magicpac HWC9 Installation Manual

INSTALLATION INSTRUCTIONS

HWC9 V-Series

This manual must be left with the homeowner for future reference.

This is a safety alert symbol and should never be ignored. When you see this symbol on labels or in manuals, be alert to

the potential for personal injury or death.

TM

Models

Table of Contents

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal

injury or loss of life. Installation and service must be

performed by a licensed professional installer (or

equivalent), service agency or the gas supplier.

WARNING

Do not store combustible materials near the furnace or

warm air ducts. The material may ignite by spontaneous

combustion creating a re hazard.

WARNING

Unit Dimensions ..........................................................2

Installation ...................................................................3

Electrical Connections .................................................9

Start-Up .....................................................................13

Operation ...................................................................13

Maintenance ..............................................................14

Wiring Diagrams ........................................................20

WARNING

For your safety, do not store or use gasoline or other

ammable vapors and liquids in the vicinity of this or any

other appliance. Such actions could result in property

damage, personal injury, or death.

These units are not approved for mobile home

applications. Such use could result in property damage,

personal injury, or death.

Installation shall be made in accordance with the

requirements of the local utility and other authorities

CAUTION

If these instructions are not followed exactly, a re

or explosion may result causing property damage,

personal injury, or loss of life.

Manufactured By

Allied Air Enterprises LLC

A Lennox International, Inc. Company

215 Metropolitan Drive

West Columbia, SC 29170

Check that equipment complies with all applicable building codes, laws, and regulations for its intended use prior to installation.

507389-03 Issue 2110

having jurisdiction, or with the National Fuel Gas

Code, ANSI Z223.1 (latest edition) and the National

Electrical Code. Any alteration of internal wiring will void

certication and warranties.

