it so that the surface accuracy reading is within the

range shown in Section <1>. Use the procedure in (4) to

make adjustments if there is no abutment surface. Also, use

the procedure in (4) when the installation surface accuracy

cannot be obtained.

(E

) 13

English

(2) Checking of mounting position and tapping

Check that the parallelism for mounting scale part meets the

specifications, and then tap for M4 screws of 10 mm/0.39"

depth referring to the outline drawing on page 34.

(3) Mounting of scale part

Mount the scale part loosely with M4×10 hexagonal socket

head cap screws and plain washers (large), and leave it for 30

minutes for the scale part to reach ambient temperature.

Then firmly mount the scale.

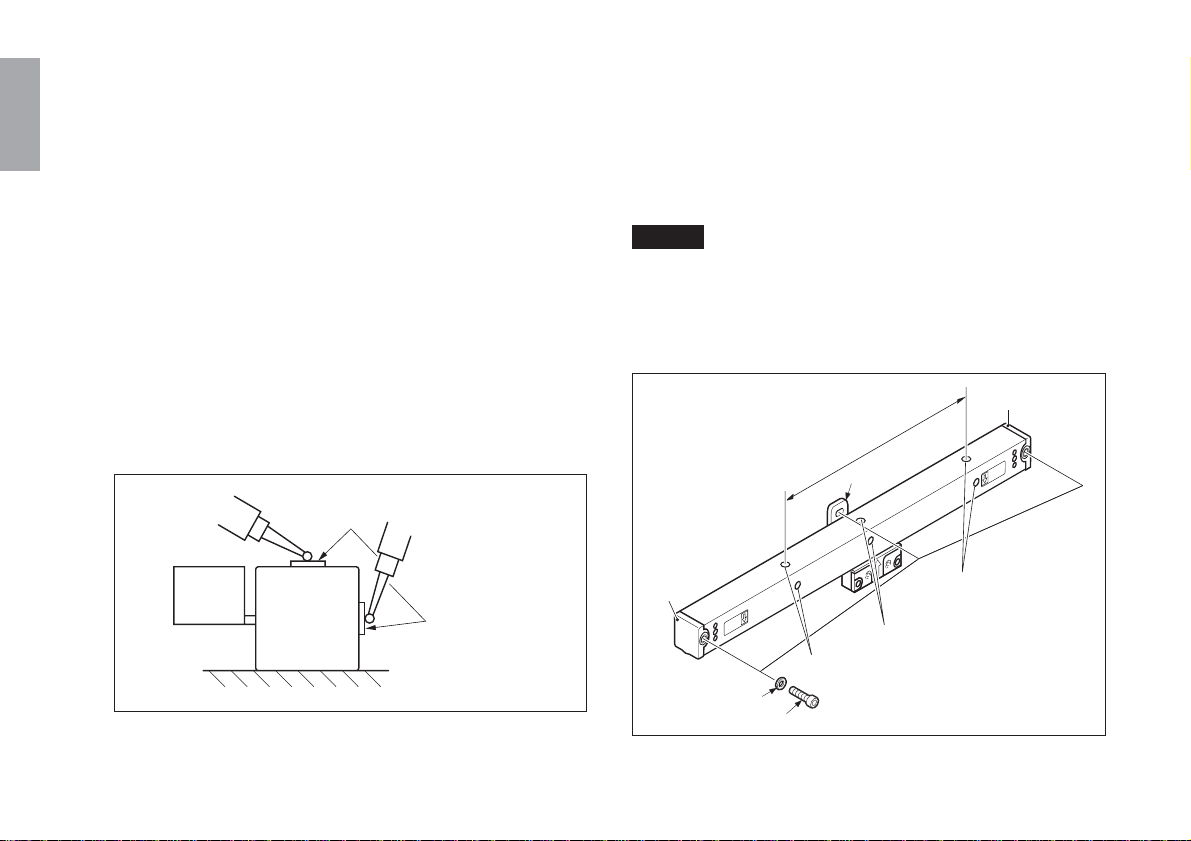

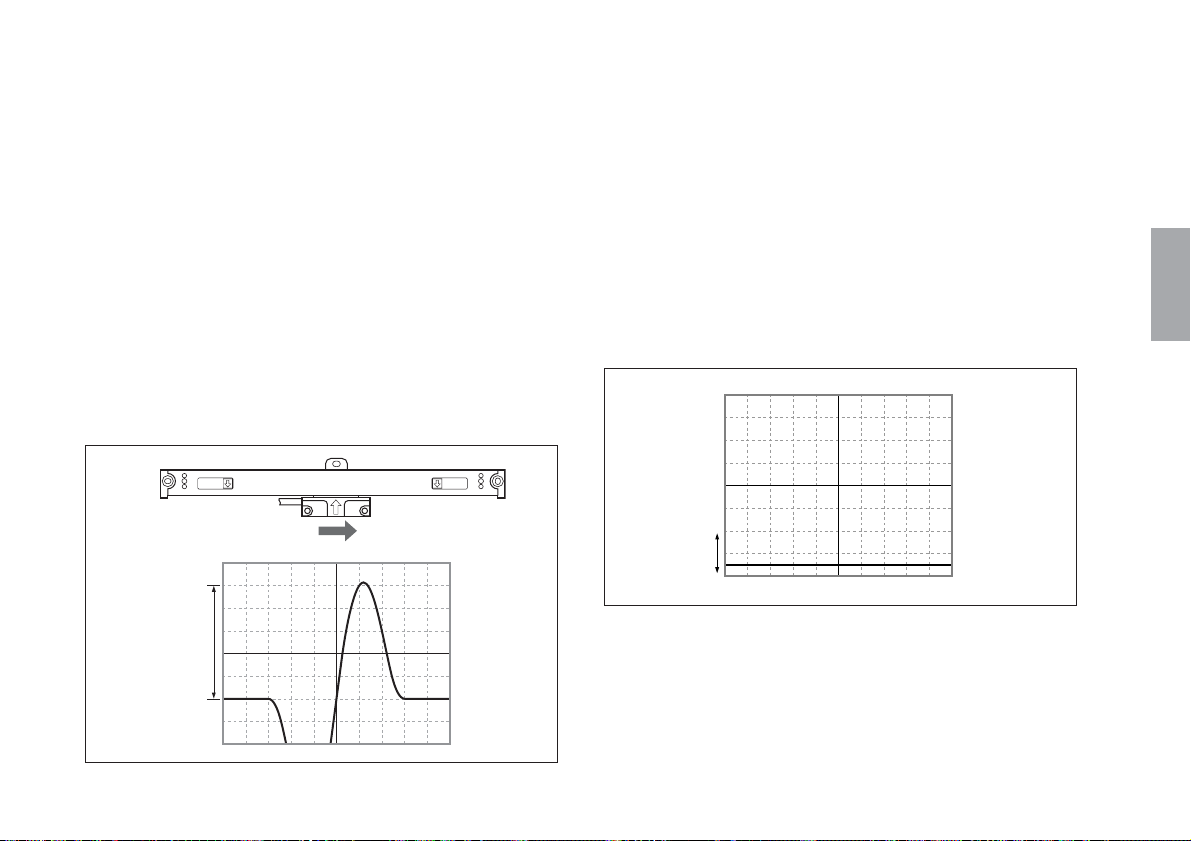

(4) Measuring parallelism of scale part with machine

table movement

Place a pick tester or dial gauge directly where the alignment

mark (Fig. 3-7 1) is positioned on the side of the scale part,

and check that the scale part is surely mounted parallel to the

machine table movement.

Adjust the parallelism of the length between the two alignment

marks to within 0.08 mm/0.003" and tighten the setscrews. For

the scale with a measuring length of 1050 mm/41.3" or more,

adjust the parallelisms of the lengths between the alignment mark

and those on both sides of it to within 0.08 mm/0.003".

Note

Since alignment marks are not provided on scales part with a

measuring length of 150 mm/5.9" or less, place the pick tester or

dial gauge on the scale part and ensure that the allowance at the

two ends of the machine travel is within 0.08 mm/0.003".

