Page 1

■

A

P

P

L

I

C

A

T

I

O

N

■

A

P

P

L

I

C

A

■

A

P

P

L

GMLB chip beads can be used in a variety of electronic applications including:

Computers and Computer Peripherals

Cellular Communication Equipment

Digital Cameras

Digital Televisions

Audio Equipment

■

F

E

A

■

F

■

the latest in multilayer technology, we have developed chip beads that are able to

resolve all EMI/EMC issues. High quality, reliability, and versatility make the

GMLB series chip beads suitable for all your design needs.

Multi-line EMI Suppression

High Density Packaging

T

E

A

F

T

E

A

T

The GMLB Series is Mag.Layers’ line of high quality ferrite chip beads. Using

M-series chip arrays contain four ferrite beads in a single package. This compact

design makes the M-series perfect for EMI suppression on multiple-lines.

M-series chip arrays have a compact package design that is an ideal for high density

packaging.

I

U

U

U

C

R

R

R

A

E

E

E

T

T

S

S

S

I

O

N

I

O

N

Multi-frequency Applications

M-series chip arrays are available in A-type and B-type. The A-type chip arrays are

designed for lower frequency applications. The B-type chip arrays are designed for

high frequency applications.

■

P

R

O

D

U

C

T

I

D

E

N

T

I

F

I

C

A

T

I

O

N

■

P

R

O

D

U

C

T

I

D

E

■

P

R

O

D

U

C

T

G M L B -

Product Code

Dimension Code

Impedance (at 100 MHz)

