Page 1

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual

for the life of the equipment:

Model #: ___________________________

Serial #: ___________________________

Date Purchased: ____________________

ENGLISH

Technical Service Manual

Models

MKG/MKH/MKGD

24,36,48,60 & 72

All Options

Solid State Thermostat Model Shown

S

I

E

G

D

N

D

C

E

E

I

R

F

T

I

CIRET IFED

L22-362 Rev 2 (11/12)

Page 2

Technical Service Manual

MKG/MKH/MKGD Series Gas Griddles

WARNING

DO NOT store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

WARNING

Improper installation, alteration, service or maintenance

can cause property damage, injury or death. Read the

installation, operating and maintenance instructions

thoroughly before installing or servicing this appliance.

WARNING

Installation, maintenance and repairs should be

performed by a MagiKitch’n Authorized Service and

Parts (ASAP) company technician or other qualified

personnel. Installation, maintenance or repairs by an

unauthorized and unqualified personnel will void the

warranty.

WARNING

Installation and all connections must be made according

to national and local regulations and codes in force.

WARNING

During the warranty period if a customer elects to use a

non-original part or modifies an original part purchased

from MagiKitch’n and/or its Authorized Service and

Parts (ASAP) companies, this warranty will be void. In

addition, MagiKitch’n and its affiliates will not be liable

for any claims, damages or expenses incurred by the

customer which arises directly or indirectly, in whole or

in part, due to the installation of any modified part

and/or received from an unauthorized service center.

WARNING

This appliance, when installed, must be electrically

grounded in accordance with local codes, or i n the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70, or the Canadian Electrical Code,

CSA C22.2, as applicable.

WARNING

Adequate means must be provided to LIMIT the

movement or this appliance without depending on the

gas or electrical cord connection. Single appliances

equipped with legs must be stabilized by installing

anchor straps. All appliances equipped with casters

must be stabilized by installing restraining chains.

WARNING

An appliance equipped with casters and a flexible gas line must be

connected to the gas supply with a quick disconnect device. This

quick disconnect must comply with ANSI Z24.41.

WARNING

DO NOT alter or remove structural material on the

appliance to accommodate placement under a

ventilation hood.

WARNING

This appliance is intended for professional use only and

should be operated by fully trained and qualified

personnel.

WARNING

If the appliance is equipped with a power cord and it is

damaged, it must be replaced by a MagiKitch’n

Authorized Service and Parts (ASAP) company

technician, or a similarly qualified person in order to

avoid a hazard.

WARNING

The power supply must be disconnected before

servicing, maintaining or cleaning this appliance.

WARNING

The appliance is NOT jet stream approved. DO NOT

clean the appliance with a water jet.

WARNING

DO NOT attempt to move this appliance or transfer hot

liquids from grease box to another container when the

unit is at operating temperature or filled with hot liquids.

Serious personal injury could result if skin comes in

contact with the hot surfaces or liquids.

WARNING

DO NOT sit or stand on this appliance. The appliance’s

front panel, cook plate, splash back, sides, workshelf is

not a step. Serious injury could result from slipping,

falling or contact with hot surfaces or hot liquids.

WARNING

NEVER use the appliance as a step for cleaning or

accessing the ventilation hood. Serious injury could

result from slips, trips or from contacting hot surfaces

or liquids.

WARNING

This appliance is intended for indoor use only.

WARNING

DO NOT operate appliance unless all panels and access

covers are attached correctly.

WARNING

It is recommended that this appliance be inspected by a

qualified service technician for proper performance and

operation on a yearly basis.

WARNING

There is an open flame inside this appliance. The unit

may get hot enough to set nearby materials on fire.

Keep the area around the appliance free from

combustibles.

WARNING

DO NOT supply the appliance with a gas that is not

indicated on the data plate. If you need to convert the

appliance to another type of fuel, contact your

equipment dealer or a MagiKitch’n Authorized Service

and Parts (ASAP) Company.

WARNING

DO NOT use an open flame to check for gas leaks!

WARNING

If gas flow to appliance is interrupted, or pilots

extinguish, wait 5 minutes before attempting to relight

the pilot to allow any residual gas in appliance to

dissipate.

WARNING

Ensure that the appliance can get enough air to keep the

flame burning correctly. If the flame is starved for air, it

can give off a dangerous carbon monoxide gas. Carbon

monoxide is a clear odorless gas that can cause

suffocation.

Page 2 L22-362 Rev 2 (11/12)

Page 3

Technical Service Manual

MKG/MKH/MKGD Series Gas Griddles

TABLE OF CONTENTS

OVERVIEW ................................................................................................................................... 4

1.1 INTRODUCTION.................................................................................................................................. 4

1.2 S

2 THEORY OF OPERATION .................................................................................................... 5

2.1 HEATING SYSTEM –SNAP ACTION SERIES .......................................................................................... 5

2.2 H

2.3 TEMPERATURE CONTROL SYSTEMS ................................................................................................... 6

3 TEMPERATURE CALIBRATION .......................................................................................... 6

3.1 TEMPERATURE MEASUREMENT: .......................................................................................................... 6

3.2 CALIBRATION PROCEDURES: .............................................................................................................. 7

4 COMPONENT CHECK & REPLACEMENT .......................................................................... 8

4.1 DISASSEMBLY OF FRONT PANELS ...................................................................................................... 8

4.2 PILOT / IGNITION SYSTEM CHECK ....................................................................................................... 9

4.3 IGNITION MODULE REPLACEMENT .................................................................................................... 12

4.4 PILOT ASSEMBLY REPLACEMENT ..................................................................................................... 12

4.5 B

4.6 ORIFICE/FUEL TYPE CONVERSION ................................................................................................... 13

4.7 MAIN BURNER REPLACEMENT ......................................................................................................... 13

4.8 GAS PRESSURE ADJUSTMENT ......................................................................................................... 14

4.9 TEMPERATURE CONTROLS CHECK ................................................................................................... 15

4.10 TEMPERATURE CONTROL REPLACEMENT .......................................................................................... 17

4.11 SAFETY VALVE REPLACEMENT ........................................................................................................ 19

4.12 SOLENOID VALVE REPLACEMENT- .................................................................................................... 19

4.13 POWER SUPPLY TRANSFORMER MATCHLESS MODELS “E” & “ST” ..................................................... 21

4.14 SWITCH AND LAMP REPLACEMENT ................................................................................................... 22

PECIFICATIONS ............................................................................................................................... 4

1.2.1 Gas Information ...................................................................................................................................... 4

1.2.2 Elevation Orifice Chart ........................................................................................................................... 4

EATING SYSTEM –MATCHLESS IGNITION SERIES (E / ST) .................................................................. 5

3.2.1 Snap Action and Matchless (E) Series ................................................................................................... 7

3.2.2 Matchless (ST) Series ............................................................................................................................ 7

4.1.1 Snap Action Series ................................................................................................................................. 8

4.1.2 Matchless Series (E & ST) ..................................................................................................................... 8

4.2.1 Ignitor Check- Snap Action Series .......................................................................................................... 9

4.2.2 Spark Failure- Matchless (E & ST) Series ............................................................................................ 10

4.2.3 Insufficient or Absence of Flame: ......................................................................................................... 11

4.2.4 Pilot Lock-in: Snap Action Series ......................................................................................................... 11

4.2.5 Pilot Lock-in- Matchless Series (E & ST) .............................................................................................. 12

URNER ADJUSTMENTS .................................................................................................................. 12

4.6.1 Changing Burner Orifice ....................................................................................................................... 13

4.9.1 Snap-Action Models ............................................................................................................................. 15

4.9.2 Matchless “E” Models ........................................................................................................................... 15

4.9.3 Matchless “ST” Models ......................................................................................................................... 16

4.9.4 Temperature Probe Check: .................................................................................................................. 16

4.9.5 Resistance Chart: Solid State Thermistor Probe .................................................................................. 17

4.10.1 Snap Action Models ............................................................................................................................. 17

4.10.2 Matchless “E” Models ........................................................................................................................... 17

4.10.3 Matchless “ST” Models ......................................................................................................................... 18

4.10.4 Thermistor Probe Replacement............................................................................................................ 18

4.12.1 Pilot Solenoid Valve ............................................................................................................................. 19

4.12.2 Main Burner Solenoid Valve ................................................................................................................. 20

4.13.1 Power Supply Transformer Check ........................................................................................................ 21

4.13.2 Power Supply Transformer Replacement ............................................................................................. 21

5 TROUBLESHOOTING GUIDE ............................................................................................. 23

5.1 TROUBLESHOOT GUIDE -SNAP ACTION MODELS ............................................................................... 23

5.2 T

5.3 SCHEMATIC: MATCHLESS “E” SERIES ............................................................................................... 25

5.4 S

5.5 S

5.6 SCHEMATIC: MATCHLESS SINGLE POWER SWITCH “ST” SERIES ........................................................ 28

L22-362 Rev 2 (11/12) Page 3

ROUBLESHOOT GUIDE - E / ST SERIES ........................................................................................... 24

CHEMATIC: MATCHLESS “ST” SERIES ............................................................................................ 26

CHEMATIC: MATCHLESS SINGLE POWER SWITCH “E” SERIES .......................................................... 27

Page 4

Technical Service Manual

A

A

r

MKG/MKH/MKGD Series Gas Griddles

1 Overview

1.1 INTRODUCTION

All models

All models are equipped with pilot safety

system, spark enabled pilots, temperature

controls for each 12” zone, heated by two

burners. Temperature sensing probes are

embedded into the plate between each pair of

burners.

MKG/MKH/MKGD Series appliances may

have suffixes that denote the following:

Numerals 24, 36, 48, 60, and 72 denote the

width of the appliance in inches.

Suffix “L”, “R” and “B” denote left, right and rear grease troughs, respectively.

