Page 1

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual

for the life of the equipment:

Model #: __________________________

Serial #: __________________________

Date Purchased: ___________________

Service Manual

MKE: MagiKitch’n Electric Griddle

March 2011

L22-334, rev. 0 (3/11)

Page 2

MKE SERVICE MANUAL

WARNING

DO NOT store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

WARNING

Improper installation, alteration, service or

maintenance can cause property damage, injury

or death. Read the installation, operating and

maintenance instructions thoroughly before

installing or servicing this appliance.

WARNING

Installation, maintenance and repairs should be

performed by a MagiKitch’n Authorized Service

and Parts (ASAP) company technician or other

qualified personnel. Installation, maintenance or

repairs by an unauthorized and unqualified

personnel will void the warranty.

WARNING

Installation and all connections must be made

according to national and local regulations and

codes in force.

WARNING

A country approved all pole circuit breaker with a

minimum open contact gap of 3mm must be used

for proper installation. (CE countries)

WARNING

During the warranty period if a customer elects to

use a non-original part or modifies an original part

purchased from MagiKitch’n and/or its Authorized

Service and Parts (ASAP) companies, this

warranty will be void. In addition, MagiKitch’n

and its affiliates will not be liable for any claims,

damages or expenses incurred by the customer

which arises directly or indirectly, in whole or in

part, due to the installation of any modified part

and/or received from an unauthorized service

center.

WARNING

This appliance, when installed, must be

electrically grounded in accordance with local

codes, or in the absence of local codes, with the

National Electrical Code, ANSI/NFPA 70, or the

Canadian Electrical Code, CSA C22.2, as

applicable.

WARNING

Adequate means must be provided to LIMIT the

movement or this appliance without depending on

the electrical cord connection. Single appliances

equipped with legs must be stabilized by

installing anchor straps. All appliances equipped

with casters must be stabilized by installing

restraining chains.

WARNING

DO NOT alter or remove structural material on the

appliance to accommodate placement under a

ventilation hood.

WARNING

This appliance is intended for professional use

only and should be operated by fully trained and

qualified personnel.

WARNING

If the supplied power cord is damaged, it must be

replaced by a MagiKitch’n Authorized Service and

Parts (ASAP) company technician, or a similarly

qualified person in order to avoid a hazard.

WARNING

The power supply must be disconnected before

servicing, maintaining or cleaning this appliance.

WARNING

The appliance is NOT jet stream approved. DO

NOT clean the appliance with a water jet.

WARNING

DO NOT attempt to move this appliance or

transfer hot liquids from one container to another

when the unit is at operating temperature or filled

with hot liquids. Serious personal injury could

result if skin comes in contact with the hot

surfaces or liquids.

WARNING

DO NOT sit or stand on this appliance. The appliance’s

front panel, cook plate, splash back, side, workshelf not

a step. Serious injury could result from slipping, falling

or contact with hot surfaces or liquids.

WARNING

NEVER use the appliance as a step for cleaning or

accessing the ventilation hood. Serious injury could

result from slips, trips or from contacting hot surfaces

or liquids.

WARNING

DO NOT use the appliance unless it is properly secured

to a table, stand or freezer / refrigerated base suited to

handle the weight of the entire appliance.

WARNING

DO NOT operate appliance unless all panels and

access covers are attached correctly.

WARNING

It is recommended that this appliance be

inspected by a qualified service technician for

proper performance and operation on a yearly

basis.

L22-334, rev. 0 (3/11)

Page 3

MKE SERVICE MANUAL

TROUBLE SHOOTING.............................................................................3

Problems and Possible Causes .........................................................................................................3

Normal Operating Component Properties ........................................................................................4

FRONT AND REAR PANELS...................................................................4

Removal of Front Panels and Access to Component Panels.........................................................4

Assembly of Front Panels...................................................................................................................5

Rear Panels ..........................................................................................................................................6

COMPONENT PANELS............................................................................7

Component Location...........................................................................................................................7

Component Replacement ...................................................................................................................7

1. Contactors ................................................................................................................................................7

2. Cord and Plug Sets..................................................................................................................................8

3. Fuses.........................................................................................................................................................8

4. Relays (Electric Thermostats Only)........................................................................................................8

5. Switches....................................................................................................................................................8

6. Thermostats.............................................................................................................................................. 8

7. Transformers............................................................................................................................................9

ELEMENTS AND PROBES....................................................................10

Location and Numbering ..................................................................................................................10

Replacing an Element .......................................................................................................................11

Replacing a Probe .............................................................................................................................12

THERMOSTAT CALIBRATION..............................................................14

Electric Thermostat ...........................................................................................................................14

Solid State Thermostat......................................................................................................................14

L22-334, rev. 0 (3/11)

