Page 1

INSTALLATION – OPERATION - MAINTENANCE

31-01-12962 rev B

L25-004 rev 0 5-2001

600 CE SERIES

GAS BROILER

MAGIKITCH’N

P.O. BOX 501

CONCORD NH 03302-0501

509 ROUTE 3A

BOW NH 03304

800-258-3708

603-225-6684

FAX 603-225-8497

WWW.MAGIKITCHN.COM

Page 2

IMPORTANT

r

j

y

g

ghly

INSTALLATION, SERVICING, OR CONVERSION OF THIS APPLIANCE

TO BE CARRIED OUT BY QUALIFIED SERVICE

TECHNICIANS/INSTALLERS IN CONFORMANCE WITH NATIONAL

AND LOCAL REGULATIONS.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN CAUSE PROPERTY DAMAGE,

INJURY OR DEATH. READ THE INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING

OR SERVICING THIS EQUIPMENT

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS

GAS MUST BE POSTED IN A PROMINENT LOCATION. THIS INFORMATION MAY BE OBTAINED BY CONTACTING YOUR LOCAL GAS

SUPPLIER.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the

vicinity of this or any other appliance.

The information contained in this manual is important for the prope

installation, use, and maintenance of this unit. Adherence to these

procedures and instructions will result in satisfactory grilling results

and long, trouble free service. Please read this manual carefully and

retain it for future reference.

THIS APPLIANCE IS INTENDED FOR PROFESSIONAL USE BY QUALIFIED

PERSONNEL ONLY, NOT FOR INDIVIDUAL/HOME USE

WARNING: Improper installation, ad

service or maintenance can cause propert

death. Read the installation, operatin

instructions thorou

equipment.

before installing or servicing this

.

ustment, alteration,

damage, injury or

and maintenance

1-01-12962 rev B L25-004 rev 0 5-2001 2

Page 3

For installation or maintenance, contact your local dealer or authorized service

agent. Installation or service by other than MagiKitch’n authorized service agencies

or personnel may void warranty coverage. Call Pitco Frialator Technical Support at

603-225-6684 who will put you in touch with the proper local service organization or

make service arrangements for you.

Page 4

Installation

Delivery and Location

Broiler Assembly

Gas Connection and Conversion

Operation

Broiler Set Up

Lighting Instructions

General Charbroiling Tips

Maintenance

Cleaning and Preventative Maintenance

Accessory and Replacement Parts List

1-01-12962 rev B L25-004 rev 0 5-2001 4

Page 5

Installation

Delivery and Location

DELIVERY

Each broiler was carefully inspected and packaged before

being tendered to the carrier. Upon delivery of your new

broiler:

• Uncrate the broiler and check for damage. Most

carriers will accept claims for damage if they are

notified within seven days of delivery and the shipping

container is retained for inspection.

NOTE: The broiler top grid is shipped underneath the

unit. Be sure to remove it before disposing of the

packing crate.

MagiKitch’n cannot assume responsibility for loss or

damage suffered in transit. The carrier assumed full

responsibility for delivery in good order when the

shipment was accepted.

LOCATION

• Place the unit in a properly ventilated area.

• Keep the area free and clear of all combustibles such

as paper, cardboard, and flammable liquids and

solvents.

• This unit requires 0cm minimum clearance to non–

combustible construction. The unit is not approved for

installation in areas with combustible construction.

• Provisions must be made for an adequate air supply to

the broiler.

• Keep the area in front of the unit free from

obstructions that could block the flow of combustion

and ventilation air.

• Be sure there is sufficient clearance at the rear of the

unit for gas connections, regulator and any master

shutoff valve(s) to be installed.

• The location must provide adequate clearance for

servicing.

Before making any gas connections to this broiler, check

that the available gas supply meets the requirements for

supply pressure and gas type shown on the rating plate on

the front of the unit.

31-01-12962 rev B L25-004 rev 0 5-2001 1

Page 6

N

Installation

Broiler Assembly

NOTE: This appliance shall be installed in accordance

with current regulations and used only in a well–

ventilated space. Refer to these instructions before

installing and using this appliance.

NOTE: Installation and connection must be performed by

a qualified installer only.

COUNTERTOP MODELS

Countertop models must be sealed to the counter surface in

compliance with National and Local Sanitation standards.

