Page 1

SCOPE

:

This specification applies to the Pb Free Common mode filters

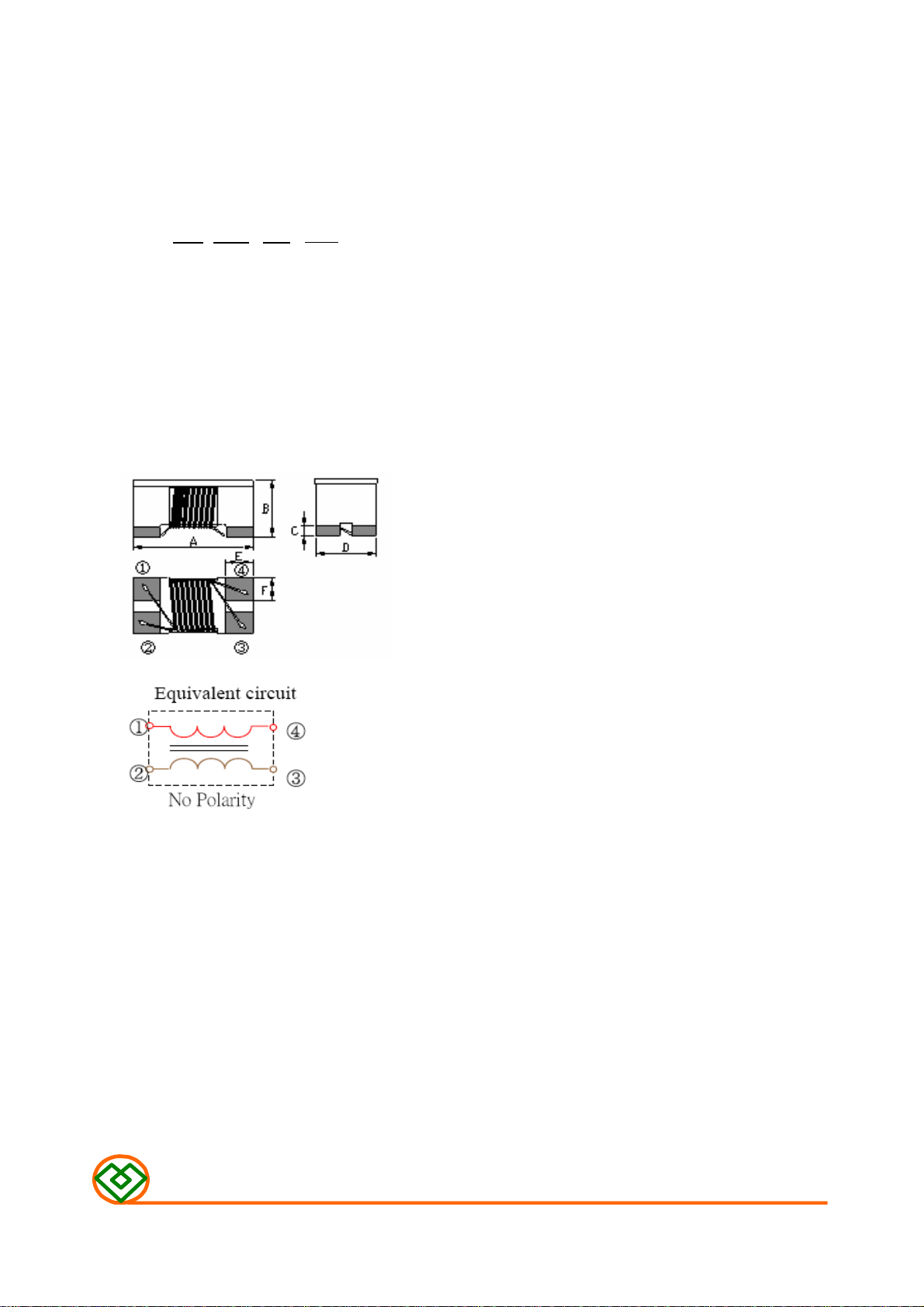

(1) SHAPES AND DIMENSIONS

(2) ELECTRICAL SPECIFICATIONS

(3) CHARACTERISTICS

for MCI-2012-SERIES-□□

PRODUCT INDENTIFICATION

MCI- 2012 - 900 -□□

① ② ③ ④

① Product Code

② Dimensions Code

③ Impedance Code

④ Inner Control Code

A: 2.0±0.20 mm

B: 1.2±0.20 mm

C: 0.17 Typ. mm

D: 1.2±0.20 mm

E: 0.45 Typ. mm

F: 0.40 Typ. mm

SEE TABLE 1

TEST INSTRUMENTS

Z : HP 4291B IMPEDANCE ANALYZER (or equivalent)

RDC : CHROMA MODEL 16502 MILLIOHMMETER (or equivalent)

I.R : CHROMA MODEL 19073 AC/DC/IR HIPOT TESTER (or equivalent)

(3)-1 Temperature rise ...................... +20℃ Max.

(3)-2 Ambient temperature ................ +60℃ Max.

(3)-3 Operate temperature range …... -25℃~+85℃

(Including self temp. rise)

