MagneQuest Seth PP-2-A-3 Service manual

How to build the Seth PP2A3

Or how I discovered that things are never as simple as planned, especially when writing

such a “How-To” thing.

By Jean-Francois Lessard ing. Ph.D.

Pantheon Audio MagneQuest distributor.

(http://www.pantheon-audio.com)

Introduction

I’ve been procrastinating for a looooong time before finally writing this. Say thanks to

my dear friend and excellent web designer Mr. Mobile Homeless, AKA Kelly Holsten,

(

http://www.i-vol.com) and Mike Lafevre, from the MagneQuest fame,

(

http://www.magnequest.com) to have bugged me so I would finally produce what I

promised on a drunken evening.

Right from the start you should be aware that the goal of this amplifier is to provide a

new “simple” tube amp for the newbie in DIY tube audio. I wanted it to be a working

platform, from which one can make the design evolve. Hopefully I’ll have achieved this

goal with the Seth. BTW, why the heck did I called this amplifier Seth? For one, I

couldn’t resist the pun as I find it as a nice SET flavour in the midrange. Second reason is

that in Egyptian mythology, Seth was Horus competitor, The Horus being another design

of mine I’ve been loving much. You’ll notice that the picture quality in this manual could

be higher. Due to the large number of pictures, having high resolution pictures would

have made for a pretty large file. A CD containing all the pictures contained here but in a

higher resolution will be given for free to all those who will have bought the Seth iron

package from Pantheon Audio.

Boring stuff and other horror stories

First and foremost before you jump into this here is the usual disclaimer. If you are

clumsy and/or do not know anything about electricity please stay away from playing with

tubes circuits and high voltage without learning the basics and being cautious...

carelessness may harm or kill you! This article is not intended as a class in electronic so it

is your responsibility to learn the safety rules when working with tube circuit. You have

to be aware that the way to build the amps that is described here (circuit wiring method,

AC wiring, etc.) might definitively not lead to a “UL approved” product. It might end up

in a device that will not meet the requirements of the regulations in your area. It is your

responsibility to do all the necessary work to make sure the amps will be “legal and safe”

to use in your home.

Still there? OK… let’s begin.

