Magic Chef CGR3520ADT, CGR3510ADH, CGR3520ADH, CGR3740ADH, CGR3740ADL Installation Instructions

...Page 1

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE APPLIANCE

' WIDE FREE-STANDING

AND SLIDE-IN

PLEASE.KEEP THIS MANUAL FOR FUTURE REFERENCE

THEMANUALIS INTENDEDTOASSISTIN THEINITIALINSTALLATIONAND ADJUSTMENTSOF THEF

!!!!i !ii!!i

CLEARANCE DIMENSIONS

Rangemaybeinstalledwithzeroinchesclearanceadjacentto (against)combustibleconstructionatther_

on the sidesbelowthe cooktop.For comp!eteinformationin regardto the installationof wallcabinets ab(

range and clearances to combustiblewall above the cooking top see the installation drawings. For SJ

CONSIDERATIONSdo notinstalla rangeinany combustiblecabinetrywhichisnot inaccordwith the inst_

drawings.

* NOTE:30 inchdimensionbetweencookingtop andwall cabinetshownonillustrationdoes notapplyto

withanelevatedoven.The30inchdimensionmaybe reducedto notlessthan24incheswhenthewall cabin

domestichomeare protectedwithfireproofmaterialsin accordancewithAmericanNationalStandards- N

FuelGasCodeor in mobilehomeswhentheyareprotectedwithfireproofmaterialsinaccordancewiththeF

Standardfor MobileHomeConstructionandSafety.

i

Toeliminatetheriskofburnsorfirebyreachingoverheatedsurfaceunits,cabinetstoragespacelocatedab(

surfaceunitsshouldbeavoided.If cabinetstorageisto be provided,the riskcanbereducedby installinga

hoodthat projects horizontallya minimumof 5 inches beyondthe bottomof thecabinets.

CAUTION:SOMECABINETSANDBUILDINGMATERIALSARENOTDESIGNEDTOWITHSTANDTHE

PRODUCED BY THE NORMAL SAFE OPERATION OF A LISTED APPLIANCE. DISCOLORATIOI

DAMAGE,SUCHAS DELAMINATION,MAYOCCUR.

YOUR RANGE MAY NOT BE EQUIPPED WITH SOME OF THE FEATURES REFERRED r

IN THtS MANUAL.

8101P1:

(08-

Page 2

INSTALLATION DRAWINGS

I" LOCATION NON-SELF

GAS LINE

1/_" CLEANING MODELS.

FOR 120 VOLT

I" GROUNDED ELECTRICAL

OUTLET IN THIS AREA.

OUTLET MUST BE FLUSH.

AREA IS 13"W X 9"H,

FLOOR, AND 1 1/2" FROM

33" RIGHT WALL,

-,_ LOCATED 9 3/8" ABOVE

%

18" \

./ff _

21/,,', ..>"

< 25" NORMAL

36" HEIGHT DEPTH

OF ABINET

/ 30" CABINET 24"

OPENI NG CABINET

RECOMMENDEDGAS LINE

LOCATION SELF-CLEAN

MODELS.

FREE-STANDING

CABINET

23 3/4" ON CABINET TOPS WITH

MIN. FLAT SHAVE RAISED SECTION

AREA TO CLEAR TOP.

._ 23 1/2" 30"

WITH THIS DIMENSION_ " OUTLET IN THIS AREA.

FILLER STRIP OR OUTLET MUST BE FLUSH.

OPTIONAL BACKGUARD AREA IS 13"W X 9"H,

IS NOT USED.

FOR CUTOUT GREATER FLOOR, AND 1 I/2" FROM

THAN 23 I/2" USE RIGHT WALL.

FILLER KIT, K6OFILL

OR CAX6OOOAXD.

OPT IONAL BACKGUARD

KIT K6OP OR

CAX6400AXO

MAY BE USED WHEN

CUTOUT IS 25".

#'OF 25" MINIMUM

INSTALLATfON, ADJUST DEPTH

BEFORE ATTEMPTING _(_ 3MMENDEOGAS CABINET

RANGE LEVELING LEGS I / _ LINE LOCATION

TO ACCOMMODATE | / 30" CABINET 2¢" CABINET

THIS DIMENSION. IL/_ _,,,..* OPENING

CAUTION:

SOMEWHITE EUROPEAN STYLE CABINETS ARE EQUIPPED WITH

DELICATE WHITE VINYL DRAWER AND DOOR FRONTS. THE VINYL

MAY NOT BE DESIGNED TO WITHSTAND THE HEAT PRODUCED BY THE

NORMALSAFE OPERATION OF A SELF-CLEANING RANGE.

