Page 1

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual

for the life of the equipment:

Model #: ___________________________

Serial #: ___________________________

Date Purchased: ___________________

ENGLISH

Installation & Operation Manual

MKE SERIES GRIDDLES

All Options

L20-369 REV. 2 (05/12)

Page 2

TO THE PURCHASER, OWNER AND STORE MANAGER

Please review these warnings prior to posting them in a prominent location for reference.

WARNING

DO NOT store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

WARNING

Improper installation, alteration, service or maintenance

can cause property damage, injury or death. Read th e

installation, operating and maintenance instructions

thoroughly before installing or servicing this appliance.

WARNING

Installation, maintenance and repairs should be performed

by a MagiKitch’n Authorized Service and Parts (ASAP)

company technician or other qualified personnel.

Installation, maintenance or repairs by an unauthorized

and unqualified personnel will void the warranty.

WARNING

Installation and all connections must be made according

to national and local regulations and codes in force.

WARNING

A country approved all pole circuit breaker with a

minimum open contact gap of 3mm must be used for

proper installation. (CE countries)

WARNING

During the warranty period if a customer elects to use a

non-original part or modifies an original part purchased

from MagiKitch’n and/or its Authorized Service and Parts

(ASAP) companies, this warranty will be void. In addition,

MagiKitch’n and its affiliates will not be liable for any

claims, damages or expenses incurred by the customer

which arises directly or indirectly, in whole or in part, due

to the installation of any modified part and/or received

from an unauthorized service center.

WARNING

This appliance, when installed, must be electrically

grounded in accordance with local and national codes. In

North America, in the absence of local codes, with the

National Electrical Code, ANSI/NFPA 70, or the Canadian

Electrical Code, CSA C22.2, as applicable.

WARNING

Adequate means must be provided to LIMIT the movement

or this appliance without depending on the electrical cord

connection. Single appliances equipped with legs must

be stabilized by installing anchor straps. All appliances

equipped with casters must be stabilized by installing

restraining chains.

WARNING

DO NOT alter or remove structural material on the

appliance to accommodate placement under a ventilation

hood.

WARNING

This appliance is intended for professional use only and

should be operated by fully trained and qualified

personnel.

WARNING

If the supplied power cord is damaged, it must be replaced

by a MagiKitch’n Authorized Service and Parts (ASAP)

company technician or a similarly qualified person in

order to avoid a hazard.

WARNING

All power supplies must be disconnected before servicing,

maintaining or cleaning this appliance.

WARNING

The appliance is NOT jet stream approved. DO NOT clean

the appliance with a water jet.

WARNING

DO NOT attempt to move this appliance or transfer hot

liquids from one container to another when the unit is at

operating temperature or filled with hot liquids. Serious

personal injury could result if skin comes in contact with

the hot surfaces or liquids.

WARNING

DO NOT sit or stand on this appliance. The appliance’s

front panel, cook plate, splash back, side, workshelf not a

step. Serious injury could result from slipping, falling or

contact with hot surfaces or liquids.

WARNING

NEVER use the appliance as a step for cleaning or

accessing the ventilation hood. Serious injury could

result from slips, trips or from contacting hot surfaces or

liquids.

WARNING

DO NOT use the appliance unless it is properly secured to

a table, stand or freezer / refrigerated base suited to

handle the weight of the entire appliance.

WARNING

DO NOT operate appliance unless all panels and access

covers are attached correctly.

WARNING

It is recommended that this appliance be inspected by a

qualified service technician for proper performance and

operation on a yearly basis.

WARNING

Some surfaces of this appliance can become extremely

hot during normal operation. The following symbol is

affixed to the appliance to remind users to exercise

caution and to always use personal safety when operating

this appliance.

WARNING

The following symbol is affixed to the appliance to remind

users that, in order to safely operate this appliance, it is

important that the user read and understand the

instruction manual before attempting to operate this

appliance.

WARNING

This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge,

unless given supervision or instruction concerning use of

the appliance by a person responsible for their safety.

ii

Page 3

Table of Contents

1. INSTALLATION SECTION ...................................................................................... 4

1.1. CHECKING YOUR NEW GRIDDLE .................................................................................................... 4

1.2. I

NSTALLATION CLEARANCES .......................................................................................................... 4

1.3. INSTALLATION SETUP .................................................................................................................... 5

1.3.1. Counter Use With Legs .................................................................................................................. 5

1.3.2. Counter Use Without Legs ............................................................................................................. 5

1.3.3. For Use On Optional Equipment Stand .......................................................................................... 5

1.3.4. Leveling Instructions ...................................................................................................................... 6

1.4. ELECTRICAL CONNECTIONS .................................................................................................. 7

1.5. VENTILATION

AND FIRE SAFETY SYSTEMS ......................................................................... 8

2. OPERATION SECTION ........................................................................................... 8

2.1. OPERATION ................................................................................................................................... 8

2.1.1. Solid State And Electric Thermostat Appliances ............................................................................ 8

2.2. INITIAL STARTUP ........................................................................................................................... 8

2.2.1. Griddle Surface Seasoning ............................................................................................................ 9

2.2.2. Surface Temperature Check .......................................................................................................... 9

2.3. SHUTDOWN PROCEDURE ............................................................................................................... 9

2.3.1. Solid State And Electric Thermostat Appliances ............................................................................ 9

3. THERMOSTAT CALIBRATION SECTION .............................................................. 9

3.1. CALIBRATION PROCEDURES .......................................................................................................... 9

3.1.1. Electric Thermostat ........................................................................................................................ 9

3.1.2. Solid State Thermostat ................................................................................................................ 10

4. BASIC OPERATION .............................................................................................. 10

4.1. OPERATIONAL HELPFUL HINTS .................................................................................................... 10

4.2. SUGGESTED COOKING TIMES AND TEMPERATURES ...................................................................... 10

5. CLEANING & MAINTENANCE SECTION ............................................................. 11

5.1. DAILY CLEANING ......................................................................................................................... 11

5.2. G

RIDDLE SURFACE CLEANING, END OF SHIFT .............................................................................. 11

5.2.1. Plain Steel Cooking Surface ........................................................................................................ 12

5.2.2. Chrome Plated Cooking Surface .................................................................................................. 12

5.3. MONTHLY MAINTENANCE ............................................................................................................. 12

5.3.1. Monthly Preventative Maintenance .............................................................................................. 12