Series Type

Design Code

Code for Special Specification

*N8=A Type,N7=B Type

N

I

D

E

N

3 2 1 6 - 0 1 2 0 M 4 - N 8

T

T

I

F

I

C

A

I

F

T

I

C

A

T

I

O

N

I

O

N

□

□

□□

MAG.LAYERS

GMLB-3216-A Series

Page 2

P

P

P

R

R

R

O

O

O

D

D

D

U

U

U

C

C

C

T

T

T

D

I

M

E

N

S

I

O

N

D

I

M

E

N

D

I

M

E

N

S

S

I

O

N

I

O

N

E

A

D P

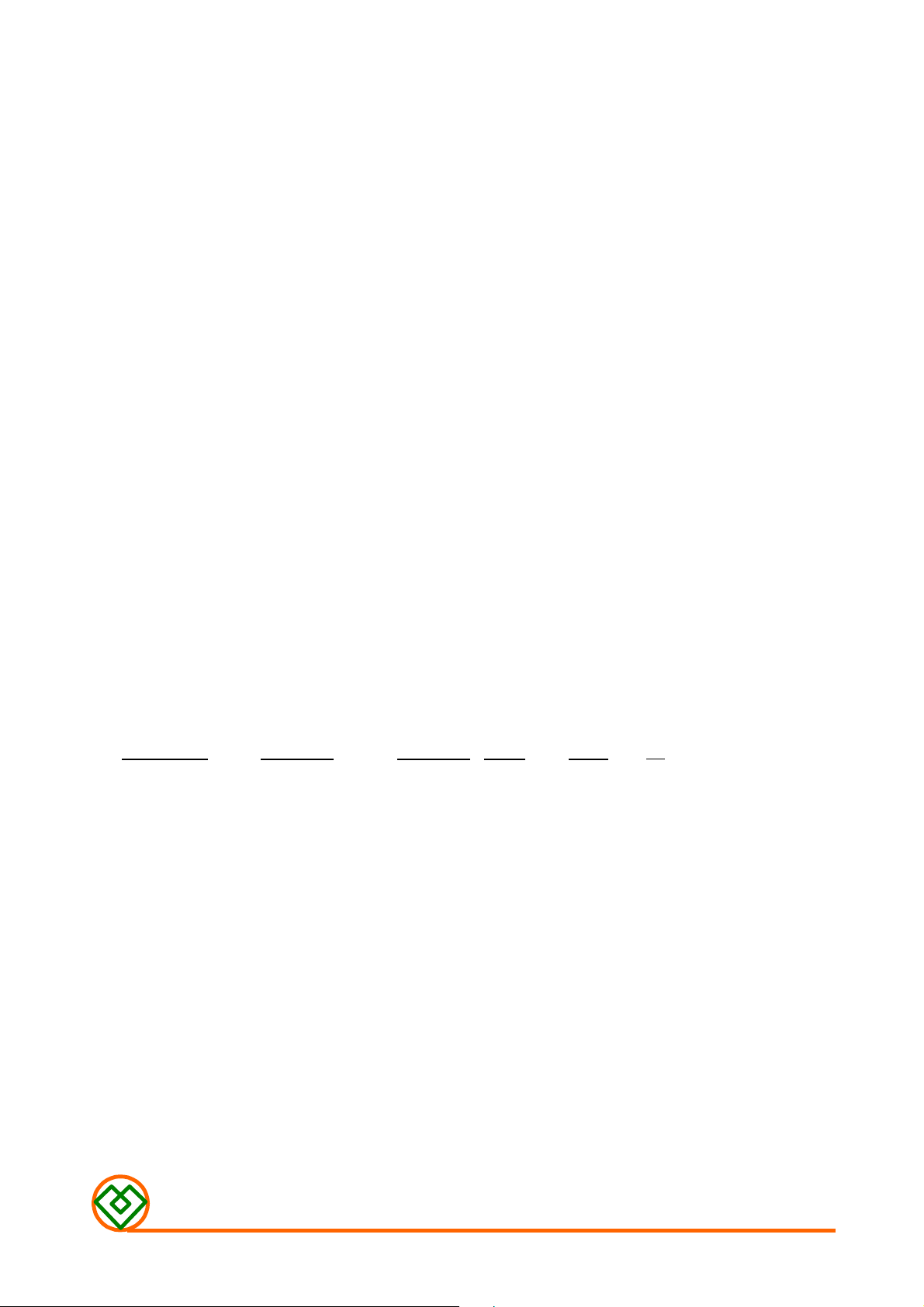

PRODUCT

NO.