Foot

Parallelness allowance

within 0.08 mm/0.003"

Center foot plate

14

2

Fig. 3-7 Parallelness check of scale part and machine table movement

1

Alignment mark

(E)

Foot

Alignment marks

Alignment marks

Plain washer

(M)

M4×10

Fig. 3-8 Parallelism check by alignment marks

Alignment marks

(5) When the specified parallelism for the scale

mounting bracket is not obtained

Insert spacers below the feet and make adjustment by

placing a pick tester or dial gauge at 2 in Fig. 3-7 to adjust

the parallelism to within 0.08 mm/0.03" throughout the

length between may be obtained at the alignment marks.

For the scale unit with a measuring length of more than

1050 mm/41.3", make sure that the parallelism near the

center foot plate is also within 0.08 mm/0.003".

<3> Mounting the slider part

(1) When parallelism and flatness of the mounting

surface are already satisfied

When the mounting surface is finished and its parallelism

and flatness satisfy the specifications below, just mount the

slider part.

Screws used / Washers used: Hexagonal socket head cap

screws M4×12 (2 pcs.), 2 plain washers (S)

Tightening torque: 350 N·cm

Flatness of C and D surface

Parallelism of C and D surface to

machine table movement

Parallelism between B and C surfaces

Parallelism between B and D surfaces

Clearance between B and C surface

Side A : Scale part abutment surface

Side B : Scale part installation surface

Side C, D : Slider part installation surface

Move the machine table till the mounting surface comes just at

the slider part.

First use the supplied spacers to fill the gap between the

mounting surface and slider part, and then secure the slider part.

Then remove the screws which fix slider holder. In this process,

be careful not to make the slider part and the mounting bracket

contact with each other.

within 0.05 mm/0.02"

within

0.05 mm/60mm

(0.002"/2.36")

8.7 to 8.8 mm/

0.343 to 0.346"

(E

English

) 15

English

[When the supplied spacers (t=0.1 mm×5) are

unable to fill the gaps between the mounting

surface and the slider part]

Loosen the screws securing the slider part of the slider

holder, press the slider part against the scale part, and tighten

the bolts in this condition.

(2) When the gap between the B and C surfaces is set

to exactly 9 mm/0.35"

Loosen the screws securing the slider holder and move the

slider part by hand to align it with the brackets. Then secure

the slider part at the position of 42±0.2 mm/1.65"±0.008" as

shown in Fig. 3-9. Spacers are not required.

Note

Do not attempt to move the bracket side with the slider

holder secured, as the brackets may strike the slider part.

42±0.2/1.65"±0.008"

8.7 to 8.8/0.34" to 0.35"

(3) When the slider mounting surface has yet to meet

the specifications

When the mounting surface of the machine is a casting

surface, use a bracket.

Place the bracket on the underside of the slider part without

loosening the screws that hold the slider holder. Adjust the

position of the bracket and mount it with the supplied

M4×12 bolts.

Slider part

Slider holder

Scale part

Mounting bracket

Fig. 3-10

2-Plain washers

(small)

2-M4×12

(accessory)

4t to 6t/0.16" to 0.24"

17/0.67" or less

16

(E)

B

C

Fig. 3-9

(4) When the bracket is mounted on the top of the

slider part

Align the mounting bracket with the top surface of the slider

part, and adjust the bracket so that the height from the scale

mounting surface is brought to 21±0.1mm/0.83"±0.004".

Ensure that the mounting bracket used comes in a shape that

accommodates the projecting part of the slider holder. As

shown in Fig. 3-11, secure the slider part using two cap

screws (M5×25 hexagonal socket head cap screws) and two

nuts (M5).

Projecting part of the slider

(5) When the bracket is mounted on the rear of the

slider part

Align the slider part rear side and mounting bracket without

loosening the screw securing the slider holder, and then

secure using the supplied two screws M4×8 while adjusting

the bracket height.