5.4. ANNUAL/PERIODIC PREVENTATIVE MAINTENANCE AND INSPECTION .............................................. 12

5.4.1. Safety Evaluation ......................................................................................................................... 12

5.4.2. Mechanical Inspection ................................................................................................................. 12

5.4.3. Control Box & Electrical Components .......................................................................................... 13

5.4.4. Systems Operation Inspection ..................................................................................................... 13

5.5. VENTILATION HOOD ..................................................................................................................... 13

5.6. T

ROUBLE SHOOTING CHARTS ...................................................................................................... 14

5.6.1. Cooking Performance .................................................................................................................. 14

5.6.2. Operating Performance ................................................................................................................ 14

6. ACCESSORIES ..................................................................................................... 15

6.1. STANDARD .................................................................................................................................. 15

6.2. O

PTIONAL ................................................................................................................................... 15

6.2.1. Service Shelves, Front ................................................................................................................. 15

6.2.2. Cutting Boards ............................................................................................................................. 16

6.2.3. Warming Shelves, Rear ............................................................................................................... 17

6.2.4. Equipment Stands ........................................................................................................................ 18

6.2.5. Miscellaneous .............................................................................................................................. 19

7. NOTES PAGE ........................................................................................................ 21

MKE Series Electric Griddle

L20-369 REV. 2 (05/12)

3

Page 4

Installation

MKE Series Electric Griddle

1. Installation Section

1.1. Checking Your New Griddle

Your new griddle has been carefully packed into one crate. Every effort has been made to ensure that

your new griddle is delivered to you in perfect condition. As you unpack your new appliance, inspect each

of the pieces for damage. If something is damaged, Contact the shipper immediately; the shipper is only

responsible for 15 days after delivery. Check the packing list enclosed with your griddle to en sure that you

have received all the parts to the griddle. If you are missing any parts, contact the dealer from whom the

griddle was purchased.

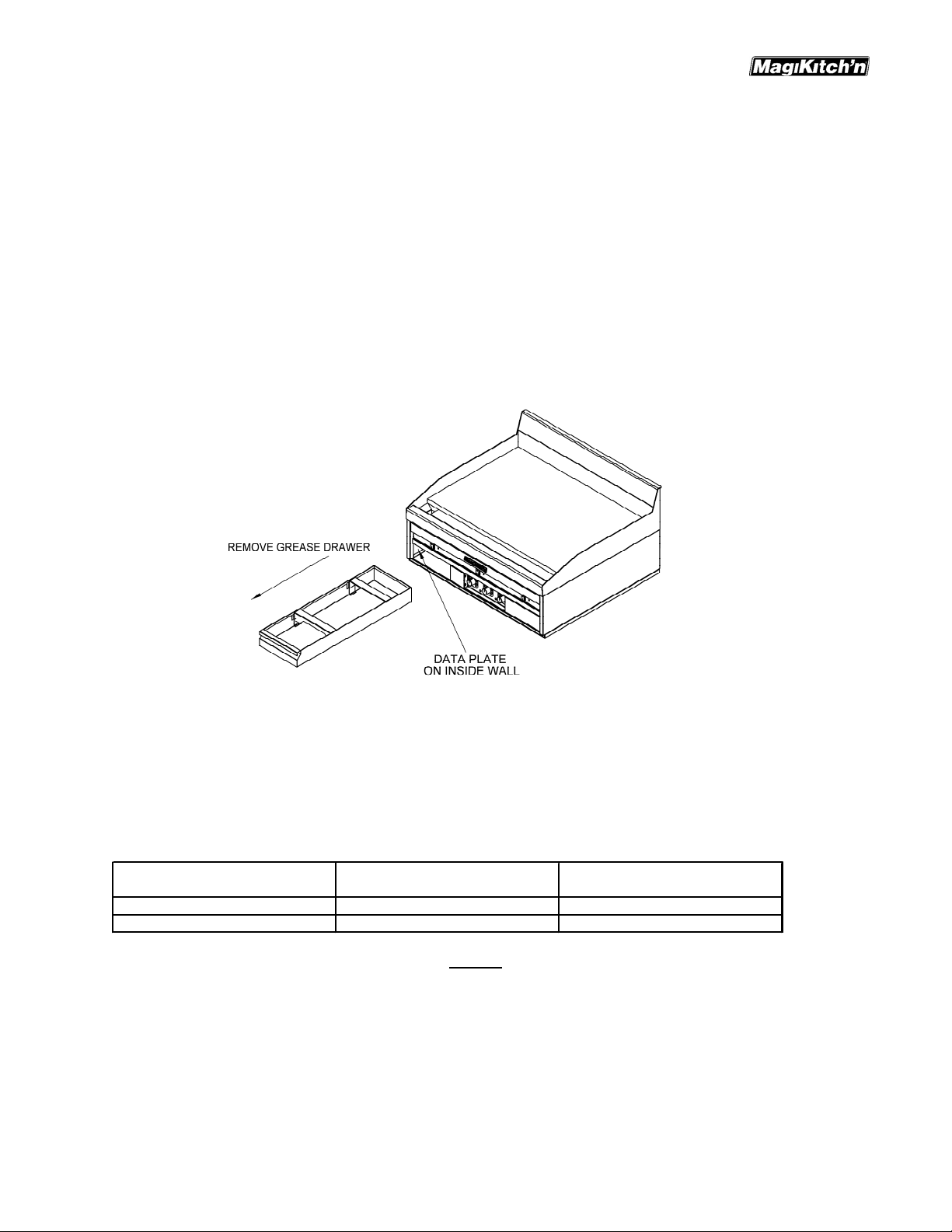

In the provided spaces on the cover of this manual, fill in the Model No., Serial No., and the date the