GMLB-3216

■

C

U

R

■

C

■

C

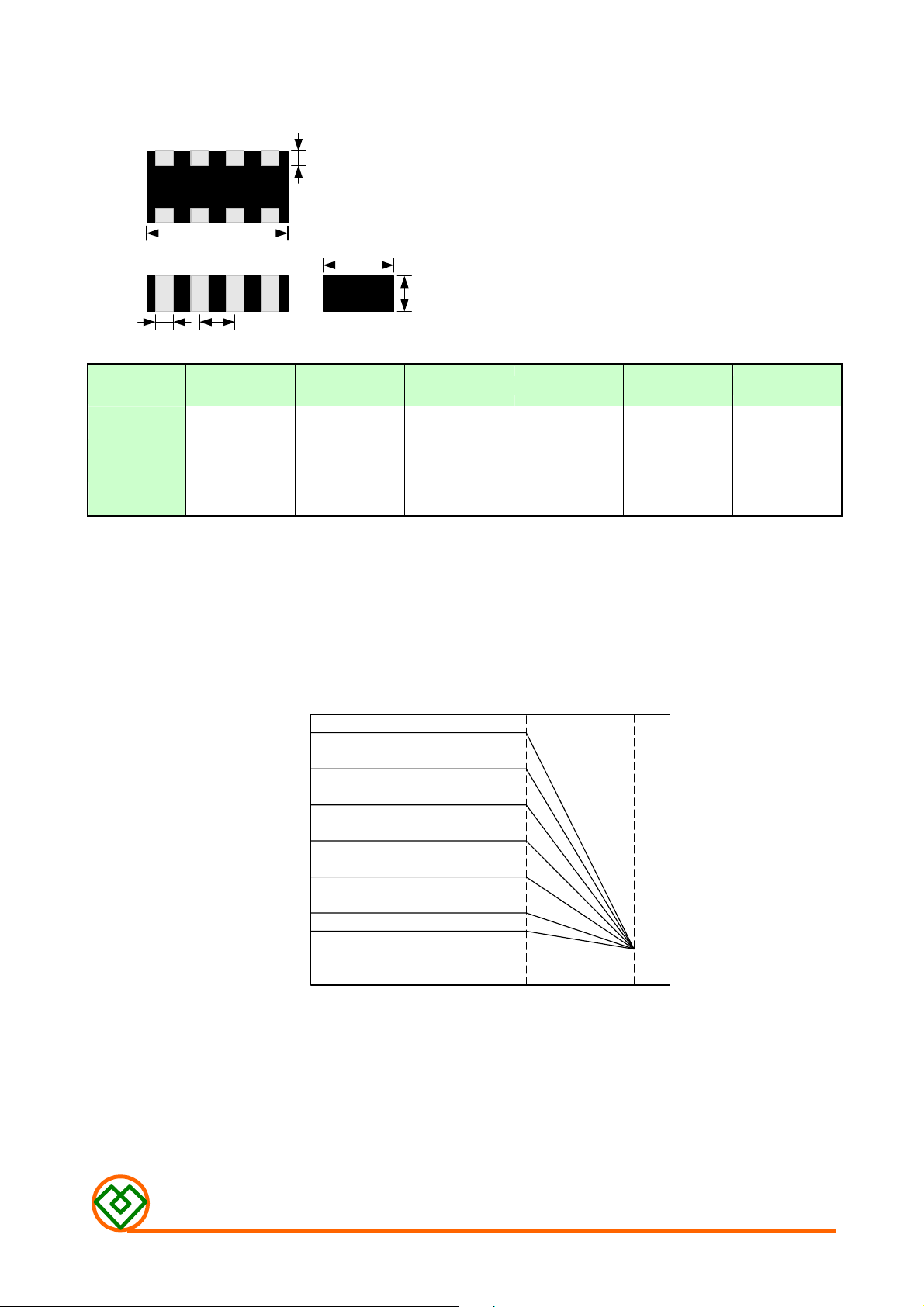

In operating temperatures exceeding +85℃, derating of current is necessary for chip

ferrite beads for which rated current is 1.5A or over. Please apply the derating curve

shown below according to the operating temperature.

U

U

R

R

R

R

R

A B C D E P

3.2±0.2

(0.126±0.008)

E

N

T

N

N

T

T

D

D

D

E

E

(0.063±0.008)

E

R

A

E

R

A

E

R

A

1.6±0.2

T

I

N

T

I

N

T

I

N

B

G

G

G

C

(0.035±0.008)

0.9±0.2

0.4±0.2

(0.015±0.008)

NOTE:Dimensions in mm

0.3±0.2

(0.012±0.008)

0.8±0.1

(0.031±0.004)

Rated Current (A)

7

6

5

4

3

2

1.5

1

85 125

Operating Temperature(℃)

