Page 1

OPERATING INSTRUCTIONS

For Magna-Matic

Precision Balancing Instruments

Covering Models:

MAG-1000 Original

MAG-1000G Gold Edition

MAG-1000GC Gold Edition

MAG-1060 SUPER

MAG-5000 Series

Protected By Patent #

2,987,924 - 2,992,388 -

5,398,550 -5,503,015

Visit us at www.magna-matic.com for more photos

of products & other helpful info.

Helping you get the most

out of your shop for the last 40 years.

Page 2

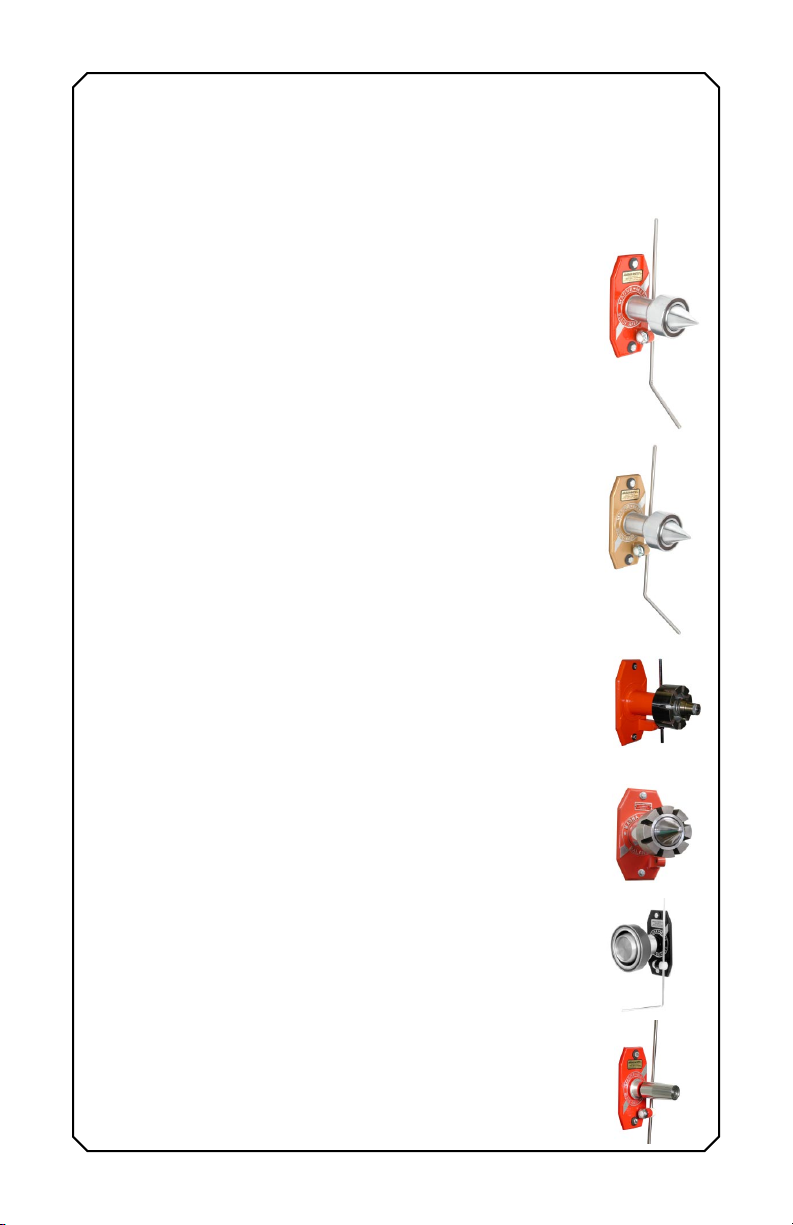

Model Descriptions

If you have further questions or do not understand any of the

instructions please contact us! We are happy to give any needed

extra explanation.

MAG-1000 Lawn Mower Blade Balancer

The industry original since 1958

Blade Hole Diameter Range of 5/16” to 1-1/2”

Can be used to balance objects that have a concentric center hole, and is made of a magnetic

material. The MAG-1000 uses a sliding magnetic

chuck to hold the blade.