42±0.2

4t/0.16"

1.65"±0.008"

English

2-ø5.5

ø0.22"

Mounting

bracket

37/1.46"

9

0.35"

7

0.27"

2-M5×25

(accessory)

6 to 8t

0.24" to 0.31"t

Fig. 3-11

21±0.1

0.83"±0.004"

2-M5 nuts

(accessory)

Slider part

Mounting bracket

15/0.59"

2-M4×8 (accessory)

Fig. 3-12

*The effective screw depth of the slider part is 4.5 mm.

If the mounting bracket has a thickness less than 4 mm,

use washers to adjust the thickness.

(E

) 17

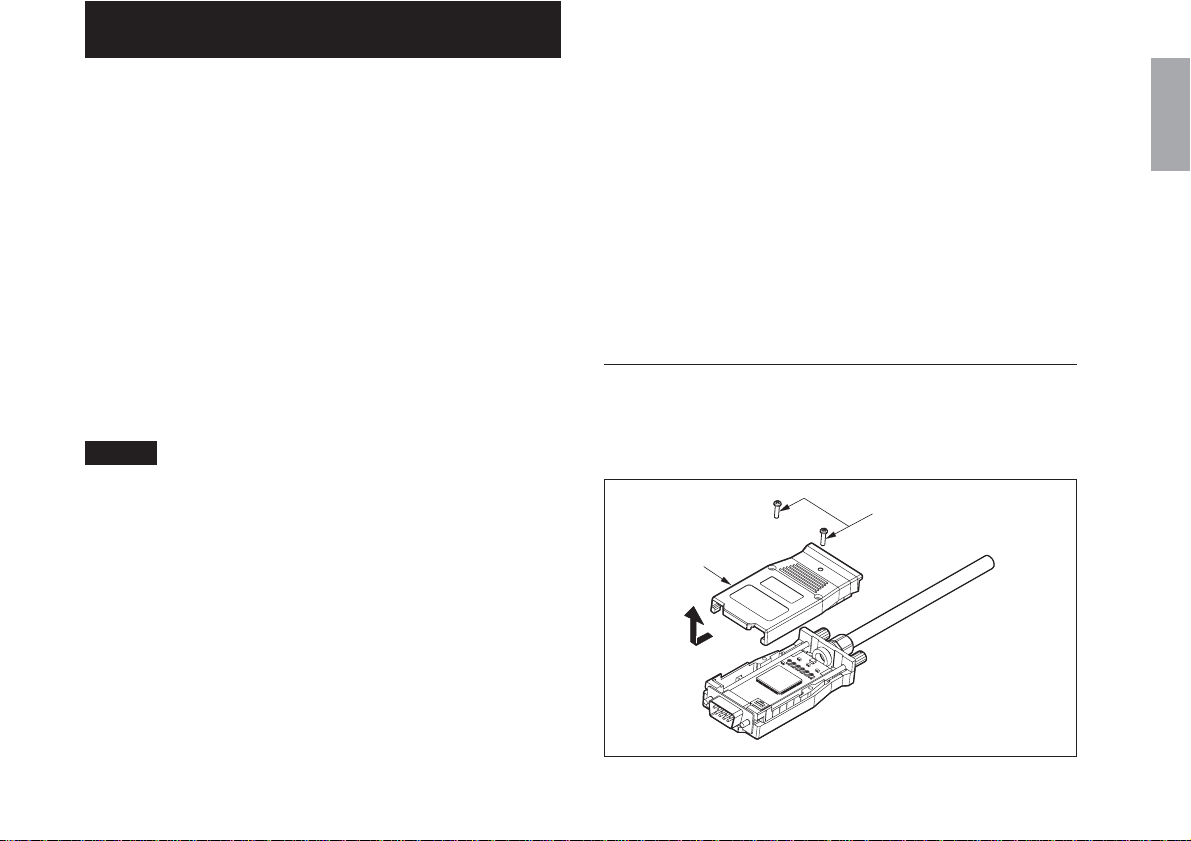

<4> Removal of the slider holder

<5> Checking the movement range

English

Remove the four M2.6 mounting screws for the slider holder and

then remove the slider holder itself.

• Be sure to adhere the screening label (accessory) to cover the

screw holes after removing the slider holder. If these holes are

not plugged, chips, cutting fluid or dust may enter and the

accuracy of the scale may be deteriorated. Use a ball-point pen

to enter the mounting date and name of the person responsible

on the label.