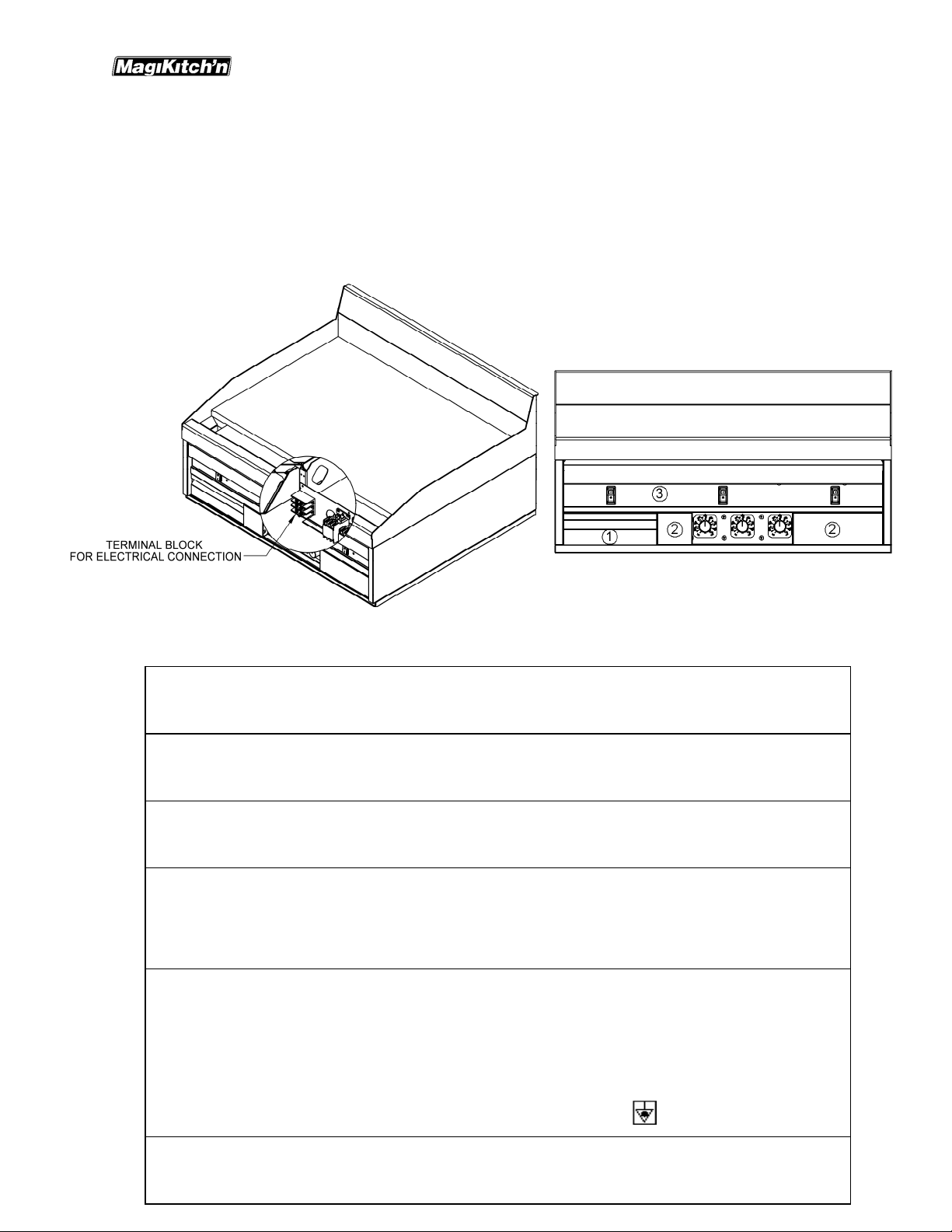

appliance was purchased. The Information is located on the data plate on the inside cabinet wall, see

Figure 1 below. Keep this information in a safe place so it can be referred to in the future.

Figure 1

1.2. Installation Clearances

Your new MagiKitch’n Griddle needs clearance around it for proper operation. Adequate clearances allow

for servicing. The clearances shown below are for installation in combustible and non-combustible

construction. Ensure that all clearances stated on the data plate and in the clearance section of this

manual are strictly followed.

Location

Cabinet Back 8.0 (20.4) 8.0 (20.4)

Cabinet Sides 2.0 (5.0) 0.0 (0.0)

Combustible Construction

Inches (Centimeters)

Non-Combustible Construction

Inches (Centimeters)

Table 1

4

L20-369 REV. 2 (05/12)

Page 5

MKE Series Electric Griddle

1.3. Installation Setup

To Start uncrate appliance and locate installation accessories shipped with the appliance.

1.3.1. Counter Use With Legs

CAUTION

To prevent equipment damage, DO NOT tilt

your MagiKitch'n griddle on only two legs, or

on its sides.

(See Figure 2) A set of 4” (10 cm) legs is

shipped with the appliance (unless appliance

was specifically ordered without legs). A

threaded receptacle is located near each corner

of the underside of the base of the appliance, on

appliances 48" (122 cm) and wider there are

threaded receptacles in the front and rear center

of the base. Each leg has a similar mating

thread. Raise appliance sufficiently to allow legs

to be screwed tightly into receptacles. The

appliance can be leveled by adjusting the feet at

the bottom of the leg assembly. This can be

done by turning the foot in or out to lower or

raise each corner as needed.

NOTICE

4" (10 cm) Legs should not to be used with

the optional Equipment Stand.

1.3.2. Counter Use Without Legs

Figure 2

(See Figure 3) The appliance must be sealed to

the counter to comply with applicable sanitation

standards. A bead of silicone sealant,

approximately ½ inch (1.3 cm) wide, is to be

applied to the bottom of the unit approximately

¼” (0.6 cm) in from the front, back and side

edges. We suggest Dow Corning , GE or

Permatex silicone ‘RTV’ adhesive sealant or

CAUTION

The appliance must be level to perform

properly. Failure to level unit may result in

improper performance of the appliance.

equivalent. (See NSF Basic Criteria C-2 for

details where applicable).

1.3.3. For Use On Optional

Equipment Stand

ATTENTION

Rear mounting brackets should be installed

to the Equipment Stand prior to placing

griddle on the stand.

CAUTION

Only two of the four supplied casters are

equipped with a locking feature. Install the

griddle so that the two locking casters are at

the front of the unit. The casters should be

LOCKED before the unit is placed into

operation.

Figure 3

L20-369 REV. 2 (05/12)

Installation

5

Page 6

Installation

g

MKE Series Electric Griddle

NOTICE

The larger units have 6 threaded receiving holes, but require only the four 1/2" bolts on each cor ner to

mount the griddle.

1. Remove (4) existing 1/4-20 nuts and bolts from the rear corners of the equipment stand.

2. Align the 2 bolt holes on the rear corners of the stand with the 2 bolt holes on the rear mounting brackets.

Orient the brackets as shown in Figure #4

on this page.