MAG-1000G Gold Edition

MAG-1000GC Gold Edition (carbide support shaft)

(Signied by the gold base bracket)

A special edition version of the standard

MAG-1000. Made to perfection, and with ultraaccurate 8 ball - ball bearings.

Celebrating over 40 years of MAGNA-MATIC.

MAG-1050 SUPER

The MAG-1050 is a large application blade balancer. For

use with ywheels, circular saws, impellers, fan blades,

etc.. It has a interchangeable spring loaded cone insert

for extra versatility.

MAG-1060 SUPER

The MAG-1060 is a large application blade balancer. For

use with ywheels, circular saws, impellers, fan blades,

etc. Functioning like the MAG-1000

MAG-5000

The MAG-5000 is a large center hole diameter blade

balancer. (2-1/2” - 3”) Can also be used with large fan

blades and impellers.

MAG-7000 SERIES

The MAG-7000 Series balancers are designed for balancing hub type products, specically ATV and Snowmobile

primary and secondary variable clutches.

1

Page 3

!BEGIN HERE!

This instruction booklet will get you “up-and-running” with

the most basic usage of your MAGNA-MATIC balancer.

For more complete information on how to service a lawn

mower blade refer to the publication “Magna-Matic Guide

to Proper Lawn mower Blade Service.”

Unpack the Balancer

1

Be sure all items listed here were included with

your balancer.

1 - Blade Balancer

2 - Instruction Booklet (this booklet)

