Page 1

Installation

Manual

Model: X9

This device complies with part 15 of the FCC rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference; and

(2) This device must accept any interference received, including interference that may cause undesired operation.

Note: The manufacturer is not responsible for any radio or TV interference caused by unauthorized modifications to this

equipment. Such modifications could void the user’s authority to operate the equipment.

For Technical Assistance, please call (800) 638-3600,

or visit www.magnadyne.com

Page 2

Table of Contents

Installer Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Component Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Wiring Harness Quick Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Wiring

Starter and Power Harness Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Door Lock Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Accessory Alarm and Remote Start Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-16

Transmitter Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Alarm Feature Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-21

Remote Start Feature Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-22

Engine Crank Detection Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-25

Remote Start Shutdown Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Safety Testing Your Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Shock Sensor Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Return to Factory Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

• Due to the complexity of this system, installation must only be performed by a qualified professional installer.

This remote start and alarm system is NOT a “Do It Yourself” product.

• This remote starter and alarm system is designed to be installed on fuel injected gasoline or diesel vehicles with

an automatic transmission ONLY. Installation of this system on a vehicle with a manual transmission (Stick

Shift) is dangerous and is contrary to it’s intended use.

• This system must be installed and wired through a safety switch so it will not start the engine while in any

forward or reverse gear. This is normally accomplished by connecting the systems provided safety wire to the

vehicles electronic Neutral Safety switch located on the transmission shifter.

• Some automatic transmission vehicles may have a mechanical type park safety lock system instead of electrical

safety switch. This mechanical type system does not interrupt the starter circuit when the transmission is any

gear and does not offer the 100% level of safety required for remote starting purposes. The next best safety

connection point on this type of vehicle would be the vehicle parking brake switch. This requires the user to set

the parking brake prior to activating the remote starting system.

• Once you install this system, you must verify that the vehicle will not start in any forward or reverse gear.

Regardless of the type of vehicle.

• Do not install any component near the brake, gas pedal or steering linkage.

• Some vehicles have a factory installed transponder immobilizer system that can severely complicate the

installation. There is a possibility that this system can not be installed on some immobilizer equipped vehicles.

• Most vehicles have an SRS air bag system. Use extreme care and do not probe any wires of the SRS system.

Disconnect the vehicle (+) or (-) battery cable before installing this system on the vehicle.

• Use conventional crimp lock type connectors on all low current wiring connections. Poor wiring, i.e. taped joints,

will introduce unreliability into the remote start and alarm system and may result in false alarms, incorrect or

failed operation.

Installer Warnings

2

Page 3

Windshield Receiver/Antenna

• The combination windshield receiver/antenna mounts on the windshield (inside).

• We suggest you mount it on the lower left-hand side of the windshield.

Warning! Do not mount in such a manner that it obstructs the driver’s view.

• The receiver/antenna whip can be vertical or horizontal.

1. Remove the protective tape backing.

2. Carefully align the receiver/antenna and apply to windshield.

3. Route the black connecting cable behind the trim and connect to

receiver/antenna.

4. Connect the other end to the control module.

Dual-Zone Shock Sensor

Select a mounting location within the passenger's compartment or trunk. Do not mount in the engine

compartment or in any location where it will get wet, greasy or will be subject to heat, direct or indirect. To

achieve the best overall level of protection, select a mounting location that is centrally located in the vehicle. It

will be necessary for the shock sensor to be somewhat accessible to make the correct sensitivity adjustment.

The mounting surface should be as flat as possible for best sensitivity. The sensor can be mounted in any

position as long as it is solidly mounted.

Valet Switch

Select a mounting location for the switch that is easily accessible to the driver of the vehicle. The switch does

not have to be concealed, however, concealing the switch is always recommended, as this provides an even

higher level of security to the vehicle. Mount the valet switch in a hidden but accessible location. Route the valet

switch wires to the control module.

LED Status Indicator

The LED indicator status should be mounted in a highly visible area. Leave at least 6mm of space behind the

mounting location for LED housing. Once a suitable location is chosen, drill a 1/4" hole. Run the LED wires

through the hole then press the 2-pin LED housing into the place. Route the LED wires to the control module.

Mount the antenna horizontally

for best reception.

Component Placement

3

• All wires that operate at currents higher than 10A should be soldered to insure a long lasting connection.

• Install wiring neatly under carpets or behind trim to prevent possible damage to wires.

• For dealer technical assistance, please call (800) 638-3600 or visit www.magnadyne.com

Installer Warnings (continued)

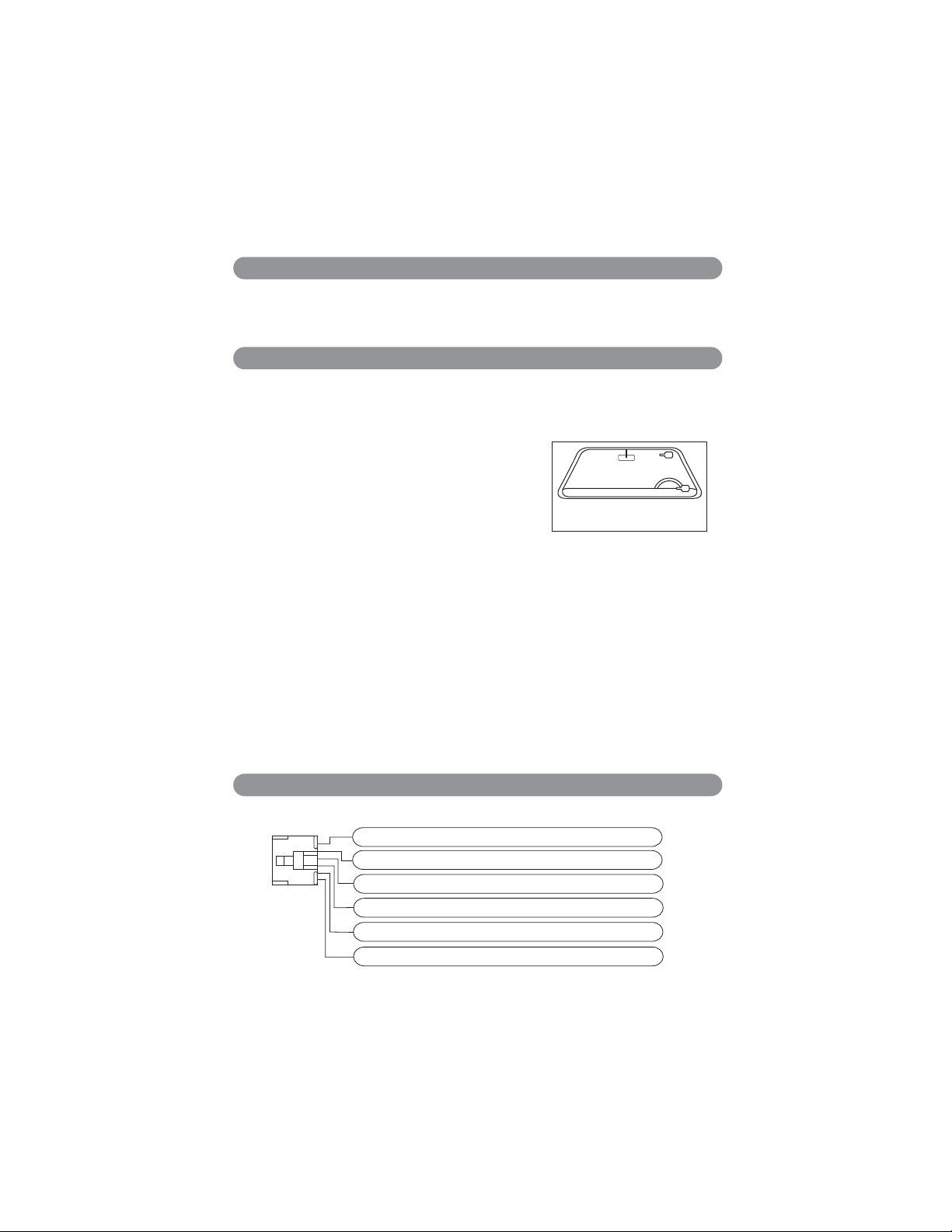

Harness Quick Reference

HC1 8-Pin Remote Start Harness

Violet Remote Starter Output

Red +12VDC Battery Input #1

Yellow +Ignition 1 Output

Red +12VDC Battery Input #1

Brown +ACC / Heater - Air Conditioner Output

Pink +Ignition 2 / ACC 2 Output

Page 4

C 5 o e pu a ess

Red/White Parking Light Relay Input

Black Chassis Ground

Brown (+) Programmable Output (Siren Default)

