Magikitch'N MKGD24 Installation Manual

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual

for the life of the equipment:

Model #: __________________________

Serial #: __________________________

Date Purchased: ___________________

Installation & Operation Manual

MKGD24, MKGD36, MKGD48, MKGD60 & MKGD72

All Options

ENGLISH

I

S

G

E

N

D

C

E

E

R

I

T

F

I

C IRE T IF ED

D

L25-054 Rev. 0 (01/12)

TO THE PURCHASER, OWNER AND STORE MANAGER

FOR YOUR SAFETY

WARNING

Please review these warnings prior to posting them in a prominent location for reference.

Post in a prominent location the instructions to be followed

TO THE PURCHASER

in the event that an operator smells gas. Obtain this

information from your local gas supplier.

DO NOT store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

Improper installation, alteration, adjustment, service or

maintenance can cause property damage, injury or

death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing

this appliance.

WARNING

Installation, maintenance and repairs should be performed

by a MagiKitch’n Authorized Service and Parts (ASAP)

company technician or other qualified personnel.

Installation, maintenance or repairs by unauthorized and

unqualified personnel will void the warranty.

WARNING

Installation and all connections must be made according to

national and local regulations and codes in force.

WARNING

During the warranty period if a customer elects to use a nonoriginal part or modifies an original part purchased from

MagiKitch’n and/or its Authorized Service and Parts (ASAP)

companies, this warranty will be void. In addition,

MagiKitch’n and its affiliates will not be liable for any claims,

damages or expenses incurred by the customer which arises

directly or indirectly, in whole or in part, due to the

installation of any modified part and/or received from an

unauthorized service center.

WARNING

This appliance, when installed, must be electrically grounded

in accordance with local codes, or in the absence of local

codes, with the National Electrical Code, ANSI/NFPA 70, or

the Canadian Electrical Code, CSA C22.2, as applicable.

WARNING

Adequate means must be provided to limit the movement of

this appliance without depending on the gas or electrical

cord connection. Single appliances equipped with legs must

be stabilized by installing anchor straps. All appliances

equipped with casters must be stabilized by installing

restraining chains, or equivalent means. If disconnection of

the restraint(s) are necessary, the restraint(s) must be

reconnected after the appliance is returned to its originally

installed position.

WARNING

An appliance equipped with casters and a flexible gas line

must be connected to the gas supply with a connector that

complies with ANSI Z21.69.CSA 6.16 and a quick disconnect

that complies with ANSI Z24.41.CSA 6.9.

WARNING

DO NOT alter or remove structural material on the appliance

to accommodate placement under a ventilation hood.

WARNING

This appliance is intended for professional use only and

should be operated by fully trained and qualified personnel.

If the appliance is equipped with a power cord and it is

WARNING

damaged, it must be replaced by a MagiKitch’n Authorized

Service and Parts (ASAP) company technician, or a similarly

qualified person in order to avoid a hazard.

WARNING

The power supply must be disconnected before servicing,

maintaining or cleaning this appliance.

WARNING

The appliance is NOT jet stream approved. DO NOT clean

the appliance with a water jet.

WARNING

DO NOT attempt to move this appliance or transfer hot

liquids from grease box to another container when the unit is

at operating temperature or filled with hot liquids. Serious

personal injury could result if skin comes in contact with the

hot surfaces or liquids.

WARNING

DO NOT sit or stand on this appliance. The appliance’s front

panel, cook plate, splash back, side, workshelf not a step.

Serious injury could result from slipping, falling or contact

with hot surfaces or liquids.

WARNING

NEVER use the appliance as a step for cleaning or accessing

the ventilation hood. Serious injury could result from slips,

trips or from contacting hot surfaces or liquids.

WARNING

DO NOT use the appliance unless it is properly secured to a

table, stand or freezer / refrigerated base suited to handle the

weight of the entire appliance.

WARNING

This appliance is intended for indoor use only.

WARNING

DO NOT operate appliance unless all panels and access

covers are attached correctly.

WARNING

It is recommended that this appliance be inspected by a

qualified service technician for proper performance and

operation on a yearly basis.

WARNING

There is an open flame inside this appliance. The unit may

get hot enough to set nearby materials on fire. Keep the area

around the appliance free from combustibles.

WARNING

DO NOT supply the appliance with a gas that is not indicated

on the data plate. If you need to convert the appliance to

another type of fuel, contact your Equipment Supplier or a

MagiKitch’n Authorized Service and Parts (ASAP) Company.