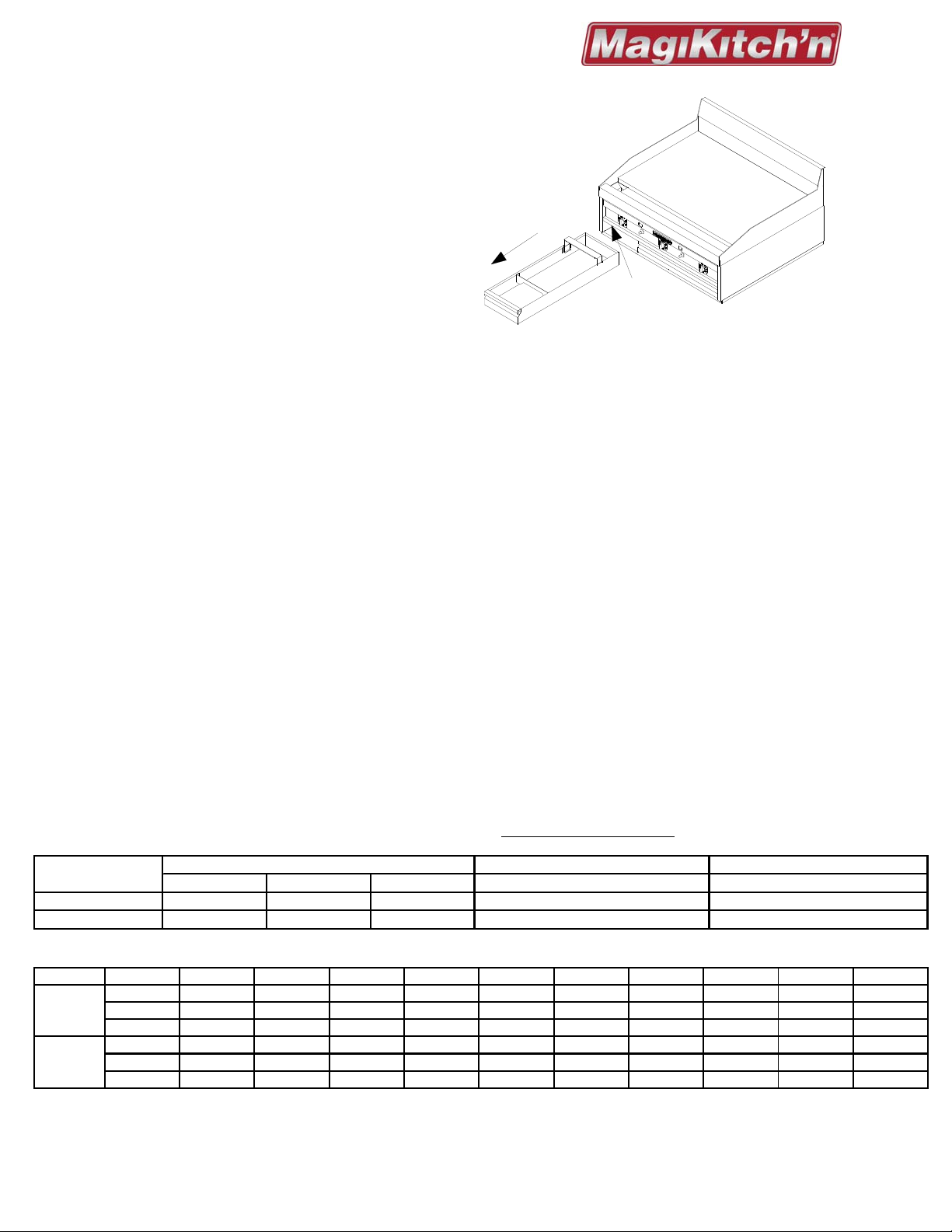

Important information located on Data Plate, See Figure 1 at right.

Snap Action Models

Snap Action models have gas safety valves, Piezo pilot ignition systems and snap action gas

temperature controls.

Snap Action models have no suffix designation.

Snap Action models require no external electrical supply.

Matchless Models

Letter designations represent matchless ignition (flame proving spark ignition), temperature control

options and grease chute options.

Suffix “E” models have flame proving spark ignition systems and electro-mechanical thermostats.

External power supply is required.

Suffix “ST” models have flame proving spark ignition systems with solid state temperature controls.

External power supply required.

Matchless models have 120 Vac 60HZ electrical supply, and 24 Vac control circuitry.

Installation, Operation and Cleaning

A qualified person, in accordance with all national and local codes, must perform the installation.

Detailed instructions are in the INSTALLATION & OPERATION manual supplied with the appliance.

1.2 SPECIFICATIONS

1.2.1 Gas Information

Gas supply line must be ¾ “ minimum, providing line pressures at least 1.0” (25mm) greater

than the specified griddle manifold pressure with all burners operating

Gas Type

Natural 15,000 (4.4) 13,333 (3.9) 18,000 (5.3) 4.0" WC (10.1cm) [10 mbar] 5.0" WC (12.7cm) [12.5 mbar]

Propane 15,000 (4.4) 13,333 (3.9) 18,000 (5.3) 10.0" WC (25.4cm) [25 mbar] 11.0" WC (27.9cm) [27.4 mbar]

1.2.2

Gas Type Model Sea level 2000 Ft. 3000 Ft. 4000 Ft. 5000 Ft. 6000 Ft. 7000Ft. 8000 Ft. 9000 Ft. 10,000 Ft,

Natural

MKGD

Propane

MKGD

Elevation Orifice Chart

MKG

MKH

MKG

MKH

BTU/hr(kW) per Burne

MKG MKH

49 50 50 50 51 51 51 52 52 52

0.066"0.066"5152525253535354

45 46 47 47 47 48 48 49 49 50

1.15mm 1.15mm 1.15mm 57 57 57 58 59 59 60

57 58 59 59 60 60 61 62 63 63

1.25mm 1.25mm 1.25mm 57 57 57 58 59 59 60

MKGD

Electrical Information

Snap Action models require no electrical supply. All Matchless Series (-E and -ST) require 115v/60hz/1ph

electrical supply. The appliance is fitted with a grounded 15-amp cord and plug (NEMA 515-P).

REMOVE

GREASE BOX

DATA PLATE

ON INSIDE WALL

.

Manifold Pressure Nominal Supply Pressure

ll Models

ll Models

Page 4 L22-362 Rev 2 (11/12)

Page 5

Technical Service Manual

MKG/MKH/MKGD Series Gas Griddles

2 Theory Of Operation

This section will demonstrate the basic sequence of

operation for Snap Action and Matchless (E/ST)

Ignition series.

2.1 HEATING SYSTEM –SNAP ACTION

SERIES

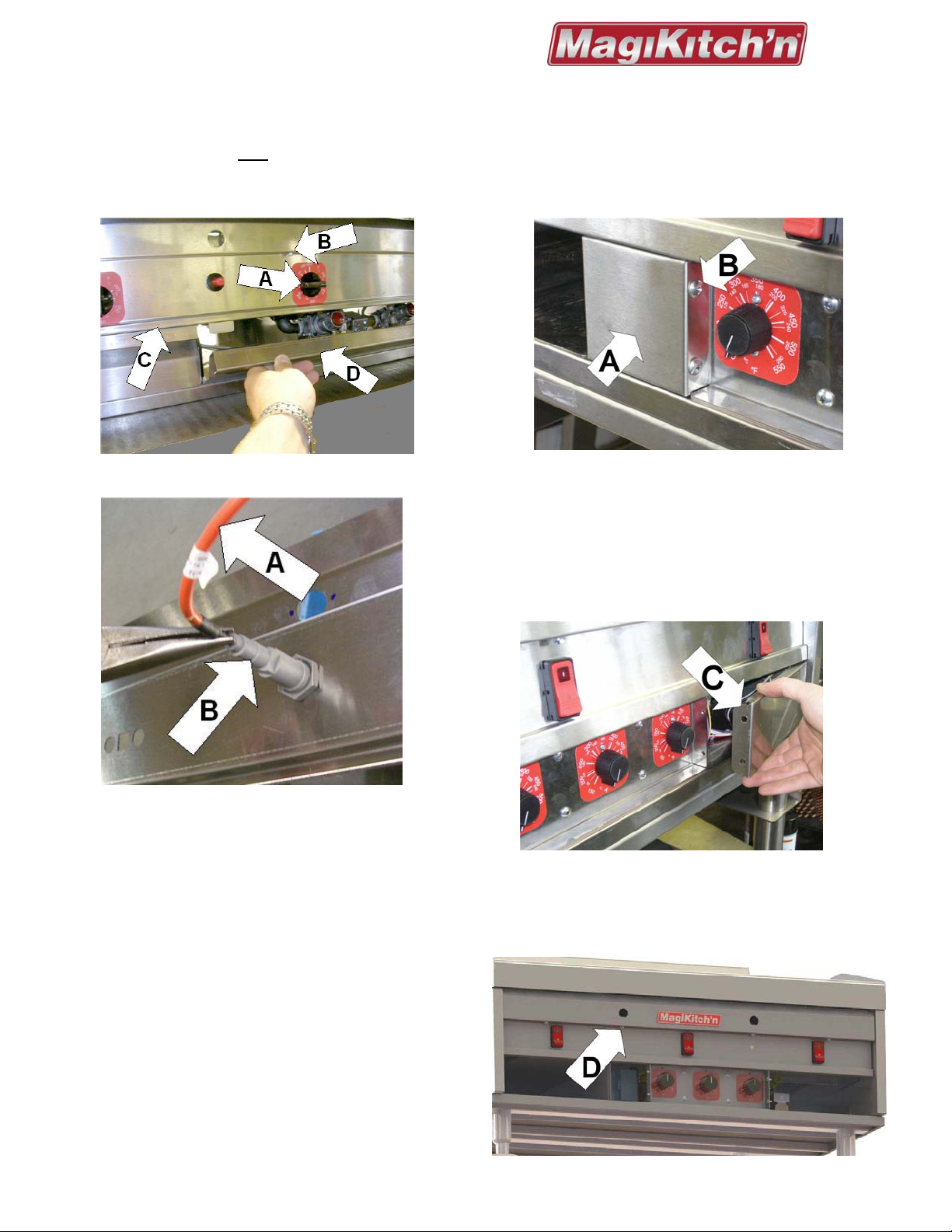

Pilots are lit by, (See Photo 1):

- Opening the shut off valve (C)

- Depressing the Piezo spark buttons (A)

while depressing and holding the button on

the safety valve (B) to ignite flame at pilot.

- Once ignited, keep button (B) depressed

for 20 seconds to lock in the safety valve.

2.2 HEATING SYSTEM –MATCHLESS

IGNITION SERIES (E / ST)

Start up of Unit, (See Photo(s) 2, and 2a):

- Open the shut off valve (C)

- Pres s Rocker Switch (A), to ON (I) for

each 12” zone to ignite pilots.