Page 4

Trouble Shooting

r

MKE SERVICE MANUAL

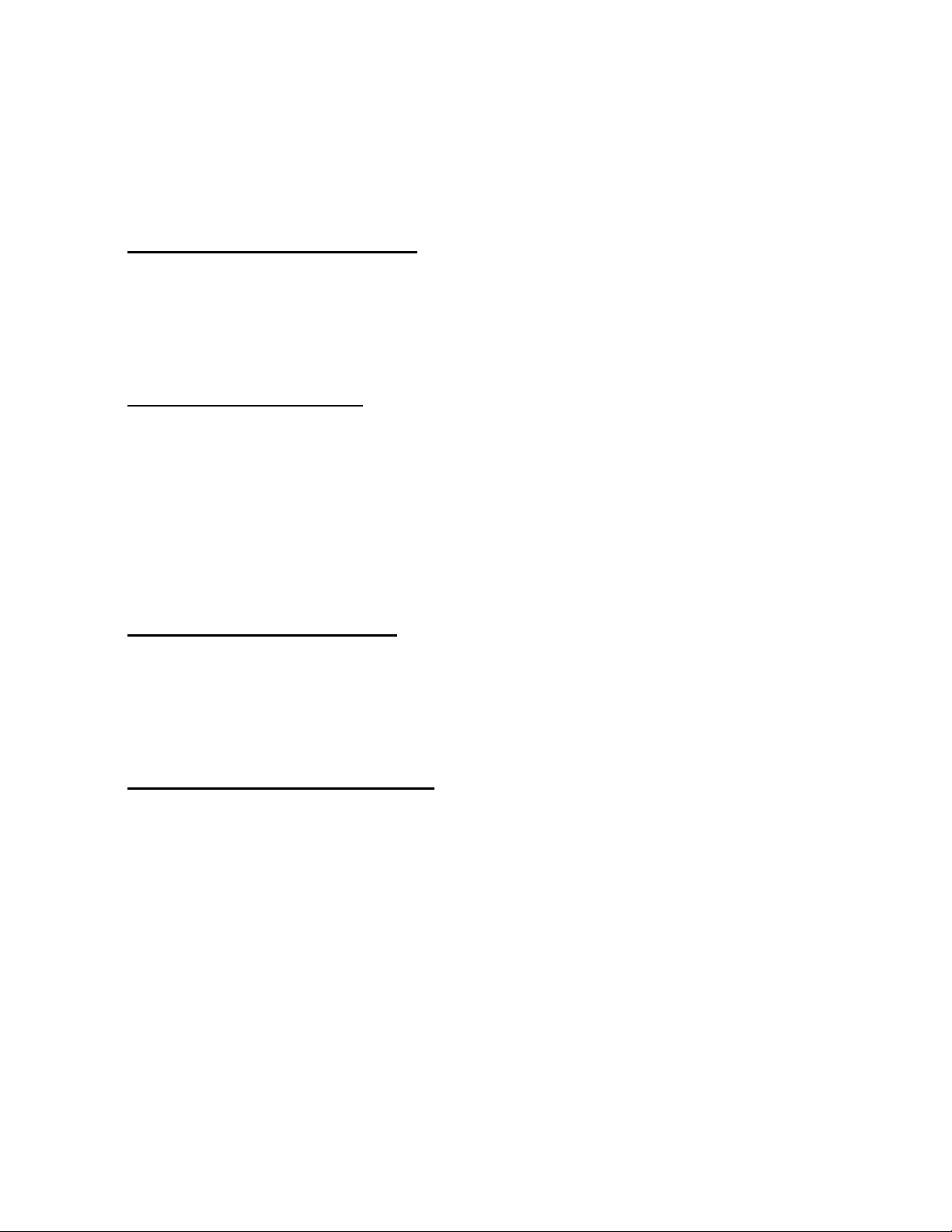

Problems and Possible Causes

PROBLEM

turn on

Zone is not heating

Switch light does not

Griddle is not plugged

in (if so equipped)

Power switch is off X X

Thermostat is set to

"OFF"

Thermostat is not

calibrated

Thermostat failure X X X

Transformer failure X X

Wire harness is

disconnected

Relay failure

(if equipped)

Probe Failure X X X X

Element Failure X X X

POSSIBLE CAUSE

Switch failure X X

Contactor failure X X

Wrong voltage tab on

transforme

Snubber failure X

Diode in Switch Circuit

has been Wired

Backwards

XX

X

XX X

XX

X

to zone

Plate temperature is

inconsistent from zone

XX

Griddle temperature is

inconsistent in one zone

overheats

Griddle stays hot or

Contactor is chattering

X

L22-334, rev. 0 (3/11)