DISCOLORATION OR DELAMI NATI ON MAY OCCUR.

TO AVOID POSSIBLE DAMAGE, WE RECOklMENDINCREASING THE 30" CABINET

OPENING TO 31 1/&" MINIMUM AND USING A HEAT SHIELD KIT--CABKIT V.

THE COUNTERTOP CUT. OUT MUST REMAIN 30".

UTOUT FOR 120 VOLT

36" HEIGHT

CABINET

FORMED FRONT EDGE,

NOTE:

GROUNDED ELECTRICAL

LOCATED 9 3/8" ABOVE

SLIDE-IN

Page 3

I

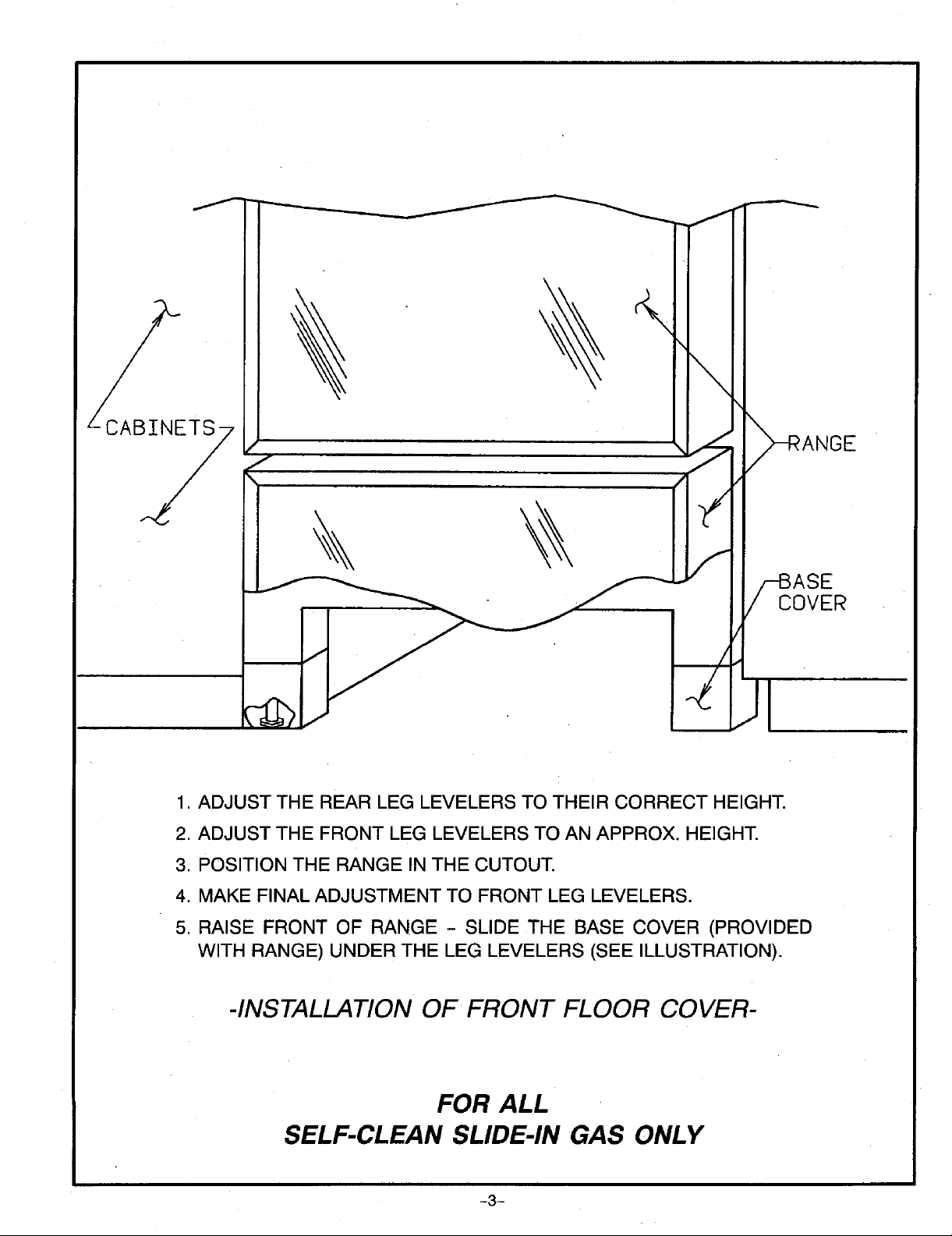

1. ADJUST THE REAR LEG LEVELERS TO THEIR CORRECT HEIGHT.

2. ADJUST THE FRONT LEG LEVELERS TO AN APPROX. HEIGHT.

3. POSITION THE RANGE IN THE CUTOUT.

COVER

4. MAKE FINAL ADJUSTMENT TO FRONT LEG LEVELERS.

5. RAISE FRONT OF RANGE - SLIDE THE BASE COVER (PROVIDED

WITH RANGE) UNDER THE LEG LEVELERS (SEE ILLUSTRATION).

-INSTALLATIONOF FRONT FLOOR COVER-

FOR ALL

SELF-CLEAN SLIDE-IN GAS ONLY

-3-

Page 4

ANY COMBUSTIBLE

I _ --- _ SURFACE

/

/

/- F

I -3o- LI

I _ (SEE NOTE ON FRONT ABOVE COOK TOP

I 'o i,L I , J I'I o"CLEARANCE

MIN. I I I i J.

""] "_- _ _-'-_" "_-'------_" I _ _ COMBUSTIBLE

i

' ' ' ' BELOWTHE COOKING

MIN. OF CABINETS

iO0 0 00'

IL I l

II| T1

li I > THE BACK AND SIDES

phil

36"

ART #9219-922

CONSTRUCTIONAND

OF THE RANGE

SURFACE.

DIMENSION "A" SIDE CLEARANCE ABOVE COOKING SURFACE

TOP BURNER RATE FOR "'CONVENTIONAL SELF-CLEAN

NATURAL GAS (SEE RATING PLATE) OVEN OVEN

9,200 BTU/HR OR LESS 0 INCHES 3 INCHES

MORE THAN 9,200 BTU/HR 1 INCH 3 INCHES

Check the range model number plate to see if the range is RECREATIONALVEHICLES

approved for installation in mobile homes and/or The installation of a range designed for recreational vehicles