2

Page 4

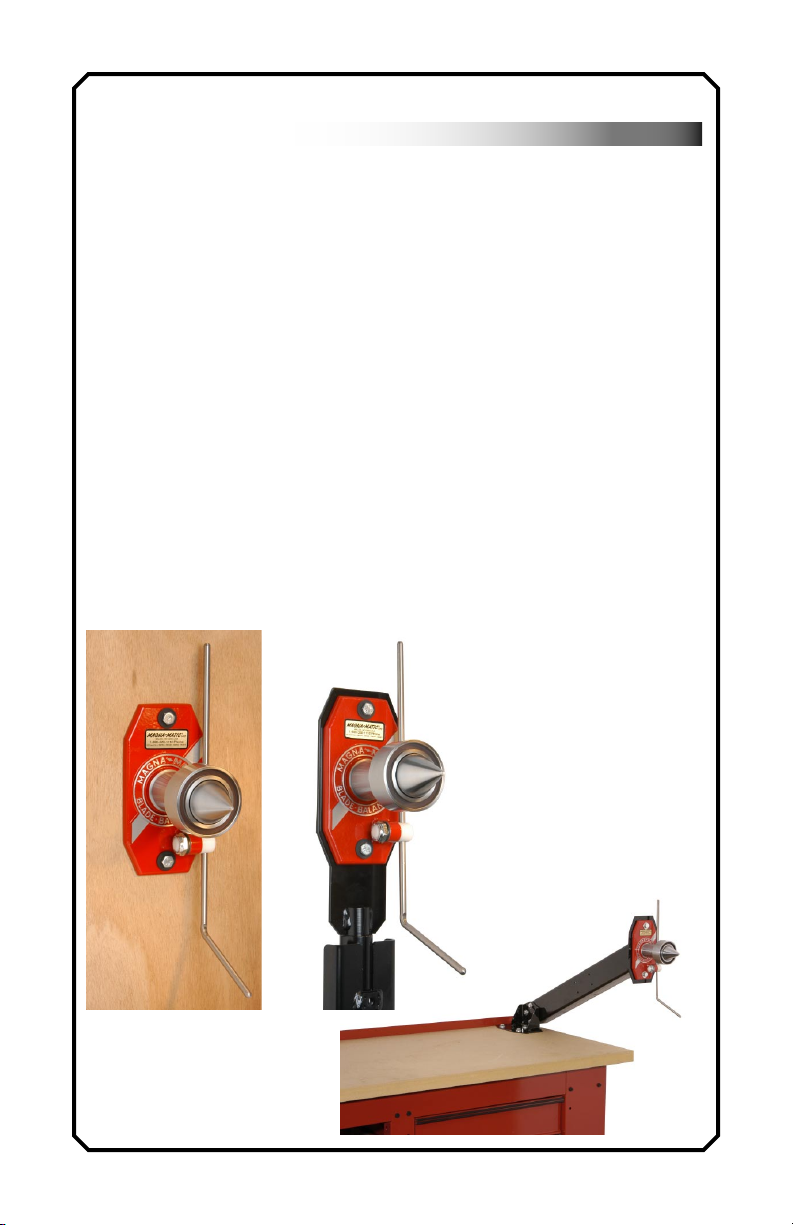

Mounting the Balancer

2

You can mount the balancer on a wall, the

MAG-10200 Service Center Stand (with your

Magna-Matic Lawn mower Blade Sharpener),

or the MAG-103 Balancer Test Stand/Mounting

Bracket. (see these various ways below)

Mounting Conditions:

A - Wall must be vertical ± 5º

B - Make sure there is enough clearance around

the balancer to allow the blade to freely

rotate without interference.

C - Balancer mounting location should not be

subjected to air ow (fans, wind, etc.). Bal ancer reading accuracy can be compromised

by wind/air movement.

D - Use (2) bolts 5/16 inch to mount the bal ancer in its (2) mounting holes.

E - See MAG-10200 or MAG-103 Instructions

for stand mounting instructions.

