Mag Layers MMD-06AB-R47M-S1, MMD-06AB-R68M-S1, MMD-06AB-1R0M-S1, MMD-06AB-1R5M-S1, MMD-06AB-2R2M-S1 User Manual

...Page 1

■

A

P

P

L

I

C

A

T

I

O

N

■

A

P

P

L

I

C

A

■

A

P

P

L

PDA, notebook, desktop, and server applications

Low profile, high current power supplies

Battery powered devices

DC/DC converters in distributed power systems

T

I

C

A

T

I

O

N

I

O

N

DC/DC converters for field programmable gate array

■

F

E

A

T

U

R

E

S

■

F

E

A

T

U

■

F

E

A

RoHS Compliant.

Super low resistance, ultra high current rating

High performance (I sat) realized by metal dust core

■

P

R

■

■

O

P

R

O

P

R

MMD - 06AB - R68 M - S1

① Product Code

② Dimensions : 7.2 x 6.7 x 1.2 mm

R

T

U

R

D

U

C

D

U

O

C

D

U

C

① ② ③ ④ ⑤

E

E

T

T

T

S

S

I

D

E

N

T

I

F

I

C

A

T

I

O

N

I

D

E

N

T

I

F

I

C

A

I

D

E

N

T

I

F

T

I

C

A

T

I

O

N

I

O

N

③ Inductance : R68 = 0.68μH

④ Tolerance : M = ±20%

⑤ Series Type : S1 Type

NOTE:Please refer to the “Product Dimension” for detail dimensions.