1. Apply a 13mm bead of silicone to the bottom of the

broiler. The silicone should run approximately 6mm

from the front, back and side edges of the unit.

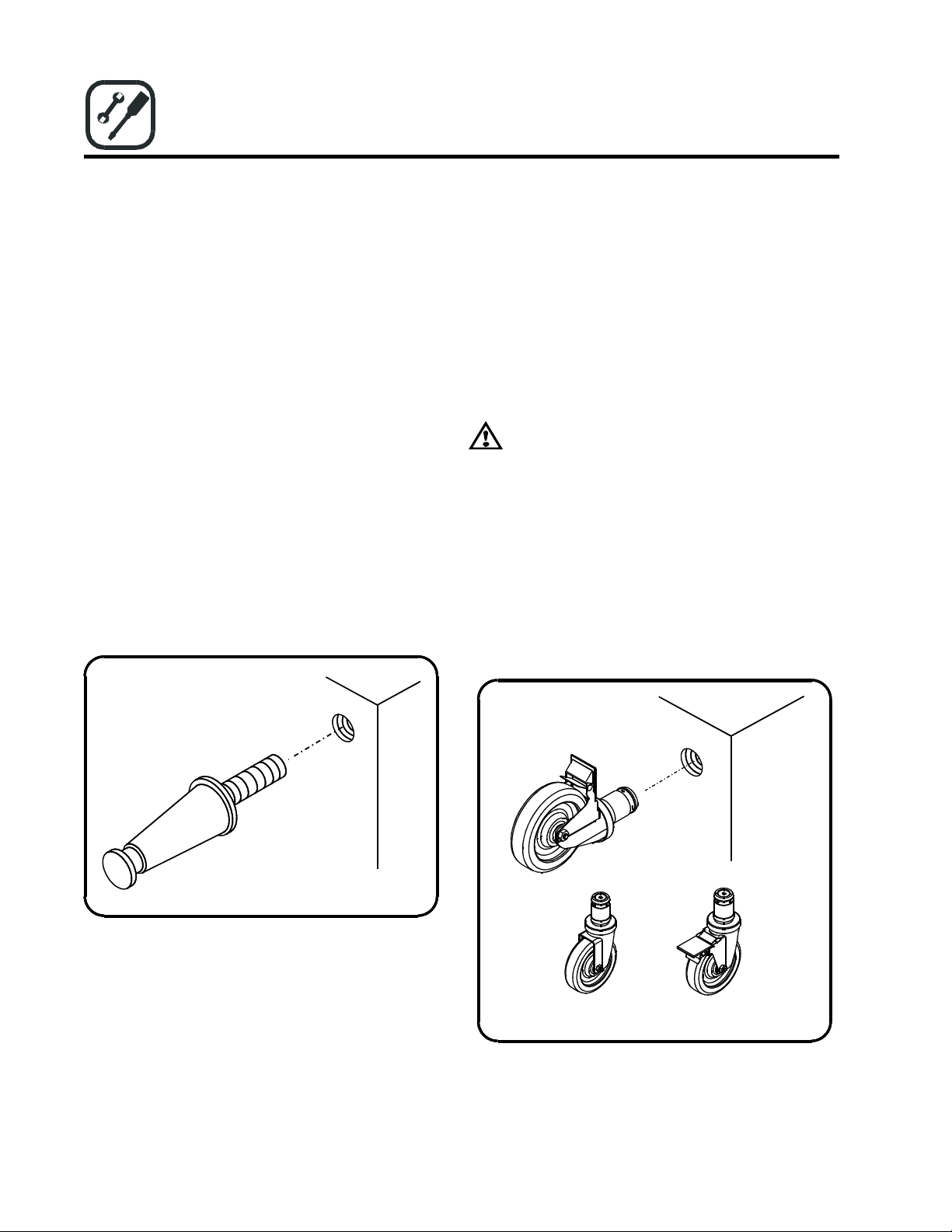

LEG ATTACHMENT

The 15 cm legs are packed in the top section of the broiler.

1. Screw the legs into the threaded holes in the corners

on the bottom of the broiler.

2. Place the broiler onto the legs.

3. Turn the adjustable leg feet to level the oven.

CASTER INSTALLATION

A flexible hose/connector must be used on any broiler

installed on casters. The connector must meet National and

Local codes.

