MODEL HWG40

MODEL HWG20

GAS FIRED

COMMERCIAL

& INDUSTRIAL

PRESSURE

WASHER

HEATERS

INSTRUCTION

MANUAL

V3.02

For heaters equipped with

ProSafe II control and

24V electronic ignition

(HSI)

or 24V standing pilot

this page was intentionally left blank

TABLE OF CONTENTS

1.0 INTRODUCTION............................................................................................1

2.0 IMPORTANT OPERATING CONDITIONS....................................................2

3.0 SAFETY .........................................................................................................2

4.0 INSTALLATION

4.1 LOCATION.........................................................................................3

4.2 MOUNTING ........................................................................................3

4.3 GAS SUPPLY ....................................................................................3

4.4 VENTING............................................................................................3

4.5 AUTOMATIC VENT DAMPER...........................................................3

4.6 POWER VENTER ..............................................................................4

4.7 FLOW SWITCH..................................................................................4

4.8 INLET PLUMBING .............................................................................4

4.9 OUTLET PLUMBING .........................................................................4

4.10 ELECTRICAL CONNECTIONS .........................................................5

5.0 PRE-OPERATION CHECKS

5.1 FLUSH DEBRIS FROM THE SYSTEM .............................................7

5.2 INITIAL POWER UP ..........................................................................7

5.3 CHECK FLOW SWITCH & AUTOMATIC VENT DAMPER...............7

5.4 BLEED OFF AIR ................................................................................7

5.5 LIGHTING THE PILOT BURNER ......................................................7

5.6 CHECK IGNITION OF MAIN BURNERS...........................................8

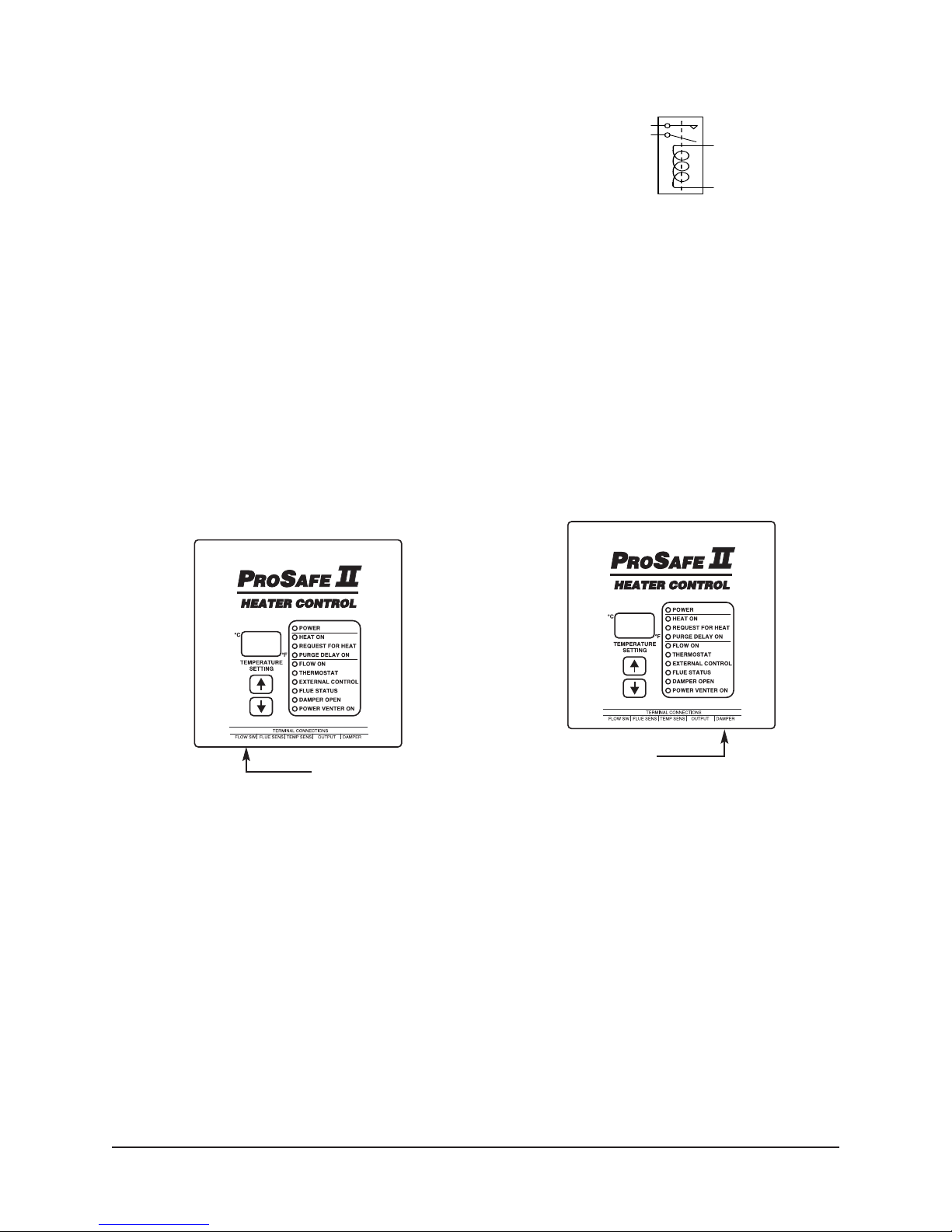

PROSAFE II CONTROL

6.0

6.1 TEMPERATURE SETTING ..............................................................9

6.2 POWER INDICATOR......................................................................10

6.3 HEAT ON INDICATOR ...................................................................10

6.4 REQUEST FOR HEAT INDICATOR...............................................10

6.5 PURGE DELAY ON INDICATOR ...................................................10

6.6 FLOW ON INDICATOR ..................................................................10

6.7 THERMOSTAT INDICATOR ..........................................................10

6.8 EXTERIOR CONTROL INDICATOR ..............................................10

6.9 FLUE STATUS INDICATOR...........................................................11

6.10 DAMPER OPEN INDICATOR.........................................................11

6.11 POWER VENT INDICATOR ...........................................................11

PROSAFE II ERROR & WARNINGS

7.0

7.1 ERROR CONDITIONS .....................................................................12

7.2

WARNING CONDITIONS ................................................................12

8.0 ELECTRONIC IGNITION OPERATION.......................................................13

9.0 MAINTENANCE

FLOW SWITCH

9.1

RELIGHTING THE PILOT BURNER ...............................................14

9.2

CARE OF MAIN BURNERS

9.3

CLEANING HEATER COIL OF SCALE

9.4

10.0 HELPFUL INFORMATION

COIL CONDENSATION

10.1

COIL SCALING

10.2

10.3 FREEZING CONDITIONS ................................................................15

USE OF ACIDS ................................................................................15

10.4

COIL TEST

10.5

TERMINAL CONNECTIONS TO

10.6

11.0 TROUBLESHOOTING ...............................................................................16

PARTS LIST

WIRING DIAGRAM

11.0 SPECIFICATIONS......................................................................................23

..............................................................................................

................................................................................

............................................................

..........................................

...................................................................

................................................................................

.......................................................................................

PROSAFE II ...................................

....................................................................................

14

14

14

15

15

15

15

19

21

this page was intentionally left blank

1.0 INTRODUCTION

The HWG20 and HWG40 are steel coil type

instantaneous hot water heaters suitable for any low or

high pressure application requiring fast recovery. They

are most suitable for high pressure wash systems

where the high pressure water from the pump may be

fed through the heater, thereby producing hot water

while only cold water is run through the pump. They

may also be used in combination with an insulated

storage tank for a low pressure hot water system.

The durable stainless steel shell of the HWG20 and

HWG40 withstands years of use and will not rust. Both

models are available with either electronic ignition

(HSI) or standing pilot. An automatic vent damper is

available as an option from the factory to save energy

and protect the heater coil from freezing conditions. In

addition, a power venter is available as an option for

sidewall venting of the heater.

The operation of the heater is controlled and monitored

by the

advanced microcontroller that monitors several

For future reference when ordering parts or requesting

service information, please take a moment to record

your heater model number and serial number which

can be found on the certification plate mounted on the

front of the heater.

PROS AFEIIindustrial heater control, an

aspects of the heater operation in order to provide safe

and effective control of the heater. The PROSAFE

control provides visual status to the operator of the

heater through a front panel display on the heater.

Should some condition arise which results in the

heater exceeding its normal operating temperature, the

PROSAFEIIcontrol provides overheat lockout

protection, thus protecting the heater and operator

from the dangers of a heater overheat condition. The

PROSAFEIIcontrol also provides coil protection via a

coil freeze warning should the temperature in the flue

ever drop near the freezing point. The ProSafe

control will effectively and safely control the optional

automatic vent damper, eliminating open/close cycling

while still providing maximum coil protection and

energy savings. The

directly control the optional power venter without

requiring any additional timers or controls. An

electronic sensor with digital display of the current

water temperature is utilized to provide precise control

of the outlet water temperature.

PROSAFEIIcontrol will also

II

II

Model#

Serial#

-

1

-

2.0 IMPORTANT OPERATING CONDITIONS

Failure to comply with any of these conditions invalidates the warranty.

Pressure - The water pressure supplied to the water

inlet of the heater must never exceed the maximum

water pressure rating of the heater. The pressure

regulator supplied with the heater must remain

installed on the heater.

Freezing Conditions - The heater must be protected

from freezing conditions otherwise severe damage to

the heater coil may result. Adequate air supply to the

area housing the heater must be supplied to prevent

the coil freezing from a reverse draft down the heater

vent. If necessary, an automatic vent damper should

be installed. See section 4.4 VENTING for further

information.

