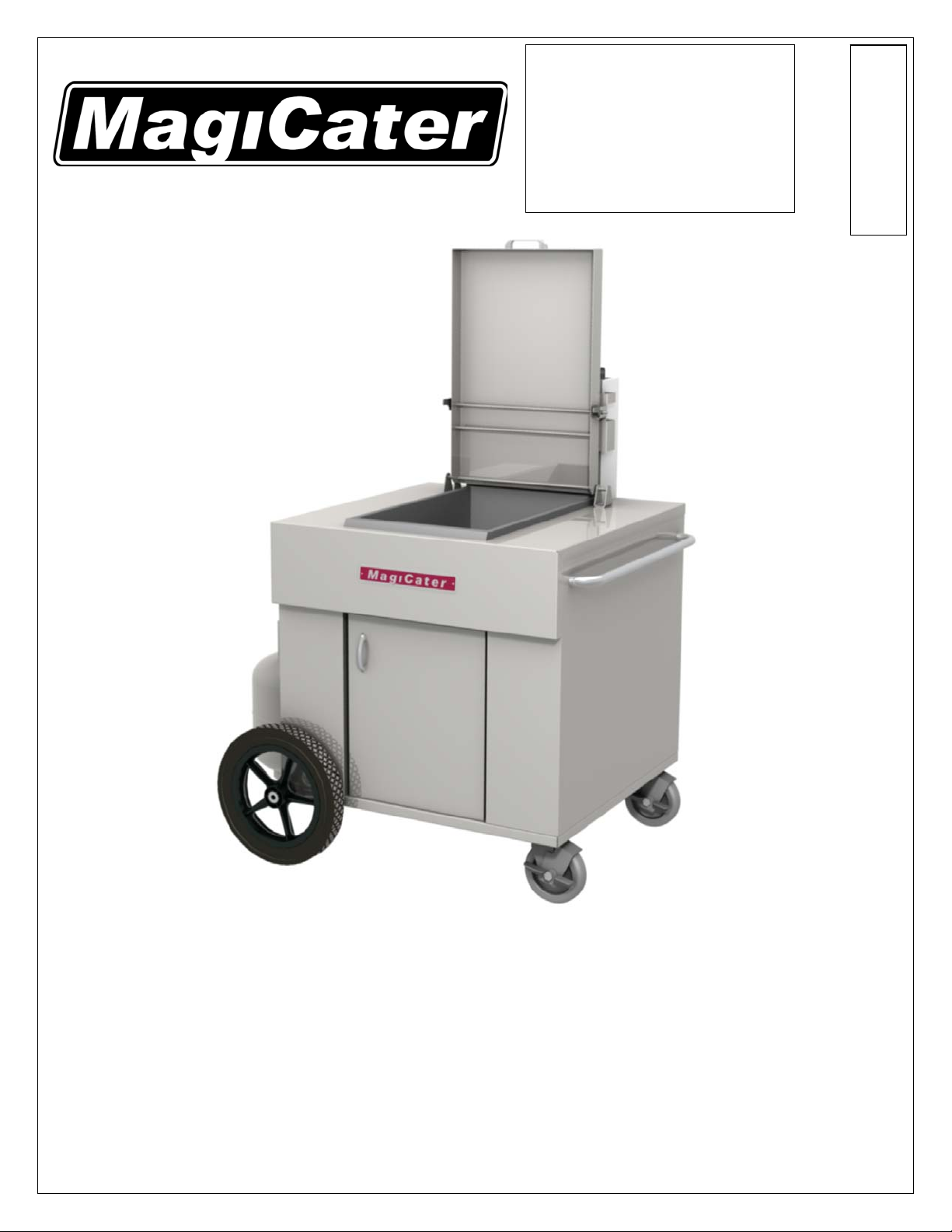

Page 1

ENGLISH

L20-373 Rev. 0 3/2012

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this

manual for the life of the equipment:

Model #: _______________________

Serial #: _______________________

Date Purchased: _________________

Installation and Operation Manual

Pitco Frialator PO Box 501 Concord, NH 03302-0501 603-225-6684

Covering MCF Series Fryers

with Millivolt Gas Valve

Includes Models: MCF14, MCF18

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE

Page 2

FOR YOUR SAFETY

DO NOT store or use gasoline or other flammable vapors or liquids in the

vicinity of this or any other appliance.

WARNING

Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the installation, operating and

maintenance instructions thoroughly before installing or servicing this

equipment.

TO THE PURCHASER

Post in a prominent location the instructions

to be followed in the event that an operator

smells gas. Obtain this information from

your local gas supplier.

WARNING

There is an open flame inside this appliance.

The unit may get hot enough to set nearby

materials on fire. Keep the area around the

appliance free from combustibles.

WARNING

DO NOT supply the appliance with a gas

that is not indicated on the data plate. If you

need to convert the appliance to another

type of fuel, contact your dealer.

WARNING

DO NOT use an open flame to check for

gas leaks!

WARNING

If gas flow to appliance is interrupted, or pilots

extinguish, wait 5 minutes before attempting to

relight the pilot to allow any residual gas in

appliance to dissipate.

WARNING

Ensure that the appliance can get enough air to

keep the flame burning correctly. If the flame is

starved for air, it can give off a dangerous carbon

monoxide gas. Carbon monoxide is a clear

odorless gas that can cause suffocation.

WARNING

Do not attempt to move this appliance when the

unit is at operating temperature or filled with hot

shortening/oil. Serious personal injury could result

if skin comes in contact with the hot surfaces or

shortening/oil.

WARNING

DO NOT sit or stand on this appliance. Serious

injury could result from falling or contact with hot

shortening/oil.

NOTICE

This appliance is equipped with a pressure

sensing device that will shut down the appliance

prior to the LP tank being completely empty.

WARNING

DO NOT operate this appliance with the lid down.

WARNING

This gas cooking appliance is intended for outdoor

use only and is not intended to be installed in or

on recreational vehicles and/or boats.

Page 3

TABLE OF CONTENTS

INSTALLATION ...................................................................................................................... 2

Checking Your New Appliance ............................................................................................................................ 2

Codes and Standards .......................................................................................................................................... 2

Assembly ............................................................................................................................................................. 2

Heat Deflector Installation.................................................................................................................................... 2

Location ............................................................................................................................................................... 3

Gas Connection ................................................................................................................................................... 3

Fuel Supply Line Leak and Pressure Testing ...................................................................................................... 3

Natural Gas Connections ..................................................................................................................................... 3

Propane Cylinders and Regulators ...................................................................................................................... 4

Propane Cylinder installation and transportation ................................................................................................. 5

Fire Safety Systems ............................................................................................................................................. 6

Installation ............................................................................................................................................................ 6

Installation Clearances ........................................................................................................................................ 6

Initial Adjustments ................................................................................................................................................ 7

Burner Ignition Systems ....................................................................................................................................... 7

Lighting Instructions ............................................................................................................................................. 8

Pilot Flame Adjustment ........................................................................................................................................ 8

Main Burner System Adjustment ......................................................................................................................... 9

Initial Cleaning ................................................................................................................................................... 10

OPERATION ......................................................................................................................... 11

Filling the Tank .................................................................................................................................................... 11

Filling the tank with liquid shortening/oil ............................................................................................................ 11

Filling the tank with solid shortening/oil ............................................................................................................. 11

Operating Instructions ........................................................................................................................................ 11

Appliance Start-Up ............................................................................................................................................. 12

Appliance Shutdown .......................................................................................................................................... 12

MAINTENANCE AND ADJUSTMENTS ............................................................................... 13

Daily Cleaning .................................................................................................................................................... 13

Thermostat Calibration Check ........................................................................................................................... 13

Thermostat Calibration ...................................................................................................................................... 14

Weekly Cleaning .................................................................................................................................................. 14

General Cleaning ............................................................................................................................................... 14

Boil Out Procedure ............................................................................................................................................ 14

TROUBLESHOOTING .......................................................................................................... 16

Basic Troubleshooting Flow Chart ..................................................................................................................... 16

WIRING DIAGRAM ............................................................................................................... 17

1

Page 4

INSTALLATION/OPERATION

INSTALLATION

Checking Your New Appliance

Your new appliance has been carefully packed into one crate. Every effort has been made to ensure that you it

is delivered to you in perfect condition. As you unpack your new appliance, inspect each of the pieces for

damage. If something is damaged, DO NOT sign the bill of lading. Contact the shipper immediately; the shipper

is only responsible for 15 days after delivery. Check the packing list enclosed with your appliance to ensure that

you have received all the parts to the appliance. If you are missing any parts, contact the dealer from whom the

appliance was purchased. As you unpack the appliance and its accessories be careful to keep the weight of the

appliance evenly distributed.

CAUTION

To prevent equipment damage and/or personal injury, do not tilt the appliance onto any

two of its casters, or pull the appliance by the flue vent.