Page 5

MKE SERVICE MANUAL

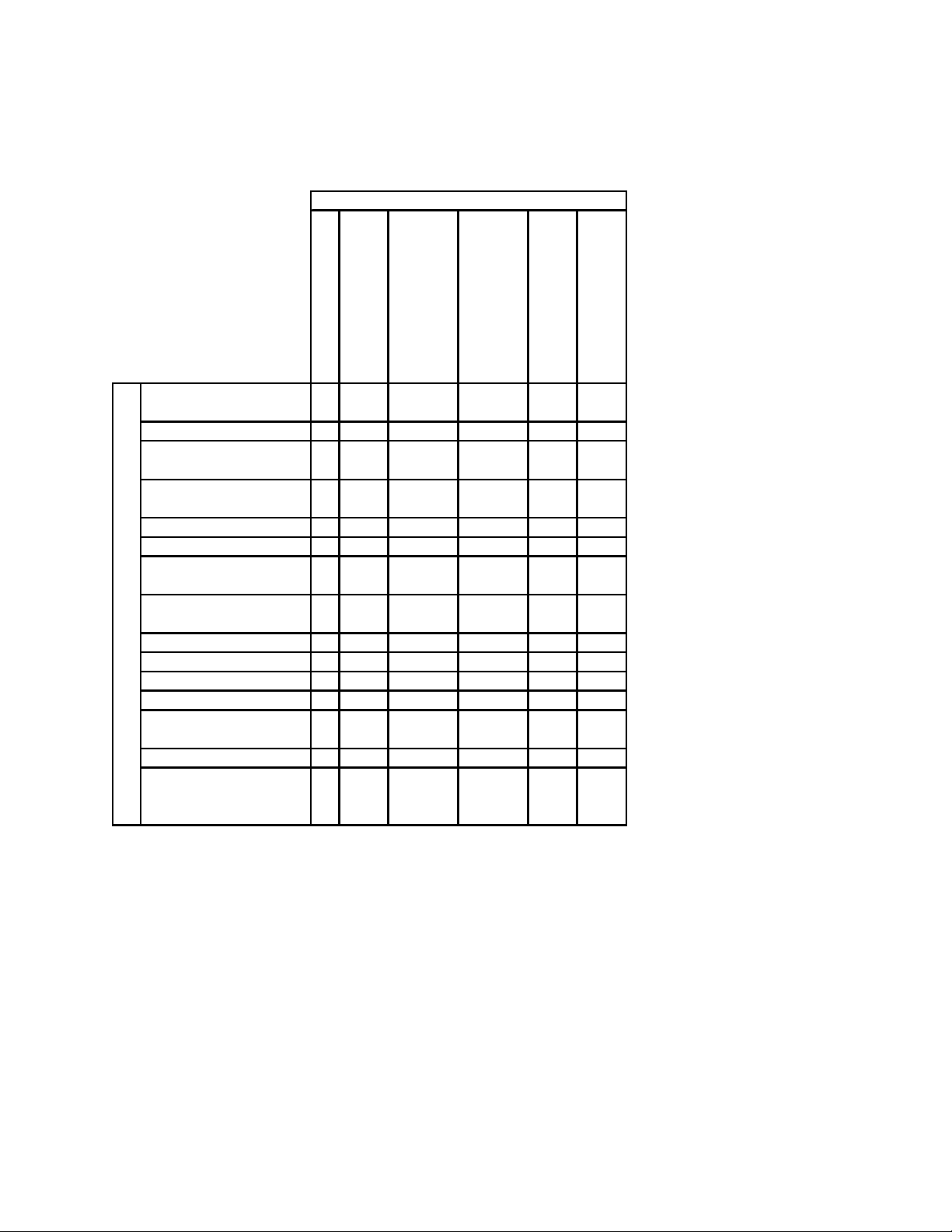

Normal Operating Component Properties

Property

Normal Re sistance

(OH MS)(A p p ro x im ate)

Relay Coil Check for Continuity

Contactor Coil 5.8 - 7.0

10" Element Check for Continuity

7" Element Check for Continuity

Solid State Relay C oil Che ck fo r Contin u ity

Component

Solid State Probe

Electric Ts ta t c o il Ch e ck fo r C ontinu ity

Transformer Check for Continuity

Fuse Check for Continuity

1466 at 250F

1680 at 250F

1894 at 250F

Front and Rear Panels

Removal of Front Panels and Access to Component Panels

Always use caution when removing any of the front panels as live contacts are inside at 24VAC

as well as the line voltage. It is highly recommended to turn off power to the unit at the circuit breaker or

unplug the unit before removing any of the front panels.

The first step to removing any of the front panels is to remove the grease drawer(s). Always

check the grease level in the drawer by slowly pulling the drawer forward. If the Unit has been in

operation recently this grease may be hot. Set aside.

The two lower front panels will be next.

There are two types of lower front panels: those

next to the cabinet wall and those next to a

grease drawer enclosure. Both types require

the removal of two phillips head screws next to

the controller panel. Once the screws are

removed the panels may spring forward on the

controller panel side. The lower front panel next

to a grease drawer enclosure is removed by

pulling the controller panel side toward you then

moved toward the grease drawer to remove it’s

tab from a slot in the grease drawer enclosure.

Set aside.