3.0 SAFETY

Your heater was designed and constructed with safety

foremost. The following safety precautions should be

taken with your heater:

1) Read and understand this manual before

operating the equipment. Ensure that all

operators of this heater are fully familiar with

the operating and safety procedures contained

in this manual. An untrained operator exposes

him or herself as well as bystanders to potential

harm.

2) Do not modify the equipment in any way.

Unauthorized modification may impair the

function and/or safety of the equipment creating

a potential or real hazard to personnel.

3) The exterior of the heater may become hot

during operation. Avoid contact with the exterior

of the heater.

4) Do not smoke near the heater. Keep open

flame and sparks away.

Gas Installation- Gas piping and installation of these

gas water heaters must be performed by qualified

licensed personnel in accordance with CAN1-B149.1 &

CAN1-B149.2 installation codes and/or local codes.

III

PROSAFE

serviceable item. Do not remove the mounting screws

holding the cover to the box.

Acids, Alkalies, or Abrasive Fluids - Consult factory

before using heater with any of these fluids.

IF AT ANYTIME YOU SMELL GAS, SHUT OFF THE

GAS SUPPLY TO THE HEATER, AND EXTINGUISH

ANY OPEN FLAME. CALL YOUR GAS INSTALLER

IMMEDIATELY.

If the heater is to be incorporated into a high pressure

system, the safety procedures applicable to high

pressure systems should be followed.

I

Control - The heater control is not a user

1) Always hold the gun and extension firmly in

both hands during operation.

2) High pressure spray presents the risk of

injection and severe injury. Always keep clear

of the spray nozzle. Do not direct discharge

stream at people or electrical apparatus.

Always keep clear of moving belts and pulleys.

3)

4) Never disconnect high pressure hose during

operation.

-

2

-

Pressure Tap

Port

0

1

2

3

4

5

6

1

2

3

4

5

6

4.0 INSTALLATION

*** HEATERS MUST BE INSTALLED BY QUALIFIED PERSONNEL ONLY ***

4.1 LOCATION

The water heater contains sensitive electronic

1)

components that must not be exposed to water

spray. Choose a location such that the heater

will not be exposed to water spray of any kind.

Failure to do so may result in damage to

electronic components and void the warranty

on such components.

2) The water heater is approved for installation on

non-combustible material with 6 inches of

clearance from combustible walls. A minimum

clearance of 48 inches is required on the heater

front for access.

3) The water heater must be located in an area

that is protected from the weather and locations

where flooding may occur.

locations that may cause pilot outage.

4) In repair garages, the point of ignition shall be

not less than 4.5 feet (54 inches) above the

floor.

5) The location of the heater should be in an area

away from moving vehicles and should be

provided with sufficient protection and support

to prevent damage.

6) If the heater is being installed with a high

pressure pump, the heater should be installed

in a suitable dry location as near to the high

pressure pump unit as practical to simplify

connecting the water supply lines and electrical

lines between the two units.

4.2 MOUNTING

The heater must be mounted to a solid, noncombustible base. Mounting holes are provided on

the inside bottom of the heater. The HWG40 has

four 1/2” holes while the HWG20 has three 1/2”

holes.

4.3 GAS SUPPLY

1)

Pipe sizing must conform to local and

applicable codes (CGA B149.1 and B149.2).

Natural gas and LP (propane) heaters

2)

incorporate different components such that they

are not interchangeable. Never supply LP

(propane) to a natural gas heater or natural gas

to a LP (propane) heater.

CAUTION: Unlike natural gas, LP (propane)

gas is heavier than air. If pilot outage should

occur, the floor areas should be vented and

blown clear before relighting the pilot.

Avoid drafty

4.4 VENTING

4.5

-

3

-

IMPORTANT:

Licensed gas installer MUST ensure:

– 3.5" W.C. for natural gas heaters or

11" W.C. using an external regulator for LP

–

gas heaters

measured at the Pressure Tap Port on the gas

valve as shown in figure 4.3.1.

Figure 4.3.1

1) Observe C.G.A. Standards B149.1 and B149.2

and local safety codes.

2) The draft hood furnished with the heater must

be attached to the flue outlet without alteration

using the same size vent as the draft hood

outlet (see specifications for flue diameter).

3) For venting in general, do not reduce size of

vent. Reductions in vent sizing for power

venters must be made after the draft hood. For

horizontal runs, maintain 1/4 inch pitch per foot.

Top of stack to be 2 feet above highest part of

roof or nearby obstructions. Provide an

approved cap for the stack outlet. Refer to

C.G.A. standards.

4) Use of type “B” venting is recommended and

must be installed in accordance with C.G.A.

standards B149.1 and B149.2 by qualified

personnel.

5) Provisions for other water heaters and/or other

gas fired appliances within the same enclosure

as the heater must be made to allow for ample

free air to enter the enclosure for combustion

and venting

. Failure to supply adequate free

air may result in the dangerous

accumulation of combustion gas and/or

severe damage to the heater coil, due to

reverse drafting of air down the heater vent.

If necessary, an automatic vent damper or

power venter should be installed.

AUTOMATIC VENT DAMPER

The following instructions, and all instructions in

this manual pertaining to automatic vent dampers,

refer to the Magikist model HWG-AD10 (for the

HWG40) or the HWG-AD7 (for the HWG20)

automatic vent dampers. Other vent dampers are

neither approved not tested for use with the

HWG40 or the HWG20 heaters.

CAUTION: HWG40 and HWG20 heaters with 24

WATER

INLET

P

ROSAFE II CONTROL

Flue

Sensor

Temp

Sensor

Flow

Switch

PROSAFE II CONTROL

Flue

Sensor

Temp

Sensor

Flow

Switch

FLOW

SWITCH

PROSAFE II CONTROL

Flue

Sensor

Temp

Sensor

Flow

Switch

volt electronic ignition come equipped for

installation of an automatic vent damper.

Heaters with 24 volt standing pilot must have

an additional or redundant gas valve installed.

Refer to the appropriate C.G.A. standards and

the instructions supplied with the automatic

vent damper.

1) Observe C.G.A. Standards B149.1 and B149.2

and local safety codes.

Ensure that the service switch located on the

2)

motor housing of the automatic vent damper is

at the “AUTOMATIC OPERATION” position.

The “HOLD DAMPER OPEN” position is for

If your heater was supplied without a flow switch,

one must be installed on the water inlet of the

heater for correct operation of the heater. The flow

switch must be a single pole, single throw,

normally open switch capable of switching a

minimum of 1 amp at 24 VAC. The switch must

also have minimum flow rate of 1.0 U.S. gpm. For

most applications where the high pressure output

of a pump is to be fed directly through the flow

switch into the water inlet of the heater,the

maximum pressure and flow rating of the flow

switch must meet or exceed the operating

pressure and gallons per minute (GPM) of the

pump.

service only.

3) The automatic vent damper must be wired

according to the instructions in section 4.10

ELECTRICAL CONNECTIONS.

Failure to do

so will result in incorrect operation of the

automatic vent damper and a potentially

dangerous condition.

4.8 INLET PLUMBING

When facing the front of the heater, the water inlet

is located on the left, top side. If a flow switch was

provided with your heater, the inlet is 3/8” FNPT

connection. If a flow switch was not provided with

your heater, the inlet is a 3/4” MNPT connection.

4) Read the manufacturer’s manual provided with

the automatic vent damper and ensure that all

instructions are followed.

In most applications, the

water inlet of the heater

is connected to the high

4.6 POWER VENTER

The following instructions, and all instructions in

this manual pertaining to power venters, refer to

the Magikist model HWG-PV6B-24 (for the

HWG40) or the HWG-PV4B-24 (for the HWG20)

power venters. Other power venters are neither

approved not tested for use with the HWG40 or

the HWG20 heaters.

1) Observe C.G.A. Standards B149.1 and B149.2

and local safety codes.

2) The power venter must be wired according to

the instructions in the separate document

HWG-PV Power Venter Wiring Instructions.

Failure to do so will result in incorrect

operation of the power venter and a

potentially dangerous condition.

3) Read the manufacturer’s manual provided with

the power venter and ensure that all

instructions are followed.

FLOW SWITCH

4.7

Most heaters are supplied with a flow switch which

you will find installed on the water inlet of the

heater.

heater is normally supplied with a short length of

high pressure hose connected to the water inlet of

the heater that you may use to attach to your inlet

plumbing to.

directly connected to the heater due to the

potential damage that may result from pump

vibration being transferred to the heater.

The plumbing to the water inlet of the heater

should be sized for the flow rate desired in order

to prevent pressure loss. There should be no

unnecessary restrictions in the inlet plumbing.

Length should be kept to a minimum as should

the number of elbows and joints. Teflon tape

should be used to seal all joints.

4.9 OUTLET PLUMBING

Figure 4.8.1

Rigid piping must never be

pressure outlet of a

pump. In such cases,

the direct connection to

the water inlet of the

heater from the pump

must be made with high

pressure hose rated for

the operating pressure

of the pump and the

water outlet temperature

of the heater. Your

When facing the front of the heater, the water

outlet is located at the front, slightly to the right of

the center on the HWG40 the HWG20. The water

outlet is a 3/8” FNPT swivel connection.

Figure 4.7.1

-

4

-

If the water outlet of the

ELECTRICAL

CONNECTION BOX

WITH FLAT LID

REMOVE THESE

4 SCREWS

PROS

AFE II

CONTROL

WATER

OUTLET

P

ROSAFE II CONTROL

Flue

Sensor

Temp

Sensor

Flow

Switch

PROSAFE II CONTROL

Flue

Sensor

Temp

Sensor

Flow

Switch

PROSAFE II CONTROL

Flue

Sensor

Temp

Sensor

Flow

Switch

24VAC

SUPPLY

ELECTRICAL

CONNECTION BOX

black

brown

purple

blue

black*

black*

purple

grey

yellow

white**

ELECTRICAL

CONNECTION BOX

120V to 24V

Transformer

120VAC

SUPPLY

black

white

black

brown

purple

blue

black*

black*

purple

grey

yellow

white**

ELECTRICAL

CONNECTION BOX

METHOD 1

METHOD 2

ELECTRICAL

CONNECTION BOX

Field wiring shown in dashed lines.