recreational vehicles. If approved the following items are must conform with state or other codes or, in the absence of

applicable, such codes, with the Standard for Recreational Vehicles,

ANSI A119.2-1atest edition.

MOBILE HOMES

In Canada the range must be installed in accordance with

The installation of a range designed for mobile home CAN/CSA- Z24062- Electrical Requirements for R V's

installation must conform with the Manufactured Home (CSA Standard CAN/CSA - Z240 RV Series) and Section

Construction and Safety Standard, Title 24 CFR, Part 3280 Z240.4.2 Installation Requirements for Propane

[formerly the Federal Standard for Mobile Home Appliances and Equipment in R.V.'s (CSA Standard

Construction and Safety, Title 24 HUD, (Part 280)] or, when CAN/CSA - Z240 RV Series).

such standard is not applicable, the Standard for

Manufactured Home installations, ANSi A225.1/NFPA LOCATINGTHE RANGE

501A, or with local codes. Do not set range over holes in the floor or other locations

In Canada the range must be installed in accordance with where it may be subject to strong drafts. Any opening in the

the current CSA Standard C22.1 - Canadian Electrical Code wall behind the range and in the floor under the range should

Part 1and Section 7240.4.1 - installation Requirements for air is not obstructed.

Gas Burning Appliances in Mobile Homes (CSA Standard

CAN/CSA- Z240MH). NOTE: A range should NOT be installed over kitchen

be sealed. Make sure the flow of combustion or ventilation

carpeting.