(3)-4 Storage temperature range ...... -40℃~+85℃

MAG.LAYERS

MCI-2012-SERIES Page 1/7

Page 2

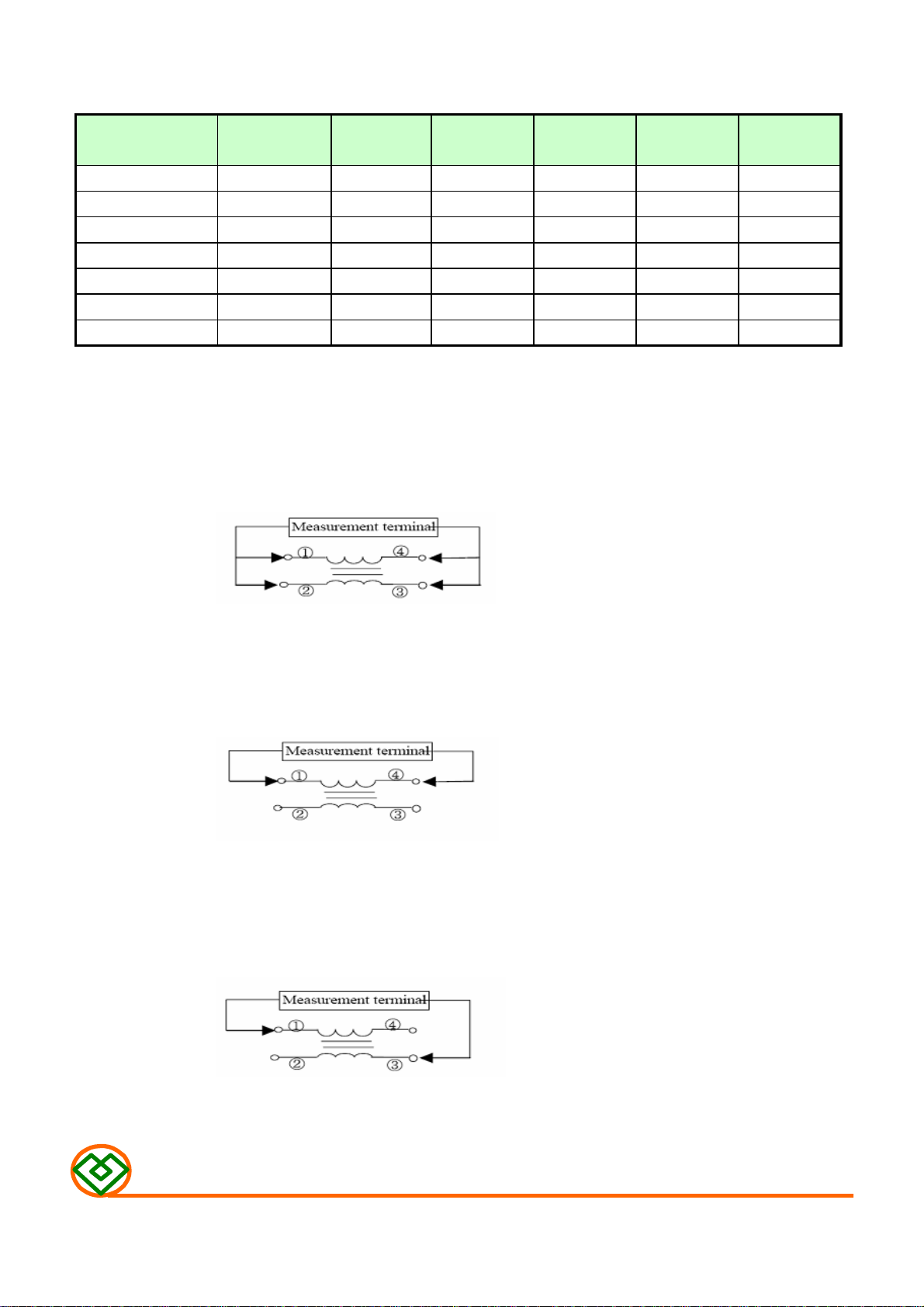

TABLE 1

MAGLAYERS

PT/NO.

MCI-2012-670 67 ±25% 0.25 50 400 125 10

MCI-2012-900 90 ±25% 0.35 50 330 125 10

MCI-2012-121 120±25% 0.30 50 370 125 10

MCI-2012-181 180±25% 0.35 50 330 125 10

MCI-2012-201 200±25% 0.35 50 330 125 10

MCI-2012-261 260±25% 0.40 50 300 125 10

MCI-2012-371 370±25% 0.40 50 280 125 10

Impedance Z(Ω)

@ 100MHz/0.5V

RDC (Ω)

Max.

Rated Voltage

Vdc(V)

Idc

Max.(mA)

Withstanding

Voltage

Vdc(V)

TEST EQUIPMENT

1. Impedance

Measured by using HP 4291B RF Impedance Analyzer.

Insulation

Resistance

(MΩ)Min.

2. DC Resistance

Measured by using Chroma 16502 mill ohm meter

3. Insulation Resistance

Measured by using Chroma 19073

Measurement voltage: 50v, Measurement time: 60 sec.