MAG.LAYERS

GMLB-3216-A Series

Page 3

E

E

■ E

L

L

L

E

E

E

C

C

C

T

T

T

R

R

R

I

C

A

L

R

E

Q

U

I

R

E

M

E

N

T

I

C

A

L

R

E

Q

U

I

R

E

M

I

C

A

L

R

E

Q

U

I

R

E

M

E

E

N

N

T

T

S

S

S

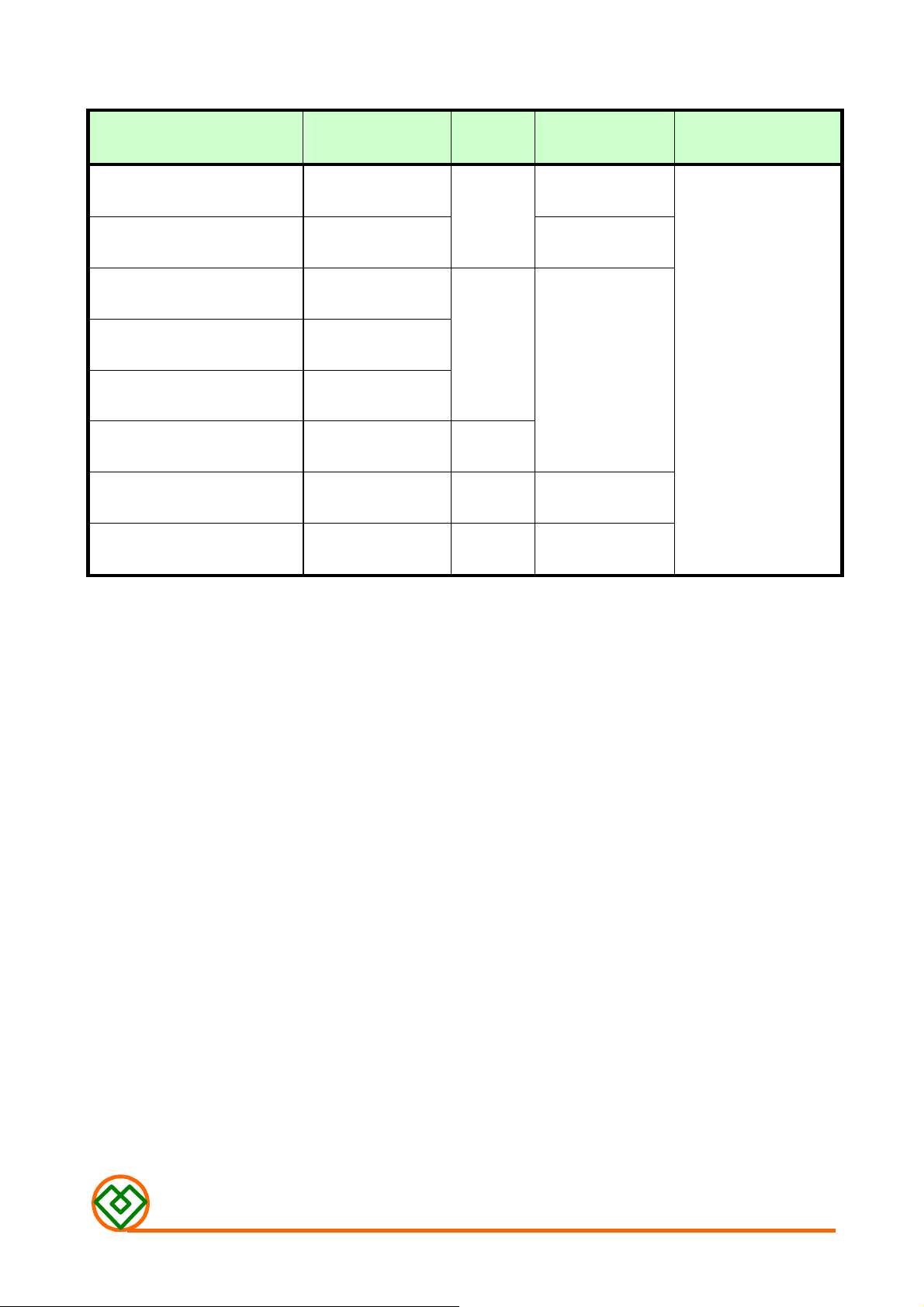

Part Number

GMLB-3216-0030M4-N8

GMLB-3216-0060M4-N8

GMLB-3216-0120M4-N8

GMLB-3216-0240M4-N8

GMLB-3216-0300M4-N8

GMLB-3216-0470M4-N8

GMLB-3216-0600M4-N8

GMLB-3216-1000M4-N8

Temperature rise should be less than 40℃ for P-type and less than 25℃ for other

types when rated current is applied.

Impedance (Ω)

at 100 MHz

30±25% 350

60±25%

120±25%

240±25%

300±25%

470±25% 1.0

600±25% 1.5 100

1000±25% 1.7 50

RDC (Ω)

Max.

0.4

0.8

Rated Current

(mA) Max.

250

150

Operating

Temp. Range (℃)

-55 ~ +125

■

M

E

A

S

U

R

I

N

G

■

M

E

A

S

U

R

■

M

E

A

S

Test Instrument:

Z:

Agilent 4291B Impedance Analyzer, Test Fixture: Agilent 16192

Osc. Level: 500mV

RDC: Agilent 34401A

Test Condition:

< Unless otherwise specified >

Temperature: 15°C to 35°C Humidity: 25% to 85% RH

< In case of doubt >

Temperature: 25°C ± 2°C Humidity: 60% to 70% RH

U

R

I

I

N

N

G

G

M

M

M

E

E

E

T

T

T

H

H

H

O

O

O

D

D

D

/

C

O

N

D

I

T

I

O

N

/

C

O

N

D

I

/

C

O

N

D

T

I

T

I

O

N

I

O

N

MAG.LAYERS

GMLB-3216-A Series

Page 4

■

■

■

T

Y

P

I

C

A

L

E

L

E

C

T

R

I

C

A

L

C

H

A

R

A

C

T

E

R

I

S

T

I

C

S

(

T

=

2

5

℃℃℃℃

)