3. Install the provided rear mounting brackets

(2) to the rear corners by using the existing

1/4-20 hardware that were removed in step

1, tighten securely.

4. Carefully place the griddle on the

equipment stand.

5. Position the griddle so that the front edge of

the base is flush with the front of the

equipment stand. If the griddle is the only

appliance to be mounted on the stand, then

both sides of the griddle should be flush

with the sides of the equipment stand.

6. When positioned properly, the threaded

receiving holes in the griddle base should

be aligned with mating clearance holes at

the front of the equipment stand, and with

the clearance holes in the rear mounting

brackets. Install the provided 1/2" bolts and

tighten securely.

1.3.4. Leveling Instructions

NOTICE

Equipment stands are shipped from the

factory with the legs or casters set to “Zero”.

Units should be leveled at time of

installation, failure to do so could cause the

griddle to operate improperly.

1. Identify the end or corner of the stand that

needs to be raised, remove the weight load

from the caster or leg to be leveled.

2. Legs- using a wrench, or pliers turn the leg

bullet, See Figure 5, CCW to raise the

height of the equipment stand. There is ½”

to ¾” (1.3 – 1.9 cm) of adjustment.

Casters- (For Stands shipped after May

2006) Using a Flat Head screwdriver,

loosen the set screws of the caster to be

leveled, See Figure 5.Turn the collar of the

caster CCW to raise the height of the

equipment stand. There is ½” to ¾” (1.3 –

1.9 cm) of adjustment.

After leveling adjustment is complete, re-

tighten set screws.

3. Repeat Step 2 for legs or casters that require leveling.

4. Check the levelness of the equipment, if necessary Repeat steps 1, 2, and 3.

MOUNT FLUSH

TO FRONT

NUTS & BOLTS

INCLUDED

WITH STAND

Figure 4

Fi

ure 5

REAR

BRACKET (2)

(SUPPLIED)

1/2" BOLTS (4)

(SUPPLIED)

6

L20-369 REV. 2 (05/12)

Page 7

Installation

,

MKE Series Electric Griddle

1.1. ELECTRICAL CONNECTIONS

It is advised that this power supply be plugged into a wall receptacle or hard wired into a circuit that is

controlled by the ventilation control. This will prevent the appliance from being operated without the

ventilator on.

Have qualified professional connect the power supply to the terminal block(s), if a cord is not supplied,

according to their labeled leg (L1, L2, L3, ground and N as applicable). Access to the terminal blocks can

be gained by first removing the grease drawer, then removing the lower rear and front panels (order of

removal is shown in figure 7). This will require a Phillips head screwdriver and a 5/16 nut driver, wrench or

ratchet. Minimum gauge copper wire is noted on the data plate.

Figure 6 Figure 7

Connecting the appliance to the wrong power supply may damage the appliance and void

the warranty.

This appliance must be connected to a power supply having the same voltage and phase as

specified on the data plate located on the wall inside the grease drawer chute.

DO NOT attempt to connect the appliance to an electrical supply other then that indicated

on the data plate. Electrical connection should be performed by qualified personnel.

The electrical connection used by this appliance must comply with local codes. In the US, if

there are no local codes that apply, refer to the National Electrical Code (NEC), ANSI/NFPA

70 for installation in the US. In Canada, refer to CSA Standard C22.2 and local codes. In all

other cases

The appliance must be grounded in accordance with local code; in North America, if there is

no local code, comply with the NEC and ANSI/NFPA No. 70 latest edition (for US and

Canadian installations). In all other cases, refer to local and national codes and regulations.

To comply with European requirements, European models are equipped with an

equalization-bonding clamp. An equalization bonding lead must be connected to this clamp

to provide sufficient protection against potential difference. This clamp, located on the rear

of the appliance is marked with the following universal symbol.

A country approved all pole circuit breaker with a minimum open contact gap of 3mm must

be used for proper installation. (CE countries)

refer to local and national codes and regulations.

CAUTION

WARNING

WARNING

WARNING

WARNING

WARNING

L20-369 REV. 2 (05/12)

7

Page 8

Installation

MKE Series Electric Griddle

WARNING

This equipment must be installed so that the plug is accessible unless other means for

disconnection from the power supply (e.g. a circuit breaker) is provided.

If this appliance is permanently connected to fixed wiring, it must be connected by means

of copper wires having a temperature rating of not less then 167°F (7 5°C).

All copper wiring for this appliance must be made in accordance with the wiring diagram(s)

located on the appliance.

1.2. VENTILATION AND FIRE SAFETY SYSTEMS

Your new appliance must have proper ventilation to function safely and properly. It is very important to install

a fire safety system. Your ventilation system should be designed to allow for easy cleaning. Frequent cleanin g

and proper maintenance of the ventilation system and the appliance will reduce the chances of fire. Ventilation

and fire safety systems must comply to local and national codes. In North America, NFDA96 will provide

guidance on ventilation and fire safety systems.

WARNING

WARNING

2. Operation Section

Ensure that a proper installation has been performed on the appliance and that all warning s, cautio ns, and

notices contained in this manual have been read, understood and adhered to before pro cee ding.

