Page 1

OPERATING INSTRUCTIONS

For Magna-Matic Sharpeners

Covering Models:

MAG-8000 Universal Lawn Mower Blade Sharpener

MAG-9000 Lawn Mower Blade Sharpener

Visit us at www.magna-matic.com for more photos

of products & other helpful info.

Helping you get the most

out of your shop for the last 40 years.

Page 2

page page

THE SAFE WAY IS THE

ONLY WAY TO GRIND!

Instructions given with this symbol are for personal safety. Be

sure you and your employees follow them. A careful operator

is the best insurance against accidents.

Before handling any equipment read and understand the

instructions.

When using electric tools, basic safety

precautions should always be followed to

WARNING

1. Grounding Instructions - This tool must be grounded

while in use to protect the operator from electric shock. The

tool is equipped with an approved three conductor cord and

three prong grounding type plug to t the proper grounding

type receptacle. The green (or green and yellow) wire is the

grounding wire.

2. Extension Cords - Use only three wire extension cords

which have three prong grounding type plugs and three pole

receptacles which accepts the tool’s plug. Replace or repair

damaged cords.

reduce the risk of re, electric shock, and

personal injury including the following.

3. Keep Work Area Clean - Cluttered areas and benches

invite accidents.

4. Consider Working Environment - Don’t use power tools

in damp or wet locations. Keep work area well lit. Don’t

expose power tools to rain. Do not use tool in presence of

ammable liquids or gases.

5. Keep Children Away - All visitors should be kept a safe

distance form the work area. Do not let visitors have contact

with the tool or the extension cord.

6. Store Idle Tools - When not in use, tools should be stored

in dry, high or locked-up places out of reach of children.

7. Don’t Force Tool - It will do the job better and safer at the

rate for which it was designed.

1

Page 3

8. Don’t Over-Reach - Keep proper footing and balance at all

times.

9. Wear Proper Apparel - Do not wear loose clothing or jewelry that can get caught in moving parts. Rubber gloves and

non-skid foot wear are recommended when working outdoors.

Wear protective hair covering to contain long hair.

10. Use Safety Glasses - Also face or dust mask-wrap

around goggles, or other eye protection.

11. Don’t Abuse Cord - Never carry tool by cord or yank it

to disconnect from receptacle. Keep cord from heat, oil, and

sharp edges.

12. Disconnect Tool - When not in use; before servicing;

when changing grinding wheel.

13. Avoid Accidental Starting - Don’t carry plugged in tool.

Be sure switch is off when plugging in.

14. Grinding Wheels - Use only grinding wheels having a

maximum operating speed of 5500 RPM. KEEP GUARDS IN

PLACE.

15. Guard Against Electrical Shock - Prevent body contact

with grounded surface. For example: pipes, radiators, etc.

16. Stay Alert - Watch what you are doing. Use common

sense. Do not operate tool when you are tired, or under the

inuence of any drugs or alcohol.

17. Check Damaged Parts - Before further use of the tool,

a guard or other part that is damaged should be carefully

checked to determine that it will operate properly and perform

its intended function. Check for alignment of moving parts,

breakage of parts, mounting and any other condition that effect

its operation. All parts should be properly repaired or replaced.

Do not use this tool if the switch does not turn it on or off.

18. Never Leave Tool Unattended - Turn the power off.

Don’t leave the tool until it comes to a complete stop.

19. Replace Cracked Wheels Immediately.

20. Read - the enclosed A Primer on Grinding Wheel

Safety (NORTON® Publication)

21. Never attach the provided spanner wrench ,arbor

wrench, or any other object to the grinder.

