Magnescale LT10A-105, LT10A-105B, LT10A-105C, LT10A-205B, LT10A-205C Instruction Manual

...

取扱説明書/InstructionManual/Bedienungsanleitung

表示ユニット/ Counter Unit / Anzeigeeinheit

LT10A / LT11A Series

お買い上げいただき、ありがとうございます。

ご使用の前に、この取扱説明書を必ずお読みください。

ご使用に際しては、この取扱説明書どおりお使いください。

お読みになった後は、後日お役に立つこともございますので、必ず保管してください。

Read all the instructions in the manual carefully before use and strictly follow them.

Keep the manual for future references.

Lesen Sie die ganze Anleitung vor dem Betrieb aufmerksam durch und folgen Sie beim

Betrieb des Geräts den Anweisungen. Bewahren Sie diese Bedienungsanleitung zum

späteren Nachlesen griffbereit auf.

[For U.S.A. and Canada]

THIS CLASS A DIGITAL DEVICE COMPLIES

WITH PART15 OF THE FCC RULES AND THE

CANADIAN ICES-003. OPERATION IS SUBJECT

TO THE FOLLOWING TWO CONDITIONS.

(1) THIS DEVICE MAY NOT CAUSE HARMFUL

INTERFERENCE, AND

(2) THIS DEVICE MUST ACCEPT ANY

INTERFERENCE RECEIVED, INCLUDING

INTERFERENCE THAT MAY CAUSE

UNDERSIGNED OPERATION.

CET APPAREIL NUMÉRIQUE DE LA CLASSE A

EST CONFORME À LA NORME NMB-003 DU

CANADA.

(E) (1)

LT10A / LT11A Series

Safety Precautions

Magnescale Co., Ltd. products are designed in full consideration of safety. However,

improper handling during operation or installation is dangerous and may lead to fire, electric

shock or other accidents resulting in serious injury or death. In addition, these actions may

also worsen machine performance.

Therefore, be sure to observe the following safety precautions in order to prevent these types

of accidents, and to read these "Safety Precautions" before operating, installing, maintaining,

inspecting, repairing or otherwise working on this unit.

Warning Indication Meanings

The following indications are used throughout this manual, and their contents should be

understood before reading the text.

Warning

Failure to observe these precautions may lead to fire, electric shock or other accidents

resulting in serious injury or death.

Caution

Failure to observe these precautions may lead to electric shock or other accidents resulting in

injury or damage to surrounding objects.

Symbols Requiring Attention Symbols Prohibiting Actions

CAUTION ELECTRICAL DO NOT

SHOCK DISASSEMBLE

(2) (E)

LT10A / LT11A Series

Warning

•Do not use this unit with voltages other than the specified supply voltage as this may

result in fire or electric shock.

• Do not handle the I/O connector with wet hands as this may result in electric shock.

• Do not open the cover of the counter unit to disassemble or modify the unit, as this

may result in burns or injury. These actions may also damage the internal circuitry.

• This device operates with DC power supply. Absolutely do not connect an AC power

supply to the I/O connector as this may result in fire or electrical shock. Doing so may

also damage the internal circuitry.

Caution

• The unit does not have an explosion-proof structure. Therefore, do not use the unit in

an atmosphere charged with inflammable gases as this may result in fire.

•Be sure to turn off the power before connecting or disconnecting power and signal

connectors in order to prevent damage or misoperation.

• The unit does not have an earthquake-proof structure. Therefore, do not use the unit

in moving areas or areas exposed to strong shocks.

(E) i

LT10A / LT11A Series

Contents

1. Note to users ..............................................................1

1-1. General precautions............................................. 1

1-2. Handling instructions............................................ 1

1-3. Cautions on operation .......................................... 2

1-4. Instructions for connecting to the measuring

unit ....................................................................... 2

2. Summary .................................................................... 3

2-1. Features ............................................................... 3

2-2. System structure .................................................. 4

3. Connecting and installating ...................................... 5

3-1. Connecting the cables ......................................... 5

3-2. Installing the counter unit ..................................... 5

4. Name and function of each part ............................... 6

4-1. Front panel .......................................................... 6

4-2. Rear panel ........................................................... 8

4-3. Function description ............................................. 9

4-3-1. Reset key .................................................. 9

4-3-2. Preset functions ........................................9

4-3-3. Result evaluation .................................... 10

4-3-4. Peak-hold function ..................................10

4-3-5. Peak-hold pause function ....................... 11

4-3-6. Latch functions ....................................... 12

5. Operation ..................................................................13

5-1. Initial settings ..................................................... 13

5-1-1. Basic settings ......................................... 13

5-1-2. BCD model (only LT10A-105B/205B,

LT11A-101B/201B) ................................. 15

5-1-3. RS-232C model (only LT10A-105C/205C,

LT11A-101C/201C) ................................ 16

5-2. Various settings ................................................. 19

5-2-1. Setting the preset value .......................... 19

5-2-2. Setting the measuring mode ................... 20

5-2-3. Setting the comparator values ................21

5-2-4. Setting the key lock ................................ 22

6. I/O connector ............................................................ 23

6-1. Connector pin assignment ................................. 23

6-2. I/O circuitry (I/O connector area)........................ 25

6-3. Signal timing ...................................................... 26

7. BCD output (only BCD model) ................................ 27

7-1. Connector pin assignment ................................. 27

7-2. Signal timing ...................................................... 29

7-3. Interface cable ................................................... 30

7-4. BCD input/output circuits ................................... 31

ii (E)

LT10A / LT11A Series

8. RS-232C Interface (only RS-232C model) .............. 32

8-1. Terminal pin assignment .................................... 32

8-2. Connecting a personal computer ....................... 33

8-3. RS-232C Interface ............................................. 34

8-4. RS-TRG circuit ................................................... 34

8-5. Output ................................................................ 35

8-6. Commands......................................................... 36

9. Alarm display/output ............................................... 40

10. Specifications .......................................................... 41

10-1. LT10A/LT11A (Specifications) ......................... 41

10-2. Accessories ...................................................... 43

10-3. Options .............................................................43

10-4. Dimensions ...................................................... 44

11. Troubleshooting ...................................................... 45

(E) 1

LT10A / LT11A Series

1-1. General precautions

When using Magnescale Co., Ltd. products, observe the

following general precautions along with those given

specifically in this manual to ensure proper use of the

products.

• Before and during operations, be sure to check that our

products function properly.

• Provide adequate safety measures to prevent damage in

case our products should develop a malfunction.

• Use outside indicated specifications or purposes and

modification of our products will void any warranty of the

functions and performance as specified for our products.

• When using our products in combination with other

equipment, the functions and performance as noted in

this manual may not be attained, depending upon the

operating environmental conditions. Make a thorough

study of the compatibility in advance.

• Design and specifications are subject to change without

notice.

1. Note to users

1-2. Handling instructions

• Do not open the cover of this device or put your hand

inside. Otherwise the internal circuit may be broken by

static electricity.

• To prevent malfunctions caused by static electricity,

always turn off the power when touching other parts than

the key switches.

• Do not route the connecting cable through the same duct

as the machine power line.

• To prevent misoperation of surrounding equipment due

to noise emitted from this counter unit and vice versa,

connect the power cable in a twisted manner when

supplying DC power.

• When providing DC power, be sure to use within the

specified voltage range.

• Absolutely do not connect an AC power supply to the I/O

connector. Doing so may damage the internal circuits.

• Do not use connection prohibited I/O connector pins as

relay pins.

• When connecting the BCD connector, be sure to wire the

connector correctly.

Failure to do so may damage the internal circuits.

2 (E)

LT10A / LT11A Series

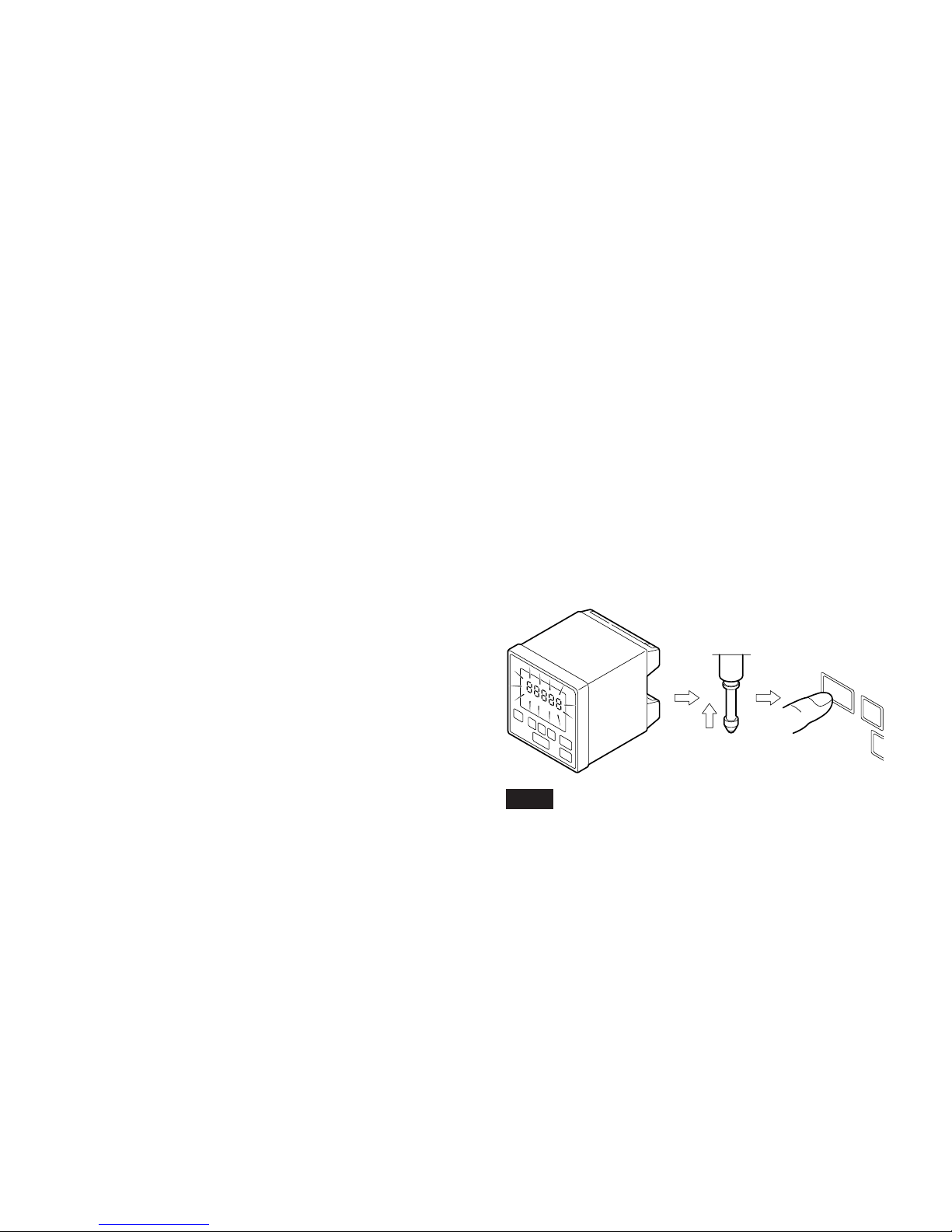

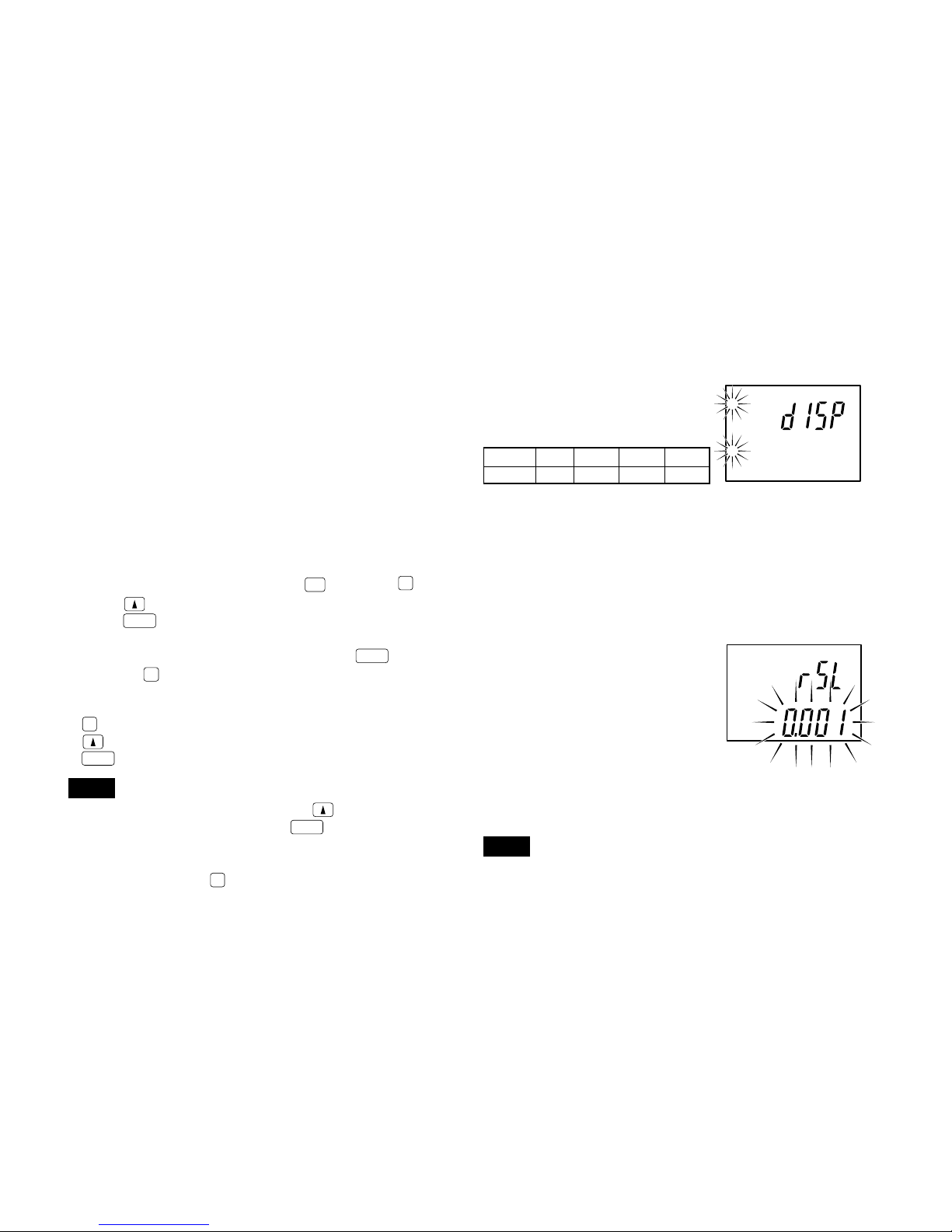

1-4. Instructions for connecting to

the measuring unit

• The LT10A/LT11A is a counter unit designed for the DT

series measuring unit.