- Set thermostat controls (B) to set point

When the appliance is plugged in, line voltage

is supplied to an 80 VA transformer located in

the power supply boxes located in the rear of

the unit. The transformer then supplies 24

VAC to the rocker switches for the control

circuitry, the switches are located on the

control panel, centered on each 12” zone.

The rocker switches (A) are double pole (DP).

Photo 1

Once safety valve is locked in, the "snap acting”

gas thermostats supply gas to their respective

burners upon “call for heat “.

The thermostats cycle gas to the

burners to maintain cooking surface

temperatures at set point.

On snap action models the burner operating

pressure is measured at the pressure tap on

the shut off valve (C), and controlled by the gas

regulator (D), mounted in the back of the unit,

See Photo 1a.

Photo 2

One set of contacts supplies power to the

ignition modules (and to the Solid State

temperature control boards on -“ST” Series).

The second set of contacts switches power

from the thermostat control (B), to the main

gas valve solenoids allowing gas to the main

burners.

The ignition modules supply spark energy to

the ignitor electrodes and power to the pilot

gas valve solenoids to establish pilot flames.

The modules also rectify pilot flame by means

of integral flame sense (spark and flame sense

supplied through the ignition wire).

Photo 1a

Photo 2a

L22-362 Rev 2 (11/12) Page 5

Page 6

Technical Service Manual

MKG/MKH/MKGD Series Gas Griddles

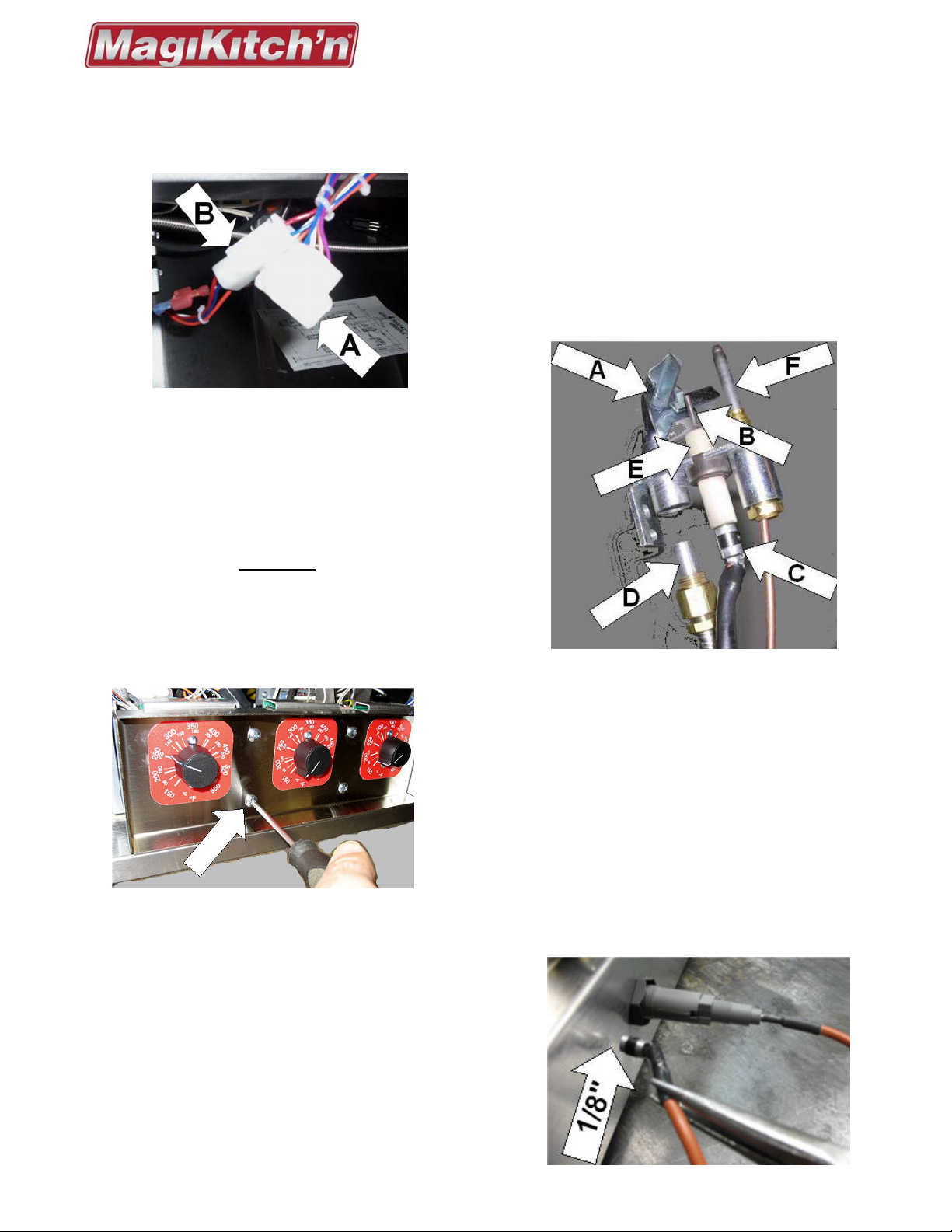

Photo 2b

Once pilots ignite, the ignition modules will

send power to the burner valves, traveling first

through the thermostat control, then through the

second contacts of the rocker swit ches.

The Solid State temperature controls or the

Electric thermostats, cycle the power to

maintain set temperature.

Supply line gas pressure on matchless models

is measured at the pressure tap on the shut off

valve (C), mounted in the back of the unit,

accessible from the back of the appliance only,

See Photo 2a.

Matchless models the burner operating

pressure is measured at the pressure tap (E)

on the burner supply line, and controlled by the

gas regulator (D), See Photo(s) 2a.(rear view)

and 2b (front view). The Pressure tap and

regulator adjustment are front accessible with

the lower panel removed, see section 4.

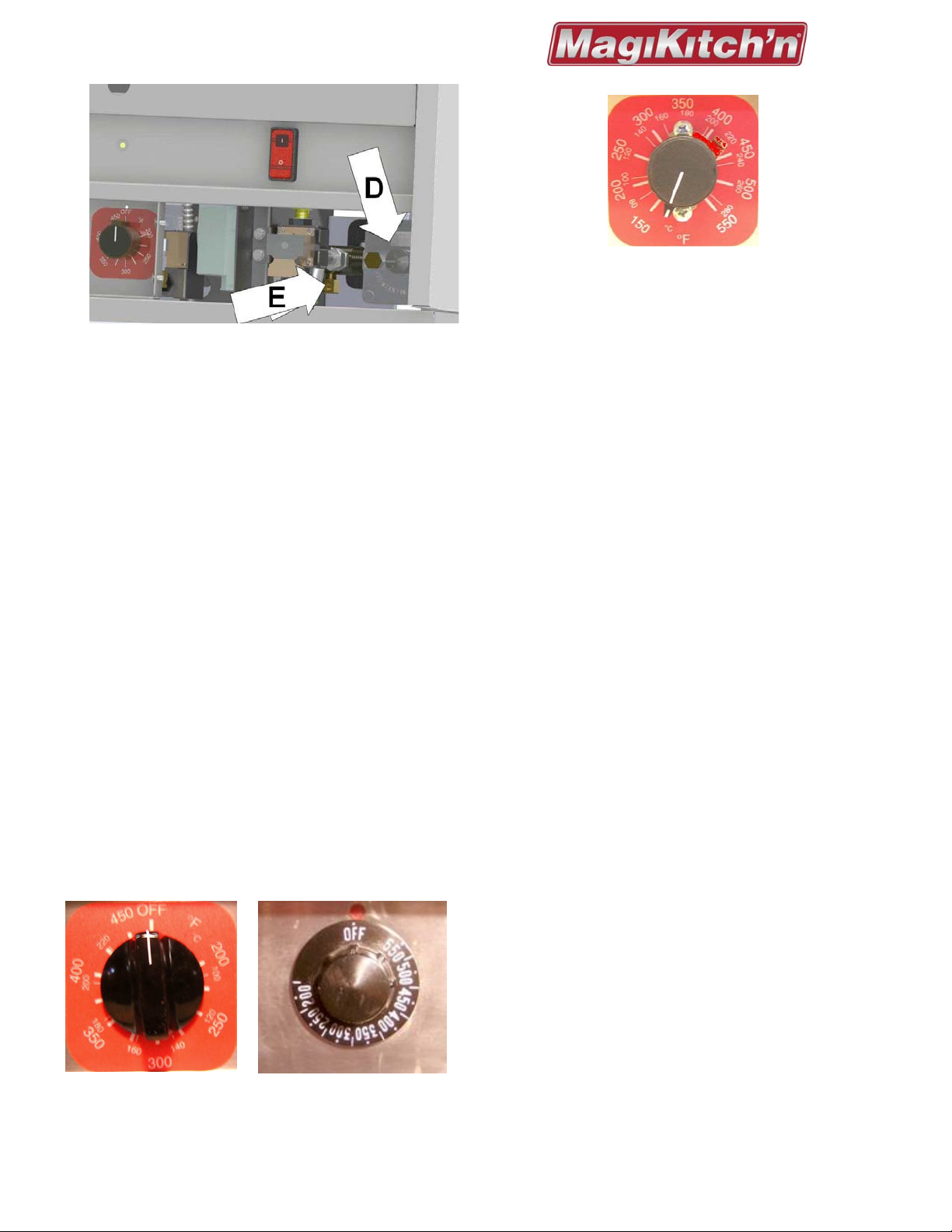

2.3 TEMPERATURE CONTROL SYSTEMS

Snap action appliances have bulb and capillary

style “Gas Operated” thermostats. The

thermostat has a temperature range of 200° to

450°F, See Photo 3.

Electric thermostat (-E) models have a bulb and

capillary style “Electro-mechanical Operated”

thermostats. The thermostat has a temperature

control range of 200° to 550°F, See photo 4.

Photo 3

Photo 4

Photo 5

The Solid State (-ST) model has temperature

control system consisting of a solid state

board, and a Thermistor probe. The sensing

probe is connected to the control board via

“push-on” terminals. The control has a

temperature range of 150° to 550°F, See

Photo 5.

Notice:

Matchless Ignition (E/ST) models have flame

proving park ignition systems. An external power

supply is required on these models.

Notice:

The sensing bulbs or Thermistor probes for each

of the controls are embedded in a slot on the

underside of the cooking surface. The Snap-Action

and Electric thermostat bulbs are “pressed” into

the slot. The Thermistor probe is “inserted” into a

hole at the end of the slot.