© 2004 Jean-François Lessard

1

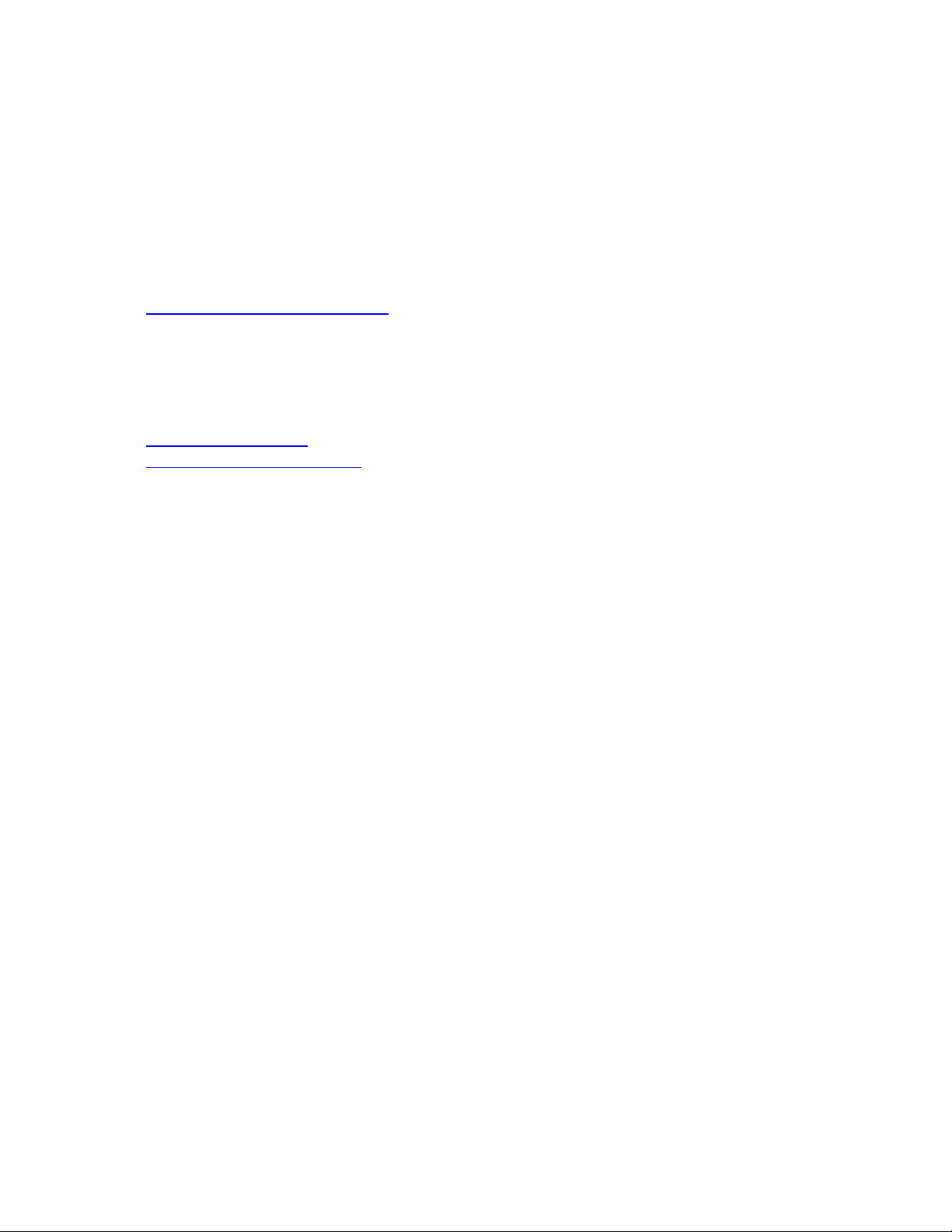

Schematic

The Seth has a very low part count. It is actually deceptively simple. It is in fact an out of

fashion design. No choke loading on the driver stage, no CCS, no bells and whistles.

Why? Simply for the newbie to build this amp easily. Does it sound good despite being

more or less fashionable? You bet.

Have a look at the schematic (note if you can’t read a schematic would it be to save your

life, I suggest you learn how to. Ain’t that complicated). The heart of this amp simplicity

is L

, the EXO-173 PPS center tapped choke. It acts as the phase splitter in a simple but

2

so elegant way. Putting the choke center tap to ground will create a reflected signal

inverted 180

connected).

o

on the bottom leg from the one that is fed on the top leg (where C2 is

The rest of the amp is as simple. It is a two stage design where a 6C45-Pi drives a pair of

2A3 in push pull class A. The PSU is a double pi filter, making for a very low ripple.

This amp is self biased. The pair of 2A3 shares a single bias resistor so this will ask for

closely matched tubes. The list of the parts I used in these amps is given below. Feel free

2

to experiment with the parts and please do not follow my choices blindly. After all, it’s

your amp your building, not mine.

R1

R2

R3

R4

C1

C2

C3

C4

C5a,b

T1

T2

T3

L1

L2

L3

L4

Two Dale metal film 100 ohms 1/4W in parallel

Holco metal film 43.5 ohms 1/2W

Mills Wirewound 4.02 K 12W

Mills Wirewound 12W 1 K in parallel with Mills Wirewound 12W 750 ohm

Black Gate "FK" 100 uF /16 V (optional I did remove it after listening with and without)

Solen 3.3 uF/630V

Black Gate "FK" 100 uF/100 V

Solen 1.5 uF/630V

Cerafine 47 uF+47 uF/500 V

MagneQuest "Peerless" S-240-A Ni

Hammond 374BX 375V-0-375 V 175 mA

Hammond 166Q2 2.5 V CT 6A

MagneQuest BCP16 GC Ni

MagneQuest EXO-173 PPS Ni

Hammond 193H 5 H 200 mA 65 ohms

Hammond 193H 5 H 200 mA 6 5ohms

3

Building the wood chassis.