2

Page 4

page page

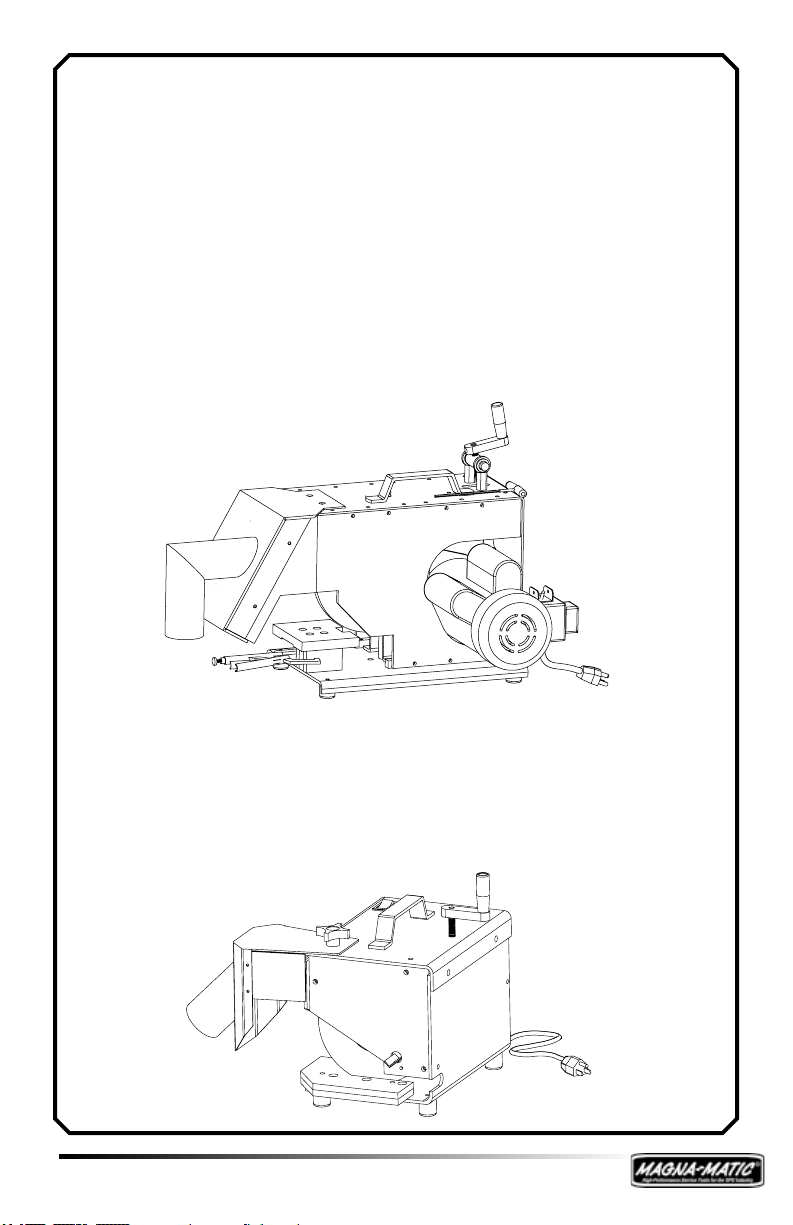

Model Descriptions

If you have further questions or do not understand any of the

instructions please contact us! We are happy to give any needed

extra explanation. Thank you for your purchase of MAGNAMATIC high-performance service tools.

MAG-8000 Universal Lawn Mower Blade Sharpener

The MAG-8000 is the latest technology in rotary lawn mower blade

sharpening. It holds 3 patents for its revolutionary design. Since its

release in 1999 the MAG-8000 has quickly become the standard in

the Outdoor Power Equipment Industry. The MAG-8000 is designed to

sharpen almost all lawn mower blades, conventional blades (straight

at cutting edges) and mulching blades (curved cutting edges.)

Instructions

begin on page 4

MAG-9000 Lawn Mower Blade Sharpener

The MAG-9000 is a solid low cost solution in rotary lawn mower blade

sharpening. It provides you with 60 second per blade sharpening per-

formance in a small package. Since its release in 1987 the MAG-9000

has become a best friend of lawn care professionals The MAG-9000 is

designed to be a compact sharpener for conventional blades (straight

at cutting edges).