3 Temperature Calibration

Each temperature control operates a twelve- (12)

inch zone. Each zone consists of two burners

(except for zones containing a left or right grease

chute/trough). There are three different control

options as noted in Section 2.3. The controls are

factory set. However, if the cooking surface

temperature varies greatly from the setting on the

thermostat knob, adjust the thermostat using the

following procedure:

3.1 TEMPERATURE MEASUREMENT:

Using a calibrated instrument with a surface probe,

measure the temperature in the center of each

zone, 12” in from the front edge of the cooking

surface. The zone centers are located side to side

by the following: (1) Matchless ignition I/O

switches, (2) Snap-Action thermostat knobs, or (3)

Arrows located on the griddle front top rail. The

zone should run at set temperature for at least 30

minutes to allow the zone to stabilize prior to the

calibration check. The temperature will vary with

burner cycling but should stay within +/- 15° F of

the knob setting. The thermostat knob should

indicate the average temperature of the

corresponding zone. If adjustment is required,

follow the instructions in Section 3.2 for the control

type in use.

Page 6 L22-362 Rev 2 (11/12)

Page 7

Technical Service Manual

MKG/MKH/MKGD Series Gas Griddles

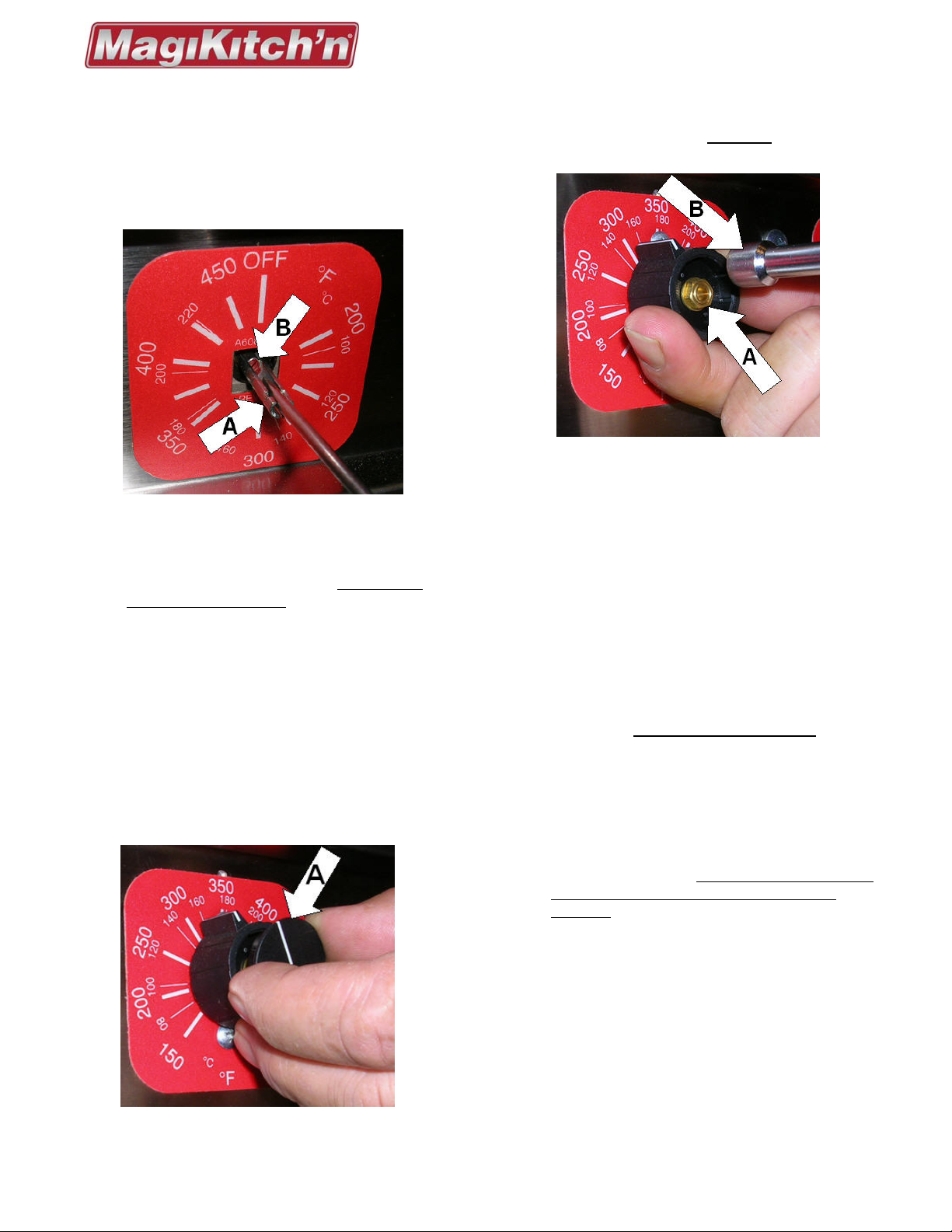

3.2 CALIBRATION PROCEDURES:

3.2.1 Snap Action and Matchless (E) Series

Light pilots as described in section 2.1.

Set thermostat knobs to the desired

Photo 6

temperature and allow cooking surface to

stabilize for 30 minutes (1 hour if cold).

Remove the knob to expose the screw in the

center of the thermostat shaft. Do not allow

thermostat shaft to turn. For snap action

thermostat knobs refer to section 4.1.1. For

electric thermostat (E Series), remove knob by

pulling straight off thermostat shaft.

Remove any sealant over the head of the screw

with the tip of your screw driver.

Tightly hold the thermostat shaft (A) and turn

the adjustment screw (B) in small increments to

shift temperature (1/4 turn is approximately

30°F.). To increase temperature, turn the screw

counter-clockwise, or to reduce temperature

turn screw clockwise.

Snap Action thermostat, See photo 6.

Photo 7

Electric thermostat, (E Series), use same

sequence as Snap Action thermostat. Electric

thermostat appliances DO NOT

have a

temperature indicator label.

Photo 8

Check temperature after 15 minutes. Repeat

procedure until all zones are maintaining the

correct temperature.

3.2.2 Matchless (ST) Series

Turn on all power switches.

Set knobs to the desired temperature.

Allow appliance to stabilize for 30 minutes (1

hour if cold).

Carefully remove knob cap (A), See Photo 7.

Hold knob firmly in place and loosen the 5/16”

retaining nut (A) with an appropriate socket or

nut driver (B), See Photo 8.

NOTE: Do not remove the knob.

Once the retaining nut is loose, pull straight

out on the knob to insure that the knob can

move freely on the shaft.

Align the white indicator line with the average

temperature of the corresponding cooking

zone.

Hold knob firmly on shaft, while retightening

the retaining nut (A), do not allow knob or shaft

to move or temperature setting will not be

accurate.

Replace knob cap as seen in Photo 7, the

white indicator lines on the cap and knob

should line up with each other.

NOTE:

Diagrams or photos may have some parts or

details removed for clarity. Actual appliances

may appear differently.

L22-362 Rev 2 (11/12) Page 7

Page 8

Technical Service Manual

MKG/MKH/MKGD Series Gas Griddles

4 Component Check & Replacement

With the exception of calibration, appliance control

checks or replacement May

control cover front panels. The front panels are

removed as follows:

require removal of the

Photo 9

4.1.2 Matchless Series (E & ST)

To remove the left lower panel (A), remove the

grease box from the appliance. Then remove

two (2) 10-24 truss head screws (B) from the

inner flange, See Photo 11.

Photo 11

To remove the right lower panel (C), remove

the two (2) 10-24 truss head screws (B) that

secure it to the inner flange. With the

mounting screws removed, the left and right

lower panels swing away from the appliance

and will release from the retaining clips, See

Photo 12.

Photo 10

4.1 DISASSEMBLY OF FRONT PANELS

4.1.1 Snap Action Series

Remove all thermostat knobs by loosening the

shaft retaining (set) screws (A), located in the

bottom of the knob, See Photo 9.

Remove all #10 self threading screws (B),

With the lower panels removed from the

appliance you will have access to the gas

valves, ignition modules, and temperature

controls.

Photo 12

holding the upper control panel (C) in place.

Lower door panel(D) rotates down to allow

access to gas train components.

Slowly pull front panel away from front of

appliance and place in a safe location. Be

careful not damage the Piezo ignition wire as it

will still be attached at this step.

See Photo 10, Using needle nose pliers,

carefully disconnect the Piezo ignition wire(A),

from the Piezo ignitor assembly(B). The upper

panel is now disassembled from the appliance.

Photo 12a

Page 8 L22-362 Rev 2 (11/12)

Page 9

Technical Service Manual

MKG/MKH/MKGD Series Gas Griddles

To remove the upper switch panel, remove the

#10 self threading screws,(D in Photo 12a),

similar to those of the snap action panel. This

will give access to the burner manifolds.

Verify both terminal connections of the ignition

wire, (A, in Photo 10), and check the wire for

visible damage and electrical continuity.

Note: Front panel must be “grounded” to the

appliance to establish sufficient spark

Check to ensure that the Piezo ignitor, (B, in

Photo 10). is tightly mounted to the panel. A

loose connection may create an open

“ground”.

Inspect the electrode(B), and the ceramic

insulator(E) for visible damage, See Photo 14.

Verify the spark gap between the electrode(B),

and the pilot hood(A), nominal gap is .090”.

Photo 12b

The panel will be loose, but there will wire

harness connections that may need to be

disconnected to put the panel aside for further

service, the 9 position plug(s) connect the

switch panel to the gas valve assemblies, and

the 6 position plug(s) connect the switch panel

to the thermostat controls, See Photo 12b.

Important!

Carefully support switch panels so wiring

connections will not be strained. Failure to

comply may cause wiring damage.

Remove the temperature control mounting

panel by removing the four (4) 10-24 truss head

screws, see photo 13.

Photo 14

If all parts are in good condition, check for

sufficient spark by first removing the ignition

wire,(C) from the electrode terminal.

Hold the “open” terminal of the ignition wire

1/8” from front panel with insulated pliers, and

depress the red button of the Piezo ignitor.

Check for a visible spark to the panel, See

Photo 15.

If no spark is produced, replacement of the

Piezo ignitor may be required.

Photo 13

To replace the piezo igniter, remove the

ignition wire from the igniter and set aside.