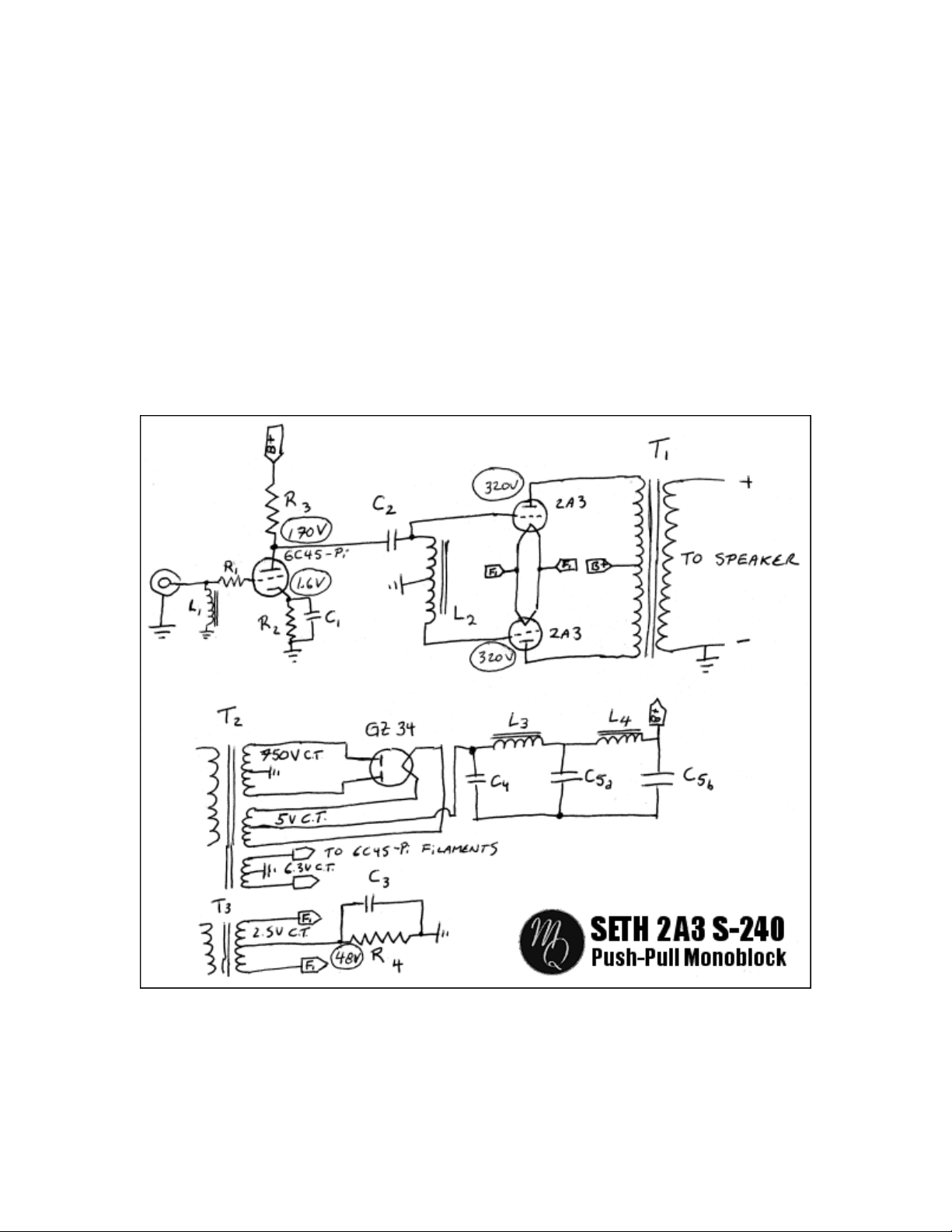

I always use wood chassis. I’ll be pretty vague here since you’ll find better advises that I

could give on the miscellaneous woodworking web sites so I’ll skip the details here. In a

nutshell I used a copper plate 18 AWG thick measuring 16” by 9” for the top plate.

Bottom plate is the same size but in aluminum (utility grade). I will usually oil the chassis

with either boiled linseed oil or Tung Oil for finishing the chassis.

I usually use a router to do a recess on the top and bottom of the chassis so the plates will

rest flush in them. I always use hard woods for my chassis so I can tap 6/32” threaded

holes into the wood in order to secure the plates with 6/32” machine screws. I always

work with 1” to 1”1/2 thick wood planks (once planed). I cut the wood with a mitre saw

according to my top plate size then I glue the four side with a special holding jig to

ensure square enclosure will be well … square!. You can find those jigs in most hardware

stores. Figure 1 illustrates a picture of a chassis drying while being clamped by the jig.

Once the chassis as set dry, I round the corners with a router despite a certain Kelly

Holsten always giving me shit about it.

Figure 1. Drying chassis (no it is not the chassis from the Seth…).