MAG.LAYERS

MCI-2012-SERIES Page-2/7

Page 3

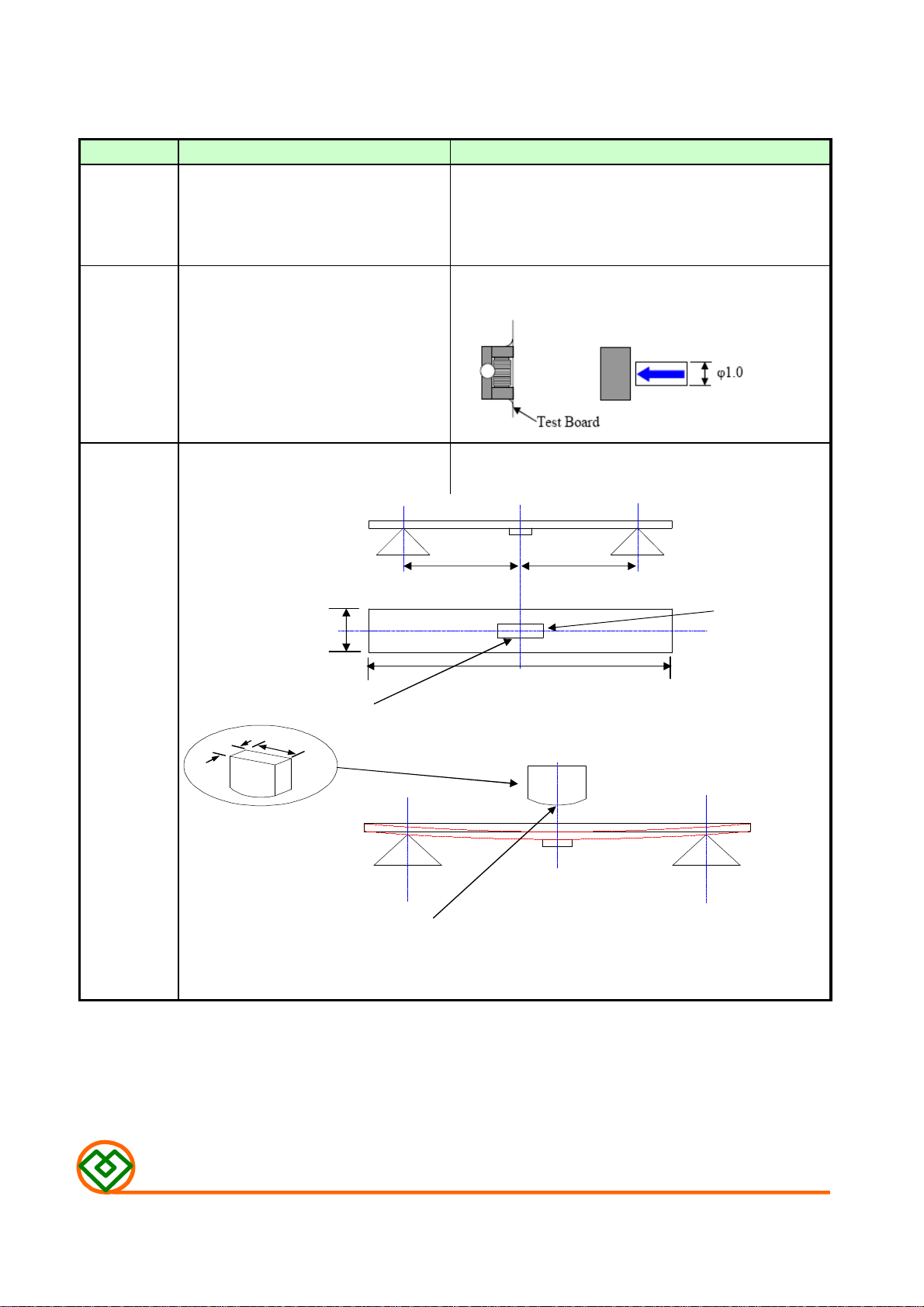

(4) RELIABILITY TEST METHOD

Item

Solder ability It can be connected on the Apply cream solder to the test circuit board .

Recommendation soldering condition. It is mounted on the recommendation soldering condition.

Terminal The terminal electrode and the ferrite Solder a chip to test substrate , and then laterally

strength must not be damaged. apply a load 0.5Kg in the arrow direction.

The terminal electrode and the ferrite Soldering a chip to a test substrate ,

must not be damaged. bend the substrate by 2mm and then return.

Specifications Test conditions

Dip pads in flux and dip in solder pot ( 96.5 Sn/3.5 Ag

solder) at 260°C ±5°C.

45

40

45

Width side

Strength on

pc board

bending

10

100

length

20

R10

Test board : Glass base epoxy multiplayer board pc board pattern.

PC board pattern : Recommended PC board pattern.

Force

Dimensions in mm

MAG.LAYERS

MCI-2012-SERIES

Page-3/7

Page 4

Item Specifications Test conditions

Temperature : +85±2℃

Applied voltage : Rated voltage

High

temperature

Applied current : Rated current

Testing time : 500±12 hours

Measurement :After placing for 24 hours min.

Temperature : +85±2℃

Humidity : 90 to 95%RH

Humidity

resistance

Thermal shock

Appearance : Ferrite shall not be

damaged.

Impedance:Within±20% of the

initial value.

insulation resistance: >10(MΩ)

DC resistance : standard value

inside.

Applied current : Rated current

Applied voltage : Rated voltage

Testing time : 500±12 hours

Measurement :After placing for 24 hours min.

Temperature : -25℃,+85℃

kept stabilized for 30 minutes each.

Cycle : 100 cycle

Measurement :After placing for 24 hours min.

1 cycle

30 min.

+85℃

30 sec

-40℃

30 min.

Low

temperature Testing time : 500±12 hours

Storage Measurement :After placing for 24 hours min.