White Parking Light Relay Output

Red +12VDC Battery Input

HC3 3-Pin Door Lock Harness

Green (-) Lock / (+) Unlock Output

Blue (-) Unlock / (+) Lock Output

4

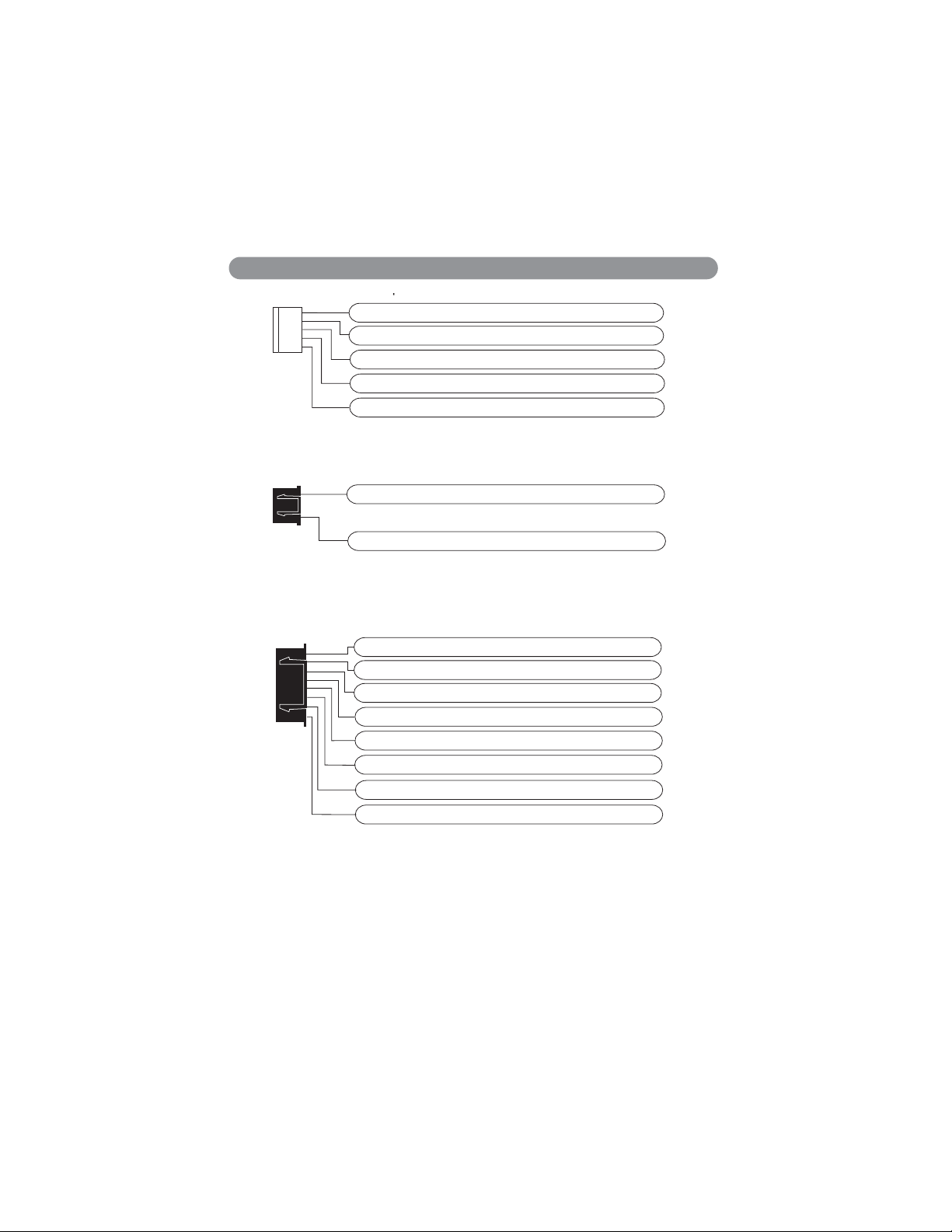

Harness Quick Reference (continued)

HC8 8-Pin Accessory Harness

Blue (-) Hood/Trunk Alarm Pin Input

Green (-) Common Door Pin Input

Violet (+) Common Door Pin Input

White/Blue (-) AUX Start and Turn Off Input

Gray (-) Remote Start Hood Pin Safety Input

Black/White (-) Neutral Safety Switch Input

Brown (+) Brake Switch Input

Violet/White Tach Input

Page 5

5

Harness Quick Reference (continued)

HC6 6-Pin Accessory Harness

HC1: White 6-Pin High Current Remote Starter Harness

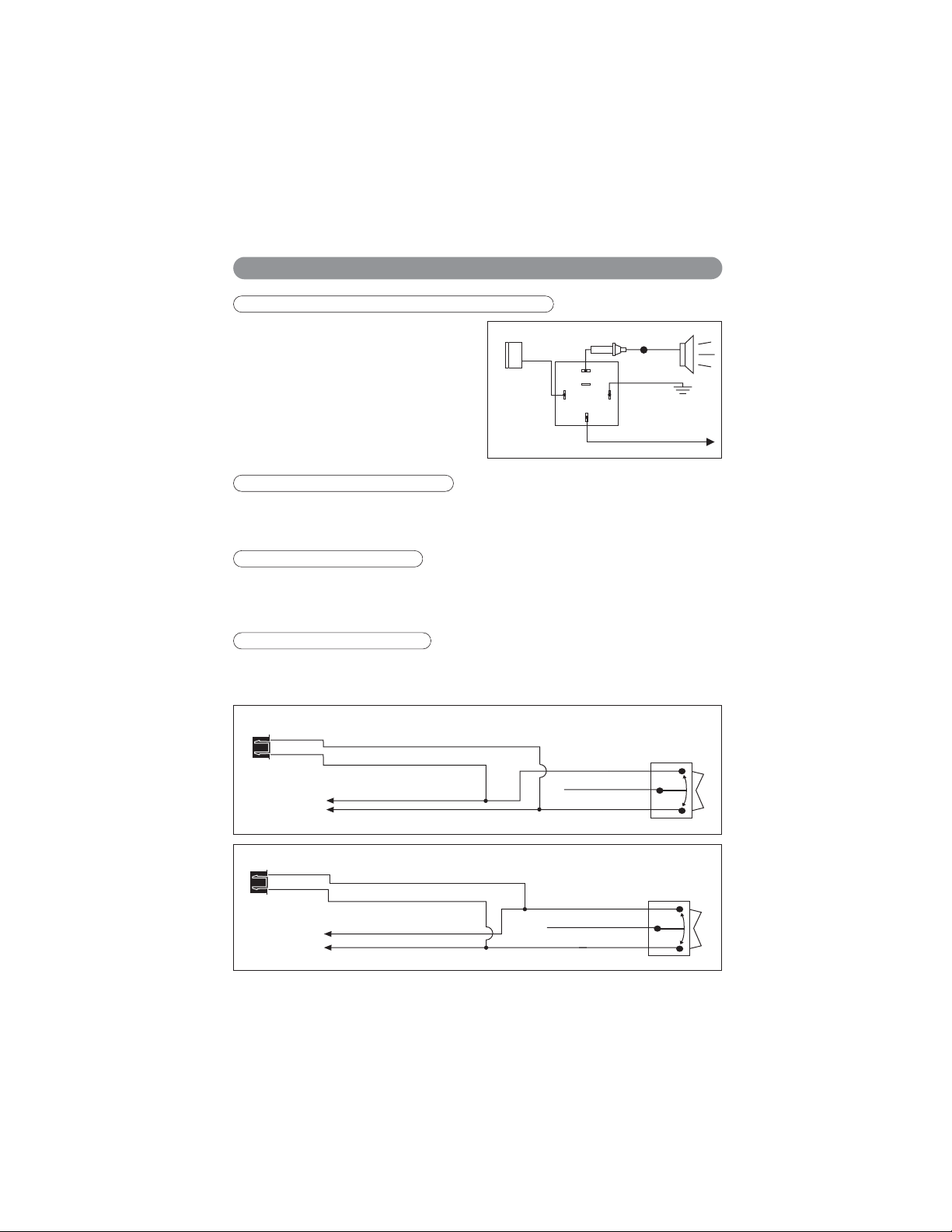

The method that the remote starter uses to start the vehicle is a duplicate of the ignition switch

function. Below, is an explanation of the 3 basic functions of the ignition switch. Since this

installation will require analysis of the ignition switch functions, it is recommended that you

make the three connections below at the ignition switch harness directly.