WARNING

DO NOT use an open flame to check for gas leaks!

WARNING

If the gas flow or the electrical power supplied to the

appliance is interrupted, or pilots extinguish, wait five (5)

minutes before attempting to re-light the pilot to allow any

residual gas in appliance to dissipate. Do not attempt to

operate this appliance during a power failure.

WARNING

In the event of a power failure turn all controls to the “Off”

position and do not attempt to operate this appliance.

WARNING

Ensure that the appliance can get enough air to keep the

flame burning correctly. If the flame is starved for air, it can

give off a dangerous carbon monoxide gas. Carbon

monoxide is a clear odorless gas that can cause suffocation.

L25-054 Rev. 1 (01/12)2

Table of Contents

MKH Series Gas Griddle

1. INSTALLATION SECTION.......................................................................................4

1.1. CHECKING YOUR NEW GRIDDLE.................................................................................................... 4

1.2. ELECTRICAL CONNECTION(S)........................................................................................................ 4

1.3. INSTALLATION CLEARANCES......................................................................................................... 5

1.4. GAS CONNECTION(S).................................................................................................................... 5

1.4.1. Fuel Type(s).................................................................................................................................. 5

1.4.2. Quick Disconnect Connection....................................................................................................... 5

1.4.3. Fuel Supply Line and Leak Pressure Testing................................................................................ 5

1.5. VENTILATION AND FIRE SAFETY SYSTEMS..................................................................................... 5

1.6. INSTALLATION SETUP.................................................................................................................... 6

1.6.1. Counter Use With Legs................................................................................................................. 6

1.6.2. Counter Use Without Legs............................................................................................................ 6

1.6.3. Equipment Stand........................................................................................................................... 6

1.6.4. Leveling Instructions ..................................................................................................................... 7

1.7. FINAL GAS CONNECTION............................................................................................................... 8

1.7.1. Regulator Assembly...................................................................................................................... 8

1.7.2. Gas Settings ................................................................................................................................. 8

2. OPERATION SECTION............................................................................................9

2.1. LIGHTING INSTRUCTIONS............................................................................................................... 9

2.1.1. Solid State Thermostat Appliance................................................................................................. 9

2.2. INITIAL STARTUP........................................................................................................................... 9

2.2.1. Griddle Surface Seasoning ......................................................................................................... 10

2.2.2. Surface Temperature Check....................................................................................................... 10

2.2.3. Shutdown Procedure................................................................................................................... 10

3. THERMOSTAT CALIBRATION SECTION.............................................................11

3.1. CALIBRATION PROCEDURES........................................................................................................ 11

3.1.1. Solid State Thermostat................................................................................................................ 11

4. BASIC OPERATION ..............................................................................................12

4.1. OPERATIONAL HELPFUL HINTS.................................................................................................... 12

4.2. SUGGESTED COOKING TIMES AND TEMPERATURES ..................................................................... 12

5. CLEANING & MAINTENANCE SECTION .............................................................13

5.1. GRIDDLE SURFACE CLEANING, DURING OPERATION HOURS ........................................................ 13

5.2. GRIDDLE SURFACE CLEANING, END OF SHIFT............................................................................. 13

5.2.1. Plain Steel Cooking Surface ....................................................................................................... 13

5.2.2. Chrome Plated Cooking Surface................................................................................................. 13

5.3. MONTHLY MAINTENANCE ............................................................................................................ 13

5.3.1. Monthly Preventative Maintenance............................................................................................. 13

5.4. ANNUAL/PERIODIC PREVENTATIVE MAINTENANCE AND INSPECTION.............................................. 14

5.4.1. Safety Evaluation........................................................................................................................ 14

5.4.2. Mechanical Inspection................................................................................................................. 14

5.4.3. Systems Operation Inspection.................................................................................................... 14

5.5. VENTILATION HOOD.................................................................................................................... 14

5.6. TROUBLE SHOOTING CHARTS ..................................................................................................... 15

5.6.1. Cooking Performance ................................................................................................................. 15

5.6.2. Operating Performance............................................................................................................... 15

6. ACCESSORIES......................................................................................................16

6.1. STANDARD................................................................................................................................. 16

6.2. OPTIONAL................................................................................................................................... 16

6.2.1. Service Shelves, Front................................................................................................................ 16

6.2.2. Cutting Boards ............................................................................................................................ 17

6.2.3. Warming Shelves, Rear.............................................................................................................. 18

6.2.4. Equipment Stands....................................................................................................................... 19

6.2.5. Miscellaneous ............................................................................................................................. 20

7. NOTES PAGE ........................................................................................................21

L25-054 Rev. 1 (01/12) 3

Installation

CAUTION

WARNING

cases, refer to local and national codes and regulations.