*P507389-03*

CAUTION

(P) 507389-03

Page 1 of 22

27-7/8

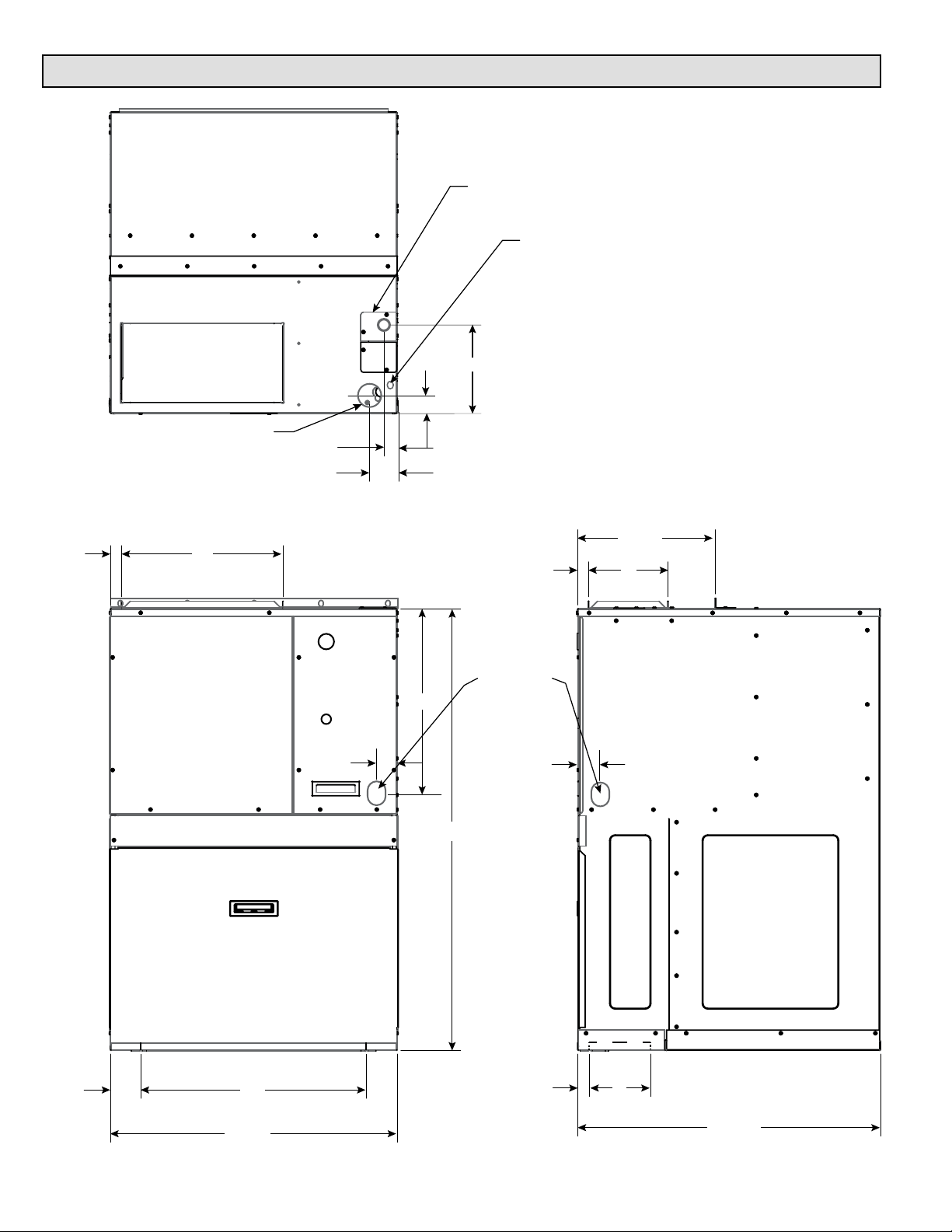

Unit Dimensions

Line Voltage

Box

Low

Voltage

Supply

1/2 Gas Inlet

161

Supply

1-1/2

2-3/4

1-3/4

8

13-3/8

81

Supply

Condensate

18-1/4

2

Drain

(HWC9 Only)

2

43-3/16

Return

2-7/8

Page 2 of 22 507389-03Issue 2110

22

61

Return

29-7/16

Installation

General

These instructions must be hung on or near the furnace in

a conspicuous place.

The MagicPak All-In-One™ HVAC system model HWC9

V-Series™ units are self-contained, gas-red heating with

electric cooling models. The unit design has been certied

by Intertek Testing Services for compliance with the latest

edition of the American National Standard – ANSI Z21.47/

National Standard of Canada – CAN/CGA-2.3 for direct

vent central furnaces. The HWC9 models are certied

to be in compliance with the latest edition of A.H.R.I.

Standard 210/240. All models are design certied for

heating operation when red with natural or propane gas.

These installation instructions are intended as a general

guide only, for use by an experienced, qualied contractor.

Inspection

The unit is shipped in one package, completely assembled

and wired. The Evaporator drain tubing is in the cooling

compartment behind the lter access panel. Fittings for

furnace condensate drainage are located in the hardware

kit bag.

If any damage is found, proper notation should be made on

the carrier’s freight bill. Damage claims should be led with

the carrier as quickly as possible.

Check the rating plate to conrm heating and cooling

capacities. The unit should be operated only with the type

of gas and electrical supply noted on the rating plate.

NOTE: Remove the chassis hold down shipping bracket

before installation. These brackets are located on the

outdoor side of the unit below the louver panels.

Location

The design is certied for indoor installation only. The

interior portions of the unit may be surrounded by a closet

with minimum clearances to combustible material of 0”

sides, 2” top, and 1” front and plenum. Adequate clearance

must be provided to install gas line union and manual

shuto valve , condensate drain connections as well as

providing accessibility for eld wiring.

NOTE: Approximately 2” of clearance is required if using

side exit furnace condensate drain connection. 2” to 4” of

clearance (depending on choice of ttings) is required if

using front exit furnace condensate drain connection. Do

not install directly on carpeting, tile, or other combustible

material other than wood ooring.