Careful consideration for the connection of this wire must be made to prevent the vehicle from starting while in

gear. Understanding the difference between a mechanical and an electrical Neutral Start Switch will allow you to

properly identify the circuit and select the correct installation method. In addition you will realize why the

connection of the safety wire is required for all mechanical switch configurations.

WARNING! Failure to make this connection properly can result in personal injury and property damage.

In all installations it is the responsibility of the installing technician to test the remote start unit and assure that

the vehicle can not start via RF control in any gear selection other than park or neutral.

In both mechanical and electrical neutral start switch configurations, the connection of the “Violet” wire will be

made to the “Starter Side” of the low current start solenoid wire at the ignition switch. This wire must have +12

volts when the ignition switch is turned to the “START” (crank) position only. Cut the starter wire and connect

the Violet wire to the Starter Side of the cut wire. DO NOT connect the Violet wire to the starter side of a

mechanical neutral safety switch. Failure to connect the Violet wire to the ignition switch side of the neutral

safety switch can result in personal injury and property damage (see Neutral Start Safety Test for further

details).

"ACC" "START"

"OFF" "ON"

Starter

Violet Wire

Closed in Park

or Netral Only

Neutral Safety

Switch

6-Pin

White Connector

Do not make the

Violet wire

connection

like this

Wiring

Violet Wire: Starter Output

White (-) Programmable Output (Dome Lt - Default)

Pink (-) Ignition #3 Output

Violet/Black (-) Programmable Channel #4 Output

Red/White (-) Channel #3 Output (Trunk Release)

Light Brown (-) Programmable Output (Horn- Default)

Orange (-) Ground When Armed Output

Page 6

HC1: White 6-Pin High Current Remote Starter Harness (continued)

Remove the two 20A fuses prior to connecting these wires and do not replace them until the harness has been

plugged into the control module. These wires are the source of current for all the circuits the relay harness will

energize. They must be connected to a high current source. Connection to 12V battery terminal recommended.

Connect the Yellow wire to the ignition 1 wire from the ignition switch. The ignition wire should receive

+12 volts when the ignition key is in the “ON” or “RUN” and “START” or “CRANK” position. When the ignition is

turned “OFF”, the ignition wire should receive “0” voltage. The yellow wire must be connected.

Some vehicles have 2 ignition wires that must be powered. Connect the “Pink” wire to the ignition 2 wire from

the ignition switch. No connection required on vehicles without second ignition.

Connect the Brown wire to the accessory wire that powers the climate control system. An accessory wire will

show +12 volts when the ignition switch is turned to the “ACCESSORY” or “ON” and “RUN” positions, it will

show 0 volts when the key is turned to the “OFF” and “START” or “CRANK” position. There will often be more

than one accessory wire in the ignition harness. The correct accessory wire will power the vehicle’s climate

control system. Some vehicles may have separate wires for the blower motor and the air conditioning

compressor. In such cases, it will be necessary to add a relay to power the second accessory wire.

HC2: White 5-Pin Power Harness

The Red/White wire has already been assembled to work with a +12 volt switched parking light system (most

vehicles). For vehicles with ground switched parking light activation cut this wire and connect it to ground.

Connect the White wire to the parking light wire coming from the headlight switch. Do not connect the White

wire to the dashboard lighting dimmer switch (damage to the dimmer will result). The limitation of the White

wire is 10 amp maximum. Do not exceed this limit or damage to the alarm and parking relay will result.

This is main ground connection of the alarm module. Make this connection to a solid section of the vehicle

chassis. Do not connect this wire to any existing ground wires supplied by the factory wire loom, make the

connection to the vehicle’s chassis directly.

6

Red Wires (2): +12V Power Input

Yellow Wire: Ignition 1 Output

Pink Wire: Ignition 2 Output

Brown Wire: Accessory Output, Heater/AC Output

Red/White Stripe: Parking Light Relay Input

White Wire: Parking Light Relay Output, + or - Selectable

Black Wire: System Ground

Wiring (continued)

Page 7

7

Wiring (continued)

By default, the Brown wire is the positive (+) output

connection for the siren. Current capacity is 2 amps.

Make connection to the (+) red wire from the siren.

Connect the (-) black wire coming from the siren to a

good chassis ground.

Option: (+) Horn Output (See “Alarm Feature

Programming” to change the function to horn)

Connect this wire to the existing vehicle’s horn relay

trigger. Some vehicle horn systems may be (-) trigger

and a relay will need to be added for proper operation

as shown.

The “Red” wire supplies power to the system. Connect this wire to a constant +12 volt source.

Brown Wire: (+) Programmable Output - Siren Default Setting

Red Wire: System Power, +12V Constant

HC3: Black 3-Pin Door Lock Harness

If the door lock control system on the vehicle is (-) type, connect the Blue wire to the unlock wire from the door

lock switch . If the door lock control system on the vehicle is (+) type, connect the Blue wire to the lock wire

from the door lock switch.

If the door lock control system on the vehicle is (-) type, connect the Green wire to the lock wire from the door

lock switch . If the door lock control system on the vehicle is (+) type, connect the Green wire to the unlock wire

from the door lock switch.

Blue Wire: (+/-) Door Lock Control

Green Wire: (+/-) Door Lock Control

3 Wire Ground Trigger Door Lock System

(-) Lock Out

Ground Input

(-) Unlock Out

To Door Lock

Control Relays

Lock Control

Switch

Blue Wire: Connect to Unlock

Green Wire: Connect to Lock

Black 3-Pin

Mini Connector

3 Wire Positive Trigger Door Lock System

(+) Lock Out

+12 Volts Input

(+) Unlock Out

To Door Lock

Control Relays

Blue Wire: Connect to Lock

Green Wire: Connect to Unlock

Lock Control

Switch

Black 3-Pin

Mini Connector

White

5-Pin

Connector

Brown

Wire

Fuse

87

87a

86

30

To Horn

To Ground

85

+12V or Ground

Depending on

System Requirements

Page 8

Wiring (continued)

8

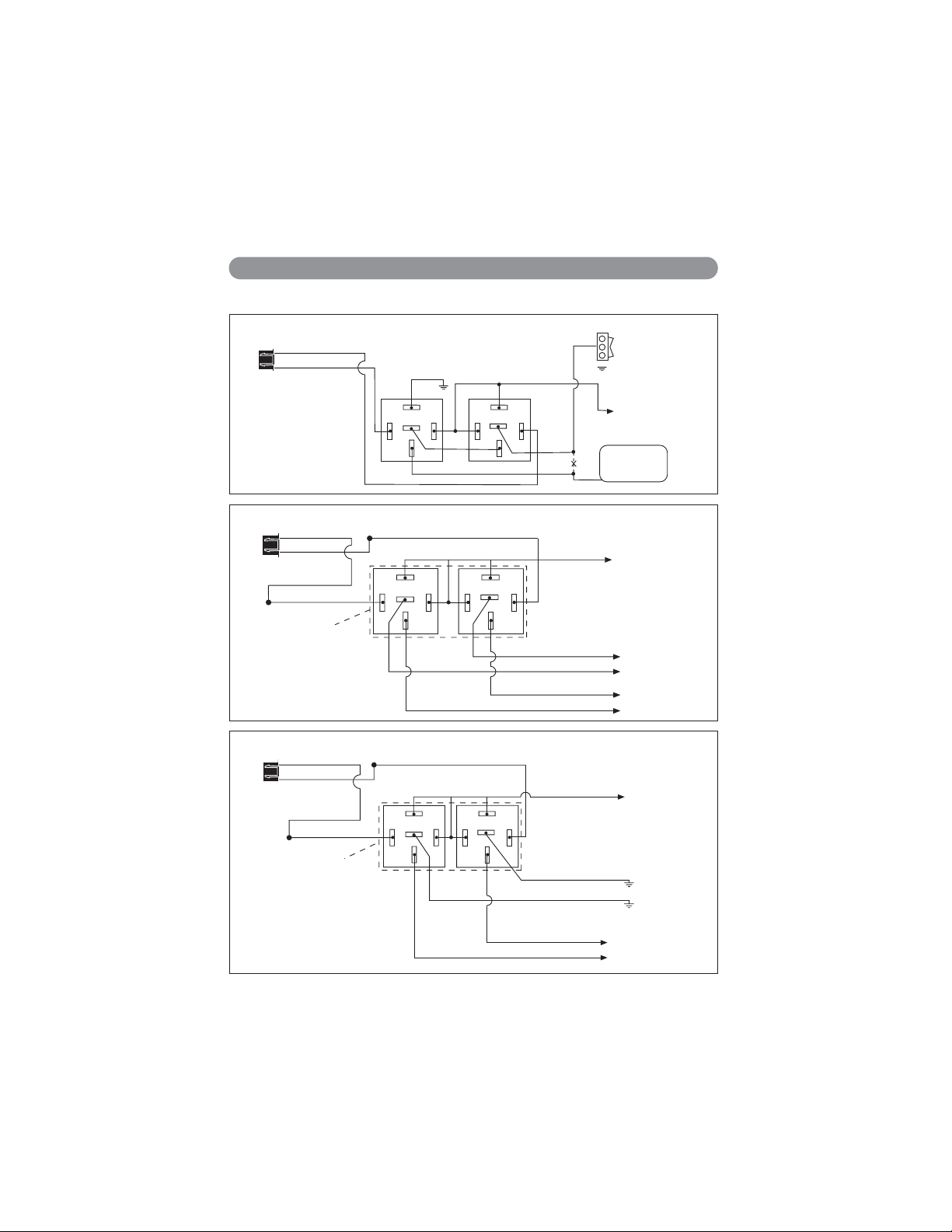

HC3: Black 3-Pin Door Lock Harness

(continued)