Remove the four M2.6 screws.

Slider holder

Adhere the screening label

(accessory).

Fig. 3-13 Removal of slider holder

Note

Keep slider holder and four M2.6 screws after the installation.

After mounting the scale part and slider part, be sure to move the

machine over the overall length of the scale to check that the

machine moves within the measuring length.

Remember that the scale unit may be damaged if the machine

moves beyond the movable range of the scale unit (measuring

length + leeway).

<6> Mounting the headcable

Fix the head cable with cable clamps so that they will not

interfere with moving parts of the machine.

Note

The head cable has an integrated design with the scale unit, and

so mount the scale unit while being careful not to put pressure on

the cable. Take care not to pull the head cable forcefully or bend

it repeatedly or the cable may break.

Secure the cable clamp using a M4×5

cable clamp screw (accessory).

18

(E)

Fig. 3-14

<7> Connecting cables

The distance between the SR138R and GB-ER series and the

connection cable can be extended by using an optional extension

cable (CE10 series).

Scale unit

Extension cable (CE10-**C)

Cable length

CE10-**C

44/1.73" 44/1.73"

ø18

ø0.70"

Round connector (female)

Note

The maximum total cable length when extended is 30 m/98.4 ft.

Connection cable (CH04-03C)

**

Unit : mm/inch

Model

CE10-01C

CE10-03C

CE10-05C

CE10-10C

ø9

ø0.35"

Round connector (male)

ø18

ø0.70"

English

Cable length

1 m/3.2 ft

3 m/9.8 ft

5 m/16.4 ft

10 m/32.8 ft

Fig. 3-15

(E

) 19

English

Note

• For the GB-ER series, be sure to connect the cable so that the

serial No. of the scale unit matches the combination No. of the

connection cable.

• When the SR138R series and optional connection cable (CH04

series) are procured together in the electrically adjusted

condition, connect the cable so that the serial No. of the scale

unit matches the combination No. of the connection cable in

the same manner as for the GB-ER series.

• When procuring the optional connection cable (CH04 series)

separately, be sure to perform the electrical adjustments.