Remove the igniter from the panel by

Disconnect all wiring harness’ and place both

loosening the igniter retaining nut.

the switch panel, and the control panel in a safe

location so they will not become damaged.

Once the panels have been disassembled from

the unit, there will be access to the gas valves,

pilots, fuse(s), and ignition modules.

4.2 PILOT / IGNITION SYSTEM CHECK

4.2.1 Ignitor Check- Snap Action Series

Verify actuation of Piezo ignitor by depressing

red button on front panel, (A in Photo 1). A loud

“click” or “snap” sound should be detected.

Photo 15

L22-362 Rev 2 (11/12) Page 9

Page 10

Technical Service Manual

MKG/MKH/MKGD Series Gas Griddles

Install new Piezo ignitor in reverse order,

making sure to replace all hardware, and insure

all wires and gas tubing are re-connected to

original condition.

4.2.2 Spark Failure- Matchless (E & ST) Series

Turn on power switch, look and listen for a

steady arc from the pilot assembly. An unstable

arc may be caused by spark leakage, or an

insufficient gas supply to the pilot.

Spark leakage can be due to an excessive

spark gap between the pilot(A), and the

electrode(B), nominal gap is .090”. Damaged

parts, or a loose Ignition wire at the spark

terminal(C), may result in spark leakage also,

See Photo 16.

Photo 16

Inspect all parts and wiring connections for form

fit, function, and repair or replace as needed.

Insufficient gas supply to the pilot can be

caused by a dirty pilot orifice(D), or insufficient

gas supply pressure. The gas for the pilot line is

supply from the incoming gas supply before the

regulator that controls the manifold pressure.

Disconnect pilot tubing from pilot to access the

pilot orifice(D), the pilot orifice is threaded into

the pilot(A), use an open end wrench to remove

the orifice, clean or replace as needed.

The pilot mounting bracket (E) shown in photo

16 is for MKH models. The pilot Bracket may

appear differently for MKG and MKGD models.

If no spark is evident, check for 24 VAC to the

ignition module between the 24V terminal (A)

and chassis ground, also verify all other

ground connections, See Photo 17.

Photo 17a

Access to the ignition module (A), can be

gained by removing two (2) self tapping

screws (B) to dismount the mounting bracket,

wiring not shown for clarity, see Photo 17a.

If 24 VAC IS NOT

present at the ignition

module, check that the external power cord (B)

is plugged in to live 115V outlet, and securely

plugged into the power supply box (A). Check

all connections for any jumper cords (C) that

may be present to see that they are tight, and

securely fastened into the power supply box

(C), See photo 17b.

If 24 Vac is still not present at the ignition

module, check the 24 Vac inline fuse for

continuity, it is located on the output side of the

power supply box. Also check the output

voltage of the transformer located in the power

supply box, refer to section 4.13.

If 24 VAC IS

present at the ignition module,

but no spark generated, replace the ignition

module, See Section 4.3.

Photo 17

Page 10 L22-362 Rev 2 (11/12)

Page 11

Technical Service Manual

MKG/MKH/MKGD Series Gas Griddles

4.2.3 Insufficient or Absence of Flame:

An insufficient pilot flame can result in a loss of

flame sense to the ignition module on a

Matchless ignition appliance, or loss of

sufficient mill voltage to actuate the safety valve

on a Snap Action appliance.

Photo 18

Look through the pilot view ports and check for

the pilot flame originating from the pilot hood

(A). A strong flame should visibly extend above

each pilot runner tube (B). If flame is not visible,

the ignition system may fail to activate the main

burner system See Photo 18.

the gas regulator. Pilot gas flow on matchless

ignition models can be adjusted with a needle

valve (A, in photo 18a) to increase pilot flame

after all pressures have been verified at the

nominal settings.

Pilot orifices can be checked by disconnecting

the ¼” tubing from the pilot assembly, (D, in

Photo 14 for Snap Action, and D, in Photo 16,

for Matchless Ignition models. Refer to section

4.4 for pilot removal from the appliance.

The gas flow to the pilot can be checked by

connecting a manometer to the disconnected

¼” tubing going to the pilot. Refer to Section 2

for each model to initiate gas flow to the pilot.

4.2.4 Pilot Lock-in: Snap Action Series

If a sufficient pilot flame is present, but the

main valve will not engage, check the millivolt

output of the thermocouple (F, in Photo 14) .

Disconnect the thermocouple contact (D, in

Photo 41) from the safety valve and measure

the output between the contact and ground.

Open circuit output should be greater than

15mv. closed circuit should be greater than

8mv (thermocouple connected).

Note: To measure a closed circuit use of a

thermocouple test adapter. The thermocouple

contact must not be cross threaded, and must

be tightened to1/4-1/2 turn past finger tight.

If the millivolt output does not meet the

minimum voltage, replace thermocouple.

Photo 18a

Common causes of insufficient pilot flame are

NO,

or LOW gas supply pressure, a pilot orifice

that has become clogged with foreign debris.

Verify gas pressure at the manual shut off

valves, (C), in Photo 1 for Snap Action models,

and (C), in Photo 2a for Matchless Ignition

models. The table in Section. 1.2.1 has the

nominal gas pressure for each gas type.

Pilot gas supply on matchless ignition models is

supplied before the gas regulator. The gas

pressure should be the nominal supply

pressure listed for the type of gas being used.

If the thermocouple is properly connected, and

the millivolt output is sufficient (25-35mV, No

Load), but safety valve will not engage,

replace the safety valve, see section 4.11.

If pilot flame and millivolt readings are normal

but there is no flame at the main burner, check

thermostat operation, refer to section 4.9.1.

Photo 19

Pilot gas flow on snap action models cannot be

adjusted since it is dependant on the setting of

L22-362 Rev 2 (11/12) Page 11

Page 12

Technical Service Manual

MKG/MKH/MKGD Series Gas Griddles

4.2.5 Pilot Lock-in- Matchless Series (E & ST)

The electronic ignition system is an integral

flame sense system. This means that the

module supplies spark, and senses flame

current with the same electrode. The pilot

assembly, ignition module, and the appliance

must be properly grounded to operate properly.

The ignition module is grounded to the chassis

directly at the pilot bracket (A, in Photo 19). The

appliance is equipped with a NEMA 5-15

grounded plug, extension cords are not

recommended for use with the appliance.

Photo 20

When properly grounded, and adequate pilot

flame are established as described in section

4.2.2, but spark continues for 90 seconds

followed by an ignition module lock out, there is

a flame sense failure. Replace the ignition

module as described in section 4.3.

Photo 21

4.3 IGNITION MODULE REPLACEMENT

Remove the two (2) self tapping screws (A)

holding the ignition module bracket in place,

See Photo 20. Take care not to damage any

wiring or terminals.

Disconnect ignition wire (B) from the spark

terminal, and control wiring (C) from the 24 Vac

terminal by carefully pulling upward on the wire

terminals with electrical pliers. It is advised to

label the wires to avoid miss wiring the new

ignition module.

Remove module from the bracket by removing

the two (2) 6-32.mounting screws (B), See

photo 20.

Mount the new module to the bracket with the

6-32 screws removed from the old module.

Wire the module with the 24Vac control wiring,

and the high voltage ignition wire. Refer to the

schematics in Section 5 of this manual to avoid

miss wiring the control.

Remount the assembly back onto the

component bracket. Take care to route the

wiring harness to avoid straining terminal

connections or pinching wires.

4.4 PILOT ASSEMBLY REPLACEMENT

Pilot assemblies and are held in place by two

(2) screws (A). The assembly can be accessed

from under the burners, See Photos 19.

Remove the Ignition wire (C), the ignition wires

may appear differently between snap action

models, and matchless ignition models.

Loosen gas line fitting (B) prior to removing

mounting screws (A). The screws will stabilize

the pilot assembly during this procedure.

Remove the mounting screws (A) and pull pilot

assembly down until clear from burner

chamber. Remove the tubing and change

orifice and pilot burner as needed.

Install new assembly in reverse order, verify

nominal spark gap, see sections 4.2.1 & 4.2.2.

4.5 BURNER ADJUSTMENTS

To maintain optimum griddle performance, the

burners, and burner manifold must be properly

aligned, and the air inlets free of debris.

Misalignment of the burner manifold (D), or an

obstructed air shutter (B) opening can cause

incomplete combustion, or yellow flames at the

burner ports, See Photo 22.

To align the burner manifold (D), loosen, or

tighten manifold Bracket screws (E) until the

manifold orifices are in line with the burners.

The air shutters (B) are opened fully for all gas

types, if flames appear yellow, check for any

obstruction in the air inlet, clear as necessary.

If flames appear to blow off the burner ports,

loosen the air shutter screw (C) adjust shutter

(B) CCW until flames settle down, then

retighten the screw(C). If yellow flame occurs,

adjust the air shutter(B) CW until all flames are

blue. Note: The appliance must be cold when

making this adjustment.

If appliance is hot, above 300°F., make certain

that burner flame cones are well defined and

Page 12 L22-362 Rev 2 (11/12)

Page 13

Technical Service Manual

MKG/MKH/MKGD Series Gas Griddles

that there are NO yellow flames. If yellow flame

appears, open air shutters gradually until

flames are blue. Check for proper burner

ignition after allowing the appliance to be off for

10 minutes. Note: Proper ignition is when all

burner ports are lit within 4 seconds.

4.6 ORIFICE/FUEL TYPE CONVERSION

Poor performance may be an indication of a

clogged or damaged burner orifice that needs

replacement. In addition, the gas type of the

appliance may need to be changed to another fuel,

see section 1.2.1 for approved gases.

While securing the manifold in a safe manner,

remove the two main burner orifices( A), and

the runner tube orifice(B). Take care to not

damage the brass fittings or pipe threads, See

Photo 24.

Prior to installing the new orifices, insure that

the fittings are not clogged, and reapply thread

sealant to all male threads where necessary.

Install new orifices onto manifold as stated

above, if no further service is required replace

manifold to original position.

Photo 24

Photo 22

4.6.1 Changing Burner Orifice

To replace clogged, or convert burner orifices follow

the steps below: Refer to section 1.3.2 to check the

proper orifice size for the appliance.

After the upper front panel has been removed,

remove the mounting screws (E), then slide the

manifold bracket(D) off of the burner manifold,

See Photo 22.

If Converting Fuel Type, continue here:

Change orifices as described in section 4.6.1.