Instructions begin

on page 16

3

Page 5

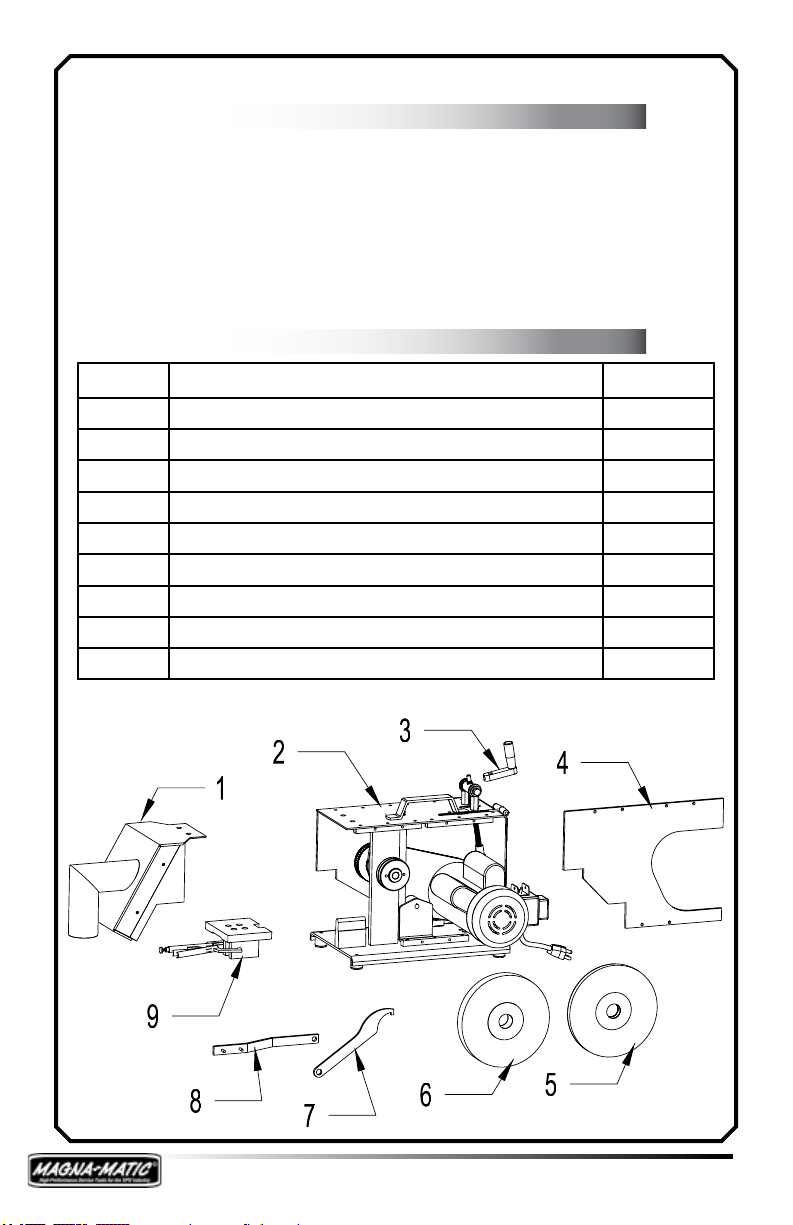

Begin The Assembly

Step 1: MAG-8000

Unpack the MAG-8000, please keep the box and packaging incase of shipping damage or any need for return. When

unpacking the MAG-8000 take stock of all the items in the box.

Parts Inventory

Qty Description Key #

1 Grit Guard 1

1 Sharpener Body 2

1 Crank Handle 3

1 Motor Side Lexan® Guard 4

1 Grinding Wheel (1/2” wide) 5

1 Grinding Wheels (1” wide) 6

1 Arbor Wrench 7

1 Spanner Wrench 8

1 Mobile Work Table 9

4

Page 6

page page

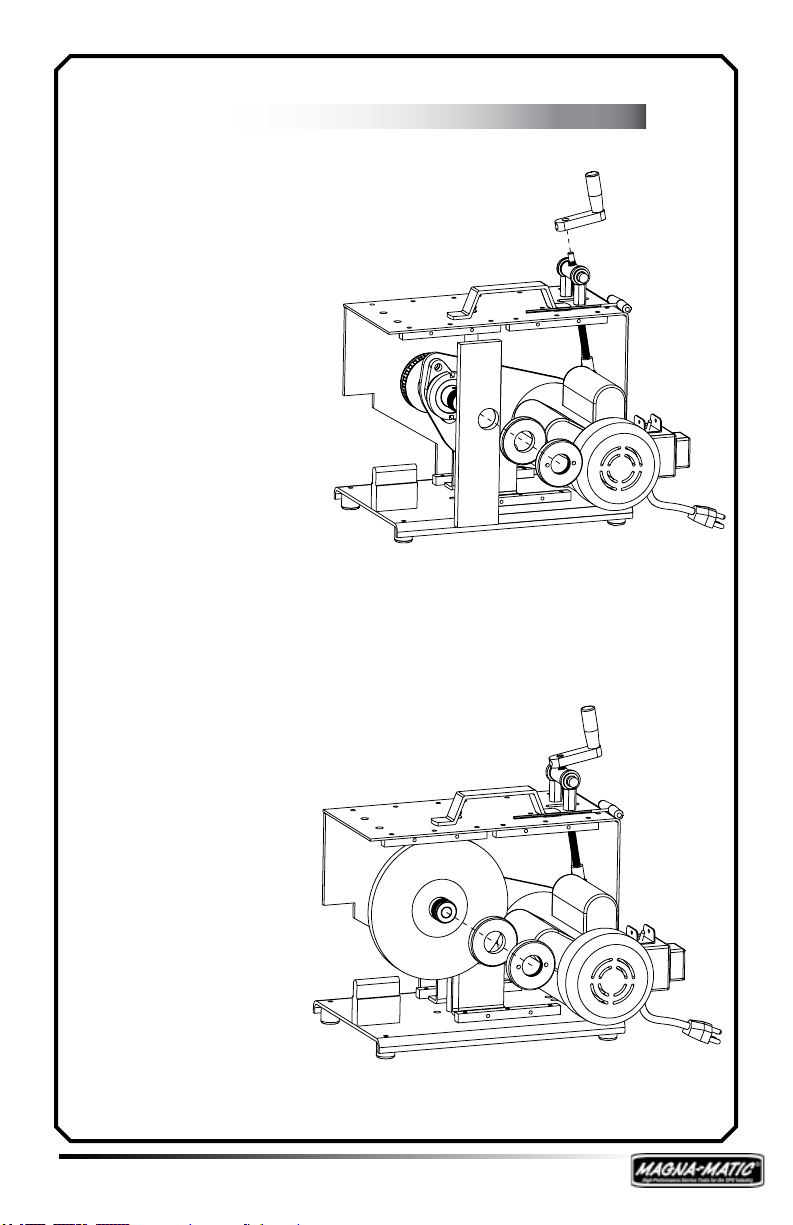

MAG-8000 Assembly

Step 2:

First remove the TRANSPORT BRACKET from the

MAG-8000 arbor, keep

the transport bracket

for any future shipping

needs. You will need to

remove the black bolting bar to allow clearance for the transport

bracket to be removed.