• When the LT10A/LT11A is connected to a DT series and

turned on, the digits corresponding to the channel

connected may flash. This shows that initialization is

required to calibrate the new pairing of both device and

unit. Here you should move the measuring unit at least

1 mm, as shown in the figure, and then press the reset

key on the LT10A/LT11A corresponding to the channel.

The device will now return to its normal measuring state.

Note

Once this procedure has been carried out the digits will not

flash while the device is connected to that measuring unit,

even if the power is turned off.

• Place the counter unit more than 0.5 m (20") away from a

high voltage source, large current source, large power

relay, etc.

• For installation of the counter unit, avoid a location

exposed to chips, cutting oil, or machine oil. If

unavoidable, take adequate countermeasures.

• Do not put a vinyl cover directly over the counter unit or

put it in a closed container.

• The ambient temperature should be in the range of 0 °C

to 40 °C (32 °F to 104 ° F). Avoid exposure to direct

sunlight, hot air currents, or heated air.

1-3. Cautions on operation

Carry out the key operations or I/O (BCD, etc.) connections

and operations in line with the explanations given in the

appropriate sections. Failure to correctly operate this

device may result in a malfunction.

RESET

P

1 mm or more

(E) 3

LT10A / LT11A Series

2. Summary

2-1. Features

• Compact size suited to inclusion in systems.

DIN size (72 × 72 mm). Can be panel-mounted.

• Devices such as PLCs are connectable from the counter

unit.

Go/No Go output is standard to all models. Models

capable of BCD and/or RS-232C also outputs are

available.

• Resolution

LT10A series : 0.005 mm (0.0002")

LT11A series : 0.001 mm (0.0001")

• As well as the current value, maximum and minimum

values and peak-to-peak values can also be measured.

• Add/Sub calculation is standard feature (only for 2

channel models).

Can measure the widths or steps.

• Can carry out Go/No Go test on different lots. (BCD

output models.)

Four different upper and lower limits can be stored in

memory for the Go/No Go comparison.

• Power is compatible to DC 9 to 24V.

Provided via the power input connector.

Use a power cable less than 10 meters long.

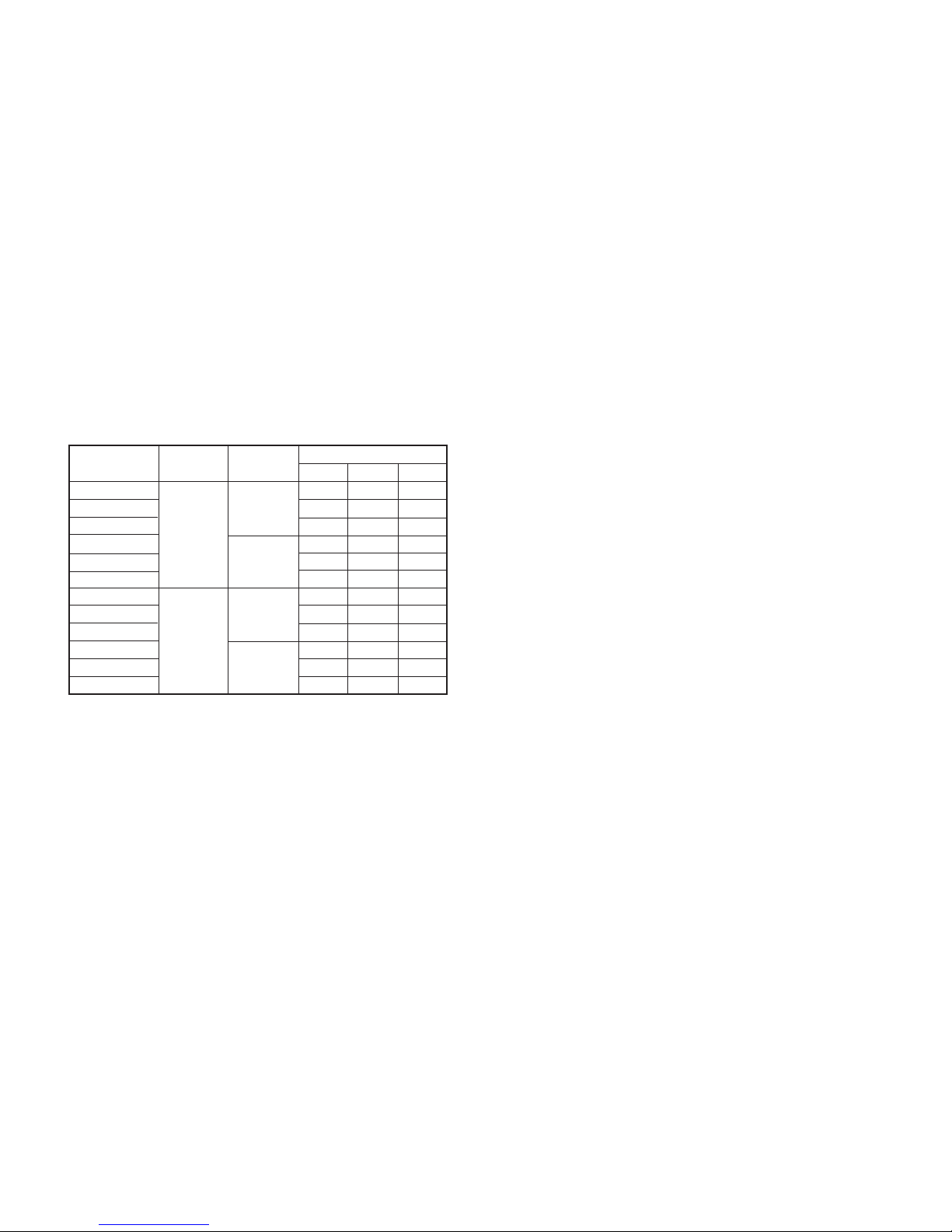

The counter unit LT10A/LT11A series is designed to be

incorporated into assembly lines or jigs, and to be used for

measuring components or Go/No Go.

Use in combination with a DT series measuring unit. Types

are available to suit various uses.

Number of

input channel

1

2

1

2

Model

LT10A-105

LT10A-105B

LT10A-105C

LT10A-205

LT10A-205B

LT10A-205C

LT11A-101

LT11A-101B

LT11A-101C

LT11A-201

LT11A-201B

LT11A-201C

Output

Go/No Go

◯◯

◯◯

◯

◯◯

◯◯

◯

◯◯

◯◯

◯

◯◯

◯◯

◯

◯◯

◯◯

◯

◯◯

◯◯

◯

◯◯

◯◯

◯

◯◯

◯◯

◯

◯◯

◯◯

◯

◯◯

◯◯

◯

◯◯

◯◯

◯

◯◯

◯◯

◯

RS-232C

◯◯

◯◯

◯

◯◯

◯◯

◯

◯◯

◯◯

◯

◯◯

◯◯

◯

BCD

◯◯

◯◯

◯

◯◯

◯◯

◯

◯◯

◯◯

◯

◯◯

◯◯

◯

Resolution

(mm)

0.005

0.001

4 (E)

LT10A / LT11A Series

RESET

SET

P

MODE COMP

A

B

RESET

A

RESET

B

SET

P

MODE COMP

RESET

SET

P

MODE COMP

A

B

RESET

A

RESET

B

SET

P

MODE COMP

RESET

SET

P

MODE COMP

A

B

RESET

A

RESET

B

SET

P

MODE COMP

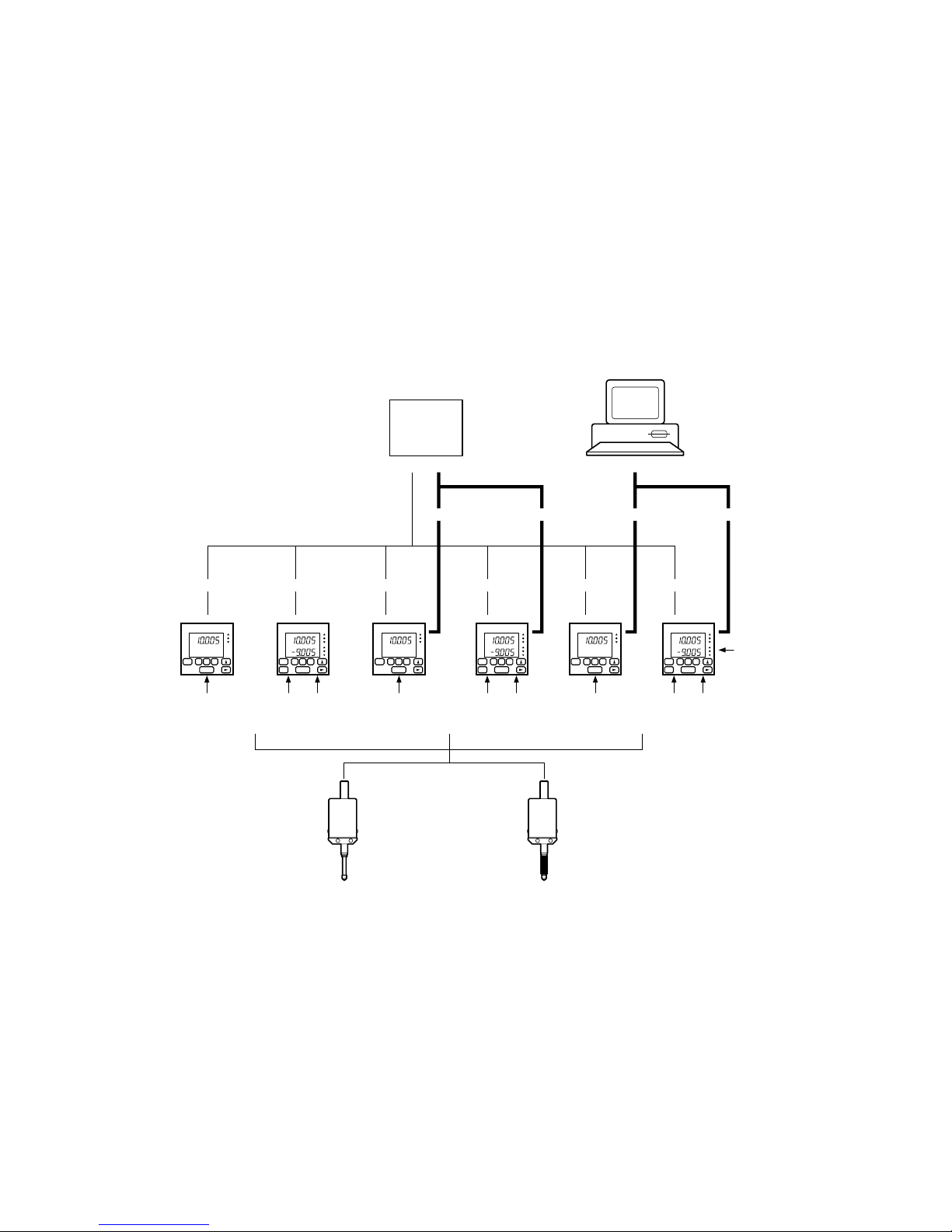

Go/No GoGo/No GoGo/No GoGo/No GoGo/No Go Go/No Go

PLC etc.

Computer

Counter unit

Measuring unit

LT10A-105

LT11A-101

1 CH

LT10A-205

LT11A-201

2 CH (including Add/Sub)

DT12N/512N

DT32N

DT12P/512P (IP64 Compatible)

DT32P (IP64 Compatible)

RS-232C RS-232CBCDBCD

LT10A-105B

LT11A-101B

1 CH

LT10A-205B

LT11A-201B

2 CH (including Add/Sub)

LT10A-105C

LT11A-101C

1 CH

LT10A-205C

LT11A-201C

2 CH (including Add/Sub)

Power source 9 to 24 V

(Power input connector.)

2-2. System structure

(E) 5

LT10A / LT11A Series

3-1. Connecting the cables

• Secure all connecting cables so as to prevent accidental

disconnection.

• Make certain the counter unit’s power is off before

connecting or disconnecting the measuring unit.