Figure 2 is a photo of the Seth chassis. Note the recess on the top of the chassis and the

tapped holes to secure the top plate. Figure 3 shows a detailed view of the “major holes”

to do in the chassis.

4

Once the chassis is done and finished, it’s time to install the components that will go on

the side of the chassis and start doing some of the AC wiring. Figures 4 to 8 will show

you how.

Figure 2. Completed chassis

Close up of the recessed

hole for the on-off switch,

fuse holder installation and

hole for the AC socket

Figure 3. Detail of the chassis holes.

5

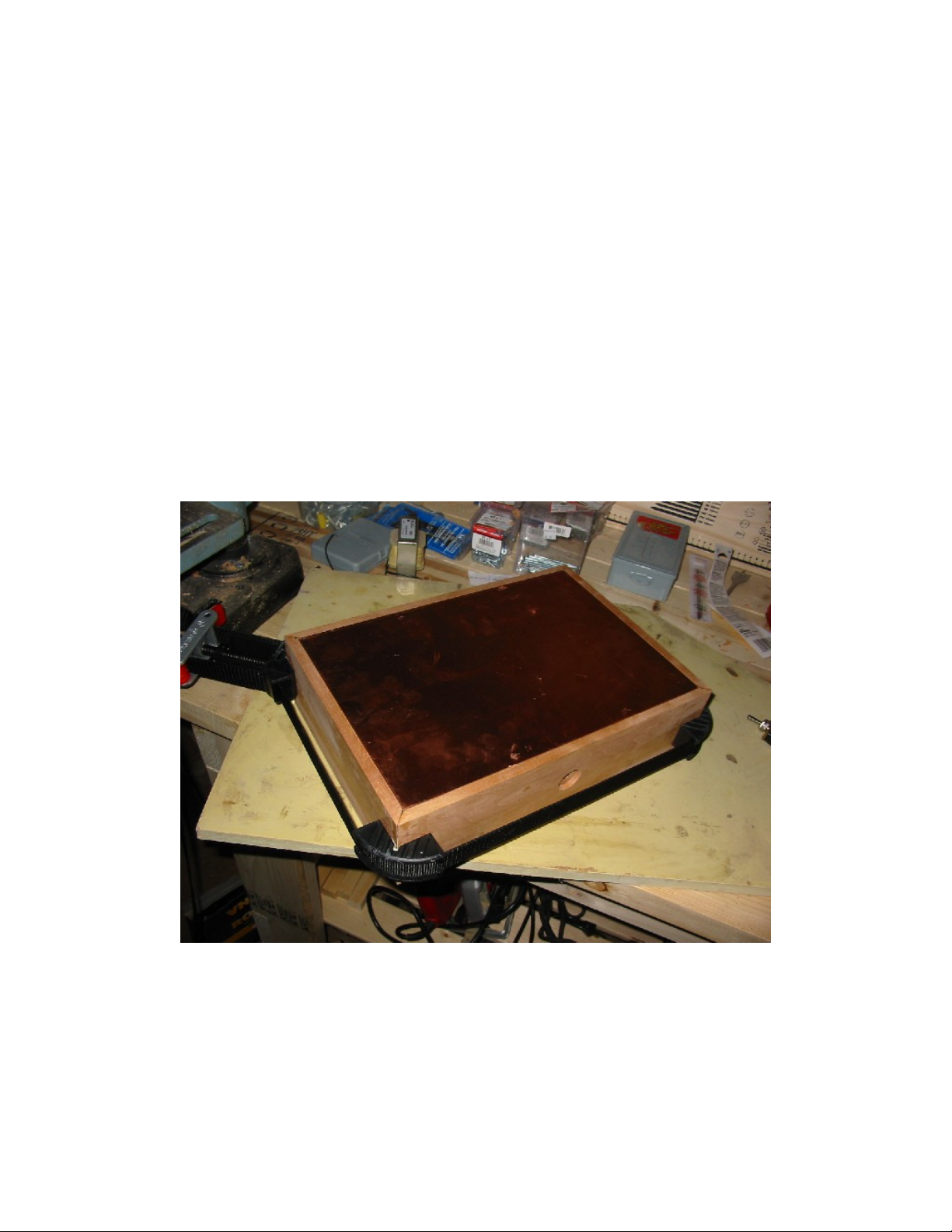

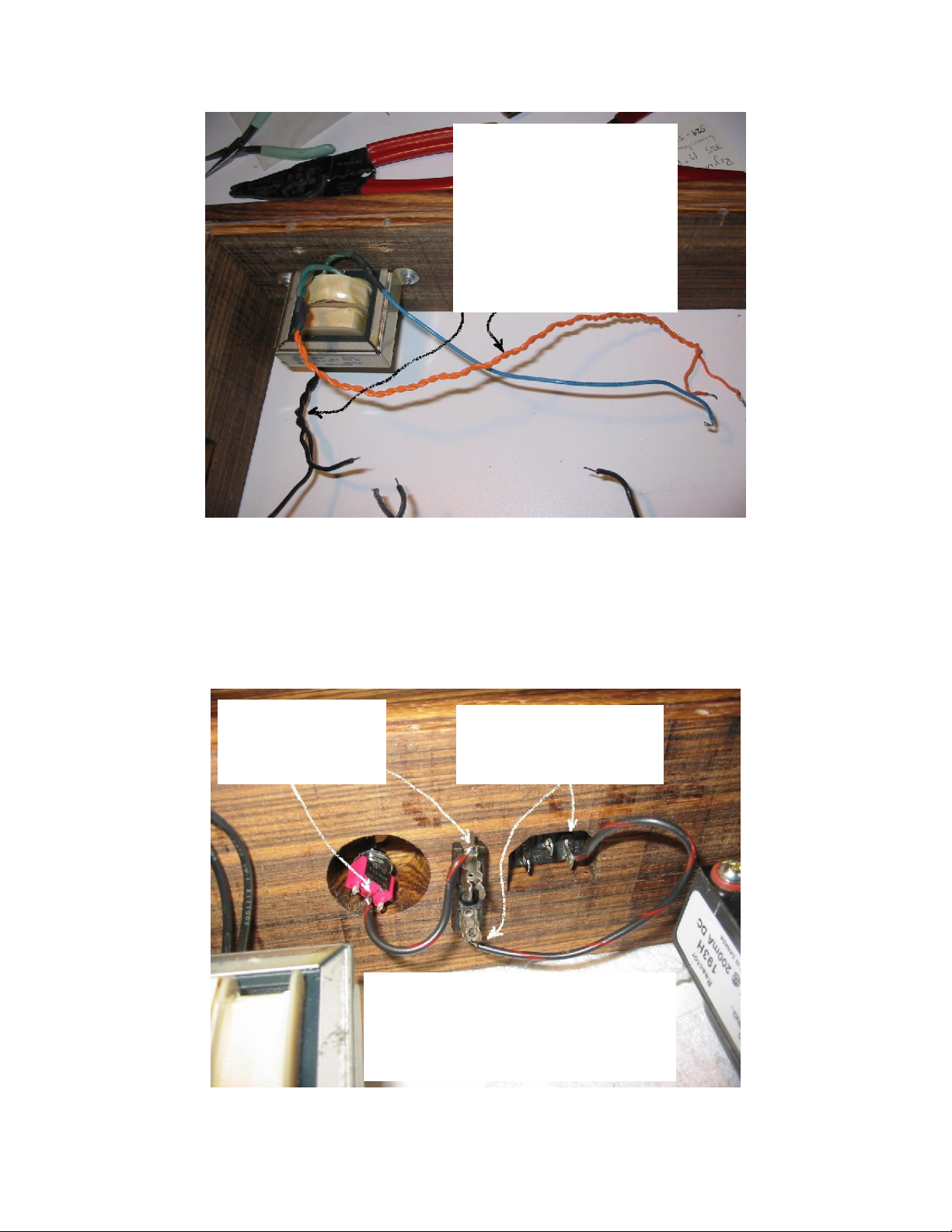

Figure 4 illustrate an overview of the parts location on the internal sides of the chassis.

Figures 5 and 6 shows close up of the PSU chokes and the two 2A3 filament transformer

installation. I used a “recycled” filament transformer (T

) so I had to make the leads

3

longer.

A top view of the location

of L3, L4 and T3 fixed on

the side of the chassis

Figure 4. Location of the chokes and the 2A3s filament transformer

Note that the laminations of L3 and

L4 are perpendicular to each other.

I fixed the chokes with wood

screws.

Figure 5 Close up of the PSU chokes (L3 and l4 on the schematic of the amp)

6

This is T3, the filament

transformer for the 2A3

filaments. It is fixed to the

chassis side with wood screws.