Use the spanner wrench

if needed to remove the

arbor nut. Assemble the

crank handle, align the

set screw to the milled

at on the threaded adjustment rod, and use the Bondhus 1/8”

wrench to tighten the set screw.

Step 3:

Mount a grinding

wheel to the MAG-

8000 arbor. One inch

wide wheels are best

used with conventional

lawn mower blades,

and the half-inch wide

wheels are required

for mulching blades.

NOTE: when mounting

the half-inch grind-

ing wheel the ARBOR

SPACER is required.

The ARBOR SPACER is

NOT required for 1 inch wide wheels. See above diagram.

5

Page 7

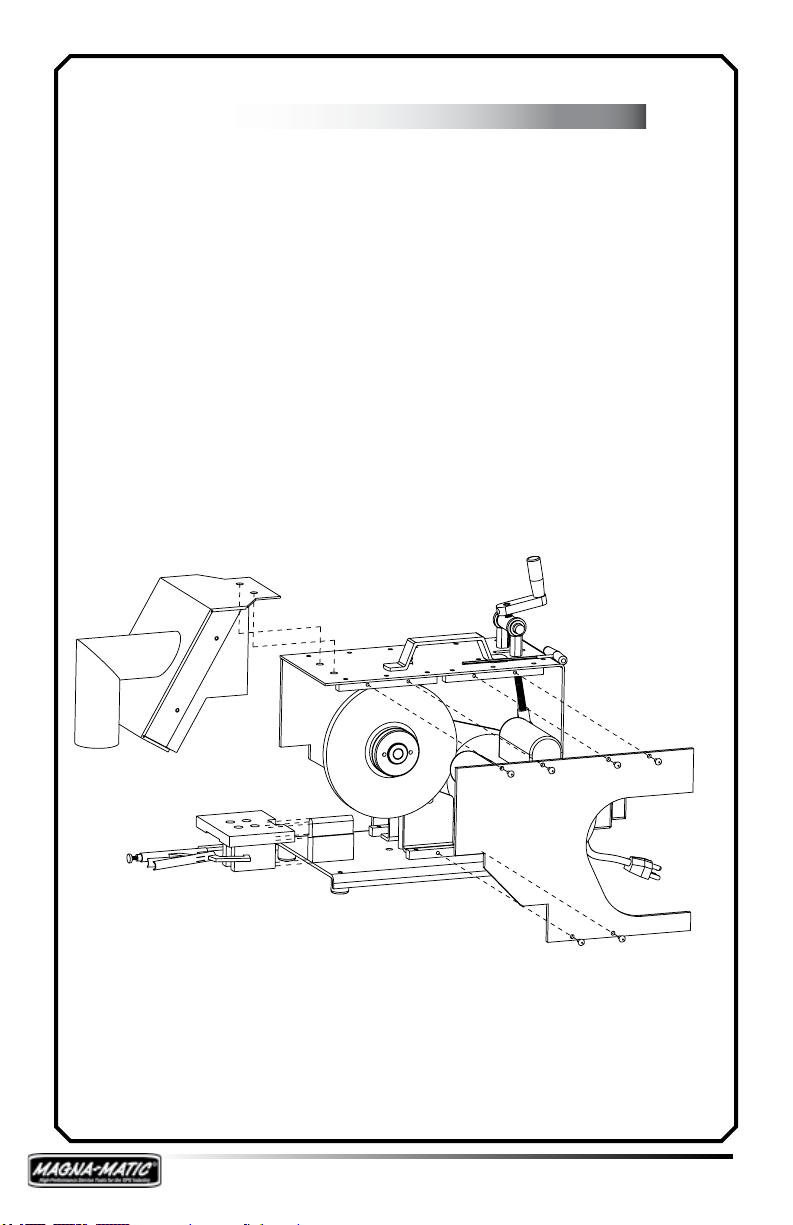

MAG-8000 Assembly Con’t

Step 4:

Assemble the grit guard to the MAG-8000 using the bolts found

on the grit guard. Do not tighten the Lexan® windows on the

grit guard (they will be tightened in a later step).

Assemble Motor Side Lexan® Guard to the MAG-8000. The

motor side Lexan® guard will slide behind the grit guard

Lexan® window - slide it forward to clear the motor capacitors

- then align the holes and fasten the guard to the bolting bars.

Raising or lowering the motor with the angle adjustment crank

will provide more clearance. Use the hardware in the holes and

the Bondhus T-handle wrench. Be sure to tighten 3 bolts under

the MAG-8000, and the 6 along the top to secure the bolting

bars holding the Lexan® guard. Lastly tighten the grit guard’s

Lexan® windows.

Step 5:

Testing the unit, be sure the grinding wheel moves freely.

