Page 1

SCOPE

:

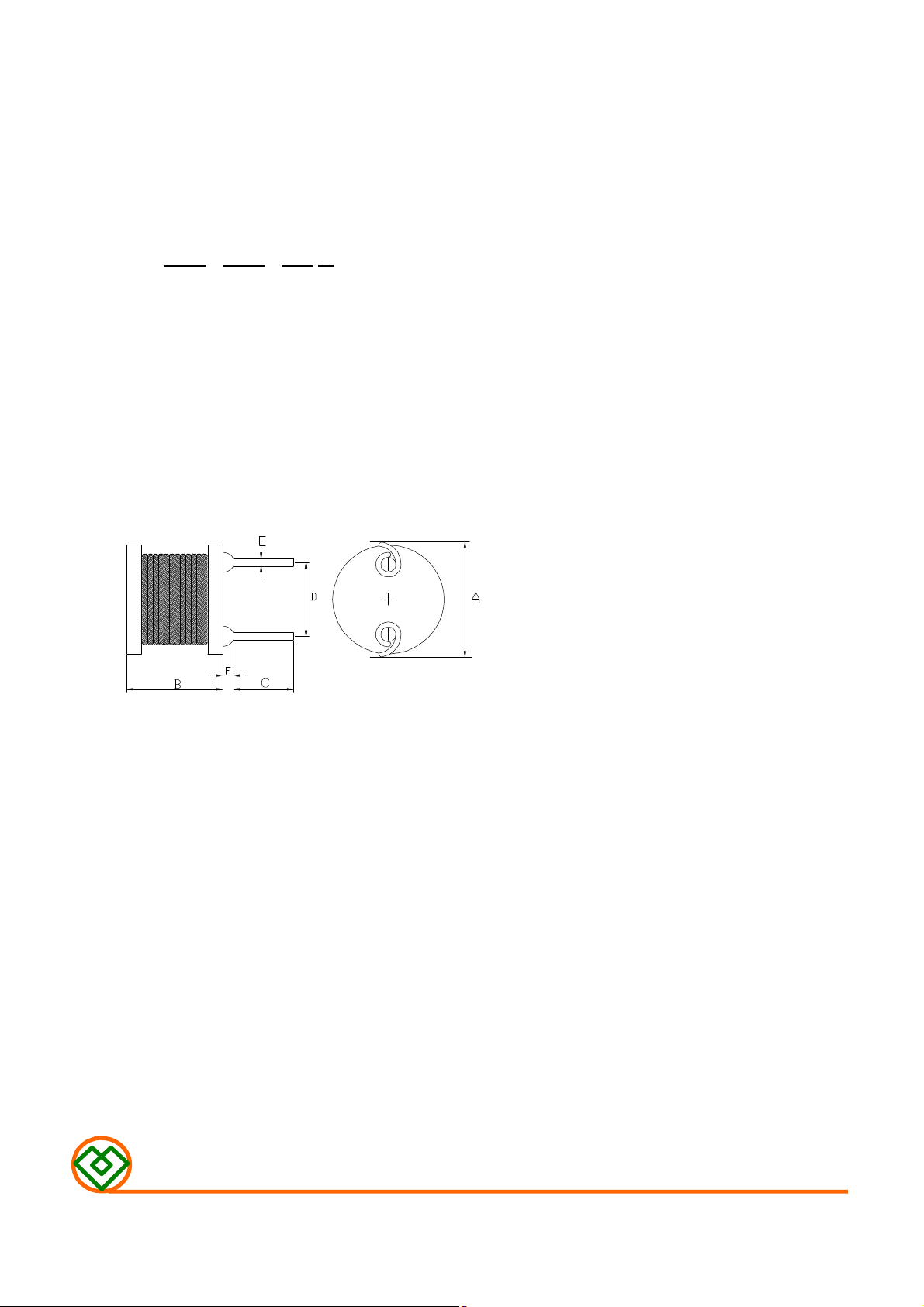

(1) SHAPES AND DIMENSIONS

(2) ELECTRICAL SPECIFICATIONS

(3) CHARACTERISTICS

This specification applies to the current type Radial Leaded Inductor

for MCD-0405-SERIES

PRODUCT INDENTIFICATION

MCD - 0405 - 330 M

① ② ③ ④

① Product Code

② Dimensions Code

③ Inductance Code

④ Tolerance Code

A: 5.0Max. mm

SEE TABLE 1

TEST INSTRUMENTS

L : HP 4284A PRECISION LCR METER (or equivalent)

RDC : CHROMA MODEL 16502 MILLIOHMMETER (or equivalent)

(3)-1 Ambient temperature ……......... +60℃ Max.