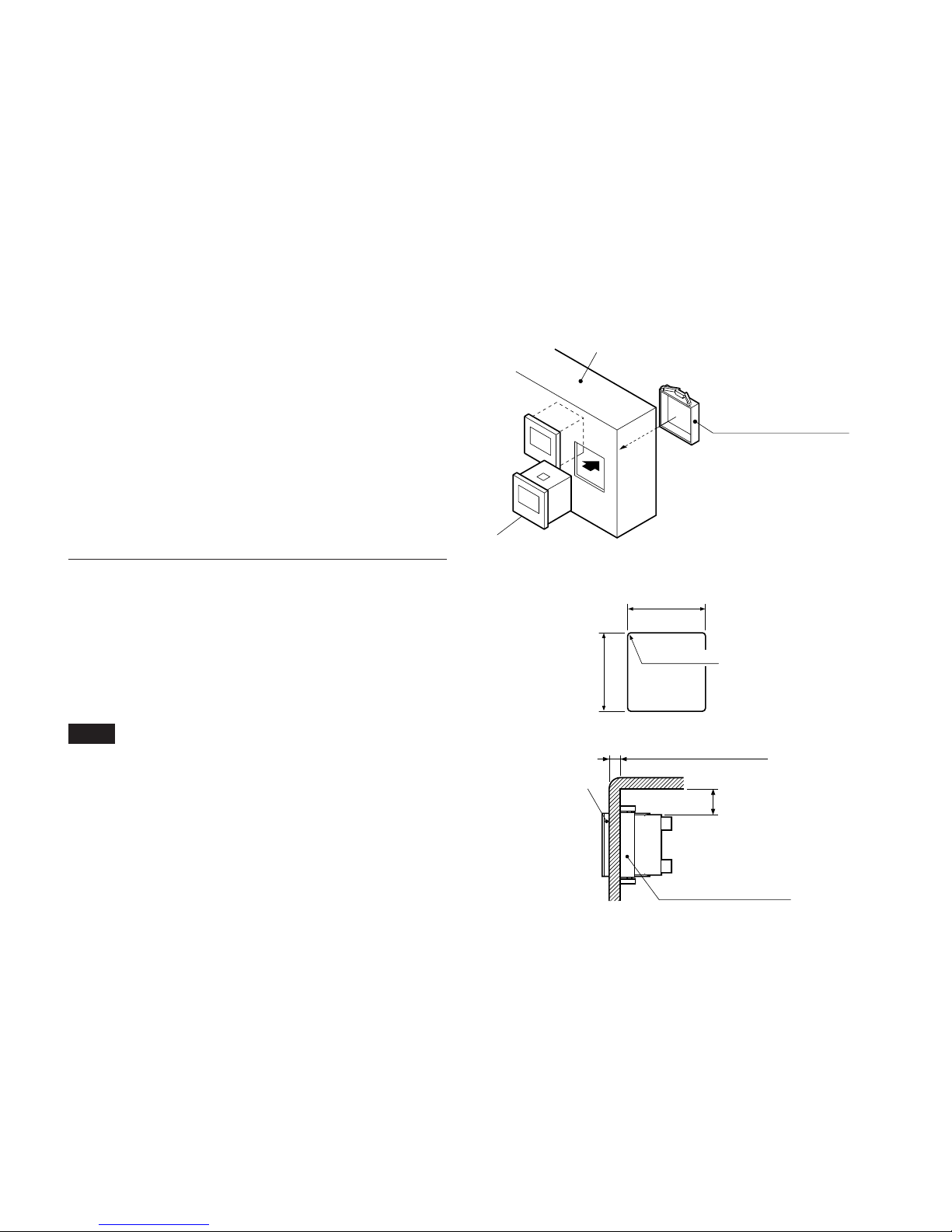

3-2. Installing the counter unit

When mounting in a panel

1. Cut out an opening to match the dimensions shown

(Fig. 2).

2. Insert the counter unit into the cut-out opening in the

panel from the front.

3. Attach the supplied counter stopper from the rear.

4. Press in the counter stopper until it touches the panel.

Note

When attaching the counter stopper to the counter unit,

leave enough space (min. 30 mm/1.18") between the top

and bottom. (Fig. 3)

3. Connecting and installating

Fig. 2

Fig. 3

Panel thickness: max. 12/0.47"

Cut-out dimensions

Panel box

Front of counter unit

68 /2.68"

+1.0

+0.4

+0.039"

+0.016"

68 /2.68"

+1.0

+0.4

+0.039"

+0.016"

4-R1 or less

Fig. 1

Counter stopper

(supplied)

Front of counter unit

Counter stopper

(supplied)

30/1.18"

30

6 (E)

LT10A / LT11A Series

4-1. Front panel

4. Name and function of each part

q

: Go/No Go test result indicator

Gives the result of comparing the displayed value to

the comparator’s upper and lower limits. ∆ Over upper

limit, \ between upper and lower limit, ∇ under lower

limit.

w

RESET

RESET

A

RESET

B

: Reset key

• Resets the displayed value to zero.

• When a value has been preset it returns to this.

e

P

: Preset key

Enters the preset mode. (For the current value,

maximum value, and minimum value.)

r

MODE

: Measuring mode setting key

Key to enter the mode for selecting one of maximum,

minimum, peak-to-peak (maximum–minimum), or

current values.

t

COMP

: Comparator value setting key

Key to enter the mode for setting the comparator upper

or lower limit.

y

SET

: Setting key

Set a mode or a value.

u

: Number selection key

Selects the number for the digit chosen.

i

: Digit selection key

• Selects the digit to change when setting numeric

values.

• Normally, when it is held down for 5 seconds, key

lock is established; alternatively, if key lock is already

established, it is released.

Main display

1 CH input model : LT10A-105/105B/105C

LT11A-101/101B/101C

2 CH input model : LT10A-205/205B/205C

LT11A-201/201B/201C

mm

M A X M I N P — P C P H1 2 3 4

P

RESET

SET

P

MODE COMP

q

r

u

i

tye

w

mm

M A X M I N P — P C P H1 2 3 4

P

RESET

SET

P

MODE COMP

mm

M A X M I N P — P C P L1 2 3 4

P

A+B

BA

A

RESET

B

(E) 7

LT10A / LT11A Series

Note

• If upper display A+B and lower display A have been

selected, the comparator setting values of channel A will

be applied on both the upper and lower limits.

• When the upper display A+B is selected, the lower

display only shows the current value of the selected

channel and no operation can be made on the lower

display.

Preset status indicator

When

is displayed the preset value is set.

Peak-hold indicator

When MAX/MIN/P-P is displayed the data shown is the

maximum/minimum/maximum–minimum value.

When neither of the them is shown, the current value is

displayed.

Comparator upper limit setting indicator

Displayed when the comparator value has been set. The

upper digits are the upper limit.

Comparator lower limit setting indicator

Displayed when the comparator value has been set.

The lower digits are the lower limit.

• Up to four different comparator upper and lower limit

settings (CPH1 to CPH4 and CPL1 to CPL4) can be

stored in the memory for LT10A-105B/205B and LT11A101B/201B.

• LT10A-105/205/105C/205C and LT11A-101/201/101C/

201C have only one setting each.

Key lock indicator

Lighted when key lock is established; off when key lock is

released.

Comparator upper

limit setting indicator

Comparator lower

limit setting indicator

Peak-hold indicator

Preset status indicator

Main display

Displays the measured data, setting data for various

modes, or alarms, etc.

Selected channel indicator (2 channel model)

Choose one of these four.

• A:data from measuring unit,

input channel A

B:data from measuring unit,

input channel B

A+B: sum of data from channel A and B

• In order to carry out calculations such as A–B or –A+B,

change the direction of A or B to “+” or “–”.

(Initial settings)

Upper AA+BA+BA+B

Lower BA B –

Selected channel indicator

Key lock indicator

mm

M A X M I N P — P C P H1 2 3 4

P

mm

M A X M I N P — P C P L1 2 3 4

P

A

B

8 (E)

LT10A / LT11A Series

q Power input connector

Connected to the external power supply (+9 V to +24 V

DC).

Use a power cable less than 10 meters long.

Connector used : MC1.5/3-ST-3.5 (provided) made

by Phoenix Contact

w I/O connectors→See “6. I/O connector”.

There are three kinds of I/O connectors: one type is

used for channel A, one for channel B and one for both

channels A and B.

Input : Reset, Peak-hold start, Peak-hold pause, RS

trigger.

Output: Go/No Go output.

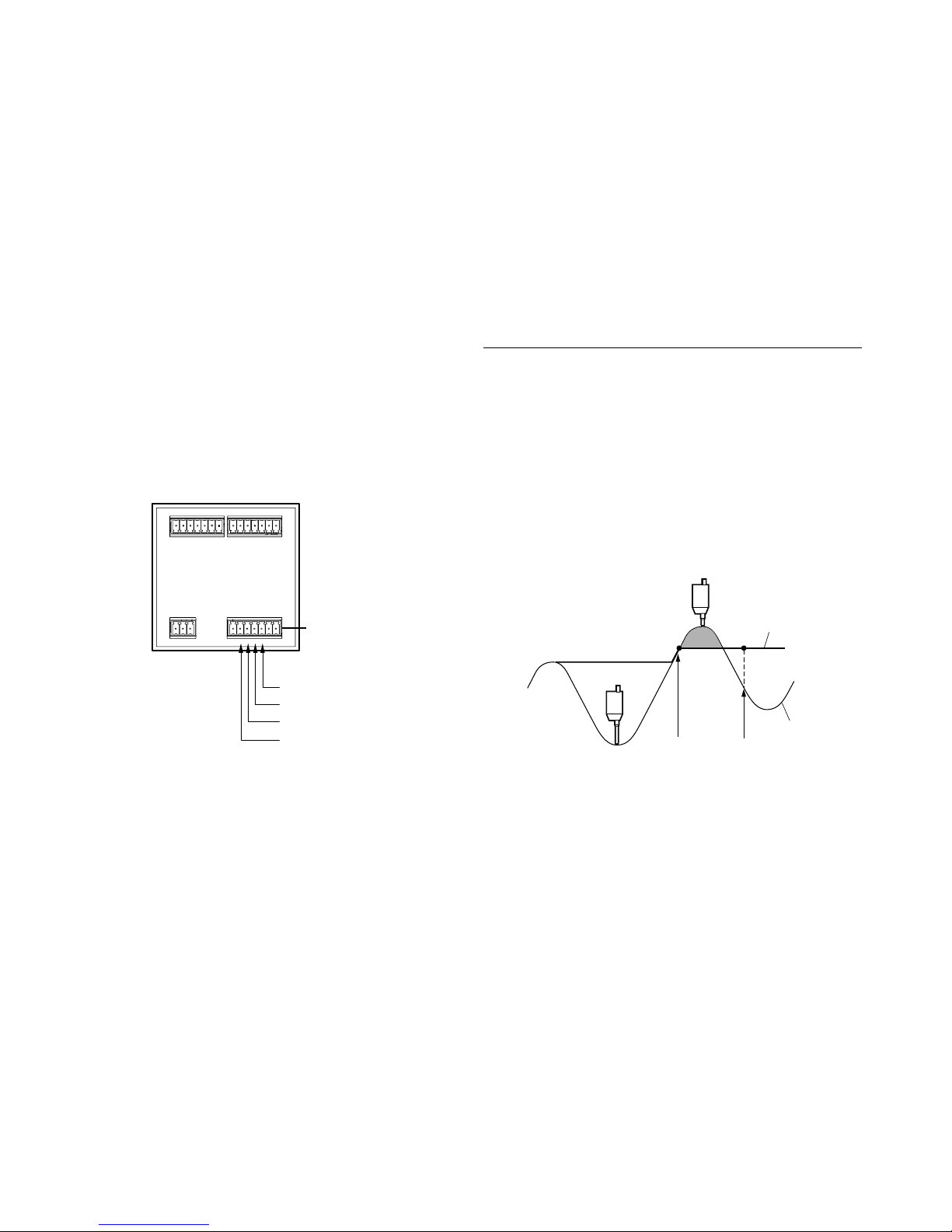

4-2. Rear panel

7 6 5 4 3 2 1 7 6 5 4 3 2 1

1 2 3 4 5 6 7

AB

SIG. IN A

SIG. IN B

FG +V 0V

DC IN

7 6 5 4 3 2 1 7 6 5 4 3 2 1

1 2 3 4 5 6 7

AB

SIG. IN A

SIG. IN B

FG +V 0V

DC IN

7 6 5 4 3 2 1 7 6 5 4 3 2 1

BCD OUT

1 2 3 4 5 6 7

AB

SIG. IN A

SIG. IN B

FG +V 0V

DC IN

RC-232C

7 6 5 4 3 2 1 7 6 5 4 3 2 1

1 2 3 4 5 6 7

AB

SIG. IN A

SIG. IN B

FG +V 0V

DC IN

7 6 5 4 3 2 1 7 6 5 4 3 2 1

BCD OUT. B

BCD OUT. A

1 2 3 4 5 6 7

AB

SIG. IN A

SIG. IN B

FG +V 0V

DC IN

RC-232C

7 6 5 4 3 2 1 7 6 5 4 3 2 1

1 2 3 4 5 6 7

AB

SIG. IN A

SIG. IN B

FG +V 0V

DC IN

1 channel-models 2 channel-models

LT10A-105, LT11A-101 LT10A-205, LT11A-201

LT10A-205B, LT11A-201BLT10A-105B, LT11A-101B

LT10A-105C, LT11A-101C LT10A-205C, LT11A-201C

Common I/O

connector

q

e

t

u

r

w

y

w

FG +V 0V

DC IN

No. 1 2 3

No.

1

2

3

Signal name

FG

+ V

0 V

Signal

Frame ground

Main DC power

(+9 V to +24 V) input

GND for power

(E) 9

LT10A / LT11A Series

e Measuring unit input :SIG. IN A

r Measuring unit input : SIG. IN B (2 channel models)

ty BCD Output

With the 2 channel models the upper and lower

selections of the front panel’s main display correspond

to the BCD OUT. A/BCD OUT. B. So if “A+B” is

selected the output is to BCD OUT. A.

The following operations are possible when BCD

input/output terminal is used.