Duplicate black wires for convenience.

On some heaters this wire may be brown.

*

**

heater is to be

connected to rigid piping

that is to be distributed

through a facility, it is

recommended that a

short “snubber” hose be

used to connect the

water outlet of the

heater to the rigid

piping. The “snubber”

hose must be rated for

Figure 4.9.1

the operating pressure

of the pump and the

water outlet temperature

of the heater.

The plumbing from the water outlet should be

properly sized for the flow rate desired in order to

prevent pressure loss. As with inlet plumbing,

teflon tape should be used to seal all joints.

4.10 ELECTRICAL CONNECTIONS

The heater is supplied with an electrical

connection box where all electrical connections

are to be made.

The second wiring configuration is used when

installing the heater without a Magikist control

panel. If 24VAC is not available you will need to

mount the supplied transformer to the electrical

connection box and wire the heater according to

method 1 in figure 4.10.2. If the heater is being

added to a system where an existing transformer

has available 24VAC at a minimum of 40VA, you

may wish to simply tap off this transformer and

wire the heater according to method 2.

Figure 4.10.1

Remove the 4 screws holding the flat lid cover to

the front of the electrical connection box as shown

in figure 4.10.1 The inside of the electrical

connection box has been divided into 2 sides. The

right hand side is for the 120 volt connection to a

transformer (if required), while the left hand side is

for all low voltage connections.

There are two typical wiring configurations for the

HWG40 heater. The first configuration is utilized

when the heater is installed in conjunction with a

Magikist control panel such as the CPTX

shutdown control panel.

connections including power for the heater are

For this configuration, all

timed

made between the heater and the control panel.

(the only exception to this is the optional power

venter). Please refer to the wiring diagram

supplied with the Magikist control panel for the

most up to date instructions on wiring the heater

to the control panel. For connections to the power

venter, refer to the power venter wiring

instructions later on in this section.

Figure 4.10.2

Even though in most cases it is not recommended

that the 24vac supply be earth grounded, if the

24vac supply is to earth grounded then the earth

ground MUST be connected to the black wire.

The EXTERNAL CONTROL connections (purple

wires) provide an external means of enabling or

disabling the heater. The EXTERNAL CONTROL

connections are wired together at the factory,

thereby always enabling the heater. For

installations that utilize a Magikist control panel,

follow the wiring diagram supplied with the control

panel for the EXTERNAL CONTROL connections.

For installations that do not utilize a Magikist

-

5

-

control panel, the EXTERNAL CONTROL

Relay with

24VAC coil

to black wire

of ProSafe II

to blue wire

of ProSafe II

contacts of

relay follow

open/close

of flow switch

connections may be left as is or they may be

wired to an external switch, relay, or contactor.

The switch will then act as an overriding master

enable/disable for the heater. For example, the

external switch may be used to provide a cold

water rinse. Likewise, a keyswitch could be used

to prevent unauthorized use. Alternately, if

connected to the auxiliary contact of the motor

contactor for the high pressure pump, the heater

will be disabled whenever the pump is shut down.

The switching device must be a single pole switch

with a minimum rating of 100mA at 24 VAC.

These wires can only be switched, external

power must NEVER be applied to the

EXTERNAL-CONTROL purple wires

.

If your heater was provided with a flow switch, it is

already connected to the

PROSAFEIIcontrol. If

the heater was not supplied with a flow switch, the

flow switch installed in section 4.7 must be

connected to the flow switch terminal connection

located at the bottom of the

(see figure 4.10.3).

External power must NEVER

PROSAFEIIcontrol

be applied to the flow switch terminal

connections.

Figure 4.10.4

If a Magikist automatic vent damper is installed,

locate the damper terminal connection located at

the bottom of the

PROSAFEIIcontrol (see figure

4.10.5) . Remove the jumper plug and connect the

damper cord to the damper terminal connection

(see section 10.6 TERMINAL CONNECTIONS TO

PROSAFE II for important information on

connecting and disconnecting electrical

connectors to the

PROSAFEIIcontrol). This

procedure must be followed if an automatic

vent damper is installed, otherwise the damper

will not be controlled properly and a

potentially dangerous situation may arise.

If an

automatic vent damper is not installed, the jumper

plug must remain installed on the damper terminal

connection.

Flow switch

terminal connections

Figure 4.10.3

The EXT-FLOW connection (blue wire) provides

an external signal as to whether the flow switch is

opened or closed. For installations that utilize a

Magikist control panel, follow the wiring diagram

supplied with the control panel for the EXT-FLOW

connection (blue wire). For installations that do not

utilize a Magikist control panel and another

component of your system requires the flow

switch for some control aspect, the black wire and

the EXT-FLOW blue wire may be used to drive a

relay whose operation will then follow that of the

flow switch. When the blue and black wires are

connected to the 24 VAC coil of the relay (as

shown in figure 4.10.4), the contacts of the relay

will follow the opening and closing of the flow

switch.

Never connect the blue and black wires

together.

terminal connections

Damper

Figure 4.10.5

If a Magikist power venter is installed, the power

venter must be wired to the

PROSAFEIIcontrol

according to the separate document HWG-PV

Power Venter Wiring Instructions.

-

6

-

5.0 PRE-OPERATION CHECKS

THE FOLLOWING PRE-OPERATION CHECKS MUST BE CARRIED OUT, PREFERABLY BY A

LICENSED GAS FITTER, AFTER INSTALLATION OF THE HEATER AND BEFORE OPERATION.

5.1 FLUSH DEBRIS FROM THE SYSTEM

During shipment and installation of your heater,

debris may accumulate that should be removed

before operating your heater. Following are steps

that should be taken to remove any debris from

the heater and the water inlet and outlet plumbing.

1) If your heater is part of a high pressure system,

remove any spray nozzle(s) from the wash

gun(s) attached to the water outlet of the

heater. If your heater is part of a low pressure

system direct the water output of the heater to

a drain.

2) Run water through the heater for 5 to 10

minutes by either operating your high pressure

pump or turning on the water supply to the

water inlet of the heater.

3) Once complete the spray nozzle(s) may be

reinstalled or the water output reconnected.

5.2 INITIAL POWER UP

With the gas supply still off, power-up the heater

by energizing the power source to the heater. The

power-up state of the

indicated by the buzzer sounding and the

temperature setting displaying 888. Following

power-up, the POWER and FLUE STATUS

indicators on the

on. The status of the other indicators depends on

the current state of various inputs to the control.

Refer to section 6.0 PROSAFE II CONTROL for a

detailed explanation of the indicator lights of the

PROSAFE

5.3 CHECK FLOW SWITCH &

AUTOMATIC VENT DAMPER

Before operating your heater, the flow switch and

the automatic vent damper must be checked to

ensure that they are operating correctly. If your

heater does not have an automatic vent damper

installed, the following sequence regarding the

DAMPER-OPEN indicator will not apply as the

DAMPER-OPEN indicator will always be on.

If the FLOW indicator does not follow the steps

below, the flow switch may need adjustment.

Refer to section 9.1 FLOW SWITCH for

instructions on adjusting the flow switch. If the

DAMPER-OPEN indicator does not follow the

steps below, refer to section 11.0

TROUBLESHOOTING.

1) Turn on the high pressure pump or other

I

I

control.

PROS AFEIIcontrol is

PROSAFEIIcontrol should be

source supplying water to the heater such that

water is flowing through the heater. The FLOW

indicator on the

on. If an automatic vent damper is installed, the

DAMPER-OPEN indicator will turn on

approximately 15 to 20 seconds after the

FLOW indicator has turned on.

2) Next, close the trigger gun or turn off the pump

or other source supplying water to the heater

such that there is no water flow through the

heater. The FLOW indicator on the

control should turn off.

3) Repeat these steps 5 to 10 times to ensure that

when there is water flow through the heater that

the FLOW indicator is on, and when there is no

water flow through the heater that the FLOW

indicator is off.

4) Finally, turn off the pump or other source

supplying water to the heater such that there is

no water flow through the heater and the FLOW

indicator turns off. If an automatic vent damper

is installed the DAMPER-OPEN indicator will

turn off after approximately a 5 minute period.

For the automatic vent damper to operate

correctly, power to the heater must remain on.

Removing power from the heater may result in

the automatic vent damper being left in an

open position before the

has had the opportunity to close the damper. If

your heater is equipped with an automatic

vend damper, ensure that the DAMPER-OPEN

indicator is off before powering down the

heater.

BLEED OFF AIR

5.4

As with any new gas installation, the gas lines

supplying the heater must be bled of air.

must be carried out by qualified personnel

only. This step must be completed before

proceeding to the next step.

LIGHTING THE PILOT BURNER

5.5

(STANDING PILOT HEATERS ONLY)

CAUTION: Should pilot outage occur, wait 5

minutes before relighting to clear combustion

chamber of accumulated gas. If an automatic

vent damper is installed, you must also move

the service switch on the motor housing of the

vent damper to “HOLD DAMPER OPEN”

position and wait 5 minutes before relighting

(return switch to “AUTOMATIC OPERATION”

PROSAFEIIcontrol should turn

PROSAFE

PROSAFE

III

I

control

II

This

-

7

-

once relighting procedure is complete).