2.1. Operation

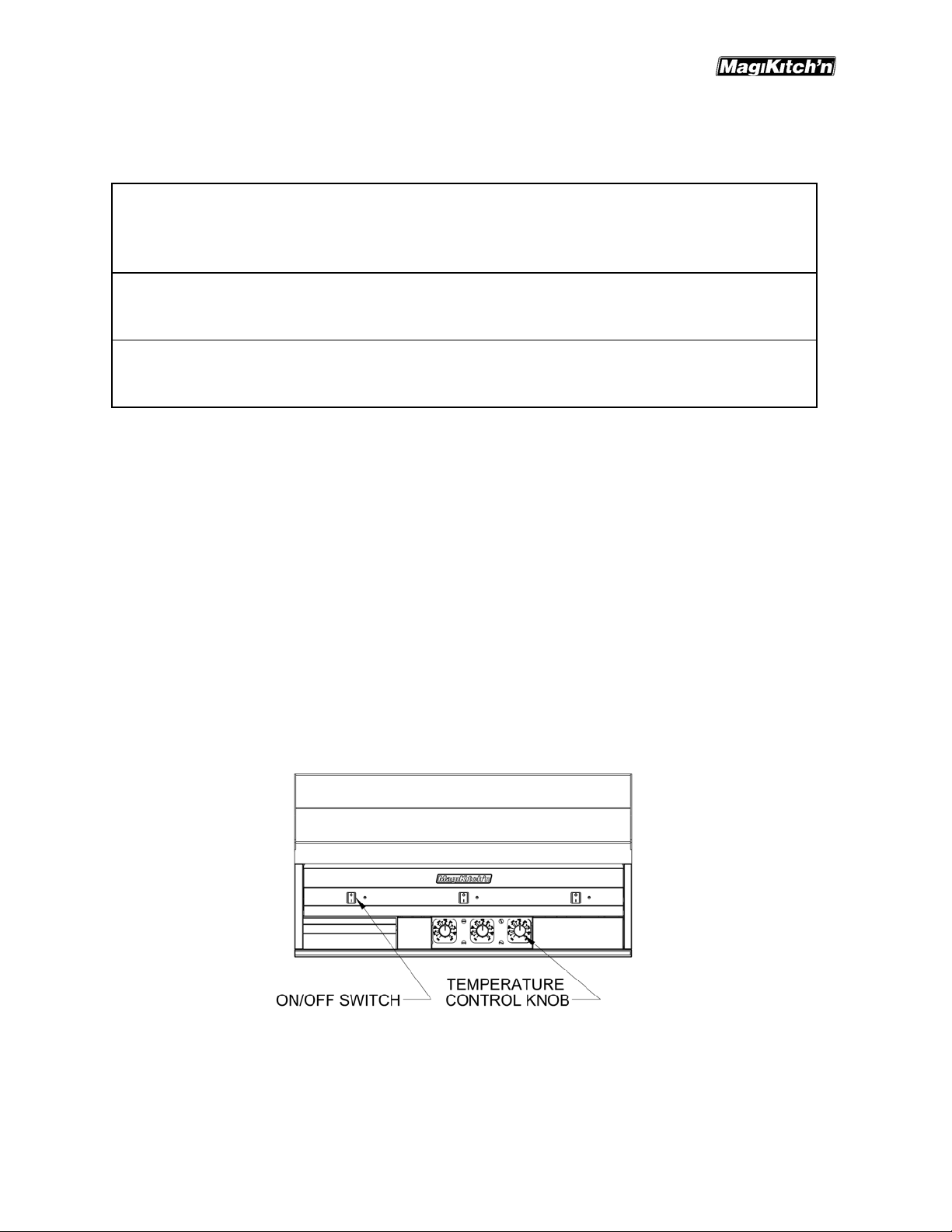

2.1.1. Solid State And Electric Thermostat Appliances

1. Turn the "I/O" switch to the “ I ” (ON) position for all desired thermostats to be operated.

2. Operate thermostats by turning knobs to the desired temperature. The "I/O" switch will illuminate when

the thermostat calls for heat.

Figure 8

2.2. Initial Startup

NOTICE

New griddles should be carefully tempered and cared for in order to avoid possible damage. To break

in a new griddle, do the following:

8

L20-369 REV. 2 (05/12)

Page 9

Calibration

Wipe the griddle surface clean. A mild soapy water solution may be used to clean the surface, if this solution is

used be sure to rinse thoroughly with potable water to eliminate any soap residue. Also it is important to wipe

the griddle surface and surrounding areas to remove any standing water. Never allow water on a hot griddle

surface.

Seasoning is not required on chrome plated cooking surfaces, but the following procedure may be performed

to improve the non-stick qualities of the chrome plated cooking surface.

2.2.1. Griddle Surface Seasoning

1. To season the griddle, turn on all thermostat switches and set knobs to 200°F (93°C). As

the unit heats to 200°F (93°C), apply a light film of cooking oil or beef suet over the entire

cooking surface, wiping off any excess build up. This step may be repeated as necessary

to apply an even coating on the griddle surface. Seasoning will help create and maintain a

non-stick surface on your griddle.

2. Allow the seasoned surface to idle for one hour at 200°F (93°C), Then set the thermostats

to your desired cooking temperature, once your griddle surface has reached temperature

apply another coating of seasoning oil, wiping off any excess that may cause build up.

2.2.2. Surface Temperature Check

1. If available, place grill surface thermometer over each thermostat sensing probe 12"

(30.5cm) from the front edge of the griddle surface. The first sensing probe is located 6"

(15 cm) from the left side of the griddle, additional sensing probes are every 12" (30.5cm)

to the right thereafter.

2. Heat the griddle to the desired cooking temperature; check the surface temperature

reading on the grill thermometer. If necessary, adjust the thermostats that control any area

of the surface that are not within +/- 15°F (8°C) of the thermostat setting. The procedure

for adjusting the thermostats is in Section 3.

2.3. Shutdown Procedure

2.3.1. Solid State And Electric Thermostat Appliances

1. Turn “I/O” Switch to “O” position.

2. Allow griddle surface to cool normally.

MKE Series Electric Griddle

3. Thermostat Calibration Section

Each control operates a set of three elements. The controls were set at the factory. However, if the griddle’s

surface temperature varies greatly from

the setting on the thermostat knob, adjust

the thermostat using the following

procedure:

3.1. Calibration Procedures

3.1.1. Electric Thermostat

1. Turn all the control knobs to the

desired temperature setting.

2. Wait 30 minutes (or 1 hour if

griddle was cold) for surface to

stabilize.

3. Place a reliable Griddle surface

thermometer,

or test instrument

thermocouple, (able to register 300°F (149°C)), in the location above the thermostat being calibrated

as described in section 2.2.2. Check the temperature every 5 minutes until the temperature stabilizes

and does not change by more than 30°F (17°C) over a 15 minute span.

4. If the average temperature over any burner set is not within +/-15°F (8°C) of the knob setting (300°F)

(149°C), adjust the corresponding thermostat. This is done by removing the knob, holding the

THERMOSTAT ADJUSTMENT SCREW

TURN CW TO DECREASE TEMPERATURE

TURN CCW TO INCREASE TEMPERATURE

THERMOSTAT KNOB

REMOVED, SNAP ACTION

ELECTRIC THERMOSTATS SHOWN FOR REFERENCE

THERMOSTAT STEM

Figure 9

L20-369 REV. 2 (05/12)

9

Page 10

Basic Operation

MKE Series Electric Griddle

thermostat knob stem, see picture above, (do not allow the stem to turn or the temperature setting

will not be accurate), then turn the adjustment screw located within the center of the stem in small

increments. Turn this screw counter clockwise to increase the temperature, and clockwise to decrease

the temperature.