2

The lower front panel next to the

cabinet wall is very similar except the tab / slot

is reversed. After removing the two retaining screws at the controller panel, pull the lower front panel

toward you, then move it towards the controller panel. This removes a tab attached to the cabinet wall

from a slot in the lower front panel. Set aside.

L22-334, rev. 0 (3/11)

Page 6

MKE SERVICE MANUAL

At this point, wires may be visible in the two openings where the lower front panels once were. It

is recommended that servicing the unit is not attempted through these openings as visibility is poor.

Remove at least the switch panel.

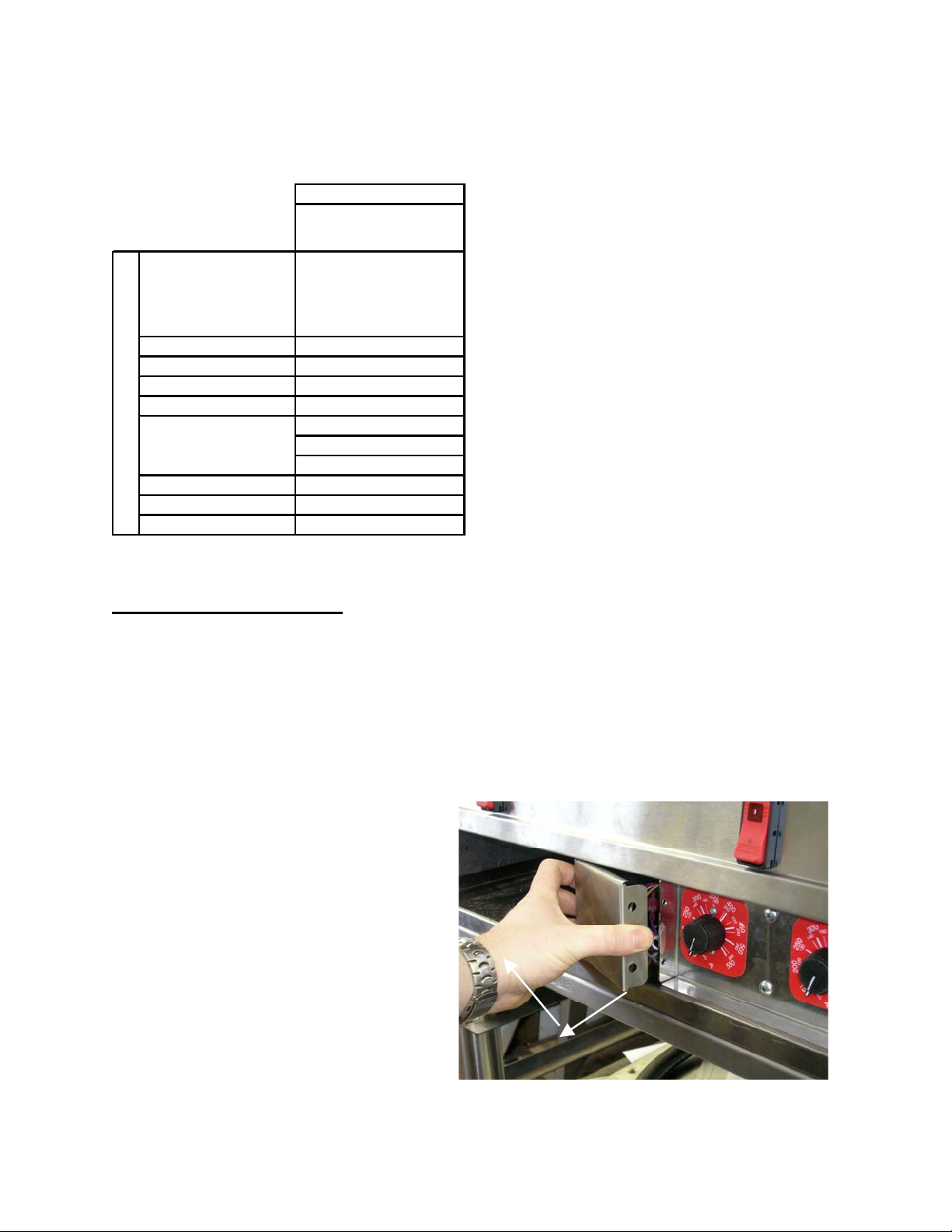

Remove the switch

panel by first removing the

screws above the switches.

The screws will have 5/16 hex

heads. Once the screws are

removed the may drop so

support the panel as the last

screws are removed. The

panel can then be pulled

down and toward you. The

panel is still connected to the

controller circuit. There will

be one Molex connector per

switch. Remaining on the panel will be the switches, and small harnesses terminating in the pin side of

the Molex connectors. This harness contains the diode for the LED light in each of the switches. The

Diode will be covered in heat shrink tubing. If this is not the subject of service, set aside.