Because LP (propane) gas is heavier than air,

heaters utilizing these gases should have the

floor areas vented and blown clear before

relighting the pilot.

WARNING:

IF YOU SMELL GAS, SHUT OFF THE GAS

SUPPLY TO THE APPLIANCE AND

EXTINGUISH ANY OPEN FLAME. IF THE

ODOUR PERSISTS, CALL YOUR GAS

INSTALLER IMMEDIATELY.

ADVERTISSEMENT:

SI UNE ODEUR DE GAZ EST DÉCELÉE,

COUPER L’ALIMENTATION EN GAZ DE

L’APPAREIL ET ÉTEINDRE TOUTES LES

FLAMMES. SI L’ODEUR PERSISTE, AVERTIR

IMMÉDIATEMENT LE FOURNISSEUR DE GAZ.

To light the pilot, turn the knob on the combination

gas valve from “off” to the “pilot” position. While

pressing down on the knob, light the pilot. Once lit,

hold down the knob (approximately 30 seconds)

until pilot remains lit when the knob is released.

5.6 CHECK IGNITION OF MAIN BURNERS

1) Ensure that the POWER and FLUE STATUS

indicators on the

PROSAFEIIcontrol are both

on. If a automatic vent damper is NOT installed

the DAMPER OPEN indicator should be on. If a

power venter is NOT installed the POWER

VENTER ON indicator should be on. For

installations that do NOT utilize a Magikist

control panel and have wired the EXTERNAL

CONTROL to an external switch, relay, or

contactor, you will need to perform the action

necessary to turn the EXTERNAL CONTROL

indicator on.

2) If the THERMOSTAT indicator is not on, press

the up arrow button located below the

temperature setting display on the

PROSAFE

control to increase the desired water outlet

temperature, until the the THERMOSTAT

indicator turns on.

3) FOR ELECTRONIC IGNITION HEATERS:

Turn the switch on the combination gas valve

from “off” to “on”.

FOR STANDING PILOT HEATERS: Turn the

knob on the combination gas valve from “pilot”

to “on”. On new installations, the pilot may be

extinguished when moving the knob from “pilot”

to “on” initially due to air inside the gas valve. If

this occurs, repeat the steps in section 5.5.

FLOW ON indicator will turn on once flow is

started. If an automatic vent damper is

installed, the the DAMPER-OPEN indicator will

turn on approximately 15 to 20 seconds after

the FLOW ON indicator is on. If a power venter

is installed, the POWER VENTER ON indicator

will turn on once air flow in the power venter is

proven.

With FLOW ON, THERMOSTAT, EXTERNAL

5)

CONTROL, FLUE STATUS, DAMPER OPEN,

and POWER VENTER ON indicators all on, the

REQUEST FOR HEAT and HEAT ON

indicators will turn on. The main burners should

light within a few seconds. If the main burners

do not light, see section 11.0

TROUBLESHOOTING

6) Close the wash gun or shut off the water supply

to the heater. The FLOW ON indicator will turn

off and the main burners should go off within 10

seconds.

For complete shutdown of the main burners,

including the pilot, turn the switch or knob on the

combination gas valve to “off” position.

WARNING:

RISK OF INJECTION OR SEVERE INJURY. KEEP

CLEAR OF NOZZLE. DO NOT DIRECT DISCHARGE

STREAM AT PERSONS. THIS EQUIPMENT IS TO BE

USED ONLY BY TRAINED OPERATORS

ADVERTISSEMENT:

RISQUE D’INJECTION ET DE BLESSUREES

GRAVES. SE TENIR À L’ÉCART DU JET. NE PAS

DIRIGER LE JET DE SORTIE VERS D’AUTRES

PERSONNES. CONFIER L’UTILISATION DE CE

MATÉRIEL À UN OPÉRATEUR QUALIFIÉ.

WARNING:

IF YOU SMELL GAS, SHUT OFF THE GAS SUPPLY

TO THE APPLIANCE AND EXTINGUISH ANY OPEN

II

FLAME. IF THE ODOUR PERSISTS, CALL YOUR GAS

INSTALLER IMMEDIATELY.

ADVERTISSEMENT:

SI UNE ODEUR DE GAZ EST DÉCELÉE, COUPER

L’ALIMENTATION EN GAZ DE L’APPAREIL ET

ÉTEINDRE TOUTES LES FLAMMES. SI L’ODEUR

PERSISTE, AVERTIR IMMÉDIATEMENT LE

FOURNISSEUR DE GAZ.

If the water inlet of the heater is connected to a

4)

high pressure pump, start the pump and open

the trigger gun to allow water flow through the

heater. If the water source for the heater is not

a pump, open the source of water so that water

flows through the heater. In either case the

-

8

-

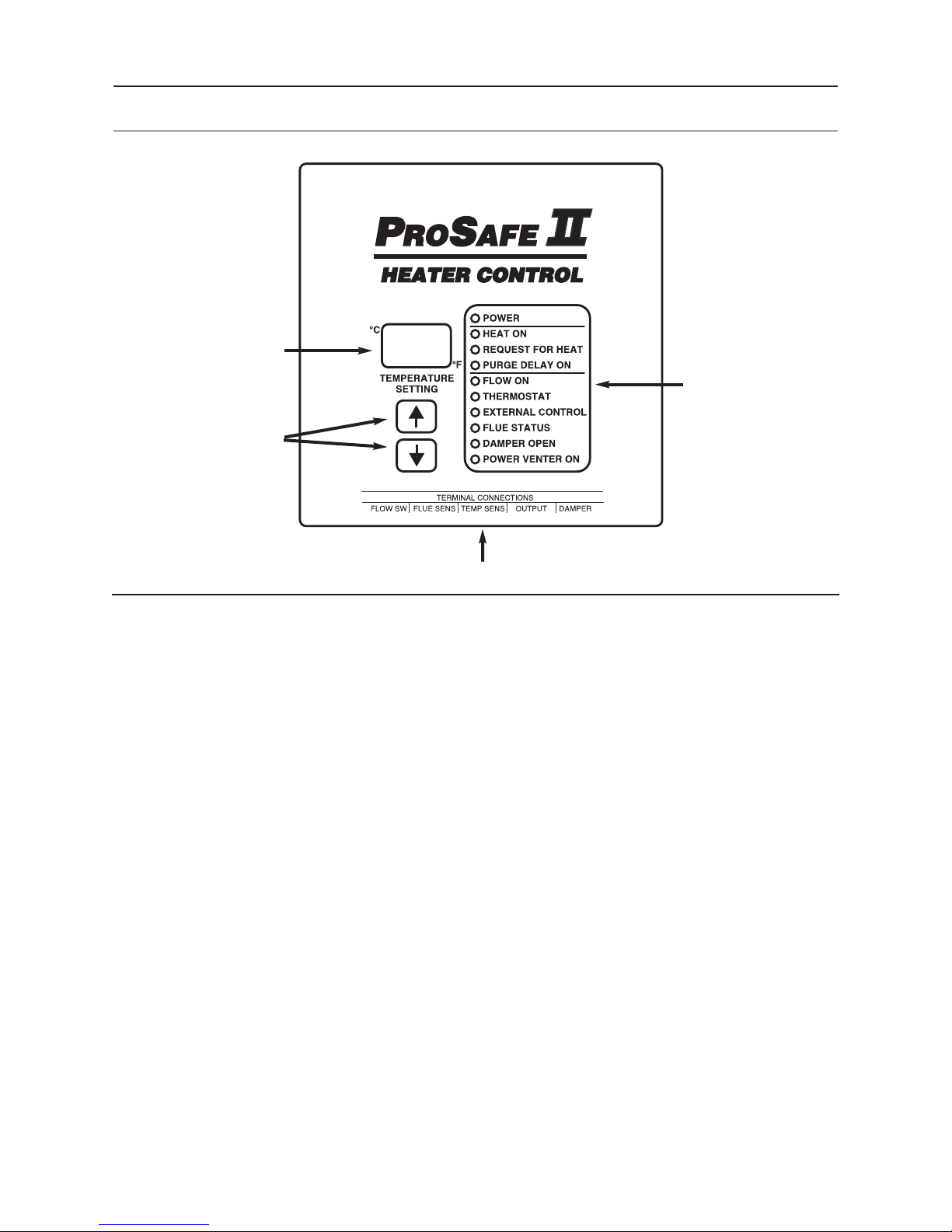

Current desired outlet

temperature setting.

Dot indicates °C or °F.

Use up and down arrows

to adjust current desired

outlet temperature.

6.0

PROSAFE

I

III

CONTROL

Indicators provide

operational status

of heater.

Connections to ProSafe II

The HWG20 and HWG40 heaters are designed to

provide hot water on demand at a given temperature

setting. These heaters will automatically regulate the

temperature of the outlet water to that which you

desire by cycling on and off as required. Because

these heaters are not storage type heaters, they must

also cycle on and off dependent on whether or not

there is water flow.

The operation of the heater is controlled and monitored

by the

advanced microcontroller that monitors several

aspects of the heater operation in order to provide safe

and effective control of the heater. The

control provides visual status to the operator of the

heater through it’s front panel display on the heater. It

also provides the setting for the outlet water

temperature desired from the heater.

Should some condition arise which results in the

heater exceeding its normal operating temperature, the

PROSAFEIIcontrol provides overheat lockout

protection, thus protecting the heater and operator

from the dangers of a heater overheat condition. The

PROSAFEIIcontrol also provides coil protection via a

coil freeze warning should the temperature in the flue

ever drop near the freezing point. Other conditions

which affect the operation of the heater are detected

and displayed to the operator by the

control.

