V4.0

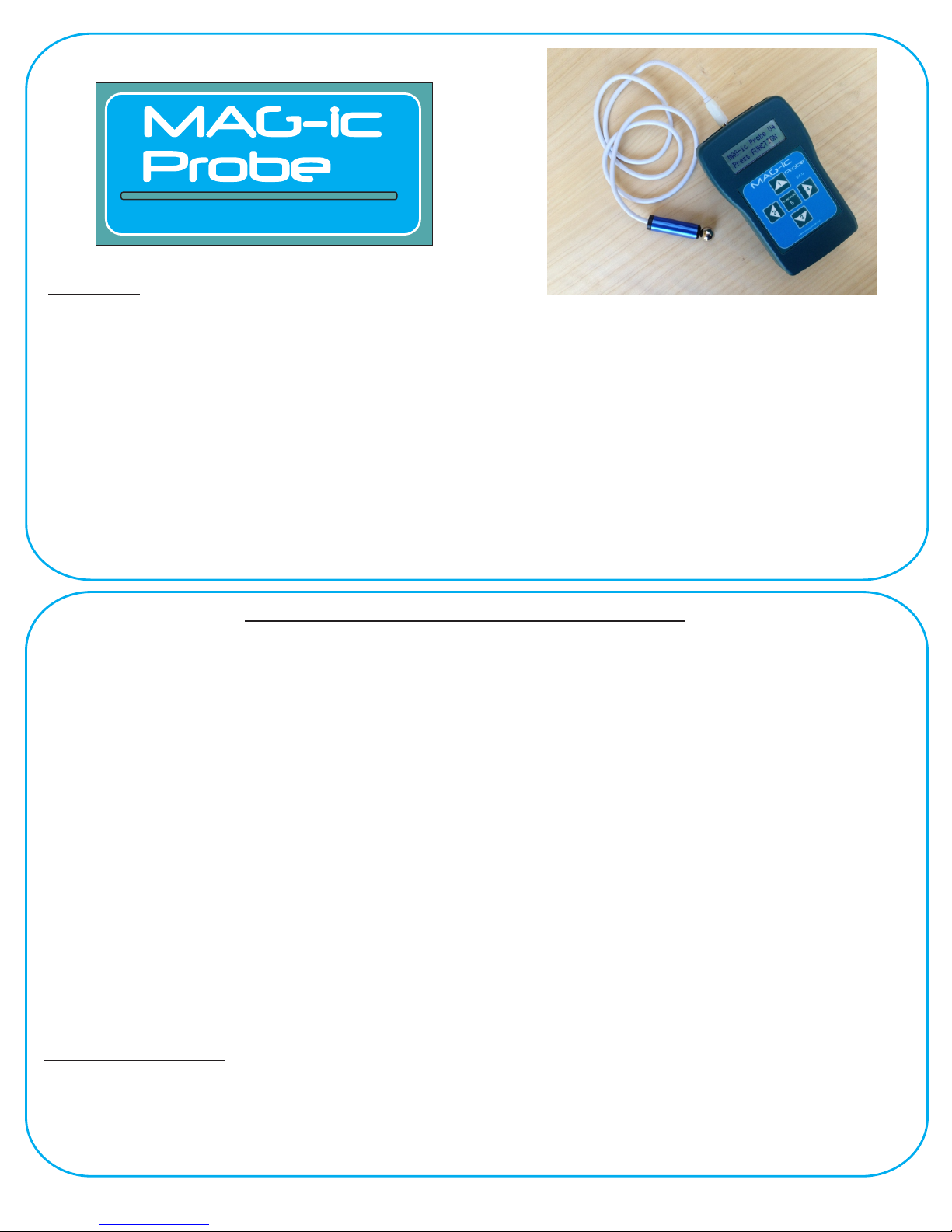

Electronic Thickness Gauge

Disclaimer:

WARNING !! - This device uses extremely strong NEODYMIUM magnets. These magnets can cause injury or

damage if misused. KEEP AWAY FROM CHILDREN!!. DO NOT OPEN or USE if you have a pacemaker or

other medical condition that may be affected by magnetic fields. The strong magnetic fields can erase computer

hard drives, magnetic access and credit cards, Use at your own RISK.