WARNING

WARNING

plug; it should be plugged into a properly grounded three-prong receptacle.

North America

International

MKGD Series Gas Griddle

1. Installation Section

1.1. Checking Your New Griddle

Your new griddle has been carefully packed into one crate. Every effort has been made to ensure that

your new griddle is delivered to you in perfect condition. As you unpack your new appliance, inspect each

of the pieces for damage. If something is damaged, Contact the shipper immediately; the shipper is only

responsible for 15 days after delivery. Check the packing list enclosed with your griddle to ensure that you

have received all the parts to the griddle. If you are missing any parts, contact the dealer from whom the

griddle was purchased.

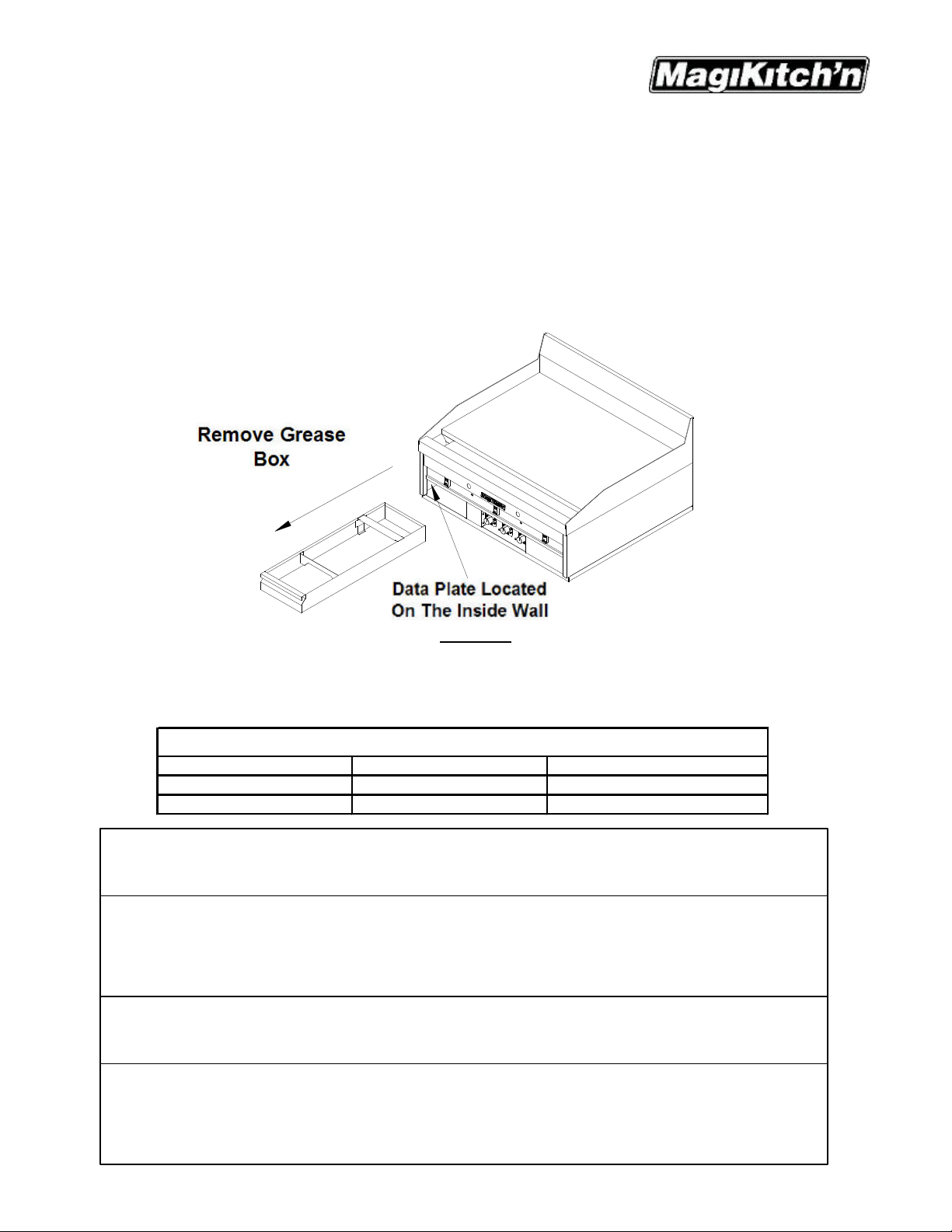

In the provided spaces on the cover of this manual, fill in the Model No., Serial No., and the date the

appliance was purchased. The Information is located on the Data plate on the inside cabinet wall, see

Figure 1 below. Keep this information in a safe place so it can be referred to in the future.

