Page 1

SCOPE

:

This specification applies to the current type Radial Leaded Inductor

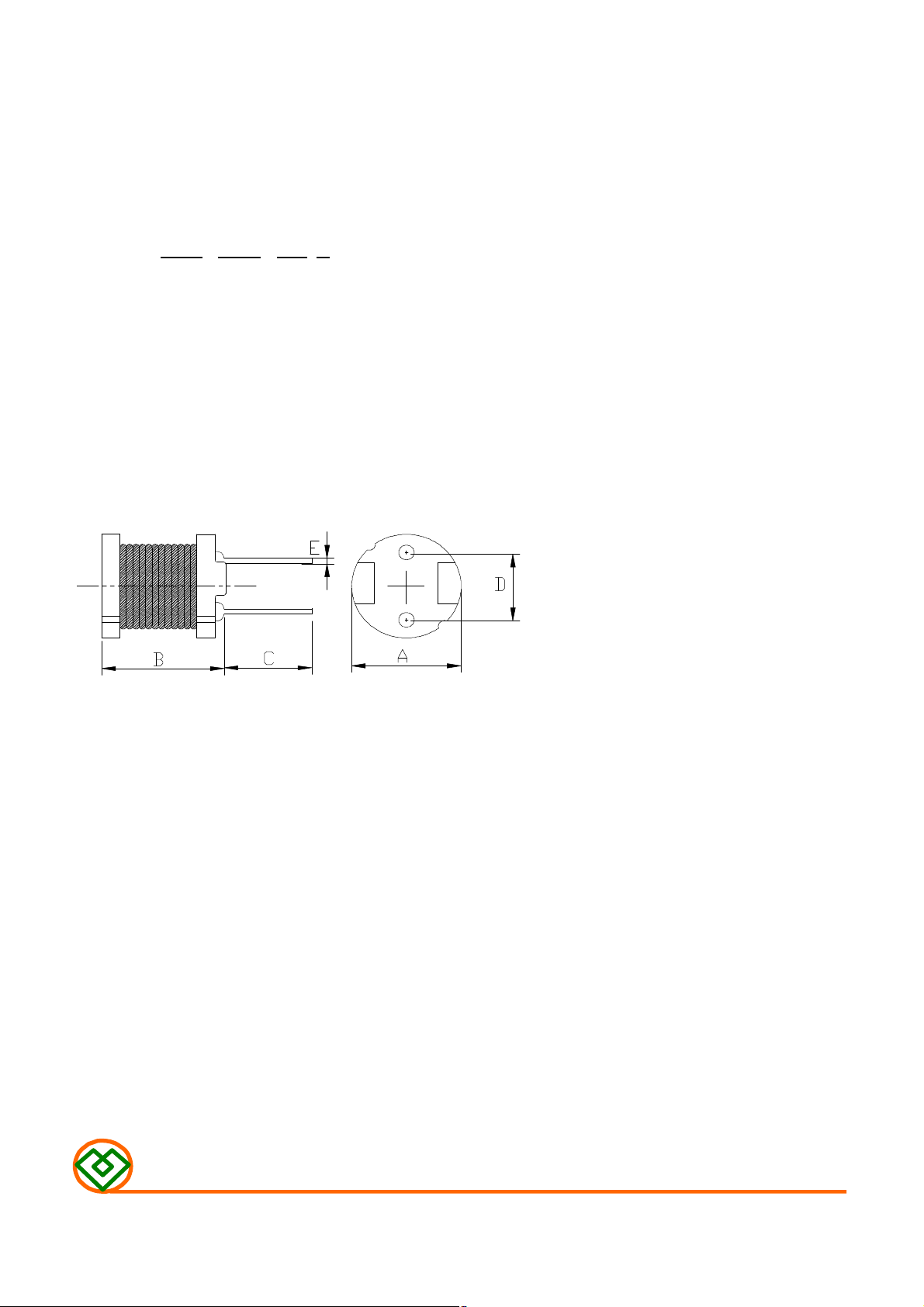

(1) SHAPES AND DIMENSIONS

(2) ELECTRICAL SPECIFICATIONS

SEE TABLE 1

(3) CHARACTERISTICS

for MCD-108C-SERIES

PRODUCT INDENTIFICATION

MCD - 108C - 102 K

① ② ③ ④

① Product Code

② Dimensions Code

③ Inductance Code

④ Tolerance Code

A: 10.0±0.5 mm

B: 8.5 Max. mm

C: 15.0±2.0 mm

D: 6.5±0.5 mm

E: φ0.65±0.1 mm

TEST INSTRUMENTS

L : HP 4284A PRECISION LCR METER (or equivalent)

RDC : CHROMA MODEL 16502 MILLIOHMMETER (or equivalent)

(3)-1 Ambient temperature ……......... +60℃ Max.