MAG-ic Tech or its owners neither assumes nor accepts any liability for damages resulting from the handling or

use of this equipment. With your purchase, the buyer agrees that he/she is responsible for all damages and

injuries caused by the use of this product , which include personal injuries , property damages and any other

damage whatsoever. The buyer must agree with the terms before using the product.

Pay special attention when using this device to measure finished instruments. The probe tip is fabricated from

Delrin and may scratch or leave marks on finished surfaces.

DO NOT DRAG THE PROBE TIP OVER FINISHED SURFACES!! To avoid scratches and marks, you should

slightly lift the probe before moving it. A good method is to lift the tip and place a piece of soft cloth under before

moving and removing the cloth at the new measuring location.

Calibration - a Word about magnetics

This device uses magnets and magnetic sensors to measure the thickness of non-ferrous materials. This

technique is very effective because magnetic fields can penetrate these materials with no attenuation or

deformation. However, as with most technologies, some tolerance and knowledge is required for achieving the

best results.

Ÿ Magnetic fields are strong at the magnet surface and deteriorate rapidly in a non-linear manner as distance

increases.

Ÿ Magnetic fields will vary with changing temperatures.

Ÿ Magnetic and most other sensors are unstable and vary their output with changing temperatures.

Ÿ Friction may cause the inner magnet to not be centered on the probe tip when moving the probe across the

measured object.

Considering the above and following the usage tips will enable you to get the most out of your MAG-ic Probe.

MAG-ic Probe is supplied with 2 magnets. The ½” ball provides the strongest magnetic field and thus the highest

resolution and should always be your first choice. The smaller magnet should only be used when access to the

inside of a finished instrument is limited due to small f-holes etc.

MAG-ic Probe starts with a calibration sequence to detect the magnet size and also to try and compensate for

small variations in field measurement tolerances. This initial calibration is suitable for most quick measuring jobs,

for example where you are making a few measurements, shaping or sanding and then measuring again etc.

Note, MAG-ic Probe can be powered by the USB connection without the power switch turned ON, however

because computer power supplies may have slightly different outputs, MAG-ic Probe was calibrated with the

internal battery connected and power switch in the ON position.

Advanced Calibration.

When preparing for a more serious prolonged measuring session such as mapping a complete top or plate with

many measurements, a two step calibration sequence is advised.

MAG-ic probe is factory calibrated using a precisely machined stepped surface in a temperature controlled

environment. The largest effect that may cause a drift in the measurement value, is from variance in probe

temperature due to heating by the hand of the user.

Advanced calibration continued...

After the initial calibration sequence and before attempting a prolonged measuring session, the

following sequence is advised. The purpose is to perform a calibration only once the probe has reached

a stable temperature.

Hold the probe in your hand in the same way as you would while measuring. Important, do not envelop

the entire probe in your hand, simply hold it just as you would while measuring. Your hand will heat the

probe It may take 3-5 minutes for the probe to reach a stable temperature.

Then perform a re-calibration, by pressing the FUNCTION key and choosing the Re-Calibrate option.

You can also perform a Re-Calibration at any time should you feel the need. Take care to keep the

environmental temperature stable and avoid direct exposure to fans or heater vents.

Additional Information.

There is an additional information source provided by menu option 1 called Ref. It is important to

understand the significance and objective of this option before using it. The Ref option can be

engaged by pressing FUNCTION ^1.

Firstly, the initial calibration procedure, will compensate for differences between your shop

environment and the factory environment where MAG-ic Probe was calibrated. The problem is that

after this calibration your hand may heat the probe causing a small drift in value. This is the reason

for the 2nd calibration as described above. To assist in this 2nd calibration, the Ref option can be

used.