MAG-10200 Service

Center Stand Mounting

Wall Mounting

3

MAG-103 Test Stand/

Mounting Bracket

shown mounted on a

work bench

Page 5

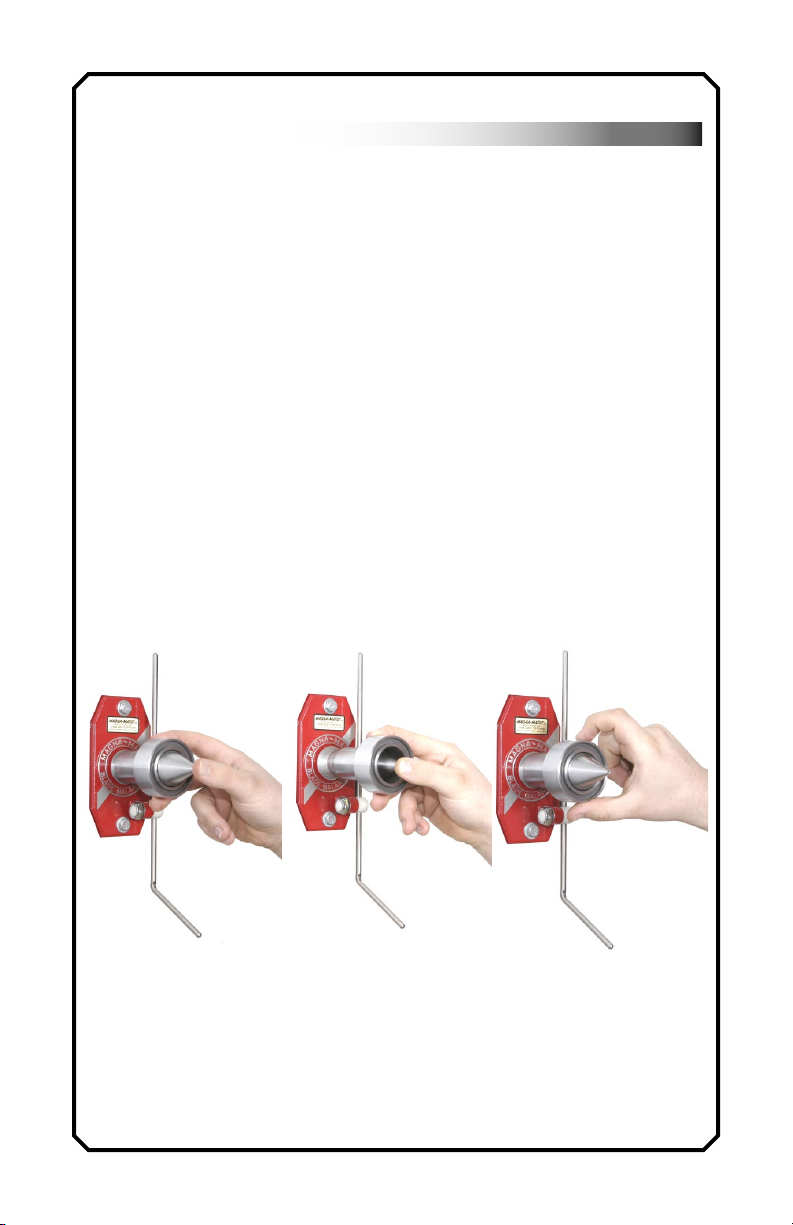

Inspecting the Balancer

3

Test the Magnet

Inspect the balancer for proper function. The

balancer must be rst mounted before inspection can be done.

A - The Magnet sleeve should slide smoothly

over the cone. Manual (hand) force is neces sary to move the magnet. With use, the

sliding force will decrease - warmer room

temperatures will also make the slide move

more easily. SEE BELOW IMAGES

B - Rotate the balancer - one revolution to

assure the bearings are free to rotate.

Only a 1/2 of a revolution is necessary to

check the balance of a blade.

Slide

DO NOT SPIN THE BALANCER

Test the Magnet

Slide

Test Balancer

Rotation

NOTE: Always wear protective gloves when handling lawn mower

blades - gloves were not worn in photos to show maximum detail

of hand positions.

4

Page 6

Safety FIRST

4

Lawn mower blade knives have sharp, cutting

edges. Wear protective clothing recommended by

MAGNA-MATIC magnets have a magnetic pull in

excess of 120 LBS (using a test place 3.5” x .25” x

3.5”.) Magnetic PULL is DRASTICALLY reduced by

surface dirt, rust, paint, thin metal, and irregular

Read the following safety notes

for your protection!

the blade manufacturer.

DO NOT BE INJURED

By The Cutting Edges

!DO NOT BE INJURED! - !SAFETY FIRST!

shapes.

DO NOT BE INJURED

By a FALLING BLADE

!DO NOT BE INJURED! - !SAFETY FIRST!

ADDITIONAL SAFETY NOTES - READ

MAGNA-MATIC balancers use a magnet to hold the lawn

mower blade. Blades made of non-magnetic materials

will not be held by the magnet.

Blades that do not have a CLEAN FLAT STEEL SURFACE

and at least 3” in diameter around the center hole; shall

not be mounted on the balancer.

These blades may not be held by the magnet and may

fall.

5

Page 7

Mounting the Blade

5

1 - Clean the blade of all dirt and vegetable material.

Make sure that the blade is clean down to the steel

at the mounting hole, where the magnet will contact

the blade. This will greatly improve the magnetic

“holding force” of the balancer, and the accuracy of the

reading.

Use a hand wire brush or the MAG-12000 lawn mower

blade cleaning machine to clean a lawn mower blade.

2- Hold the blade with two hands, and locate the center

hole of the lawn mower blade on the cone.

Now with your index ngers, pull the sliding magnetic

chuck towards the blade. The result should be that the

blade is now securely located on the cone, and held

there by the magnet. SEE BELOW the overhead view

of the balancer and blade

3 - Slowly remove your hands and check that the blade is

held rmly before completely removing your hands.

This will guide you through the process to properly mount a blade on the balancer.

1

3

NOTE: Always wear protective

gloves when handling lawn

mower blades - gloves were

not worn in photos to show

maximum detail of hand positions.

2

4

5

6

Page 8

Check Blade Straightness

6

1 - While the blade is mounted on the balancer. Turn

the blade on the balancer so that it is vertical on

the balancer (have one cutting edge pointing to the

sky, and one to the ground.

2 - Now position the gauge rod to almost touch the back side of the blade SEE IMAGES TO THE RIGHT

3 - Rotate the blade to compare the distances of one end

of the blade to the other. If they are the same - the

blade is “at” or “straight.”

4 - See your blade manufactures tolerance requirements

to determine if the blade should be discarded.

NOTE about BLADE STRAIGHTNESS

The longer the blade, the greater the deviation that can

be allowed between the two blade ends. Conversely,

the shorter the blade, the lesser the deviation that can

be allowed between the two blade ends.

This will guide you through the process to see if a

blade has become bent from use damage.