The grille side of the unit may be ush with, or extend

beyond, the face of the exterior wall, but should not be

recessed more than 2” from the face of the building and

should not be obstructed with trees, landscape materials,

or building structure.

There is no minimum clearance required on locating the

unit to an interior corner of a building.

If the unit is to be enclosed, provisions should be made

allowing access to the indoor side of the unit for changing

lters and for inspection. At least 29” of unobstructed space

should be provided in front of the indoor side, whether

enclosed or not, to permit removal of the cooling chassis

should repairs or inspection be required.

If the unit is installed in a residential garage, it must be

located or protected to avoid physical damage by vehicles.

Unit must be installed so the burners and ignition source

are not less than 18” (457 mm) above the oor. This unit

must be installed so that no electrical components are

exposed to water.

WARNING

In the State of Massachusetts:

This product must be installed by a licensed Plumber

or Gas Fitter. When exible connectors are used, the

maximum length shall not exceed 36”. When lever-type

gas shutos are used, they shall be T-handle type.

507389-03 Issue 2110 Page 3 of 22

This appliance should be installed in a location such that

the vent outlet is located in the following manner:

1. Distances to windows that open, building openings, or

public walkways should be consistent with the National

Fuel Gas Code Z223.1 or CAN/CGA-B149.1 & .2.

2. For U.S. installations, the vent system shall terminate

a minimum horizontal clearance of 4’ from electric

meters, regulators, and relief equipment. For

installations in Canada, refer to the current CAN/

CGA-B149.1 & .2 or with the authorities having local

jurisdiction.

3. Flue products will not cause degradation to building

materials.

This furnace design is not listed for installation in mobile

homes, recreational vehicles, or outdoors.

Use of Furnace as a Construction Heater

Allied Air does not recommended the use of these units

as a construction heater during any phase of construction.

Very low return air temperature, harmful vapors and

operation of the unit with clogged or misplaced lters will

damage the unit.

Units may be used for heating of buildings or structures

under construction, if the following conditions are met:

• The unit must be permanently installed per these

installation instructions.

• A room thermostat must control the furnace. The use

of xed jumpers that will provide continuous heating is

not allowed.

• The return air duct must be provided and sealed to the

furnace.

• Return air temperature range between 60°F (16°C)

and 80°F (27°C) must be maintained.

• Air lters must be installed in the system and must be

maintained during construction.

• Air lters must be replaced upon construction

completion.

• The input rate and temperature rise must be set per

the furnace rating plate.

• One hundred percent (100%) outdoor air must be

provided for combustion air requirements during

construction.

• The furnace heat exchanger, components, duct

system, air lters and evaporator coils must be

thoroughly cleaned following nal construction clean-

up.

• All furnace operating conditions (including ignition,

input rate, temperature rise and venting) must be

veried according to these installation instructions.

Installing with a Wall Sleeve

Refer to the installation instructions packed with the wall

sleeve and Figure 1 for guidance in assembly and mounting

using a wall sleeve.

• Make sure the gaskets attached to the sleeve are not

damaged.

• Seal the space between the wall sleeve and the building

opening with non-hardening caulking compound. The

seal must be weather-tight to prevent entrance of

moisture and water into the building.

• Assure that the unit is completely seated against the

gaskets on the wall sleeve.

• Slide the unit into the sleeve. When properly nested,

the angle on top of the unit should line up with the top

ange of the sleeve and should almost touch. Fasten

the unit to the sleeve with ve screws furnished with

the sleeve.

CAUTION

The sleeve is not intended as the sole support for the

unit. An additional support must be provided near the

return opening on the unit for adequate support. The

use of vibration isolation material between the unit and

the support is recommended.

Wall Sleeve

.

n

" Mi

8

2

F

LO

O

R

Plywood

Figure 1. HWC Installation

Page 4 of 22 507389-03Issue 2110

""

6 x 22 Minimum Opening

to Align with Return Air

Opening in Unit.