Since I recycled this transformer

from a previous project I had to

make the leads longer. You may

or may not have enough length

in your case. Just make sure to

twist the leads from the primary

and the secondary

Figure 6. Close up of the filament transformer (the blue wire is the secondary center tap)

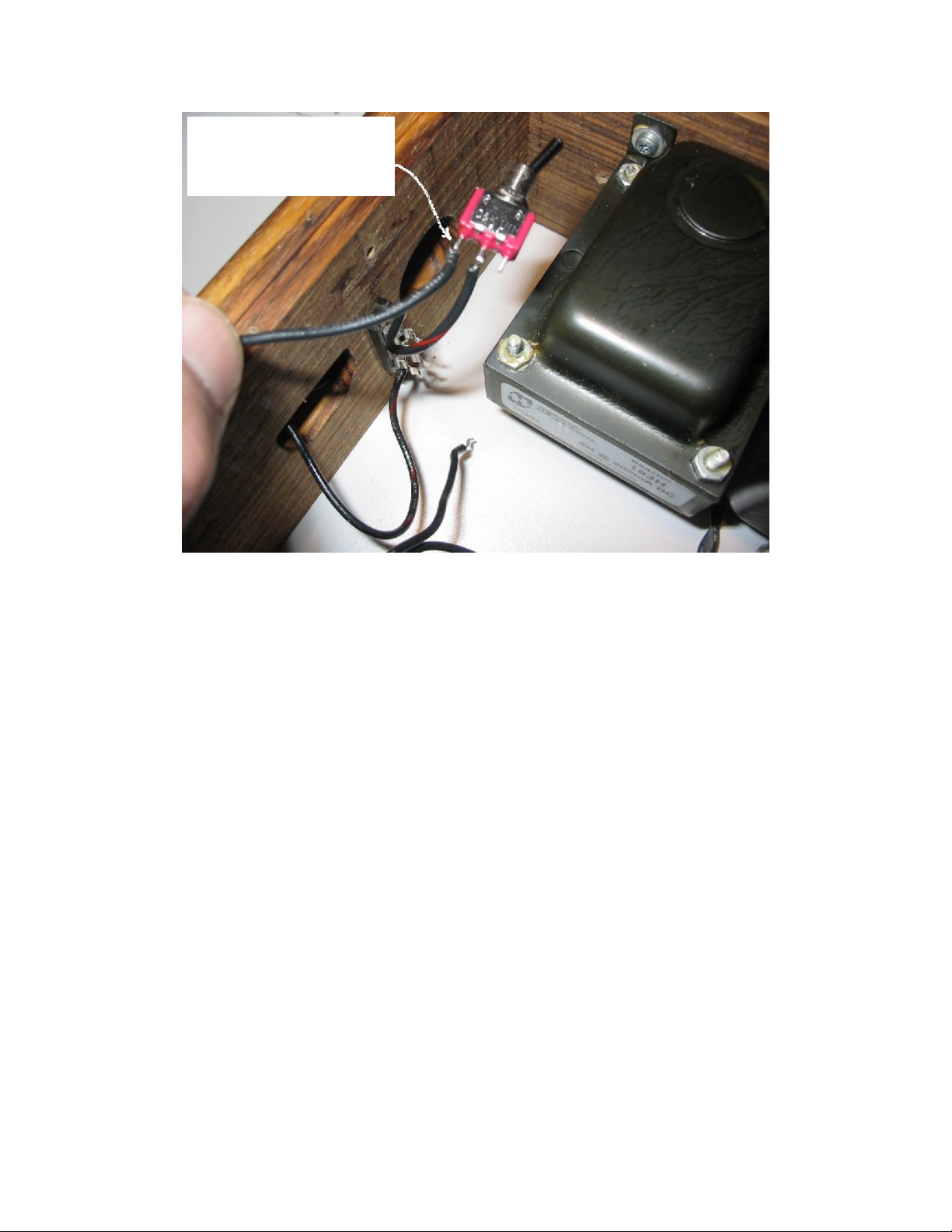

Time to start wiring the AC now. It is important that you understand the method I

show here might be illegal in your area. This is your responsibility to make sure your

amp is safe and “legal” to use. Most electronic technician will be able to help you on this.

I am not. Figures 7 and 8 show the wiring of the fuse and the switch. I install them on the

“live” lug of the AC socket (often denoted by a “L” in the socket near the lug).