1

2

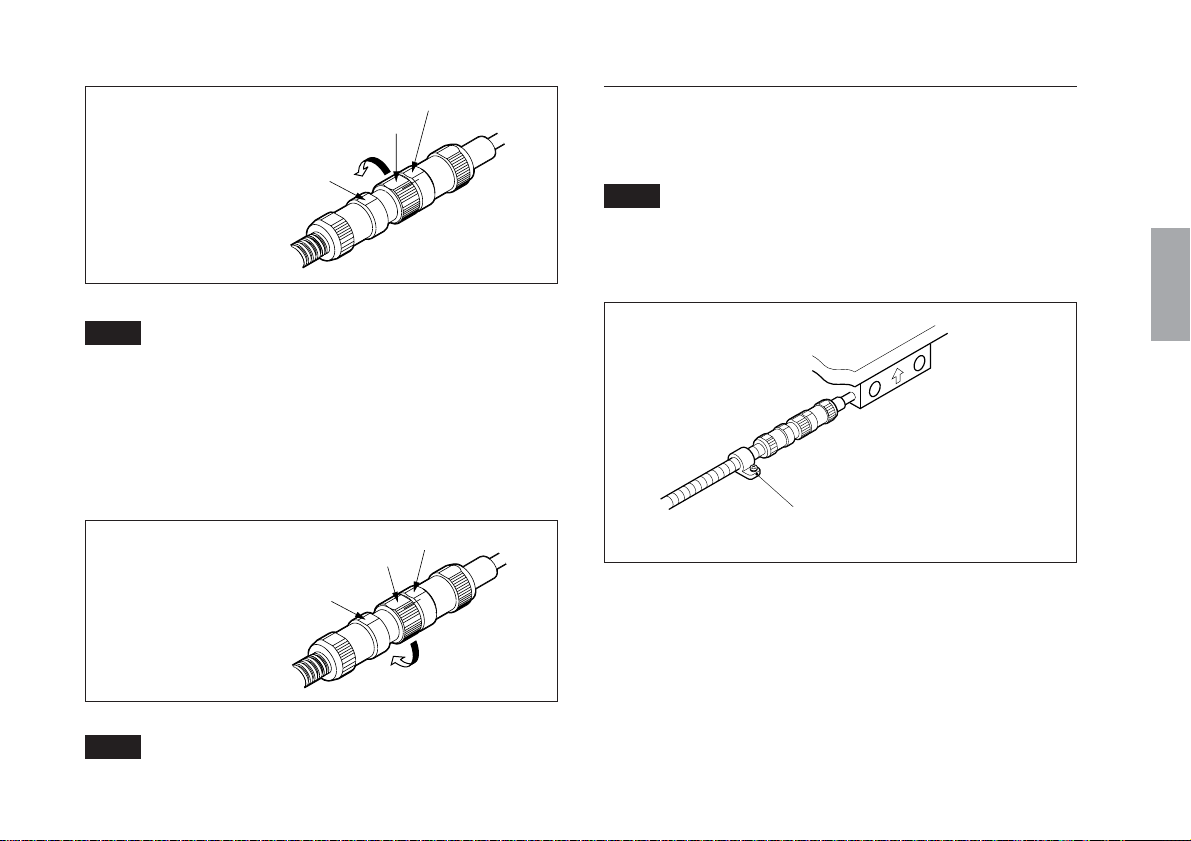

Female side

Rotate by hand

Part B

Male side

Notch matches

Part C

Part A

Male side

20

Female side

Coupling nut

Fig. 3-16

(E)

3 Use a spanner on

parts A and B to

turn in the direction

of the arrow.

Female side

3/4 of a

revolution

Part B

Fig. 3-17

Part A

Part C

Male side

Note

• Use a wrench or other tool to tighten the connectors to a torque

of 150 to 250 N·cm. Waterproof performance cannot be

guaranteed unless the connectors are tightened to the specified

torque.

• Do not tighten the connectors by attaching wrenches to parts A

and C.

<8> Mounting the conduit cable

Fix the conduit cable with cable clamps so that they will not

interfere with moving parts of the machine.

Note

Care should be taken at this time as it may be necessary to

provide the cable with some leeway with respect to the machine

operation.

English

To remove

Use a spanner on parts

A and C to turn in the

direction of the arrow.

Female side

Part C

Part A

Part B

Fig. 3-18

Male side

Note

Do not loosen the connectors by attaching wrenches to parts A

and B.

Secure the cable clamp using a M4×10 cable

clamp screw (accessory).

Fig. 3-19

(E

) 21

English

<9> Mounting the round connectors

Secure the connected male and female round connectors with the

accessory clamp.

Be sure to secure the connectors, as they are dangerous if loose.

1 Fit the connectors into the open side of the clamp.

2 Tighten the top and bottom edges of the clamp together

using the two accessory screws (+B M4×10).

3 Tighten the screws firmly until the top and bottom edges of

the clamp touch.

Then check that the connectors are secured firmly.

Clamp mounting dimensions and outer dimensions

6/0.23"

34/0.33"

4.4/0.17"

30/1.17"

54/2.11"

Clamp

Tighten with binding pan

head screws (+B M4×10).

22

The height dimension after mounting should be the same as the

outer diameter of the connectors.

(E)

Tighten until the

edges touch.

Fig. 3-20

<10> Connecting the interface unit to a counter

unit

When the connection cable must be electrically adjusted for the

SR138R series, see “4. Electrical Adjustment of the Connection

Cable Circuit”.

1 Check that the counter unit power is off. Then, connect the

interface unit of the connection cable with the connector 1-3

on the rear panel of counter unit.

Note

Check the scale unit mounting axis and counter unit insertion.

2 Secure the interface unit using the screws. (Tightening

torque: 60 N·cm)

Rear panel of counter unit

Fig. 3-21

Interface unit

English

(E

) 23

English

<11> Connecting the interface unit to a

controller

1 Use the screw (M3×5) to mount the supplied fixing plate to

the interface unit.

