Page 1

(1) SHAPES AND DIMENSIONS

(2) ELECTRICAL SPECIFICATIONS

(3) CHARACTERISTICS

B

Terminal

E

A

G

F

E

Terminal wraparound :

Approx. 0.38mm both ends

C

D

A : 2.2 ± 0.2 mm

B : 1.45 ± 0.2 mm

C : 1.30 ± 0.15 mm

D : 0.65± 0.25 mm

E : 0.44 ± 0.1 mm

F : 1.15 ± 0.1 mm

G : 1.27± 0.1 mm

Equivalent circuit

No Polarity

SEE TABLE 1

TEST INSTRUMENTS

L,Q : HP 4291B IMPEDANCE ANALYZER (or equivalent)

SRF : ENA E5071B NETWORK ANALYZER (or equivalent)

RDC : CHROMA MODEL 16502 MILLIOHMMETER (or equivalent)

(3)-1 Operate temperature range ...... -40℃~+125℃

(Including self temp. rise)

(3)-2 Storage temperature range ...... -40℃~+125℃

MAG.LAYERS

MHSC-2012C-SERIES Page-1/7

Page 2

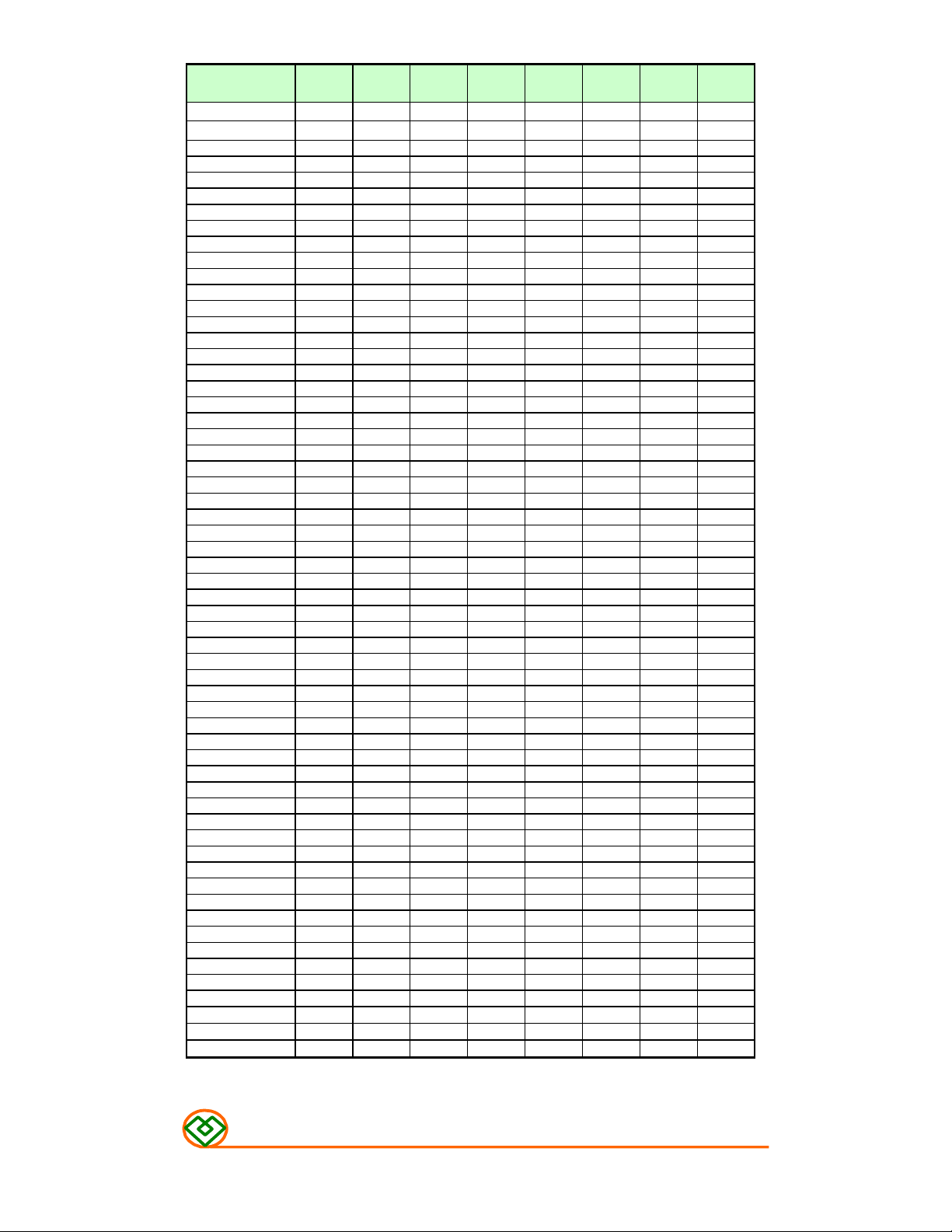

TABLE 1

MAGLAYERS

PT/NO.

MHSC-2012C-2N2□

MHSC-2012C-2N7□

MHSC-2012C-2N8□

MHSC-2012C-3N0□

MHSC-2012C-3N3□

MHSC-2012C-5N1□

MHSC-2012C-5N6□

MHSC-2012C-6N2□

MHSC-2012C-6N8□

MHSC-2012C-7N5□

MHSC-2012C-8N2□

MHSC-2012C-8N7□

MHSC-2012C-10N□

MHSC-2012C-12N□