Change pilot assembly, see section 4.4.

Change the gas supply regulator (D, photo’s

1a & 2a), a new regulator will require thread

sealant on all mating male threads.

Perform a gas leak test, and check operating

gas pressure of the appliance, see section

1.2.1. Insure that burners are operating in

accordance with section 4.5.

Place the appropriate information label stating

the change in fuel type of the appliance in

close proximity to the data plate, or other

prominent area.

4.7 MAIN BURNER REPLACEMENT

If a burner needs to be removed for replacement

or cleaning, use the following procedures:

Disconnect the manifold supply tubing at the

brass compression fitting(A). the manifold will

slide out of the burners and runner tube, See

Photo 23. Note the thread engagement of the

orifices for reinstallation, See Photo 24.

Photo 25

L22-362 Rev 2 (11/12) Page 13

Page 14

Technical Service Manual

6

MKG/MKH/MKGD Series Gas Griddles

Remove the manifold, see section 4.6.1.

Remove the mounting screws (C) from the pilot

cover plate (A), and the burner seal plate (B),

See Photo 25.

Note: Some burners may require two (2) pilot cover

plates to be removed to access the burner(s).

Photo 2

Remove the pilot cover plate and the burner

seal plate and set aside for reuse later.

Remove the runner tube mounting screws(C)

and remove the runner tube and set aside, See

Photo 26. There are left and right hand pilot

runner tubes so take care to keep parts

identified for reinstallation.

Lift up the burner (B) to be removed slightly and

pull straight out through the front of the griddle,

See photo 27. The will slide off the indexing pin

located at the rear of the burner mount bracket.

Install the replacement burner into the mounting

bracket.

4.8 GAS PRESSURE ADJUSTMENT

Before checking the operating pressure of the

appliance, the incoming supply pressure to the

appliance must be verified. The minimum dynamic

pressure for natural gas is 5.0” WC, and LP gas is

11.0” WC.

Important! Make sure the manual shut off valve

is in the closed position prior to making any

test connections.

With the shut off valve is closed, connect a

manometer to the pressure tap on the shut-off

valve (C), See Photo 29.

Note: On Snap Action models the shut-off is valve

behind the front panel, See Photo 1 in section 2.1.

Photo 29

Open the shut of valve and verify the incoming

pressure as stated in section 1.2.1.

If incoming supply pressure is correct the

Photo 27

Make certain that the end of the burner (B) is

located on the indexing pin (A) of the burner

mounting plate, See Photo 28.

Re-install the remaining screws, runner tube

and sheet metal in reverse order. Insure that all

burners, runner tubes, and pilots have been

properly positioned for optimum performance

after the repair.

manifold gas pressure can be adjusted as

needed.

NOTE: A properly sized and installed gas line will

deliver a minimum supply pressure of 7.0” W.C.

(17.4mbars, 1.74kPa) natural gas or 11.0” W.C.

(27.4mbars, 2.75kPa) propane to all appliances

connected to the supply line, operating at full

demand. If regulated gas pressure cannot be

achieved with all appliances in the store running,

there may be a building gas supply deficiency.

Page 14 L22-362 Rev 2 (11/12)

Page 15

Technical Service Manual

MKG/MKH/MKGD Series Gas Griddles

The gas pressure regulator on matchless

ignition models is located behind the right hand

lower panel at the front of the unit, (See D in

Photo 2b). The manifold pressure is checked at

the pressure tap (E), see Photo 29.

The gas pressure regulator (D) on snap action

models is located in the rear of the unit. The

manifold pressure is checked at the shut off

valve pressure tap (C), see Photos 1 & 1a.

Photo 29a

To adjust manifold pressure, remove the

regulator cap (A), to expose adjustment screw

(B). Turn CW to increase pressure, or CCW to

decrease pressure, See Photo 29a.

The pressure should be adjusted while all the

burners are “ON”, set the manifold pressure in

accordance with section 1.2.1.

If gas pressure will not change, verify that vent

fitting (C) is free from grease or debris. The

vent has a hole in the side of the fitting.

If supply pressure is adequate, but proper

manifold pressure cannot be obtained, replace

regulator.

Photo 30

4.9 TEMPERATURE CONTROLS CHECK

4.9.1 Snap-Action Models

If there is no burner response when the

temperature control has been activated, verify that

gas is supplied by the safety valve as follows:

Remove front panels, refer to Section 4.1.

Turn off gas at the manual shut-off valve, See

Photo 1.

Disconnect 3/8” supply tubing from thermostat

inlet (A), and attach pressure test equipment to

open tubing, See Photo 30.

Light the pilot and engage Safety valve, refer

to Section 2.1.

Once the safety valve is engaged, gas should

flow through the 3/8” tubing (A) and there

should be a pressure reading at the

manometer. If there is pressure at the 3/8” inlet

tubing (A) the safety valve is operating, and

the thermostat gas flow should be verified. If

there is no pressure indicating gas flow, test

the operation of the safety valve (D, Photo 30),

refer to Section 4.2.4.

Shut down the appliance in accordance with

the operators manual and reconnect the inlet

tubing (A) to the thermostat.

Disconnect the thermostat outlet fitting (B),

and connect a manometer to the brass elbow.

Light the pilot and engage Safety valve, refer

to Section 2.1.

Turn the thermostat (C) on and check for gas

pressure at the outlet fitting (B), If there is no

gas pressure coming from the outlet replace

the thermostat, refer to Section 4.10.1

4.9.2 Matchless “E” Models

If there is no burner response after start up, verify

electrical supply to the Electric thermostat control

and operation of the contacts as follows:

Remove the lower front panel(s), refer to

Section 4.1.2.

Light pilots as in Section 2.2, when pilots are

lit, turn all thermostats to the “Off” position.

Using a voltmeter, check for 24 VAC input to

the thermostat (A), measure across the orange

wire (B) and Chassis Ground, See Photo 31.

If voltage is not present and the pilots are

operating, verify 24 VAC output voltage from

MV terminal (D) on the ignition module, See

Photo 32. If there is no voltage at MV terminal

check the function of the ignition module, refer

to Section 4.3.

If voltage is present at the MV terminal, check

the operation of thermostat contacts by

measuring an electrical open/close of contacts

when turning the thermostat “Off” and “On”.

Measurements are taken between contacts(B

& C). Resistance continuity can also be tested

L22-362 Rev 2 (11/12) Page 15

Page 16

Technical Service Manual

MKG/MKH/MKGD Series Gas Griddles

across these contacts by turning off electrical

power and disconnecting one wire from

terminal B or C, See Photo 31.

Photo 31

If temperature controls fail to respond, or

cannot be calibrated to operate according to

Section 3.2, replace control, refer to Section

4.10.

4.9.3 Matchless “ST” Models

If there is no burner response, verify electrical

supply to the Solid State control and operation of

the contacts as follows:

Photo 33. (Note: The white wires (B) is the

common Neutral wire.

If there is no voltage at the blue wire (A)

terminal check the output of the corresponding

rocker switch on the upper panel.

If there is no voltage present at the orange

wire (D) terminal, check output voltage of MV

terminal at the ignition module (The other end

of orange wire), See Photo 32.

If 24-volt input is measured at both the blue

and orange wires, check for 24 volt output on

the gray or violet wire (C) with the control set

to the maximum temperature setting. This

output supplies voltage to the gas solenoid for

the main burners.

Photo 33

Photo 32

Remove the lower front panel(s), refer to

Section 4.1.2.

Light pilots as in Section 2.2, when pilots are lit,

turn all controls to the minimum temperature

setting until the next step.

Turn the control to the maximum temperature

setting, Using a voltmeter, check for 24 VAC

across the blue wire (A), and white wire (B)

terminals. Also check for 24 VAC across the

orange wire (D) and white wire (B) terminals.

Voltage is necessary on both input lines, See

If there is no output voltage on wire terminal

(C), then check the sensor probe for the

proper resistance, Refer to Section 4.9.4.

If all the above conditions are satisfactory and

no main burner response, refer to Section

4.10.3 to replace the control.

4.9.4 Temperature Probe Check:

Resistance of the Temperature Probe changes as

the temperature changes. As temperature rises,

the probe’s resistance decreases.

If the probe is suspect, remove wire

connections (E) from the Solid State

temperature control, See Photo 33.

Using a multi-meter, check the probe

resistance against the cooking surfa ce

temperature. Use the Resistance Chart in

Section 4.9.5 to compare the two values.

Note: Measure surface temperatures

according to section 3.1.

If the probe measures open circuit (OL),

shorted (0 Ohms), or if the resistance is +/-30

Ohms from the chart value, replace the probe,

refer to Section 4.10.4.

Page 16 L22-362 Rev 2 (11/12)

Page 17

Technical Service Manual

MKG/MKH/MKGD Series Gas Griddles

Remove the Pilot cover plates and burner seal

plates to access thermostat sensor, Refer to

Section 4.7.

NOTE: Do not remove bulb clamp.

Loosen the sensing bulb clamp(A) from griddle

plate by removing the two (2) mounting

screws(B). This bulb clamp is spring loaded

and the sensing bulb can be removed by

pushing downward on the bottom edge(C) of

the clamp, See Photo 34.

Photo 35

IMPORTANT! Before performing any

service to this appliance, make sure any

4.9.5 Resistance Chart: Solid State

Thermistor Probe

Degrees

Celsius

(°C)

Degrees

Fahrenheit

(°F)

Resistance

Ohms ()

0 32 1000.000

20 68 1077.928

40 104 1155.392

60 140 1232.392

80 176 1308.928

100 212 1385.000

120 248 1460.608

140 284 1535.751

In

Gas or Electrical supplies are turned off

and disconnected

Pull the sensing bulb “Out & Down” from the

slot, the loosened bulb clamp will move so the

bulb can be removed.

With the sensing bulb removed, the control can be

disconnected and removed from the appliance:

Disconnect inlet(A) and outlet(B) gas tubing

from thermostat.

Remove mounting screws(C), save for re-use.

Install replacement thermostat in reverse

order. Make certain that there is no strain on

the flexible gas tubing, or the capillary line for

the thermostat.

160 320 1610.430

180 356 1684.645

200 392 1758.396

220 428 1831.683

240 464 1904.505

NOTE: For best results check while the unit is hot,

between 320-374°F, (160-190°C).