FIGURE 1

1.2. Electrical Connection(s)

It is advised that this appliance be plugged into a wall receptacle that is controlled by the ventilation

control. This will prevent the appliance from being operated without the ventilator on. A schematic is

located on the inner side of the front or access panel. The power requirements are listed below.

Electrical Requirements

Input Voltage 120 Vac 50/60 Hz 220,230, or 240 Vac 50/60 Hz

Current/Control 0.22 Amps 0.11 Amps

Connecting the appliance to an electrical supply other than that indicated on the data plate.

may damage the appliance and void the warranty.

The electrical connection used by this appliance must comply with local codes. If there are no

local codes that apply, refer to the National Electrical Code (NEC), ANSI/NFPA 70 for

installation in the US. In Canada, refer to CSA Standard C22.2 and local codes. In all other

This equipment must be installed so that the plug is accessible unless other means for

disconnection from the power supply (e.g. a circuit breaker) is provided.

If your appliance uses line current, it is equipped with an oil proof, electrical supply cord with a

three-prong safety plug. This is to protect operators from electrical shock hazard in the event

of an equipment malfunction. DO NOT cut or remove the grounding (third) prong from this

L25-054 Rev. 0 (01/12)4

Installation

Location

Combustible Construction

Non-Combustible Construction

MKGD Series Gas Griddle

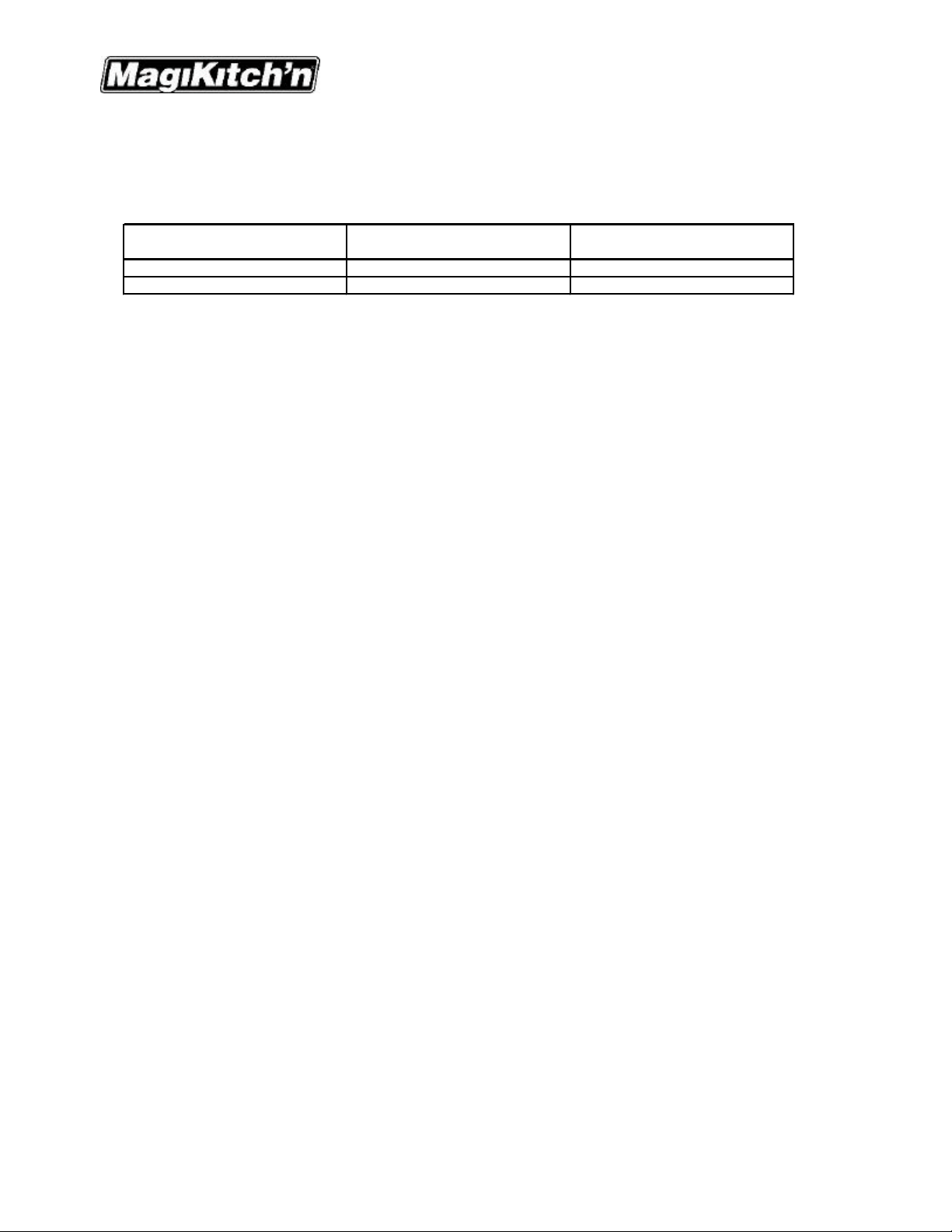

1.3. Installation Clearances

Your new MagiKitch’n Griddle needs clearance around it for proper operation. Adequate clearances allow

for servicing and proper burner operation. The clearances shown below are for installation in combustible

and non-combustible construction. The appliance can be serviced from the front of the unit, however it

may need to be pulled away from the wall for access to the gas supply and electrical supply connections.

Ensure that all clearances stated on the Data plate and in the table below are strictly followed.

Inches (Centimeters)

Cabinet back 8.0 (20.4) 8.0 (20.4)

Cabinet Sides 2.0 (5.0) 0.0 (0.0)

Inches (Centimeters)

1.4. Gas Connection(s)

Your gas appliance will give you peak performance when the gas supply line is of sufficient size to

provide the correct gas pressure. The gas line must be installed to meet the local building codes or

National Fuel Gas Code ANSI Z223.1/NFPA 54 Latest Edition, or the Natural Gas and Propane

Installation Code, CSA-B149.1 as applicable, and local codes. Gas line sizing requirements can be