5 Wire Ground at Rest Door Locking Systems

87

87A

85

86

30

87

87A

85

86

30

To +12 Volts

(Battery +)

To Power

Lock Switch

To Power

Lock Motors

White Wire: Lock

Brown Wire: Unlock

Green Wire: Lock

Blue Wire: Unlock

Violet Wire

ALA-DL1

Relay Pack

Red Wire: Lock

Black Wire: Unlock

Black 3-Pin

Mini Connector

Green Wire

Blue Wire

Note: Orange wire from ALA-DL1

must be connected to +12V

Mercedes Door Lock Activation

Door Lock

Switch

Unlock

Lock

B+

87

87A

85

86

30

87

87A

85

86

+

++

To +12 Volts

(Battery +)

Door Lock

Compressor

Cut

Green Wire

Unlock

Lock

Black 3-Pin

Mini Connector

Green Wire: Lock

Blue Wire: Unlock

Newly Installed Power Door Lock Motors

Blue Wire

Green Wire

Black 3-Pin Connector

Black Wire: Unlock

ALA-DL1

Relay Pack

Note: Orange wire from ALA-DL1

must be connected to +12V

Red Wire: Lock

87A

85

Violet Wire

87

86

30

87

87A

85

86

30

White Wire

Brown Wire

Green Wire: Lock

Blue Wire: Unlock

To +12 Volts

(Battery +)

To Ground

To Newly

Installed Power

Door Lock Motors

Page 9

Wiring (continued)

9

HC3: Black 3-Pin Door Lock Harness

(continued)

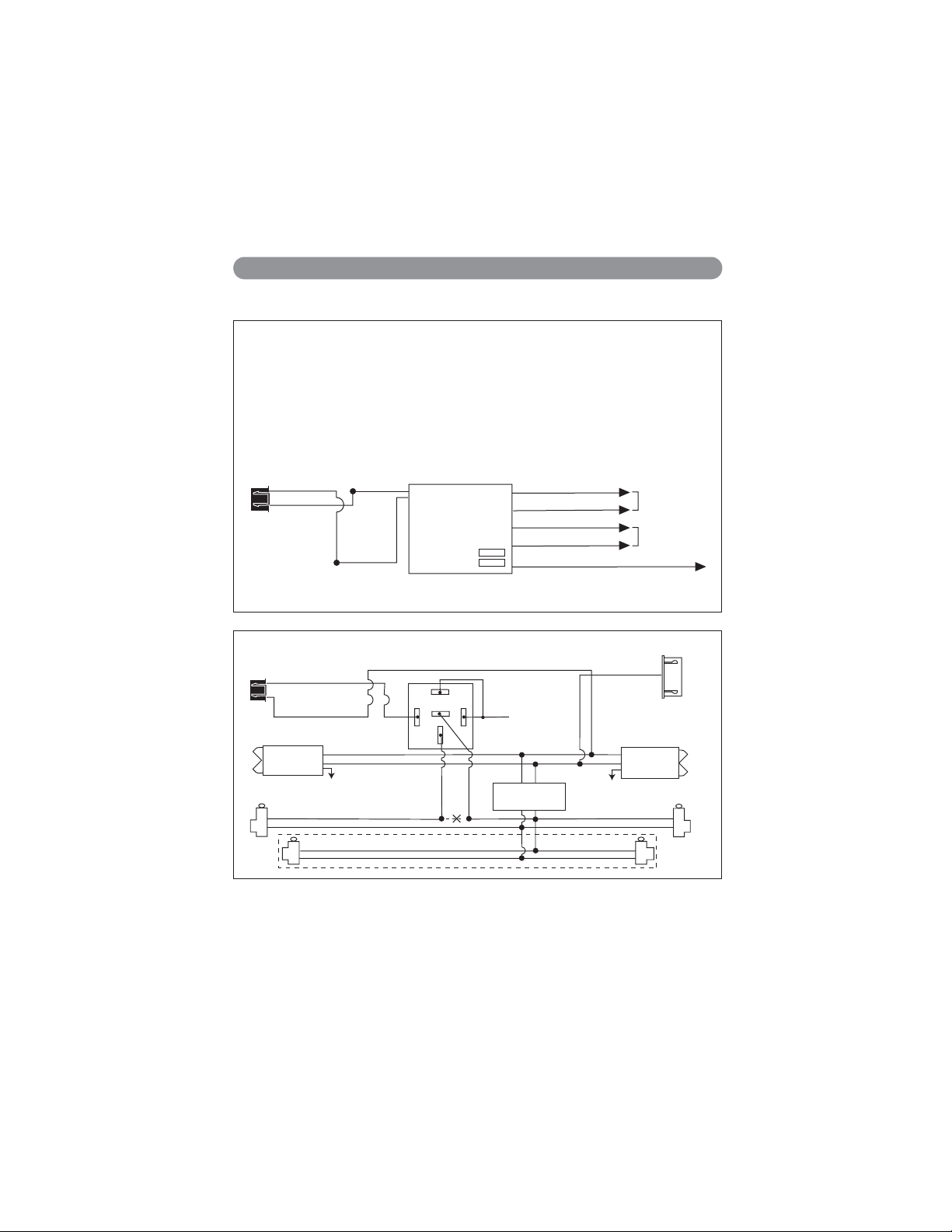

One Wire Multiplexing Door Locking Systems

Some vehicle’s (Chrysler, Mazda and Ford Probe and others) use one wire to lock and unlock the doors.

Example: When the door lock controller sees a signal thru a resistor it will unlock. If a signal is received

without a resistor the doors will lock. Some use 2 resistors. One for lock and one for unlock. We have

developed patented plug-in fuse resistors for this application. Simply remove the fuse from our door lock

module and replace with correct resistor value fuses that matches the vehicles door lock switch.

Wiring:

1. Connect both the green (lock) and the blue (unlock) wires to the vehicles one wire lock/unlock wire.

2. Connect our violet polarity input wire to +12v or to ground. To match vehicles door lock polarity.

3. The white and the brown wires will not be used.

Blue Wire

Green Wire

Black 3-Pin

Mini Connector

Red Wire

Black Wire

ALA-DL1

Lock Fuse 1

Unlock Fuse 2

Note: Orange wire from ALA-DL1 must be connected to +12V.

Unlock Driver's Door First for 3-Wire Negative Door Lock Systems

Blue Wire

Green Wire

Driver's Door

Switch

To +12V or Ground

Driver's Door

Lock

Unlock

Unlock Wire

87

87A

85

Rear Doors

ALA984H

86

30

Cut

White Wire Lock

Brown Wire Unlock

Green Wire Lock

Blue Wire Unlock

Violet Wire To +12 Volts Constant

+12V

Relay

Unlock

Lock

Door Lock Relay

Control Module

To Power

Lock Switch

To Power

Lock Motors

White 6-Pin Mini

Connector

White Wire

Passenger's

Door Switch

To +12V or Ground

Passenger's Door

Page 10

10

Unlock Driver's Door First Wiring for 3-Wire Positive Door Lock System

87

87A

85

86

30

87

87A

85

86

30

To +12

Volts

(Battery +)

To Power

Door Lock

Switch Lock/

Unlock Wires

Lock

Unlock

87

87A

85

86

30

+ Unlock

Cut

Driver's

Door Motor

White 6-Pin Mini

Connector

White Wire

Black 3-Pin

Mini Connector

Green Wire

Blue Wire

HC3: Black 3-Pin Door Lock Harness

(continued)

Unlock Driver's Door First Wiring for 5-Wire Ground at Rest Door Locking Systems

87

87A

85

86

30

87

87A

85

86

30

To +12 Volts

(Battery +)

To Power

Lock Switch

To Power

Lock Motors

Lock

Lock

Unlock

Unlock

87

87A

85

86

30

+ Unlock

Cut

Driver's

Door Motor

Green Wire

Blue Wire

White Wire

White

6-Pin Mini

Connector

Wiring (continued)

Page 11

The Black/White wire is a safety input wire. The remote start unit will not activate unless this wire is grounded.