Locate your warranty and fill in the serial number of the appliance and the date of purchase and write them on

the cover of this manual for future reference. You will find the serial number on the date plate located inside the

door or on the back lower panel

Codes and Standards

The fryer must be installed in accordance with:

In the United States:

State and local codes, or in the absence of local codes, with:

National Fuel Gas Code, ANSI-Z223.1/NFPA #54 (latest edition).

In Canada:

Local Codes

CSA-B149.1 Natural Gas and Propane Installation Code (latest edition)

Assembly

When you receive your appliance it is completely assembled with the possible exception of the heat deflector.

Heat Deflector Installation

If the appliance requires a heat deflector, you will find a removable label at the rear top edge of the unit. This

label has instructions for positioning and installation of the heat deflector. Refer to the label and the instructions

below to install the deflector.

a. Remove the two self-drilling screws from the top, back area of the appliance.

b. Position the heat deflector so that the angled portion of the deflector is facing toward the front of

appliance. Secure the heat deflector to the back of the unit using the two previously removed

fasteners.

c. When properly installed the angled section of the heat deflector will extend over the flue

opening to redirect the heat. It SHOULD NOT cover the flue opening. Never allow anything to

block the flue opening; this will cause the appliance to overheat and inhibit proper combustion,

which could produce dangerous gases

2

Page 5

INSTALLATION/OPERATION

Location

This appliance must be installed with the casters provided by the manufacturer, it cannot be curb mounted.

Curb mounting will seriously inhibit the appliance’s ability to effect proper combustion.

This appliance is for outdoor use only. To be used in well ventilated areas, and shall not be used in a building,

garage, or any other enclosed space. Do not locate this appliance under overhead unprotect combustible

surfaces.

Do not operate this appliance in adverse weather conditions. Operating or storing this appliance in adverse

weather conditions such as rain, sleet, snow, or high winds could cause property damage, injury or death.

Do not obstruct the flow of combustion and ventilation air.

Do not install near open windows and/or doors.

Minimum ambient temperature for safe use is -13°F (-25°C)

WARNING

This appliance must be installed with the casters provided by the manufacturer.

WARNING

This appliance must be installed on a firm and level surface, free of debris. Ensure the

appliance is stable (will not move or tip) prior to operation

WARNING

Lock swivel casters and place wheel chocks underneath large wheels prior to use. Do not

remove wheel chocks or unlock casters during operation.

Gas Connection

The gas line must be installed to meet the local building codes or National Fuel Gas Code ANS Z223.1 a nd

NFPA 54 (latest editions). In Canada, install the appliance in accordance with CSA B149.1 or .2 and local

codes. A properly sized and installed gas line will deliver a minimum supply pressure of 7.0 ± 2.0 inches w.c.

(17.4 ± 5 mbar) for natural gas and 12.0 ± 2.0 inches w.c. (29.9 ± 5 mbar) fo r propane gas to all appliances

connected to the supply line, operating simultaneously at full demand.

WARNING

NEVER supply the appliance with a gas other than the one that is indicated on the data

plate. Using the incorrect gas type will cause improper operation and could result in

serious injury or death. If you need to convert the appliance to another type of fuel,

contact the dealer you purchased it from.

NOTICE

NEVER use an adaptor to make a smaller gas supply line fit the appliance connection.

This may not allow proper gas flow for optimum burner operation, resulting in poor

performance and improper operation.

Fuel Supply Line Leak and Pressure Testing

The fuel supply system must be tested before the appliance is used. If the fuel line is going to be tested at a

pressure greater than ½ PISG (3.45 kPa), insure that that appliance is disconnected from the fuel line. If the fuel

line is to be tested at a pressure equal to or less than ½ PSIG (3.45 kPa), the appliance can be connected

during the test, but the unit’s gas valve must be shut. Test all gas line connections for leaks with a solution of

soap and water when pressure is applied. Do not test with an open flame.

Natural Gas Connections

3

Page 6

INSTALLATION/OPERATION

WARNING

Adequate means must be provided to limit the movement of the appliance without

depending on the gas line connection. The appliance must be stabilized by installing

restraining chains and/or wheel chocks. If a flexible gas line is used, an additional

restraining cable must be connected at all times when the appliance is in use. If

disconnection of the restraint(s) is necessary, the restraint(s) must be reconnected after

the appliance is returned to its originally installed position.

WARNING

This appliance, when equipped with a flexible gas line, must be connected to the gas

supply with a connector that complies with the Standard for Connectors for Mov able Gas

Appliances, ANSI Z21.69 • CSA 6.16 and a quick disconnect device that complies with the

Standard for Quick-Disconnect Devices for Use With Gas Fuel, ANSI Z24.41 • CSA 6.9.

Adequate means must be provided to limit the movement of this appliance without

depending on the connector, quick disconnect device, or its associated piping to limit the

movement of the appliance. Restraining means may be attached to the back of the

appliance if necessary.

NOTICE

All gas supply connections and any pipe joint compound must be resistant to the action of

propane gases

Codes require that a gas shutoff valve be installed in the gas line ahead of the fryer.

The NATURAL GAS supply line must be at least the equivalent of ¾” (19.1 mm) iron pipe.

Make sure the pipes are clean and free of obstructions, dirt, and piping compound.

After piping has been checked for leaks, fully purge gas pipes to remove air.

NOTICE

Inspect the hose assembly regularly. Replace with original manufacturer’s parts only.

Propane Cylinders and Regulators

NOTICE

Pressure regulators and hose assemblies supplied with the appliance must be used. All

gas supply connections and any pipe joint compound must be resistant to the action of

propane gases.

The standard, self contained propane system fryer is designed for use with a 40 lb. (18.1 kg.) propane cylinder,

equipped with a Type I cylinder valve

WARNING

Do not store propane cylinder in or on the appliance, explosion, fire, or injury may result.

The Type I (Q.C.C. 1) cylinder valve is recognizable by the large external thread on the outlet part of the valve.

Standard valves do not have these exterior threads. Any attempt to fit the regulator with anything other than the

mating Type I (Q.C.C. 1) connector, (recognized by the large plastic coupling nut) will negate the important

safety features designed into the Type I (Q.C.C. 1) system. Fitting a standard #510 P.O.L. connector, will not

provide the flow control or temperature shut-off safety features built into the complete Type I (Q.C.C. 1) system.

When purchasing a cylinder for your appliance, it must be constructed and marked in accordance with the

specifications of:

The U.S. Department of Transportation (DOT), or CAN/CSA B339.

The cylinder must also be equipped with:

4

Page 7

INSTALLATION/OPERATION

a) A shut-off valve terminating in a proper cylinder valve outlet specified in current standards.

b) A safety relief valve having direct communication with the vapor space of the cylinder.

c) A collar to protect the cylinder shut-off valve.

d) An arrangement for vapor withdrawal only.

e) A bottom ring for securing to the cylinder support assembly.

WARNING

Protect regulator vent openings from the elements. Do not expose regulators to rain,

snow, or ice. Store regulators in cabinet when not in use.

WARNING

Only install and operate cylinders in the retaining brackets on the appliance. Cylinders

must be secured against tip-over and from heat sources at all times. Do not store unused

gas cylinders in any compartments on the appliance that are not intended for cylinder

storage. Unauthorized storage could lead to an explosion, fire, or personal injury.

NOTICE

This appliance is not intended for use with a remote gas system.

Propane Cylinder installation and transportation

Handling, storage, and transportation of propane cylinders must be in accordance with Storage and Handling of

Liquid Petroleum Gases, ANSI/NFPA 58 or Natural Gas and Propane Installation Code, CSA B149.1.

Therefore:

Always use the protective cap provided with your cylinder whenever it is not connected to your

appliance.

Do not store in a building, garage or any other enclosed area. Store only in a well ventilated area.

Do not store in the vicinity of any gas burning apparatus or in any high heat area such as a closed car or

trunk, or in direct sunlight.

Do not smoke while transporting a cylinder in your vehicle.

Transport and store cylinder(s) in an upright position only.

Store out of reach of children.

Allow only qualified LP gas dealer to fill or repair cylinder(s).

Do not allow the cylinder to be over filled.

Make sure the LP gas dealer checks the cylinder for leaks after filling.

Mount LP cylinder securely on brackets provided. Slide top cylinder bracket down onto cylinder, and tighten

wing nuts. Connect gas hose by inserting connector into LP cylinder and securing by turning green knob, until

tight. Open valve on LP cylinder.

Turn off valve on LP cylinder when appliance is not in use.

Storage of the appliance indoors is permissible, only if the LP cylinder is disconnected and removed from the

appliance.

To transport, ensure valve on LP cylinder is closed. Leave LP cylinder mounted upright in brackets on

appliance. If completely disconnected from appliance, LP cylinder must be transported and stored in an upright

position. Remove all liquid from cook tank prior to transporting appliance.

WARNING

The Pressure regulator and the hose assembly supplied with the appliance must be used.

A replacement pressure regulator and hose assembly must be that specifie d by the

manufacturer.