Solder a wire from the

on-off switch center pin

to one side of the fuse

holder.

Figure 7. First step of the AC wiring

Solder a piece of wire from

the other side of the fuse

holder to the live (hot) pin of

the AC socket.

IMPORTANT NOTE: THE WAY OF WIRING

THE AC SHOWN HERE MIGHT NOT BE

ACCORDING TO YOUR LEGISLATION,

CODES, ETC. IT IS YOUR RESPONSIBILITY

TO WIRE THE AC ACCORDING TO THE

RULES YOU ARE SUBMITTED TO.

7

Solder a piece of wire to one

of the two outside pins of the

on-off switch. Leave the other

end of the wire loose for now.

Figure 8. Wiring the on-off switch.

Metal work.

Here is the part of the amp building process I don’t really enjoy. But that is just me…

About 90% of the amp building time is spent on the chassis (both wood and metal work).

I usually start by covering the top plate with masking tape and try out different layout that

will be both functional and aesthetic (at least to me…). Figure 9 illustrate this process.

Once the lay out is figured out I mark the location of the holes to be done and start the

punching process. Most holes are small holes for machine screws so they can be done

with a power drill. I personally use a small press drill. It goes like a charm. The larger

tube socket holes are done with Greenlee punches. I won’t recommend any dimension

here as it will be up to you to make sure you have the good punch dimension that will fit

your tube sockets size. For example, depending of the type of octal tube socket you will

get, you will need a 1” or a 1”1/8 punch.

Once all the holes are punched, I sand both side of the plate with an orbital sander. Figure

10 shows a finished and punched top plate waiting for the painting or coating or

whatever. I’ll be honest with you, I don’t paint those myself. I have a cat in the house and

no matter how careful I am, I always end up with a cat hair or two landing on the wet

paint. So I send them to the paint shop instead. Do I hear some of you say “Oh! What a

gorgeous copper plate! He should polish them and clear coat them!” Well be my guest

and go for it. Expect to spend a huge amount of time polishing these plates! Life is too

short in my case.

8

Figure 9. “Honey… What do you think of that one?”.

Figure 10. Once you are there you’ll have done 90% of the job.

9

Figure 11 shows the mechanical mounting of the parts. The capacitor mounting bracket is

a nice gizmo I have made by batch of 20 by a machinist. But it is something you can do

yourself easily. This bracket will allow you to install the filtering cap (C5) in a

convenient way. Don’t bother with figuring out why the stick-on tying pads are already

on the copper plate. I cheated and dismantled a perfectly operating Seth to write this

“How-to” so they were already installed. See how I like you guys!

EXO-173 PPS Ni

Rectifier

socket

CAPACITOR

MOUNTING

BRACKET

BINDING POSTS

2A3 socket

RCA JACK

2A3 socket

6C45-Pi

socket

BCP16GC Ni

Figure 11. Internal mechanical mounting of the parts.

So… where will you punch your tube socket holes? Assuming you want a layout like

mine, all the tubes are straight on the centerline according to the long axis of the plate.

Assuming that the side of the plate on the rear of the amplifier is the reference point, the

rectifier tube is located at 6.25", the first 2A3 is at 9", the second 2A3 is at 11.5" and the

driver tube is at 14". I suggest you punch the other holes by locating all the transformers,

choke, binding posts, RCA jack in a similar fashion than I did. Mark the holes location

and punch them. Sorry not to be more precise but I was too lazy to make a plan.

You’ll need 3 solder lug strips for each monoblock for building this amp the way I did.

Two of these will be single lug strips and one will be a dual lug strip. Make sure the lugs

are not of the grounded type. Install them as shown in Figure 12. Done? How about a

beer now?

10

Solder lug strip

p

r

(2 lugs)

Solder lug strip

(1 lug)

Solder lug strip

(1 lug)

Figure 12 localisation of the solder lug strip.

IMPORTANT WARNING: IF YOU

ARE A US CITIZEN, DON’T

DRINK AND SOLDER AT THE

SAME TIME BECAUSE THE

GENERAL SURGEON WILL KICK

YOUR ASS. DRINKING MIGHT

IMPAIR YOUR SOLDERING

ABILITY.

The Belle Gueule Originale was

the official beer while building

this am

lifie

Figure 13. Time for a cold one.

11

Loading...

Loading...