Input : Comparator value selection (4 settings),

measuring mode (current value, maximum value,

minimum value, peak-to-peak values) selection

Output: 5 digits

Outputs one of the current, maximum,

minimum, and peak-to-peak values selected

via the keys on the front panel and the

external input.

Alarm output

u RS-232C interface

(See “8. RS-232C Interface”.)

Reset, peak-hold start, setting/recall of preset values,

setting the comparator value, selecting and outputting

the current value/maximum value/minimum value/

peak-to-peak value.

4-3. Function description

4-3-1. Reset key

Counter unit

Measuring mode

(Current value, maximum

value, minimum value,

peak-to-peak value)

Preset mode

(

and the selected digit

will flash.)

“Error” is displayed

All the numbers for the

channel with an error

flash.

Operation performed when reset

key is pressed

Display is set to zero.

When a preset value has been set, it

is recalled.

Preset value is set to zero.

“Error” is canceled and then returnes

to the measuring state.

Automatically carries out initialization

to calibrate the device to a new

measuring unit. (Before resetting the

measuring unit must be moved at

least 1 mm.)

4-3-2. Preset functions

• It is possible to set preset values for each of the current,

maximum, and minimum value measuring modes.

• For instructions on setting the preset value, please refer

to P18, “5-2-1. Setting the preset value.”

10 (E)

LT10A / LT11A Series

4-3-4. Peak-hold function

• Stores the maximum, minimum, and peak-to-peak

(maximum–minimum) values of the measured values.

• The above mentioned measuring mode is set using the

keys on the front panel.

• The device starts storing values either when a start signal

is supplied to the start/latch pins (channel A: pin w,

channel B: pin r) of the lower 7-pin I/O connector

(common) (See “6. I/O connector”.) or when the reset key

has been pressed.

4-3-3. Result evaluation

• Go/No Go test is carried out by comparing data from the

current measuring mode (current value, maximum value,

minimum value, or peak-to-peak value) to the comparator

upper and lower limits.

• This result is displayed on the front panel and output from

the I/O connector (See “6. I/O connector”.).

Result

High

Go

Low

Display

>

\

?

=

Condition

Data > upper limit

Upper limit > data > lower limit

Lower limit > data

=

Operation

I/O connector (common) A CH:

starts on “L” (ON) signal from pin

w; I/O connector (common) B

CH: starts on “L” (ON) signal

from pin r.

Reset key is pressed

Result

Starts storing from the current

value.

Starts storing from zero.

When a preset value is set the

device starts storing from the

preset value.

(E) 11

LT10A / LT11A Series

4-3-5. Peak-hold pause function

• Pause the storing of the maximum, minimum and peakto-peak (maximum-minimum) values of the measured

values.

• When the peak-hold function is to be paused, set the

pause pin of the lower 7-pin I/O connector (common) to

ON; to resume storing, set it to OFF.

Maximum value

Current value

Pause ON Pause OFF

Peak value data update stop (pause)

When pause is ON

The peak value updating is stopped. The current value is

constantly updated.

If the maximum value mode, minimum value mode or peakto-peak value mode is set as the measuring mode, the Go/

No GO judgment output and the output data are not

updated even when the measuring unit is operated.

When pause is OFF

The peak values are constantly updated.

7 6 5 4 3 2 1 7 6 5 4 3 2 1

1 2 3 4 5 6 7

DC IN

PAUSE (B)

START (B)

PAUSE (A)

START (A)

Common

I/O connector

w

e

r

t

12 (E)

LT10A / LT11A Series

4-3-6. Latch functions

In the current value mode, this function holds output data

and Go/No GO output for that value.

[Latch conditions]

• The start input signal is set as the latch input by the

parameter setting.

• Current value mode

Note

This function does not operate when the measuring mode

is peak value mode.

Current value

Latch OFF

Latch ON

LT10A / LT11A Series

(E) 13

5. Operation

This sections uses the 2 channel model in its explanations.

The 1 channel model is the same as the 2 channel model

without the B channel.

BCD and RS-232C models are noted in the text.

5-1. Initial settings

An initialization is carried out at the time of shipping;

however it is possible to make the following selections

depending on intended use. Details of the settings at the

time of shipping are given in each section.

• Changing between inches/mm

Turn on power while holding down

RESET

A

and press

MODE

key.

Press

to change between inches/mm.

Press

SET

to set and return to the measuring state.

• Device is set to mm at the time of shipping.

• To change the initial settings hold down the

SET

key and

press the

MODE

key for approximately 2 seconds.

Basic operation

MODE

: to the next item.

: Select item.

SET

: Set item.

Note

• Even if you select an item with the

key, no changes

will be mode until you press the

SET

key.

• Once the initial setting mode has been entered it is not

possible to return to the measuring state partway

through. Press the

MODE

key repeatedly to skip the items.

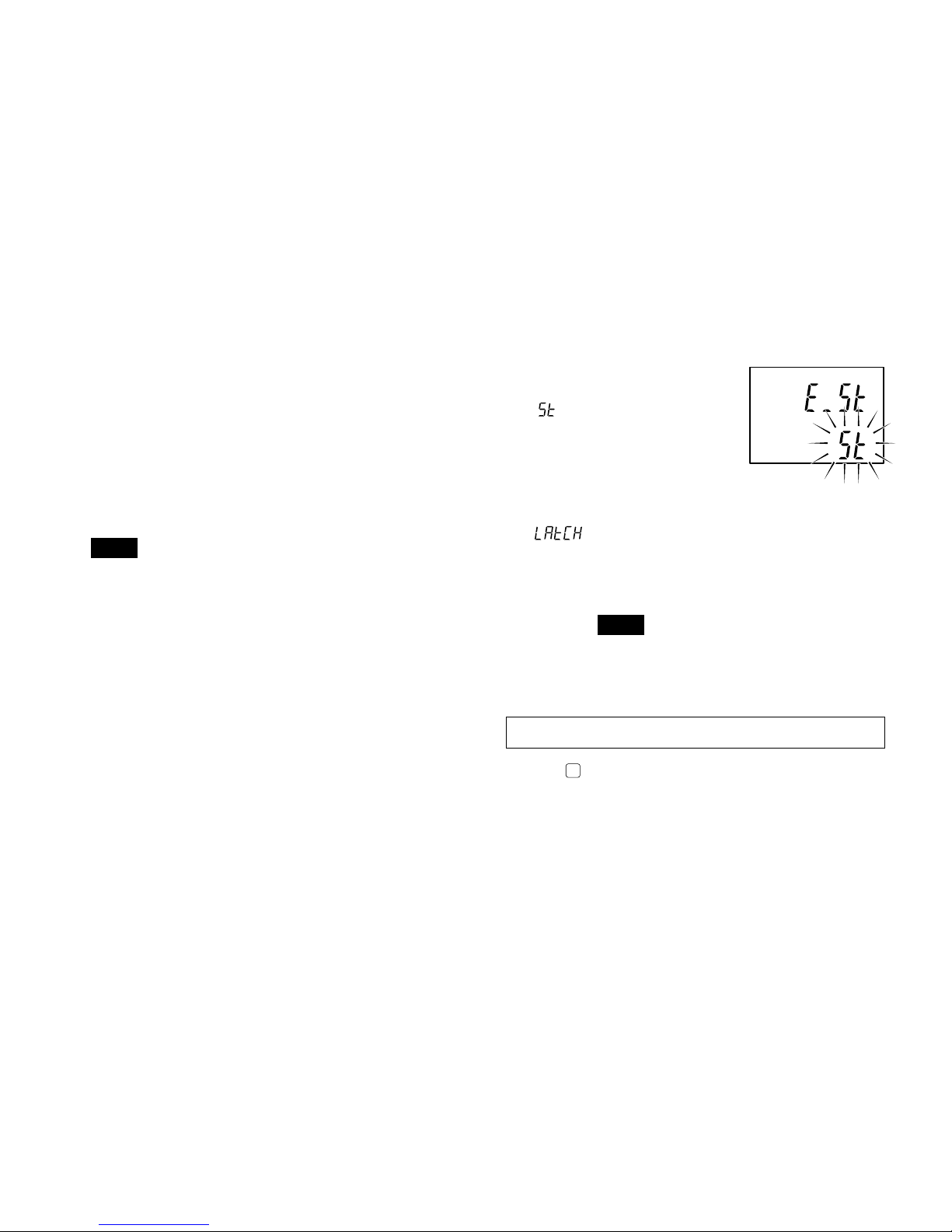

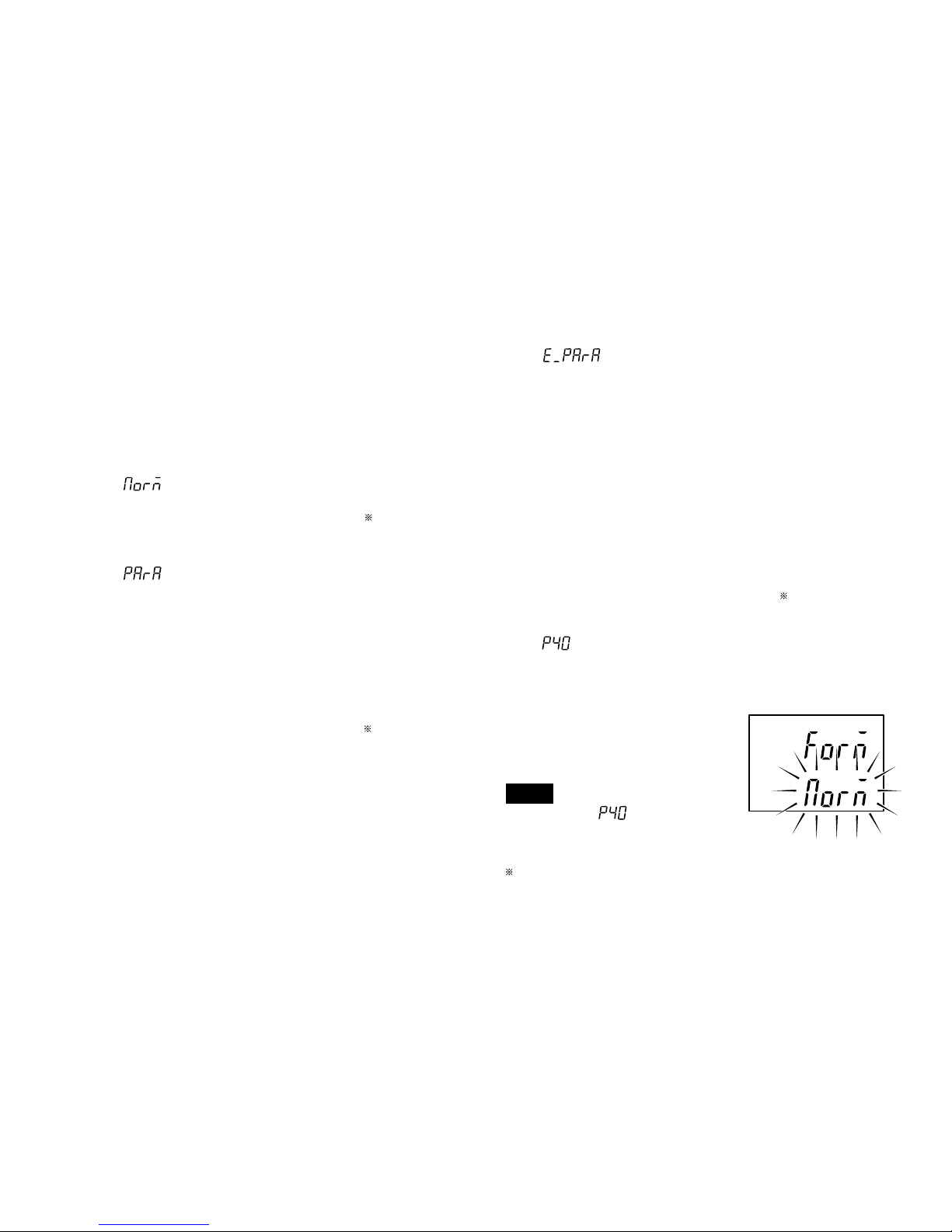

5-1-1. Basic settings

1. Setting the display

(2 channel models)

One of the following may be

chosen:

When the upper display A+B is

selected, the lower display only

shows the current value of the

selected channel and no

operation can be made on the

lower display.

2. Setting the display resolution or direction

(channel A)

0.001/0.005/0.01/–0.001/–0.005/

–0.01 mm

• With the measuring unit’s

spindle pushed in:

+: positive direction

–: negative direction

∗ When set to inches, values are chosen from 0.0002,

0.0005, –0.0002, and –0.0005.

Note

With the LT10A series, 0.001 mm and –0.001 mm (0.0001"

and –0.0001") are not avaible.

Upper AA+BA+BA+B

Lower BA B –

factory-set

factory-set (LT11A)

A

A

B

LT10A / LT11A Series

14 (E)

4. Selecting the start input terminal (I/O connector)

function

(See “6. I/O connector”.)

:

Start function

Setting this terminal

to “L” (ON) sets the

peak-hold value to

the current value and

restarts the storing

procedure.

: Latch function

When using the current value measuring

mode, setting this terminal to “L” (ON) stores

the output and display of the Go/No Go

comparison at that point in time.

Note

When the latch is ON, display and Go/No Go

output storage by the DRQ input for the BCD

model and RS-TRG input for the RS-232C

model is invalidated.

Initial settings are now complete for the standard model.

Pressing

MODE

.. Standard model → Returns to the measuring

state.

BCD model → Go to section 5-1-2.

RS-232C model → Go to section 5-1-3.

3. Setting the display resolution or direction

(channel B, 2 channel models)

0.001/0.005/0.01/–0.001/–0.005/–0.01 mm.

• With the measuring unit’s spindle pushed in:

+: positive direction

–: negative direction

• When displaying A+B:

If you set the direction of A to “–” the data displayed is

the calculation “–A+B”.