CAUTION

5

Page 8

INSTALLATION/OPERATION

Inspect gas pressure regulator and hose assembly before each use. If it evident that there

is excessive abrasion or wear, or the hose or regulator is cut or damaged in any way, it

must be replaced prior to the appliance being put into operation. A replacement pressure

regulator and hose assembly must be that specified by the manufacturer.

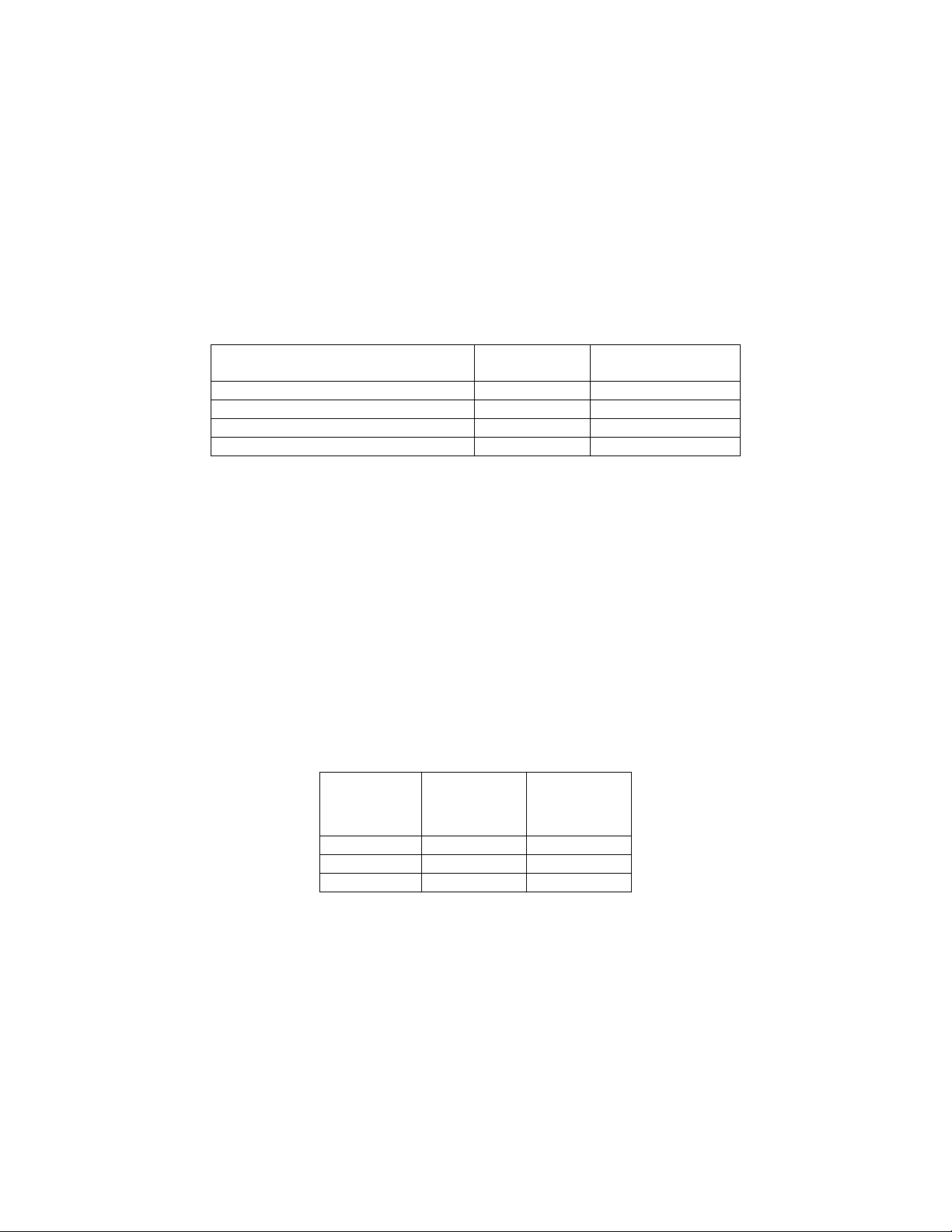

Fire Safety Systems

Your new appliance must have proper ventilation to function safely and properly. Exhaust gas temperatures can

reach as high as 1100 °F (593 °C). Therefore, it is very important to have a fire safety device readily accessible

during operation. Your ventilation system should be designed to allow for easy cleaning. The following tables

contain a list of reference documents that will provide guidance on fire safety devices. It is not necessarily

complete. Additional information can be obtained from CSA International, 8501 East Pleasant Valley Road,

Cleveland, OH, 44131 or visit their website at www.csa-international.org.

Types of Fire Extinguishers

Topic UL Document

CO2 Type Extinguishers ANSI/UL 154 ANSI/NFPA 12

Dry Chemical Type Extinguishers ANSI/UL 299 ANSI/NFPA 17

Water Type Extinguishers ANSI/UL 626 ANSI/NFPA 13

Foam Type Extinguishers ANSI/UL 8 ANSI/NFPA 11

Installation

If you have completed the above steps that are applicable to the appliance you purchased, the appliance is now

ready to be installed. Although it may be possible for you to install and set up your new appliance, it is

STRONGLY recommended that you have this done by qualified professionals. A qualified professional will

ensure that the installation is safe and meets local building and fire codes.

WARNING

DO NOT obstruct the flow of combustion, ventilation or air openings around the appliance.

Adequate clearance around the appliance is necessary for servicing and proper burner

operation. Ensure that you meet the minimum clearance requirements specified in this manual.

Installation Clearances

The clearances shown below are for combustible and non-combustible installations and will allow for safe and

proper operation of your appliance.

Back 6 in. (15 cm) 0

Sides 6 in. (15 cm) 0

Floor 6 in. (15 cm) 6 in. (15 cm)

In addition to the above clearances there must also be at least 28 in (71.2cm) of open space in front of the unit.

It is essential that the appliance be operated only when adequate ventilation is provided. Inadequate ventilation

many not properly evacuate all appliance emissions. Excessive winds may cause drafts, which could interfere

with proper operation of the pilot and burners. Never block the flue opening or locate this appliance under

overhead unprotected combustible surfaces.

Combustible

Construction

Combustible

Construction

CAUTION

A down draft will not allow the appliance to exhaust properly and will cause overheating, which

may cause permanent damage. Damage caused by down drafts will not be covered by the

warranty. NEVER allow anything to obstruct the flow of combustibles or ventilation exiting the

appliance. NEVER place anything on top of the flue area, or block the flue in any way.

National Fuel Gas

Code Document

Non-

6

Page 9

INSTALLATION/OPERATION

Initial Adjustments

After your appliance has been properly installed as described in the installation section of this manual, it will

need to be adjusted to ensure that it will perform as designed. These adjustments must be performed by a

qualified person. To perform these adjustments the following tools will be needed:

• Manometer • Digital Thermometer (Temperature Probe)

• DC Millivolt Meter

Before you begin filling and adjusting the appliance, perform the

following visual checks:

a. After the appliance is in its permanent location,

check the levelness. Any additional leveling that

is necessary can be performed as previously

described.

b. Check the temperature probe and high limit bulb

(in the tank) to ensure that the mounting screws

are tight.

c. Review the installation portion of this manual and

ensure that all steps have been followed and

executed properly.

Burner Ignition Systems

CAUTION

Before proceeding any further, fill the tank with WATER. Water is used for the installation

adjustments because the temperature will never exceed 212°F (100°C), thereby allowing

plenty of adjustment time. Never let the water level go below the “OIL LEVEL” mark

stamped on the tank.

Ensure that these

Parts are not loose

7

Page 10

INSTALLATION/OPERATION

WARNING

During operation there is an open flame inside this appliance. The unit may get hot

enough to set near by materials on fire. Keep the area around the appliance free from

combustibles.

Lighting Instructions

For manual pilots, refer to the following instructions.

WARNING

If pilot extinguishes, wait 5 minutes before attempting to relight the pilot to allow any built

up gas to dissipate.

a. Open gas supply valves to the appliance.

b. Turn the thermostat control knob counterclockwise to the OFF position.

c. Turn the gas valve knob counterclockwise to the PILOT position. Push knob

in and hold a flame to the pilot until the pilot ignites; this may take a little while

the first time you light the pilot because of the air in the lines. Once lit, hold

the knob in for approximately one minute and then release.

d. If the pilot goes out, wait 5 minutes and repeat step C. If after three tries the

pilot will not remain lit, refer to the operator troubleshooting section of this

manual.

e. Once a pilot flame has been established, turn the gas valve knob

counterclockwise to the ON position.

f. Set the thermostat control knob to the desired temperature setting, The main

burners will ignite and be controlled by the thermostat.

Pilot Flame Adjustment

For manual pilots, refer to the following instructions. Perform this procedure once the pilot is lit and

ensure that the thermostat is turned to the OFF position.

NOTE: This procedure requires a DC millivolt meter set to a scale of 0-1000 mV.