When this wire is disconnected from ground, the remote start system is disabled.

1.

The primary connection point for the Black/White wire is at the Neutral Safety Switch located on/at the

transmission shifting lever. The switch output must be GROUNDED when the shifter lever is in the PARK

position.

Wiring (continued)

11

HC8 Black 8-Pin Connector

Gray Wire: (-) Hood Safety Shut Down Input

The Gray wire provides instant shutdown for the remote start when it is grounded. Connect the Gray wire to an

existing hood pin switch or install the one provided in this kit. This wire must be routed through a grommet in the

firewall and connected to the hood pin switch. If the hood pin switch is also to be used as an alarm system trigger,

diodes are required as shown.

Important! This connection is a safety wire and must be connected as shown and tested as specified. Failure to

do so may result in personal injury

or property damage.

Note: The Gray wire can also be

used as the “Brake Safety”

connection if the vehicle brake light

circuit switches a ground signal to

the brake lights. An isolation diode

must be used and connected to the

output of the brake switch.

Hood Pin Switch

Gray Wire

Negative Safety

Diode Diode

To Alarm Instant

Trigger Blue Wire

Black

8-Pin

Connector

Black/White Wire

Neutral Safety Switch Input

P

R

N

2

1

Optional Enable

Switch

Ignition

Electronic Control Module (ECM)

Solid State,

Do Not Measure Resistance

Black 8-Pin

Connector

This wire is the ground trigger input wire for hood/trunk pin switches.

The Green wire is the ground trigger input wire for negative door pin switch.

The Violet wire is the positive trigger input wire for positive door pin switch.

Blue Wire: (-) Ground Instant Trigger Input (Zone 2)

Green Wire: (-) Door Trigger Input (Zone 3)

Violet Wire: (+) Door Trigger Input (Zone 3)

Black/White Wire: (-) Neutral Safety Switch Input, (-) Remote Start Enable Toggle Switch Input

White/Blue Wire: AUX Start and Turn Off Input

This wire can turn on and off the remote start system each time it sees a momentary ground signal. This wire is

normally used for testing or activating the remote starter from an after-market alarm system.

A common connection point would be at the trunk release wire or the door lock wire.

Page 12

12

Brown Wire: Positive Safety Shut Down Input

This wire provides instant shutdown for the remote start, when it receives +12 volts. If the brake lights switch in

the vehicle switches +12 volts to the brake light circuit, connect this wire to the output side of the brake switch.

This will allow the remote start to shut down if an attempt is made to operate the vehicle without the key while

running under the control of the remote start. A relay may be required if the brake light switch is (-) type.

Wiring (continued)

Brake Light

Bulbs

+12 Volts

Switch Closes when

Brake is Depressed

Brown Wire

Brake

Pedal

To Lights

Black 8-Pin

Connector

2. The second best connection point for the Black/White wire is at the Parking Brake Switch output wire.

Make sure that when the parking brake is engaged that the output wire of the switch is grounded.

3. An optional remote start toggle switch can be added to temporarily disable the Remote Start Device. It can

prevent the vehicle from being remote started accidentally. This feature is useful if the vehicle is being

serviced or stored in an enclosed area. To disable the remote start, move the optional remote start enable

toggle switch to the OFF position. To enable the remote start, move the optional remote start enable toggle

switch to the ON position.

Note: When the Black/White wire is not used for it’s intended safety purpose, connect

the Black/White wire to the “Ground” or remote start system will not function.

Violet/White Wire: (-) Tachometer Signal Connection

This input provides the remote start system with information about the engine’s revolutions per minute (RPM).

It can be connected to the negative side of the coil in vehicle with conventional coils. In multi-coil and high

energy ignition system locating a proper signal may be more difficult. Once connected, you must program the

Start Feature Stage 2 to “Tachometer Checking Type" and teach the system the RPM signal (see Start Feature

Stage 2 Programming).

In multi-coil ignition system, the system can have individual coil wires. Individual coil wires in a multi-coil

ignition system will register lower amounts of AC voltage. Common locations for a tachometer wire are the

ignition coil itself, the back of the gauges, engine computers, and automatic transmission computers.

Important! Do not test tachometer wires with a test light or logic probe. Electronic

components of the ignition system will be damaged.

How to find a tachometer wire with your multi-meter:

1. Set the ACV or AC voltage *(12V or 20V is OK).

2. Attach the (-) probe of the meter to chassis ground.

3. Start and run the vehicle.

4. Probe the wire you suspect of being the tachometer wire with the red probe of the meter.

5. If this is the correct wire the meter will read between 1V and 6V

at idle, and will increase as engine RPM

increases.

Note: No connection of this wire is required, if you use the voltage or timer checking type mode.

HC8 Black 8-Pin Connector

(continued)

Page 13

13

Wiring (continued)

HC6 White 6-Pin Connector

Some vehicles may require a 3rd ignition

connection in order to start the vehicle engine.

The Pink wire provides a 200mA (-) ground

output that becomes active during engine

cranking (default Setting).

If the vehicle starting system does not

require a

3rd ignition connection, this wire may also be used

for other functions (See Alarm Feature

Programming Group 3 for programming

information)

Pink Wire: 200mA Ignition #3 Output (Programmable Operation)

87

87a

86

85

30

Pink Wire

Ignition: 3-Wires from

Ignition Key Switch

Constant +12V:

Fused 25A Capable

White 6-Pin

Connector

Transponder Interfacing Using ALA984 Relay (may also use optional RS-TIM bypass module):

If the vehicle has transponder system installed, you will need to bypass the system while the vehicle is

operating under the control of the Remote Start Unit. To do this, follow these steps:

1. You will need a transponder key that's already programmed to the vehicle.

2. Remove the trim around the ignition switch.

3. Wrap a thin (30awg) wire tightly around ignition switch 6 to 8 times and secure it.

4. About 6" down line make another loop of approximately 2" diameter.

5. Place the key inside this loop and secure it to the loop.

6. Connect one end of the 30 awg wire to pin (87) of the relay module.

7. Connect the other end of the loop wire to pin (30) of relay module.

8. Connect pin (86) to ignition, connect pin (85) to the pink wire of the white 20-pin mini connector.

Ignition 3 Output:

Some newer vehicles use a third ignition

wire which is required to start and keep

the vehicle’s engine running. If this is the

case, wire an IGN 3 Relay (not supplied)

as shown:

DO NOT CONNECT ANY VEHICLE

CIRCUITS TOGETHER, THEY ARE

ISOLATED FOR A REASON.

Transponder Key

87

87A

85

86

30

Ignition

Switch

+12 Volt Ignition

Pink Wire

White

6-Pin

Connector

White Wire: (-) 200mA Output

Dome Light Control Output:

This wire becomes grounded when the dome

light controls circuit of the alarm is active. The

current capacity of this wire is 200mA. This wire

can control the operation of the interior lights. An

optional relay can be used as shown.

A. Upon disarming, the interior lights will

remain on for 30 seconds.

B. If the vehicle is violated, the interior light

will flash for the same duration as the siren.

87

87a

86

85

30

White Wire

Dome

Light

White 6-Pin

Connector

+12V

Common Door Pin Trigger

Ground Wire or +12V Depending

on Circuit Requirements

Page 14

This wire will provide a 1 second pulse

ground when Channel 3 is activated. The

current capacity of this wire is 200mA.

This feature allows you to remote control

trunk release or other electric device. An

additional relay may be required.

GM VATS Key Override Using ALA985H Relay:

The Violet/Black wire is a programmable (-) output wire that operates when channel #4 is activated with the

remote transmitter. The output of the wire has five different output timer settings to suit any application.