determined by your local gas company by referring to the National Fuel Gas Code, Appendix C, Table C4 (for natural gas) and Table C-16 (for propane). The gas line needs to be large enough to supply the

necessary amount of fuel to all appliances without losing pressure to any appliance.

WARNING

NEVER supply the appliance with a gas that is not indicated on the data plate. Supplying incorrect

gas will cause improper operation. Contact your Dealer for another gas type for the appliance.

1.4.1. Fuel Type(s)

Each appliance is equipped to work with one type of fuel. The type of fuel with which the

appliance is intended to operate is stamped or printed on the data plate, see Figure 1.

CAUTION

NEVER use an adapter to make a smaller gas supply line fit the appliance connection. This may

limit proper gas flow for optimum burner operation, resulting in poor performance.

1.4.2. Quick Disconnect Connection

Gas appliances equipped with casters must be installed with connectors that comply with the

Standard for Connectors for Movable Gas Appliances, ANSI Z21.69.CSA 6.16 Latest Edition.

This connection should include a quick disconnect device that complies with the Standard for

Quick Disconnect Devices for Use With Gas Fuel ANSI Z221.41.CSA 6.9 Latest Edition. When

installing a quick disconnect you must also install a means for limiting the movement of the

appliance. This device will prevent the gas line or the quick disconnects from being strained. The

restraining device should be attached to the appliance at the back panel.

1.4.3. Fuel Supply Line and Leak Pressure Testing

The fuel supply system must be tested before the appliance is used. If the fuel line is going to be

tested at a pressure greater than ½ PSIG (3.45 kPA), make sure that the appliance is

disconnected from fuel line. If the fuel line is to be tested at a pressure equal to or less than ½

PSIG (3.45 kPA), the appliance can be connected, but the unit’s gas valve must be shut. Test all

gas line connections for leaks with a solution of soap and water when pressure is applied.

1.5. Ventilation And Fire Safety Systems

Your new gas appliance must have proper ventilation to function safely and properly. Exhaust gas

temperatures can reach as high as 1000°F (538 °C). Therefore, it is very important to install a fire safety

system. Your ventilation system should be designed to allow for easy cleaning. Frequent cleaning of the

ventilation system and the appliance will reduce the chances of fire. Additional information can be

obtained from CSA International, 8501 East Pleasant Valley Rd., Cleveland, OH 44131.

