Page 1

Networking Communication Components

RT Series

Lan Transformer

Part number: RT14P03

Part name :Giga Transformer Single Port Support PoE & PoE+

Feature

●

Compliant and peak reflow temperature rating 245°C .

●

Meets IEEE802.3 specification.

●

Excellent common mode noise suppression.

●

Packaging specification is reel.

(

RT14P

□□

: Reel )

Part Number Code

RT 1 4 P

□□

Serial number

Type

Application Category

Ports

Product Symbol

Page 2

REV. Description Date Drawn

Designed Approved

A Specification issued 03.12.2012 Allen.Yu Allen.Yu James.Cheng

B 08.16.2012 Yuxuan.Xiang Yuxuan.Xiang James.Cheng

C 03.19.2013 Yuxuan.Xiang Yuxuan.Xiang James.Cheng

Page 6 & 7 Packaging Specification change :

310 -> 400 reel/piece ; 620 -> 800 reel/carton

Mechanical Dimension change :

unit B : 16.00 mm -> 15.00 mm

unit F : 13.40 mm -> 12.40 mm

Suggested Land Pattern change :

unit c : 12.70 mm -> 11.70 mm

Page 3

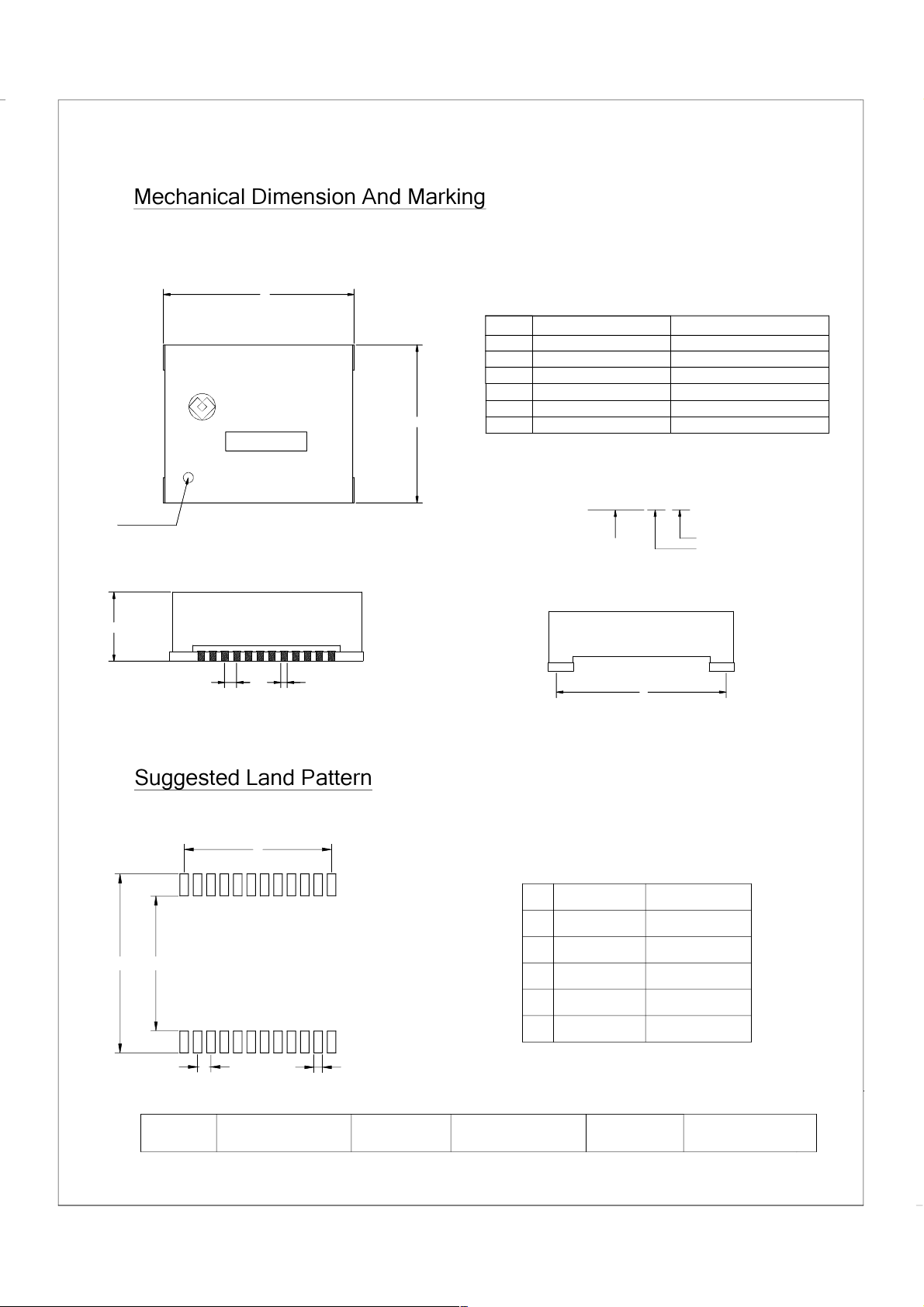

Mechanical Dimension And Marking

A

RT14P03

Date Code

B

UNIT mm inch

A 17.50 +0.254/-0.254 0.689 +0.010/-0.010

B 15.00 +0.254/-0.254 0.591 +0.010/-0.010

C 5.40 +0.254/-0.254 0.213 +0.010/-0.010

D 1.27 +0.254/-0.254 0.050 +0.010/-0.010

E 0.50 +0.127/-0.127 0.020 +0.005/-0.005

F 12.40 +0.254/-0.254 0.488 +0.010/-0.010

PIN 1

C

ED

Suggested Land Pattern

a

c

b

RT14P03 XX XX

Maglayer Part Number

F

UNIT mm inch

a

b

c

d

e

13.97

16.51

11.70

1.27

0.76

0.550

0.650

0.461

0.050

0.030

Week

Year

d

e

Drawn Yuxuan.Xiang Designed Yuxuan.Xiang Approved James.Cheng

Page 4

Schematics

RT14P03

CMT1

CABLE SIDE

TX2+ TX2- TX3+ TX3- TX4+ TX4- TX1+ TX1-

CMT2 CMT3 CMT4

18192021222324

11111111 2 3 4 5 6 7 8

TCT1

TCT2 TCT3

TD2+ TD2- TD3+ TD3- TD4+ TD4- TD1+ TD1-

9 10

PHY SIDE

Electrical Specification @ 25°C, Humidity 65% RH

Inductance @ Phy side(OCL)

100KHz, 0.1V, 8mA DC Bias

TCT4

141516

1317

11 12

Part Number

RT14P03

350uH MIN

Vrms, Sec

Phy To Cable

Turns Ratio

100KHz

Pri To Sec

1:1±3%

Hipot

1500, 60

Insertion Loss

dB MAX

1MHz-100MHz

-1.0

DC Resistance DC Current Rating

mOhms, TYP.

1/2

Winding at cable side.

750

MAX

720 mA DC at 57 V

Return Loss

dB MIN

1MHz-

125MHz

-2.0

60MHz 80MHz

