MAGNASPHERE has Created

the L

2 Series HSS

®

“High Security

Sensor” – The Next Generation

Sensors That Meet UL 634 Level 2

High Security Standards

for SCIFs,

Safes and Vaults and All Other High

Level Secure Applications.

THE INSIDER THREAT

IS REAL.

that the most devastating

threats to government

and corporate security

have come from employees

who were deemed trusted

insiders.

magnets

insiders can disable even

triple-balanced BMS

magnetic contacts while

the system is unarmed,

and enter undetected at

a later time, leaving no

evidence of tamper.

The MAGNASPHERE HSS

meets the UL 634 Level 2

High Security Standard.

Experts agree

Armed with simple

unscrupulous

MAGNASPHERE L2 HSS Technology

Resistant to External

and INTERNAL

magnetic defeat

Built-in EOL

resistors available

Unique cross hole

mounting feature

eliminates need for

L and Z brackets on

most installations

Retro-fit for existing

BMS devices

No adjustment

required for

installation

Industry’s most

secure removal

tamper sensor /

circuit

ULI HIG H SECU RITY LEVEL 2

CUL HIGH SECURITY

BP 10350

MAGNASPHERE

switch technology

resists permanent

contact welding (lightning, power

surges, stun guns)

Single and dual alarm

contacts available

American made

using award-winning

MAGNASPHERE

switch

technology

Compatible with control

panel models that accept

contact inputs

Competitively priced

INTRINSICALLY SAFE,

Simple Apparatus

(see page 4)

© MAGNASPHERE CORP. | REVISED 3/22/16

www.MAGNASPHERE.com

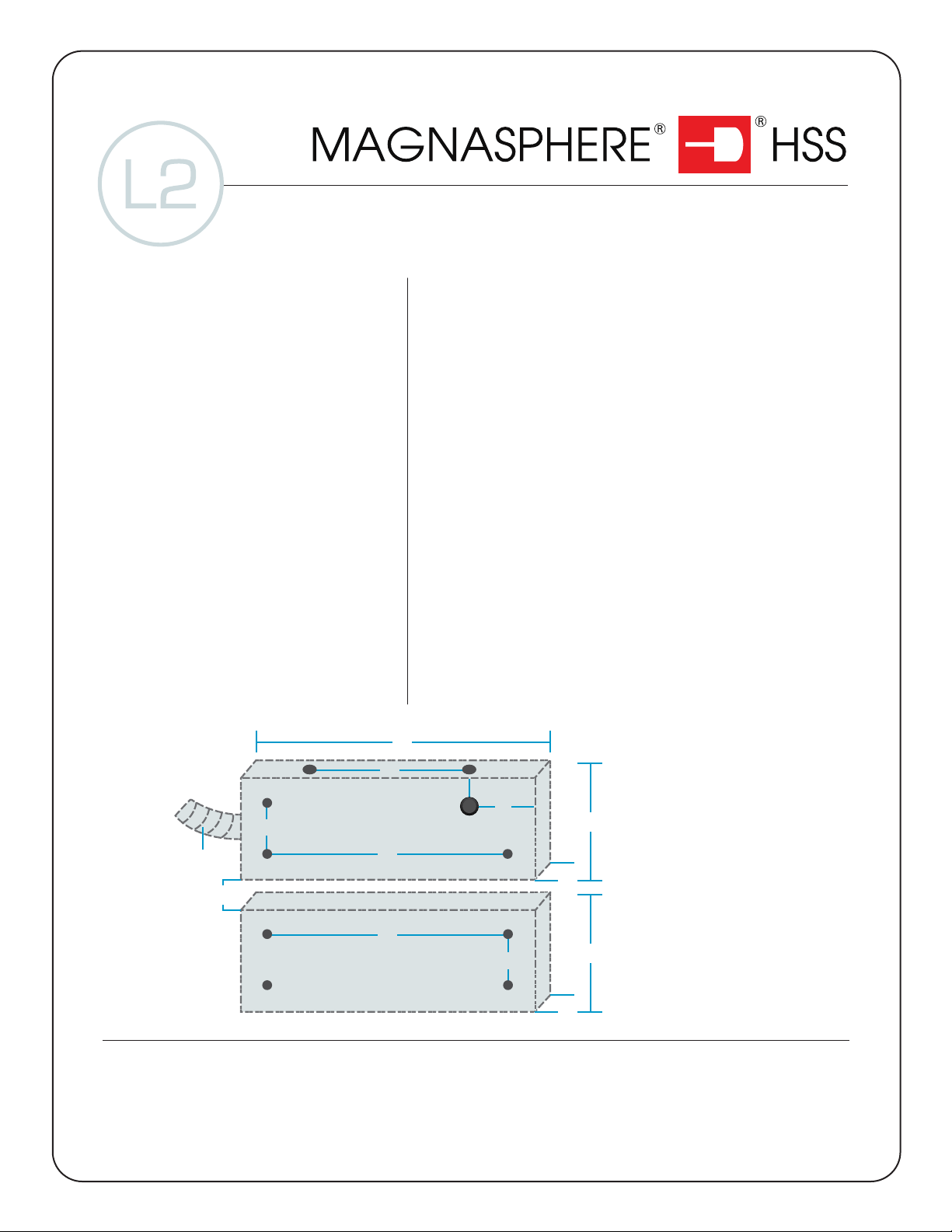

L2 HSS DIMENSIONS

CONSTRUCTION AND TECHNICAL SPECIFICATIONS

[L] 4.25” (107.9 mm)

[H] 1.5” (38.1 mm)

[D] 1.0” (25.4 mm)

[S] 3.5” (88.9 mm)