Using test leads with sharp probes will help in taking the required readings.

a. Locate the thermopile wires coming from the pilot to the

gas valve.

b. Using the positive (+) test probe, connect the probe to

the top PP terminal with the red wire.

c. Connect the negative (-) test probe to the bottom PP

terminal with the white wire.

d. The output level should be 550mv ± 50mV. If this level

is not correct, remove the cap screw and adjust the

screw in and out to achieve the proper millivolt level.

Replace cap screw.

Note: Allow 3 to 5 minutes between flame adjustments to allow the reading to stabilize.

8

Page 11

INSTALLATION/OPERATION

Main Burner System Adjustment

For the main burners to operate the gas supply valve must be open and the thermostat must be turned

on. For models with electric controls, the main power switch must be on. The main burners receive gas

from the main gas supply through the thermostatically controlled valve. When the thermostat is turned up

the gas control valve opens.

The main burners must be adjusted to deliver optimum flame. Refer to the following procedure to adjust the

main burners.

CAUTION

Before proceeding any further, fill the tank with WATER. Water is used for the installation

adjustments because the temperature will never exceed 212°F (100°C), thereby allowing plenty of

adjustment time. Never let the water level go below the “OIL LEVEL” mark stamped on the tank.

a. Ensure that the main gas valve is shut off, remove the manifold pressure tap plug and

connect an accurate pressure gauge (range of 0-16 “ w.c. in 0.1” increment s) or

manometer.

b. Turn on this and all appliances connected to the gas supply line and light their main

burners. The pressure reading of the installed pressure gauge should not drop from the

required installation pressure. Any loss of pressure indicates inadequate supply line

installation, which will cause poor performance of all appliances during peak usage.

c. The installed pressure gauge should be the same, ±0.1” w.c, as that marked on the data

plate on the inside door or on the back of the appliance. If the pressure is correct, go to

step e, if it is not, adjust the pressure as outlined in step d.

d. To adjust the pressure, remove the regulator adjustment screw cap and, with a flat head

screwdriver, adjust the regulator screw until the proper burner pressure is reached. Turning the

screw clockwise will increase the burner pressure. Turning the screw counterclockwise will

decrease the burner pressure.

e. When the pressure is correct, replace the regulator adjustment screw cover.

9

Page 12

INSTALLATION/OPERATION

Initial Cleaning

When your appliance is shipped, many of its parts are covered with a thin coat of shortening/oil for protecti on.

Before the appliance is ready for cooking it must be cleaned. This will remove the shortening/oil coating and any

foreign matter that may have accumulated during storage and shipment. Refer to the following proced ure to

clean the appliance.

a. Fill the tank with water. Light the pilot, turn the appliance on and set the thermostat to

200°F (93 °C).

b. Allow the appliance to heat for 15 minutes. Add cleaner to the water, stirring with the cleaning

brush to ensure that the cleaner dissolves thoroughly.

CAUTION

DO NOT leave the appliance unattended during cleaning. Never let the water level go below the

“OIL LEVEL” mark stamped on the tank.

c. Using the cleaning brush, scrub the inside of the tank to remove the protective coating.

d. When cleaning is complete turn the appliance off and drain the water into a container suitable

for hot water and dispose of it.

WARNING

Wear protective gloves and clothing when cleaning and draining the appliance and when

disposing of water. The water is extremely hot and can cause severe injuries.

e. When the tank has cooled, rinse thoroughly with cool water. Continue to rinse the tank

until the cleaner has been completely and thoroughly rinsed from the tank.

f. Using a clean dry cloth, wipe out all of the water. Be very thorough when removing the

water, as any residual water will cause hot shortening/oil to splatter out of the appliance.

NOTICE

Mild steel tanks must be wiped down/coated thoroughly with shortening/oil to keep the tank

from rusting

10

Page 13

INSTALLATION/OPERATION

OPERATION

Filling the Tank

Both liquid and solid shortening/oil can be used in this appliance, but liquid is preferred. If solid

shortening/oil is used it is recommended that you melt the shortening/oil before adding it to the appliance.

You can melt solid shortening/oil in the appliance, but you must be very careful not to scorch the

shortening/oil.

Filling the tank with liquid shortening/oil

To fill the tank with liquid shortening/oil refer to the following procedure.

a. Ensure that the drain valve is completely closed and that there

is no residual moisture in the tank.

b. Fill the tank with shortening/oil. You may fill the tank to the

“OIL LEVEL” mark or slightly below this nominal level mark:

the shortening/oil will expand slightly when it heats up, raising

the level slightly.

Filling the tank with solid shortening/oil

To fill the tank with solid shortening/oil refer to the following procedure.

WARNING

NEVER melt blocks of solid shortening/oil on top of the burner

tubes. This will cause a fire and could result in personal injury.

a. Remove the rack covering the tubes (tube rack).

b. Cut the solid shortening/oil into cubes no larger than one inch.

ALWAYS pack the shortening/oil below, between, and on top

of the burner tubes. DO NOT leave any large air gaps. Use

care when packing the solid shortening/oil into the tank. DO

NOT bend or break the temperature or high limit sensor

probes. If these are damaged the appliance will not function

properly.

c. Once the appliance tank is firmly packed with shortening/oil to

the level mark, the shortening/oil must be melted. Melt the

shortening/oil by cycling the main burners on for 4 seconds

and off for 30 seconds repeatedly, using the thermostat knob.

If your appliance has a Melt Cycle option, use this to melt the

EXCESSIVE

AIR GAPS

shortening/oil automatically.

Operating Instructions

To ensure the quality of the food you cook in this appliance, follow the preparation instructions from the

food manufacturer. Using the best shortening/oil makes the best fried foods. The best shortening/oil will

last longer than lower grade shortening/oil and save you money. When not in use, the shortening/oil

should be cooled and covered to prevent contamination.

WARNING

DO NOT attempt to move the appliance when it is in use or has hot liquid in it. Splashing hot

liquids can cause severe burns.

OIL LEVEL LINE

BURNER TUBES

OIL LEVEL LINE

BURNER TUBES

BURNER TUBES

11

Page 14

CLEANING AND MAINTENANCE

WARNING

Water and shortening/oil DO NOT mix. Keep liquids away from hot shortening/oil.

Dropping liquid frozen foods into the hot shortening/oil will cause violent boiling.

Appliance Start-Up

WARNING

DO NOT start the appliance without filling the tank with shortening/oil first!

To start up the appliance refer to the following instructions.

a. Light the pilot as previously described in this manual

b. Turn the temperature control knob (thermostat) to the desired temperature setting. This

knob is located behind the front doors or on the front control panel.

c. The main burners will light and raise the shortening/oil temperature to the desired setting.

Appliance Shutdown

There are two shutdown modes of appliance operation: STANDBY and COMPLETE. The standby mode

removes the ability of the appliances main burners to operate. Complete shutdown turns off the gas

supply to the appliance.

STANDBY Turn the thermostat to the OFF position. Turn the gas valve knob clockwise to

the PILOT position. The cooker is now in Standby and can remain this way for

only brief periods of time. NEVER leave the appliance in standby mode for

prolonged periods or overnight.

COMPLETE Turn the thermostat to the OFF position. To return the gas valve knob to the

OFF position, the knob must be depressed slightly to disengage its stop tab,

then rotated clockwise. The appliance is now completely shut down and can be

cleaned and filtered if desired.

12

Page 15

CLEANING AND MAINTENANCE

MAINTENANCE AND ADJUSTMENTS

Daily Cleaning

Your appliance should be cleaned every day to maintain peak performance, proper sanitation and appearance.

Perform the following procedures daily.

a. Wipe up any shortening/oil that spills onto the exterior of the appliance. This should be done with

a clean soft cloth while the shortening/oil is still warm.

b. Use warm water with a mild detergent to clean surfaces. Be careful not to get water into the

shortening/oil and be sure to completely remove any detergent from the fry tank. Use a nonabrasive scouring powder or pad to clean stains if necessary.

NOTICE

Maintenance and repairs should be performed by qualified personnel. If you are

unsure, contact the factory, factory representative to locate the nearest qualified

Service Company.

Thermostat Calibration Check

NOTICE

Thermostat calibration requires that the temperature of the appliance be raised above

boiling. If you have water in the tank you will need to drain it, dry it and fill it with

shortening/oil. Follow the filling instructions in this manual.

To check the calibration of your appliance, refer to the following procedure.

a. Remove the tube rack from the tank.

b. Place the tip of a digital thermometer probe in the shortening/oil approximately one inch

above the temperature sensor.

c. Light the pilot as described in this manual, set the thermostat to 325°F (163 °C) and allow

the shortening/oil to come up to temperature. Watch the thermometer closely as the

temperature rises.

d. If the shortening/oil temperature reaches 350°F (167 °C) and the burners do not turn off,

turn the thermostat down. Keep lowering the thermostat setting until the burners go out.

CAUTION

If the burners do not shut off at the LOWEST thermostat setting, the thermostat may be

defective. Contact your local service company.

e. Let the appliance cycle 4 to 6 times before checking the temperature. Compare the

thermometer temperature against the thermostat setting. If the values are more than 5°F

(3 °C) apart, calibrate the thermostat using procedure in this manual.