The majority of the electrical components can now be seen inside this cavity. Further access

space to the top of the cavity can be made by removing the switch panel retention bracket, which runs the

width of the unit near the top of the unit. To remove, support the bracket and remove a series of screws

whose heads now face you down the length of the bracket. When the screws are removed the bracket

will fall if not supported. Set Aside.

SCREWS

Assembly of Front Panels

Be sure that all components are in place and wires have been properly dressed and are out of the

way. If the controls panel is not in place, do so now.

Place the switch panel retention bracket at the top, front of the component heat shield and align

the mount holes. Secure with screws starting from the center and working out from there.

Reconnect the switch panel to its mating Molex connectors in each control circuit. Be sure that

the zone 1 controller is connected to the zone 1 switch and so on. Also be sure that the wire number,

configuration, and colors match from one side of the Molex union to the other.

The lower left and right corners of the switch panel hook around mounting brackets on the insid e

of the cabinet walls. Check for wires around the controls panel and above the grease drawer

enclosure(s). Grooves in the bottom edge of the switch panel match up with the grease drawer

enclosure(s) and the two sides of the controls panel. The switch panel then tips forward until it contacts

the retention bracket. Secure with screws.

The lower front panels install just as they are removed. The tab of the lower panel hooks into the

slot of the grease drawer enclosure(s) and swings into place. The slot of the other lower front panel

mates to a tab mounted to the inside of the cabinet side. Then it swings into place. Both lower front

panels have flanges that lap over one side of the controls panel and is secured with two screws.

Slide the grease drawer(s) into its enclosure.

L22-334, rev. 0 (3/11)

Page 7

MKE SERVICE MANUAL

Rear Panels

The rear panels are broken up into three sections: Upper, Middle, and Lower. To rem ove the

Upper or Middle panels, remove the screws or bolts securing them. The panel will then come free, set

aside. The lower panel contains removable brackets around the power cord(s). By loosening the upper

screw(s) and removing the lower screw(s)

the lower bracket may be swung out of

the way. Then remove the screws

securing the panel to the griddle and the

panel will come free.

To put a panel back on the

griddle, reposition it on the griddle and

secure with the screws or bolts previously

removed. The Middle and Lower panels

have a top edge that sits on the inside of

the mating edge of the panel above it.

When securing the Lower panel, swing

the lower cord bracket around the cord

and tighten both screws.

LOWER PANEL

UPPER PANEL

MIDDLE PANEL

LOOSEN

REMOVE

L22-334, rev. 0 (3/11)

Page 8

MKE SERVICE MANUAL

Component Panels

Component Location

To gain access to the component panels remove front panels, see FRONT AND REAR PANELS

section.

MKE36 with Solid State Controls

ZONE 1 ZONE 2 ZONE 3

ZONE1 ZONE 2 ZONE 3

ZONE 1 ZONE 2 ZONE 3

1. Transformers: one for each 12” zone of griddle. The left most transformer will power the 24 volt AC

control circuit for the left most 12” zone of griddle, “Zone 1”, and so on.

2. Terminal Block: one per cord. This will power 2 or 3 zones of griddle. There will be one or two

terminal blocks per griddle depending on the size (MKE24-36: one terminal block, MKE48-72 two terminal

blocks).

3. Controller panel: mounting panel for the griddle’s temperature controllers. The panel is held in

place with four screws.

4. Fuse Blocks and Fuses: Six fuses are used for each cord/ terminal block.

5. Contactors: one for each 12” zone of griddle. The left most contactor will operate three elements in

the left most 12” zone of griddle, “Zone 1”, and so on.

Component Replacement

1. Contactors

Each contactor will be connected to 6 wires,

three upper wires and three lower wires. The top

wires are from the fuse block. The lower wires are the

second of two leads from that zone’s three elements.

Each of the wires should be labeled according to what

they attach to. For example: on the contactor all of the

way to the left will be for zone 1. The lower wires will

be labeled 1 L-2, 2 L-2, and 3 L-2 from left to right.

These are leg 2 of element 1, 2, and 3. The upper

wires will be labeled by what fuse they go to. The best

practice is to transfer one wire at a time from the

contactor to be removed to the same location on the

contactor to be installed. Then remove the two screws

securing the old contactor to the component panel and

replace it with the fully wired new contactor.

SCREWS

L22-334, rev. 0 (3/11)

Page 9

MKE SERVICE MANUAL

2. Cord and Plug Sets

Each cord is secured to the griddle at two points: the terminal block in the front of the griddle and

the strain relief in the rear. Both front and rear panels

need to be removed to install, change, or remove a

cord. See the Front and Rear panel section for proper

removal. In the front of the unit, disconnect the cord

from the terminal block with the appropriate allen

wrench and from the ground lug with a flat tip

screwdriver. From the rear of the griddle the griddle

the strain relief may be loosened or the assembly can

be freed as a whole by removing four screws near the

cord. The cord is removed from the strain relief by

unthreading two retaining collars.