A restraint must be used to limit the movement of the

appliance. Limited movement cannot depend on the

flexible connector. DO NOT attach the restraint to gas

piping or electrical conduit!

WARNING!!

If the restraint is disconnected for any reason it

must be reconnected when the unit is returned to

its original position.

1. Screw the casters into the threaded holes in the corners

on the bottom of the broiler.

NOTE: The locking casters must be installed on the

front of the broiler.

2. Place the broiler onto the casters.

Figure 2

Figure 1

on-locking

Caster

1-01-12962 rev B L25-004 rev 0 5-2001 2

Locking

Caster

Page 7

Installation

GAS CONNECTION

An adequate gas supply is required for proper broiler

performance. With all burners on “HIGH”, the manifold

pressure should not show any appreciable drop.

Fluctuations of more than 25% will create pilot problems

and affect burner operation.

WARNING!!

This unit must be connected ONLY to the type

of gas specified on the rating plate.

1. Remove the hairpin clips securing the burners. This

will allow for removal of the burners for inspection,

cleaning and servicing.

2. Attach the regulator supplied with the unit. The

regulator must be installed at the entry end of the gas

manifold.

NOTE: Be sure the regulator is installed so that the

gas flows in the same direction as the

arrow on the bottom of the regulator. Use

the supplied regulator only. Use of any

other regulator will invalidate the

warranty.

3. Adjust the regulator to the burner pressure listed on

the rating plate. Refer to the table on the following

page for proper pressure settings.

NOTE: A pressure regulator is not required for all

countries.

4. Use pipe joint compound suitable for use with LP

gas on all threaded connections.

5. Turn off all burner valves.

6. Turn on the gas supply. Check all connections for

gas leaks using soap and water. Never use an open

flame to check for gas leaks!

GAS CONVERSION

All units are shipped with the appropriate orifices and

components required for the gas requested. If the unit

does not perform well or has unsatisfactory flame

characteristics (too high, yellow tips, lifting), check that

the supply pressure and orifice size are appropriate for

the gas used before making any adjustments.

Use the following directions to convert the unit to a

different type of gas if necessary. Each conversion kit

contains all the orifice sizes and markings required for

converting any size unit to any gas type in all countries.

Note that in Belgium units may not be converted. For

some conversions it may also be necessary to replace the

regulator or restrictor orifice.

NOTE: Refer to the table on the following page to

determine gas requirements, pressure settings

and orifice sizes.

1. Shut off the gas supply to the unit.

2. Disconnect the unit from the gas supply.

3. Remove the top grids, radiants, runner tubes and

burners.

4. Remove the brass runner tube orifice. Replace with

the new orifice.

5. Remove all burner orifices. Replace with the new

orifices.

6. Adjust the air shutters on all the burners to the

correct opening. Mark the air shutter at the correct

setting. Re-install the burners.

7. Re-install the runner tubes, radiants, and top grids.

8. Adjust the regulator to the correct gas pressure. If a

restrictor orifice is required in place of the regulator

to meet your countries specific codes, remove the

old restrictor orifice and replace it with a new one

correctly sized to provide the burner pressure

specified for the gas type being used.

9. Adhere the appropriate conversion sticker to the

front of the unit, near the rating plate.

31-01-12962 rev B L25-004 rev 0 5-2001 3

Page 8

Operation

Gas Connection and Conversion Information for 600-CE Model Broilers

Country

NL

BE

FR

DE

GB

IT

ES

PT

SE

DK

FI

AT

NO

IE

GR

LU

Runner Tube Orifice (mm)

Gas

Type 624/648 630/660 636/672

G20 0.87 0.98 1.065

G25 0.87 0.98 1.065

G30 0.52 0.58 0.63

G31 0.52 0.58 0.63

Heat Input (kW)

624 630 636 648 660

H

16.5 25.2 29.3 41.1 50.1

s

H

14.9 22.7 26.4 37.1 45.2

i

Supply Burner

Appliance Gas Gas Pressure Pressure

Category Category Type (mb) (mb)