Ensure the MAG-8000 ON/OFF switch is in the OFF POSITION,

plug the MAG-8000 into a 20 amp, 110 volt outlet. Switch the

ON/OFF switch to the ON POSITION to test the motor. The

motor should achieve FULL speed in 1-2 seconds. If it does

not, see page 13, or contact MAGNA-MATIC (800-328-1110).

6

Page 8

page page

MAG-8000 Use

Step 6: Mulching Blades

Be sure to wear protective clothing before handling and

sharpening lawn mower blades. Wear safety glasses and

protective gloves.

Blade & Sharpener Preparation

1. Clean the blade to its base material, using the MAG-12000

blade cleaner, or alternate cleaning process.

2. Check the straightness with the gauge rod of the MAG1000 blade balancer. (Never straighten bent blades!)

3. Obtain a balance reading from the MAG-1000 to indicate the

light end of the lawn mower blade. Once the light end

is sharpened, it is complete. The heavy end is used to

remove material for balance. SEE MAG-1000 Instruction

Manual for more info on blade balancing.

4. The MAG-8000 will require the 1/2” inch wide grinding wheel

to sharpen a mulching blade. Mount the 1/2” wide grinding wheel on the MAG-8000. (Arbor spacer req.)

5. The xed 1/2” wide curved metal work table will be needed

to sharpen a mulching blade, remove the clamp-able mo-

bile work table.

6. Lower the grinding wheel with the adjustment crank, stop

just before you grind the corner of the work table. When

the grinding wheel is almost touching the corner of the

work table (curved or mobile work tables) you will produce

a 30 degree angle on the lawn mower blade. (see page 8)

Mulching Blade Sharpening

7. Switch the ON/OFF switch to the ON position.

8. Place the mulching blade in the MAG-8000 starting at

the inside of the edge (closest to the mounting hole), and

pull the blade across the grinding wheel (perpendicular to

the rotation of the grinding wheel, see page 10.) Keep

rm pressure downward on the blade to maintain contact

with the rounded surface of the work table. Allow the

work table to follow the contours of the mulching blade.

Take one pass at a time. Use even pressure into the

grinding wheel to achieve an even stream of sparks.

7

Page 9

MAG-8000 Use Con’t

Step 6: Con’t

9. When using the MAG-8000 for mulching blades keep the

blade level, and perpendicular to the rotation of the grind-

ing wheel. Pay close attention to the TIP of the blade, see

page 25.

This view of the MAG-8000

(with the grit guard removed

for visibility) you are able

to see how the curved edge

mulching blade should follow

over the rounded work table.

Contact between the blade

and work table must be maintained

Adjusting the Edge Angle

Applies to both MAG-8000 and MAG-9000

30 Degree Reference Point - When the grinding wheel

is lowered to the work table (almost cutting the work table

corner) you will produce a 30 degree angle on the lawn mower

blade. As the grinding wheel wears and reduces in diameter,

continue to lower the grinding wheel to almost touch the work

table to maintain a consistent 30 degree edge angle on a blade.

The edge angle can be varied plus or minus the 30 degree

reference point via the adjusting crank. Lowering the grinding wheel into the work table (grinding into the work table)

will result in a greater than 30 degree angle (a steeper angle.)

Note, you will be creating a new angle reference point Raising

the grinding wheel will result in a lesser than 30 degree angle

(a more shallow angle.)

8

Page 10

page page

MAG-8000 Use Con’t

Step 7: Conventional Blades

Blade & Sharpener Preparation

1. Clean the blade to its base material, using the MAG-

12000 blade cleaner, or alternate cleaning process.

2. Check the straightness with the gauge rod of the MAG-1000

blade balancer. (Never straighten bent blades!)

3. Obtain a balance reading from the MAG-1000 to indicate the

light end of the lawn mower blade. Once the light end

is sharpened, it is complete. The heavy end is used to

remove material for balance. SEE MAG-1000 Instruction

Manual for more info on blade balancing.

4. The MAG-8000 will require the 1” inch wide grinding wheel

to sharpen a conventional blade. Mount the 1” wide grinding wheel on the MAG-8000. (1/2” wide grinding wheel

may be used for conventional blades)

5. The mobile work table will be needed to sharpen a conventional blade, slide the mobile work table over the curved

1/2” wide work table, and clamp it tight with the attached

vice grip.

6. Lower the grinding wheel with the adjustment crank, stop

just before you grind the corner of the work table. When

the grinding wheel is almost touching the corner of the

work table (curved or mobile work tables) you will produce

a 30 degree angle on the lawn mower blade. (see page 8)

7. Place the conventional blade on the at work table and pull

and push the blade across the grinding wheel (perpendicular to the rotation of the grinding wheel, see page 10.)

Keep rm pressure downward on the blade to maintain

contact with the surface of the work table. The force into

the grinding wheel should be substantial, resulting in a

continuous stream of sparks from the grinding wheel. The

grinding process should be continuous without interruption

until nished. Pay close attention to the TIP of the blade,

see page 25.