To install a cord, thread it through the strain

relief, the sheet metal retainer, then the plastic

retainer. Tighten both retainers. Reinstall the cord

into the terminal block and the ground wire to the

ground lug below the terminal block at the front of the

unit.

3. Fuses

Fuses are item #4 the component location diagram. To remove, pull the fuse away from the

block. To install a new fuse, place on contacts of the fuse block and press the metallic ends firmly into

place. Fuse will snap into place when correctly installed.

4. Relays (Electric Thermostats Only)

Relays are located above and/or below the grommets in the component panel(s). The best

practice is to transfer one wire at a time from the old relay to the new one. The relay can then be

removed by removing two screws. Replace new relay with screws.

5. Switches

All switches are located in the Switch panel. See the Front and Rear Panels section for removal

instructions. Once the panel is removed and the Molex connectors are disconnected the switch and a

small wire harness are all that remain on the panel. The wire harness must be removed from the switch

first as it cannot fit through the cutout in the panel. The switched circuits are between tabs 2 and 3, and 5

and 6. In this application only one set is used. The leads going to the other tabs are to power the LED

lamp in the switch. It is important to note that tab 8 is the positive tab and tab 7 is the negative tab. Tab

8 will be connected to the red lead with the heat shrink tubing on it. This tubing contains a diode to keep

the lamp from flickering.

To remove a switch press the thin plastic flaps at the top and bottom of the switch in toward each

other. While holding the flaps, the switch can be passed through the opening in the panel toward the

rocker side of the switch.

To install a new switch, first orient the switch so that the lamp lens and “I” marking are at the top

relative to the switch panel. Then pass the switch through the cut out in the switch panel and press it

firmly into place. Thin plastic flaps at the top and bottom of the switch should spring away from the switch

locking it in place. Reconnect the harness to the switch as described above.

6. Thermostats

Thermostats are located in the Controls Panel at the lower front of the griddle. A solid state

thermostats is connected by quick disconnect to a probe mounted with the front row of elements. This

type may be replaced independent of the probe. Electric thermostats are directly connected to a sensory

bulb by a capillary, which must all be replaced as a unit. If replacing an electric thermostat see the

Elements and Probes section for probe removal instructions.

The Controls panel may be removed from the griddle before preceding. The first step to

changing a thermostat is to remove the knob. To remove the knob of an electronic thermostat, pull it

towards you and it should slip off a central shaft. The solid state thermostat knob is held in place by a

collet. Start by removing the knob face, which is a round disk with a white line on it. This can be done

with a fingernail or a thin screwdriver. A brass collet inside the knob is now visible. Loosen the nut to

release the knob from its shaft. Do not completely remove the nut from the collet. Then pull the knob

towards you to remove.

RETAINERS

SCREWS

L22-334, rev. 0 (3/11)

Page 10

MKE SERVICE MANUAL

Both types to thermostats are secured to the Controls Panel with two small screws. Remove the

thermostat and transfer the leads to the new one. Secure the new thermostat to the Controls Panel using

the screws and reattach the knobs.

See the Calibration section to calibrate all new thermostats.

7. Transformers

Transformers are located in the upper section of the component cavity. The one powering zone 1

control circuit is on the left, then there is zone 2 to right of that and so on.

To change a transformer, remove the two screws securing it to the component heat shi eld.

Transfer the leads from the old one to the new one, and secure the new one in the old one’s pl ace using

the two screws.

L22-334, rev. 0 (3/11)

Page 11

MKE SERVICE MANUAL

Elements and Probes

Location and Numbering

Shown is the element layout of an MKE36 as seen from under the plate. The elements are numbered

from front to rear and left to right as seen below. For larger units the numbering pattern continues in the

same way. Each element is contained by an element pan. Each element pan is held in place by two

straps. The strap pairs are actually two of the same strap with one reversed. Each strap is secured with

two Grade 8 ¼-20 x 5/8 bolts through two washers. Do not replace the supplied bolts with lesser or nonrated bolts. The elements have two lead wires. The wires are labeled with the element number and the

leg number, leg one or leg two. The difference is that leg one is wired to the fuse block and leg two is

wired to a contactor.

LEFT

PAN

PROBE

1

2

3

FRONT

4

5

6

REAR

STRAP

7

RIGHT

8

9

L22-334, rev. 0 (3/11)

Page 12

MKE SERVICE MANUAL

Replacing an Element

See the Front and Rear panel section to remove all front panels. If replacing a rear element also

remove all of the rear panels.

If removing a front or middle row element then the heat shield that the transformers and fuse

blocks are attached to must now be removed.

The individual components can be removed from

the heat shield to avoid unwiring them, or they

can all be unwired, left on the panel and removed

as one.

The component heat shield attaches to a

bracket on the grease trough side and the cabinet

wall on the side without grease trough where

applicable. Support the heat shield as you

remove the screws retaining it. The assembly

can now be removed from the griddle.