II2L3B/P 2L G25 25 10.7

3B/P G30 30 29.5

II2L3P 3P G31 50 36.5

I2E+ 2E+ G20/25 20/25 16.6/20.6

I3+ 3+ G30/31 30-37 29.5-36.5

II2E+3+ 2E+ G20/25 20/25 16.6/20.6

3+ G30/31 30-37 29.5-36.5

II2ELL3B/P 2ELL G20/25 20 16.6-10.7

3B/P G30 50 29.5

II2H3P 2H G20 20 16.6

3P G31 50 36.5

II2H3+ 2H G20 20 16.6

3+ G30/31 30-37 29.5-36.5

II2H3+ 2H G20 20 16.6

3+ G30/31 30-37 29.5-36.5

II2H3+ 2H G20 20 16.6

3+ G30/31 30-37 29.5-36.5

II2H3B/P 2H G20 20 16.6

3B/P G30 30 29.5

II2H3B/P 2H G20 20 16.6

3B/P G30 30 29.5

II2H3B/P 2H G20 20 16.6

3B/P G30 30 29.5

II2H3B/P 2H G20 20 16.6

3B/P G30 50 29.5

I3B/P 3B/P G30 30 29.5

II2H3P 2H G20 20 16.6

3P G31 50 36.5

II2H3B/P 2H G20 20 16.6

3B/P G30 50 29.5

II2E3B/P 2E G20 20 16.6

3B/P G30 50 29.5

Main Air

Burner Shutter

(mm) (mm)

1.85 open

1.02 open

1.02 open

1.5 9.0

1.02 open

1.5 9.0

1.02 open

1.5-1.85 9.O-open

1.02 open

1.5 9.0

1.02 open

1.5 9.0

1.02 open

1.5 9.0

1.02 open

1.5 9.0

1.02 open

1.5 9.0

1.02 open

1.5 9.0

1.02 open

1.5 9.0

1.02 open

1.5 9.0

1.02 open

1.02 open

1.5 9.0

1.02 open

1.5 9.0

1.02 open

1.5 9.0

1.02 open

1-01-12962 rev B L25-004 rev 0 5-2001 4

Page 9

Operation

Broiler Set Up

NOTE: After initial installation, the unit must be

thoroughly cleaned prior to operation. Refer to

the Maintenance section of this manual for

cleaning instructions.

Top Cooking Grid

The cooking grid has two positions, flat or tilted.

• To place the grid in the tilted position, push down on

the grid handle and pull forward to engage the grid

hook.

• To place the grid in the flat position, pull up on the

grid handle and push back to disengage the grid hook.

When broiling, the grid must be in the tilted position.

This allows some of the grease to drain into the front

trough, reducing both smoke and flare–up. The flat

position should only be used to heat soups, sauces, etc.

DO NOT use the flat position for broiling.

Radiant

Radiants and Grease Shield

The radiants must be in place prior to operating the unit.

The radiants provide protection for the burners, create a

surface for the flare–up required for charbroiling and

provide radiant heat to the product.

Water Tubs

The tubs are designed to reduce flare–up and eliminate

flash back. Any flaming grease that drips down is

extinguished when it hits the water. The tubs should be ¾

full of water. NEVER allow the water tubs to run dry.

Grease Box

The majority of the grease will travel down the front

trough and into the grease box. The grease box must be

in place while operating the unit

.

Grid Hook

Top Cooking Grid

Top Gri d

Left Water Tub

Tilt Block

Side View of Top Grid

In tilt posit ion

Grease Box

Right Water Tub

Figure 3

31-01-12962 rev B L25-004 rev 0 5-2001 5

Page 10

Operation

Lighting Instructions

1. Turn all burners to OFF.

2. Remove the top grid.

3. Remove the last radiant on the right.

4. Turn the shut off valve to ON.

5. Press and hold the reset (blue) button on the safety

pilot valve. Wait 15–30 seconds. Light the runner

tube. DO NOT release the reset button.

NOTE: If the runner tube does not light, wait a few

seconds, then try again.

NOTE: When lighting the runner tube for the first

time after connecting the unit to the gas

source, the light time will probably increase

to 1–2 minutes.

Top Gri d

Radiant

6. Wait an additional 15–30 seconds. Release the reset

button. The runner tube should remain lit.

NOTE: If the runner tube fails to ignite, repeat step

5. If the runner tube fails to ignite after

three attempts, contact an authorized

MagiKitch’n service agent.

