■

A

P

P

L

I

C

A

T

I

O

N

■

A

P

P

L

I

C

A

■

A

P

P

L

PDA, notebook, desktop, and server applications

Low profile, high current power supplies

Battery powered devices

DC/DC converters in distributed power systems

DC/DC converters for field programmable gate array

■

F

E

A

■

■

■

■

■

F

P

P

T

E

A

F

P

T

E

A

T

RoHS compliant

Super low resistance, ultra high current rating

High performance (I sat) realized by metal dust core

R

O

D

R

O

D

R

O

D

① ② ③ ④ ⑤

I

U

U

U

C

U

U

U

R

R

R

A

C

C

C

E

E

E

T

T

T

T

T

S

S

S

I

O

N

I

O

N

I

D

E

N

T

I

F

I

C

A

T

I

O

N

I

D

E

N

T

I

F

I

C

A

I

D

E

N

T

I

F

T

I

C

A

T

I

O

N

I

O

N

MHD - 07EZP R50 M - XC

① Product Code

② Dimensions : 7.7 x 8.0 x 5.0 mm

③ Inductance : R50 = 0.50μH

④ Tolerance : M = ±20%

⑤ Series Type : XC Type

NOTE:Please refer to the “Product Dimension” for detail dimensions.

MAG.LAYERS

MHD-07EZPSERIES-XC

■

R50

P

R

O

D

U

C

T

D

I

M

E

N

S

I

O

N

■

P

R

O

D

U

C

T

D

I

M

E

N

■

P

R

O

D

U

C

T

D

I

M

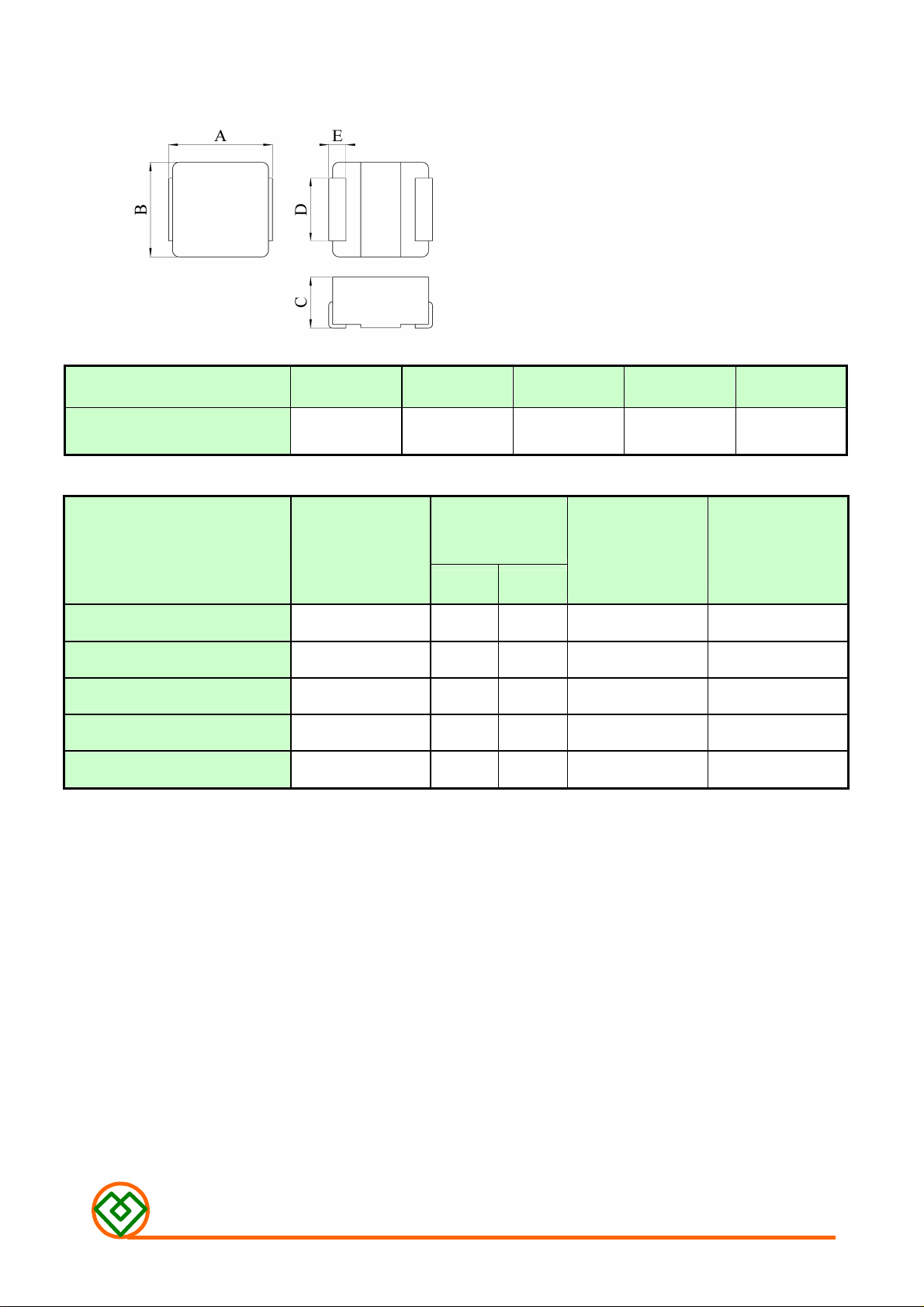

NOTE:Dimensions in mm

PRODUCT NO. A B C D E

E

N

S

S

I

O

N

I

O

N

MHD-07EZPSERIES-XC

E

L

E

C

T

R

I

C

A

E

L

E

C

T

■ E

MHD-07EZPR50M-XC

MHD-07EZPR74M-XC

MHD-07EZP1R0M-XC

MHD-07EZP1R5M-XC

MHD-07EZP2R2M-XC

L

E

PART NUMBER

TEST FREQUENCY: 100 KHz, 0.1V

TESTING INSTRUMENT L :Agilent4284A,WK4235,CH3302/G LCR METER

CH1320,CH1320S BIAS CURRENT SOURCE

C

T

R

R

L

I

C

A

I

C

A

7.2 ± 0.5 7.5 ± 0.5 5.0 Max 5.0± 0.3 1.5± 0.3

R

E

Q

U

I

R

E

M

E

N

T

L

R

E

L

Q

R

E

Q

INDUCTANCE

Lo(μH)±20%

U

I

R

E

M

E

M

E

U

I

R

@0A

0.50 2.20 2.40 28.1 40.5

0.74 3.25 3.57 27.1 27.8

1.0 4.20 4.60 23.1 24.0

1.5 6.00 6.60 18.8 20.0

2.2 8.30 9.15 16.3 18.0

S

N

T

E

S

N

T

S

R

(mΩ)

Typ. Max

dc

HEAT RATING

CURRENT(Idc)

DC AMPS

1

SATURATION

CURRENT(Isat)

DC AMPS2

R

NOTES:

1. DC current (Idc) that will cause an approximate △T of 40℃

2. DC current (I

3. All test data is referenced to 25℃ ambient

4. Operating Temperature Range -55℃ to +125℃

5. The part temperature (ambient + temp rise) should not exceed 125℃

under the worst operating conditions. Circuit design, component placement,