The output current of the Violet/Black is 200mA and can control (1) 30A Bosch type 12 volt relay. (See Alarm

Feature Programming Group 3. The default timer setting is “Pulsed” ground)

GM VATS Key Override Using ALA984 Relay

(may also use optional RS-PLM bypass module)

:

14

Wiring (continued)

87

87A

85

86

30

To Ignition

Passkey Wire

Computer Side

Orange or Black Plastic Tube

at Steering Column

Resistor

Cut

Passkey Wire

Key Side

White

6-Pin

Connector

Pink Wire

HC4 White 20-Pin Connector

(continued)

Pink Wire: 200mA Ignition #3 Output (Programmable Operation)

(continued)

Resistor

Yellow

Trucks: Orange/Black or Cars: Black

87

87A

85

86

30

To Vehicle's Ignition Wire

Trucks: Red/White or Cars: White

Pink Wire

White

6-Pin

Connector

Violet/Black Wire: (-) 200mA Channel 4 Output

87

87a

86

85

30

Red/White

Wire

Input to Relay (+ or -)

Output to Power

Trunk Switch

White 6-Pin

Connector

Constant + 12 Volts

Red/White Wire: Channel 3 (Trunk Release) Output

Page 15

This wire will become grounded when the alarm is in a armed state. This wire can be connected to an optional starter /

ignition disable relay - ECU disable relay, fuel pump disable relay or it can be used to activate other functions of the

vehicle such as window roll-up. The connection of an additional relay may be necessary

This wire can be used to activate the

existing vehicle’s horn as the alarm

system’s optional warning audible

device. It’s a 200mA transistorized

low current output, and should only

be connected to the low current

ground output from the vehicle’s

horn switch/relay. When the alarm is

triggered, the horn will sound

(depending on the vehicle’s

requirement an additional relay may

be required as shown).

87

87a

86

85

30

+12V

To Horn

+12V or Ground

Depending on System

Requirements

Fuse

Light Brown

Wire

White 6-Pin

Connector

Wiring (continued)

15

Orange/White Wire: (-) 500mA Grounded Output when Armed

HC6 White 6-Pin Connector

(continued)

Light Brown Wire: (-) Horn Output

Orange Wire

White 20-Pin

Connector

87

87a

86

85

30

"ACC" "START"

"OFF" "IGN"

Cut BlackBlack

Starter

Plug-In Harnesses

P2 Valet Switch

P1 Status LED Indicator

Page 16

16

P4 Sensor

2-Stage Sensor:

Allows easy connection with quick disconnect ability for

other optional devices.

1. Red: +12 Volt Constant Input

2. Black: Main Sensor Ground

3. Blue: Instant Trigger (-) Input

4. Green: Warn Away (-) Input

P6 Antenna / Receiver

Plug-In Harnesses (Continued)

P7 Data Adapter Communication

Data Interface Harness:

Allows direct communication between Marksman Remote Start and the vehicle’s data bus communication.

(Data Interface Modules sold separately)

Note: The DBI Connection Harness provides power and ground to the Data Interface Module. Do not

connect power and ground from Data Interface Module Harness.

Black Wire No Connection

Red Wire No Connection

DBI Conection Harness (supplied)

Page 17

17

SAVE

4

4

SAVE

4

4

Examine the 3 different feature charts enclosed and decide which feature will get changed. Circling the feature to

be changed will make the programming process much easier to perform.

Before 15 seconds has passed, push and release the

valet switch 2 times holding the button down on the

2nd press. Wait until 1 short and 1 long chirp or beep

is heard. Release the button. You

are now in “Alarm

Feature Programming (Group 1)” mode

ON

OFF

3X

1X + 1X (Hold)

With the ignition switch in the OFF position, Turn the

ignition switch On - Off - On - Off - On

Before 15 seconds has passed, push and release the

valet switch 3 times holding the button down on the

3rd press. Wait until a long chirp or beep is heard.

Release the button. You are now in transmitter

programming mode.

ON

OFF

3X

2X + 1X (Hold)

Press the “Lock” button on the first

transmitter until you hear a confirmation

chirp/beep. The transmitter is now

coded into the system.

Repeat for each additional

transmitter.

When finished, either turn off the

ignition key or wait for 15 seconds

to get out of transmitter programming

mode. You will hear 3 long chirps/

beeps to indicate you are out of the

transmitter programming mode.

OFF

Programming the Remote Transmitter

(Includes the Standard Type and LCD Transmitter Type)

Note: This mode will only retain the last 4 remote transmitters programmed. If the transmitter memory is

exceeded, the security system will start deleting transmitters from memory in chronological order.

With the ignition switch in the OFF position, Turn the

ignition switch On - Off - On - Off - On - Off

Step 1

Programming the Transmitter

Step 1

Step 3 Step 4 Step 5

Exit Programming

Alarm Feature Programming (Group 1)

Step 1 Step 2

Page 18

18

One Chirp Two Chirps Three Chirps Four Chirps

Button One LED Pulse Two LED Pulses Three LED Pulses Four LED Pulses

(Default Setting)

Remote Feature Programming

Press the transmitter buttons as illustrated to adjust the features required. Keep re-pressing the transmitter button

that relates to the feature you want to adjust until the correct amount of chirp/beeps is heard then move on to the

next feature.

All Chirps On

Siren Only

Horn Only

All Chirps Off

Automatic Arming without

Automatic Door Locking

Automatic Arming

Automatic Door Locking

Manual Arming

Automatic Rearm Off

Automatic Rearm On

Instant Door Ajar

Error Chirp

45 Second Delay

Door Ajar Warning

+

Normal Function

Horn Output

Horn Output for Alarm

Trigger, Panic and

Car-Finder Only

+

Normal Horn Output

Pulse Duration

PVID 1

Horn Output

S-S-S - L-L-L - S-S-S

PVID 2

Horn Output

S-L-S-L

PVID 3

Horn Output

S-S-S-L

PVID 4

Horn Output

S-M-L-S-M-L

PVID 5

Horn Output

S-S - L - S-S

Five Chirps

Five LED Pulses

Six Chirps

Six LED Pulses

Note: Horn output settings are valid for the

Brown wire and the White/Black wire when

they are programmed to operate as Horn

output.

+

Car-Jack Mode is Off

Manual Car-Jack

Mode is On

Automatic Car-Jack

Mode is On

OFF

Turn On the Ignition

3 long chirps and 3 flashes of the parking lights will confirm exit of the

programming mode.

Note: Waiting 15 seconds after the last command will also cause the

system to automatically exit the programming mode.

Alarm Feature Programming (Group 1) (continued)

Step 3

Step 5

Exit Programming

Page 19

19

One Chirp Two Chirps Three Chirps Four Chirps

Button One LED Pulse Two LED Pulses Three LED Pulses Four LED Pulses

(Default Setting)

Ignition Controlled

Door Lock Only

Ignition Controlled

Door Unlock Only

Ignition Key Controlled

Door Lock and Unlock

Pathway Illumination

Feature “Off”

Parking Lights “On”

for 30 Seconds Upon

Alarm Disarm

3.5 Second Door

Lock / Unlock Pulse

0.8 Second Door

Lock / Unlock Pulse

Ignition Key Door

Lock Control Off

Parking Lights “On”

for 30 Seconds When

Disarmed and “On” 10

Second when armed

Before 15 seconds has passed, push and release the

valet switch 4 times holding the button down on the

4th press. Wait until 2 short chirp/beeps + 1 long

chirp/beep is heard. Release the button. You are now in

“Alarm Feature Programming (Group 2)” mode.

ON

OFF

3X

3X + 1X (Hold)

With the ignition switch in the OFF position, Turn the

ignition switch On - Off - On - Off - On - Off

Step 3

Remote Feature Programming

Press the transmitter buttons as illustrated to adjust the features required. Keep re-pressing the transmitter button

that relates to the feature you want to adjust until the correct amount of chirp/beeps is heard then move on to the

next feature.

Comfort Feature: Some vehicles (Mercedes, BMW, VW,etc.) have a special “Comfort Feature”. When you lock the

door with the ignition key, you keep the key in the “lock” position for about 5 or 7 seconds and the windows will

close. If the vehicle has a “Comfort Feature” and you want the windows to closed upon Lock/Arm the security

system, you can set the door lock output to “Comfort Feature”.

+

Out of Range Checking

is On

Out of Range Checking

is

Disabled

Five Chirp

Five LED Pulses

Six Chirp

Six LED Pulses

Alarm Feature Programming (Group 2)

Step 1 Step 2

0.8 Lock Pulse,

Double 0.8 Second

Unlock Pulse

0.6 Second Lock Pulse

/ 0.6 Second Unlock

Pulse

Door Lock with

Comfort Feature

0.6 Second Door

Lock / Unlock Pulse

Door Lock

Before Start

Door Lock

Before Start and

After Shutdown

Door Lock

After Shutdown

Without

this Feature

Page 20

20

ON

3X

5X + 1X (Hold)

With the ignition switch in the OFF position, Turn the

ignition switch On - Off - On - Off - On - Off

Turn On the Ignition

3 long chirps and 3 flashes of the parking lights will confirm exit of the

programming mode.