T

Y

P

I

C

A

L

E

L

E

C

T

R

I

C

A

L

C

H

A

R

A

C

T

E

R

I

S

T

I

C

S

(

T

=

T

Y

P

I

C

A

L

E

L

E

C

T

R

I

C

A

L

C

H

A

R

A

C

T

E

R

I

S

T

I

C

S

2

(

T

=

2

5

5

℃℃℃℃

℃℃℃℃

)

)

GMLB-3216-0030M4-N8

60

50

40

30

20

10

0

1 10 10 0 10 0 0

GMLB-3216-0120M4-N8

250

200

150

100

Impedance(Ohm)

50

0

1 10 100 1000

Frequency(MHz)

GMLB-3216-0300M4-N8

600

Z

R

Z

R

GMLB-3216-0060M4-N8

140

120

100

80

60

X

X

40

20

0

1 10 100 1000

GMLB-3216-0240M4-N8

500

400

300

200

Impedance(Ohm)

100

0

1 10 100 1000

Frequency(MHz)

GMLB-3216-0470M4-N8

500

Z

X

R

Z

X

R

500

400

300

200

100

0

1 10 100 1000

GMLB-3216-0600M4-N8

800

700

600

500

400

300

Impedance(Ohm)

200

100

0

1 10 100 1000

Frequency(MHz)

Z

R

Z

R

400

300

200

X

X

Impedance(Ohm)

100

0

1 10 100 1000

Frequency(MHz)

GMLB-3216-1000M4-N8

1200

1000

800

600

400

Impedance(Ohm)

200

0

1 10 100 1000

Frequency(MHz)

Z

X

R

Z

X

R

MAG.LAYERS

GMLB-3216-A Series

Page 5

P

A

C

P

A

C

P

A

C

Peel-off Force

K

K

K

A

A

A

G

G

G

I

N

G

I

N

G

I

N

G

The force for peeling off cover tape is 10 grams in the arrow direction.

Dimension (Unit: mm)

A

B

C

D

TOP COVER TAPE

F

TYPE

8 mm 178±1

12 mm 178±0.3 60 ±0.2 19.3 ±0.1 13.5 ±0.1 13.6 ±0.1

E

A

B

60 +0.5

-0

C D E

- 13 ±0.2 9 ±0.5 12 ±0.5

165° TO 180°

BASE TAPE

F

-

TYPE SIZE A B W P T CHIPS/REEL

GMLB 3216 1.9 3.5 8 4 1.5 3000

MAG.LAYERS

GMLB-3216-A Series

Page 6

Taping Quantity

SERIES 3216

PCS/Reel 3000

Tape Packing Case

W

No. of

Reels

W

L H

H

■

■

■

2

L

`

3

4

5

18±0.5 18±0.5 2.4±0.2

18±0.5 18±0.5 3.6±0.2

18±0.5 18±0.5 4.8±0.2

18±0.5 18±0.5 6.0±0.2

Unit: cm

R

E

C

O

M

M

E

N

D

E

D

P

C

B

L

A

Y

O

U

T

R

E

C

O

M

M

E

N

D

E

D

P

C

B

L

A

Y

R

E

C

O

M

M

E

N

D

E

D

P

C

B

L

A

B

A

C

D

O

A

Y

O

Solder-resist

Component

Land pattern

U

U

T

T

L

W

Unit: mm

Type 3216

L 3.2

Size

W

1.6

A 0.7~0.9

B 0.8~1.0

C 0.4~0.5

D 0.8

MAG.LAYERS

GMLB-3216-A Series

Page 7

f the terminal electrode shall

n 75% of the terminal electrode shall

for 30

20% of the initial

R

E

L

I

A

B

I

L

T

Y

T

E

S

T

R

E

L

I

A

B

I

L

T

Y

R

E

L

I

A

B

I

L

T

Y

T

T

E

E

S

S

T

T

•Mechanical Performance Test

ITEM SPECIFICATION TEST CONDITION

More than 90% o

Solderability

Soldering Heat

Resistance

be covered with fresh solder.