13

Page 16

CLEANING AND MAINTENANCE

Thermostat Calibration

For Millivolt Thermostats

a. Remove the tube rack from the tank and place the tip of a digital thermometer in the

shortening/oil approximately one inch above the temperature sensor.

Light the pilot as described in this manual, set the thermostat to 325°F (163 °C) and allow the

shortening/oil to come up to temperature; let the appliance cycle 4-6 times to insure that the

shortening/oil temperature has stabilized. Compare the thermostat setting of 325°F (163 °C) to

the digital thermometer reading.

b. Remove the thermostat dial by pulling the knob straight out. DO NOT rotate the dial.

c. Holding the outside of the shaft so that it does not move, scrape away the sealing compound in

the center of the shaft with a small flat blade screwdriver.

d. Turn the adjustment screw clockwise to lower the thermostat’s temperature setting or counter-

clockwise to raise it.

e. Turn the adjustment screw until the burners come on at 325°F (163 °F).

f. Replace the knob and allow the appliance to cycle 4 to 6 times. Check the temperature of the

digital thermometer against the thermostat dial setting; if there is greater than a 5°F

(3 °C) difference, repeat the calibration procedure.

Weekly Cleaning

refer to the following procedure.

One-quarter turn of the adjustment screw changes the temperature setting

approximately 24°F (13 °C).

NOTE

General Cleaning

The appliance should be thoroughly cleaned AT LEAST once a week. This should include a thorough wipe down

of the entire appliance with a rag and mild detergent.

WARNING

NEVER spray cleaner into the main burners or pilot. This could act as a magnet for dust and

other debris, causing it to accumulate and inhibit the proper operation of your appliance.

Boil Out Procedure

The appliance should be boiled out AT LEAST once a week to remove food debris and shortening/oil build up.

You will need a container large enough to hold 1 ½ times the shortening/oil in the tank. Refer to the following

procedure for weekly boil out.

WARNING

Completely shut the appliance down when the shortening/oil is being drained and

replaced with water. This will prevent the main burners from coming on during the

draining and filling procedure.

14

Page 17

CLEANING AND MAINTENANCE

WARNING

At operating temperatures, the shortening/oil in the appliance is VERY HOT and can cause

severe burns. Do not let the hot shortening/oil touch your skin or clothing. ALWAYS wear

insulated, oil proof gloves, protective clothing and eyewear when working on a hot

appliance.

a. Drain the shortening/oil from the appliance and discard or save for reuse. Remove the tube rack

Close the drain valve and fill the tank with warm water and non-caustic detergent

b. Restart the appliance as described in this manual and set the thermostat to 200°F (93 °C). Bring

the water to a slow boil. DO NOT allow the water to boil excessively as this will cause excessive

foaming and boil over.

c. Allow the appliance to soak for 20 minutes to soften shortening/oil deposits. Use the cleaning

brush to scrub and remove any residue from the tank, tubes and side walls.

d. When finished drain the water and wipe the tank dry with a soft clean cloth.

e. Ensure that the drain valve is closed and replace the tube rack.

f. You may now refill the tank with shortening/oil per the filling instructions in this manual.

15

Page 18

TROUBLESHOOTING

TROUBLESHOOTING

Basic Troubleshooting Flow Chart

Refer to this section to correct common problems that may be encountered during the course of normal

operation. If applicable, a schematic is provided on the inside door.

16

Page 19

WIRING DIAGRAM

Diagram also found on inside door of appliance.

WIRING DIAGRAM

17

Page 20

In the event of problems with or questions about

your order, please contact the MagiKitch’n

factory at:

(603) 225-6684 World Wide

www.magikitchn.com

MAILING ADDRESS – P.O. BOX 501, CONCORD, NH 03302-0501

SHIPPING ADDRESS – 10 FERRY ST., CONCORD, NH 03301

In the event of problems with or questions

about your equipment, please contact the

MagiKitch’n Authorized Service and Parts

representative (ASAP) covering your area, or

contact MagiKitch’n at the numbers

the left.

L20-373 R0

listed to

Page 21

Ç

IMPORTANT : CONSERVER CE DOCUMENT AFIN

DE POUVOIR LE CONSULTER ULTÉRIEUREMENT

Veuillez fournir les informations requises et conservez

ce manuel pour la durée de vie de votre équipement.

Modèle N° : _________________________

N° de série : _________________________

Date d’achat : ____________________

Manuel d’installation et de fonctionnement

Pitco Frialator PO Box 501 Concord, NH 03302-0501 603-225-6684

avec commande de gaz en millivolts

Comprend les modèles : MCF14, MCF18

CONSERVER CE MANUEL AFIN DE POUVOIR LE CONSULTER ULTÉRIEUREMENT

pour friteuses MCF

L20-373 Rev. 0 (03/12)

FRAN

AIS

Page 22

POUR VOTRE SÉCURITÉ

NE PAS entreposer ni utiliser d’essence ou d’autres vapeurs ou liquides

inflammables à proximité de cet appareil ou d’un autre.

AVERTISSEMENT

Toute mauvaise installation, modification, ainsi que tout mauvais entretien ou

réglage erroné risque de provoquer des degats materiels, des blessures voire

la mort. Lire entièrement les instructions d’installation, de fonctionnement et

d’entretien avant d’installer ou de procéder à l’entretien de cet appareil.

AVIS À L’ACHETEUR

Afficher en évidence les instructions à

suivre si un utilisateur sent une odeur de

gaz. Cette information est disponible auprès

de votre fournisseur local de gaz

AVERTISSEMENT

Il y a une veilleuse à flamme nue à l’intérieur

de l’appareil. Cet appareil est susceptible

d’atteindre des températures très élevées

risquant d’enflammer des matériaux placés à

proximité. Veiller à ce qu’il n’y ait aucun

élément combustible à proximité de

l’appareil.

AVERTISSEMENT

NE PAS alimenter l’appareil avec un gaz ne

figurant pas sur la plaque signalétique. S’il est

nécessaire de convertir l'appareil pour un autre

type de combustible, communiquer avec votre

fournisseur.

AVERTISSEMENT

NE JAMAIS se servir d’une flamme nue pour

chercher une fuite de gaz!

AVERTISSEMENT

Si l’alimentation en gaz de l’appareil est

interrompue ou si la veilleuse s’éteint, attendre 5

minutes avant de tenter de rallumer la veilleuse

afin de permettre au gaz se trouvant à l’intérieur de

l’appareil de se dissiper.

Veiller à ce que l’alimentation en air de l’appareil

soit suffisante pour que la veilleuse brûle

correctement. Si la flamme manque d’air, elle

dégagera du monoxyde de carbone, qui est un gaz

dangereux. Le monoxyde de carbone est un gaz

incolore et inodore qui peut provoquer l’asphyxie.

NE PAS tenter de déplacer cet appareil quand

l'appareil est à température de fonctionnement ou

contient de l’huile ou de la matière grasse chaude.

Vous risquez de vous brûler grièvement si la peau

touche des surfaces, d’huile ou de la matière

grasse chaudes.

Ne pas s'asseoir ni monter sur cet appareil. Des

blessures graves risquent d’être causées par une

glissade, une chute ou tout contact avec de d’huile

ou de la matière grasse chaudes.

Cet appareil est équipé d’un détecteur de pression

qui éteindra l’appareil avant que la bouteille de

propane ne soit complètement vide.

NE PAS Utiliser cet appareil avec le couvercle

abaissé.

Cet appareil de cuisson à gaz doit être utilisé

uniquement à l’extérieur et ne doit pas être

installé à bord d’un véhicule récréatif ni à bord

d’un bateau.

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

AVIS

AVERTISSEMENT

AVERTISSEMENT

Page 23

TABLE DES MATIÈRES

INSTALLATION ...................................................................................................................... 2

Vérification de votre nouvel équipement ............................................................................................................ 2

Codes et normes ................................................................................................................................................. 2

Assemblage ......................................................................................................................................................... 2

Installation du déflecteur de chaleur .................................................................................................................... 2

Emplacement ....................................................................................................................................................... 3

Raccordement du gaz .......................................................................................................................................... 3

Recherche de fuite sur la conduite d'alimentation en gaz et vérification de la pression ..................................... 4

Raccordement à la conduite de gaz naturel ........................................................................................................ 4

Bouteilles de propane et régulateurs de pression (détendeurs).......................................................................... 4

Installation et transport de la bouteille de propane .............................................................................................. 5

Ventilation et systèmes de sécurité contre les incendies à la conduite de gaz naturel ...................................... 6

Installation ............................................................................................................................................................ 7

Dégagement et distances de sécurité pour l’installation ..................................................................................... 7

Premiers réglages ................................................................................................................................................. 7

Système d'allumage du brûleur .......................................................................................................................... 8

Instructions d'allumage ........................................................................................................................................ 8

Réglage de la flamme de la veilleuse .................................................................................................................. 9

Premier nettoyage ............................................................................................................................................. 10

FONCTIONNEMENT ............................................................................................................. 11

Remplir la cuve .................................................................................................................................................... 11

Remplir la cuve de matière grasse liquide/huile ................................................................................................ 11

Remplir la friteuse de matière grasse en bloc/huile .......................................................................................... 11

Instructions de fonctionnement ........................................................................................................................ 12

Mise en marche de l’équipement ....................................................................................................................... 12

Éteindre l’équipement ........................................................................................................................................ 12

ENTRETIEN ET RÉGLAGES ................................................................................................ 13

Nettoyage quotidien ........................................................................................................................................... 13

Vérification de l'étalonnage du thermostat ........................................................................................................ 13

Étalonnage du thermostat .................................................................................................................................. 14

Nettoyage hebdomadaire ................................................................................................................................... 14

Nettoyage général ............................................................................................................................................. 14

Procédure de nettoyage par ébouillantage........................................................................................................ 14

GUIDE DE DÉPANNAGE ..................................................................................................... 16

Diagramme de dépannage ....................................................................................................................................