PWB trace size and thickness, airflow and other cooling provisions all affect

the part temperature. Part temperature should be verified in the end application.

MAG.LAYERS

MHD-07EZPSERIES-XC

sat

) that will cause Lo to drop approximately 20%

:CH11025,GOM802 MICRO OHMMETER

dc

E

E

■ E

L

E

C

T

R

I

C

A

L

L

L

E

E

C

C

T

T

R

R

I

C

I

C

A

A

L

L

C

MHD-07EZPR50M-XC

C

C

H

H

H

A

A

A

R

R

R

A

A

A

C

C

C

T

T

T

E

E

E

R

R

R

I

S

T

I

C

S

R

e

f

e

r

e

n

c

e

d

a

t

I

S

T

I

C

S

R

e

f

e

r

e

n

I

S

T

I

C

S

R

e

c

f

e

r

e

n

a

e

d

a

t

c

a

e

d

a

t

a

MHD-07EZPR74M-XC

0.6

0.4

INDUCTANCE (uH)

0.2

INDUCTANCE (uH)

TEMP.Rise(℃)

0.0

0 5 1 0 15 20 25 30 3 5 40 45

MHD-07EZP1R0M-XC

1.5

1.2

0.9

0.6

INDUCTANCE(uH)

0.3

0.0

0 5 10 15 20 25 30

DC CURRENT (A)

DC CURRENT(A)

INDUCTANCE(uH)

TEMP.Rise(℃)

100

80

60

40

20

0

100

80

60

40

20

0

1.0

0.8

0.6

0.4

TEMP.Rise (℃)

INDUCTANCE(uH)

0.2

0.0

0 5 10 15 20 25 30 35 40

DC CURRENT(A)

MHD-07EZP1R5M-XC

2.0

1.6

1.2

TEMP.Rise(℃)

0.8

INDUCTANCE( uH)

0.4

0.0

0 5 10 15 20 25

DC CURRENT (A)

INDUCTANCE(uH)

TEMP.Rise(℃)

INDUCTANCE(uH)

TEMP.Rise(℃)

100

80

60

TEMP.Rise(℃)

40

20

0

100

80

60

40

TEMP.Rise(℃)

20

0

MHD-07EZP2R2M-XC

3.5

2.8

2.1

1.4

INDUCTANCE( uH)

0.7

0.0

0 5 10 15 20 25

DC CURRENT (A)

INDUCTANCE(uH)

TEMP.Rise(℃)

100

80

60

40

TEMP.Rise(℃)

20

0

MAG.LAYERS

MHD-07EZPSERIES-XC

■

P

A

■

■

C

P

A

C

P

A

C

Peel-off Force

K

K

K

A

A

A

G

G

G

I

N

G

I

N

G

I

N

G

The force for peeling off cover tape is 10 to 70 grams in the arrow direction.

Dimension (Unit: mm)

A

B

C

D

TOP COVER TAPE

F

TYPE A

330 mm 330±2

E

B

100±1

C D E

20±0.5 13 ±1.0 16 ±0.5

165° TO 180°

BASE TAPE

F

20 ±2

TYPE SIZE A B W P T

MHD 07EZ 8.2 7.9 16 12 5.3

MAG.LAYERS

MHD-07EZPSERIES-XC

END

START

200mm

NO COMPONENTS

COMPONENTS

Taping Quantity

SERIES 07EZ

PCS/Reel 500

CARTON:

MIDDLE PACKAGING : 3 Reel /BOX

400mm

NO COMPONENTS

LABEL

EXTERNAL PACKAGING : 5 BOX / CARTON

LABEL

40mm

342mm

40mm

336mm

40mm

m

m

0

7

415mm

m

m

0

8

380mm

3

40mm

MAG.LAYERS

MHD-07EZPSERIES-XC

Loading...

Loading...