(3)-2 Operate temperature range ...... -40℃~+125℃

(Including self temp. rise)

(3)-3 Storage temperature range ...... -40℃~+125℃

B: 6.0Max. mm

C: 15±2.0 mm

D: 2.0±0.5 mm

E: φ0.5±0.1 mm

F: 2.0Max. mm

MAG.LAYERS

MCD-0405-SERIES Page 1/4

Page 2

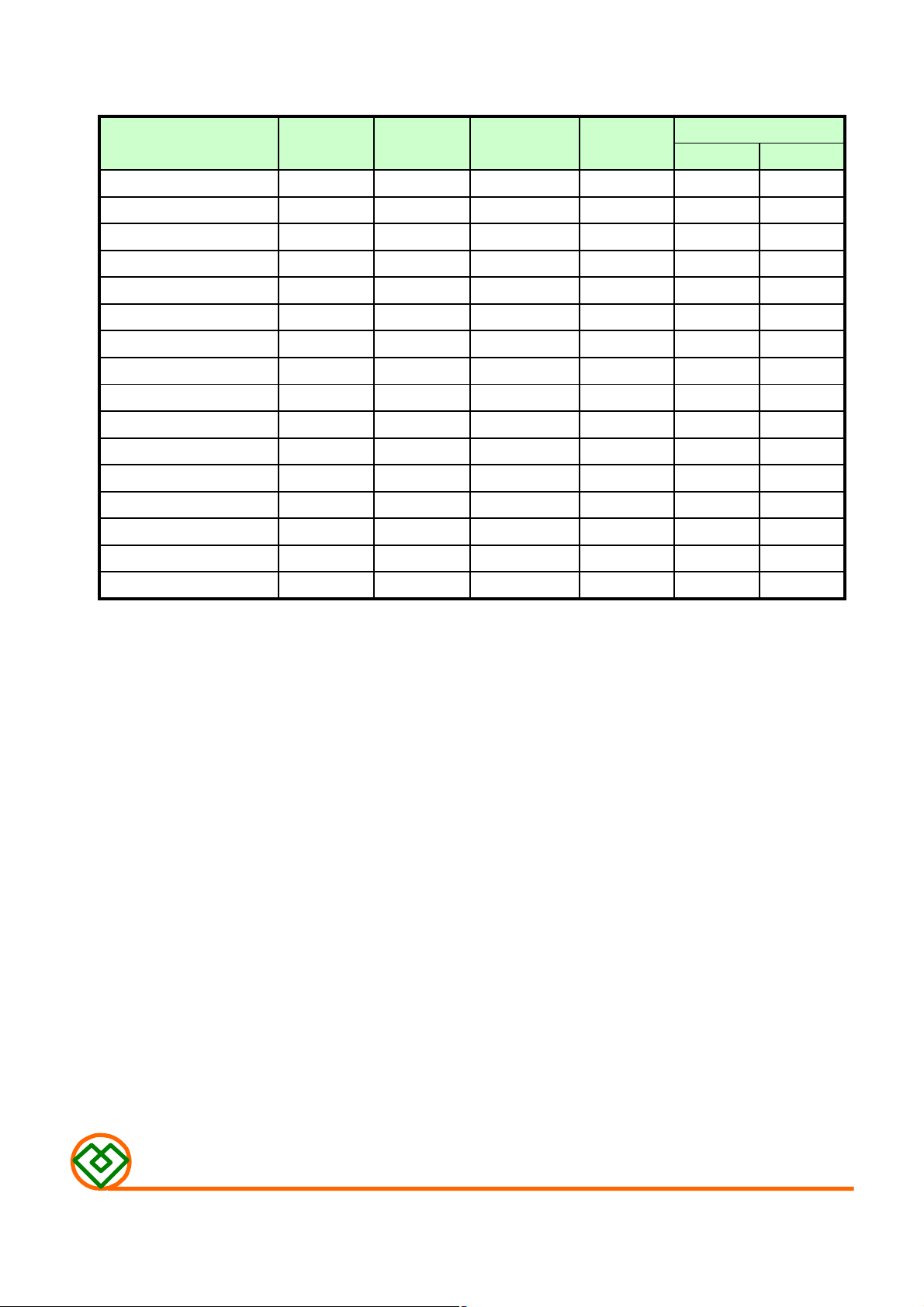

TABLE 1

MAGLAYERS

PT/NO.