[S1] 0.75” (19.1 mm)

[P] 0.84” (21.3 mm)

[P1] 0.52” (13.2 mm)

[E] 3.03” (76.9 mm)

[C] 36.0” (914.4 mm)

X 0.30” (7.6 mm)

Stainless Steel Cable

[A] 0.125" (3.18 mm)

Actuation Gap

(recommended for

maximum internal

magnetic non-defeat

characteristics)

Aluminum Case: Silver-Gray Anodized

Wire Lead Type:

Solid Color-Coded Lead Wires, 22 AWG

Hermetically Sealed Switch Contacts

Fully Epoxy Potted Assembly

Single Alarm Contact Version (L2 S): Closed or Open Loop

Dual Alarm Contact Version (L2 D): Closed Loop

Removal Tamper Circuit: Closed Loop

Max Current: 0.25 A Resistive

Max Voltage: 30 VDC

Max Power:

0.250 W

Operating Temperature: -40° C to +80°C

Suitable for Indoor and Outdoor Use

Intended for Connection to UL Listed Compatible

Control Panels

L

SENSOR

MAGNET

S1

C

A

E

P1

P

H

S

D

PATENTED DESIGN

#5977873 #6506987

#6803845 #7291794

#7944334 #8314698

#6087936 #6603378

S

S1

H

D

#7023308 #RE39731

#8228191 #8648720

& Other Patents Pending

MAGNASPHERE® Corp. provides superior performing magnetic contact sensor technology for the residential, commercial,

and federal government security markets. The HSS’s leading-edge technology aims to set new industry standards for

high security sensors while providing an affordable and more effective alternative to reed-based security contacts.

®

To learn more about the MAGNASPHERE

© MAGNASPHERE CORP.

L2 HSS High Security Sensor visit www.MAGNASPHERE.com or call 262-347-0711.

www.MAGNASPHERE.com

How the HSS Magnet / Removal Tamper Circuit Works

The MAGNASPHERE HSS Incorporates the Most

Secure Anti-Tamper Features of Any Device Available.

In addition to the sensors inside that will detect the

presence of a stronger defeat magnet placed on any

surface of the HSS, the removal tamper circuit will

alarm BEFORE the HSS can be removed.

You will notice that the mounting hole on the upper

right face of the HSS sensor is larger than the other

mounting holes and slightly off set towards the center

of the sensor. A tamper proof MAGNASPHERE

switch is positioned inside the unit facing the bore

of this mounting hole.

Whether you use the four mounting holes on the

face of the sensor (in-swinging doors), or the two

mounting holes on the bottom of the sensor (out-

swinging doors), the upper right mounting hole with

the removal tamper switch will be used.

Once the unit has been mounted, the removal

tamper magnet (included) is inserted into this

mounting hole. It will be attracted to the mounting

screw and will activate the removal tamper switch.

The mounting hole cover cap (included) is then

inserted and locked into position.

In order to access that mounting screw to remove

the sensor, the locking cap must be pried out, and

a steel rod or magnet inserted into the hole to

extract the tamper magnet. Removal of the tamper

magnet will cause the removal tamper switch

to alarm.

The HSS also includes anti-rotation pins that will

prevent an intruder from removing the non-removal

tamper mounting screws and twisting the HSS into

a position where another door actuating magnet

could be placed, simulating a secure position.

Unique Cross-Hole Mounting Feature Eliminates Need

A Unique Feature of the MAGNASPHERE HSS is the

Two Mounting Holes Located on the Bottom Surface

of the Sensor that Faces the Actuating Magnet.

Using these mounting holes allows the installation

of the sensor directly to the door stop, eliminating

the need for an L bracket.

The actuation magnet is then mounted directly to

the surface of the door so that it lines up beneath

the door stop mounted sensor, eliminating the need

for a Z bracket.

© MAGNASPHERE CORP.

for L or Z Brackets on Most Out-Swinging Doors

Depending on the “play” in the door to stop fit, it may

be necessary to use a magnet spacer(s) ( available

from MAGNASPHERE ) to insure proper alignment

between sensor and magnet.

On in-swinging doors (flush to frame), the HSS

sensor is mounted directly to the door frame, and the

actuation magnet is mounted directly to the door.

www.MAGNASPHERE.com

The MAGNASPHERE HSS High Security Sensor conforms to the requirements of

UL Standard 913

Standard for Intrinsically Safe Apparatus and Associated Apparatus

for Use in Class I, II, III, Division 1, Hazardous (Classified) Locations

for use in Hazardous locations as an INTRINSICALLY SAFE SIMPLE APPARATUS*.

INTRINSICALLY SAFE

The Construction of the HSS devices

incorporates robust, hermetically sealed

MAGNASPHERE switch technology,

complete

electrical, components and magnetic

actuation.

epoxy encapsulation of all

The MAGNASPHERE HSS models

2S and L2D used as intrinsically

L

safe simple apparatus in hazardous

locations MUST be used in conjunction

with a Div. 1 Class 1 Group B Intrinsically

Safe Barrier listed by a Nationally

Recognized Testing Laboratory (NRTL).

The necessary consideration of the

appropriate use of the apparatus in the

hazardous locations is addressed in the

instructions for the barrier (or device)

providing power to this apparatus and

to the hazardous location.

© MAGNASPHERE CORP.

* Reference UL Standard 913 (includes

UL 60079-11, the US adoption of the IEC

60079-11 standard for intrinsic safety,

taking a national deviation [identified in

the standards DV or DR] to correspond

to the definition in the national electrical

code). Sections: 3.1.1, 5.4 and associated

DV and DR deviations.

www.MAGNASPHERE.com

Loading...

Loading...