The chip shall not crack.

More tha

be covered with solder.

The terminal electrode shall not be broken off

nor the ferrite damaged.

Solder: 96.5Sn-3.0Ag-0.5Cu

Solder Temperature: 245 ± 5℃

Flux: Rosin

Dip Time: 3 ± 1 Seconds

Solder temperature : 260 ± 5℃

Flux: Rosin

Dip time: 10 ± 1 seconds

TYPE W(KGF) TIME (SEC)

Terminal Strength

Bending Strength

Bending Test

Vibration

Drop shock

W

No mechanical damage.

The ferrite shall not be damaged.

R0.5

Appearance: No damage

Impedance shall be within ± 20% of the initial

value.

There shall be no mechanical damage.

No apparent damage

1.0

Chip

P

A

GMLB-2012-M4 0.2 10 ±2

GMLB-3216-M4 0.5

TYPE A(MM) P(KGF)

GMLB-2012-M4 1.74 0.2

GMLB-3216-M4 2.0 2.0

Substrate: PCB(100mm×40mm×1.6mm)

Solder: Reflow

Speed of Applying Force: 0.5mm / s

Deflection: 2mm

Hold Duration: 30 s

The sample shall be soldered onto the printed

circuit board and when a vibration having an

amplitude of 1.52mm and a frequency of from 10

to 55Hz/1 minute repeated should be applied to

the 3 directions (X,Y,Z) for 2 hours each.

Dropped onto printed circuit board from 100cm

height three times in x, y, z directions. The

terminals shall be protected.

10 ±2

• Climatic test

ITEM SPECIFICATION TEST CONDITION

Thermal Shock

(Temperature Cycle)

Humidity Resistance

High Temperature

Resistance

Low Temperature

Resistance

1. Operating Temperature Range: -55 ℃ TO +125℃

2. Storage Condition: The temperature should be within -40℃~85℃ and humidity should be less than 75% RH.

The product should be used within 6 months from the time of delivery.

Impedance shall be within ±

value.

Temperature cycle : -55℃ ~125℃

minutes each.

Total: 100 cycles.

Temperature : +60℃

Humidity: 90% RH

Applied current: rated current

Time: 1000 ± 12 hours

Temperature : 80℃

Applied current: rated current

Time: 1000 ± 12 hours

Temperature : -40℃±2℃

Time: 1000 ± 12 Hours

MAG.LAYERS

GMLB-3216-A Series

Page 8

■

■

■

R

E

C

O

M

M

E

N

D

E

D

R

E

F

L

O

W

S

O

L

D

E

R

I

N

G

P

R

O

F

I

L

E

R

E

C

O

M

M

E

N

D

E

D

R

E

F

L

O

W

S

O

L

D

E

R

I

N

G

P

R

O

R

E

C

O

M

M

E

N

D

E

D

R

E

F

L

O

W

S

O

L

D

E

R

I

N

G

P

t

P

T

P

Ramp-up

T

L

T

s

max

T

s

Temperature

min

t=25

t

S

Preheat

℃℃℃℃

to Peak

Time

t

L

Critical Zone

F

R

O

F

TL to T

Ramp-down

I

L

E

I

L

E

P

Profile Feature Sn-Pb Pb-Free

ts 60~120 seconds 60~180 seconds

Preheat

Average ramp-up rate (T

Time main above

Peak temperature (TP)

Time within 5℃ of actual peak

temperature (tP)

Ramp-down rate

Time 25℃ to peak temperature

T

smin

T

smax

to TP)

smax

Temperature (TL)

Time (tL) 60~150 seconds 60~150 seconds

100℃ 150℃

150℃ 200℃

3℃/second max. 3℃/second max.

183℃ 217℃

230℃ 250~260℃

10 seconds 10 seconds

6℃/sec max. 6℃/sec max.

6 minutes max. 8 minutes max.

■

N

O

T

E

S

■

■

N

O

T

N

O

T

E

E

S

S

The contents of this data sheet are subject to change without notice. Please confirm

the specifications and delivery conditions when placing your order.

MAG.LAYERS

GMLB-3216-A Series

Loading...

Loading...