The same can be done with B.

Note

• With the LT10A series, 0.001 mm and –0.001 mm

(0.0001" and –0.0001") are not avaible.

• When the addition A+B is chosen the direction for B can

be selected, but its resolution will be the same as that of

A.

factory-set

LT10A / LT11A Series

(E) 15

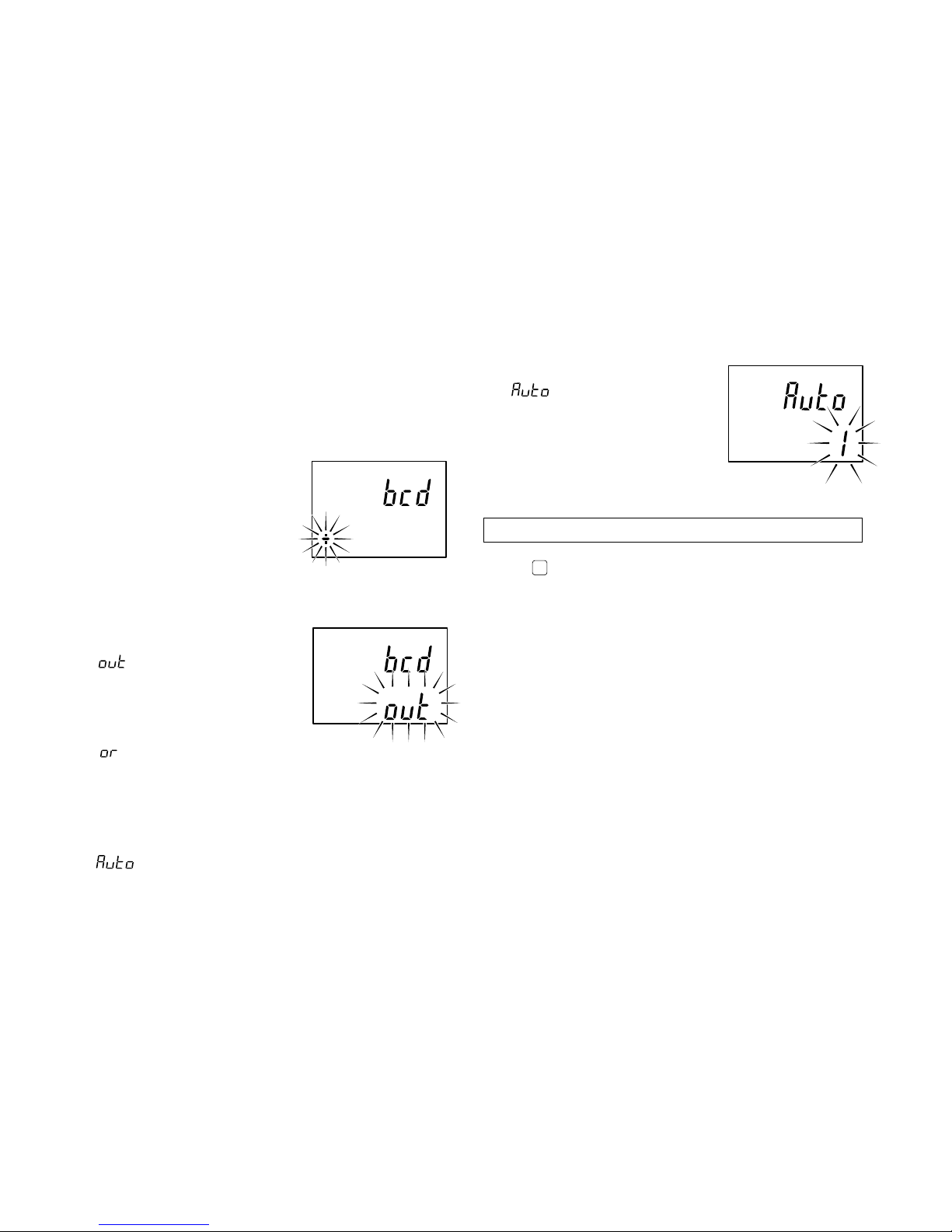

5-1-2. BCD model

(only LT10A-105B/205B, LT11A-101B/

201B)

Proceeds to the next setting mode from “5-1-1. Basic

settings” step 4.

1. BCD logic

Setting the BCD output logic.

“+” is true logic.

“–” is false logic.

Exception : Logic for the DRQ,

READY, and alarm

terminals cannot be

changed.

(See “7. BCD output”)

2. BCD output format

Setting the BCD output format.

:BCD is output

according to the DRQ

signal input, and the

resulting status is held

even if the DRQ signal

goes off.

:BCD is output

according to DRQ

signal input, and

assumes highimpedance status

when there is no DRQ

signal input.

: BCD is output at all times at the set time interval

without the input of the DRQ signal.

factory-set

factory-set

factory-set

3. Automatic BCD output time interval

This mode is established when

has been set in step 2.

Select one of the eight time

intervals listed below.

1/2/4/8/16/32/64/128 ms

(See “7-2. Signal timing” for the

BCD input/output timing)

Initial settings are now complete for the BCD model.

Press

MODE

to return to the measuring state.

LT10A / LT11A Series

16 (E)

: Outputting with measuring mode information

and comparator Go/No Go result

1st byte : Channel name (A or B)

2nd byte : Current mode

(N: Current value,

P: Peak-to-peak value,

I : Minimum value,

A: Maximum value)

3rd byte : Unit (M: mm, I: inch)

4th byte : Comparator Go/No Go

result

U : Upper limit over

G : Within range

L : Lower limit under

E : When an alarm has

occurred

5th byte : Sign (“+”

or “–”)

6th to 11th bytes

: Numerical data

(ex.00.000)

: Outputting according to the mode 1 format

(statistical calculations) of the digital

printer P40 (End of sales).

Whether, with the 2 channel model, to

output B channel data following a

space or to divide it with the

delimiter is selected by step 9.

(except for P40 mode)

Note

When set to mode even the

2 channel model only outputs the A

channel.

: (“+” or space)

factory-set

5-1-3. RS-232C model

(only LT10A-105C/205C, LT11A-101C/

201C)

Proceeds to the next setting mode from “5-1-1. Basic

settings” step 2.

1. Setting the output data format

: Normal output

1st byte : Channel name (A or B)

2nd byte : Sign (“+”

or “–”)

3rd to 8th bytes: Numerical data

(ex.12.345)

: Outputting with measurement mode

information

1st byte : Channel name (A or B)

2nd byte : Current mode

(N: Current value,

P: Peak-to-peak value,

I : Minimum value,

A: Maximum value)

3rd byte : Unit (M: mm, I: inch)

4th byte : Sign (“+”

or “–”)

5th to 10th bytes

: Numerical data

(ex.00.000)

LT10A / LT11A Series

(E) 17

factory-set

factory-set

factory-set

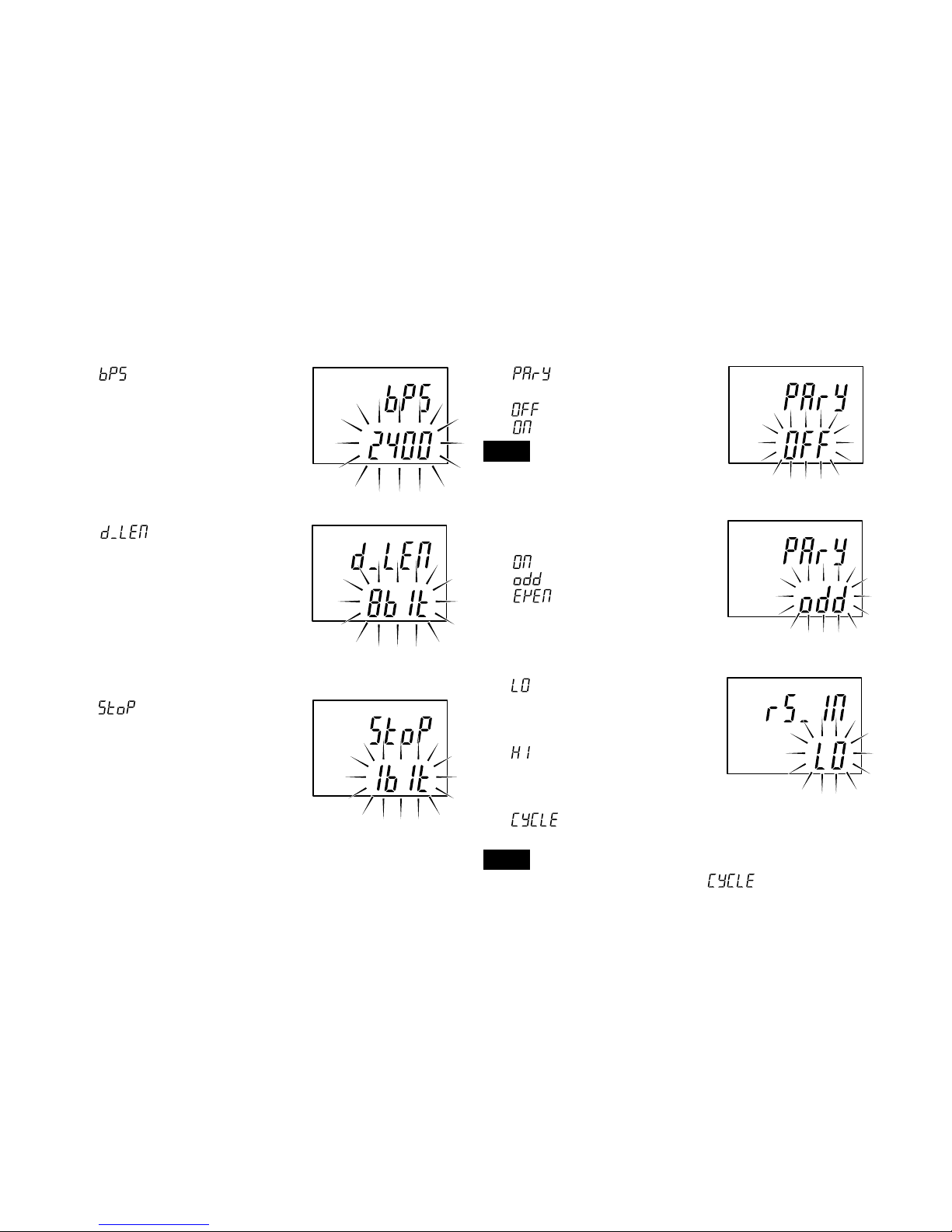

2. Setting the data signalling rate

is displayed and the data

signalling rate can be selected.

600/1200/2400/4800/9600/

19200/38400 bps

3. Setting the data length

is displayed and the

data can be set to 7 or 8 bits.

4. Setting the stop-bit

is displayed and the stop

bit can be set to one or 2 bits.

5. Setting the parity

is displayed and the

parity can be switched on or off.

: No parity

: Parity

Note

When the data length is set to 7 bits

in step 3, select “Parity”.

6. Selecting odd or even parity

Switches to this mode when

is chosen above.

: Odd parity

: Even parity

7. Selecting the function for the RS-TRG terminal

:Mode for inputting

mechanical contact

outputs (such as relay

and switch outputs).

:Mode for inputting

electronic circuit

outputs (such as

transistor outputs).

:To output at a set

interval.

Note

The RS-TRG input cannot be used when

has been selected.

factory-set

factory-set

factory-set

LT10A / LT11A Series

18 (E)

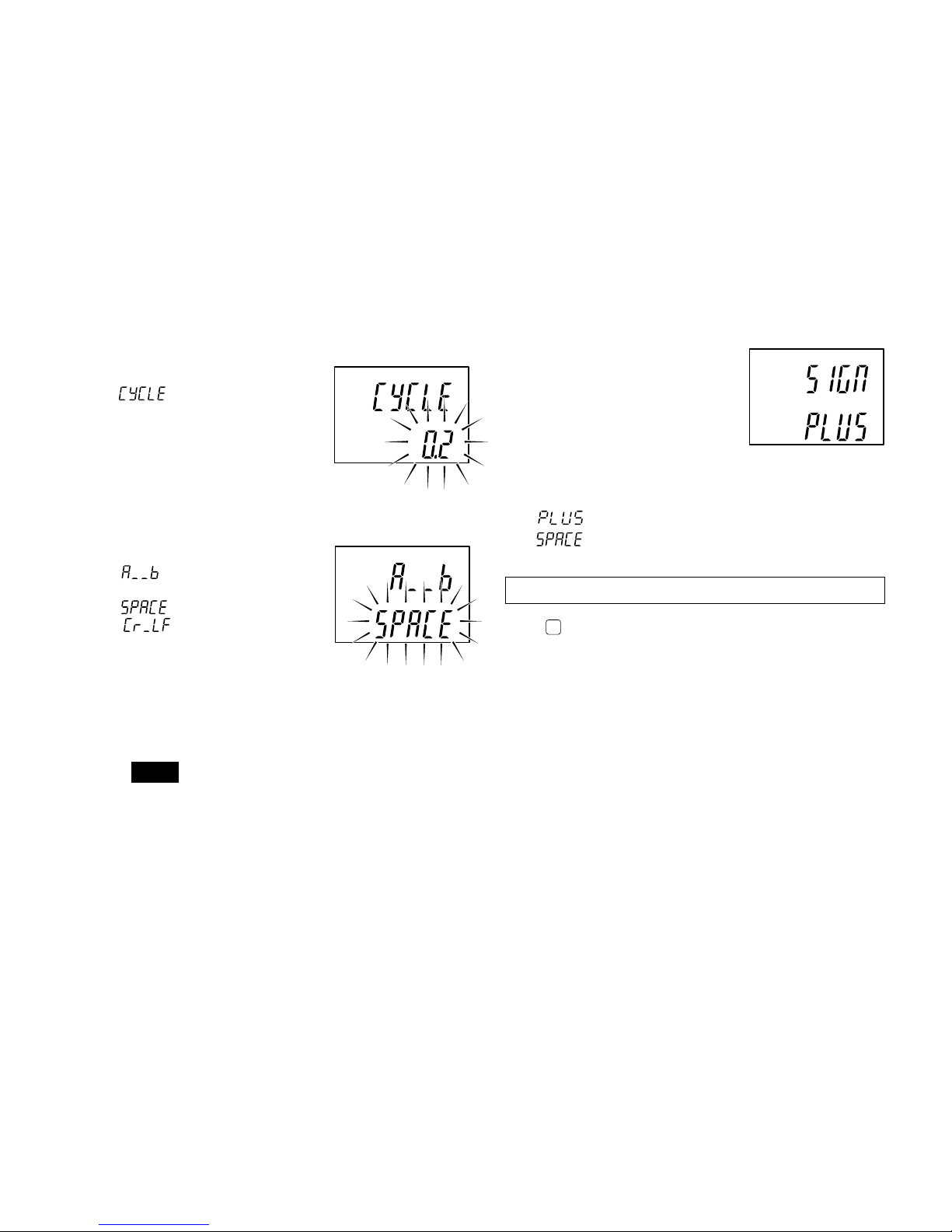

8. Selecting the output time interval.

This mode is selected when

has been chosen in

step 7.