PROS AFEIIindustrial heater control, an

PROSAFE

PROSAFE

II

II

Following is a description of the indicators and their

function on the

6.1 TEMPERATURE SETTING

The temperature setting display on the PROSAFE

II

water temperature from the heater. To change the

temperature setting press the up or down arrow

buttons located below the temperature setting

display. Pressing and holding either of the up or

down arrow buttons will result in the temperature

setting changing slowly until a change of 5°, after

which the setting will change rapidly until either

button is released.

The temperature setting ranges from 40 to 200°F

or 5 to 95

chosen. The current temperature scale is

indicated by a red dot next to either the

°F by the temperature setting display.

The temperature setting display is also used to

indicate any error condition detected by the

PROSAFE

exists the current desired outlet water temperature

is replaced by a flashing error code(s). Refer to

the section 7.0

WARNINGS for diagnosing error conditions.

PROSAFEIIcontrol.

control displays the current desired outlet

C depending on the temperature scale

°

C or the

°

II

control. When an error condition

PROSAFE

I

I

ERRORS &

-

9

-

6.2 POWER INDICATOR

The power-up state to the heater and the PROSAFE

II

control is indicated by the buzzer sounding and

the temperature setting displaying 888 for 1

second. Following power-up, the POWER

indicator on the

on.

6.3 HEAT ON INDICATOR

For electronic ignition (HSI) heaters the HEAT ON

indicator on the

the SmartValve gas valve has provided positive

feedback that the intermittent pilot is lit and the

main section of the gas valve is open.

For standing pilot heaters the HEAT ON indicator

simply follows the on and off action of the

REQUEST FOR HEAT indicator.

6.4 REQUEST FOR HEAT INDICATOR

The REQUEST FOR HEAT indicator on the

PROSAFE

conditions have been met to request that heat be

turned on. The conditions required to request for

heat are flow on, thermostat call for heat, external

control on, flue status good, damper is open,

power venter is on, and purge delay is off.

Essentially if the six indicators FLOW ON,

THERMOSTAT, EXTERNAL CONTROL, FLUE

STATUS, DAMPER OPEN, and POWER

VENTER ON are all on, and PURGE DELAY ON

indicator is off, then REQUEST FOR HEAT will

turn on. Should any of the six indicators turn off,

then REQUEST FOR HEAT will turn off as well.

6.5 PURGE DELAY ON INDICATOR

The PURGE DELAY ON indicator on the PROSAFE

II

control indicates that the heater is currently in

a purge delay. The purge delay is intended to

provide a delay to eliminate rapid on/off cycling of

the gas valve.

The purge delay occurs when there is an end to

the current request for heat and the REQUEST

FOR HEAT indicator turns off. At this point the

PURGE DELAY ON indicator turns on and

remains on for a period of six seconds. During this

period if all conditions required to request for heat

are met, the REQUEST FOR HEAT indicator will

not turn on. If the conditions required to request

for heat remain, the REQUEST FOR HEAT

indictor will turn on once the purge delay is over

and the PURGE DELAY ON indicator turns off.

FLOW ON INDICATOR

6.6

The FLOW ON indicator on the PROS AFE

control indicates whether there is water flow

through the heater or not. If the indicator is on

then there is water flow through heater. If the

indicator is off then there is no flow of water

through the heater.

PROSAFE

PROSAFEIIcontrol indicates that

II

control indicates whether all

I

I

control should remain

If the FLOW ON indicator is flashing slow, the

PROSAFE

there is water flow through the heater and that it

has been continuous for at least 10 minutes. This

warning is strictly for information purposes as it

may indicate a problem with the flow switch, since

the wash gun in high pressure washing

applications is typically not held open continuously

for 10 minutes.

If the wash gun is held open continuously for more

than 10 minutes in your operation, or your heater

is being used in a different application where

water flows through the heater continuously for

more than 10 minute periods, then simply

disregard the flashing FLOW ON indicator. If,

however, the FLOW ON indicator is flashing and

you have

continuously for more than 10 minutes, the flow

switch may not be operating correctly.

should immediately turn off the gas flow to the

main burners by manually turning the knob on

the gas valve from ON to pilot (standing pilot

heaters) or from ON to OFF (for electronic

ignition heaters). This is important as the main

burners of the heater may be continuing to fire

with no water flow through the heater.

Following this, the operation of the flow switch

must be checked. The FLOW ON indicator should

be on when there is water flow through the heater

and off when there is no water flow through the

heater. If the FLOW ON indicator remains on or

continues to flash even after flow through the

heater has stopped, see section 9.1 FLOW

SWITCH for servicing the flow switch.

6.7 THERMOSTAT INDICATOR

The THERMOSTAT indicator on the PROSAFE

control indicates whether the temperature of the

outlet water of the heater is below, at, or greater

than the current temperature setting on the

temperature setting display. If the THERMOSTAT

indicator is on, then the outlet water temperature

of the heater is below the current temperature

setting. If the THERMOSTAT indicator is off, then

the outlet water temperature of the heater is at or

above the current temperature setting.

If the THERMOSTAT indicator is flashing fast and

the temperature setting display is flashing an error

code, the

error condition exists. Refer to section 7.0

PROSAFE

diagnosing error conditions.

I

I

6.8 EXTERNAL CONTROL INDICATOR

The action displayed by the EXTERNAL

CONTROL indicator is dependent on how this

option was setup with your heater. The

EXTERNAL CONTROL is intended to show

whether an external control has enabled or

disabled the heater from operating.

I

I

control is indicating a warning that

not had the wash gun open

PROSAFE

II

I

I

control is indicating that an

ERRORS & WARNINGS for

You

II

-

10

-

For installations that utilize a Magikist control

panel, the EXTERNAL CONTROL indicator

should be on only when the pump is running.

on/off cycling a damper experiences in high

pressure wash systems where wash guns are

opened and closed frequently.

For installations that do not utilize a Magikist

control panel, the EXTERNAL CONTROL, as

supplied from the factory, will always be on. If the

installer has chosen to use the EXTERNAL

CONTROL with and external switch, relay, or

contactor, the EXTERNAL CONTROL indicator

will follow the opening and closing action of that

device.

6.9 FLUE STATUS INDICATOR

The FLUE STATUS indicator provides status as to

one of the key safety components of your heater,

the flue sensor. For normal operation of the heater

The FLUE STATUS indicator remains on.

If the FLUE STATUS indicator is flashing fast and

the temperature setting display is flashing an error

code, the

error condition exists. Refer to section 7.0

PROSAFE

diagnosing error conditions.

If the FLUE STATUS indicator is flashing slow, the

PROSAFEIIcontrol is indicating that a warning

condition exists. Refer to section 7.0

ERRORS & WARNINGS for diagnosing error

conditions.

6.10 DAMPER OPEN INDICATOR

The PROSAFEIIcontrol provides the necessary

control to operate the Magikist damper effectively

and safely. The

damper whenever there is water flow through the

heater. In addition the

close the damper only after there is no water flow

for a preset period of time. This eliminates the

PROSAFEIIcontrol is indicating that an

II

ERRORS & WARNINGS for

PROSAFE

PROSAFEIIcontrol will open your

PROSAFEIIcontrol will

If your heater is not equipped with an automatic

vent damper, the DAMPER OPEN indicator will be

on whenever there is power to the heater.

If your heater is equipped with a Magikist

automatic vent damper, the DAMPER OPEN

indicator is on when the damper is in the open

position and off when the damper is closed or in

the process of opening or closing. Because of the

time required to open and close the damper, there

will be a delay of approximately 15 to 20 seconds

from the time the FLOW ON indicator turns on

(indicating water flow through the heater) and the

DAMPER OPEN indicator turns on.

6.11

POWER VENTER ON INDICATOR

The PROSAFE

control to operate the Magikist power venter

effectively and safely. The

turn on your power venter whenever there is water

flow through the heater. In addition the

II

control will shut off the power venter only after

there is no water flow for a preset period of time.

This eliminates the on/off cycling a power venter

II

experiences in high pressure wash systems where

wash guns are opened and closed frequently.

If your heater is not equipped with a power venter,

the POWER VENTER ON indicator will be on

whenever there is power to the heater.

If your heater is equipped with a Magikist power

venter, the POWER VENTER ON indicator is on

only when air flow in the power venter is proven.

I

I

control provides the necessary

PROSAFEIIcontrol will

PROSAFE

-

11

-

7.0

PROSAFE

I

III

ERRORS & WARNINGS

7.1 ERROR CONDITIONS

The PROSAFEIIcontrol indicates error conditions via

the indicator lights and the temperature setting display.

Error conditions require immediate attention in order to

ensure continued operation of the heater. Whenever

an error condition is present, the heater will not fire.

Some error conditions lockout the operation of the

heater until the error is cleared by a power down/up

sequence. The alarm buzzer sounds on all errors.

Should an error condition arise, the indicator light that

relates to the error condition will flash on and of at a

fast rate. In addtion, the temperature setting display wil

no longer show the desired outlet water temperature,

but instead will display a flashing error code Exx where

xx is the error code.

Please see section 11.0 TROUBLESHOOTING for

diagnosing error conditions.