Note: Waiting 15 seconds after the last command will also cause the

system to automatically exit the programming mode.

Step 4

Exit Programming

Alarm Feature Programming (Group 2) (continued)

Alarm Feature Programming (Group 3)

Step 1 Step 2

Before 15 seconds has passed, push and release the

valet switch 6 times holding the button down on the

6th press. Wait until 3 short chirp/beeps + 1 long

chirp/beep is heard. Release the button. You are now in

“Alarm Feature Programming (Group 3)” mode.

One Chirp Two Chirps Three Chirps Four Chirps

Button LED One Pulse LED Two Pulses LED Three Pulses LED Four Pulses

(Factory Default Setting)

Step 3

Use the transmitter buttons as illustrated to adjust the features required. Keep repressing the transmitter button

that relates to the feature you want to adjust until the correct amount of chirps/beeps is heard. Move on to the

next feature.

HC2 Brown Wire

5 Sec On - 5 Sec Off

Pulsing (+) Siren Output

HC2 Brown Wire

Constant (+) Siren Output

HC2 Brown Wire

Car Horn Type (+) Output

+

HC6 Violet/Black Wire

(-) Channel 4 Output

1 Pulse Output

HC6 Violet/Black Wire

(-) Channel 4 Output

Latched Output and Reset

with Ignition "ON"

HC6 Violet/Black Wire

(-) Channel 4 Output

Output as Long as TRX

Button is Held Down

HC6 Violet/Black Wire

(-) Channel 4 Output

Output for 15 Seconds

HC6 White Wire = 2-Step

Door Unlock Output

HC6 White Wire =

Factory Security Disarm

Signal Output

HC6 White Wire =

Dome Light Output

HC6

White Wire =

Ground Output

During Start (Crank)

HC8

White/Blue Wire =

1 Pulse Activate

HC8

White/Blue Wire =

2 Pulse Activate

HC8

White/Blue Wire =

3 Pulse Activate

HC6 Light Brown Wire =

Horn Output

HC6 Light Brown Wire =

Factory Security Rearm

Signal Output

HC6 Light Brown Wire =

Start Status (Shock Sensor

Bypass Control) Output

OFF

Page 21

21

Alarm Feature Programming (Group 3) (continued)

Before 15 seconds has passed, push and release the

valet switch 8 times holding the button down on the

8th press. Wait until four (4) short chirps/beeps + one

(1) long chirp/beep is heard. Release the button. You

are now in “Remote Start Feature Programming”

mode.

ON

OFF

3X

7X + 1X (Hold)

Examine the 2 feature charts enclosed and decide which features will get changed. Circling the feature to be

changed will make the programming process much easier to perform.

With the ignition switch in the OFF position, Turn the

ignition switch On - Off - On - Off - On - Off

Remote Start Feature Programming

Use the transmitter buttons as illustrated to adjust the features required. Keep repressing the transmitter button

that relates to the feature you want to adjust until the correct amount of chirps/beeps is heard. Move on to the

next feature.

OFF

Turn On the Ignition

3 long chirps & 3 flashes of the

parking lights will confirm exit of

the programming mode.

Note: Waiting 15 seconds after the

last command will also cause the

system to automatically exit the

programming mode.

Step 4

Exit Programming

Remote Start Feature Programming

Step 1 Step 2

Step 3

One Chirp Two Chirps Three Chirps Four Chirps

Button One LED Pulse Two LED Pulses Three LED Pulses Four LED Pulses

(Default Setting)

Diesel Engine and

10 Second

Warm-Up Timer

Gasoline

Engine

Five Chirps

Five LED Pulses

Diesel Engine and

15 Second

Warm-Up Timer

Diesel Engine and

20 Second

Warm-Up Timer

Diesel DBI

Page 22

22

10 Minute Run Time

20 Minute Run Time

30 Minute Run Time 5 Minute Run Time

Factory Alarm Disarm

when trunk release

(CH#3) is activated

Without this Feature

Step 3 (continued)

One Chirp Two Chirps Three Chirps Four Chirps

Button One LED Pulse Two LED Pulses Three LED Pulses Four LED Pulses

(Default Setting)

Constant Parking Light

Output When Running on

Remote Start

Flashing Parking Light

Output When Running

on Remote Start

-

to Activate Remote Start

Press

-

to Activate Remote Start

Press

to Activate Remote Start

Press

One Chirp Two Chirps Three Chirps Four Chirps

Button LED One Pulse LED Two Pulse LED Three Pulse LED Four Pulse

(Factory Default Setting)

OFF

Turn On the Ignition

3 long chirps & 3 flashes of the

parking lights will confirm exit of

the programming mode.

Note: Waiting 15 seconds after the

last command will also cause the

system to automatically exit the

programming mode.

Step 4

Exit Programming

Button

Four Chirps, LED Four Pulses

Five Chirps, LED Five Pulses

Six Chirps, LED Six Pulses

Built-in Turbo Timer Control is

Active

Press the ( + ) buttons

before removing the ignition key

to activate the 1 minute Turbo

timer control. The alarm system

can be armed and the shock

sensor will be bypassed.

Built-in Turbo Timer Control is

Active

Press the ( + ) buttons

before removing the ignition key

to activate the 3 minute Turbo

timer control. The alarm system

can be armed and the shock

sensor will be bypassed.

Built-in Turbo Timer Control is

Active

Press the ( + ) buttons

before removing the ignition key

to activate the 5 minute Turbo

timer control. The alarm system

can be armed and the shock

sensor will be bypassed.

+

3 Hour Time Start

+

2 Hour Time Start

(Factory Default Setting)

Turbo Timer Control

Function is Off.

The alarm can not be armed

while the engine is running.

Button

One Chirp, LED One Pulse

Two Chirps, LED Two Pulses

Three Chirps, LED Three Pulses

The vehicle has an aftermarket

turbo timer installed.

The alarm system can be armed

with the engine running. The

shock sensor will be bypassed

as long as the engine is run

ning.

The vehicle has an aftermarket

turbo timer installed.

the alarm system can be armed

with the engine running. The

shock sensor will be bypassed

for 3 minutes.

+

Remote Start Feature Programming (continued)

Page 23

23

Engine Crank Detection Programming Explanations

Use the transmitter buttons as illustrated to adjust the features required. Keep re-pressing the transmitter button that

relates to the feature you want to adjust until the correct amount of chirp/beeps is heard. Move on to the next feature.

In this programming group you will set the type of engine starting detection you want to use in your installation.

There are 3 types available:

1. Tachometer (RPM) Detection: (Most reliable and recommended) This type of detection requires a wire

connection to the vehicles ignition coil. You must also “teach” the remote start unit the engine idle RPM level

before you can start the engine by remote.

2. Voltage Detection: This method detects the drop and rise in the battery voltage when the vehicle is started by

remote. This type of detection requires a solid main power input connection but it does not require any

additional hard wire connections.

Enter the crank detection programming mode, select the engine checking type, then follow the procedures to test

and re-set the cranking perimeters as needed.

Note: The default detection setting is “Voltage Detection”. Once your wiring is completed, you can press the

button (2) times and start the engine to make sure all your connections are good to this point.

With the ignition switch in the OFF position, turn the

ignition switch On - Off - On - Off - On - Off.

Before 15 seconds has passed, push and release the

valet switch 10 times holding the button down on the

10th press. Wait for 5 short chirps/beeps + 1 long

chirp/beep. Release the button. You are now in “Engine

Crank Detection Programming” mode.

Engine Crank Detection Programming

ON

3X

9X + 1X (Hold)

Step 1 Step 2

One Chirp Two Chirps Three Chirps Four Chirps

Button LED One Pulse LED Two Pulse LED Three Pulse LED Four Pulse

(Factory Default Setting)

Exit the Programming Mode (3 long chirps and 3 parking light flashes to confirm this exit)

Tachometer

Checking Type

RPM Learning Start

Timer:

0.6 second (1 chirp)

0.8 second (2 chirps)

1.0 second (3 chirps)

1.2 second (4 chirps)

1.4 second (5 chirps)

1.6 second (6 chirps)

1.8 second (7 chirps)

2.0 second (8 chirps)

3.0 second (9 chirps)

4.0 second (10

chirps)

Voltage Checking

Type

Fixed Crank

Mode

+

Hi Check Level

Low Check Level

Start/Stop the System for Testing and Adjustment

-

Shock Sensor Test

Mode is Off

-

Shock Sensor Test

Mode is On

ON

Page 24

24

Press

Buttons

Chirp/

LED Flash

Checking

Type

Follow Programming and Test Procedure

1

Voltage

Type

A. Press two times to start the engine. Allow engine to run for more

than 10 seconds.