-4-

Page 5

ANTI-TIP DEVICE INSTALLATION INSTRUCTIONS

NOTE:A riskofrangetipoverexistsiftheapplianceisnot the rangeand the levelingfootthat will engage the

installed in accordance with the installation instructions ANTI-TIP bracket,see figure 2.

provided.Theproperuseof thisdeviceminimizesthe riskof B. ForSAFETY CONSIDERATIONSas well as optimum

TIP-OVER. In using this device the consumer must still performanceadjusttherangesothatit islevel.Thismay

observethe safety precautions as stated in the USEand be checked by placing a spirit level or a large pan of

CAREMANUALandavoidusingtheovendoorand/or lower wateronthecooktoportheovenrack. Ifan adjustment

draweras a step stool, is requiredon freestanding,pull the rangeforward, tip

Installationinstructionsareprovidedforwoodandcementin the range and rotate the leveling feet as required.

either floor or wall. Any other type of construction may

require special installation techniques as deemed beforean adjustmentcanbemade.

necessaryto provideadequate fastening of the ANTI-TIP C. Tocheck the rangefor proper installationoftheanti-tip

bracketto thefloororwall. bracket: Use a flashlight and look underneath the

STEP1 - LocatingThe Bracket(see figure 1) legsisengaged inthe bracketslot.

A. Markthefloor or wallwhere either the rightor left rear D. Proceed with the remainder of the installation

"EDGE"of the rangeisto belocated, instructions.

B. Placethe BRACKET15/16"from the marked"EDGE"

towardcenterof openingand againstthe backwall as

showninfigure 1. "*,lI_,,.

C. Use the bracket as a templateand markthe required '*'_

holes,as shownin figure 1,for the typeofconstruction ANTI-T IP _f-HOLESFO_

Slide-in ranges require total removal from cabinet

bottomofthe rangeto see that one ofthe rear leveling

BRAOKET\ I)L WALL

yOUwillbe using. X "'TJIP_/, _

STEP2 - Anti-Tip BracketInstallation HOLES FOR--_---_ _ _/_ - (_, I I

A. WoodConstruction:

FLOOR /_ _--/_-,,, #1I'

1. Floor:Locatethecenterofthetwoholesidentifiedin t_1_ _,_3 t::_

figure1 as"HOLESFOR FLOOR".Drilla 1/8" pilot _ ___

holeinthe centerof eachhole(anailorawl maybe -" ___

usedif a drillis not available).Securethe ANTI-TIP _'_ __"_

bracket to the floor with the two screws provided. _ .........**,/ ,, OF RANGE

oceo0,osT

2. Wall:Locatethecenterofthetwoholesidentifiedin RANGEFOOT EDGEOF RANGE

figure 1 as "HOLES FOR WALL".Drill an angled

1/8"pilotholeinthe centerofeachholeasshownin FIGURE 1

figure2. (Anailor awl may be used if a drillis not

available).SecuretheANTI-TIPbracketto thewall

with the twoscrews providedasshown infigure 2. NOTE:USEA MINIMUMOF(2)

Proceedto STEP 3. SCREWSTOINSTALLBRACKET

1. Suitable screwsfor concrete construction can be

B. Cementor ConcreteConstruction: __M

STEP3 - RangeInstallation _' ,C_/- I

A, Alignthe rangeto itsdesignatedlocationand slide it

obtainedat a hardwarestore. Drillthe requiredsize _ BRACKET,.

holeforthescrewsobtainedintotheconcreteatthe TmRANGEi \ Ii_ / EN:rER-WGOusT

FORFLOOR",SecuretheANTI-TIPbrackettothe

centerofthe holesidentifiedinfigure t as"HOLES \ _ } [1/4' M,N. ]_/_J fW'A'LCP_ATE

floor.Proceedto STEP3. /,._Jj _,, __b-_. /

backintoposition'Makesurethatthelevelingfootisfully AR-• 92_9-76_ I

inserted into and secured by the ANTI-TIP bracket.

Note:A minimumclearanceof 1/4"is requiredbetween

/_ "_3 |- _ *" . / "'-MARKED EDGE

TO THE WALL OR FLOOR.

\ BOTTOMI , "_.JF_ ] Oi_META[..