5. Check the temperature after 15 minutes and repeat adjustment as needed until the correct

temperature is indication on the measuring instrument.

NOTICE

The adjustment screw on the thermostat is sealed by the Manufacturer to protect the calibration. It

may be necessary to remove this seal to be able to adjust the thermostat.

3.1.2. Solid State Thermostat

1. Turn all the control knobs to the

desired temperature setting.

2. Wait 30 minutes (or 1 hour if griddle

was cold) for surface to stabilize.

ALIGNED WITH ACTUAL TEMP.

THIS CAP SNAPS

ON AND OFF

ROTATE KNOB UNTIL

TEMP. INDICATOR IS

5/16" NUT

3. Place a reliable Grill surface

thermometer,

or test instrument

thermocouple, (able to register

300°F (149°C)), In the location

above the thermostat being

calibrated described in section 2.2.2.

Check the temperature every 5

minutes until the temperature

Figure 10

CAP LINE

stabilizes and does not change by

more than 30°F (17°C) over a 15 minute time period. You will need to remember the average

temperature for the next step.

4. Carefully remove the cap on the thermostat knob with the white indicator line see picture this section.

While holding the knob, loosen the 5/16" nut on the thermostat shaft, (DO NOT REMOVE), once the

nut is loose the knob can be rotated so that the cap line marker is aligned with the actual temperature

that the Grill surface thermometer is indicating.

5. Re-tighten the 5/16" nut while holding the knob in position, (do not allow the stem to turn or the

temperature setting will not be accurate). Replace cap.

4. Basic Operation

4.1. Operational Helpful Hints

1. Each thermostat controls 12" (30.5cm) of griddle surface, whenever possible, use the leftmost or

rightmost thermostats for the lowest cooking temperatures. The adjacent thermostats set at higher

temperatures will effect centrally located thermostats.

2. For quicker thermostat response during heavy loading of the griddle, load product directly over the

thermostat sensing probe. For slower periods of use, load product to one side of the sensing probe to

limit possible overheating of unused griddle surface.

3. Whenever possible, rotate the location of where product is cooked, this will keep the entire 12"

(30.5cm) of the controlled area at a more even temperature.

4. If any product sticking occurs, apply a thin coat of cooking oil to the surface before loading product.

5. When using spatulas or scrapers, it is Highly Recommended

the griddle surface with any force. This could cause damage to the surface that could collect food

particles, and make it difficult to clean.

4.2. Suggested Cooking Times And Temperatures

NOTICE

The times and temperatures in this chart are suggestions only. Your experience with your own menu

items will be your best guide to achieving the best food product.

that the corners of the tools never strike

10

L20-369 REV. 2 (05/12)

Page 11

Calibration

Product Temperature°F (°C) Time

Breakfast Items

Pancakes 2 Minutes

French Toast 400° (204°) 4-5 Minutes

*Breakfast Potatoes 375°-400° (191°-204°) 15-20 Minutes

Eggs

Scrambled 300° (149°) 3-4 Minutes

Sunny Side Up 225°-300° (107°-149°) 3-4 Minutes

Over Easy 250°-300° (121°-149°) 2-3 Minutes

Over Hard 225°-300° (107°-149°) 3-4 Minutes

Breakfast Meats

Sausage, Link and Patty 350° (177°) 3 Minutes

Bacon 350° (177°) 2-3 Minutes

Canadian Bacon 350° (177°) 2-3 Minutes

Ham Steaks 375° (191°) 3-4 Minutes

Broiled Ham 375° (191°) 2 Minutes

Ham, Pre-Cooked 375° (191°) 2 Minutes

Fish

Salmon 350° (177°) 6-8 Minutes

Hamburgers

2 Patties per Lb. 350° (177°) 6-8 Minutes

4 Patties per Lb. 350° (177°) 4-6 Minutes

6 Patties per Lb. 350° (177°) 3-4 Minutes

Steaks, Etc.

1/2"-3/4" Thick, Medium 375° (191°) 5-7 Minutes

3/4"-1" Thick, Medium 375° (191°) 8-10 Minutes

Beef Tenderloin 400° (204°) 3-4 Minutes

Sandwiches, Etc.

Grilled Cheese 375° (191°) 3-4 Minutes

Hot Dogs 325° (163°) 2-3 Minutes

*Based on cubed potatoes brought to a boil then cooled prior to finishing on griddle. To reduce

burning and sticking of the potatoes coat the griddle surface with vegetable oil and turn potatoes

375° (191°)

Table 2

frequently.

MKE Series Electric Griddle

5. Cleaning & Maintenance Section

5.1. Daily Cleaning

NOTICE

Do not use Grill Bricks, Grill Screens, or any other type of abrasive material on your

MagiKitch'n Chrome Griddle Surface. USING ABRASIVE MATERIALS WILL VOID YOUR WARRANTY.

1. Clean the griddle surface often to prevent sticking and poor food product quality. Scrape the griddle

plate regularly with a scraper intended for your type of griddle surfaces to remove all surface grease

and food debris.

2. Clean and wipe out grease chutes.

3. Wipe down the exterior, the sides and front of the griddle are stainless steel, any stainless steel

cleaner can be used to clean these surfaces.

4. Remove and empty grease box(es) of any and all debris, also wipe down the inside of the grease box

compartment for food particles that may have come free from the grease box.

NOTICE

The grease box is designed to contain grease run off from the griddle surface. The grease box should

NEVER

be allowed to overfill, and should be emptied accordingly and grease disposed of properly.

5.2. Griddle Surface Cleaning, End Of Shift

L20-369 REV. 2 (05/12)

11

Page 12

Cleaning & Maintenance

MKE Series Electric Griddle

NOTICE

Wear protective gloves and clothing when cleaning the appliance, HOT

may cause personal injury.

5.2.1. Plain Steel Cooking Surface

1. Scrape griddle surface completely with a scraper to remove grease and food debris.

2. Use a grill brick or grill screen to clean any heavy build up of carbon from the griddle surface.

Never use steel wool pads, small fibers may be left behind on the cooking surface.

3. When griddle surface is cool, polish surface with MagiKleans'r, or similar type non-abrasive,

non-caustic cleaners that are approved for stainless steel.