Excessive ventilation causes drafts, which will interfere with the operation of the appliance. Leave

at least 18 inches of open space between the flue opening and the intake of the exhaust hood.

Ensure that your ventilation system does not cause a down draft at the appliance’s flue opening.

Down drafts will not allow the appliance to exhaust properly and will cause overheating which

may cause permanent damage. Damage caused by down drafts will not be covered under

equipment warranty. NEVER allow anything to obstruct the flow of combustibles or ventilation

CAUTION

CAUTION

exiting the appliance flue.

L25-054 Rev. 1 (01/12) 5

Installation

MKGD Series Gas Griddle

1.6. Installation Setup

The installation of this appliance MUST conform to

local codes. In the absence of local codes The gas

line must be installed to meet the local building

codes or National Fuel Gas Code ANSI Z223.1/

NFPA 54 Latest Edition, or the Natural Gas and

Propane Installation Code, CSA-B149.1 as

applicable, and local codes. To Start uncrate

appliance and locate installation accessories.

1.6.1. Counter Use With Legs

CAUTION

To prevent equipment damage, DO NOT tilt

your MagiKitch'n griddle on only two legs, or

on its sides.

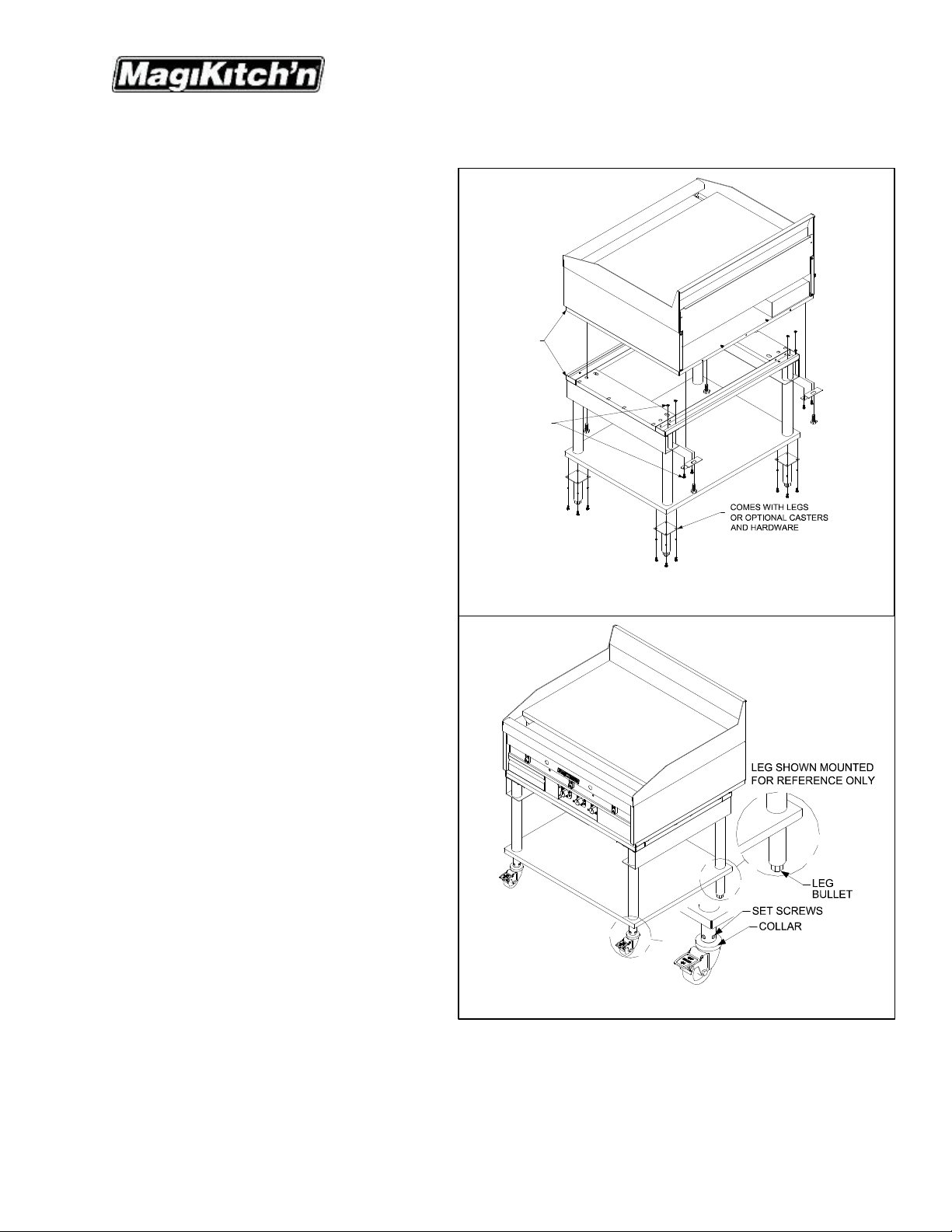

(See Figure 2) A set of 4” legs is shipped with

the appliance (unless appliance was specifically

ordered without legs). A threaded insert for the

leg bolt is located near each corner of the

bottom appliance. Raise the appliance to allow

legs to be screwed tightly into inserts. The

appliance can be leveled by adjusting the feet at

the bottom of the leg assembly. This can be

done by turning the foot in or out to lower or

raise each corner as needed.

Figure 2

NOTICE

4" Legs should not to be used with the

Equipment Stand.