(3)-2 Operate temperature range ...... -40℃~+125℃

(Including self temp. rise)

(3)-3 Storage temperature range ...... -40℃~+125℃

MAG.LAYERS

MCD-108C-SERIES Page 1/4

Page 2

TABLE 1

MAGLAYERS

Inductance Percent Test Resistance Rated DC Current

PT/NO.

MCD-108C-100□

MCD-108C-120□

MCD-108C-150□

MCD-108C-180□

MCD-108C-220□

MCD-108C-270□

MCD-108C-330□

MCD-108C-390□

MCD-108C-470□

MCD-108C-560□

MCD-108C-680□

MCD-108C-820□

MCD-108C-101□

MCD-108C-121□

MCD-108C-151□

MCD-108C-181□

MCD-108C-201□

MCD-108C-221□

MCD-108C-271□

MCD-108C-331□

MCD-108C-391□

MCD-108C-471□

MCD-108C-561□

MCD-108C-681□

MCD-108C-821□

MCD-108C-102□

L(μH) Tolerance Frequency RDC(Ω)Max. IDC(A)

10 M 100kHz/0.25V 27m

12 M 100kHz/0.25V 31m

15 M 100kHz/0.25V 36m

18 M 100kHz/0.25V 49m

22 M 100kHz/0.25V 55m

27 M

33 K,M

39 K,M

47 K,M

56 K,M

68 K,M

82 K,M

100 K,M

120 K,M

150 K,M

180 K,M

200 K,M

220 K,M

270 K,M

330 K,M

390 K,M

470 K,M

560 K,M

680 K,M

820 K,M

1000 J,K

100kHz/0.25V

100kHz/0.25V

100kHz/0.25V

100kHz/0.25V

100kHz/0.25V

100kHz/0.25V

100kHz/0.25V

100kHz/0.25V

100kHz/0.25V

100kHz/0.25V

100kHz/0.25V

100kHz/0.25V

100kHz/0.25V

100kHz/0.25V

100kHz/0.25V

100kHz/0.25V

100kHz/0.25V

100kHz/0.25V

100kHz/0.25V

100kHz/0.25V

100kHz/0.25V

62m

79m

87m

99m

0.13

0.14

0.16

0.21

0.24

0.32

0.35

0.37

0.45

0.61

0.69

0.78

1.0

1.2

1.4

1.8

2.1

4.5

4.1

3.7

3.4

3.1

2.8

2.5

2.3

2.1

1.9

1.7

1.6

1.4

1.3

1.2

1.1

1.0

0.96

0.87

0.79

0.72

0.66

0.60

0.55

0.50

0.45

※ □ specify the inductance tolerance,J(±5%),K(±10%),M(±20%)

※ IDC : Based on inductance change (△L/Lo:drop 10% Max.) @ ambient temperature 25℃ and

Based on temperature rise (△T: 40℃ TYP.)

MAG.LAYERS

MCD-108C-SERIES

Page-2/4

Page 3

(4) RELIABILITY TEST METHOD

MECHANICAL

NO. ITEMS

More than 90% of the

1 Solderability test

2 lead tensile 1.0 Kg MIN. The lead of product is pulled with a load of

strength test 1.0kg mininum until lead breakdown. The tensile

termnial electrode

should be covered

with solder.

Dipping: 245 ± 5 ℃, 3 ± 1 seconds

force shall be recorded.

CONDITIONSSPECIFICATIONS

3 Vibration test

4 Soldering heat Visual:OK The leads of product are dipped into a solder pot

resistance test Circuit:OK

△L/L≦±7%

Visual:OK

The product is fixed ento the vibration with

amplitude of 1.52m/m at a frequency of 10~55Hz

sweeping for lmin. The vibration is done at X,Y,

Z direction respectively for 2 houes, totally 6

hours.

of 260±5℃ for a duration of 10±1sec. Nothing

particular on visual and open circuitry as a

result of ore testing.

ENVIRONMENTAL

NO. ITEMS

1 Humidity

endurance

test

2 High temp

endurance test for 72 hours. Measurement is done after recovery

SPECIFICATIONS

△L/L≦±5% The product is placed in a chamber of 40±2℃,

90~95%RH for 96 hours. Measurement is done

after the reaovery of 4~24 hours.

△L/L≦±5% The product is placed in a chamber of 80±2℃,

of 4~24 hours.

CONDITIONS

3 Low temp test

4 Thermal shock

test

MAG.LAYERS

△L/L≦±5% The product is placed in a chamber of -40±2℃,

for 96 hours. Measurement is done after

recovery of 4~24 hours.

△L/L≦±5%

The specimens are placed in a chamber and the

temp is then lowered to -20±2℃ for one hour.

The temp will raised to +80±2℃ for one hour.

This constitues one cycle. Ten cycles of such

testing shall be completed. Measurement is made

after recovery for 4~24 hours from the

completion of testing.

MCD-108C-SERIES

Page-3/4

Page 4

(5) PACKAGE SPECIFICATION (mm)

MAG.LAYERS

MCD-108C-SERIES

Page-4/4

Loading...

Loading...