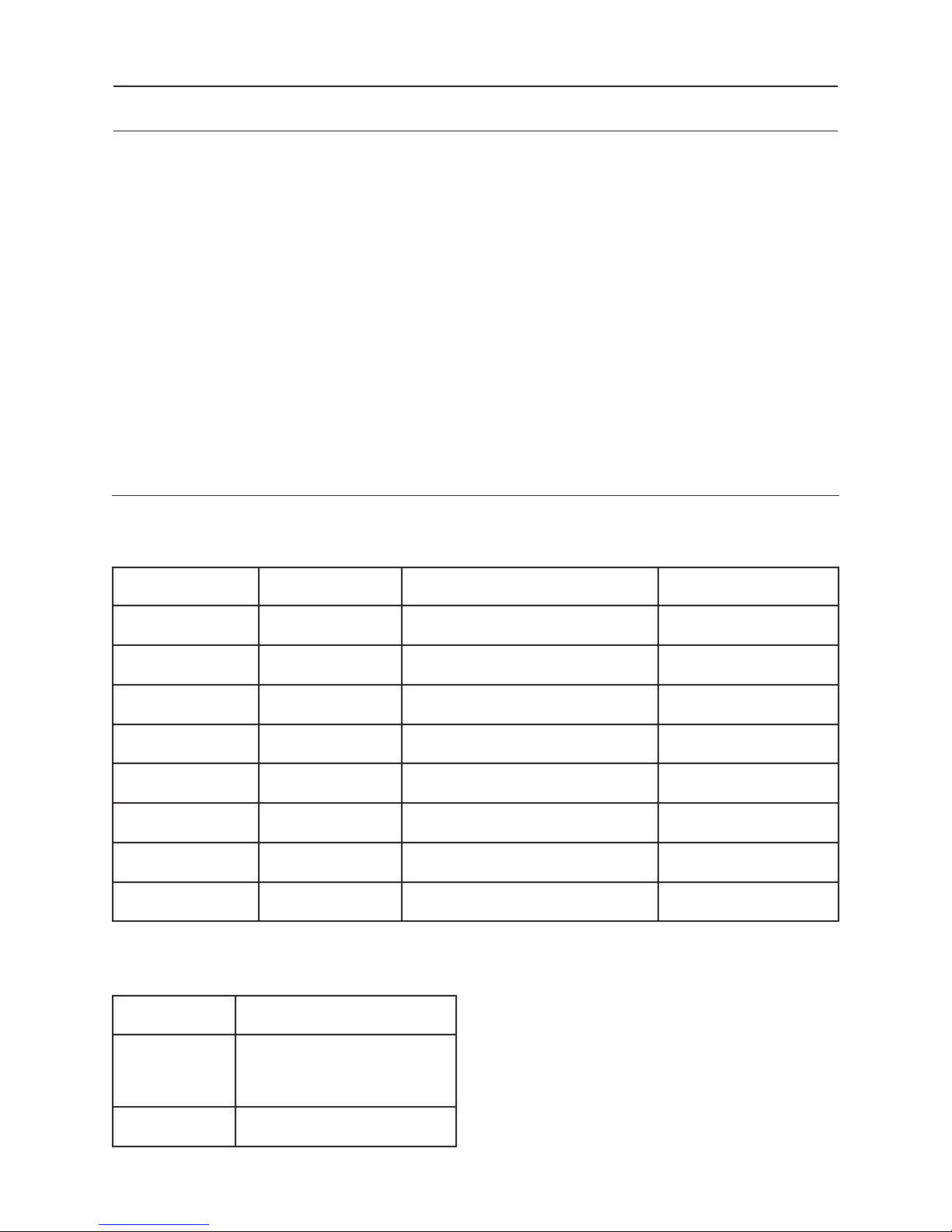

Table 7.1 - ERROR CONDITIONS

Temperature Setting

Display Flashes

E10 FLUE STATUS Problem with communication to flue

E11 FLUE STATUS Problem with communication to flue

E15 FLUE STATUS Flue overheat condition. Yes

Indicator Light

Flashing Fast Description

sensor (open).

sensor (short).

7.2 WARNING CONDITIONS

The PROSAFEIIcontrol indicates warning conditions

via the indicator lights. Unlike error conditions, warning

conditions do not prevent the heater from firing.

Warning conditions should be attended to promptly in

order to ensure the continued safe operation of the

heater.

Should a warning condition arise, the indicator light

that relates to the warning condition will flash on and of

at a slow rate.

Please see section 11.0 TROUBLESHOOTING for

diagnosing warning conditions.

Requires Power Down/Up

Sequence to Clear

No

No

E20 THERMOSTAT Problem with communication to

temperature sensor (short).

E21 THERMOSTAT Problem with communication to

temperature sensor (short).

E30 REQUEST FOR

HEAT

E31 REQUEST FOR

HEAT

E59 (none) Problem with internal memory. Yes

Table 7.2- WARNING CONDITIONS

Indicator Light

Flashing Slow Description

FLUE STATUS Temperature in flue is near or

below freezing. Water in heater

coil is in danger of freezing and

damaging coil.

FLOW ON Flow has been asserted for more

than 10 minutes.

Problem with OUTPUT driver (open). Yes

Problem with OUTPUT driver (short). Yes

No

No

-12-

8.0 ELECTRONIC IGNITION OPERATION

This section is applicable only to heaters which utilize

electronic ignition (HSI).

When there is a request for heat as shown by the

REQUEST FOR HEAT indicator on the

control, the PROSAFE

gas valve (hereafter referred to as the SmartValve) to

start the ignition sequence. In response the

SmartValve will begin the pilot trial period, where the

SmartValve attempts to light the pilot for a period of 90

seconds. This 90 second period consists of the the

following sequence: hot surface ignitor (HSI) on for 30

seconds; HSI off for 30 seconds; HSI on for an

additional 30 seconds. If the attempt to light the pilot is

successful during the pilot trial period, the main section

of the SmartValve will then energize for main burner

ignition to occur. If the attempt to light the pilot is

unsuccessful after 90 seconds, the SmartValve will

begin a 5 minute delay period before reattempting

another pilot trial period. The SmartValve is a

continuous retry control. Thus it will continuously

repeat the pilot trial period followed by the 5 minute

I

I

control signals the SmartValve

PROSAFE

II

delay period, until the pilot is successfully lit or the

PROSAFEIIcontrol no longer indicates REQUEST

FOR HEAT.

If after successful lighting of the pilot, the SmartValve

detects that the pilot is no longer lit, it will once again

begin the pilot trial period. If the pilot is not relit after 90

seconds, the SmartValve will begin the 5 minute delay

period. Continuous retry will occur as described above.

The HEAT ON indicator of the ProSafe II control

indicates that the SmartValve gas valve has provided

positive feedback that the pilot is lit and the main

section of the gas valve is open. If the REQUEST FOR

HEAT indicator of the PROSAFE

indicator of the the

ON

no indication of what state the SmartValve is in with

regards to it’s continuous retry sequence. In other

words the SmartValve could be in the pilot trial period

(HSI on or HSI off), or the 5 minute delay period.

PROSAFE

II

is lit but the HEAT

I

I

is not lit, there is

-

13

-

9.0 MAINTENANCE

9.1 FLOW SWITCH (MODEL HPFS38)

On heaters where the mineral content of the water

is high or where chemicals or soaps are used, it

may be necessary on occasion to

disassemble the housing

and clean any debris and

build up inside the flow

switch. This maintenance

will allow the magnet to

continue to move smoothly

and freely, and will

eliminate nuisance failures

due to scale buildup. It is

suggested that the flow

switch be inspected and

cleaned as necessary

each time the heater (or

possibly the high pressure

Figure 9.1.1

To adjust the flow switch, the reed switch will need

to be repositioned. The reed switch is housed

inside the cylindrical metal can from which the

jacketed wire comes out. To reposition the reed

switch loosen the friction bolt/nut and slide the

cylindrical metal can in or out such that the FLOW

indicator is on when there is flow and off when

there is no flow through the switch. Retighten the

friction bolt/nut to secure the position of the reed

switch.

9.2 RELIGHTING THE PILOT BURNER

(STANDING PILOT HEATERS ONLY)

CAUTION: Should pilot outage occur, wait 5

minutes before relighting to clear combustion

chamber of accumulated gas. If an automatic

vent damper is installed, you must also move

the service switch on the motor housing of the

vent damper to “HOLD DAMPER OPEN”

position and wait 5 minutes before relighting

(return switch to “AUTOMATIC OPERATION”

once relighting procedure is complete).

Because LP (propane) gas is heavier than air,

heaters utilizing these gases should have the

floor areas vented and blown clear before

relighting the pilot.

WARNING:

IF YOU SMELL GAS, SHUT OFF THE GAS

SUPPLY TO THE APPLIANCE AND

EXTINGUISH ANY OPEN FLAME. IF THE

ODOUR PERSISTS, CALL YOUR GAS

INSTALLER IMMEDIATELY.

ADVERTISSEMENT:

SI UNE ODEUR DE GAZ EST DÉCELÉE,

COUPER L’ALIMENTATION EN GAZ DE

L’APPAREIL ET ÉTEINDRE TOUTES LES

FLAMMES. SI L’ODEUR PERSISTE, AVERTIR

IMMÉDIATEMENT LE FOURNISSEUR DE GAZ.

pump) receives routine

maintenance or service.

Should pilot outage occur, refer to section 5.5

LIGHTING THE PILOT BURNER for instructions

on relighting the pilot burner.

9.3 CARE OF MAIN BURNERS

Due to condensation from heater coils dripping on

the burners, a scale build-up may occur in the

burner jet orifices.

To remove the burner bar from the heater, turn off

the gas to the heater by turning the knob on the

gas valve to the “off” position. For standing pilot

heaters, disconnect the pilot tube and

thermocouple at the gas valve. For electronic

ignition heaters, disconnect the pilot tube and the

electrical connections between the pilot assembly

and the electronic ignition module (take care to

note the connections so that they may be

reconnected correctly). Disconnect the union

joining the burner bar to the modulating gas valve,

and the U-bolt retaining the feed pipe at the

bottom of the heater inside the door. Slide the

burner bar out through the shell opening.

To clean burner jets select the proper size drill for

type of gas involved. Use a pin vise to hold the

drill and ream out each jet orifice by hand

recommended that the burner jets not be removed

from the burner bar except for jets that require

replacing.

size than shown.