■

P

R

O

D

U

C

T

D

I

M

E

N

S

I

O

N

■

■

P

R

O

D

U

C

T

D

I

M

E

N

P

R

O

D

U

C

T

D

I

M

E

N

S

S

I

O

N

I

O

N

MAG.LAYERS

MMD-06AB-SERIES-S1

Page 2

NOTE

:Dimensions in mm

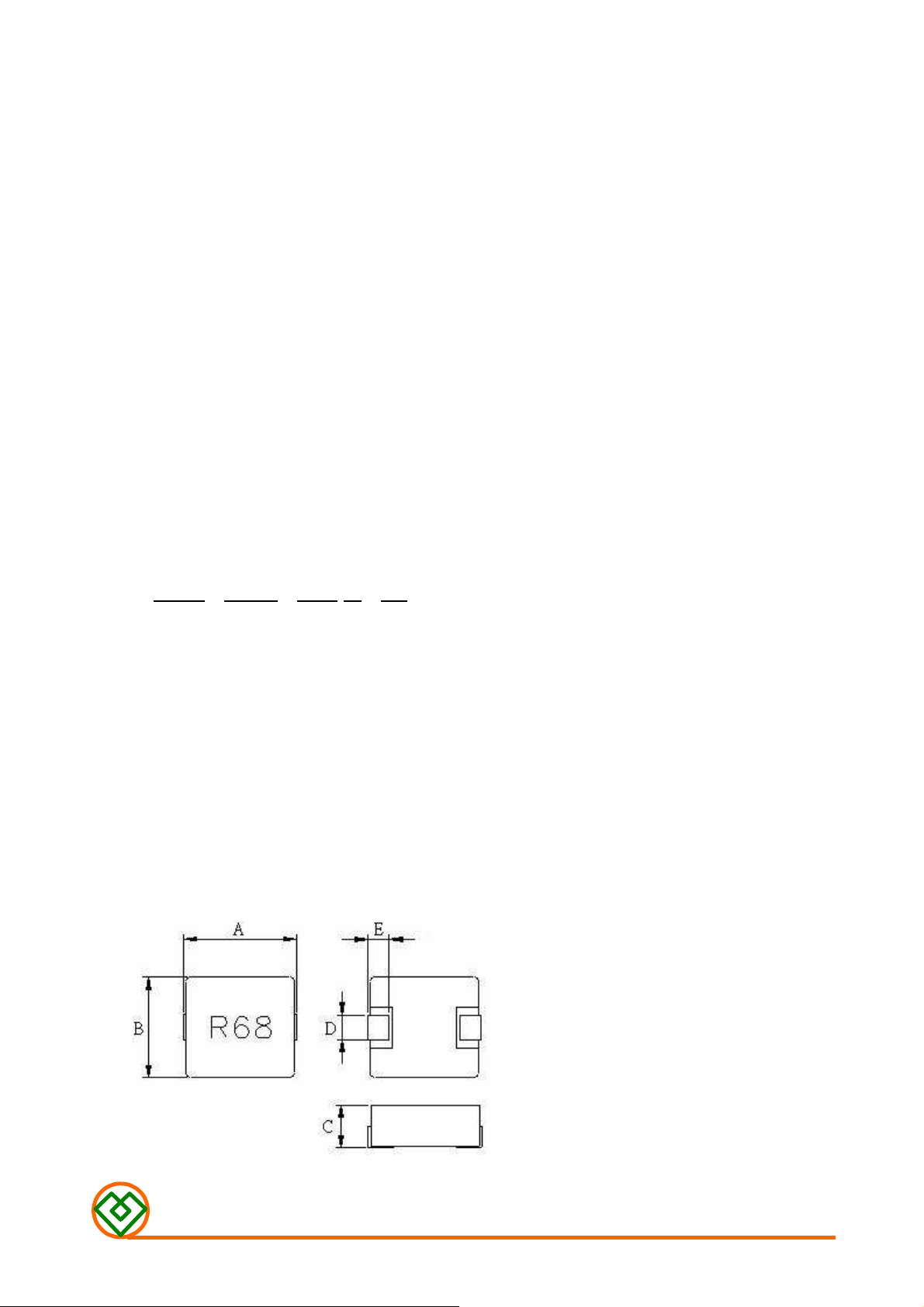

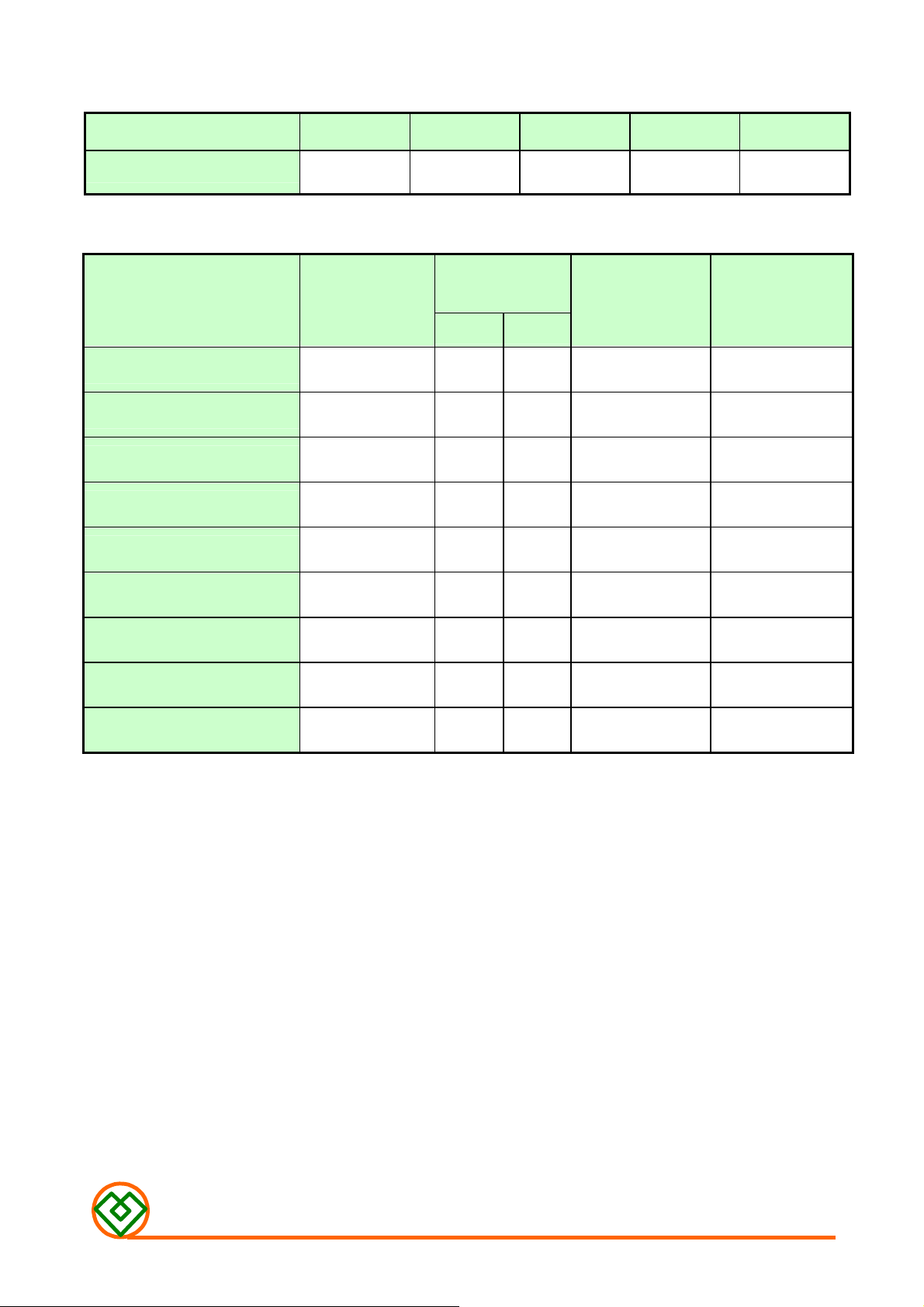

PRODUCT NO. A B C D E

MMD-06AB-SERIES-S1

E

L

E

C

T

R

I

C

A

E

L

E

C

T

■ E

L

E

PART NUMBER

MMD-06AB-R47M-S1 0.47 15 17 8 11

MMD-06AB-R68M-S1 0.68 17 19 7 8

MMD-06AB-1R0M-S1 1.0 26 28 6 7

MMD-06AB-1R5M-S1 1.5 35.5 40.8 4 6

MMD-06AB-2R2M-S1 2.2 75 82.5 3.5 4.4

MMD-06AB-3R3M-S1 3.3 90 103 3 3.6

C

T

R

R

L

I

C

A

L

I

C

A

6.86 ± 0.38 6.47 ± 0.25

R

E

Q

U

I

R

E

L

R

E

Q

R

E

Q

INDUCTANCE

Lo(μH)±20%

U

U

@0A

M

I

R

E

M

I

R

E

M

E

N

T

E

S

N

T

E

S

N

T

S

(mΩ)

Typ. Max

R

1.2Max 3.0 ± 0.3 1.3 ± 0.3

dc

HEAT RATING

CURRENT(Idc)

DC AMPS

1

SATURATION

CURRENT(Isat)

DC AMPS2

MMD-06AB-4R7M-S1 4.7 155 170 2.4 2.8

MMD-06AB-6R8M-S1 6.8 189 217 2.1 2.4

MMD-06AB-100M-S1 10 250 290 1.8 2.2

TEST FREQUENCY:100KHz,0.25V