7. Replace the radiant and top grid.

8. Push and turn the burner valves to operate the

individual burners as needed.

Broiler Shut Down

1. Turn the shut off valve to OFF.

2. Turn all burners to OFF.

Off

On

Shut-off

Valve

Thermocouple

(located on far

end of runner tube)

Safety Pilot Valve

(located under

shelf)

Reset Button

Safety Pilot Valve

Figure 4

1-01-12962 rev B L25-004 rev 0 5-2001 6

Page 11

Operation

General Charbroiling Tips

PREHEATING

The broiler must be preheated before cooking. We

recommend a preheat time of 10-15 minutes. After

preheating, the broiler will be hot enough to cook on

without sticking and will produce the proper searing

effect.

COOK ZONES

There are three separate cooking zones on your

MagiKitch’n charbroiler:

• The front 1/3 of the broiler is the coolest section.

• The center 1/3 of the broiler has medium heat.

• The rear 1/3 of the broiler is the hottest. (even though

it is the farthest from the burner in the tilt position)

The three cook zones enable more efficient cooking

without flame adjustment. It is possible to cook a rare,

medium and well done steak in the same amount of time

simply by placing the product in different cook zones.

The cooking process can also be slowed or increased by

moving product between zones.

FLARE–UP

In charbroiling, a certain amount of flare–up is desirable

in order to flavor the product. However, excess flare–up

burns product and leaves a bitter taste. Generally, flare–

up increases with the heat of the broiler and the fat

content of the product.

Heat Product Fat Content

High

Low

High Low

High Flare–up Moderate

Moderate Low Flare–up

The cook zones can be used to advantage during peak

periods. High fat product can be cooked in the cool front

section, while lean product is placed on the hotter rear

section. This allows for better control of flare–up and

product quality.

31-01-12962 rev B L25-004 rev 0 5-2001 7

Page 12

R

r

F

r

R

r

F

r

R

r

F

r

Operation

General Charbroiling Tips

MARKING PRODUCT

1. Place the product diagonally on the back 1/3 of a

clean broiler grid.

NOTE: For white fleshed product (chicken, fish) be

sure Marking product to baste the product

and brush the grid with pure vegetable oil.

2. When the product is marked, rotate it ¼ turn to

provide the diamond pattern.

NOTE: This step can be eliminated if only one line

is desired.

ear of Broile

Hot

Medium

ear of Broile

3. When the diamond mark is achieved, turn the food

over and move to the middle cook zone to finish

broiling. DO NOT turn the food over to the marked

side or the pattern will be marred.

NOTE: For thicker and well done products, move

the product to the front cook zone.

NOTE: Check the internal product temperature on

the unmarked side.

4. Serve the food with the pattern facing up.

ear of Broile

Hot

Medium

ront of Broile

Step 1

Cool

ront of Broile

Step 2

Cool

ront of Broile

Step 3

Figure 5

1-01-12962 rev B L25-004 rev 0 5-2001 8

Page 13

Maintenance

Cleaning and Preventative Maintenance

Proper maintenance of your broiler will prolong the life

of the appliance and ensure proper performance.

DAILY CLEANING

Top Grid

1. Remove the grid.

2. Use the MagiKitch’n scraper to remove any cooking

debris from the rods, especially the underside.

3. Clean the frame including the tubes and angles on

the sides, front and back with steel wool.

Cabinet, Shelves, Water Tubs, and Grease Boxes

These parts are stainless steel and can be cleaned with

any non–toxic industrial stainless steel cleaner.

1. Apply cleaners when the broiler is cold. Always rub

with the grain of the metal.

Water Tubs

Empty the excess grease and water. Wipe the tubs clean.

Grease Box

The grease box should be emptied daily.

WEEKLY CLEANING

Soak the top grid in a degreasing solution. The grid will

need to be re–seasoned after soaking.

ANNUAL MAINTENANCE AND INSPECTION

The unit should be inspected annually by a qualified gas

appliance service personnel.

The main burner valves should be greased annually, or as

necessary, to maintain smooth operation and prevent gas

leakage.

1. Remove the knobs from the front of the unit.

2. Remove the outer front panel.

3. Loosen the two screws securing the collar to each

valve.

4. Carefully disassembly the valves. See Figure 6.

5. Clean all parts.

6. Apply high temperature valve grease to the rotor

assembly.