SCHÉMA DE CÂBLAGE .............................................................................................................................. 17

1

Page 24

INSTALLATION/FONCTIONNEMENT

INSTALLATION

Vérification de votre nouvel équipement

Votre nouvel équipement a été emballé avec précaution dans une caisse. Tout a été prévu afin que l'équipement

vous soit livré en parfait état. Lorsque vous déballez votre nouvel équipement, vérifiez toutes les pièces afin de vous

assurer qu'elles ne sont pas endommagées. Si une des pièces a été endommagée, veuillez NE PAS signer le

connaissement (lettre de transport). Contactez immédiatement le transporteur car ce dernier ne peut être tenu

responsable que pendant les 15 jours suivant la livraison. Vérifiez le bordereau d'expédition fourni avec

l'équipement afin de vous assurer que vous êtes en possession de toutes les pièces. Si des pièces s'avèrent

manquantes, contactez le revendeur auprès duquel vous avez acheté l'équipement. Lorsque vous déballez

l'équipement et ses accessoires, veillez à ce que le poids de l’équipement demeure réparti uniformément.

ATTENTION

Afin d'éviter d'endommager l'équipement ou de vous blesser,

ne pas le pencher sur deux de ces roues ni tirer sur le conduit d'évacuation de fumée.

Recherchez la garantie et inscrivez à titre de référence le numéro de série de l'équipement et la date de réception

de l'équipement sur la couverture du manuel. Vous trouverez le numéro de série sur la plaque à l'intérieur de la

porte ou sur au dos sur le panneau inférieur.

Codes et normes

La friteuse doit être installée conformément à la réglementation suivante:

Aux États-Unis :

Code locaux, de votre état ou province, et en l’absence de codes locaux, conformément au National Fuel Gas

Code (Code national d'installation des appareils à gaz), ANSI-Z223.1/NFPA nº 54 (dernière édition).

Au Canada:

Codes locaux.

CSA-B149.1 Natural Gas and Propane Installation Code / Code national sur l’installation du gaz naturel et du

propane (dernière édition).

Assemblage

Lorsque vous prenez réception de l'équipement, toutes les pièces ont été complètement assemblées sauf peut-être

le déflecteur de chaleur.

Installation du déflecteur de chaleur

Si l’équipement requiert un déflecteur de chaleur, vous trouverez une étiquette amovible située sur le bord

arrière de la friteuse. Cette étiquette comporte des instructions sur la position et l'installation du déflecteur de

chaleur. Reportez-vous à l’étiquette et aux instructions ci-dessous pour installer le déflecte ur.

a. Retirez les deux vis autotaraudeuses du dessus et de l’arrière de l’équipement.

b. Placez le déflecteur de chaleur de manière à ce que la partie inclinée du déflecteur se trouve

orienté vers l’avant de l'équipement. Fixez le déflecteur de chaleur au dos de la friteuse en

utilisant les deux vis que vous avez retirées auparavant.

c. Si le déflecteur de chaleur a été correctement installé, la partie inclinée du déflecteur devrait

dépasser au-dessus de l’ouverture du conduit de fumée afin de réacheminer la chaleur dans

une autre direction. Il NE DOIT PAS couvrir l’ouverture du conduit de fumée. Ne jamais laisser

quoi que ce soit bloquer l’ouverture du conduit de fumée, ceci risquerait de faire surchauffer

l’équipement et de nuire à la combustion et entraînerait la formation de gaz dangereux.

2

Page 25

INSTALLATION/FONCTIONNEMENT

Emplacement

Cet équipement doit être installé avec les roulettes fournies par le fabricant, il ne peut doit pas être installé sur

une pente. Toute installation sur une surface en pente nuira dangereusement au fonctionnement de

l'équipement et affectera la combustion.

Cet équipement doit être utilisé uniquement à l’extérieur. Il doit être utilisé dans un endroit largement ventilé et

aéré et ne doit pas être utilisé à l’intérieur d’un immeuble, garage ou tout autre espace clos ou fermé. Ne pas

placer cet équipement sous une surface en surplomb combustible non protégée.

Ne pas utiliser cet équipement en cas de mauvais temps. Le fait d’utiliser ou de remiser cet équipement en

présence de mauvaises conditions météorologiques telles que de la pluie, de la grêle, de la neige ou de vents

forts risque de provoquer des dégâts matériels, des blessures voire la mort.

Ne pas bloquer le flux d’air de combustion et de ventilation.

Ne pas installer cet équipement à proximité des fenêtres et/ou de portes.

La température ambiante minimale pour pouvoir utiliser cet équipement en toute sécurité est de -25°C (-13°F).

AVERTISSEMENT

Cet équipement doit être installé avec les roulettes fournies par le fabricant.

AVERTISSEMENT

Cet équipement doit être installé sur une surface dure et à niveau, sans débris. Assure z-

vous que l’appareil est stable (veillez à ce qu’il ne bouge pas et ne risque pas de se

renverser) avant de l’utiliser.

AVERTISSEMENT

Bloquez les roulettes pivotantes et placez des cales sous les grosses roues avant

d’utiliser l’appareil. Ne pas retirer les cales ni débloquez des roulettes pendant que vous

utilisez l’appareil.

Raccordement du gaz

Le tuyau de gaz doit être installé conformément aux codes du bâtiment de votre localité ou à la norme ANSI

Z223-1 de la dernière édition du Code national d'installation des appareils à gaz (NFPA 54-de rniè re édition). Au

Canada, installez l'équipement conformément aux normes CSA B149.1 ou 2 et à la réglementation locale. Un

circuit d'alimentation de gaz qui a été correctement installé doit pouvoir alimenter toutes les machines à une

pression adéquate entre 7 po./177 mm avec une marge de ± 2 po/5 cm de colonne d’eau (17 , 4 mbar avec une

marge de ± 5 mbar) pour le gaz naturel ou de 12 po./304 mm avec une marge de 2 po./5 cm (29,9 mbar avec

une marge de ± 5 mbar) de colonne d’eau pour le propane fonctionnant toutes en même temps et à plein

rendement.

AVERTISSEMENT

NE JAMAIS alimenter en gaz l'équipement avec un gaz ne figurant pas sur la plaque

signalétique. L'emploi de tout autre gaz entraînera un dysfonctionnement de

l'équipement et risque de provoquer des blessures graves voire mortelles.

Si vous devez convertir l'équipement afin de l'utiliser avec un gaz différent, contactez

votre revendeur.

AVIS

NE JAMAIS utiliser un adaptateur afin de raccorder un tuyau de gaz plus petit. Vous

risquez de nuire au rendement de l'équip ement et au bon fonctionnement du brûleur

en empêchant un débit de gaz optimal.

3

Page 26

INSTALLATION/FONCTIONNEMENT

Recherche de fuite sur la conduite d'alimentation en gaz et vérification de la

pression

Le cir c u it d ' al i m e nt a t i o n d o it êt r e t es t é av a nt d ' ut i l i se r l'équipement. S i v o u s c o m pt e z t es t e r l e tu y a u d ' a li m e n ta t i o n

en gaz à une pression supérieure à 1/2 PSIG (3.45 kPa), veillez à ce que ce dernier soit débranché de

l'équipement. Si v ou s co m p t e z t e st e r le t uy a u d ' a li m e n ta t i o n e n ga z à u n e pr e ss i o n égale ou inférieure à 1/2 PSIG

(3.4 5 k P a ), l'équipement peut être raccordé mais la commande de gaz de l'équipement doit êtr e fe r m é e. U n e f o i s

la pression rétablie, testez tous les points de raccordements du gaz afin de vous assurer qu'ils ne comportent

aucune fuite avec le l'eau savonneuse. Ne pas tenter de détecter une fuite avec une flamme nue.

Raccordement à la conduite de gaz naturel

AVERTISSEMENT

Cet appareil doit obligatoirement disposer de moyens adéquats pour limiter ses déplacements

indépendamment des raccordements au gaz ou à l’électricité. Cet appareil doit obligatoirement

être stabilisé à l’aide de chaînes de retenue et/ou de cales ou des moyens équivalents. Si vous

utilisez un tuyau de gaz flexible, vous devrez raccorder un câble de retenue supplémentaire qui

devra être en place en tout temps lorsque vous utilisez l’appareil. S’il est nécessaire de

désolidariser un dispositif de retenue, celui-ci devra obligatoirement être remis en place après que

l’appareil soit remis en position d'origine.