4. It may be necessary to season the grill again after this cleaning.

5.2.2. Chrome Plated Cooking Surface

NOTICE

Do not use Grill Bricks, Grill Screens, or any other type of abrasive material on your

MagiKitch'n Chrome Griddle Surface. USING ABRASIVE MATERIALS WILL VOID YOUR WARRANTY.

1. Scrape griddle surface completely with supplied scraper to remove grease a nd food debris.

2. When griddle surface is cool, scrub the chrome surface with the supplied palmetto cleaning

brush and cool water.

3. Shine the chrome griddle cooking surface with MagiKleans'r, water and a soft cloth.

4. Rinse with clean water and wipe away any residue with a dry cloth.

5.3. Monthly Maintenance

NOTICE

Regular maintenance of your MagiKitch'n griddle is Recommended

to keep the appliance operating

properly.

5.3.1. Monthly Preventative Maintenance

Food debris and grease can buildup in and around the griddle . Performing the monthly preventative

maintenance steps below will keep your equipment safe and at peak performance. If you are

producing high quantities of grilled foods, it may be necessary to clean these components more then

once a month

Use a grill surface thermometer to make sure thermostats are operating properly.

Make sure that all electrical connections have not been tampered with or damaged.

Check to see that the ventilation hood and make up air systems are working properly.

Inspect griddle surface for any visible damage.

5.4. Annual/Periodic Preventative Maintenance and Inspection

This section should ONLY be performed by a qualified service technician as part of a regular kitche n

maintenance program. This inspection should take place a minimum of once a year by an Authorized

Service Technician recommended by MagiKitch’n. It may be necessary perform this inspection more then

once a year.

5.4.1. Safety Evaluation

Check all electrical connections, and verify that the griddle retention/lanyard system is in place.

Check for food debris and grease migration in and around the cabinet of the appliance.

Check legs/casters, and ensure all nuts and bolts are secured. (If Equipped)

Check all exposed wiring connections, switches and indicator lights.

5.4.2. Mechanical Inspection

Check griddle surface for damage, rust, and any cracks in the chrome plating if applicable.

Check grease box for leaks.

Check for grease and water migration, clean as necessary.

Check ventilation hood drain cup and filters, clean as necessary.

Check vents for foreign debris.

Check for loose parts.

Check for missing parts and fasteners, replace as necessary.

Surfaces

12

L20-369 REV. 2 (05/12)

Page 13

Cleaning & Maintenance

5.4.3. Control Box & Electrical Components

Verify amp-draw is within range as compared to the information on the data plate.

Verify that heating contactors are in good condition. Check for worn or pitted contacts. Verify that

wires are tight and in good condition.

Verify that all components (transformer, terminal block, relays, etc…) are in good condition. Verify

that wires are tight and in good condition.

Verify enclosures are free of leaks. Check for water stains and wet surfaces.

Verify that the covers and panels are intact and provide a safe condition. Check for loose parts.

Verify power cord is in good condition. Check for frayed or exposed wires.

5.4.4. Systems Operation Inspection

Check all wire terminations, check for broken, or frayed wires.

Check temperature calibration.

Check thermostat operation and features for proper operation.

Verify all components are in good physical condition.

Ensure that all components are clean, and do not have any grease or water damage.

5.5. Ventilation Hood

Proper ventilation hood operation is very important for the correct operation of this appliance and the

safety of personnel. The ventilation hood should be inspected at the time of installation of this appliance to

insure that it will operate properly in conjunction with the appliance. Perform a regular schedule of

examination, in accordance with local and national codes. In North America, ANSI/NFPA 96 latest edition

and/or local codes must be followed.

MKE Series Electric Griddle

L20-369 REV. 2 (05/12)

13

Page 14

Cleaning & Maintenance

-

r

MKE Series Electric Griddle

5.6. Trouble Shooting Charts

The following charts may help to eliminate any basic operational problems that you may be experiencing with

your appliance. Locate the problem on the left side of the chart, and cross-reference with the possible cause .

Once the problem has been identified take the appropriate action to rectify the problem.

5.6.1. Cooking Performance

If you are having poor cooking performance or any inconsistencies in product quality, please refer to

the following chart for help.

Possible Cause

Excessive

Smoke

From Fat

Product

Sticking

Product

Edges

Burning

Product

Centers

Problem

Underdone

Greasy Or

Undesirable

Flavo

Grease

Build Up On

Griddle

Surface

Heat

Moisure

In Food

Set

Turning

too

High

XX

XXX

XXX

XX

XX X

To

Stream

Griddle

Surface

Dirty or Un

Seasoned

Cook

Times

Too Short

Product

Shelf Life

Expired

Improperly

Stored

Product

XXX

Table 3

5.6.2. Operating Performance

The following chart may help to diagnose any operational issue you may be experiencing with your appliance.

Some issues may REQUIRE that a qualified service technician perform the repairs. If a qualified service

technician is required, please contact the factory service department.

Possible Cause

Thermostats

Not

Calibrated

Power Switch Will

Not Illuminate

Griddle Will Not

Heat UP

Inconsistent

Problem

Surface

Temperatures

Griddle Stays Hot

or Overheats

Unit Not

Plugged In (if

so equipped)

XXX X

XXX X

Power

Switch Off

Thermostat

"OFF"

Table 4

NOTICE

All parts and service for your MagiKitch'n griddle should be ordered and installed by a MagiKitch'n

Authorized Service and Parts (ASAP) dealer. Failure to do so might result in the warranty being voided.

Excessive

Oil Or

Grease On

Griddle

Surface

Heat

Set

Too

Low

Thermostat

Failure

XX

XX

14

L20-369 REV. 2 (05/12)

Page 15

A

6. Accessories

6.1. Standard

All plain steel and chrome plated griddles are shipped with a set of 4” (10 cm) adjustable legs. The

appliance also comes equipped from the factory with a manual gas shutoff valve, and the specified

gas regulator for the model and gas type purchased.

Each MKE chrome surfaced griddle is equipped with a Chrome Kit which includes a cleaning brush,

cleaning powder, spatula, scraper, and scraper blade replacements. See the table below for Re-Order

Part Nos.