9

Page 11

The above diagram shows the application of movement and

force to the blade during sharpening a conventional blade. Note,

for curved edge mulching blades, it is the same except for the

“forth” or inward fed motion. You will maintain much more control if you only “pull” mulching blades through the MAG-8000. It

is critical with both blade types that the operator keeps downward pressure “force” on the blade, this will prevent chattering

and keep the grinding wheel “true” or round.

Overhead view of blade

approach - applies to both conven-

tional and curved edge mulching

blades.

10

Page 12

page page

MAG-8000 Wheel Replacement

Be sure the MAG-8000 is unplugged. Using a 1/8” Allen

wrench (supplied with MAG-8000) remove the (6) screws of the

front Lexan® guard. Locate your spanner wrench and arbor

wrench (both supplied by Magna-Matic.) The arbor wrench ts

into a square notch in the arbor, behind the grinding wheel, and

the spanner wrench ts into the two holes in the arbor nut. See

diagrams below.

Always inspect grinding wheels for possible damage - never

mount a cracked grinding wheel.

For optimum performance use only grinding wheels specied

by Magna-Matic. All NORTON® brand grinding wheels sold by

Magna-Matic are speed tested for 5500 RPM

NOTE: Arbor has LEFT HANDED THREADS.

MAG-8000 OEM WHEEL = 9000-35RP &

8000-30RP

11

Page 13

MAG-8000 Care & Service

General Care:

Keep the MAG-8000 clean, use compressed air to blow the

machine off periodically. Use mild soapy water to clean powder

coated surfaces and Lexan® guards.

Greasing of Bearing Blocks:

Care should be taken when re-greasing bearings to avoid overlling. Overlling can lead to excessive heat and or unseating

of the seals. Grease should be introduced in small increments

and under light pressure. The use of pneumatic greasing is not

recommended unless low pressure is assured. Whenever possible, the shaft should be rotated during re-lubrication to insure

proper grease distribution throughout the raceways.

3-6 Months OR 500-1000 Machine Hours - Fill with 2 grams.

Timing Belt Replacement

See the diagram to the right

for proper belt tension. Tension can be applied either

at the bolts of the motor

or bearing blocks. There is

slight play in the holes to

apply or relieve belt tension.

Angle Adjustment Timing

When replacing the adjustment trunnion allow one inch

of space from the top of the

threaded rod to the top of the

trunnion. When replacing the

yoke, the threaded rod should

be ush with the end of the

threads of the yoke before con-

necting to the pivot plate.

12

Page 14

page page

MAG-8000 Trouble-Shooting

The MAG-8000 will not start.

Double check that the MAG-8000 is plugged in a 20 amp (minimum) circuit. Due to the “instant starting” of the MAG-8000 it

has a tremendous starting draw, therefore a minimum 20 amp

circuit is required.

Check all building fuses or circuit breakers.

To diagnose a ON/OFF switch problem, (unplug from power

source.) Open the square access panel below the switch, and

disconnect the (2) wires from the switch (label the wires before

disconnecting.) Directly connect and insulate the (2) wires.

Plug the MAG-8000 into a power source, this should start the

motor without the switch.

If the MAG-9000 still does not start after this test, the solid

state switch, capacitors, or the motor is no longer function-

ing and must be replaced. Call 800-328-1110 for replacement

parts or a warranty issue.

The MAG-8000 is vibrating.

This is caused by a grinding wheel that is “out-of-round” or

“out-of-balance” - this will happen when the user does not

apply downward pressure on the blade when sliding it back and

forth in the MAG-8000. Also, on occasion, grinding wheels can

have a “hard spot” which will also cause this.

To repair the wheel you can dress it with a grinding wheel

dressing tool, or you can use an old lawn mower blade. When

using the old lawn mower blade nd a portion of the blade

that is square stock (near the mounting hole - not on an edge)

and grind it with the MAG-8000, but do not go back and forth

- simply keep pressure down on the work table and into the

wheel evenly. This will re-shape the wheel back into a circle.

The MAG-8000 belt is not tight (or making excessive

noise.)

See page 12 on how to re-tension the belt. Also note having

the blade extremely tight will create a high pitched noise, and

signicantly reduce the life of the belt.

13

Page 15

MAG-8000 Specications

MAG-8000 MAG-8000 (Euro)

Length 24 inches 60.9 cm

Width 12 inches 30.5 cm

Height 17 inches 43.1 cm

Weight 80 LBS 36 kg

Ship Weight 1 box 85 LBS 38 kg

Motor Specs BALDOR® ELECTRIC BALDOR® ELECTRIC

Horse Power 1 1

RPM 3450 2850

Duty Cycle Continuous Continuous

Hertz 60 50

Volts 115 220

Phase Single Single

Capacitors Dual (2) Dual (2)

Solid State Switch Yes Yes

Motor Type Industrial - Totally

Insulation Class F Class F

Direction Single Direction Single Direction

Fan Cooled Yes Yes

Transmission Timing belt/pulley Timing belt/pulley

Grinding Wheels NORTON® Abrasives NORTON® Abrasives

Wheel Dimensions

Enclosed

7” dia x 1” thick x 1-1/4”

dia arbor

7” dia x 1/2” thick x 11/4” dia arbor

Industrial - Totally

Enclosed

17.7 cm dia x 2.5 cm

thick x 3.18 cm dia

arbor

17.7 cm dia x 1.27 cm

thick x 3.18 cm dia arbor

14

Page 16

page page

15

Page 17

Begin The Assembly

Step 1: MAG-9000

Unpack the MAG-9000, please keep the box and packaging

incase of shipping damage or any need for return. When un-

packing the MAG-9000 take stock of all the items in the box.