Do Not attempt to straighten a

hardened blade. You may create

WARNING

7

fractures not visible to the eye.

REPLACE ALL BENT BLADES

Page 9

6

Check Blade Straightness

General Guide:

18” - 24” long blades can allow up to 3/8” deviation

24” - 28” long blades can allow up to 1/2” deviation

28” - and larger blade can allow up to 5/8” deviation

Do Not attempt to straighten a

hardened blade. You may create

WARNING

fractures not visible to the eye.

REPLACE ALL BENT BLADES

8

Page 10

Check Blade Balance

7

1 - Have the blade mounted on the balancer.

2 - Rotate the blade to a horizontal attitude. SEE

BELOW. Then remove your hands and allow the blade

to freely rotate.

3 - If the blade remains HORIZONTAL the blade is “HORI ZONTALLY IN-BALANCE.”

4 - If one end of the blade rotates to the 6 o’clock

position of the clock face - THIS IS THE HEAVY

END. Material will need to be removed from this

end to bring the blade “IN-BALANCE.” Remove material

from the cutting edge during sharpening - USE a

MAGNA-MATIC [MAG-8000 or MAG-9000] to properly

sharpen a lawn mower blade.

NOTE: The blade will still be “IN-BALANCE-TOLARANCE” if

it moves slightly from the horizontal position. ALL MAGNAMATIC Balancers are delicate instruments that are to be

operated with manual force only. Do not misuse the balancer.

This will guide you through the process to gauge

a blade’s out-of-balance condition.

1

NOTE: Always

3

2

9

wear protective

gloves when

handling lawn

mower blades gloves were not

worn in photos

to show maximum detail of

hand positions.

Page 11

Check Blade Balance (cont)

7

RE-EXPLAINED - (clock face example)

Think of a “scale,” “balance,” or “see-saw.” As with any of

these, when there is an IMBALANCE of weight on one end

it will rotate toward the ground, because of gravity. This

is the same way MAGNA-MATIC Precision Static Balancers

work. After you have the blade mounted on the balancer,

look at the blade on the balancer and think of a CLOCK

FACE.

With your hand rotate the blade so that it is horizontal, with

one end pointing at 3 o’clock and the other end pointing

at 9 o’clock. Now let go of the blade, so that it will freely

rotate or remain stationary.

When a blade is “out-of-balance” the “heavy end” will

rotate to 6 o’clock. Take note of which end of the blade falls

to 6 o’clock AND how fast it falls. These two factors will

indicate which end of the blade is the “heavy end,” and how

“out-of-balance” the blade is.

This will guide you through the process to gauge

a blade’s out-of-balance condition.

With experience you will be able to quickly determine how

much steel you will need to grind off, by recognizing the

speed at which the “heavy end” rotates downward.

NOTE: Always wear protective gloves when handling lawn mower

blades - gloves were not worn in photos to show maximum detail

of hand positions.

10

Page 12

Blade Removal

8

After you have checked the straightness and the balance

of the blade you will need to remove the blade from the

balancer.

The best way to remove a blade from the balancer without

damaging the balancer is to twist the blade. This will

release the blade from the magnetic pull with the least

amount of force, preventing injury to the operator or

damage to the balancer. See BELOW showing the twisting

motion. Use the blade as a lever to remove it from the

balancer’s magnet.

This will guide you how to remove a blade from

your MAGNA-MATIC balancer.

NOTE: Always wear protective gloves when handling lawn mower

blades - gloves were not worn in photos to show maximum detail

of hand positions.

11

Page 13

Balancer CARE

9

This will guide you through the proper care of

your MAGNA-MATIC balancer.

CARE of your MAGNA-MATIC BALANCER

All MAGNA-MATIC balancers are precision, highly accurate

measuring instruments to measure the balance condition

of rotary blades, hub products, impellers, and the atness/

straightness between the cutting edges of lawn mower

blades. Note: run-out gauges can be attached to the guage

rod to get run-out readings.

!DO NOT DROP OR MISUSE!

FOR ALL BALACNERS WITH magnetic sliding chucks

BE SURE to always push the magnet (chuck) to the base

bracket after you are nished using it. IF DIRT and DUST

collect on the slide surface it will damage the slide. This

will signicantly reduce the usability of the balancer. If

possible cover the balancer with a plastic bag when not

in use.