MHSC-2012C-14N□

MHSC-2012C-15N□

MHSC-2012C-16N□

MHSC-2012C-18N□

MHSC-2012C-22N□

MHSC-2012C-24N□

MHSC-2012C-27N□

MHSC-2012C-33N□

MHSC-2012C-36N□

MHSC-2012C-39N□

MHSC-2012C-43N□

MHSC-2012C-47N□

MHSC-2012C-56N□

MHSC-2012C-68N□

MHSC-2012C-75N□

MHSC-2012C-82N□

MHSC-2012C-91N□

MHSC-2012C-R10□

MHSC-2012C-R11□

MHSC-2012C-R12□

MHSC-2012C-R15□

MHSC-2012C-R16□

MHSC-2012C-R18□

MHSC-2012C-R20□

MHSC-2012C-R22□

MHSC-2012C-R24□

MHSC-2012C-R25□

MHSC-2012C-R27□

MHSC-2012C-R33□

MHSC-2012C-R36□

MHSC-2012C-R39□

MHSC-2012C-R43□

MHSC-2012C-R47□

MHSC-2012C-R56□

MHSC-2012C-R62□

MHSC-2012C-R68□

MHSC-2012C-R75□

MHSC-2012C-R82□

MHSC-2012C-R91□

MHSC-2012C-1R0□

MHSC-2012C-1R2□

MHSC-2012C-1R5□

MHSC-2012C-1R8□

MHSC-2012C-2R2□

MHSC-2012C-2R7□

※ 1. Please specify the inductance tolerance, G(±2%),J(±5%),K(±10%)

2. IDC for a 15°C rise above 25°C ambient.

Inductance Percent L Freq. Quality Q Freq. SRF DCR IDC

L(nH) Tolerance (MHz) Min. (MHz) (MHz)Min. (Ω) Max. (mA) Max.