One of the following eight

intervals can be chosen.

0.2/0.5/1.0/5.0/10/30/60/300 s

9. Selecting the data transmission format

(2 channel models)

is displayed and one of

the following is chosen.

: format (a) given below

: format (b) given below

• To output from channel A –12.345, and from channel

B 67.891:

(a) A–12.345MB+67.891

C

R

L

F

(b) A–12.345

CR L

F B+67.891 CR LF

Note

M means a space.

factory-set

factory-set

10. Plus sign setting of the

output data

When the output data is

positive, output characters will

be set as a plus sign.

This setting will also be

reflected in the input data

(preset value, comparator

value).

: Outputs plus as a sign.

: Outputs space as a sign. (compatible to

previous model)

Initial settings are now complete for the RS-232C model.

Press

MODE

to return to the measuring state.

factory-set

LT10A / LT11A Series

(E) 19

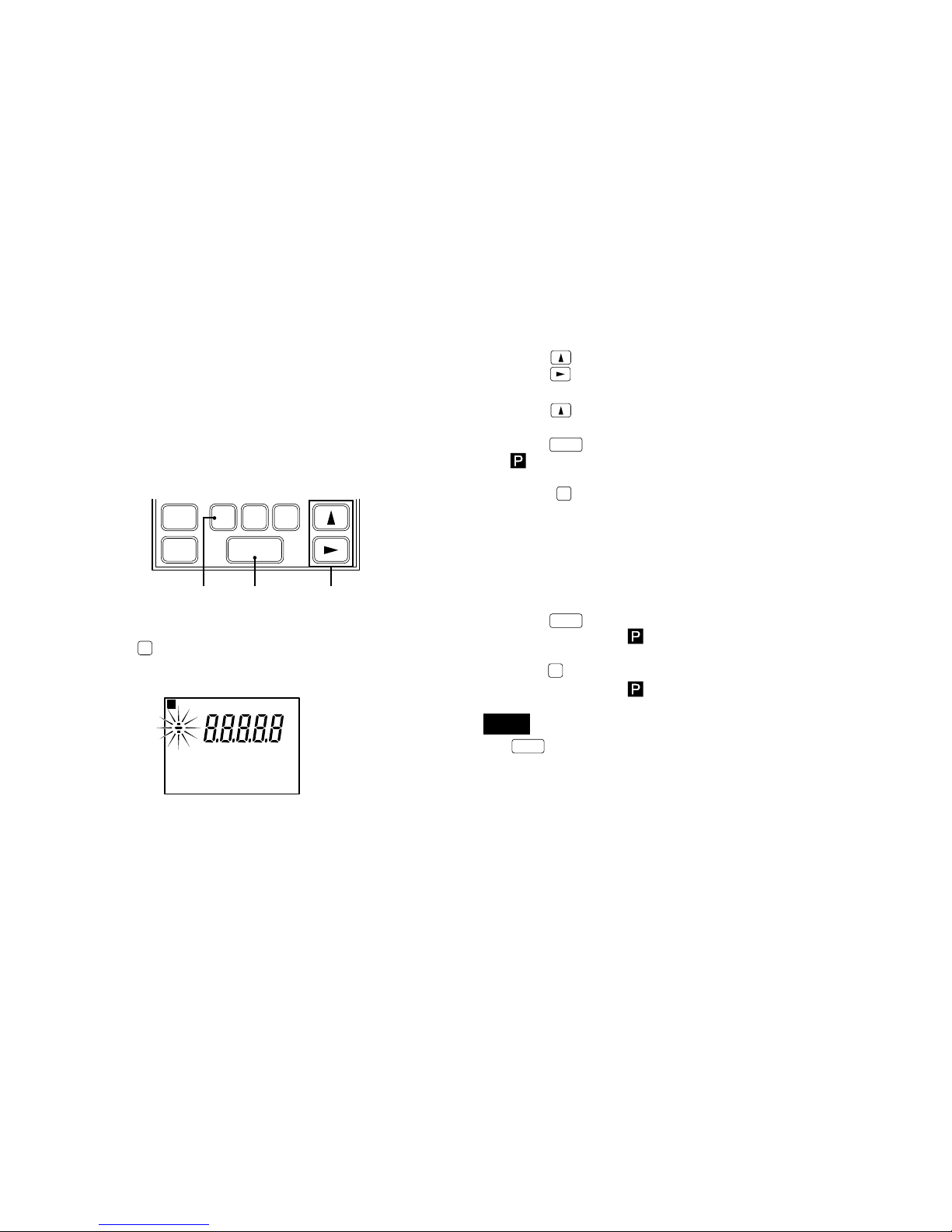

5-2. Various settings

In the setting modes there is always an indicator flashing in

the main display.

5-2-1. Setting the preset value

1 Push

P

to select.

The A channel preset value setting mode.

SET

P

MODE COMP

1, 4, 7 3, 6 2, 5

RESET

B

RESET

A

P

A

2 Push to select a sign.

Push

to select a digit to be set.

The selected digit flashes.

Push

to select a numeral.

3 Push

SET

to set.

for A channel flashes.

4 Push

P

to select B channel preset value setting

mode.

B channels sign flashes “+”.

Single channel models return to the measuring state.

5 Same as 2.

6 Push

SET

to set.

Both A/B channel

flashes.

7 Push

P

to returns to the measuring state.

Both A/B channel

lights.

Note

• If

SET

is not pressed the previous setting is kept.

• If the maximum value mode, minimum value mode or

peak-to-peak value mode is set as the measuring mode,

the peak value of each mode has been set is set to the

preset value when the preset value is set to the value

which has more than the peak value.

LT10A / LT11A Series

20 (E)

3 Push

SET

to set.

Set mode flashes.

The other channel A modes disappear.

4 Push

MODE

to select the setting mode for channel B.

Currently set channel B mode flashes.

5 Same as 2.

6 Push

SET

to set.

Modes set for channels A and B flash.

7 Push

MODE

to return to the measuring state.

Modes set for channels A and B light.

Note

If you do not press

SET

the previous settings will be kept.

M A X AM A X

P ―P

A

B

5-2-2. Setting the measuring mode

1 Push

MODE

to select the mode for setting a measuring

mode (current value, maximum value, minimum value,

or peak-to peak value) for channel A.

∗ Each of there modes are indicated “A”, “MAX”, “MIN”

and “P-P”, respectively.

2 Push

to select a measuring mode.

The selected mode’s indicator flashes.

3, 6 2, 5

1, 4, 7

SET

P

MODE COMP

RESET

B

RESET

A

M A X M I N P ―P

A

LT10A / LT11A Series

(E) 21

5-2-3. Setting the comparator values

1 Push

COMP

to select the mode for setting the channel A

comparator values. Start from the CPH (comparator

upper limit) setting.

2 Push

to select a sign.

Push

to select digits.

A selected digit flashes.

Push

to select a number.

RESET

SET

P

MODE COMP

A

RESET

B

3, 6, 9, 12 2, 5, 8, 11

1, 4, 7, 10, 13

C P H

C P L

A

3 Push

SET

to set.

“CPH” flashes.

4 Push

COMP

to select the CPL comparator lower limit

setting mode. Sign of the CPL value flashes.

5 Same as 2.

6 Push

SET

to set.

“CPH” and “CPL” flash.

7 Push

COMP

to select the mode for setting the channel B

comparator values.

∗ Single channel models return to the measuring state.

8

9

10 Same as 2, 3, 4, 5, 6.

11

12

13 Push

COMP

to return to the measuring state.

LT10A / LT11A Series

22 (E)

5-2-4. Setting the key lock

Set the key lock to invalidate the key operations. This

stores the displayed values or set values should a key is hit

by accident. The key lock can be set during normal

operations.

Setting

1. Press and hold

(for about 5 seconds). Keep

pressing until the key lock indicator in the main display

changes from flashing to on.

Note

The setting is not performed unless the key is pressed

while the indicator is flashing.

Release

1. Press and hold

(for about 5 seconds). Keep

pressing until the key lock indicator in the main display

changes from flashing to off.

Note

The release is not performed unless the key is pressed

while the indicator is flashing.

Key lock indicator

mm

M A X M I N P — P C P L1 2 3 4

P

B

Note 1

With the BCD models four different settings can be stored

in memory. The operations are as follows.

A CH CPH1 CPH2 CPH3 CPH4

CPL1 CPL2 CPL3 CPL4

↓↓↓↓

B CH CPH1 CPH2 CPH3 CPH4

CPL1 CPL2 CPL3 CPL4

• When the 4 settings are not required press

COMP

repeatedly.

• Changing the 4 different setting values is carried out via

the BCD connector input terminal.

• When the BCD connector is not connected the setting is

CPH1 and CPL1.

Note 2

If

SET

is not pressed the previous setting is maintained.

Note 3

When the

SET

key is pressed to set the CPL the sign (“+”

or “–”) of the CPH value may flash. This is because the CPH

(upper limit) is less than the CPL (lower limit), and the

device is in the CPH setting mode. In this case, return to

and start from the CPH setting.

→

→

→

LT10A / LT11A Series

(E) 23

6. I/O connector

The I/O connector on the rear panel of the counter unit has

functions for Go/No Go output based on the comparator

function, start input, pause input, RS-232C trigger input and

reset input.

6-1. Connector pin assignment

Rear of counter unit

• Use a shielded cable for connection to the FG pin on the

rear of the counter unit.

(Prepare a shield cable by yourself.)

Connector used : MC1.5/7-ST-3.5 (provided) made

by Phoenix Contact

Outer cover

Knitted shield

Cross section of the cable

Signal

(See “4-3. Function description”.)

I/O connector A

Pin Signal

IN/OUT Signal

No. name

1 GND –

2NC – Connection prohibited

3 RESET (A) IN Reset input (A CH)

4 LO (A) OUT Go/No Go output Low (A CH)

5 GO (A) OUT Go/No Go output Go (A CH)

6 HI (A) OUT Go/No Go output High (A CH)

7 GND –

I/O connector B (not provided for 1-channel models)

Pin Signal

IN/OUT Signal

No. name

1 GND –

2NC – Connection prohibited

3 RESET (B) IN Reset input (B CH)

4 LO (B) OUT Go/No Go output Low (B CH)

5 GO (B) OUT Go/No Go output Go (B CH)

6 HI (B) OUT Go/No Go output High (B CH)

7 GND –

7 6 5 4 3 2 1 7 6 5 4 3 2 1

1 2 3 4 5 6 7

AB

FG +V 0V

DC IN

I/O connector BI/O connector A

Power input

connector

Common

I/O connector

LT10A / LT11A Series

24 (E)

Start/latch input

• The “L” (ON) signal sets the maximum, minimum, and

peak-to-peak values to the current value and restarts

their storing. (Start function)

• If, when the initial setting of

which was set at the time

of shipping is changed to

, the current value mode

serves as the measuring mode, the “L” (ON) signal will

hold the Go/No Go output (I/O connector) and display.

(Latch function)

Note

While the Go/No Go output is at the “L” level, reset/preset

value recall cannot be effected by reset key or external

reset/preset value recall input.

Reset input

“L” (ON) sets the measured value to zero.

When there is a preset value this is recalled.

Note

Even when the “L” level is held, the Go/No Go output (I/O

connector) and the display are not held.

I/O connector (common)

Pin Signal

IN/OUT Signal

No. name

1 GND –

2 START (A) IN Start/latch input (A)

3 PAUSE (A) IN Pause input (A)

4 START (B) IN Start/latch input (B)

∗1

5 PAUSE (B) IN Pause input (B)

∗1

6 RS-TRG IN

RS-232C data output/trigger input

∗

2

7 GND –

✽

1 : The connection of this pin is prohibited for 1-channel

models.

✽

2 : The connection of this pin is prohibited except in RS-

232C models.

Go/No Go output

High: displayed value > upper limit → “L” (ON)

Go : upper limit

displayed value lower limit → “L” (ON)

Low : lower limit > displayed value → “L” (ON)

Note

All Go/No Go outputs are “H” (OFF) when an alarm is set.

LT10A / LT11A Series

(E) 25

6-2. I/O circuitry (I/O connector area)

Output circuit

Intput circuit

Counter unit

Externally connected device

(Connection Type)

Start input

Pause input

Reset input

RS trigger input

External power

supply:

DC +5 to +24 V

Go/No Go

output

Counter unit

Externally connected device

(Connection Type)

• Output specifications

NPN open collector output

DC+5 to +26.4 V 10 mA or less (150 mW or less)

Note

When connecting a device such as a relay to output pins,

first check the operational coil rating of the relay.