HWG40:

#55 drill for natural gas 0-2000ft. (0-610 m)

#56 drill for natural gas 2000-4000ft. (610-1370 m)

#68 drill for LP gas 0-2000ft. (0-610 m)

#70 drill for LP gas 2000-4000ft. (610-1370 m)

HWG20

#52 drill for natural gas 0-2000ft. (0-610 m)

#53 drill for natural gas 2000-4000ft. (610-1370 m)

#63 drill for LP gas 0-2000ft. (0-610 m)

#64 drill for LP gas 2000-4000ft. (610-1370 m)

CLEANING HEATER COIL OF SCALE

9.4

Excessive scale in heater coils can reduce the

recovery rate of the heater and restrict the flow of

water through the heater. Use of hard water

through the heater tends to accelerate scale buildup. Should heater coils develop excessive scale

build-up it may be necessary to use a coil cleaner

to remove the scale build-up. Use only an

approved coil cleaner specially designed for

cleaning scale and mineral deposits from steel

coils, such as Magikist

To clean the heater coil of scale build-up, follow

the directions provided with the coil cleaner. Never

allow the coil cleaner to sit in the coil overnight or

for long periods of time. Always flush out the coil

thoroughly with water after cleaning.

Do not ream out orifices to a larger

MAGIKCOIL de-liming acid.

. It is

-

14

-

10.0 HELPFUL INFORMATION

10.1 COIL CONDENSATION

During the operation of your heater, you may

notice water in the base of the heater or you may

hear the sizzling of water drops falling on the

flames of the main burner. This collection of water

or “dripping” of water is typical in the operation of

all steel coil heaters. It is caused by the products

of gas combustion which produce gaseous carbon

dioxide and water vapour. The water vapour

condenses on the coils which have cold water

running through them. The lower the temperature

of the incoming water, and the higher the rate of

combustion and/or the higher the relative

humidity, the more “drip” that occurs. Over a

period of time this tends to decrease.

If you suspect that the water in the base of the

heater is not from coil condensation, turn the

heater off such that the main burners are not lit

and run water through the heater. The “dripping”

of water from coil condensation will stop after a

short period of time.

10.2 COIL SCALING

Scale build-up in the heater coil can reach a point

where the recovery rate of the heater is reduced

and/or the flow of water through the heater is

restricted. Use of hard water through the heater

tends to accelerate scale build-up. Should scale

build-up reach a point where the operation of the

heater is affected, descaling with an approved coil

cleaner may be required. See section 8.4

CLEANING HEATER COIL OF SCALE for more

information.

10.4 USE OF ACIDS

If acids of any type are used then a form of

downstream chemical injection or suitable check

valve should be used to protect the coil.

10.5 COIL TEST

After manufacture each coil is hydrostatically

pressure tested to 3500 PSI. Each heater also has

a final hydrodynamic leak test performed after

final assembly (with all fittings installed) before the

heater leaves the factory.

10.6 TERMINAL CONNECTIONS TO PROSAFE

Except for the FLOW SW connection, the

PROSAFE

it’s terminal connections. To remove a plug you

must press down on the locking pin and then pull

the plug out. Never use excessive force to remove

the plugs. When reinserting a plug, simply align

the plug with the correct terminal connection and

insert. Plugs are polarized and will only fit into the

correct terminal connection.

I

I

uses lockable polarized plugs for all

III

I

10.3 FREEZING CONDITIONS

Freezing conditions can result in severe damage

to the heater coil. Coils must be drained

completely with compressed air or have antifreeze run through them if they are exposed to

freezing weather. Note that heater coils installed

in a heated building can still freeze. If the building

has a negative pressure cold air will be drawn

down the chimney and could freeze the top of the

coil. This can normally be prevented by the use of

an automatic vent damper.

-

15

Connections to ProSafe II

-

11.0 TROUBLESHOOTING

Symptom Probable Cause Corrective Action

•Heater does not power-up

(POWER indicator on PROSAFE II

control does not turn on).

•Power to heater not turned on.

•24 VAC power not connected to

brown & black wires.

•Turn on power supply to the heater.

•See section 4.10 ELECTRICAL

CONNECTIONS.

•Main burner does not light. •Gas supply turned off.

•Gas valve not in “on” position.

•Pilot burner is not lit or has been

extinguished (standing pilot models

only).

•REQUEST FOR HEAT indicator on

P

ROSAFE II control is not on.

•Main burner does not shut off. •Flow switch misadjusted.

•Incoming gas pressure is too high

•Pilot goes out frequently (standing

pilot heaters only).

•Heater is in location that is too

drafty.

•Pilot assembly requires service.

•Turn on gas supply to heater.

•Turn knob on gas valve to “on”

position.

•Relight pilot burner. See section 5.5

LIGHTING THE PILOT BURNER.

•See section 6.0 P

CONTROL.

•See section 5.3 CHECK FLOW

SWITCH & AUTOMATIC VENT

DAMPER for instructions on

checking the operation of the flow

switch. See section 9.1 FLOW

SWITCH for instructions on

adjusting the flow switch.

•Have gas service personnel check

and adjust supply gas pressure.

•Relocate heater. See section 4.1

LOCATION.

•Have gas service personnel check

operation of pilot assembly and

thermocouple.

ROSAFE II

•Pilot cannot be lit (standing pilot

heaters only).

•Water collecting in the base of

heater.

•FLOW ON indicator is on when

there is no water flow.

FLOW ON indicator is off when

•

there is water flow.

FLOW ON indicator flashes.

•

•Pilot assembly requires service. •Have gas service personnel check

operation of pilot assembly and

thermocouple.

•A fair amount of condensation which

can collect in the base of the heater

is a normal product of the operation

of your heater.

•Flow switch misadjusted. •See section 5.3 CHECK FLOW

Flow switch misadjusted or

•

inoperative.

Warning condition that consistent

•

water flow through the heater has

been detected.

-

16

-

•No action is required. For more

information refer to section 10.1

COIL CONDENSATION.

SWITCH & AUTOMATIC VENT

DAMPER for instructions on

checking the operation of the flow

switch. See section 9.1 FLOW

SWITCH for instructions on

adjusting the flow switch.

This indication is only informative

•

and may not indicate a problem.

Refer to section 6.6 FLOW ON

INDICATOR for more information.

Symptom Probable Cause Corrective Action

EXTERNAL CONTROL indicator is

•

always off.

If the installer of your heater has

•

utilized an external master

enable/disable for the heater (i.e. a

keyswitch to prevent unauthorized

use), then that master

enable/disable is not enabled (i.e.

the switch is not turned on).

Enable the external master

•

enable/disable.

•EXTERNAL CONTROL indicator is

always on.

•FLUE STATUS indicator is

flashing but temperature setting

shows no error and heater

operates correctly.

•DAMPER-OPEN indicator is

always on.

•EXTERNAL CONTROL connections

are not wired correctly.

•The heater is supplied with the

EXTERNAL CONTROL option

bypassed such that the EXTERNAL

CONTROL indicator will always be

on. If your installer has not utilized

an external master enable/disable

for the heater, then it is correct for

the EXTERNAL CONTROL

indicator to be on all the time.

•Warning condition that temperatures

in flue are at or near freezing.

•If an automatic vent damper is not

installed, then this is normal and

correct operation.

•The automatic vent damper may not

have been correctly connected, or

may be jammed due to improper

installation.

•See section 4.10 ELECTRICAL

CONNECTIONS for proper wiring

of the EXTERNAL CONTROL

connections.

•No action required.

•Take necessary steps to increase

temperature in flue so that coil does

not freeze.

•No action required.

•See section 4.10 ELECTRICAL

CONNECTIONS for proper wiring

of an automatic vent damper.

Section 5.3 CHECK FLOW

SWITCH & AUTOMATIC VENT

DAMPER provides instructions to

ensure the damper is operating

correctly.

DAMPER-OPEN indicator is

•

always off.

The service switch on the motor

•

housing of the damper is in “HOLD

DAMPER OPEN” position.

If an automatic vent damper is

•

installed then the jumper plug

required may not be installed.

The automatic vent damper may not

•

have been correctly connected, or

may be jammed due to improper

installation.

-

17

-

not

Move service switch to the

•

“AUTOMATIC OPERATION”

position.

See section 4.10 ELECTRICAL

•

CONNECTIONS for proper wiring

of the heater with and without an

automatic vent damper. Section 5.3

CHECK FLOW SWITCH &

AUTOMATIC VENT DAMPER

provides instructions to ensure the

damper is operating correctly.

Symptom Probable Cause Corrective Action

Temperature setting display

•

flashes E10 and FLUE STATUS

indicator is flashing.

•Temperature setting display

flashes E11 and FLUE STATUS

indicator is flashing.

Temperature setting display

•

flashes E15 and FLUE STATUS

indicator is flashing.

•Temperature setting display

flashes E20 and THERMOSTAT

indicator is flashing.

•Temperature setting display

flashes E21 and THERMOSTAT

indicator is flashing.

•Temperature setting display

flashes E30 and REQUEST FOR

HEAT indicator is flashing.

•Temperature setting display

flashes E31 and REQUEST FOR

HEAT indicator is flashing.

•Temperature setting display

flashes E59.

Communicaton problem with flue

•

sensor (open).

•Communicaton problem with flue

sensor (short).

Overheat condition detected.

•

•Communicaton problem with

temperature sensor (open).

•Communicaton problem with

temperature sensor (short).

•Problem with output driver for gas

valve (open). PROSAFE II is

attempting to energize the gas valve

but is not receiving the correct

internal feedback that the gas valve

is being energized.

•Problem with output driver for gas

valve (short). P

ROSAFE II is not

attempting to energize the gas valve

but is not receiving the correct

internal feedback that the gas valve

is not being energized.