30MHz

-18 -14.4 -12 -10 -35 -25 -21.6

100MHz

2MHz 30MHz 60MHz

CMRR Crosstalk

dB MIN dB MIN

Operating Temperature: -40°C to +85°C.

Storage Temperature : -25°C to +105°C

JSDEC Moisture : Level 1.

100MHz 150MHz 200MHz

-15.4 -10.5 -7.0

30MHz 60MHz 100MHz

1MHz

-41 -33

-50

-37

Page 5

Reflow Soldering

245°C

217°C

200°C

150°C

3°C /sec MAX.

6°C /sec MAX.

Temperature(°C)

Pre-heating

53sec TYP.

60sec MIN.

180sec MAX.

Time(s)

●

IR Reflow soldering :

Preheat at 3℃ per second to 217℃ and using lead free solder ,

IR at 245℃ for 30seconds Max.

●

Rework flow:

Component must withstand two IR reflow cycles with a cool down

between cycles

●

Temperature is measured at the terminal portion of product

(Using thermocoupler for measurement).

●

This profile is reference data we recommend. Please check in your

actual process.

60sec MIN.

150sec MAX.

Soldering

Natural

cooling

●

For reliable soldering, the thickness of solder paste screen should

be over the terminal co-planality.

●

The cutted end of terminal has no plating

(out of subject of solder ability).

Page 6

Packaging Styles

Per 13" reel: 400 pieces

Tape Dimensions

F

E

G

B

R0.75

Reel Dimensions

C

0.20±0.05

H

D

11.85

b

UNIT mm

a

A

c

A

B

C

D

E

10*E

32.00± 0.30

24.00± 0.10

1.75± 0.10

14.20± 0.10

4.00± 0.10

40.00± 0.20

UNIT

F

G

H

a

b

c

mm

2.00± 0.10

1.50± 0.02

16.85± 0.10

17.85± 0.10

7.50± 0.10

0.40± 0.05

330typ.

ø

2

1

±

0

,

8

2

±0,5

5

,

0

±

3

1

ø

38.4 max.

Dimensions in mm

Recommended Condition For Long Term Store

When it stores for a long term, please avoid place of high

temperature and high humidity.

Recommend that it uses after the delivery within 1 year.

●

Temperature renge: +5 to +30°C.

●

Humidity: 60(%)RH max..

●

All dimensions meet EIA-481-C requirement.

Page 7

Package Specification

400 pieces / reel

LABELLABEL

REELREEL

CARRIER TAPECARRIER TAPE

COVER TAPECOVER TAPE

PAPER TAPEPAPER TAPE

2 BOX / CARTON

800 pieces / CARTON

1 reel / BOX

ANTI-STATIC (HEAT SEAL

ANTI-STATIC (HEAT SEAL

)

)

VAPOR CAPSULE TO PREVENT OXIDATIONVAPOR CAPSULE TO PREVENT OXIDATION

DRYERDRYER

BOXBOX

PAPER PADPAPER PAD

CARTONCARTON

Loading...

Loading...