NOTE: The valve grease must be suitable for all

gas types.

7. Reassemble the valves and broiler.

Orifice Body Rotor Spring Stem Collar

Figure 6

31-01-12962 rev B L25-004 rev 0 5-2001 9

Page 14

Maintenance

Accessory and Replacement Parts List

NOTE: This is a partial parts list for parts not shown here, call MagiKitch’n or a MagiKitch’n service representative.

Always give the Model and Serial Numbers of your unit when ordering parts and accessories.

Item Description

Top grid

1

Radiant

2

Burner

3

Burner clip

4

Baffle, right side

5

Baffle, left side

6

Outer side

7

Inner side (right)

8

Inner side (left)

9

Drip cup

10

Outer back

11

Inner back

12

Rear support angle

13

Rear burner support

14

Water tub

15

Grease trough

16

Towel bar

17

Lower shelf

18

Upper shelf

19

Base assembly

20

Upper shelf

21

Inlet manifold

22

Runner tube

23

Inner front assembly

24

90° elbow with clip

25

Item Description

Valve (push to turn)

26

Pressure tap orifice

27

Heat shield

28

29

Manifold, weld assembly

30

Outer front

31

Knob

32

Grease trough

33

Service shelf

34

Service shelf support

35

Thermocouple (not shown)

36

Thermocouple bracket (not shown)

37

38

39

40

½” NPT Jam nut

41

½” FNPT Shut off valve

42

½” NPT nipple

43

¾” MNPT x ½” FNPT adaptor

44

180° return elbow

45

¾” close nipple

46

Safety pilot valve

47

Runner supply tube

48

49

1-01-12962 rev B L25-004 rev 0 5-2001 10

Page 15

Maintenance

Maintenance

Figure 7

31-01-12962 rev B L25-004 rev 0 5-2001 11

31-01-12962 rev B L25-004 rev 0 5-2001 11

Page 16

SMB

600 SERIES-CE

GAS BROILER

MODEL SPECIFIC INSTRUCTIONS

MAGIKITCH’N

P.O. BOX 501

CONCORD NH 03302-0501

509 ROUTE 3A

MAGIKITCH’N

A MAYTAG COMP

BOW NH 03304

180 Penn Am Dr nsylvania 18951-2435 USA

WWW.BLODGETTCORP.COM

800-258-3708

ive Quakertown , Pen

603-225-6684

Telepho x: (215) 538-3644

ne 800-441-1492 Fa

FAX 603-225-8497

WEBSITE: WWW.MAGIKITC

© 2000– MagiKitch’n

ANY

HN.COM

31-01-12962 rev B L25-004 rev 0 5-2001 12

Page 17

Table of Contents

1. Lighting Instructions

2. Initial Set Up

3. SMB 600 Series Illustration

4. Accessories and Parts List

31-01-12962 rev B L25-004 rev 0 5-2001 13

Page 18

Page 19

1. LIGHTING INSTRUCTIONS

SMB 600 Series -CE Models with safety pilot

1. Turn all burners to OFF.

2. Remove the top grid.

3. Turn the shut off valve to ON.

4. Press and hold the reset (blue) button on the safety pilot valve. Wait 15–30 seconds. Light the runner tube.

DO NOT release the reset button.

NOTE: If the runner tube does not light, wait a few seconds, then try again.

NOTE: When lighting the runner tube for the first time after connecting the unit to the gas source, the light time

will probably increase to 1–2 minutes.

5. Wait an additional 15–30 seconds. Release the reset button. The runner tube should remain lit.

NOTE: If the runner tube fails to ignite, repeat step 5. If the runner tube fails to ignite after three attempts,

contact an authorized MagiKitch’n service agent.

5. Replace the top grid.

6. Push and turn the burner valves to operate the individual burners as needed.

Broiler Shut Down

1. Turn the shut off valve to OFF.

2.

Turn all burners to OFF.

31-01-12962 rev B L25-004 rev 0 5-2001 15

Page 20

SMB 600 Series -CE Models with safety pilot

2. INITIAL SET-UP

SMB 600 Series-CE models

COAL SUPPORT - The coal support must be installed so that it is pushed against the back wall

of the unit. This creates an air gap over the runner tube to allow proper ventilation.