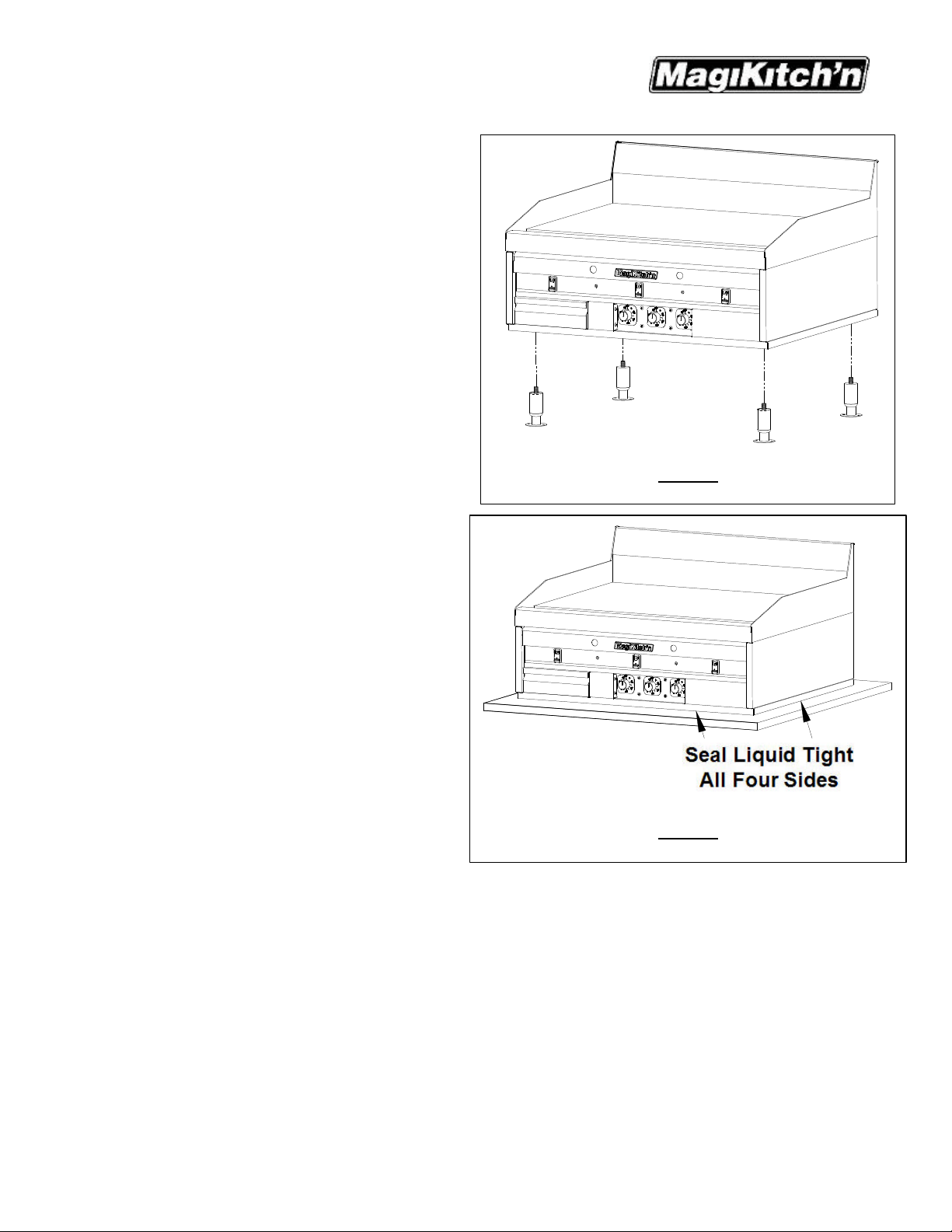

1.6.2. Counter Use Without Legs

(See Figure 3) The appliance must be sealed to

the counter to comply with applicable sanitation

standards. A bead of silicone sealant,

approximately ½ inch wide, is to be applied to

the bottom of the unit approximately ¼” in from

the front, back and side edges. We suggest Dow

Corning →, GE → or Permatex → silicone ‘RTV’

adhesive sealant or equivalent. (See NSF Basic

Criteria C-2 for details).

1.6.3. Equipment Stand

ATTENTION

Rear mounting brackets should be installed

to the Equipment Stand prior to placing

griddle on the stand.

CAUTION

Install the griddle so that the two locking

casters are at the front of the unit. The

casters should be LOCKED before the unit is

placed into operation.

Figure 3

(See Figure 4). To mount the griddle to the

stand, locate joining kit supplied with stand. The

joining kit should include (2) rear mounting

brackets, and (4) 1/2" mounting bolts. To mount

the griddle to the equipment perform the steps

on the following page:

IMPORTANT

The appliance must be level to perform

properly. Failure to level unit may result in

improper performance of the appliance.

L25-054 Rev. 0 (01/12)6

Installation

MKGD Series Gas Griddle

NOTICE

Larger models have 6 threaded receiving holes, but require only the four 1/2" bolts on each corner to

mount the griddle.

1. Remove (4) existing 1/4-20 nuts and bolts

from the rear corners of the equipment

stand.

2. Align the 2 bolt holes on the rear corners of

the stand with the 2 bolt holes on the rear

mounting brackets. Orient the brackets as

shown in Figure #4 on this page.

3. Install the provided rear mounting brackets

(2) to the rear corners by using the existing

1/4-20 hardware that were removed in step

1, tighten securely.

4. Carefully place the griddle on the

equipment stand.

5. Once the griddle is on the stand, position

the griddle on the stand so that the front