Parts Inventory

Qty Description Key #

1 Grit Guard 1

1 Sharpener Body 2

1 Spanner Wrench 3

1 Arbor Wrench 4

16

Page 18

page page

MAG-9000 Assembly

Step 2:

First assemble the grit guard to the MAG-9000 body using the

plastic knob located on the top of the MAG-9000.

Step 3:

Be sure the MAG-9000 is unplugged, and adjust the angle

adjustment crank to make sure the grinding wheel freely

rotates. SEE PAGE 8 for information on EDGE ANGLE ADJUST-

MENT

17

Page 19

MAG-9000 Use

Step 4: Conventional Blades

Be sure to wear protective clothing before handling and sharpening lawn mower blades. Wear safety glasses and protective

gloves.

Blade & Sharpener Preparation

1. Clean the blade to its base material, using the MAG-12000

blade cleaner, or alternate cleaning process.

2. Check the straightness with the gauge rod of the MAG-1000

blade balancer. (Never straighten bent blades!)

3. Obtain a balance reading from the MAG-1000 to indicate the

light end of the lawn mower blade. Once the light end

is sharpened, it is complete. The heavy end is used to

remove material for balance. SEE MAG-1000 Instruction

Manual for more info on blade balancing.

4. Lower the grinding wheel with the adjustment crank, stop

just before you grind the corner of the work table. When

the grinding wheel is almost touching the corner of the

work table you will produce a 30 degree angle on the lawn

mower blade. (see page 8)

The above diagram shows left and

right-handed blade approach into the

MAG-9000. The blade must stay parallel to the 45 degree angle cut in the

work table.

18

Page 20

page page

MAG-9000 Use

Step 4: Conventional Blades

Conventional Blade Sharpening

7. Switch the ON/OFF switch to the ON position.

8. Place the conventional blade on the at work table and pull

and push the blade across the grinding wheel. Keep rm

pressure downward on the blade to maintain contact with

the surface of the work table. The force into the grinding wheel should be substantial, resulting in a continuous

stream of sparks from the grinding wheel. The grinding

process should be continuous without interruption, until

nished. Take extra care when near the TIP of the blade,

it is critical that the TIP does not become rounded. SEE

PAGE 25 TIP GEOMETRY. Note: the grinding wheel will

dress to a 45 degree angle - this is normal and intended.

19

Page 21

MAG-9000 Wheel Replacement

Be sure the MAG-9000 is unplugged. Using a 5/32” Allen

wrench remove the (3) screws of the front Lexan® guard.

Locate your spanner wrench and arbor wrench (both supplied

by Magna-Matic.) The arbor wrench ts into a square notch in

the arbor, behind the grinding wheel, and the spanner wrench

ts into the two holes in the arbor nut. See diagrams below.

Always inspect grinding wheels for possible damage - never

mount a cracked grinding wheel.

For optimum performance use only grinding wheels specied

by Magna-Matic. All NORTON® brand grinding wheels sold by

Magna-Matic are speed tested for 5500 RPM

NOTE: Arbor has LEFT HANDED THREADS.

MAG-9000 OEM WHEEL = 9000-23RP

20

Page 22

page page

MAG-9000 Trouble-Shooting

The MAG-9000 will not start.

Double check that the MAG-9000 is plugged in a 15 amp (minimum) circuit.

Check all building fuses or circuit breakers.

First determine what type of switch your MAG-9000 has.

(1987 - 1996 metal toggle switch)

(1997 - 2005 plastic lit rocker switch)

(2006 - present metal toggle switch)

To diagnose a ON/OFF switch problem, (unplug from power

source) remove the back screen cover. Disconnect the (2)

black wires, one from the motor and one from the cord set.

Directly connect and insulate the (2) black wires. Plug the

MAG-9000 into a power source, this should start the motor

without the switch. The third “red or blue” wire is only for the

switch’s light [MAG-9000 sharpeners with the metal toggle

switch do not have this wire because there is no light.]

If the MAG-9000 still does not start after this test, the capacitor or the motor is no longer functioning and must be replaced.

(SEE WIRING DIAGRAM PAGE 22)

Call 800-328-1110 for replacement parts or a warranty issue.

The MAG-9000 is vibrating.