Vibrat ion Isol ating Mater ial

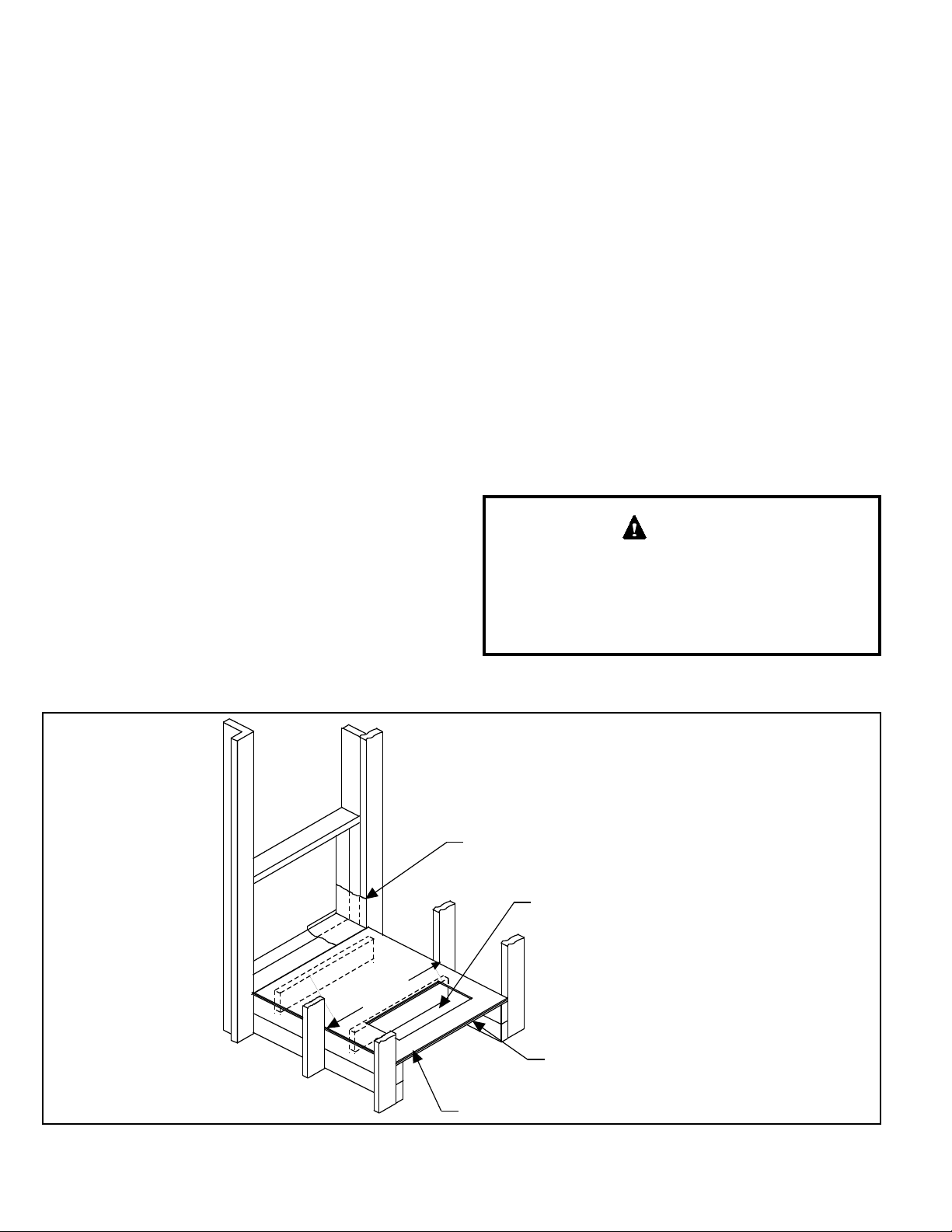

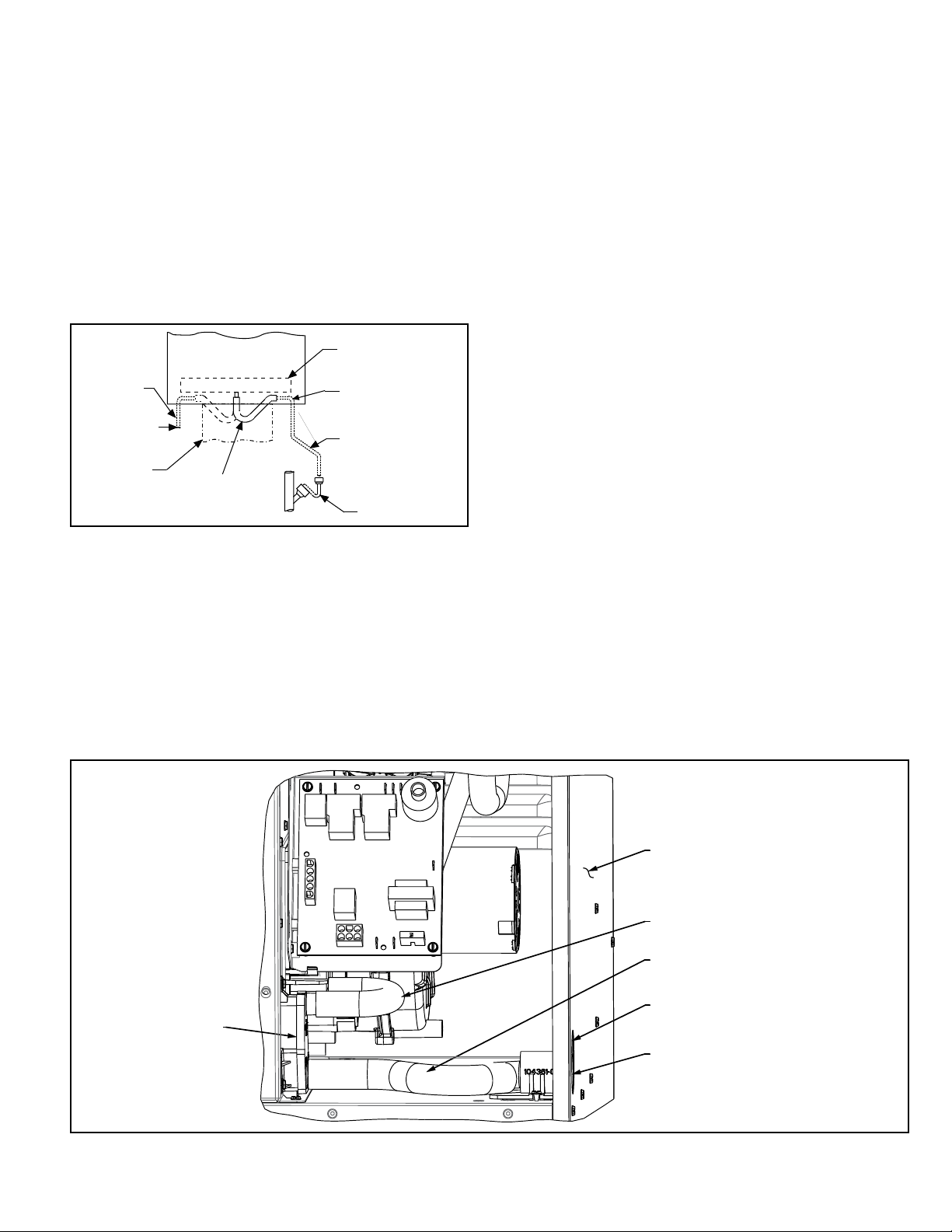

Evaporator Condensate Drain

Install the plastic drain tube (furnished) over the 5/8” O.D.

tting in the center of the Evaporator condensate pan.

Connect other end of the drain tube to the open trap (see

Figure 2). The plastic drain connection is provided so that

it may be disconnected from the permanent drain tubing in

the building in the event it becomes necessary to remove

the cooling chassis assembly.

The drain line should pitch gradually downward at least 1”

per 10’ of horizontal run to the open drain trap.