BEFORE performing the 2nd Calibration, invoke the Ref option. The Ref (reference) option shows a

value, normally a negative value, for example -53. This value represents a difference measured in

the conditions of your environment to the factory environment where MAG-ic Probe was calibrated. If

this value is negative as in the example -53, hold the probe in your fingers as described above. The

Ref value should start to increase, and the zero (0) point is where the probe temperature conditions

are similar to the factory calibration conditions.

When the Ref value is approaching the 0 mark, return to the menu and perform the 2nd calibration

as described above. Please note that you do not have to be overly fussy about this setting as even a

difference count of 300 represents well under 0.1mm deviation.

USB Serial Connection

MAG-ic Probe V4 uses a common USB driver for communication with your computer. This driver

should be automatically installed by most Windows operating systems. When first connecting MAG-ic

probe to your computer USB port, be aware of on-screen messages to indicate if the driver has been

successfully installed. You may see a message as follows -

The COM PORT # is the information you need for the MAG-ic Probe Software. If you do not see the

above message, open the Control Panel and then click on Device Manager. In the Device Manager

window, click on the small triangle next to Ports (COM & LPT). This will list the ports currently installed

on your pc. Look for the USB Serial Port (COM #) and note the port number. If you double click this

line, you should see a similar properties window as below right.

In the above example, COM 3 is the port that will be used when we connect to the MAG-ic Probe

Software.

If a driver is not automatically installed.Please return to the website and click

www.magicprobe.net

on Document and Driver Downloads.

Download the driver files for your operating system and also download the correct Driver Installation

Instruction Manual on this page.

Follow the instructions in the manual on how to get your driver working.

Once you have the driver properly installed, check back in your Device Manager and take note of the

COM PORT # so that you can use that # in the MAG-ic Probe Software.

MAC Serial Connection

One problem with Mac OSX is that it does not easily list the available serial ports to the user or

applications the way that Windows does. To identify the correct serial port in Mac, the easiest way is to

follow the below procedure.

Download a small free application from

10915190.html http://freeware.the-meiers.org/

or

Run this application and in the top menu Bar, click on Connection/Options

Click on the <Port> button to see the

available ports. The Serial port should

be identified as something like

USBmodem or USBSerial etc. Pick

this option and then click on the small

box to the right of this line. This box

will provide the full detail of the Port

Name.

In this example it is Usbmodem411 but

each computer will be different.

The full name is

/dev/cu.usbmodem411.

Make a note of this full name as you

will need it in the MAG-ic probe

Software.

http://download.cnet.com/CoolTerm/3000-2383_4-

You can test that the probe is working by

clicking on the OK button and then clicking

on CONNECT button.

You should see some data messages from

the probe appear in the window.

Connecting to MAG-ic Probe Software

Start the MAG-ic Probe Software and click on the PortSelection and Calibration menu and select

Serial Port. In the Settings box, either select the correct Com Port from the drop-down box or manually

type in the Com Port information from above. If connection is successful, a green light should turn on

in the top right corner.

/dev/cu.usbmodem411

Operating Instructions

Powering ON

Ÿ Ensure the battery is fresh (voltage above 7.2v)

Ÿ Set the power switch to the ON Position. MAG-ic probe can also be powered via the USB cable

to your PC. However, computers differ and cannot guarantee that the 5V standard is exact. The

initial calibration will take care of small differences in USB power but may not be as accurate as

when using battery power.

Ÿ Press Function Button.

Ÿ Attach magnet to Probe. MAG-ic probe is supplied with 2 magnets, a ½” ball and a smaller

magnet. Your first choice should always be the ½” ball and only use the smaller magnet when

access is limited by small f-holes etc.

Ÿ Press Function button and Remove Magnet at least 6 inches from probe when prompted.

Ÿ If Calibration is Successful, you will be prompted to re-attach the magnet and press function key.