AVERTISSEMENT

Cet appareil, s’il est équipé d’un flexible de gaz, doit obligatoirement être raccordé à la

source de gaz par l’intermédiaire d’un raccord conforme à la norme ANSI Z21.69 • CSA

6.16 et d’un dispositif de débranchement rapide conforme à la norme ANSI Z24.41.CSA 6.9.

Un dispositif doit être prévu pour limiter le déplacement de l’appareil sans dépendre du

raccord, du dispositif de débranchement rapide ni de la tuyauterie de l’équipement. Les

dispositifs de retenue peuvent être fixés au dos de l’appareil si nécessaire.

AVIS

Les branchements à la conduite d’alimentation de gaz ainsi que la pâte à joint utilisée sur les points de raccord

doivent être résistants au GPL.

Les codes de votre localité requièrent que le robinet de fermeture du gaz soit installé sur la conduite de gaz,

avant la friteuse.

La conduite de GAZ NATUREL doit être un tuyau en fer mesurant au moins 3/4 po (19,1 mm) de diamètre.

Assurez-vous que les tuyaux sont propres et ne comportent pas d’obstruction, de saleté ni de pâte à joint.

Après avoir vérifié que la tuyauterie ne présente pas de fuites, purgez complètement les tuyaux de gaz pour

retirer tout l’air.

AVIS

Vérifier l’ensemble des tuyaux flexibles. Remplacer toute pièce endommagée ou usée par

une pièce provenant du fabricant uniquement.

Bouteilles de propane et régulateurs de pression (détendeurs)

AVIS

Utiliser uniquement les régulateurs de pression et les flexibles fournis avec l’appareil. Les branchements

à la conduite d’alimentation de gaz ainsi que la pâte à joint utilisée sur les points de raccord doivent être

résistants au GPL.

4

Page 27

INSTALLATION/FONCTIONNEMENT

La friteuse standard autonome au propane a été conçue pour fonctionner avec une bouteille de 40 lb (18,1 kg),

équipée d’un robinet avec valve de Type I.

AVERTISSEMENT

Ne pas entreposer de bouteille de propane sur ou à proximité de cet appareil car cela

risquerait d’entraîner une explosion, un incendie et des blessures.

La valve de Type I (Q.C.C. 1) des bouteilles de gaz est reconnaissable par le gros filetage externe sur la sortie

de la valve. Les valves standard ne comportent pas ce filetage externe. Le fait de tenter de brancher un

régulateur équipé d’un raccord autre qu’un raccord de Type I (Q.C.C. 1) (comporte un gros écrou de fixation en

plastique) rendra inefficaces les importants dispositifs de sécurité du système de Type I (Q.C.C. 1).

La pose d’un raccord standard nº 510 P.O.L. ne vous permettra pas de contrôler correctement le débit ni

l’extinction de l’appareil contrairement au système de Type I (Q.C.C. 1) qui comporte des dispositifs de sécurité

intégrés.

Lorsque vous achetez une bouteille de gaz pour votre équipement, elle doit être construite et marquée

conformément aux organismes et normes suivants:

Le U.S. Department of Transportation (DOT) (ministère des transports des États-Unis), ou la norm e CAN/CSA

B339.

La bouteille doit également comporter:

a) Un robinet d'arrêt terminé avec une sortie type valve aux normes en vigueur spécifiées.

b) Une soupape de sûreté en communication directe avec l’espace de la bouteille où les vapeurs se

trouvent.

c) Un col pour protéger le robinet d'arrêt de la bouteille.

d) Un dispositif pour l’extraction des vapeurs uniquement.

e) Un anneau inférieur en tant que socle pour pouvoir installer la bout eille de manière sécuritaire.

AVERTISSEMENT

Protéger les ouvertures d’aération du régulateur de pression. Ne pas laisser les

régulateurs en contact avec la pluie, la neige ou la glace. Remiser les régulateurs de

pression dans une armoire lorsqu’ils ne sont pas utilisés.

AVERTISSEMENT

Installer et utiliser uniquement les bouteilles de gaz après les avoir placées dans les

supports de retenue de l’équipement. Les bouteilles de gaz doivent être fixées afin d’éviter

qu’elles ne se renversent et être protégées à tout moment contre les sources de chaleur.

Ne pas entreposer de bouteilles de gaz dans un compartiment de cet équipement qui n’est

pas destiné à cet usage. Tout entreposage ou remisage non autorisé risque d’entraîner

une explosion, un incendie ou des blessures.

AVIS

Cet équipement ne doit pas être utilisé avec un système d’alimentation de gaz à distance.

Installation et transport de la bouteille de propane

La manutention, l’entreposage et le transport des bouteilles de propane doit être effectué conformément à la

réglementation sur le stockage et la manipulation des gaz de pétrole liquéfié, la norme ANSI/NFPA 58 ou le

Code d’installation du gaz naturel et du propane, CAN/CGA-B149.1.

Par conséquent:

Utilisez toujours le capuchon protecteur fourni avec la bouteille lorsque la bouteille n’est pas raccordée

à l’équipement.

N’entreposez pas la bouteille dans un immeuble, bâtiment, garage ou tout autre espace clo s ou fermé.

Entreposez la bouteille uniquement dans un endroit bien aéré et largement ventilé.

N’entreposez pas la bouteille dans le voisinage de tout autre appareil à gaz ni à proximité d’une source

de chaleur telle qu’à l’intérieur d’une voiture fermée, d’un coffre ou en plein soleil.

Ne fumez pas lorsque vous transportez la bouteille à bord de votre véhicule.

5

Page 28

INSTALLATION/FONCTIONNEMENT

Transportez et entreposez la(les) bouteille(s) debout, en position droite uniquement.

Entreposez la bouteille hors de la portée des enfants.

Assurez-vous que seul le revendeur de GPL qualifié soit autorisé à remplir ou à réparer la(les)

bouteille(s) de gaz.

Ne remplissez pas trop la bouteille.

Assurez-vous que le revendeur de GPL vérifie la bouteille après avoir été remplie afin de déterminer si

elle comporte une fuite.

Montez la bouteille de propane sur les supports de manière sécuritaire. Glissez le support supérieur vers le bas

afin qu’il repose sur la bouteille puis serrez les écrous à oreilles. Branchez le flexible de gaz en insérant le

raccord dans la bouteille de gaz et fixez-le en tournant le bouton vert jusqu’à ce qu’il soit serré. Ouvrez le

robinet sur la bouteille de propane.

Ferme le robinet de la bouteille de propane lorsque vous n’utilisez pas l’équipement.

Il vous est uniquement possible de remiser l’équipement à l’extérieur si la bouteille de propan e a été

débranchée et retirée de l’équipement.

Pour transporter l’équipement, assurez-vous que le robinet de la bouteille de propane a bien été fermé. Laissez

la bouteille de propane montée sur les supports de l’équipement. Si la bouteille de propane a été compl ètement

débranchée de l’équipement, transportez-la et remisez-la debout, en position verticale. Retirez tout liquide de la

cuve de cuisson avant de transporter l’équipement.

AVERTISSEMENT

Utiliser le régulateur de pression et le tuyau flexible fournis avec l’appareil. Tout tuyau

flexible de rechange devra être celui spécifié par le fabricant.

ATTENTION

Vérifier le régulateur de pression et son tuyau flexible avant chaque utilisation. Si le

régulateur ou son tuyau flexible présentent une usure ou abrasion excessiv e et si ces

pièces s’avèrent coupées ou endommagées d’une façon quelconque, ces pièces devront

être remplacées avant de mettre en marche l’appareil. Le régulateur et le tuyau de

rechange doivent être ceux spécifiés par le fabricant.

Ventilation et systèmes de sécurité contre les incendies

Votre nouvel équipement doit être correctement ventilé afin de fonctionner en toute sécurité. La température des

gaz d'échappement peut atteindre 1100F (593C). Par conséquent, il est indispensa ble d'installer un système

de protection contre les incendies. Votre système de ventilation doit être conçu afin de pouvoir être facilement

nettoyé. Nettoyez fréquemment le système de ventilation et l'équipement afin de réduire les risques d'incen die.