Be certain that the plastic drain tube has free drainage and

is not crimped or attened at any bend.

Drain Pan

Alternative

Method

To Open

Drain Trap

Return

Air Duct

" I .D.

5/8

Plastic Tube

(Suppli ed)

Top of Drain Tube

Must be Below

Bottom of Drain Pan

Drain Tube - Pit ch 1"

for every 10 ft .

(Field Supplied)

Open Drain Trap

Figure 2. HWC Evaporator Condensate Drain

Installation

Furnace Condensate Drain

The HWC9 furnace is provided with an internal condensate

drain and drain tting. A street elbow, a hose barb and a

spigot adapter for connection to the drain tting are factorysupplied in the manual bag. All other piping is eld-supplied

to suit the installation and local codes.

If the furnace is installed in an unconditioned space, the

condensate drain elbow outside the unit cabinet must

have heat tape suitable for PVC pipe installed, and the

elbow insulated. This heat tape and insulation are eld-

supplied from standard hardware items that are available

locally, and they must be installed in accordance with the

instructions provided by their manufacturers.

Units are shipped with the drain tting installed for side-exit

condensate drainage. The drain tting can be repositioned

for front-exit condensate drainage if desired. Do not

relocate or remove the internal condensate trap.

If unit will be started immediately upon completion of

installation, the drain must be primed as described in the

procedure outlined in the “Start-up” section.

Field-installed piping from the furnace must slope downward

a minimum of 1/2” per foot toward the oor drain.