Inductance Percent Test Resistance Rated DC Current

L(μH) Tolerance Frequency RDC(Ω)Max. IDC1(A) IDC2(A)

MCD-0405-1R5□

MCD-0405-2R2□

MCD-0405-3R3□

MCD-0405-4R7□

MCD-0405-5R6□

MCD-0405-6R8□

MCD-0405-8R2□

MCD-0405-100□

MCD-0405-270□

MCD-0405-330□

MCD-0405-390□

MCD-0405-820□

MCD-0405-101□

MCD-0405-151□

MCD-0405-181□

MCD-0405-102□

1.5 M 100kHz/0.25V 34m 3.6 3.5

2.2 M 100kHz/0.25V 40m 3.0 2.7

3.3 M 100kHz/0.25V 58m 2.5 2.2

4.7 M 100kHz/0.25V 72m 2.2 2.0

5.6 M 100kHz/0.25V 81m 2.0 1.9

6.8 M 100kHz/0.25V 87m 1.8 1.8

8.2 M 100kHz/0.25V 0.108 1.6 1.6

10 K,M 100kHz/0.25V 0.124 1.5 1.5

27 K,M 100kHz/0.25V 0.330 0.90 0.90

33 K,M 100kHz/0.25V 0.375 0.85 0.70

39 K,M 100kHz/0.25V 0.460 0.80 0.70

82 K,M 100kHz/0.25V 1.105 0.50 0.55

100 K,M 100kHz/0.25V 1.431 0.46 0.48

150 K,M 100kHz/0.25V 1.770 0.37 0.39

180 K,M 100kHz/0.25V 1.815 0.35 0.35

1000 K,M 100kHz/0.25V 10.20 0.14 0.16

※ □ specify the inductance tolerance,K(±10%),M(±20%)

※ IDC1: Based on inductance change (△L/Lo: ≦drop10%) @ ambient temp. 25℃

IDC2: Based on temperature rise (△T: 40℃ TYP.)

Rated DC Current: The less value which is IDC1 or IDC2.

MAG.LAYERS

MCD-0405-SERIES

Page-2/4

Page 3

(4) RELIABILITY TEST METHOD

MECHANICAL

NO. ITEMS

More than 90% of the

1 Solderability test

2 lead tensile 1.0 Kg MIN. The lead of product is pulled with a load of

strength test 1.0kg mininum until lead breakdown. The tensile

termnial electrode

should be covered

with solder.

CONDITIONSSPECIFICATIONS

Dipping: 245 ± 5 ℃, 3 ± 1 seconds

force shall be recorded.

3 Vibration test

4 Soldering heat Visual:OK The leads of product are dipped into a solder pot

resistance test Circuit:OK

ENVIRONMENTAL

NO. ITEMS

1 Humidity

endurance

test

2 High temp

endurance test for 72 hours. Measurement is done after recovery

△L/L≦±7%

Visual:OK

The product is fixed ento the vibration with

amplitude of 1.52m/m at a frequency of 10~55Hz

sweeping for lmin. The vibration is done at X,Y,

Z direction respectively for 2 houes, totally 6

hours.

of 260±5℃ for a duration of 10±1sec. Nothing

particular on visual and open circuitry as a

result of ore testing.

SPECIFICATIONS CONDITIONS

△L/L≦±5% The product is placed in a chamber of 40±2℃,

90~95%RH for 96 hours. Measurement is done

after the reaovery of 4~24 hours.

△L/L≦±5% The product is placed in a chamber of 80±2℃,

of 4~24 hours.

3 Low temp test

4 Thermal shock

test

MAG.LAYERS

△L/L≦±5% The product is placed in a chamber of -40±2℃,

for 96 hours. Measurement is done after

recovery of 4~24 hours.

△L/L≦±5%

The specimens are placed in a chamber and the

temp is then lowered to -20±2℃ for one hour.

The temp will raised to +80±2℃ for one hour.

This constitues one cycle. Ten cycles of such

testing shall be completed. Measurement is made

after recovery for 4~24 hours from the

completion of testing.

MCD-0405-SERIES

Page-3/4

Page 4

(5) PACKAGE SPECIFICATION (mm)

MAG.LAYERS

MCD-0405-SERIES

Page-4/4

Loading...

Loading...