4.10 TEMPERATURE CONTROL

REPLACEMENT

4.10.1 Snap Action Models

The thermostat sensing bulb is pressed into a

slot on the underside of the cooking surface.

The sensing bulb should be removed from this

slot first:

Remove the burner manifold bracket, and

burner manifold for the corresponding control to

be replaced. Refer to Section 4.6.1.

Insure that the sensing bulb is seated firmly up

into the slot prior to securing the bulb clamp in

position.

Photo 36

4.10.2 Matchless “E” Models

Remove sensing bulb according to section

4.10.1

Carefully disconnect the “push-on” wire

terminals(B&C) from the thermostat with

needle nose pliers or other adequate tool,

Photo 31.

Pull the thermostat knob off the thermostat

shaft. Remove the thermostat from the

mounting bracket by removing the two

Photo 34

exposed screws(A) found under the knob, See

Photo 37.

L22-362 Rev 2 (11/12) Page 17

Page 18

Technical Service Manual

MKG/MKH/MKGD Series Gas Griddles

NOTE: If necessary, the thermostat mounting

bracket can be carefully dismounted to allow

additional access to the controls.

Install replacement thermostat in the reverse

order.

CAUTION: Do not allow the capillary to short

circuit electrical connections.

Photo 37

4.10.3 Matchless “ST” Models

Remove the Solid State control knob by

loosening the locking nut(A, Photo 8) under the

knob cap(A, Photo 7).

Pull the control knob off the shaft. Remove the

Solid State control from the mounting bracket

by removing the two exposed screws(A) found

under the knob, See Photo 38.

Carefully disconnect the wires from the Solid

State control with needle nose pliers or other

adequate tool, See Photo 33).

4.10.4 Thermistor Probe Replacement

The Solid State control has a separate

temperature sensing probe, the thermistor probe

can be removed without removing the Solid State

control.

Remove the upper panel assembly according

to Section 4.1.2.

Remove the burner manifold bracket, Pilot

cover plate, and the burner seal plates

according to Sections 4.6 & 4.7.

Photo 39

Remove the two (2) screws (A) that hold the

probe retention plate in place, See Photo 39.

Slide the probe and plate outward together.

Disconnect the probe wires (E) from the Solid

State control, See Photo 33.

Photo 40

Slide the defective probe out from the retention

Photo 38

plate. Insert replacement probe into the

vacated hole of the plate to install together

Note: Label the wires for rewiring the control,

miss wiring could damage the appliance.

Install the replacement control in reverse order,

calibrate the control according to Section 3.2.2.

Locate the probe hole (A) in the rear of the

sensing bulb slot, carefully align, and slide the

thermistor probe all the way into the slot, See

Photo 40.

Slide the retention plate up to the “V” bracket

and align the mounting holes and secure with

“New” self tapping screws if available.

Page 18 L22-362 Rev 2 (11/12)

Page 19

Technical Service Manual

oto

MKG/MKH/MKGD Series Gas Griddles

4.11 SAFETY VALVE REPLACEMENT

Snap Action Models

If the test criteria from Section 4.2.4 have been met,

but the appliance does not operate properly,

replacement of the Safety valve may be required.

Shut off gas supply to appliance at the 1/2“

manual shut off valve(C), See Photo 1.

Remove the lower front panel(s) and the

temperature control panel, refer to Section

4.1.2.

Disconnect the pilot valve outlet tubing (B)

from the needle valve, See Photo 42.

Remove the two (2) mounting screws (A) that

hold the pilot gas in place. With the screws

removed you will be able to pull the pilot valve

towards you, be careful to not stress the

flexible pilot supply tubing, or the wire harness,

See Photo 42.

Ph

41

Disconnect 1/2” gas inlet(A) connection, 3/8”

gas outlet(B) connection(s), pilot gas outlet(C)

connection, and the pilot thermocouple(D)

connection, See Photo 41.

Note: Insure correct gas flow direction on the

replacement valve

Disassemble piping and fittings from defective

gas valve, and assemble onto the replacement

gas valve in the same orientation. Use pipe

sealant compound on all male threads.

Once piped, install the replacement valve into

the appliance. Re-secure all gas connections to

be leak free.

Re-attach the thermocouple to the safety valve

junction, take care to thread part correctly,

cross threading the junction may result in

component failure.

Test appliance for leaks, and proper operation

of the burner system.

4.12 SOLENOID VALVE REPLACEMENT-

Matchless Models “E” & “ST”

If all test criteria has been met according to

Section(s) 4.2.2 & 4.2.3, it may be required to

replace the either the pilot gas or main gas valve

solenoid.

4.12.1 Pilot Solenoid Valve

Disconnect the power cord from the electrical

supply, and shut of the gas supply at the

manual shutoff valve(C, Photo 2a).

Photo 42

Disconnect the 24 Vac supply wiring (A) from

the solenoid terminals, See Photo 43.

Disconnect the pilot valve outlet flexible

tubing(C) from the rear of the valve, See Photo

43. The valve and bracket can be removed

from the unit..

Photo 43

Remove the existing piping from the defective

valve, and install the piping and bracket onto

the replacement valve. Use Fluropolymer

thread tape where necessary.

Re-install the pilot valve assembly back into

the unit in the reverse order of removal.

The pilot solenoid(D), and the main burner

solenoid(E) are connected by a single pipe

nipple. Twist the two(2) solenoids apart and

replace the bad component.

L22-362 Rev 2 (11/12) Page 19

Page 20

Technical Service Manual

MKG/MKH/MKGD Series Gas Griddles

4.12.2 Main Burner Solenoid Valve

To replace a faulty main burner solenoid valve it

may be required to disconnect both of the main

burner solenoids from the gas valve assembly.

Some assemblies may only have a single main

burner solenoid.

Disconnect the power cord from the electrical

supply, and shut of the gas supply at the

manual shutoff valve(C, Photo 2a).

Remove the lower front panel(s) and the

temperature control panel, refer to Section

4.1.2.

Label the wiring (A) on the solenoid valves to

avoid miss wiring the valves. miss wiring the

solenoid valves can cause damage to the unit,

and cause the unit to operate improperly.

Remove the two (2) mounting screws (D)

holding the solenoid valve brackets to the

assembly, See Photo 44.

The valve assembly is not completely

disconnected, the inlet tubing to the solenoid

valves is still connected in the rear of the

valves. Gently move the assembly aside,

taking care not to strain the flexible inlet

tubing.

Disconnect the 3/8” Flexible inlet tubing (E),

See photo 45. Single valve assembly shown

for clarity. The valve assembly is now free

from the unit and the valves may be

disassembled.

Photo 44

Disconnect the wiring (A) from the solenoid

valves. Place the wiring neatly to the side to

avoid damaging the wires, See Photo 44.

Label and disconnect both of the 3/8” flexible

outlet tubing to the burner manifolds, first tubing

(B), then tubing (C), See Photo 44.

Photo 45

Photo 46

Remove the existing piping from the defective

valve(s), and install the piping and bracket

onto the replacement valve. Use Fluropolymer

thread tape where necessary, See photo 46.

Page 20 L22-362 Rev 2 (11/12)

Page 21

Technical Service Manual

MKG/MKH/MKGD Series Gas Griddles

4.13 POWER SUPPLY TRANSFORMER

MATCHLESS MODELS “E” & “ST”

There is one (1) power supply box with a 80 VA

transformer that controls one (1) ignition module

and gas valve assembly. Each additional module

and valve assembly are connected to the 120 Vac

supply with IEC jumper cables.

4.13.1 Power Supply Transformer Check

To check the operation of the transformer first

check the inline fuse (A), See Photo 47.

Prior to replacing the transformer, inspect all

the wiring for damage, and make sure all

connections are secure.

4.13.2 Power Supply Transformer

Replacement

Disconnect the power cord from the electrical

supply.

Disconnect the power cord (B), and the IEC

jumper cable (C) from the power supply box to

be serviced, See Photo 17b.

Disconnect the Vac connection (A) to the

control circuitry of the appliance, See Photo

48. Access to the connection is from the rear

of the unit, the red arrows display a path.

Photo 47

Disconnect the power cord from the electrical

supply.

Remove the lower front panel(s), and the

temperature control panel if needed, refer to

Section 4.1.2.

With the panels removed, disconnect the inline

fuse (A) from the switch panel at the .250” red

terminal (B) that corresponds with the

transformer box being tested, See Photo 47.

Place the terminal in a location where it will not

short out to adjacent panels or components and

plug in the 115 Vac power cord into a

functioning outlet.

Using a voltmeter, check for 24 Vac between

inline fuse terminal (B), and chassis ground. If

voltage IS

present the transformer and fuse are

functioning properly.

If voltage IS NOT

present, unplug the 115 Vac

plug from the outlet and remove the 2A fuse

from the inline fuse holder (A), See Photo 47.

Visually inspect the fuse, and using an

Ohmmeter for resistance continuity across the

fuse. If there IS NOT

continuity, replace fuse

and recheck for voltage at the fuse terminal (B).

If there IS

continuity through the fuse, the

transformer may be defective and need to be

replaced.

Photo 48

With the power cord(s) and control wiring

disconnected, dismount the power supply box

from the appliance by removing the front

mounting screw (B, See Photo 48), and the

rear mounting screws (A, See Photo 49).

Note: A 5/16” nut driver or socket is

recommended to remove these screws.

Photo 49

Pull power supply box out of the cabinet and

turn over to access the transformer.

L22-362 Rev 2 (11/12) Page 21

Page 22

Technical Service Manual

5

MKG/MKH/MKGD Series Gas Griddles

Remove the two (2) 10-24 screws (A) that

secure the transformer in the power box and

set aside, then remove the old transformer from

the box. Take care not to put excessive strain

on the connections, See Photo 50.

The wiring connections (B), should be labeled

prior to disconnecting the wires from the

terminals, See Photo 50.

Photo 50

Install the replacement transformer into the

power supply box in reverse order.

Re-install the transformer and the power supply

box with all the removed hardware.

Ensure that all wiring connections are correct

and secure. If any strain relief materials were

removed, make sure to properly secure all

wiring to its original condition.

4.14 SWITCH AND LAMP REPLACEMENT

The upper front panel is where the power switches

and the pilot ready lights are mounted. If the lamps

or switches are damaged, do not illuminate, or

malfunction they should be replaced,

The Pilot ready light (A) will illuminate when

ignition module flame sense has been satisfied.