Vibration

Appearance : Ferrite shall not be

damaged.

Temperature : -25±2℃

Frequency : 10 to 50 Hz

Amplitude : 1.52 mm

Dimension and times : X ,Y and Z directions

for 2 hours each.

MAG.LAYERS

MCI-2012-SERIES Page-4/7

Page 5

(5) RECOMMENDED SOLDERING CONDITIONS

(Please use this product by reflow soldering)

(5)-1 RECOMMENDED FOOTPRINT

Unit: mm

(5)-2 RECOMMENED REFLOW PATTERN

Temperature(℃ )

300

260

200

150

100

50

Preheating

Solding

260℃

Natural Cooling

10 sec1 to 4 min. more than 2 min.

(5)-3 IRON SOLDERING

Use a solder iron of less than 30W when soldering ,do not allow the soldering

iron tip directly touch the Ceramic body outside of terminal electrode.

3 seconds max. at 260℃.

Time

MAG.LAYERS

MCI-2012-SERIES Page-5/7

Page 6

(6) PACKAGING

W : 8.0

P : 4.0

P0 : 4.0

P1 : 2.0

(6)-1 CARRIER TAPE DIMENSIONS (mm)

P

1

mm

mm

mm

mm

W

P

P

0

(6)-2 TAPING DIMENSIONS (mm)

There shall not continuation more than two vacancies of the product.

(360 mm)

Leader.

ChipBlank

(50 pitches)

Blank

(70 pitches)

(6)-3 REEL DIMENSIONS

C

MAG.LAYERS

D

A : 180 mm

B : 60 mm

C : 13 mm

AB

D : 12 mm

E : 8.4 mm

E

MCI-2012-SERIES

Page-6/7

Page 7

(6)-4 COVER TAPE PEEL STRENGTH

The force for tearing off cover tape is 0.1~0.6(N) in the arrow direction at

the following conditions:

Temperature : 5 ~ 35℃

Humidity : 45 ~ 85%

Atmospheric pressure : 860 ~ 1060 hpa

160 ~ 180

。

Top cover tape

Base tape

(6)-5 QUANTITY

2000 pcs/Reel

(6)-6 The products are packaged so that no damage will be sustained.

(7) ATTENTION IN CASE OF USING

In case of using product ,please avoid following matters:

Splashing water or salt water

Dew condenses

Toxic gas (Hydrogen sulfide, Sulfurous acid ,Chlorine, Ammonia)

Vibrations or shocks which exceed the specified condition

Please be careful for the stress to this product by board flexure or something

after the mounting.

MAG.LAYERS

MCI-2012-SERIES

Page-7/7

Page 8

TYPICAL ELECTRICAL CHARACTERISTICS

1000

100

10

Common Mode

Differential Mode

Impedance(Ω)

MCI-2012-670

1

0.1

1 10 100 1000

Frequency(MHz)

MCI-2012-121

1000

100

Common Mode

Differential Mode

MCI-2012-900

10000

1000

100

10

Impedance(Ω)

1

0.1

1 10 100 1000

10000

1000

Common mode

Differential mode

Frequency(MHz)

MCI-2012-181

Common Mode

Differential Mode

10

Impedance(Ω)

1

0.1

1 10 100 1000

Frequency(MHz)

100

10

Impedance(Ω)

1

0.1

1 10 100 1000

Frequency(MHz)

MAG.LAYERS

MCI-2012-SERIES

ATTACHMENT-1

Page 9

TYPICAL ELECTRICAL CHARACTERISTICS

Common Mode

1000

10000

1000

MCI-2012-201

100

10

Impedance(Ω)

1

1 10 100 1000

Frequency(MHz)

MIC-2012-371

Common Mode

Differential Mode

MCI-2012-261

10000

1000

100

10

Common Mode

Differential Mode

Impedance(Ω)

1

0.1

1 10 100 1000

Frequency(MHz)

100

10

Impedance(Ω)

1

0.1

1 10 100 1000

Frequency(MHz)

MAG.LAYERS

MCI-2012-SERIES

ATTACHMENT-2

Loading...

Loading...