This is caused by a grinding wheel that is “out-of-round” or

“out-of-balance” - this will happen when the operator does not

apply downward pressure on the blade when sliding it back and

forth in the MAG-9000. Also, on occasion, grinding wheels can

have a “hard spot” which will also cause this.

To repair the wheel you can dress it with a grinding wheel

dressing tool, or you can use an old lawn mower blade. When

using the old lawn mower blade nd a portion of the blade

that is square stock (near the mounting hole - not on an edge)

and grind it with the MAG-9000, but do not go back and forth

- simply keep pressure down on the work table and into the

wheel evenly. This re-shape the wheel back into a circle

21

Page 23

MAG-9000 Trouble Shooting

22

Page 24

page page

MAG-9000 Specications

MAG-9000 MAG-9000 (Euro)

Length 12 inches 30.5 cm

Width 8 inches 20.3 cm

Height 8 inches 20.3 cm

Weight 45 LBS 20 kg

Ship Weight 1 box 48 LBS 22 kg

Motor Specs LEESON® ELECTRIC LEESON® ELECTRIC

Horse Power 1/2 1/2

RPM 3450 2850

Duty Cycle Std / Intermittent Std / Intermittent

Hertz 60 50

Volts 115 220

Phase Single Single

Capacitors Single (1) Single (1)

Solid State Switch No No

Thermal Protection Yes Yes

Motor Type Industrial - Totally

Enclosed

Insulation Class F Class F

Direction Single Direction Single Direction

Fan Cooled Yes Yes

Transmission Direct Drive Direct Drive

Grinding Wheels NORTON® Abrasives NORTON® Abrasives

Wheel Dimensions 7” dia x 1” thick x 1-

1/4” dia arbor

Industrial - Totally

Enclosed

17.7 cm dia x 2.5 cm

thick x 3.18 cm

23

Page 25

24

Page 26

page page

Rotary Mower Blade Tip Geometry

Consider the following if you sharpen rotary lawn

mower blades.

The tip of the blade

does the majority

of the cutting. To

produce a tip, three

reliefs are necessary.

Think of a lawn

mower blade as a

circular saw with

only “TWO TEETH”

and remember the

tip does the majority

of the cutting work.

Repetitive observa-

tion of worn cutting

edges shows that

the rst one inch

does the majority of

the cutting work.

IMPORTANT

NOTES:

Attempting to

straighten a lawn

mower blade may

cause fractures in

the hardened steel

of the blade and

shall be avoided.

Anytime you alter

the steel of the

blade due to resharpening, wear or

build-up, you change

the balance.

Description Diagram

Relief 1:

Top View - built

into the blade.

(generally 2-5

degrees)

Relief 2:

End View - To be

re-sharpened.

(generally 60

degrees)

1

Generally 0˚

Relief 3:

End View - built

into the blade.

Top View:

Worn Blade

Edge

Worn away bottom

surface at tip, as

shown, is a sign

of poor blade

maintenance. The

blade will tear the

grass, resulting

in a poor looking

lawn.

Optimum

3

NOT ACCEPTABLE

2

25

Page 27

Key Description

A Trailing edge of the cutting edge face

B Mounting hole

C Leading edge of the cutting edge face

D Lift

E Cutting edge face

F Cutting edge angle (30˚ shown)

G Blade cutting tip (or tooth)

H Overall cutting diameter

Anatomy of a

Lawn Mower

Blade

Use this diagram when asking questions

to Magna-Matic representatives, or as it is

referenced in this manual.

26

Page 28

WARRANTY

This warranty is extended only to MAGNA-MATIC’s commercial customers. To protect the quality of this tool, every

step in its manufacture has been carefully controlled. It is

constructed of only the nest materials by skilled craftsmen who take pride in their work. MAGNA-MATIC CORP.

warrants the tools manufactured and/or repaired to be

free of defects in material and workmanship for a period

of 365 days after purchase. Any tool or part proved to

MAGNA-MATIC’s satisfaction to be defective during that

period will be repaired or replaced at MAGNA-MATIC’s

option if returned prepaid. MAGNA-MATIC’s sole obligation and your exclusive remedy under this warranty shall

be limited to such repair or replacement. In no event shall

MAGNA-MATIC be liable for any consequential or incidental

damages. This warranty does not apply to parts (motor

& grinding wheel) not manufactured by MAGNA-MATIC or

failing due to ordinary wear, subjected to abuse, accidental

damage, improper operations, maintenance or repair, or to

other damage by circumstances beyond MAGNA-MATIC’s

control.

This warranty is exclusive and in lieu of all other expressed

or implied warranties including without limitation, the

implied warranties of merchantability and tness for a particular purpose.

Magna-Matic Corporation

W4599 County Road IW

Waldo WI 53093

USA

Phone: (920) 564-2366

FAX: (920) 564-2368

Toll Free USA & Canada

1-800-328-1110

© 2002-2006 Magna-Matic Corporation, all rights reserved.

http://www.magna-matic.com

sales@magna-matic.com

Loading...

Loading...