2.2 K 250 50 1000 7900 0.05 800

2.7 J,K 250 50 1500 7900 0.058 800

2.8 J,K 250 55 1500 7900 0.06 800

3.0 J,K 250 55 1500 7900 0.08 800

3.3 J,K 250 45 1500 7900 0.12 600

5.1 J,K 250 60 1000 5800 0.06 600

5.6 J,K 250 65 1000 5500 0.08 600

6.2 J,K 250 50 1000 5500 0.11 800

6.8 J,K 250 50 1000 5500 0.11 600

7.5 J,K 250 50 1000 4500 0.14 600

8.2 J,K 250 50 1000 4700 0.16 600

8.7 J,K 250 50 1000 4700 0.23 600

10 G,J,K 250 60 500 4200 0.10 600

12 G,J,K 250 50 500 4000 0.15 600

14 G,J,K 250 50 500 3400 0.17 600

15 G,J,K 250 50 500 3400 0.17 700

16 G,J,K 250 50 500 3300 0.19 600

18 G,J,K 250 50 500 3300 0.20 600

22 G,J,K 250 55 500 2600 0.22 500

24 G,J,K 250 50 500 2000 0.22 500

27 G,J,K 250 55 500 2500 0.25 500

33 G,J,K 250 60 500 2050 0.27 500

36 G,J,K 250 55 500 1700 0.27 500

39 G,J,K 250 60 500 2000 0.29 500

43 G,J,K 200 60 500 1650 0.34 500

47 G,J,K 200 60 500 1650 0.31 700

56 G,J,K 200 60 500 1550 0.34 500

68 G,J,K 200 60 500 1450 0.38 500

75 G,J,K 200 60 500 1400 0.40 400

82 G,J,K 150 65 500 1300 0.42 400

91 G,J,K 150 65 500 1200 0.48 400

100 G,J,K 150 65 500 1200 0.46 400

110 G,J,K 150 50 250 1000 0.48 400

120 G,J,K 150 50 250 1100 0.51 400

150 G,J,K 100 50 250 920 0.56 400

160 G,J,K 100 50 250 900 0.60 400

180 G,J,K 100 50 250 870 0.64 400

200 G,J,K 100 50 250 865 0.68 400

220 G,J,K 100 50 250 850 0.70 400

240 G,J,K 100 44 250 690 1.00 350

250 G,J,K 100 48 250 680 1.00 350

270 G,J,K 100 48 250 650 1.00 350

330 G,J,K 100 48 250 750 1.40 310

360 G,J,K 100 48 250 650 1.45 300

390 G,J,K 100 48 250 560 1.50 290

430 G,J,K 50 33 100 430 1.70 290

470 G,J,K 50 30 100 375 1.76 250