The element to be replaced will need to

be unwired at two points: the Fuse Block (leg 1)

and the contactor (leg 2) for the zone the element

is in. Refer to the photograph in the previous

section to determine the element number. The leads of the element will be labeled with this number as

well as a leg number.

At least one side of the upper heat shield,

front or rear needs to be lowered to access the

elements. Remove all of the screws along the

support to be lowered being sure to prevent the

heat shields from dropping. The heat shield

panels associated with the element to be

changed need to be removed to properly route

the wires. Each heat shield panel to be removed

can be pulled toward you and out of the griddle.

Note: the panel will drop off of the support on the

other side of the griddle when it is pulled out. Use

caution not to rub a sheet metal edge on an

element lead wire when the panel is being

removed.

The element will be secured with 4 bolts

or 6 bolts if it is zone 1 of a Left-Hand Trough

griddle. You will most likely need a 7/16 socket

and ratchet to remove the bolts. Note: as you

remove all of the bolts supporting a strap it will

come free. As you remove the last bolt, support

the element pan to prevent it from dropping on

your arm. The element and pan can now be

removed from the griddle. If removing an element

in the first row, in the front of the griddle, see the

Replacing a Probe section. Note: Solid state

probes may be left in place when replacing the

associated element. The element leads will need

to be pulled through the grommet in the contactor

panel and the grommet in the middle heat shield.

Remove the element from the pan.

To install a new element, first place the

new element into the element pan by threading

the leads through the appropriate cutout (there

may be more than one). Use caution not to rub

PANELS

SCREWS

SUPPORT

L22-334, rev. 0 (3/11)

Page 13

MKE SERVICE MANUAL

the element leads on the edge of the cutout. Seat

the element in the pan. Some manipulation of the

element may be necessary to get to sit flat in the

pan. Route the leads through the middle heat

shield grommet and the contactor panel grommet

where the old element was removed. The

contactor panel may need to be pivoted to do this.

To pivot the contactor panel, remove all of the

screws along to top edge. Pull on the right side to

let the panel pivot on the cord connection to the

terminal block. Reconnect the leads and secure

the contactor panel with its screws.

Place the element and pan in its position

on the underside of the griddle plate. If replacing

a front element, be sure that the grooved tab in

the element pan supports the probe sheath or the

capillary. While holding it in place secure a strap

to the pan with a bolt and washer. Thread and tighten the remainder of the bolts with washers. Note:

only tighten each bolt to 35 inch-pounds or 3 footpounds torque. Always verify that the element is

sitting flush with the griddle plate. There should

be a .020 to .040 gap between the underside of

the griddle plate and the element pan. A mirror

may be necessary to observe this. It is possible

for an element pane to be too close to the

perimeter of the griddle and get hung up on the

weld bead in this area. If this occurs, loosen the

four bolts for the affected element and slide it off

of the weld bead and retighten the bolts.

The upper heat shield must now be put

back in place. The notch in the upper heat shield

is positioned toward the front side of the griddle.

Then slide the panel into the griddle below the

elements and above the middle heat shield. The

first edge into the griddle must be lifted onto the

ledge of the opposite support bracket. Note: as each panel is slid into position, do not rub any wires on

the sheet metal edges. Now the panel should have its far edge supported by the opposite support

bracket and the near edge resting on the support bracket that was previously removed. The probe

sheath or capillary should be positioned to pass through the notch in the panel on the front side of the

griddle. The smaller panels fit between the larger panels next to the vertical legs of the elements. It may

be necessary to insert them with their short edge vertical and twist them flat once in position. As always,

be careful not to rub the sheet metal edges on any wires when inserting a heat shield panel into the

griddle. They are supported on the support brackets the same way the larger panels are. Once all panels

are in place, there will not be any open spaces in the heat shield layer, lift the support bracket and all of

the heat shield panels into place. Be careful not to catch the small vertical flanges of the panels on the

element legs or the cabinet sides. Secure the bracket with the center screw first, then secure the others.

The component heat shield must now be lifted back into position and secured on the left and right

sides with screws. If removed, all components must be secured to the panel and any disconnected

connectors reconnected.

PROBE

NOTCH

Replacing a Probe

Remove the front element associated with the probe from the griddle plate per instructions listed

in the previous section. Keep the element in the pan and do not unwire it.

Solid State Probe: Disconnect the probe from the thermostat. Pull the probe toward you until it

reached the metal plate as shown. Then tip the metal sheath to one side or the other until it is parallel

with the floor. The probe will want to move in the opposite direction that you are tipping it. Now the probe

can be pulled down at the bend to clear the sheet metal edge. Pull the probe straight toward you and out

L22-334, rev. 0 (3/11)

Page 14

MKE SERVICE MANUAL

of the griddle. Remove the leads from the cutout in the element pan. Thread the new element leads

through the cutout being careful not to rub the leads on the edge of the cutout. Insert the tip of the new

probe into the slot in the griddle plate where the old probe came out of. At the end of the slot there is a

drilled whole for the probe. Insert the probe into the

hole with the last leg of the probe sheath parallel to

the floor. Rotate the leg to be perpendicular to the

floor and push it forward into the griddle plate until

it stops. Reattach the element.