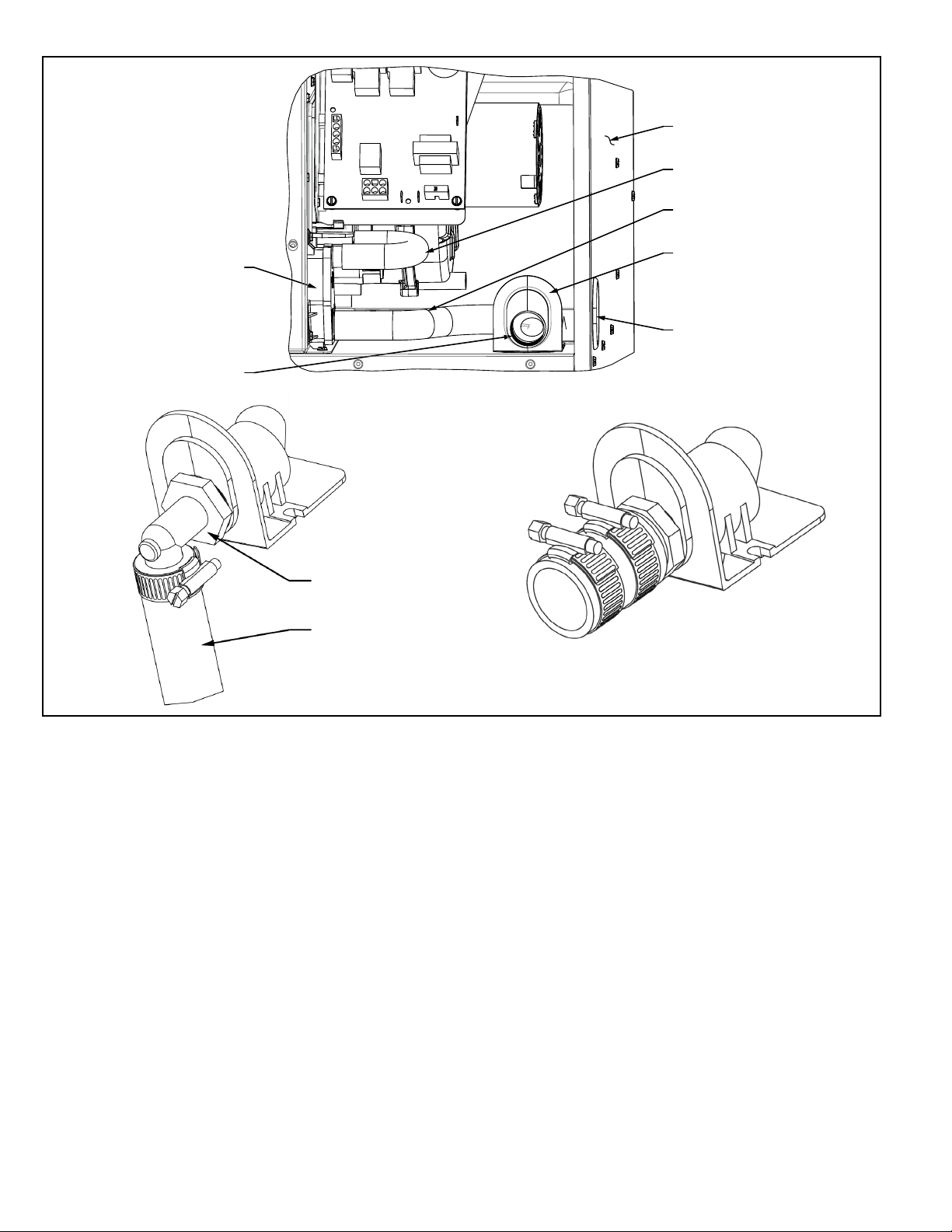

Piping for Side-Exit Condensate Drain

Determine whether the installation better suits a side-exit or

a front-exit furnace condensate drain. For side condensate

drain, see Figure 3 for component locations and additional

details. A 2” clearance to the cabinet side is required for

service access to the condensate drain tting when using

the side location.

1. Install the factory-supplied street elbow to the drain

tting by threading into place. Use a thread sealant

suitable for PVC; do not use thread tape.

2. Use the appropriate primer and solvent cement to

bond eld-supplied drain line piping or ttings to the

PVC street elbow. Do not use copper tubing or existing

copper condensate lines for drain line.

3. Route the piping to an open oor drain. Do not connect

directly to evaporator condensate drain line.

Side Panel

Upper Drain Hose

(from Collector Box)

Lower Drain Hose

(to drain tting)

Condensate

Trap

Drain Fitting

Install threaded street elbow into

drain tting. Solvent weld piping to

street elbow.

Figure 3. Furnace Condensate Drain Component Locations - Side Exit

507389-03 Issue 2110 Page 5 of 22

Condensate

Trap

Install threaded hose barb or

threaded spigot adapter into

drain tting

Threaded

Hose Barb

Side Panel

Upper Drain Hose

(from Collector Box)

Lower Drain Hose

(to drain tting)

Drain Fitting

(repositioned to front)

Grommet Plug

(remove from access panel

and use here)

5/8” ID Tubing

(eld provided)

Figure 4. Furnace Condensate Drain Component Locations - Front Exit

Piping for Front-Exit Condensate Drain

For front condensate drain, see Figure 4 for component

locations and additional details. Use the factory-supplied

hose barb with eld-supplied exible tubing or spigot and

hose coupling for these installations. A 2” or 4”(depending

of choice of ttings) clearance to the cabinet front is

required for service access when using the front location.

The modications necessary to convert to front-exit

condensate drain are:

1. Disconnect the lower drain hose from the drain tting.

2. Remove the screw securing the drain tting to the

division panel.

3. Remove the drain tting and rotate it so that it faces

the front of the furnace.

4. Replace the securing screw.

5. Disconnect lower drain hose from drain trap and rotate

the hose so that the angled end will connect to the

drain tting in its new orientation.

Spigot adapter with hose coupling

and clamps

6. Reconnect the lower drain hose to the drain trap and

drain tting. Verify hose level to allow drainage.

7. Remove the grommet plug from the front access panel

and insert it into the oval opening in the side panel.

8. Remove the perforated insulation from inside the front

access panel around the oval opening. Be sure the

area is clean and free of insulation and glue, as it will

be used as a sealing surface for the drain tting gasket.

9. Prior to setting the unit into operation, replace the

access panel.