Be sure to connect a back-voltage absorption diode in

parallel with the coil.

• Input specifications

OFF voltage: +4 to +26.4 V or open

ON voltage : +0.8 V or less

Between IN and GND, either open (OFF) or short (ON) is

possible

GND

OUT IN

+COM

–COM

GND

OUT

IN

–COM

5 V

1 k

Output signal rating

On: VOL = MAX. 1.4 V (when output current IOL = 10 mA)

Off: VOH = MAX. 26.4 V (output current IOH = MAX. 50 µA)

LT10A / LT11A Series

26 (E)

6-3. Signal timing

Start input to I/O connector (common) pins wr

Reset input to I/O connector A pin e, B pin e

I/O connector A pins rty B pins rty

Note

When the initial settings of the start/latch pins w and r of the

I/O connector (common) are

, the

“L”

(ON) signal will

hold the Go/No Go output and display value immediately

before.

Sampling 50 µs

MAX. 0.2 ms

Go/No Go output

and display value.

Note

High-speed sampling is performed where the Go/No Go

output is updated every 50 µs.

For this reason, when the count value is close to the

comparator setting value, the ON-OFF time may be output

repeatedly every 50 µs. Be careful because reception may

not be possible, depending on the sampling time on the

connected device side. In this situation, use the latch

function to first store the Go/No Go output and then receive

the result.

I N

MIN. 0.1 ms

wr

LT10A / LT11A Series

(E) 27

7. BCD output (only BCD model)

The current value, maximum value, minimum value, and

peak-to-peak value data is output from the BCD connector.

There are also features for alarm output, comparator value

selection input and measuring mode (current value,

maximum value, mimimum value, peak-to peak value)

selection input. The output is all an open collector

equivalent to the IC “74LS06”. With the 2 channel model,

both channel A and B have the same features.

7-1. Connector pin assignment

As seen from the rear of the counter unit.

Connector to be procured

Manufactured by Hirose Electric, Co., LTD

DX10-36S (Counter unit receptacle)

DX40-36P (Plug: accessory)

DX-36-CV (Plug case: accessory)

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Pin

No.

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Signal

1st digit Q1 (A)

Q2 (B)

Q3(C)

Q4 (D)

2nd digit Q1 (A)

Q2 (B)

Q3 (C)

Q4 (D)

3rd digit Q1 (A)

Q2 (B)

Q3 (C)

Q4 (D)

4th digit Q1 (A)

Q2 (B)

Q3 (C)

Q4 (D)

5th digit Q1 (A)

Q2 (B)

Signal

Q3 (C)

Q4 (D)

MOD 0

MOD 1

M-VALID

Connection prohibited

Connection prohibited

GND

GND

GND

SIGN output

DRQ input

READY output

Start input

Reset input

Alarm output

Comparator value selection A

Comparator value selection B

Signal

18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

1936 2021222324252634 33 32 31 30 2935 28 27

LT10A / LT11A Series

28 (E)

1st digit

Note

• The counter unit’s least significant digit (rightmost digit) is

the first digit.

The letters in parentheses have the following meanings

A: 1, B: 2, C: 4, D: 8.

BCD output

In the

mode, mode

(See “7-2. I/O timing”.)

When DRQ has been received from at #0, and when the

READY output at #1 goes “L” (ON), the BCD data is output.

In the

mode

The data is output at the output time interval which was set

as the initial setting even when DRQ is not input.

• Output logic

True logic or false logic can be selected.

(See “5-1-2. BCD model”)

True logic : “L” (ON) is “0”.

“H” (OFF) is “1”.

• Output format

Whether to hold the BCD output data or to assume

high-impedance when there is no DRQ signal input can

be selected.

(See “5-1-2. BCD model”)

In the

mode, the unit cannot enter the high-

impedance state.

Measuring mode selection input

Current value, maximum value, mimimum value, peak-to

peak value can be selected.

×: Either setting possible

SIGN output

Tells whether the output data is positive or negative.

With true logic “H” (OFF) is “–”, and “L” (ON) is “+”.

Start input

When the peak-hold function has been chosen the “L” (ON)

input will cause the maximum value and minimum value, to

be come the current value (peak-to-peak value = 0) and

restart their storing.

Reset input

“L” (ON) sets the measured value to zero.

When there is a preset value this is recalled.

Note

Even when the “L” level is held, the Go/No Go output

(terminals) and the display are not held.

Measuring mode

Current value

Maximum value

Minimum value

P-P values

According to the

key switch settings

@

1pin (MOD 0)

L

H

L

H

✕

@2pin (MOD 1)

L

L

H

H

✕

@

3pin (M-VALID)

L

H

LT10A / LT11A Series

(E) 29

Alarm output

“H” (OFF) is output when the unit enters the alarm state.

This is set to “L” (ON) by pressing the reset key or by the I/O

connector reset input after eliminating the various causes

of the alarm.

Comparator value selection input

The four comparator value pairings set in the counter unit

can be selected.

DRQ display/output hold feature

While the DRQ signal is “L” (ON) the display and output

(BCD, Go/No Go output of I/O connector) of termianls are

stored.

(When the BCD output form is set to

, only the BCD

output data is held on DRQ becoming “H” (OFF).)

However, when the initial settings of pins w and r of the I/O

connector (common) are changed from

which was set at

the time of shipping to

, the hold function for the

display and I/O connector Go/No Go output is enabled only for

pins w and r of the I/O connector (common), and the DRQ

hold is valid only for the BCD output data.

Pin #5

H

L

H

L

Pin #6

H

H

L

L

Comparator value

(Upper limit CPH, lower limit CPL)

CPH1, CPL1

CPH2, CPL2

CPH3, CPL3

CPH4, CPL4

7-2. Signal timing

q-@0 Data, #0 DRQ input, #1 READ output

• When Initial setting

(See P15 for factory-set.)

• When Initial setting

DRQ (IN)

READY (OUT)

DATA (OUT)

MAX. 0.2 ms MAX. 0.2 ms

MIN. 1 ms

DRQ (IN)

READY (OUT)

DATA (OUT)

MAX. 0.2 ms MAX. 0.2 ms MIN. 0.2 ms

MIN. 1 ms

LT10A / LT11A Series

30 (E)

• When Initial setting

#5#6 Comparator value selection input

50 % 50 %

Time set

(Inifial setting)

READY(OUT)

BCD Data(OUT)

7-3. Interface cable

• Use a shielded cable with thickness less than φ8.7 mm,

and length under 2 m.

In addition, connect the shielded cable of the connected

equipment to frame GND.

• The plug case is connected to FG of the counter unit.

Connect the braided wire to the case after folding back

and securing with the metal clips.

Note

Be sure to insulate (with insulation tubes, etc.) the soldered

areas of the plug and cable to prevent a malfunction caused

by contact between the case and plug pins.

Assembling the plug provided

Fold back the braided wire and

secure with the metal clips.

Cable

Case

Plug

Case

I N

DATA (OUT)

MAX. 0.2 ms

LT10A / LT11A Series

(E) 31

7-4. BCD input/output circuits

Output circuit

Input circuit

Counter unit

Counter unit

External power

supply:

DC

+

5 to +24 V

Externally connected device

(Connection Type)

Externally connected device

(Connection Type)

• Output specifications

NPN open collector output

DC+5 to +26.4 V 24 mA or less

• Input specifications

OFF voltage: +4 to +26.4 V or open

ON voltage : +0.8 V or less

Between IN and GND, either open (OFF) or short (ON) is

possible

GND

OUT IN

+COM

–COM

74LS06

GND

OUT

IN

–COM

5 V

1 k

Output signal rating

On: VOL = MAX. 1.4 V (when output current IOL = 10 mA)

Off: VOH = MAX. 26.4 V (output current IOH = MAX. 50 µA)

32 (E)

LT10A / LT11A Series

Signal

N.C

SG (Signal GND)

RXD (Received data)

TXD (Transmit data)

CTS (Clear to send)

RTS (Request to send)

+10 V

N.C

Pin

No.

1

2

3

4

5

6

7

8

<

>

<

>

I/O

I

O

I

O

Signal

—

SG

TXD

RXD

RTS

CTS

DSR

• RS-TRG (I/O connector (Common))

An “L” (ON) input 1 causes the measured values to be

output via the RS-232C connector.

8. RS-232C Interface (only RS-232C model)

The counter unit is connected to a personal computer to

use the computer to control the counter unit. (See “5-1-3.

RS-232C model”.)

8-1. Terminal pin assignment

Rear panel of counter unit

RS-232C

Connected

equipment side

Signal

• RS-232C

8 7 6

5 34

12

RC-232C

7 6 5 4 3 2 1 7 6 5 4 3 2 1

1 2 3 4 5 6 7

AB

SIG. IN A

SIG. IN B

FG +V 0V

DC IN

(Common)

I/O connector

(E) 33

LT10A / LT11A Series

8-2. Connecting a personal computer

Use a DZ252 or DZ253A RS-232C cable (sold seperately)

for connecting personal computers.

(See “8-6. Commands”.)

Note

The shielded cables of the DZ252 and DZ253A connectors

are connected to FG of the counter unit.

The DZ252 and DZ253A connectors for the personal

computer side are 9 and 25-pin Dsub connectors,

respectively. Please check the form of the personal

computer’s RS-232C connector before purchasing the

cable for connection. For further information please consult

your dealer.

Pin No.

1

2

3

4

5

6

7

8

Case

Pin No.

1

2

3

4

5

6

7

8

9

Case

Pin No.

1

2

3

4

5

6

7

8

Case

Pin No.

1

2

3

4

5

6

7

to

25

Case

9pin Dsub

Female

25pin Dsub Male

8pin mini DIN8pin mini DIN

DZ252 DZ253A

Personal

computer side

Personal

computer side

Shield

cable

Shield

cable

LT10A/

LT11A side

Connection

LT10A/

LT11A side

34 (E)

LT10A / LT11A Series

8-4. RS-TRG circuit

Input circuit : Common I/O connector pin y

RS-TRG input

8-3. RS-232C Interface

1. Signals (Conforming to EIA-RS-232C)

Signals : Asynchronous, start-stop system,

full duplex system

Data signalling rate : 600, 1200,

2400, 4800, 9600,

19200, 38400 bps

Data length : Switchable between 7 or

8 bits

Parity :

None, odd, or even selectable.

Stop bits : Switchable between

1 or 2 stop bits

Cable length : Max.15 m

• Switching of the various parameters is performed in

the initial settings (P16).

• The above underlined items are the settings at the

time of shipping.

Externally connected device

(Connection Type)Counter unit

GND

OUT

IN

–COM

5 V

1 k

(E) 35

LT10A / LT11A Series

8-5. Output

To output measured data from the RS-232C choose one of

the following four methods.

1. Input to the RS-TRG terminal q

Initial setting:

(set at time of shipping)

This mode is for inputting mechanical contact outputs

(such as relay and switch outputs). Data is output

20 ms after an “L” level signal has been received.

2. Input to the RS-TRG terminal w

Initial setting:

This mode is for inputting electronic contact outputs

(such as transistor outputs).

However, there must be no chattering in the input

signal. Data is output after an “L” level signal has been

received.

3. Output at set interval

Initial setting:

Eight intervals available, 0.2/0.5/1.0/5.0/10/30/60 and

300 s.

∗ This interval is set with the initial settings.

(See “5-1-3. RS-232C model”.)

4. Commands

Data is output by input ASCII code commands. For

more details see section 8-6.

Commands are received even in the output method 1,

2 and 3 modes.

• Holding display and output.

While the RS-TRG signal is “L” (ON), the display and

output (RS-232C data and I/O connector Go/No Go)

are held. However, when the initial settings of pins w

and r of the I/O connector (common) are changed

from which was set at the time of shipping to

, the hold function for the display and I/O

connector Go/No Go output is enabled for the inputs

of pins w and r of the I/O connector (common), and

the RS-TRG input is canceled.

RS-TRG

MIN. 20 ms

RS-TRG

MIN. 0.1 ms

36 (E)

LT10A / LT11A Series

Note

• When there is a preset value the “reset” command will set

the value to zero. To recall the preset value input the

“recall preset value” command.

• The data set by the commands given in the table will not

be stored by the counter unit.

If the power is turned off the settings must be repeated.

• Provide intervals of at least 5 ms between command

inputs.

However, input the commands after data output is

completed for operations accompanied by data output.

Command

∗P-P

∗MAX

∗MIN

∗REAL

∗RCL

∗RES

∗START

∗P= ¥ ¥ ¥ ¥ ¥ ¥/∗P=?

∗CH= ¥ ¥ ¥ ¥ ¥ ¥/∗CH=?

∗CL= ¥ ¥ ¥ ¥ ¥ ¥/∗CL=?

∗r

R

KEYON

KEYOFF

∗PAUON

∗PAUOFF

∗LCHON

∗LCHOFF

VER=?

Operation

Switch to peak-to-peak value mode.

Switch to maximum value mode.

Switch to minimum value mode.

Switch to current value mode.

Recall the preset value.

Reset.

Start.

Set/read preset value.

Set/read comparator upper limit.

Set/read comparator lower limit.

Request for output for one channel.

Request for outputs for 2 channels.

Allow use of front panel key.

Prohibit use of front panel key.

Stop peak value update

Release peak value update stop

Latch the current value.

Release the current value latch

Read software version

8-6. Commands

1. Command table (Converted to ASCII code)

∗ : For the 1 channel model or the 2 channel model A

channel use “A”, for the 2 channel model B channel

use “B”.