edge of the base is flush with the front of

the equipment stand. If the griddle is the

only appliance to be mounted on the stand,

then both sides of the griddle should be

flush with the sides of the equipment stand.

6. When positioned properly, the threaded

receiving holes in the griddle base should

be aligned with mating clearance holes at

the front of the equipment stand, and with

the clearance holes in the rear mounting

brackets. Install the provided 1/2" bolts and

tighten securely.

MOUNT FLUSH

TO FRONT

NUTS & BOLTS

INCLUDED

WITH STAND

Figure 4

REAR

BRACKET (2)

(SUPPLIED)

1/2" BOLTS (4)

(SUPPLIED)

1.6.4. Leveling Instructions

NOTICE

Equipment stands are shipped from the

factory with the legs or casters set to the

minimum height adjustment. Units should be

leveled at time of installation, failure to do so

could cause the griddle to operate

improperly.

1. Identify the corner of the stand that needs to

be adjusted, remove the weight load from

the corner to be leveled.

2. Legs- using a wrench, or pliers turn the leg

bullet, See Figure 5, CCW to raise the

height of the equipment stand. There is ½”

to ¾” of adjustment.

Casters- Using a Flat Head screwdriver,

loosen the set screws of the caster to be

leveled, See Figure 5.Turn the collar of the

caster CCW to raise the height of the

Figure 5

equipment stand. There is ¾” of adjustment.

After leveling adjustment is complete, re-tighten set screws.

3. Check the levelness of the equipment, if necessary Repeat steps 1 and 2.

NOTICE

This appliance may only be installed with casters provided by the manufacturer. When installed with

casters, a gas connection complying with ANSI Z21.69/CGA-6.16 and a quick disconnect device

complying with ANSI Z21.41/CAN 1-6.9. It must also be installed with a restraining device to guard

against putting any strain on the gas connections when the unit is moved.

L25-054 Rev. 1 (01/12) 7

Loading...

Loading...