Preventative Maintenance

MKE Series Gas Griddle

Pal me tto Brus h Part No. 9825-1524901

Spatula, (Chrome Surf ace) Part No. 9825-1525001

Scraper, (W/ Bl ade and Cover Part No. 9825-1528001

Replacement Blades Part No. 9825-1528002

Chrom e Griddle

Magi Kleans'r Part No. 9825-1525101

ccessories

Table 5

Using MagiKitch’n chrome griddle accessories are

important to maintaining the life of the griddle’s chrome

surface

6.2. Optional

To order accessories for your griddle, call your local MagiKitch’n dealer for prices and availability.

The list of available accessories for your new appliance will give you the flexibility to customize your

griddle to the best fit for your operational requirements.

This section will show you a variety of front and rear work shelves, cutting boards, equipment stands, and

other accessories to provide you with an efficient working appliance.

6.2.1. Service Shelves, Front

Shelf Model MKG24 MKG36 MKG48 MKG60 MKG72

8" Service Shelf, W/O Towel Bar 5125-1511601-C 5125-1511602-C 5125-1511603-C 5125-1511610-C 5125-1511611-C

*10" Service Shelf, W/O Towel Bar 5125-1511604-C 5125-1511605-C 5125-1511606-C 5125-1511612-C 5125-1511613-C

*12" Service Shelf, W/O Towel Bar 5125-1511607-C 5125-1511608-C 5125-1511609-C 5125-1511614-C 5125-1511615-C

8" Service Shelf, W/ Towel Bar 5225-1511701-C 5225-1511702-C 5225-1511703-C 5225-1511710-C 5225-1511711-C

*10" Service Shelf, W/ Towel Bar 5225-1511704-C 5225-1511705-C 5225-1511706-C 5225-1511712-C 5225-1511713-C

*12" Service Shelf, W/ Towel Bar 5225-1511707-C 5225-1511708-C 5225-1511709-C 5225-1511714-C 5225-1511715-C

Towel Bar Only 5225-1511801-C 5225-1511802-C 5225-1511803-C 5225-151804-C 5225-1511805-C

Table 6

10” and 12” service shelves are also available with pan cutouts. Consult factory for sizes and

availability.

L20-369 REV. 2 (05/12)

15

Page 16

Accessories

MKE Series Electric Griddle

TOWEL BAR ONLY

WORKSHELVES WITH AND

WITHOUT TOWEL BARS

PAN CUTOUTS AND

CUTTING BOARDS ARE AVAILABLE ON

LARGER WORKSHELVES

Figure 11

6.2.2. Cutting Boards

Size Part No.

8" X 12" Cutting Board 1604-0643600-C

8" X 24" Cutting Board 1604-0643700-C

8" X 48" Cutting Board 1604-0643800-C

8" X 72" Cutting Board 1604-0643900-C

Table 7

Other sizes are available, consult factory for size, price, and availability.

16

L20-369 REV. 2 (05/12)

Page 17

Accessories

6.2.3. Warming Shelves, Rear

Shelf Model Part No.

C/A, Shelf Rear MKG24 5225-1535701-C

C/A, Shelf Rear MKG36 5225-1535702-C

C/A, Shelf Rear MKG48 5225-1535703-C

C/A, Shelf Rear MKG60 5225-1535704-C

C/A, Shelf Rear MKG72 5225-1535705-C

Table 8

Shelf Kits can be attached to existing models. The Stainless Steel shelf is removable from the shelf

framework for easier cleaning if necessary.

REMOVABLE SHELF

MKE Series Electric Griddle

EXISTING BOLTS

ON APPLIANCE

Figure 7

L20-369 REV. 2 (05/12)

17

Page 18

Accessories

MKE Series Electric Griddle

6.2.4. Equipment Stands

Equipment stands can be ordered with legs or casters (stand s with casters shipped after May 2006 are

equipped with adjustable casters).

NOTE:

It should also be noted that when ordering an equipment stand for your MKE appliance, you will also

need to order and MKE Joining Kit, Part No. 7225-1512101.

Equipment Stand Model Part No.

MKG24, W/ Legs 5225-1512001-C

MKG24, W/ Casters 5225-1512002-C

MKG36, W/ Legs 5225-1512005-C

MKG36, W/ Casters 5225-1512006-C

MKG48, W/ Legs 5225-1512007-C

MKG48, W/ Casters 5225-1512008-C

MKG60, W/ Legs 5225-1512009-C

MKG60, W/ Casters 5225-1512010-C

MKG72, W/ Legs 5225-1512011-C

MKG72, W/ Casters 5225-1512012-C

Table 9

18

L20-369 REV. 2 (05/12)

Page 19

Accessories

MKE Series Electric Griddle

Figure 13

Equipment stands may be used to hold multiple MKE Griddles. They are also compatible with

MagiKitch’n Series 600 APM Charbroilers.

6.2.5. Miscellaneous

Your appliance can also be used with the following miscellaneous accessorie s so you can customize

your operation to your specific demands.. The wall spacers listed below insure that you cannot push

the appliance too close to the rear wall. The Utensil box gives you a handy location to store your

cooking tools. The Utensil box does not interfere with any controls, and can be moved from one end of

the griddle to the other without the use of tools.

6" Wall Spacer, RH MKG 5425-1526702-C

Utensil Box, MKG Towel Bar Only 9825-1532502-C

Accessory Part No.

6" Wall Spacer, LH MKG 5425-1526701-C

Utensil Box, MKG 9825-1532501-C

Table 10

L20-369 REV. 2 (05/12)

19

Page 20

Accessories

MKE Series Electric Griddle

Figure 14

20

L20-369 REV. 2 (05/12)

Page 21

7. Notes Page

Accessories

MKE Series Electric Griddle

L20-369 REV. 2 (05/12)

21

Page 22

Notes

MKE Series Electric Griddle

This Page Intentionally Left Blank

22

L20-369 REV. 2 (05/12)

Page 23

Notes

MKE Series Electric Griddle

This Page Intentionally Left Blank

L20-369 REV. 2 (05/12)

23

Page 24

In the event of problems with or questions

about your order, please contact the

MagiKitch’n factory at:

(603) 225-6684 World Wide

www.magikitchn.com

MAILING ADDRESS – P.O. BOX 501, CONCORD, NH 03302-0501

SHIPPING ADDRESS – 10 FERRY ST., CONCORD, NH 03301

In the event of problems with or questions

about your equipment, please contact the

MagiKitch’n Authorized Service and Parts

representative (ASAP) covering your area,

or contact MagiKitch’n at the numbers

listed to the left.

L20-369 REV. 2 (05/12)

Loading...

Loading...