Electric Thermostat Probe: Once the

element has been dropped, the bulb can be fed

through the cutout on the element pan and

removed. Thread the new bulb through the cutout

and place in the center of the cradle. While

reattaching the element to the griddle, use caution

to keep the bulb in the center of the cradle and not

to damage the capillary.

L22-334, rev. 0 (3/11)

Page 15

MKE SERVICE MANUAL

Thermostat Calibration

Each control operates a set of three elements. The controls were set at the factory. However, if the

griddle’s surface temperature varies greatly from the setting on the thermostat knob, adjust the thermostat

using the following procedure:

Electric Thermostat

1. Turn all the control knobs to the

desired temperature setting.

2. Wait 30 minutes (or 1 hour if

griddle was cold) for surface to

stabilize.

3. Place a reliable Griddle surface

thermometer,

or test instrument

thermocouple, (able to register

300°F), in the location above the

REMOVED, SNAP ACTION

thermostat being calibrated as

described in section 2.2.2. Check

the temperature every 5 minutes

until the temperature stabilizes

and does not change by more

than 30°F over a 15 minute span.

4. If the average temperature over

any burner set is not within +/-15°F of the knob setting (300°F), adjust the corresponding

thermostat. This is done by removing the knob, holding the thermostat knob stem, see picture

above, (do not allow the stem to turn or the temperature setting will not be accurate), then

turn the adjustment screw located within the center of the stem in small increments. Turn this

screw counter clockwise to increase the temperature, and clockwise to decrease the temperature.

5. Check the temperature after 15 minutes and repeat adjustment as needed until the correct

temperature is indication on the measuring instrument.

THERMOSTAT ADJUSTMENT SCREW

TURN CW TO DECREASE TEMPERATURE

TURN CCW TO INCREASE TEMPERATURE

THERMOSTAT KNOB

THERMOSTAT STEM

ELECTRIC THERMOSTATS SHOWN FOR REFERENCE

Figure 1

NOTICE

The adjustment screw on the thermostat is sealed by the Manufacturer to protect the calibration. It

may be necessary to remove this seal to be able to adjust the thermostat.

Solid State Thermostat

1. Turn all the control knobs to the

desired temperature setting.

2. Wait 30 minutes (or 1 hour if griddle

was cold) for surface to stabilize.

ALIGNED WITH ACTUAL TEMP.

THIS CAP SNAPS

ON AND OFF

ROTATE KNOB UNTIL

TEMP. INDICATOR IS

5/16" NUT

3. Place a reliable Grill surface

thermometer,

or test instrument

thermocouple, (able to register

300°F), In the location above the

thermostat being calibrated

described in section 2.2.2. Check

the temperature every 5 minutes

until the temperature stabilizes and

350

4

1

8

0

0

0

0

2

6

0

3

0

4

1

0

0

5

2

2

1

0

0

0

1

0

2

8

0

1

5

0

0

1

0

0

2

2

4

0

5

0

2

4

0

5

2

6

0

0

0

0

8

2

0

5

°

C

5

°F

Figure 2

350

4

1

8

0

0

0

0

2

6

0

3

0

4

1

0

0

5

2

2

1

0

0

0

1

0

2

8

0

1

5

0

0

1

0

0

2

2

4

0

5

0

2

4

0

CAP LINE

5

2

6

0

0

0

0

8

2

0

5

°

C

5

°F

does not change by more than 30°F

over a 15 minute time period. You will need to remember the average temperature for the next

step.

4. Carefully remove the cap on the thermostat knob with the white indicator line see picture this

section. While holding the knob, loosen the 5/16" nut on the thermostat shaft, (DO NOT

REMOVE), once the nut is loose the knob can be rotated so that the cap line marker is aligned

with the actual temperature that the Grill surface thermometer is indicating.

Re-tighten the 5/16" nut while holding the knob in position, (do not allow the stem to turn or the

temperature setting will not be accurate). Replace cap

L22-334, rev. 0 (3/11)

Page 16

MKE SERVICE MANUAL

In the event of problems with or questions

about your order, please contact the

MagiKitch’n factory at:

(800) 258-3708 US and Canada only

(603) 225-6684 World Wide

www.magikitchn.com

MAILING ADDRESS – P.O. BOX 501, CONCORD, NH 03302-0501

SHIPPING ADDRESS – 10 FERRY ST., CONCORD, NH 03301

L22-334, rev. 0 (3/11)

In the event of problems with or questions

about your equipment, please contact the

MagiKitch’n Authorized Service and Parts

representative (ASAP) covering your area,

or contact MagiKitch’n at the numbers

listed to the left.

Loading...

Loading...