10. Install the factory-supplied hose barb or spigot adapter

to the drain tting by threading into place. Use a thread

sealant suitable for PVC; do not use thread tape.

11. For the hose barb tting, ax a suitable length of

exible tubing and route to an open oor drain. Secure

the end of the tubing to the drain. Do not connect

directly to evaporator condensate drain line.

Page 6 of 22 507389-03Issue 2110

12. For the spigot adapter, attach the provided rubber

coupling and then route 3/4” PVC pipping to an open

oor drain. Do not connect directly to evaporator

condensate drain line.

Combustion Air

This unit is a direct-vent furnace which obtains all air

needed for combustion from outdoors.

WARNING

Insucient combustion air can cause headaches,

nausea, dizziness or asphyxiation. It will also cause

excess water in the heat exchanger resulting in rusting

and premature heat exchanger failure. Excessive

exposure to contaminated combustion air will result

in safety and performance related problems. Avoid

exposure to the following substances in the combustion

air supply:

• Permanent wave solutions

• Chlorinated waxes and cleaners

• Chlorine base swimming pool chemicals

• Water softening chemicals

• De-icing salts or chemicals

• Carbon tetrachloride

• Halogen type refrigerants

• Cleaning solvents (such as perchloroethylene)

• Printing inks, paint removers, varnishes, etc.

• Hydrochloric acid

• Antistatic fabric softeners for clothes dryers

• Masonry acid washing materials

Venting

The venting system is an integral part of the appliance.

The venting system must not be modied or added on

to.

The unit contains a combustion inducer. The inducer

draws the combustion products out of the heat exchanger

and forces them from the unit to the outside. No special

provisions are required for supplying air for combustion,

nor is a chimney required.

appliances connected to the common venting system are

not in operation.

1. Seal any unused openings in the common venting

system.

2. Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage

or restriction, leakage, corrosion, or other deciencies

which could cause an unsafe condition.

3. Insofar as is practical, close all building doors and

windows between the space in which the appliances

remaining connected to the common venting system

are located and other spaces in the building. Turn on

clothes dryers and any appliance not connected to the

common venting system. Turn on exhaust fans, such

as range hoods and bathroom exhausts, so they will

operate at maximum speed. Do not operate a summer

exhaust fan. Close replace dampers.

4. Following the lighting instructions, place the unit being

inspected in operation. Adjust the thermostat so the

appliance will operate continuously.

5. Test for spillage at the draft control relief opening after

5 minutes of main burner operation. Use the ame of

a match or candle.

6. Follow the preceding steps for each appliance

connected to the common venting system.

7. After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, replace dampers,

and any other fuel burning appliance to their previous

condition of use.

8. If improper venting is observed during any of the

above tests, the common venting system must be

corrected. See National Fuel Gas Code, ANSI Z223.1

(latest edition) or CAN/CGA B149.1 & .2 Canadian

Installation Codes to correct improper operation of

common venting system.

Gas Connections

The gas line to the unit should be adequately sized to

prevent undue pressure drop and should never be smaller

than the manual valve used. Consult the local utility or

National Fuel Gas Code for complete details on special

requirements in sizing gas piping.

The vent outlet must not be altered or extended.

The venting system is designed for proper operation under

all weather conditions and for winds up to 31 m.p.h.

Removal of Unit from Common Venting System

When an existing furnace is removed from a common

venting system serving other appliances, the venting

system is likely to be too large to properly vent the

remaining attached appliances. The following test

should be conducted with each appliance while the other

507389-03 Issue 2110 Page 7 of 22

The units supplied for operation with natural gas contain

a gas regulator which must be operated with inlet gas

pressures specied on the rating plate. If gas line pressure

exceeds this gure, an additional high pressure regulator

must be installed to reduce this pressure.

Units for operation with propane must be converted with a

kit supplied by the manufacturer and require for operation

an inlet pressure of 11” W.C. minimum and 13” W.C.

maximum. A regulator is also required on the propane tank.

Loading...

Loading...