¥ : Value to be set. (Example: 12.345)

(E) 37

LT10A / LT11A Series

2. Example of data transmission

• External device → counter unit

To preset 12.345 for A channel

AP=12.345

CR L

F

• Counter unit → external device

q When a 1 channel model has received the “R”

command, or a 2 channel model has received the “Ar”

command :

During normal operation : A+

12.345

C

R

L

F

(Output the A channel value of 12.345)

When an alarm is triggered : AE

C

R

L

F

w When a 2 channel model has received the “R”

command :

During normal operation :

(a) A–12.345MB+

67.891

CR L

F

(b) A–12.345

C

R

L

F B+

67.891

C

R

L

F

(Output the A channel value of –12.345 and the

B channel value of 67.891)

When an alarm is triggered :

(a) AEMBE

C

R

L

F

(b) AE

CR L

F BE CR LF

(a) or (b) can be chosen with the initial settings.

(See “5-1-3. RS-232C model”.)

Note

M means a space.

3. The output data format

Changing according to the initial settings (See P16.).

q Normal condition

Initial setting :

Normal output (set at time of shipping)

1st byte : Channel name (A or B)

2nd byte : Sign (“+”

or “–”)

3rd to 8th bytes : Numerical data (ex.12.345)

Initial setting :

(Outputting with measurement

mode information)

1st byte : Channel name (A or B)

2nd byte : Current mode

( N : Current value,

P : Peak-to-peak value,

I : Minimum value,

A : Maximum value)

3rd byte : Unit (M: mm, I: inch)

4th byte : Sign (“+”

or “–”)

5th to 10th bytes : Numerical data (ex. 00.000)

: (“+” or space)

38 (E)

LT10A / LT11A Series

w When an alarm is triggered

Initial setting :

For an overflow alarm

1st byte : Channel name (A or B)

2nd byte : Sign (“+”

or “–”)

3rd byte : F

4th to 9th bytes : Numerical data

For a non-overflow alarm

1st byte : Channel name (A or B)

2nd byte : E

Initial setting :

1st byte : Channel name (A or B)

2nd byte : E

3rd byte : F (For an overflow alarm)

O (For a non-overflow alarm)

: (“+” or space)

Initial setting :

Outputting with measuring mode information

and comparator Go/No Go result

1st byte : Channel name (A or B)

2nd byte : Current mode

(N: Current value,

P: Peak-to-peak value,

I : Minimum value,

A: Maximum value)

3rd byte : Unit (M: mm, I: inch)

4th byte : Comparator Go/No Go

result

U : Upper limit over

G : Within range

L : Lower limit under

E : When an alarm has

occurred

5th byte : Sign (“+”

or “–”)

6th to 11th bytes

: Numerical data

(ex.00.000)

Initial setting :

Outputting according to the mode 1

format (statistical calculations) of the

digital printer P40 (P40 is sold

separately).

Note

• For the 2 channel model, whether to output B channel

data following a space or to divide it with the delimiter is

selected by the initial setting (See P18, step 9.).

• When set to

mode even the 2 channel model only

outputs the A channel data only.

(E) 39

LT10A / LT11A Series

Initial setting :

For an overflow alarm

1st byte : Channel name (A or B)

2nd byte : Current mode

( N : Current value,

P : Peak-to-peak value,

I : Minimum value,

A : Maximum value)

3rd byte : Unit (M: mm, I: inch)

4th byte : E

5th byte : Sign (“+”

or “–”)

6th byte : F

7th to 11th bytes

: Numerical data

(ex.2.345)

For a non-overflow alarm

1st byte : Channel name (A or B)

2nd byte : Current mode

( N : Current value,

P : Peak-to-peak value,

I : Minimum value,

A : Maximum value)

3rd byte : Unit (M: mm, I: inch)

4th byte : E

5th to 11th bytes

: “MErrorM”

Initial setting :

Outputting according to the mode 1 format

(statistical calculations) of the digital printer

P40 (End of sales).

Note

• M means a space.

: (“+” or space)

40 (E)

LT10A / LT11A Series

RS-232C

(Note)

Output

9. Alarm display/output

I/O connectors

Item

LCD

Fifth digit is F

Value for axis is flashing.

Solution

Cause

(Note) When the output data format is the initial setting . See P38, 39 for other formats.

Note

If the alarm is again displayed/output after solving the problem

Has the measuring unit or its spindle received some strong shock?

Try replacing with the measuring unit used for the other channel.

Reset

Fix problem and

reset.

Reset

Fix problem and

reset.

Limit input to 5 digits

and reset.

Move the measuring

unit at least 1 mm

and reset.

The measuring unit was

exchanged with the power on.

Measuring unit i s n ot

connected or connection

has been cut

The measuring unit’s

spindle exceeded the

maximum response

speed.

Abnormality in measuring

unit’s output signal or

connection has been cut.

Value exceeded 5 digits.

Initialization is required to

calibrate the new pairing of

both device and measuring

unit.

∗E

CR L

F output.

(∗ is A or B.)

∗>FX.XXX

CR L

F output.

(∗ is A or B, > is a plus

sign

or a minus sign, X

is a numeral.)

: (“+” or space)

∗E

CR L

F output.

(∗ is A or B.)

Alarm terminal is

“H”

True logic: fifth

digits are all “H”.

False logic: fifth

digits are all “L”.

Alarm terminal is

“H”

All “H”

—

All “H”

Measuring unit is

not connected or

connection has

been cut.

Speed over

Signal disorder or

connection cut

Overflow

Initialization is

required.

BCD

(E) 41

LT10A / LT11A Series

LT10A-105 105B 105C 205 205B 205C

LT11A-101 101B 101C 201 201B 201C

5 digit backlit LCD, mode display

1 channel 2 channel

\

— \ ——\ —

— \ — \

— \ — \

Reset key or external input (I/O connectors)

—

BCD terminal

RS-232C

—

BCD terminal

RS-232C

command command

Preset value set with preset key, recalled with reset key.

—

Recalled with BCD Set or recalled with

—

Recalled with BCD Set or recalled with

reset terminal

RS-232C command

reset terminal

RS-232C command

Three-level comparator

Comparator value set with keys on the front panel.

Result evaluation: LED and I/O connector output (photocoupler)

Set with RS-232C Set with RS-232C

command command

——

Model

Item

Display

Measuring unit input

I/O connectors

*1

BCD

*2

RS-232C

*3

RS-TRG

*4

Reset function

Preset function

Conparetor function

∗∗

∗∗

∗ 1: I/O connector

Input : Reset, peak-hold start, peak-hold pause, RS trigger (RS-

232C models only)

Output : Result evaluation (photocoupler)

∗∗

∗∗

∗ 2: BCD (36 pin half-pitch connector)

Input : Reset, peak-hold start, comparator value selection (4 settings)

Output : five digits (open collector)

One of current value/maximum value/minimum value/peak-to-peak

value selected and output.

Alarm output

I/O

Up to 4 values

can be set for

comparator (key

input).

Switched with

BCD terminal.

Up to 4 values

can be set for

comparator (key

input).

Switched with

BCD terminal.

10. Specifications

10-1. LT10A/LT11A (Specifications)

42 (E)

LT10A / LT11A Series

∗∗

∗∗

∗ 3: RS-232C (8 pin mini-DIN connector)

Reset, preset value setting/recall, peak-hold start, peak-hold pause,

current value hold, software version read, comparator value setting,

current value/maximum value/minimum value/peak-to-peak measuring

mode selection and output, key lock and release.

∗∗

∗∗

∗ 4: RS-TRG pin

Trigger input for RS-232C data output

∗∗

∗∗

∗ 5: With measuring unit connected.

LT10A-105 105B 105C 205 205B 205C

LT11A-101 101B 101C 201 201B 201C

Maximum, minimum, and peak-to-peak values. Measuring started by the start input of the I/O connector;

update stop by pause input.

—

Can be started with

RS-232C can set

—

Can be started with

RS-232C can set

the BCD terminal.

or start.

the BCD terminal.

or start.

0.001 mm, 0.005 mm, 0.01 mm selectable (0.001 mm (0.0001") is LT11A series only.)

Can be switched

100 m/min 80 m/min

— A+B, A–B, B–A can be set with the direction setting.

Displayed on LCD or the I/O connector’s comparator outputs are all “H” (OFF).

—

BCD alarm

——

BCD alarm

—

terminal “H” (OFF) terminal “H” (OFF)

Resolution, direction, comparator value, preset value, modes, etc.

— BCD sign

Data signalling rate, etc.

— BCD sign

Data signalling rate, etc.

Operating temperature: 0 to 40°C Storage temperature: –10 to 50°C

1.8 W 2.9 W 2.0 W 2.3 W 4.0 W 2.5 W

Approx. 200 g Approx. 230 g Approx. 220 g Approx. 210 g Approx. 270 g Approx. 230 g

Power input connector (3 pins) : DC9.0 to 26.4 V.

DT series

Model

Item

Peak hold function

Resolution

Direction

Maximum response speed

Addition and subtraction function

Alarm

Data storage

Temperature

Power consumption

*5

Mass

Power voltage

Compatible measuring unit

(E) 43

LT10A / LT11A Series

10-2. Accessories

Instruction Manual ............................................................. 1

Counter stopper .................................................................1

BCD output connector plug ....... 1 (1 ch BCD models only)

2 (2 ch BCD models only)

I/O connectors (7-pin) .................................. 2 (1 ch models)

3 (2 ch models)

Power input connector (3-pin) ............................................. 1

10-3. Options

RS-232C connection cable (2 m)

• Round 8-pin ↔ D-sub 9-pin ................................... DZ252

• Round 8-pin ↔ D-sub 25-pin ............................... DZ253A

• Round 8-pin ↔ open-end ...................................... DZ254

44 (E)

LT10A / LT11A Series

10-4. Dimensions

Cut out Opening

Counter stopper

Unit : mm/inch

68.1/2.68"

74/2.91"

68/2.68"

88/3.46"

78/3.07"

73/2.87"

16/0.63"

33/1.30"

2-R

2

60/2.36"

72/2.83"

72/2.83"

mm

M A X M I N P P C P H1 2 3 4

P

RESET

SET

P

MODE COMP

mm

M A X M I N P P C P L1 2 3 4

P

A+B

BA

A

RESET

B

68/2.68"

(71.8)/(2.83")

□68/2.68"

4-R1 or less

15/0.59"

1/0.04"

8/0.31"

68 /2.68"

+1.0

+0.4

+0.039"

+0.016"

68 /2.68"

+1.0

+0.4

+0.039"

+0.016"

(E) 45

LT10A / LT11A Series

11. Troubleshooting

When the unit does not work properly, check the following before calling Magnescale Co., Ltd. Representative for service

• Turn off the power and turn it on 1 minute later.

• Check the connection and continuity of the power line.

• Check for the proper range of power voltage.

• Reset the unit after moving the measuring unit at least 1 mm.

• Has the measuring unit’s cable been disconnected?

• Has the maximum response speed for the measuring unit been exceeded?

• Perform resetting operation.

• First carry out the reset procedure.

• Was the measuring unit exchanged with the power on?

• Is the measuring unit’s connector locked?

• Is the measuring unit’s cable disconnected?

• Connect a correctly functioning measuring unit and reset.

• Is the preset value too large (Overflow)?

Fifth digit is “F”

Channel display is

(Alarm)

is displayed (Alarm)

The power cannot

be turned on.

Value is flashing

46 (E)

LT10A / LT11A Series

Erroneous counting.

Accuracy cannot be

obtained

Data cannot be obtained

after replacement of the

previous LT model.

(when RS-232C output)

• Check that the grownding is made correctly.

• Is there a large amount of noise?

• Check the power voltage is in the specified range.

• Check to see if the unit occasionally miscounts.

• Check for any mechanical trouble that may affect accuracy.

(Any trouble due to machine adjustment, deflection on play.)

• Check to see if the temperature difference between the measuring unit, machine and

workpiece is great.

Is the plus sign of the output data set properly?

(previous LT model: output space as a plus sign)

LL

LL

L Cleaning

To remove heavy dirt

Use dry cotton cloth.

To clean the display and casing

Use diluted neutral

detergent.

Do not use.

LT20

mm

M A X M I N P ―P C P H1 2 3 4

P

RESET

SET

P

MODE COMP

mm

M A X M I N P ―P C P L1 2 3 4

P

A+B

BA

A

RESET

B

neutral

detergent

alcohol

thinner

benzine

• Turn off the power switch and turn it on 5 seconds later.No counting

LT10A / LT11A Series

(G) (1)

Sicherheitsmaßnahmen

Bei dem Entwurf von Magnescale Co., Ltd. Produkten wird größter Wert auf die Sicherheit

gelegt. Unsachgemäße Handhabung während des Betriebs oder der Installation ist jedoch

gefährlich und kann zu Feuer, elektrischen Schlägen oder anderen Unfällen führen, die

schwere Verletzungen oder Tod zur Folge haben können. Darüber hinaus kann falsche

Behandlung die Leistung der Maschine verschlechtern.

Beachten Sie daher unbedingt die besonders hervorgehobenen Vorsichtshinweise in dieser

Bedienungsanleitung, um derartige Unfälle zu verhüten, und lesen Sie die folgenden

Sicherheitsmaßnahmen vor der Inbetriebnahme, Installation, Wartung, Inspektion oder

Reparatur dieses Gerätes oder der Durchführung anderer Arbeiten durch.

Bedeutung der Warnhinweise

Bei der Durchsicht dieses Handbuchs werden Sie auf die folgenden Hinweise und Symbole

stoßen. Machen Sie sich mit ihrer Bedeutung vertraut, bevor Sie den Text lesen.

Warnung

Eine Missachtung dieser Hinweise kann zu Feuer, elektrischen Schlägen oder anderen

Unfällen führen, die schwere Verletzungen oder Tod zur Folge haben können.

Vorsicht