TESTING INSTRUMENT L :Agilent4284A,WK4235,CH3302/G LCR METER

CH1320,CH1320S BIAS CURRENT SOURCE

R

NOTES:

1.DC current (Idc) that will cause an approximate △T of 40℃

2.DC current (I

3.All test data is referenced to 25℃ ambient

4.Operating Temperature Range -55℃ to +125℃

5.The part temperature (ambient + temp rise) should not exceed 125℃under worst case

operating conditions. Circuit design, component placement, PWB trace size and

thickness, airflow and other cooling provisions all affect the part temperature. Part

sat

) that will cause Lo to drop approximately 30%

:CH11025,GOM802 MICRO OHMMETER

dc

temperature should be verified in the end application.

MAG.LAYERS

MMD-06AB-SERIES-S1

Page 3

■

■

■

E

L

E

C

T

R

I

C

A

L

C

H

A

R

A

C

T

E

R

I

S

T

I

C

S

R

e

f

e

r

e

n

c

e

d

a

t

a

E

L

E

C

T

R

I

C

A

L

C

H

A

R

A

C

T

E

R

I

S

T

I

C

S

R

e

f

e

r

e

n

c

E

L

E

C

T

R

I

C

A

L

C

H

A

R

A

C

T

E

R

I

S

T

I

C

S

R

e

f

MMD-06AB-R47M-S1

MMD-06AB-R68M-S1

e

e

r

e

n

c

d

a

t

a

e

d

a

t

a

0.5

0.4

0.3

0.2

INDUCTANCE (uH)