560 G,J,K 25 23 50 340 1.90 230

620 G,J,K 25 23 50 220 2.20 210

680 G,J,K 25 23 50 188 2.20 190

750 G,J,K 25 23 50 200 2.30 180

820 G,J,K 25 23 50 215 2.35 180

910 J,K 25 22 50 210 2.40 180

1000 G,J,K 25 22 50 200 2.45 180

1200 G,J,K 7.9 16 7.9 160 2.45 170

1500 G,J,K 7.9 16 7.9 120 2.50 170

1800 G,J,K 7.9 16 7.9 80 2.50 170

2200 G,J,K 7.9 16 7.9 60 2.70 160

2700 G,J,K 7.9 16 7.9 50 3.80 160

MAG.LAYERS

MHSC-2012C-SERIES

Page-2/7

Page 3

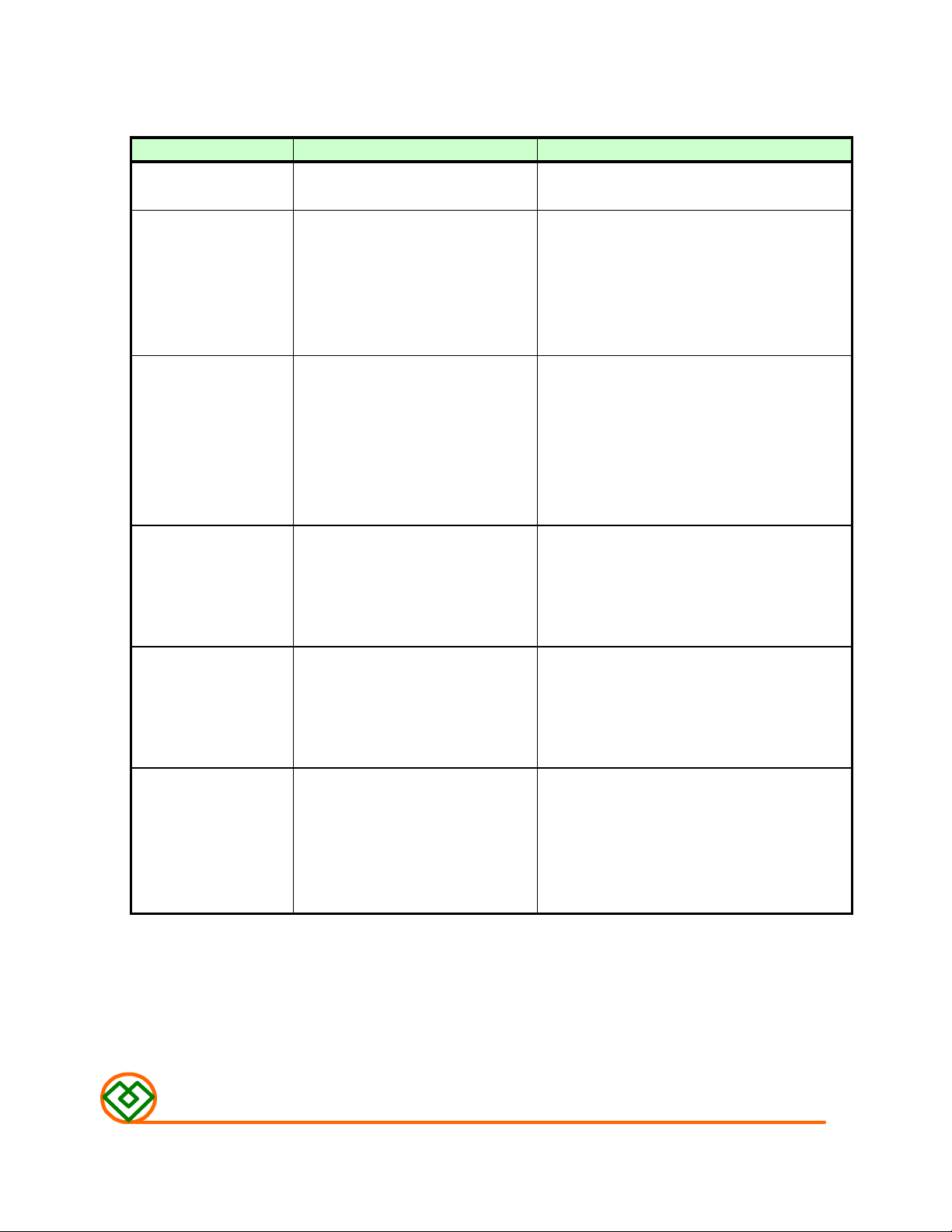

(4) RELIABILITY TEST METHOD

Item Specifications Test conditions

Solderability The metalized area must have 90% Dip pads in flux and dip in solder pot

minimum solder coverage. (96.5 Sn/3.5 Ag solder) at 260°C ±5°C.

Resistance to There must be no case deformation Inductors shall be reflowed onto a PC board

soldering heat or change in dimensions. using 96.5 Sn/3.5 Ag solder paste.

Inductance must not change more Solder process shall be at a maximum

than the stated tolerance. temperature of 260°C.

For 96.5 Sn/3.5 Ag solder paste:>217°C for

90 seconds

Vibration There must be no case deformation Solder specimen inductor on the test printed

or change in dimensions. circuit board.

Inductance must not change more Apply vibrations in each of the x,y and z

than the stated tolerance. directions for 2 house for a total of

6 hours.

Frequency : 10~50 Hz

Amplitude : 1.5 mm

High There must be no case deformation Inductors shall be subjected to temperature

temperature or change in dimensions.

resistance

Static Inductors must not have a shorted Inductors shall be subjected to temperature

Humidity or open winding.