DO NOT attempt to clean the greased slide surface. It is

greased with an engineered grease that will last the life of

the balancer. Using any other grease with damage/reduce

the usability of the balancer.

FOR ALL BALANCERS

DO NOT hit - hammer - drop or cause any other impact to

the balancer, it will denitely damage the balancer.

DO NOT attempt to replace the bearings.

MAGNA-MATIC balancers - if cared for properly will last a

lifetime under normal use.

12

Page 14

Balancer Calibration TEST

10

1 - Balancer must be mounted to test this.

2 - Make a mark on the face or magnet ring of the balancer

(use a felt marker).

3 - Rotate the mark to every position of the clock face (1

o’clock - 2 o’clock - etc.) then let go of the balancer

at every position very carefully - to see if it will rotate

on its own. Your mark should not move at any position,

this shows that the balancer itself is in balance.

4 - Be sure your hand or the mounted surface is not

moving, the balancer will pick up the slightest vibration

or motion. Air ow/wind will also affect this reading,

be sure you are indoors and not near a fan or open

window/door. Also make sure the magnet does not

have any metal chips in it to throw off the reading.

If the unit does not meet any of these requirements return

the unit to us for evaluation.

This will guide you through how can test the

calibration of your balancer.

RECONDITIONING SERVICE

MAGNA-MATIC can recondition your balancer if it has

become damaged. Send the balancer to us for a reconditioning evaluation and quote. Or call us 800.328.1110 or

920.564.2366

Balancer Reconditioning

Magna-Matic Corp.

W4599 County Road IW

Waldo WI 53093

USA

13

Page 15

guarantee

The MAG-1000, MAG-8000, & MAG-9000 Series

Products come with a *30 day 100% satisfaction

guarantee. In the event you are not satised with

any of the above products we will provide you

with a return authorization and a UPS call tag for

pick-up. You will be provided with 100% credit less

the shipping cost (to & from) your facility and one

grinding wheel. The returned product must be in

good order, or further charges will apply.

*30 days from invoice date

Magna-Matic Free Start-Up Service &

LIFETIME Toll Free Phone Support

Once you have any of our products ready to operate CALL US AT 800.328.1110 and we will instruct

you of the proper operating procedure. We want

you to be the most protable with any of our

high-performance tools. Also, you get LIFETIME

PHONE SUPPORT with all of our products. Call

our toll free number to talk to a real live person,

and get personalized help. Or visit our web site www.magna-matic.com - and read support info

or ask a question via E-mail.

14

Page 16

WARRANTY

This warranty is extended only to MAGNA-MATIC’s commercial customers. To protect the quality of this tool,

every step in its manufacture has been carefully controlled. It is constructed of only the nest materials by

skilled craftsmen who take pride in their work. MAGNAMATIC CORP. warrants the tools manufactured and/or

repaired to be free of defects in material and workmanship for a period of 365 days after purchase.

Any tool or part proved to MAGNA-MATIC’s satisfaction

to be defective during that period will be repaired

or replaced at MAGNA-MATIC’s option if returned prepaid. MAGNA-MATIC’s sole obligation and your exclusive

remedy under this warranty shall be limited to such

repair or replacement. In no event shall MAGNA-MATIC

be liable for any consequential or incidental damages.

This warranty does not apply to parts (motor & grinding

wheel) not manufactured by MAGNA-MATIC or failing due

to ordinary wear, subjected to abuse, accidental damage,

improper operations, maintenance or repair, or to other

damage by circumstances beyond MAGNA-MATIC’s control.

This warranty is exclusive and in lieu of all other

expressed or implied warranties including without limitation, the implied warranties of merchantability and t-

ness for a particular purpose.

Magna-Matic Corporation

W4599 County Road IW

Waldo WI 53093

USA

Phone: (920) 564-2366

FAX: (920) 564-2368

Toll Free USA & Canada

1-800-328-1110

© 2002-2003 Magna-Matic Corporation, all rights reserved.

http://www.magna-matic.com

sales@magna-matic.com

Loading...

Loading...