The power switch (B) will illuminate when the

temperature control for that zone activates the

main burner solenoid valve, See Photo 51.

Remove the Upper and lower front panels as

shown in Section 4.1.2.

With all other components functioning properly,

the pilot ready light (A), should illuminate when

there is 24 Vac across the orange and white

wires connected to the lamp terminals, See

Photo 52.

The power switch (B) will illuminate when there

is 24 Vac across the wire at terminal 5, (red or

red w/ white wire), and the white wire at

terminal 3, refer to schematics in Section 5 for

further information.

To replace a damaged or faulty lamp, first

disconnect the wiring (A) from the terminals on

the lamp. Remove the retaining nut (B) that

Photo

2

secures the lamp to the panel, the lamp can be

removed and discarded. Install replacement

lamp in reverse order, See Photo 53.

To replace a damaged or faulty power switch

label and disconnect the wiring (A) from the

switch terminals. Notice the orientation of the

switch in the panel for reference in installing

the replacement switch, See Photo 54.

Photo 53

Pry the 4 prongs at the corner of the switch

down, and push the switch out of the cutout.

Install the replacement switch in reverse order,

refer to schematics in Section 5 for further

information, See Photo 54.

Photo 51

Photo 54

Page 22 L22-362 Rev 2 (11/12)

Page 23

Technical Service Manual

MKG/MKH/MKGD Series Gas Griddles

5 TROUBLESHOOTING GUIDE

5.1 TROUBLESHOOT GUIDE -SNAP ACTION MODELS

Problem Cause Corrective Action

1. Check that all gas connections are turned

on, and verify gas pressure at the regulator.

2. Verify gas supply, light pilot burner.

3. Turn thermostat to desired temperature.

4. Replace safety valve.

5. Replace thermostat.

1. Replace pilot assembly.

2. Replace pilot assembly.

3. Replace wire.

4. Replace Piezo ignitor.

1. Check that all gas connections are turned

On, verify gas pressure at the regulator.

2. Verify that all connections are fully

Engaged and leak free.

3. Verify that the shut off valve is fully open.

4. Replace safety valve.

1. Calibrate thermostat.

2. Replace thermostat.

3. Set incoming gas pressure according to the

appliance data plate.

4. Verify gas type, Discontinue use until

1. Level cooking surface.

2. Set incoming gas pressure according to the

appliance data plate.

3. Divert drafts away from flue outlet.

4. Diagnose problem with use of this guide

and repair as needed.

Griddle won’t heat.

No pilot spark

No pilot gas

Temperature too low

or high

Griddle surface has

inconsistent

temperatures.

1. No gas supply.

2. No pilot flame.

3. Thermostat turned off

4. Safety valve defective.

5. Thermostat defective.

1. Wrong spark gap.

2. Defective electrode.

3. Defective ignition wire.

4. Defective Piezo ignitor.

1. No gas to Safety valve.

2. Faulty gas connection.

3. Manual shut off closed.

4. Defective Safety valve.

1. Thermostat out of

calibration.

2. Defective thermostat.

3. Incorrect gas pressure.

4. Wrong gas/fuel type.

1. Appliance is out of level.

2. Incorrect gas pressure.

3. Excessive drafts on flue

outlet.

4. A section of the griddle may

be out of service..

L22-362 Rev 2 (11/12) Page 23

Page 24

Troubleshooting Guide

MKG/MKH/MKGD Series Gas Griddles

5.2 TROUBLESHOOT GUIDE - E / ST SERIES

Problem Cause Corrective Action

1. Appliance power cord, Check power at wall

outlet, check appliance fuse.

2. Refer to “Pilot Lock-in” section of manual.

3. Check gas supply pressure, quick disconnect

engagement, shut off valve and regulator.

4. Check actuation and electrical input/output of

part. Replace if defective.

5. Same as 4.

1. Plug in power cord to grounded wall outlet

2. Reset breaker

3. Replace or reconnect appliance inline fuse.

4. Replace Switch.

1. Check for 24 VAC. at module connection.

2. Check connections at both ends of wire and test

for continuity. Replace if defective.

3. Check electrode for damage and correct spark

gap (.090”). Listen for any spark leakage.

replace/repair as needed.

4. Check for continuity between griddle body and

ground prong on plug. Verify internal ground

connection. Replace power cord if ungrounded.

1. Check pilot solenoid valve, check incoming gas

supplies.

2. Set gap to 1/8” (.125”)

3. Check electrode for damage, replace as needed

4. Check all power connections to have a 3 prong

grounded power cord. Note: Extension cords

are not recommended for use with this

appliance.

5. Check supply plumbing for proper gas flow.

6. Make certain that quick disconnect fitting is fully

engaged and snapped in place.

7. Verify that shut off valve is in the open position.

8. Check wiring connections at pilot solenoid and

verify 115 VAC.

9. If voltage is supplied and valve remains closed,

replace solenoid valve.

Appliance won’t

heat.

No power

No pilot spark

Pilot will not stop

sparking

No pilot gas

1. No electrical power.

2. Pilot not lit, or dropping out.

3. Low gas pressure.

4. Thermostat malfunction

5. Gas valve malfunction.

1. Appliance unplugged

2. Wall circuit breaker tripped

3. Internal fuse blown or is

disconnected.

4. On/Off switch defective

1. No power to ignition module.

2. Ignition wire not connected.

3. Broken or bleeding electrode.

4. Improper grounding of

appliance.

1. No gas to pilot burner.

2. Spark gap incorrect.

3. Spark leakage

4. Un-grounded power cord

5. No gas supply

6. Quick disconnect not fully

engaged

7. Shut off valve closed.

8. No electrical input to pilot

solenoid.

9. Pilot solenoid closed

1. Thermostat out of calibration.

2. Thermostat is defective.

Operating

Temperature

incorrect

Page 24 L22-362 Rev 2 (11/12)

3. Solenoid valve defective.

4. Operating on wrong fuel type.

5. Appliance is out of level.

6. Incorrect gas pressure.

7. Drafts on outlet of flue.

8. A zone not heating properly.

1. Refer to calibration section of this manual.

2. Replace thermostat.

3. Replace solenoid valve.

4. Discontinue use. Convert to proper gas.

5. Level appliance in both directions.

6. Refer to Section 1.3 of this manual.

1. Divert drafts away from flue outlet.

2. Diagnose with the use of this manual and repair

as needed.

Page 25

Trouble Shooting Guide

MKG/MKH/MKGD Series Gas Griddles

5.3 SCHEMATIC: MATCHLESS “E” SERIES

TABLE 3, T1

115VAC/60Hz

N

GND

SJTO

16 AWG

J13

TERMINAL

L

L

BLK

N

G

FRAME

WHT

2.5A

VOLTAGE

1

240 VAC

2

208 VAC

3

120 VAC

1

2

3

5

T1

6

10

FRAME

BLU

24 VAC

WHT

J/P10

3

2

1

BRN

LEFT

ON/OFF

S1A

2

S2A

2

RIGHT

ON/OFF

GRN/Y

WHT

MV1 LEFT

MAIN VALVE

MOV

WHT

PILOT VALVE

PV1

MOV

TYPICAL LAST BURNER

WHT

RED

D1B

GND

(5)

MV/PV

(10)

BGND

(4)

HV

(2)

PV

(3)

J/P1-2

J/P1-4

YEL

LT1

A

PILOT OK

P/N 601422801

GRY

HEAT

TC1

TEMP

CONTROL

3

3

BLU

ORG

J/P1-1

J/P1-3

LEFT

ON/OFF

5

6

7R8

S1B

ORG

MV

24V

(1)

(6)

K3

K1

P/N 60152001

IM1

IGNITION

MODULE

TYPICAL TWO BURNER SET

RIGHT

P/N 601422801

HEAT

TC2

TEMP

CONTROL

VIOL

ORG

WHT

ON/OFF

6

7 8

R

5

S2B

W/RED

D2B

J/P1-5

MV1 RIGHT

MAIN VALVE

MOV

L22-362 Rev 2 (11/12) Page 25

Page 26

Troubleshooting Guide

MKG/MKH/MKGD Series Gas Griddles

5.4 SCHEMATIC: MATCHLESS “ST” SERIES

115VAC/60Hz

N L

GND

SJTO

16 AWG

J13

L

N

G

BLK

FRAME

WHT

2.5A

TABLE 3, T1

TERMINAL

1

2

3

1

2

3

5

VOLTAGE

240 VAC

208 VAC

120 VAC

T1

6

10

FRAME

BLU

24 VAC

WHT

J/P10

3

2

1

BRN

LEFT

ON/OFF

S1A

2

S2A

2

RIGHT

ON/OFF

GRN/Y

WHT

MV1 LEFT

MAIN VALVE

MOV

WHT

PILOT VALVE

PV1

MOV

TYPICAL LAST BURNER

WHT

RED

D1B

GND

(5)

MV/PV

(10)

BGND

(4)

HV

J/P1-2

J/P1-4

(2)

PV

YEL

(3)

LT1

A

PILOT OK

24V(9)

COM (8)

GRY

NO (7)

HEAT

COM (6)

P/N 60142502

TC1

TEMP

CONTROL

31

SET POINT

3

3

BLU

2

CW

5

TP1

4

ORG

J/P1-1

J/P1-3

LEFT

ON/OFF

5

6

7

8

R

S1B

ORG

MV

24V

(1)

(6)

K3

K1

P/N 60152001

IM1

IGNITION

MODULE

TYPICAL TWO BURNER SET

RIGHT

24V(9)

COM (8)

HEAT

COM (6)

P/N 60142502

TC2

TEMP

CONTROL

31 2

NO (7)

ON/OFF

ORG

VIOL

WHT

5

TP2

4

5

6

7

W/RED

J/P1-5

D2B

8

R

S2B

MV1 RIGHT

MAIN VALVE

MOV

CW

SET POINT

Page 26 L22-362 Rev 2 (11/12)

Page 27

Trouble Shooting Guide

MKG/MKH/MKGD Series Gas Griddles

5.5 SCHEMATIC: MATCHLESS SINGLE POWER SWITCH “E” SERIES

TABLE 3, T1

115VAC/60Hz

N L

GND

SJTO

16 AWG

J13

TERMINAL

L

BLK

N

G

FRAME

WHT

2.5A

VOLTAGE

1

240 VAC

2

208 VAC

3

120 VAC

1

2

3

5

T1

6

10

FRAME

BLU

24 VAC