•Problem with internal memory of

PROSAFE II.

Check connection of flue sensor to

•

PROSAFE II. Replace flue sensor if

necessary.

•Check connection of flue sensor to

PROSAFE II. Replace flue sensor if

necessary.

Temperature in flue has exceeded

•

maximum limit. Most common

condition is that main burner of

heater is on with no water flow the

heater. Investigate and correct

immediately.

•Check connection of temperature

sensor to P

ROSAFE II. Replace

temperature sensor if necessary.

•Check connection of temperature

sensor to P

ROSAFE II. Replace

temperature sensor if necessary.

•Contact qualified service personnel.

•TURN KNOB ON GAS VAVLE TO

OFF POSITION IMMEDIATELY.

SHUT OFF GAS SUPPLY TO

HEATER IMMEDIATELY.

EXTINGUISH ANY OPEN FLAME

IMMEDIATELY. Contact qualified

service personnel.

•Contact qualified service personnel.

-

18

-

-

20

-

-

21

-

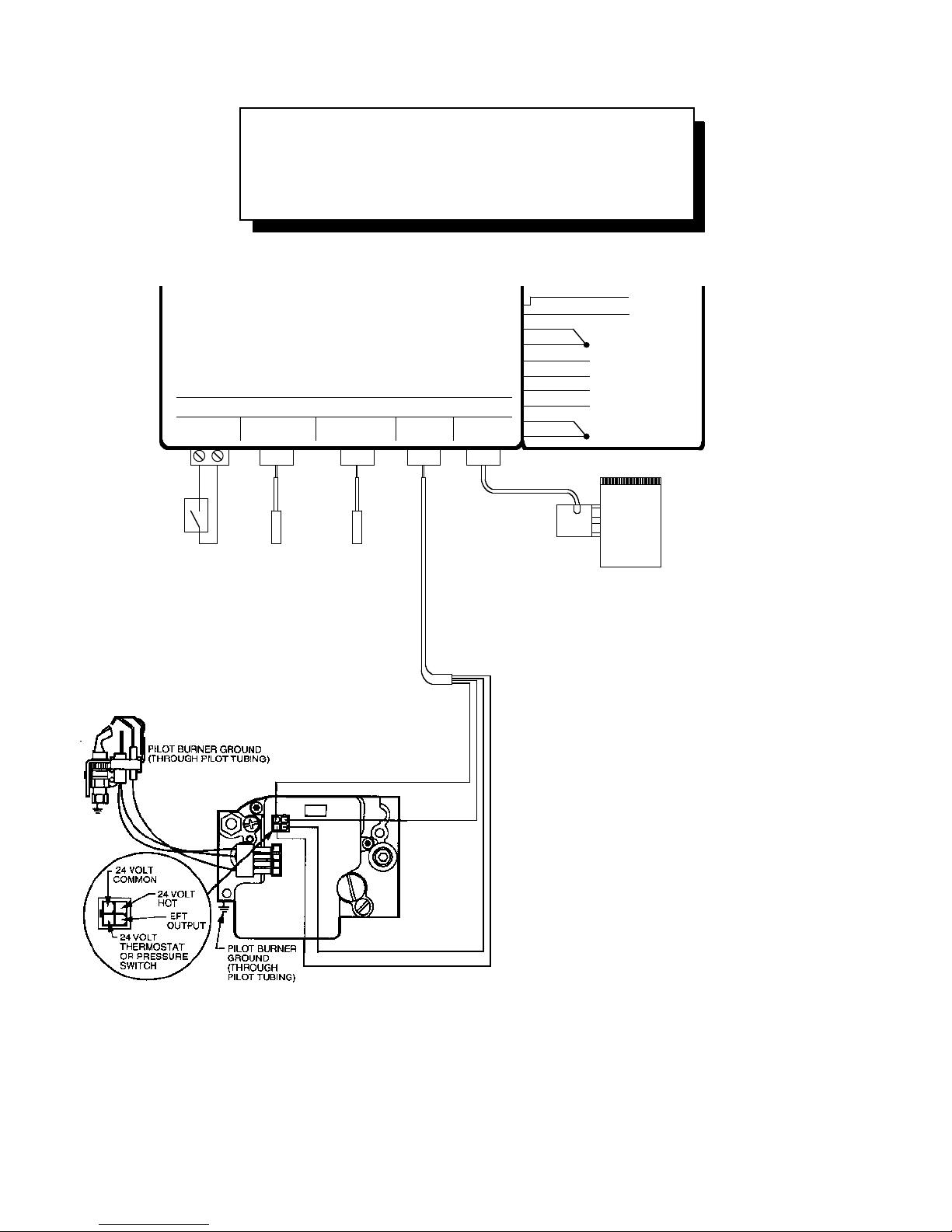

HWG20 & HWG40 Wiring

24 volt hot surface ignition systems

(HSI)

HWG-AD10 (HWG40) or

HWG-AD7 (HWG20)

Automatic Vent Damper (optional)

If not installed then Damper jumper

plug must be installed.

Flue

Sensor

Temp

Sensor

Flow

Switch

PROSAFE II

CONTROL

TERMINAL CONNECTIONS

FLUE SENS TEMP SENSFLOW SW OUTPUT DAMPER

brown

black

24vac

supply**

b

lack*

b

lack*

purple

purple

b

lue

g

rey

yellow

white***

Refer to manual for

wiring of purple, blue,

grey, yellow & white

*

Duplicate black

w

ires for

c

onveni ence

Electrical

Connection

Box

black

red

green

IMPORTANT: If the 24 vac supply

is to be earth grounded, earth

g

round must be connected to

t

he black wire.

**

***On some heaters

this wire may

be brown

white

HWG40

24V Gas Valve

#HWG40-16x24H

Pilot Igniter/Sensor

#HWG40-13NH

-

21

-

HWG20 & HWG40 Wiring

24 volt electronic ignition systems

(intermittent pilot)

Wiring-di agram.cad

HWG20 & HWG40 Wiring

24 volt standing pilot systems

Damper

jumper plug

HWG40 & HWG20

24V Gas Valve

#HWG40-16x24

#HWG20-16x24

Flue

Sensor

TH TR

O

F

F

P

I

L

O

T

TH-TR

O

N

Temp

Sensor

Flow

Switch

PROSAFE II

CONTROL

TERMINAL CONNECTIONS

F

LUE SENS TEMP SENSFLOW SW OUTPUT DAMPER

b

rown

b

lack

black*

b

lack*

p

urple

p

urple

blue

g

rey

y

ellow

R

efer to manual for

w

iring of purple, blue,

g

rey, yellow & white

*

Duplicate black

w

ires for

c

onveni ence

Electrical

Connection

Box

24vac

supply**

IMPORTANT: If the

2

4 vac supply is to be

earth grounded, earth

ground must be

connected to

the black wire.

**

red

green

black

H

WG-AD10N (HWG40) or

H

WG-AD7N (HWG20)

Automatic Vent Damper (optional)

If not installed then Damper jumper

plug must be installed.

F

lue

Sensor

T

emp

Sensor

F

low

Switch

Electronic Ignition Control

#HWG-125

P

ilot Sensor/Ignitor

h

igh voltage lead

Burner Bar Ground

M

V

MV/PV

PV

GND

24V

GND

24V

TH-W

SPARK

P

ROSAFE II

CONTROL

T

ERMINAL CONNECTIONS

FLUE SENS TEMP SENSFLOW SW OUTPUT DAMPER

brown

b

lack

24vac

supply**

black*

black*

p

urple

purple

blue

grey

y

ellow

white***

Refer to manual for

wiring of purple, blue,

grey, yellow & white

*Duplicate black

wires for

convenience

Electrical

Connection

Box

black

red

green

HWG40

24V Gas Valve

#HWG40-16x24R

T

R

T

H

2

34

IMPORTANT: If the 24 vac supply

i

s to be earth grounded, earth

ground must be connected to

the black wire.

*

*

*

**On some heaters

this wire may

b

ebrown

white***

***On some heaters

this wire may

be brown

-

22

-

12.0 SPECIFICATIONS

HWG40

Type ............................................................................................Instantaneous steel coil

Gas supply ..................................................................................Natural (-N models)/LP (-P models)

Coil specifications .......................................................................3/4” I.P.S. steel pipe Sch 80

Maximum recovery capacity (100°F rise)....................................331.9 U.S. gallons per hour

Maximum operating pressure......................................................3000 P.S.I.

Maximum operating temperature ................................................200°F

Minimum water flow rate

Flue outlet size ............................................................................10” diameter

Normal input ratings

0 - 2000 ft (0 - 610 m) ..........................................................395,000 BTU/hour (maximum)

2000 - 4000 ft (610 - 1370 m) ..............................................355,500 BTU/hour (maximum)

Manifold gas pressure

Natural gas...........................................................................3.5” W.C.

LP (propane) gas .................................................................11.0” W.C.

Maximum supply gas pressure

Natural gas...........................................................................14” W.C.

LP (propane) gas .................................................................11.0” W.C.

Flooring type required .................................................................Non-combustible

Shell diameter .............................................................................24”

Width ...........................................................................................32”

Depth...........................................................................................32”

Height (without draft hood)..........................................................46”

Height (with draft hood)...............................................................66-3/4”

Shipping weight...........................................................................418 lbs.

.............................................................1.0 U.S. gallons per minute

HWG20

Type ............................................................................................Instantaneous steel coil

Gas supply ..................................................................................Natural (-N models)/LP (-P models)

Coil specifications .......................................................................3/4” I.P.S. steel pipe Sch 80

Maximum recovery capacity (100°F rise)....................................150 U.S. gallons per hour