Les tableaux suivants offrent une liste de documents de référence sur la ventilation et les systèmes d e protection

contre les incendies. Cette liste n'est pas forcément complète. Il vous est possible d'obtenir des informations

supplémentaires auprès du CSA International, 8501 East Pleasant Valley Road, Cleveland, OH 44131 ou visitez

notre site internet www.csa-international.org

Extincteurs et systèmes de détection d'incendie

Document du Code

Équipement Document UL

Extincteurs CO2 ANSI/UL 154 ANSI/NFPA 12

Extincteur à poudre ANSI/UL 299 ANSI/NFPA 17

Extin c t eu r à e a u ANSI/UL 626 ANSI/NFPA 13

Extincteur à mousse ANSI/UL 8 ANSI/NFPA 11

national sur le gaz

combustible

6

Page 29

INSTALLATION/FONCTIONNEMENT

Installation

Après avoir terminé les étapes précédentes concernant l'équipement en votre possession, vous pouvez à présent

l'installer. Bien qu'il vous soit possible d'installer votre nouvel équipement, il est VIVEMENT conseillé que des

professionnels qualifiés effectuent l'installation. Les professionnels qui installeront le nouvel équipement

connaissent la réglementation locale ainsi que les codes du bâtiment et les codes de prévention des incendies en

vigueur dans votre localité et procéderont à l'installation en toute sécurité.

AVERTISSEMENT

NE PAS gêner le flux d'air de combustion, la ventilation ni boucher les ouvertures d'air autour

de l'équipement. S’assurer que le périmètre demeure dégagé pour que les ouvertures d'air

autour de l'équipement et ne soient pas bloquées afin de les brûleurs puissent fonctionner

correctement et que l’on puisse accéder à l'équipement pour le réparer si nécessaire. Veiller

à ce que les distances de dégagement et de sécurité minimum autour de l'équipement

indiquées dans ce manuel soient rigoureusement respectées.

Dégagement et distances de sécurité pour l’installation

Les distances indiquées ci-dessous sont pour l'installation de l'équipement dans un environnement combustible et

non-combustible et permettront d'utiliser l'équipement en toute sécurité.

Dos 6 po. (15 cm) 0

Côtés

Sol 6 po. (15 cm) 6 po. (15 cm)

En plus des distances de sécurité ci-dessus, il doit également exister un e spa ce de 28 po. (71,2 cm) devant

l'équipement. Il est primordial que l'équipement soit utilisé uniquement en présence d'une ventilation adéquate.

Votre hotte de ventilation doit être nettoyée et entretenue correctement. Une ventilation insuffisante risque de ne

pas évacuer toutes les vapeurs et fumées de l'équipement. Toute ventilation excessive ou non équi libré e

entraînera des courants d'air. Ceci nuira au bon fonctionnement de la veilleuse et des brûleurs. Ne bloquez jamais

l’ouverture du conduit d’évacuation de fumée et ne placez jamais cet équipement sous une surface en surplomb

combustible non protégée.

Construction

combustible

6 po. (15 cm) 0

ATTENTION

Toute rupture de tirage empêchera l'équipement d'évacuer correctement la fumée et les gaz et

entraînera une surchauffe risquant d'endommager l'équipement de façon irréversible. Aucun dégât

provoqué par une rupture de tirage ne sera couvert par la garantie de l'équipement. NE JAMAIS

laisser quoi que ce soit pouvant gêner le débit des combustibles ou de la ventilation sortant du

conduit de fumée de l'équipement. NE RIEN placer sur le dessus du conduit de fumée et ne gêner

le tirage du conduit en aucune façon

Premiers réglages

Après avoir correctement installé l'équipement en suivant les instructions du chapitre « Installation » de ce manuel,

vous devrez la régler afin qu'elle fonctionne à plein rendement. Ces réglages doivent être effectués par une

personne qualifiée. Pour effectuer ces réglages, vous aurez besoin des outils suivants:

• Manomètre • Thermomètre numérique (sonde de température)

• Milliampèremètre de courant continu (DC)

Avant de remplir et de régler l'équipement, effectuez les vérifications visuelles suivantes:

7

Construction

non-

combustible

Page 30

INSTALLATION/FONCTIONNEMENT

a. Après avoir placé l'équipement à son emplacement

définitif, assurez-vous que l'équipement est à niveau.

Tout réglage supplémentaire pourra être effectué en

suivant les instructions précédentes.

b. Vérifiez la sonde de température et l'ampoule de

température maximum (à l'intérieur de la cuve) afin de

vous assurer que les vis sont serrées.

c. Relisez le chapitre « Installation » de ce manuel et

assurez-vous que toutes les étapes ont bien été suivies

et correctement effectuées.

Système d'allumage du brûleur

ATTENTION

Avant de poursuivre, remplissez la friteuse avec de l'EAU. Utilisez de l'eau afin de procéder aux réglages

d'installation car la température de l'eau ne dépassera pas 212F (100C) et vous donnera suffisamment de

temps pour effectuer les réglages. Ne laissez jamais le niveau d'eau descendre en-dessous du repère "OIL

LEVEL" (niveau d’huile) à l'arrière de la cuve.

AVERTISSEMENT

Il existe une veilleuse à flamme nue à l'intérieur de l'équipement. L'équip ement peut chauffer à des

températures très élevées et risque d'enflammer des matériaux placés à proximité.

Veillez à ne placer a u c u n é l é m ent combus ti b l e à proximi té de l'équipe m e n t .

Instructions d'allumage

Pour veilleuse électronique, reportez-vous aux instructions suivantes:

AVERTISSEMENT

Si la veilleuse s'éteint, attendez 5 minutes avant de tenter de rallumer la veilleuse afin de

permettre à toute accumulation de gaz de se dissiper.

a. Ouvrez le robinet de gaz alimentant l’équipement.

b. Tournez le bouton du thermostat dans le sens des aiguilles d’une montre

jusqu’à OFF (arrêt).

c. Tournez le bouton de la commande de gaz principale dans le sens inverse à

celui des aiguilles d’une montre jusqu’à PILOT (veilleuse). Pressez le bouton

et maintenez-le pressé jusqu’à ce que la flamme allume la veilleuse, ceci

risque de prendre un peu de temps la première fois que vous allumez la

veilleuse en raison de la présence d'air dans les conduites. Après avoir

allumé la veilleuse, maintenez le bouton pressé environ une minute puis

relâchez le bouton.

8

Page 31

INSTALLATION/FONCTIONNEMENT

d. Si la veilleuse s’éteint, attendez 5 minutes puis reprenez l’étape C. Si après trous

tentatives la veilleuse ne demeure pas allumée, reportez-vous au guide de dépannag e

de ce manuel.

e. Après avoir obtenu une flamme, tournez le bouton de la commande de gaz

principale jusqu'à la position ON (marche).

f. Réglez le bouton du thermostat à la température désirée. Les brûleurs

principaux s'allumeront et pourront être contrôlés par le thermostat.

Réglage de la flamme de la veilleuse

Pour les veilleuses à allumage manuel, reportez-vous aux instructions suivantes: Suivez cette procédure

après avoir allumé la veilleuse et assurez-vous que le thermostat est sur OFF (arrêt).

REMARQUE: Cette procédure requiert un milliampèremètre de courant continu (DC) réglé sur une

plage de 0 à 1000 mV. Pour faciliter le relevé des températures, utilisez des fils d’essai avec des sondes

pointues.

a. Placez les fils de la thermopile provenant de la veilleuse et allant à la commande de gaz.

b. En utilisant la sonde d’essais positive (+), raccordez la sonde à la borne PP supérieure avec

le fil rouge.

c. Raccordez la sonde d’essais négative (-) à la borne inférieure PP avec le fil blanc.

d. Le niveau de sortie devrait être de 550 mv (avec une marge de ± 50mV). Si le niveau n’est

pas bon, retirez la vis de fixation et réglez la vis de réglage afin d’obtenir le bon niveau en

millivolts. Remettez en place la vis de fixation.

Remarque: Attendez 3 à 5 minutes entre chaque

réglage de la flamme afin de permettre que le relevé se

stabilise.

Réglage des brûleurs principaux

Pour que les brûleurs puissent fonctionner, le robinet de gaz alimentant l’équipement doit être ouvert et le

thermostat doit être allumé. Pour les modèles à commandes électriques, l'interrupteur d'alimentation doit être

sur « ON » (marche). Les brûleurs principaux sont alimentés en gaz par la conduite de gaz principale par

l'intermédiaire de la soupape thermostatique. Lorsque la température de l'eau descend en-dessous de la

température préréglée, la soupape de contrôle du gaz s'ouvre.

Les brûleurs principaux doivent être réglés afin d’offrir une flamme optimale. Reportez-vous à l'opération suivante

pour régler les brûleurs principaux.

ATTENTION

Avant de poursuivre, remplissez la cuve de la friteuse avec de l'EAU. Utilisez de l'eau afin de procéder aux

réglages d'installation car la température de l'eau ne dépassera jamais 212F (100C) et vous donnera

suffisamment de temps pour effectuer les réglages. Ne laissez jamais le niveau d'eau descendre en-

dessous du repère "OIL LEVEL" (niveau d’huile) de la cuve.

9

Page 32

INSTALLATION/FONCTIONNEMENT

a. Assurez-vous que la commande de gaz principale est fermée. Retirez le bouchon de la prise

manométrique de pression d'alimentation et raccordez un contrôleur de pression exacte

ayant une plage de 0 à 16 po. (0 à 40,6 cm) de colonne d'eau et comportant une graduation