This completes the initial calibration and MAG-ic Probe is ready to perform your measurements. The

display should read 0.00 when the magnet is attached to the probe. If the advanced calibration is

required, perform it now - (see Advanced Calibration)

HOLD Function

MAG-ic Probe features a HOLD mode to assist you in obtaining accurate measurements. There are 2

ways to invoke the HOLD feature. Either slide the power switch to the HOLD position, OR, press

BUTTON 3. The HOLD mode is indicated by an “H” preceding the mils display. A HOLD mode can also

be activated in the MAG-ic Probe Software by clicking on the HOLD/FREE icon.

The HOLD mode can be used at every measuring location, to ensure that the lowest reading is being

displayed. The HOLD mode will freeze the display and only allow lower readings to update the display.

Release the hold mode to continue normal display reading.

Menu Functions

The MENU can be activated at any time during measurement, by pressing the FUNCTION button.

OFFSET adjustment.

MAG-ic probe now provides a facility for adding or subtracting an OFFSET value to the output

reading. There may be various reasons for wanting to add an offset. For example, to protect

expensive instrument finishes, it may be desirable to add a protective paper between the probe and

the instrument surface. In this case the paper can be measured and this value then subtracted from

the output reading by using the OFFSET function and entering a negative value. The output should

then be 0 when the paper is included in a zero measurement.

Another reason may be when comparing to your own measuring instrument, you want to equalize the

2 instruments by adding or subtracting a value. The OFFSET value is set in mils (1/1000th inch).

Please remember to set the offset back to zero when completed for normal measures.

Press 2 for OFFSET, followed by either 2 for negative decrement or 4 for positive increment.

Re-Calibration.

Press 4 for Re-calibration. This will restart the complete initial calibration procedure. Alternatively, you

may also restart the MAG-ic Probe unit by turning the power OFF and ON again.

Ref (Reference)

Press 1 for Ref indication. This is an advanced calibration feature if required. See Advance Calibration

section.

Battery Replacement

MAG-ic Probe uses a 9v Pp3 battery located on the back of the unit. Press down in the top-center of

the back cover to release the battery cover. The backlit LCD display is the major source of battery

drain so ensure you turn the Power Switch OFF when not in use.

Usage Tips

MAG-ic Probe is capable of measuring very small distances to 1/1000th inch. It

should make sense then that the probe should be absolutely square to the surface

being measured and the opposing magnet. If the probe is slightly tilted, the

distance from the center of the probe will be slightly farther from the magnet and

introduce false readings. It is a good idea to use the HOLD mode to ensure the

Correct

Wrong

Ÿ Turn OFF the unit when not in use to conserve battery life

Ÿ Take care of the magnets, they are fragile and will shatter or splinter if allowed to snap onto each

other or metal objects.

Ÿ Ensure your instrument does not contain any metallic objects to which the internal magnets can be

attracted. Removing a magnet from a finished instrument can be difficult.

Ÿ Do not drag the probe across finished surfaces. Either lift the probe slightly from the surface before

moving to a new location, or insert a protective material under the probe before moving.

Ÿ Use the larger magnet if possible. This will provide the highest resolution because of a stronger

magnetic field.

Ÿ Only connect and remove the Probe connector when the unit is completely powered off. If this is

attempted while the unit is powered, damage may occur.

Ÿ Avoid temperature changes after calibration.

Ÿ

lowest reading by making small rocking and circling motions at each measuring

location.

IMPORTANT. MAG-ic Probe makes approximately 100 measurements per second

but uses an advanced internal algorithm to average out the readings to ensure a

smoother display and more stable output. This is the reason that the change in

displayed values will seem to LAG behind rapid changes made between the probe

and magnet. Consequently it is important that you pause at every measuring

location to allow the output reading to stabilize. This should also be considered

when using the HOLD mode.

Measuring range (Large Magnet) 1 - 600mil (0-15mm)

(Small Magnet) 0 - 300 mil (7.5mm)

Resolution 1mil (decreasing after 10mm)

Battery Voltage 9V DC PP 3 Battery

Power Consumption 60mA

Specifications

(0-10mm High Resolution)

Contact Info

We welcome any feedback and suggestions. If

you have any problems with your device please

contact us.

email -

info@magicprobe.net

Phone (901) 212-6979

Loading...

Loading...