0.1

0.0

0 3 6 9 12 15

DC CURRENT (A)

INDUCTANCE (uH)

TEMP.Rise(℃)

MMD-06AB-1R0M-S1

1.5

1.2

0.9

0.6

INDUCTANCE (uH)

0.3

0.0

0 2 4 6 8 10

DC CURRENT (A)

INDUCTANCE (uH)

TEMP.Rise(℃)

100

80

60

40

20

0

1.0

0.8

0.6

TEMP.Rise(℃)

0.4

INDUCTANCE (uH)

0.2

0.0

0 3 6 9 12

DC CURRENT (A)

INDUCTANCE (uH)

TEMP.Rise(℃)

100

80

60

TEMP.Rise(℃)

40

20

0

MMD-06AB-1R5M-S1

100

80

60

TEMP.Rise(℃)

40

20

0

2.0

1.6

1.2

0.8

INDUCTANCE (uH)

0.4

0.0

0 2 4 6 8

DC CURRENT (A)

INDUCTANCE (uH)

TEMP.Rise(℃)

100

80

60

TEMP.Rise(℃)

40

20

0

MMD-06AB-2R2M-S1

3.0

2.5

2.0

1.5

INDUCTANCE (uH)

1.0

0.5

0.0

0 1 2 3 4 5 6

DC CURRENT (A)

INDUCTANCE (uH)

TEMP.Rise(℃)

MMD-06AB-3R3M-S1

100

80

60

TEMP.Rise(℃)

40

20

0

4

3

2

INDUCTANCE (uH)

1

0

0 1 2 3 4 5

DC CURRENT (A)

INDUCTANCE (uH)

TEMP.Rise(℃)

100

80

60

TEMP.Rise(℃)

40

20

0

MAG.LAYERS

MMD-06AB-SERIES-S1

Page 4

MMD-06AB-4R7M-S1

MMD-06AB-6R8M-S1

6

5

4

3

INDUCTANCE (uH)

2

1

0

0.0 1.0 2.0 3.0 4.0

DC CURRENT(A)

INDUCTANCE (uH)

TEMP.Rise(℃)

MMD-06AB-100M-S1

15

12

9

6

INDUCTANCE uH

3

0

0.0 0.5 1.0 1.5 2.0 2. 5 3.0 3.5

DC CURRENT (A)

INDUCTANCE uH

TEMP.Rise(℃)

100

80

60

TEMP.Rise(℃)

40

20

0

100

80

60

40

TEMP.Rise(℃)

20

0

8.0

6.0

4.0

INDUCTANCE (uH)

2.0

0.0

0.0 0.5 1.0 1.5 2.0 2.5 3.0

DC CURRENT (A)

INDUCTANCE (uH)

TEMP.Rise(℃)

100

80

60

TEMP.Rise(℃)

40

20

0

MAG.LAYERS

MMD-06AB-SERIES-S1

Page 5

■

P

A

■

■

C

P

A

C

P

A

C

Peel-off Force

K

K

K

A

A

A

G

G

G

I

N

G

I

N

G

I

N

G

The force for peeling off cover tape is 10 to 70 grams in the arrow direction.

Dimension (Unit: mm)

A

B

C

D

TOP COVER TAPE

F

TYPE A

330 mm 330±2

E

B

100±1

C D E

20±0.5 13 ±1.0 16 ±0.5

165° TO 180°

BASE TAPE

F

26 ±2

TYPE SIZE A B W P T

MMD 06AB 6.9 7.5 16 12 1.5

MAG.LAYERS

MMD-06AB-SERIES-S1

Page 6

END

START

200mm

NO COMPONENTS

COMPONENTS

Taping Quantity

SERIES 06AB

PCS/Reel 2000

CARTON:

MIDDLE PACKAGING : 3 Reel /BOX

400mm

NO COMPONENTS

LABEL

EXTERNAL PACKAGING : 5 BOX / CARTON

LABEL

415mm

m

m

0

8

380mm

3

40mm

40mm

342mm

40mm

336mm

40mm

m

m

0

7

MAG.LAYERS

MMD-06AB-SERIES-S1

Loading...

Loading...