\ F._ _ /SLIDE IN TO SECUREI_ I t

FIGURE2

-5-

Page 6

CONNECTING THE RANGE

ELECTRICSUPPLY NATURALGAS SUPPLYLINE MUSTHAVEA NATURAL

The appliance, when installed, must be electrically GAS SERVICE REGULATOR. INLET PRESSURE TO

groundedinaccordancewith localcodesor,intheabsence MAXIMUM OF 14 INCHES WATER COLUMN (0.5

oflocalcodes,withtheNationalElectricalCode,ANSI/NFPA POUNDS PER SQUARE INCH (P.S.I.) LIQUEFIED

70. PETROLEUM (L.P.)/PROPANE GAS SUPPLY LINE

In Canadathe range must be installedin accordancewith MUST HAVE A L.P. GAS PRESSURE REGULATOR.

thecurrentCSAStandardC22.1-CanadianElectricalCode INLET PRESSURETO THIS APPLIANCE SHOULD BE

Part1. REDUCED TO A MAXIMUM OF 14 INCHES WATER

ELECTRICALSUPPLYCONNECTION: PRESSURE REGULATOR AND OTHER GAS

The rangerequires120volts,60 cyclealternatingcurrent COMPONENTSINTHIS APPLIANCEAND CAN RESULT

fromanoutletcapableof supplying15 amperes. INA GAS LEAK.

THIS APPLIANCE SHOULD BE REDUCED TO A

COLUMN (0.5 P.S.I.).INLET PRESSURESIN EXCESS

OF 0.5 P.S.I. CAN DAMAGE THE APPLIANCE

a. A GAS CUTOFF VALVE SHOULD BE PUT IN AN

ACCESSIBLE LOCATION IN THE SUPPLY LINE

AHEAD OF THE RANGE, FOR TURNING ON AND

TURNING OFF GAS SUPPLY, If range is to be

connectedto housepipingwithflexibleor semi-rigid

metal connectorsfor gas appliances,CONNECTOR

NUTS MUST NOT BECONNECTED DIRECTLYTO

PIPE THREADS. THE CONNECTORS MUST BE

INSTALLEDWITHADAPTORSPROVIDEDWITHTHE

CONNECTOR.

b. The house piping and/or range connectorused to

connecttherangetothemaingassupplymustbeclean,

freeofmetalshavings,rust,dirtandliquids(oilorwater).

Dirt, etc.in the supply linescan work its way into the

range manifold and in turn cause failure of the gas

valvesorcontrolsandclog burnersandor pilot orifices.

CAUTION: DO NOT LIFT OR MOVE RANGE BY

DOOR HANDLES,OR BACKGUARD,

GAS SUPPLY

InstallationofthisrangemustconformwithIocalcodeser,in c. Turnoff all pilotsand main gas valve of other gas

the absenceof localcodes,withthe NationalFuel Gas appliances.

Code,ANSI Z223.1-1atestedition.

In Canadathe rangemustbe installedin accordancewith

the currentCGA StandardCAN/CGA.B149 - Installation

Codesfor GasBurningAppliances and Equipmentand/or approvedfor LPGto all threads.

local codes.

GASSUPPLYCONNECTION:(SEEFIGURE3) regulator using adaptors supplied with flexible

A TRAINED SERVICEMAN OR GAS APPLIANCE connector.Rigidpipemayalsobeused.Seeratingplate

INSTALLER MUST MAKE THE GAS SUPPLY fortypeofgas rangehasbeenmanufacturedfor,

CONNECTION.Leak testing of the appliance shall be

conductedbytheinstalleraccordingtothe instructions g. Turnon maingas valve at meter,and relightpilotsat

givenin sectionh. othergas appliances.

d. Turnoffmaingasvalveatmeter.

e. Beforeconnectingrange,applypipethreadcompound

f. Connect range to gas supply at appliance pressure

-6-

Page 7

h. Apply a non-corrosiveleak detection fluid to all

jointsandfittingsinthe gasconnectionbetweenthe

supplylineshut-offvalveandtherange.Includegas

fittingsand joints in the rangeif connectionswere

disturbed during installation. Check for leaks!

_11 SUPPLY LJ_E

/_ FLEX,eLE Bubblesappearingaroundfittingsandconnections

willindicatealeak.Ifa leakappears,turnoffsupply

linegasshut-offvalve,tightenconnections,turnon

1 2 N,P.T.