2 Use the supplied screw (M4×5) to secure 1 to the mounting

surface.

Note

Prepare two M4 tap holes on the mounting surface.

20/0.79"

Fig. 3-22

<12> Removal of the scale unit

When removing a mounted scale unit from the machine, be sure

to secure the slider part to the scale part with the slider holder.

Follow the numerical sequence.

2 Secure the slider part using four M2.6 cap screws.

1 Peel off the

screening plate.

3 Loosen screws and

remove them from

machine.

Fig. 3-23 Removing a scale unit

Securing the slider part to the scale part keeps the alignment of

the scale part and slider part after removal from the machine and

makes reinstallation easy.

24

(E)

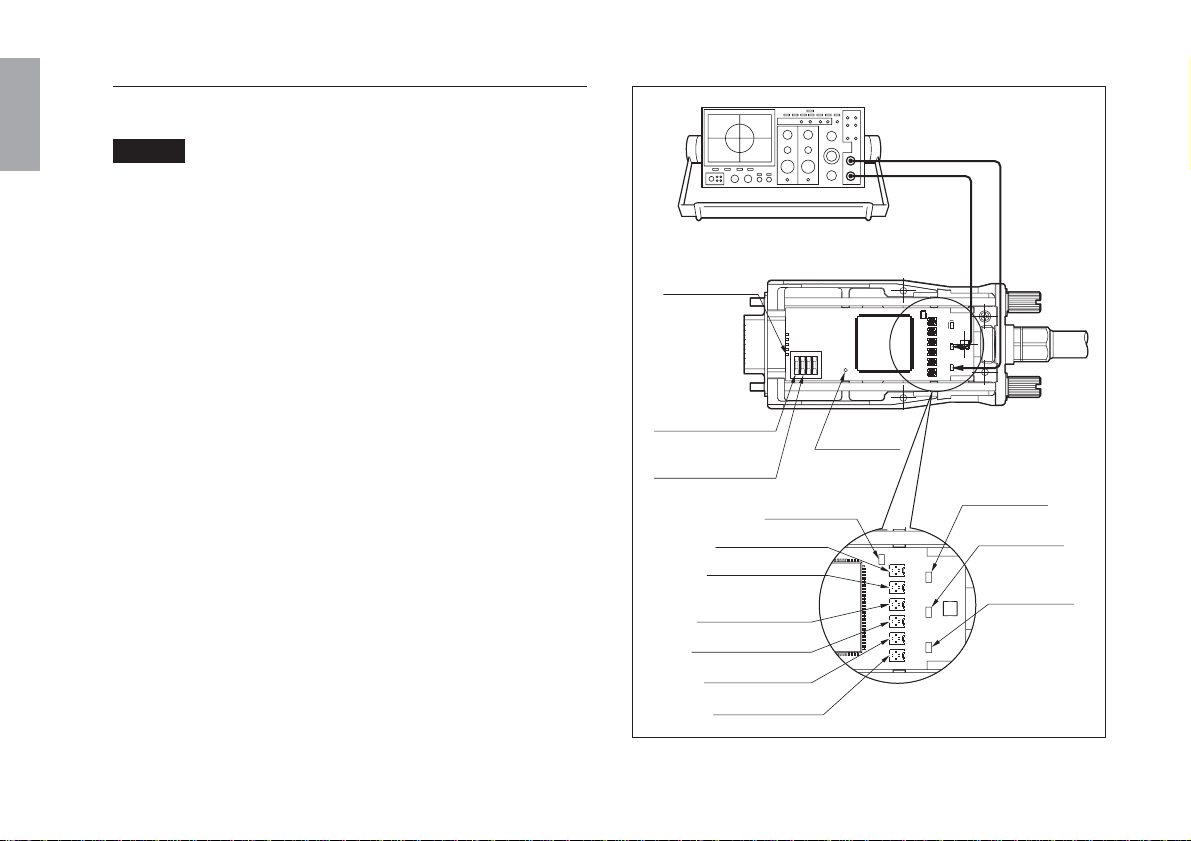

4.

Electrical Adjustment of the Connection Cable Circuit

(SR138R series only)