Component Inductors shall be subjected to Inductors shall be reflow soldered (260°C

adhesion 1.8Kg ±5°C for 10 seconds) to a tinned copper

(push test) substrate. A force gauge shall be applied

Inductance must not change more Measure the test items after leaving the

than the stated tolerance. inductors at room temperature and humidity

Measure the test items after leaving the

125±2℃ for 50±12 hours.

for 2 hours.

85±2℃ and 90 to 95%RH. for ten 24-hours.

inductors at room temperature and humidity

for 2 hours.

to the side of the component.

The device must withstand the stated force

without a failure of the termination.

MAG.LAYERS

MHSC-2012C-SERIES Page-3/7

Page 4

Item Specifications Test conditions

Low There must be no case deformation Inductors shall be subjected to temperature

temperature or change in dimensions.

storage Inductance must not change more Measure the test items after leaving the

than the stated tolerance. inductors at room temperature and humidity

Resistance to There must be no case deformation, Inductors must withstand 6 minutes of

solvent change in dimensions, or alcohol or water.

obliteration of marking.

Thermal There must be no case deformation Inductors shall be subjected to 10 cycles

shock or change in dimensions. to the the following temperature cycle:

Inductance must not change more

than the stated tolerance.

-40±2℃ for 48±12 hours.

for 1 to 2 hours.

1 cycle

30 min.

+125℃

30 sec

-40℃

30 min.

Measure the test items after leaving the

inductors at room temperature and humidity

for 2 hours.

MAG.LAYERS

MHSC-2012C-SERIES Page-4/7

Page 5

(5) RECOMMENDED SOLDERING CONDITIONS

(Please use this product by reflow soldering)

(5)-1 RECOMMENDED FOOTPRINT

Unit: mm

0.76

1.02

1.02

1.78

(5)-2 RECOMMENED REFLOW PATTERN

Temperature(℃)

300

260

200

150

100

50

Preheating

Solding

260℃

10 sec1 to 4 min. more than 2 min.

Natural Cooling

Time

(5)-3 IRON SOLDERING

Use a solder iron of less than 30W when soldering ,do not allow the soldering

iron tip directly touch the Ceramic body outside of terminal electrode.

3 seconds max. at 260℃.

MAG.LAYERS

MHSC-2012C-SERIES Page-5/7

Page 6

(6) PACKAGING

W : 8.0

P : 4.0

P0 : 4.0

P1 : 2.0

t : 0.23

(6)-1 CARRIER TAPE DIMENSIONS (mm)

P

1

t

mm

mm

mm

mm

mm

W

P

P

0

(6)-2 TAPING DIMENSIONS (mm)

There shall not continuation more than two vacancies of the product.

(360 mm)

Leader.

ChipBlank

(50 pitches)

Blank

(70 pitches)

(6)-3 REEL DIMENSIONS

C

MAG.LAYERS

MHSC-2012C-SERIES

D

A : 180 mm

B : 60.0 mm

C : 13.0 mm

AB

D : 12.0 mm

E : 8.4 mm

E

Page-6/7

Page 7

(6)-4 TOP TAPE PEEL STRENGTH

The force for tearing off cover tape is 0.1~0.6(N) in the arrow direction at

the following conditions:

Temperature : 5 ~ 35℃

Humidity : 45 ~ 85%

Atmospheric pressure : 860 ~ 1060 hpa

160 ~ 180

。

Top cover tape

Base tape

(6)-5 QUANTITY

2000 pcs/Reel

(6)-6 The products are packaged so that no damage will be sustained.

(7) ATTENTION IN CASE OF USING

In case of using product ,please avoid following matters:

Splashing water or salt water

Dew condenses

Toxic gas (Hydrogen sulfide, Sulfurous acid ,Chlorine, Ammonia)

Vibrations or shocks which exceed the specified condition

Please be careful for the stress to this product by board flexure or something

after the mounting.

MAG.LAYERS

MHSC-2012C-SERIES

Page-7/7

Page 8

TYPICAL ELECTRICAT CHARACTERISTICS

MAG.LAYERS

MHSC-2012C-SERIES

ATTACHMENT-1

Loading...

Loading...