COALS

- Use only Magicoals supplied by MagiKitch’n. Do not use lava rock or other replacement

coals. They do not perform as well or last as long as the Magicoals that were designed for this

application. Place the coals evenly across the surface of the coal support. Do not pile them up.

This will cause excessive flare up, reduce ventilation, and cause overheating of the valves and

other components.

PREHEATING

coal style charbroilers, at which time the cooking grid should be hot enough to cook on without sticking, and will produce the

proper searing effect.

- It is necessary to preheat a cold broiler each time before cooking. The recommended time is 15-20 minutes for

31-01-12962 rev B L25-004 rev 0 5-2001 16

Page 21

3. TYPICAL SMB 600 SERIES ILLUSTRATION (Model SMB 636 shown)

Note: Your unit may vary from this typical diagram.

31-01-12962 rev B L25-004 rev 0 5-2001 17

Page 22

4. ACCESSORY / PARTS LIST FOR SMB 600 SERIES MODELS

Not all parts are illustrated, nor are all parts are listed. If you need a part that is not listed here, call MagiKitch’n for a quote. Always

have your model and unit serial numbers available when phoning or ordering.

THESE PARTS SOLD THRU OUR DEALER NETWORK ONLY.

Ref. No. Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Top Grid, Standard

Radiant

Burner

Burner retaining clip (not shown)

Runner tube (not shown)

Water Tub, Left Hand

Water Tub, Right Hand

Grease Box

Leg, 6” (not shown)

Caster, 6” (not shown)

Knob, main burner

Knob, runner tube

Scraper (not shown)

Brush (not shown)

Regulator

Ref. No. Description

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

Gas valve, main burner

Gas valve,runner tube (not shown)

Orifice, main burners (not shown)

Orifice, runner tube (not shown)

Manifold assembly (not shown)

Manifold heat shield

Inner heat shield (not shown)

Inner front (not shown)

Front burner support

Outer side

Inner side

Side baffle

Side baffle support (not shown)

Top grid center support (not shown)

(48/60/72 only)

Outer back (not shown)

16

17

18

19

20

21

22

Utility bar

Service shelf

Service shelf support (not shown)

LH Frame mtg brkt (not shown)

RH Frame mtg brkt (not shown)

Grease trough

Outer front

38

39

40

41

42

43

44

45

46

Inner back

Back stiffener (not shown)

Back splash liner

Rear burner support

Shelf

Inner bottom (FM only, not shown)

Outer bottom (not shown)

Coal Rack

Coals

31-01-12962 rev B L25-004 rev 0 5-2001 18

Page 23

Original Equipment Limited Warranty

MagiKitch'n appliances are designed to give you long and satisfactory service if

installed and operated in accordance with our instructions. We warrant this appliance

against defective workmanship and material for one year form installation or 15

months from ship date, and agree to replace free of charge and defective parts or

equipment returned to us. This warranty does include travel time not to exceed 2

hours and mileage not to exceed 50 miles.

WARRANTY LIMITATIONS OR EXCLUSIONS :

Radiants and coal support are warranted for 6 months only.

Accidental damage, misuse, harsh cleaning chemical usage, and normal

wear of this appliance are not warranted.

Conversion or adjusting of gas components (i.e.; pilots, orifices, burners, valves or

regulators) unless duly authorized by MagiKitch’n or it’s ASAP agent.

Not Warranted:

Accident to, misuse of, harsh chemical cleaners, or natural wear of this

appliance.

Conversion or adjusting of gas components (i.e.; pilots, orifices, burners, valves

or regulators).

IMPORTANT: DO NOT destroy any defective part – it must be returned for

replacement under this warranty.

When writing, be sure to mention the Serial Number and Model Number appearing on

the nameplate on the front of your equipment.

Keep for your records

This Warranty cannot protect you unless your MagiKitch’n appliance is registered at the factory.

For your own protection, mail the attached card WITHIN TEN DAYS after this appliance has been

installed, or the WARRANTY WILL BE VOID.

MAGIKITCH’N

P.O. BOX 501

CONCORD NH 03302-0501

509 ROUTE 3A

BOW NH 03304

800-258-3708

603-225-6684

FAX 603-225-8497

WWW.MAGIKITCHN.COM

31-01-12962 rev B L25-004 rev 0 5-2001 19

Loading...

Loading...