B. If engine starts without cranking too long or too short and runs for more

than 10 seconds, press to exit programming mode (3 chirps confirm

exit). Programming is complete.

C. If the engine shuts off before 10 seconds, press to change “low

check level” to “hi check level” (2 chirps). Repeat A/B above.

D. If the engine cranks too long or too little, press to select a different

crank duration (see chart enclosed). Repeat A/B above.

Step 3A Crank Detection Programming and Procedure

3. Elapsed Timer: This method is the easiest for installation but is not always the best method for year round

usage (Summer and Winter). To operate this method, you will program a specific time window for the remote

start to crank the engine. Battery strength, environment and the aging process of the vehicle may require the

timer to reset from time to time or season to season.

+

Engine Crank Detection Programming Explanations (continued)

Press

Buttons

Chirp/

LED Flash

Checking

Type

Follow Programming and Test Procedure

2

Tachometer

Type

A. Learn the engine idle RPM.

1. Push and release the button on the transmitter

2. Start the engine with the ignition key and allow the choke to turn off.

3. With the engine at true idle speed, press and hold the valet switch

until you hear (1) long chirp and the LED is on solid for two seconds.

3A. If you do not get a response from holding down the valet switch,

check your tach connection. It may be loose or incorrect.

4. Turn off the ignition key.

B. Press two times to start the engine. Allow engine to run for more than

10 seconds.

C. If engine starts without cranking too long, press to exit programming

mode (3 chirps confirm exit). Programming is complete.

D. If the engine cranks too long, press to change “high check level” to

“low check level” (1 chirps). Repeat B/C above.

Step 3B Crank Detection Programming and Procedure

Press

Buttons

Chirp/

LED Flash

Checking

Type

Follow Programming and Test Procedure

3

Fixed Crank

Mode

A. Press two times to start the engine. Allow engine to run for more than

10 seconds.

B. If engine starts without cranking too long or too short, press to exit

programming mode (3 chirps confirm exit). Programming is complete.

C. If the engine cranks too long or too little, press to select and different

crank duration (see chart enclosed). Repeat A/B above.

Step 3C Crank Detection Programming and Procedure

+

+

Page 25

25

The unit has the ability to report the cause of the last shutdown of the remote start system.

1. Turn the ignition switch to “On” position.

2. Press the ( ) button on the transmitter

3. The LED will now report the last system shutdown by flashing for 3 cycles in the following grouped patterns:

Shutdown Diagnostics

Safety Testing Your Installation

Caution! The follow procedure must be performed after the installation of the Remote Start Device. It is the

responsibility of the installing technician to complete these tests. Failure to test the unit in the following manner

may result in personal injury, property damage, or both.

1. Test the brake shutdown circuit: With the vehicle in “Park” (P), start the vehicle using the remote

transmitter, Once the engine is running, press the brake pedal. The vehicle should shut down immediately.

If the vehicle continues to run, check the brake circuit White/Violet wire.

2. Test the “Hood Pin” shutdown circuit: Start the vehicle using the remote transmitter, Once the engine is

running, pull the hood release and raise the hood. The vehicle should shut down immediately. If the vehicle

continues to run, check the hood pin “White/Black” wire connection.

3. Neutral Start Safety Test:

A. Set the vehicle parking brake.

B. Block the drive wheels to prevent vehicle movement.

C. Sitting in the vehicle, turn the ignition switch “On” or “Run” position. But do not start the engine.

D. Step on the brake pedal and shift the gear selector into “Drive” (D).

E. Put you foot over the brake pedal but do not press down on it. Be ready to step on the brake to shut

down the Remote Start Device.

F. Start the vehicle using remote transmitter.

a. If the starter does not engage, the test is complete.

b. If the starter engages, immediately step on the brake pedal to shut down the system, recheck your

Violet wire (6-Pin White, Starter Output) connection. The heavy gauge Violet wire must be connected

to the ignition switch side of the Neutral Start Switch. If the vehicle you are working on does not

have an Electrical Neutral Safety Switch, it will be necessary to reconfigure the Remote Starts Wiring

to accommodate this vehicle. The information concerning the Mechanical Neutral Safety Switch

provided below will help you to determine if the vehicle you are working on has this type of safety

switch and will provide alternate wiring methods to accommodate this situation.

LED Shutdown Mode

Flashes

1 (-) Safety Shutdown Input (Hood)

1. Close the Hood

2. Check White/Black Wire Connection (Black 8-Pin Mini)

1. Set the Hand Brake

(+) Safety Shutdown Input (Brake) 2. Check White/Violet Wire Connection (Black 8-Pin Mini)

2 or Neutral Safety Switch Input Fail 3. Move the Enable Toggle Switch to “On” Position (If Installed)

4. Move the gear selector to “Park”/ “Neutral” Position

5. Check Black/White Wire Connection (Black 8-Pin Mini)

3 No RPM (Engine Checking Tach) Check White/Red Wire Connection

Low Voltage (Engine Checking Voltage) Program the “Check Level” from “Hi Check Level” to

“Low Check Level”

5 Over-Rev

6 System Timed-Out

7 Transmitter

8 Tach Signal has Not Been Learned Check Tach Signal Feature Programming

Page 26

26

In this test mode, the installer can save time adjusting the optional sensor sensitivity without using the traditional

arming/disarming procedures to adjust the sensor.

With the ignition switch in the OFF position, turn the

ignition switch On - Off - On - Off - On - Off.

ON

3X

Before 15 seconds has passed, push and release the

valet switch 6 times holding the button down on the 6th

press. Wait until five (3) chirps/beeps and a long chirp

then release it. You are now in “Shock Sensor” Test

mode.

5X + 1X (Hold)

Shock Sensor Test Mode

Step 1 Step 2

Press the button. 2 chirps will confirm you are now in

Shock Sensor test mode.

1. Walk around the vehicle and slap the body panels with

the palm of your hand

2. A short Chirp indicates a pre-warning level detection

3.

A long Chirp indicates a system trigger level detection

4. Adjust the sensor with a flat blade screwdriver.

Continue to test the sensor until you reach the desired

settings.

Turn On the ignition key to exit the test mode. The horn/siren will chirp 3

long chirps and the parking lights will flash 3 times.

Step 4

Exit Programming

Step 3

Adjust the Shock Sensor

ON

OFF

Page 27

27

Turn the ignition switch from the

OFF position to the ON position 3

times leaving it in the Off position

the third time.

ON

3X

Step 1

Before 15 seconds has passed, push

and release the valet switch 12 times.

Holding on the 12th press. You will

hear 6 short beeps. Release the

button.

11X + 1X (Hold)

Step 2

Press and release the (Trunk) button

first, then press (Lock) and (Trunk)

button on the transmitter together for

5 seconds, there will be a six chirp

confirmation with 3 long chirps and 3

parking light flashes to confirm the

system “Start Features 1 and 2

Programming” all returned to the

factory default settings.

Step 3

ON

Turn On the Ignition

3 long chirps and 3 flashes of the parking lights will confirm exit of the

programming mode.

Note: Waiting 15 seconds after the last command will also cause the

system to automatically exit the programming mode.

Step 4: Exit Programming

Returning Programmable Alarm Features to Factory Default Settings

Turn the ignition switch from the

OFF position to the ON position 3

times leaving it in the Off position

the third time.

3X

Step 1

Before 15 seconds has passed, push

and release the valet switch 12 times.

Holding on the 12th press. You will

hear 6 short beeps. Release the

button.

11X + 1X (Hold)

Step 2

Press (Lock) and (Trunk) button on

the transmitter together for 5 seconds,

there will be a six chirp confirmation

with 3 long chirps and 3 parking light

flashes to confirm the system “Start

Features 1 and 2 Programming” all

returned to the factory default

settings.

Step 3

ON

Turn On the Ignition

3 long chirps and 3 flashes of the parking lights will confirm exit of the

programming mode.

Note: Waiting 15 seconds after the last command will also cause the

system to automatically exit the programming mode.

Step 4: Exit Programming

Returning All Programmable Features to Factory Default Settings

5 Sec Hold

ON

ON

ON

Page 28

Wiring Diagram

X9-IM 7-24-08 Rev. A

© Copyright 2008/2009 Magnadyne Corporation

P2

Blue 2-Pin

HC1 White

6-Pin

HC3

HC8

Black

Black

2-Pin

8-Pin

White

HC6

6-Pin

P6

Blue 4-Pin

White 5-Pin

P4

White

4-Pin

HC2

P7

Data

Brown

Port

4-Pin

P1

White

2-Pin

Loading...

Loading...