_F('t_AL E ELBOW

CADAPTOR/ CAUTION:NEVERCHECK FORLEAKSWITHA

/

__'_g' @ @ ALLWHENREsIDuE.LEAKCHECKIS COMPLETE,WIPEOFF

TO CONNECTGAS SUPPLYTO 1/2 N.P.T. MALE INLET J. Adjust burnerair shutterto thewidestopeningthat

"_4kAoAP_OR willnot causethe flameto liftorblowofftheburner

TO CONNECTGAS SUPPLYTO 1/2 N,P.T, FEMALEINLET REMOVESHIPPINGSCREW-

_PPL_*,CE SH_r-,_ holdthe burnersinplace on the burner bracketfor

:_< _REPGEP_SL_i__PRESSURE _tl ii _ LOwERVALVEovEN shippingpurposesonly.(Seefigure4).

CETEL NOTE:Correctlyadjustedsealedburners,canhave

APPL tAtVCE SHUT-OFF

REGULATOR " rr-T1 L

leaks.

FLAME.

the supply line gas shut off valve, and retest for

i. Remove shipping screw from ALL top burners,

(Conventionaltopburnermodelsonly).This is to

whencold.

flamesthatwill liftor blow off withouta potoverthe

burner. These should be adjusted with a pot in

0aoe

_-LEXIBLE SUPPLY LINE ADAPTOR _ __

FIGURE4

CHECKINGPRESSUREOF HOUSE PIPING

FIGURE3 SYSTEM

APPLIANCEPRESSUREREGULATOR&ALTERNATECONNECTORS1. The applianceand its individualshutoffvalvemustbe

THEAPPLIANCEPRESSUREREGULATORONYOURRANGEMAY disconnected from the gas supply piping system during

DIFFERFROMTHISILLUSTRATION. any pressuretestingofthatsystemattestpressuresin

-7-

excessof 1/2 Ibs./sq. in. (3.5 kPa) (13.8 in. water

column).

2. The appliancemustbe isolatedfromthe gas supply

pipingsystemby closingitsindividualmanualshutoff

valveduringany pressuretestingof the gas supply

pipingsystemattestpressuresequaltoorlessthan1/2

Ibs./sq.in.(3.5 kPa) (13,8in.watercolumn).

Page 8

RANGE ADJUSTMENTS

TOP SECTION - GAS TOP PILOT TOP BURNER ADJUSTMENT

ADJUSTMENT (Seefigure5) ALL TOP BURNERVALVES:

Purgeallairfromsupplysystembyturningononetopburner The approximateheightoftheflameat the highor full-on

valve.Thenturnoffvalveandadjusttoppilotflameusing positionisshownbelow.

adjustingscrew"A"(figure5)sothatflameisevenwithtopof

flashtube.Tolighttheburner,pushandturntopburnerknob Adjustburnerair shutterto thewidestopeningthatwillnot

tothe liteposition.NOTE: Some modelshave ONLYone causethe flame to lift or blowoffthe burnerwhencold.

pilotadjustmentatthe manifoldpipe. NOTE:Correctlyadjustedsealedburners,canhaveflames

thatwillliftorblowoffwithouta potoverthe burner.These

shouldbeadjustedwitha potinplace.

ILOT ADJUSTMENT SCREW "A"

RIGHT PIL_ REMOVESHIPPING SCREW- @

_-- 3/4"FLAME

FIGURE5 CONVENTIONALBURNERS

TOP SECTION - ELECTRIC IGNITION ,J_

To operate, push and turn top burner knob to the LITE _ _ j

position.Thetopburnerwilllight.ToturnOFFsparkafterthe "]-_-[" _- AIR SHUTTFR

topburnerhas ignitedturn knobto HI setting.

-8-

SEALEDBURNERS

FIGURE6

Page 9

AIR SHUTTER-OVEN BURNER

a. The approximatelengthofthe flameof ovenburnerisa REMOVING SEALED BURNER FOR

1/2 inchdistinctinnerblueflame,figure7. ADJUSTMENT OR SERVICE:

Markignitorlocationrelativeto maintopwithpencil.This

replacingthe burner assemblyto insure that the burner is

tightenedto its original position.

_ Placeburnerwrench(partno.8312D075-60,availablefrom

your dealer or authorized service agency) over surface

burnerassemblywithignitorpositionedinsidegapinwrench

ring (figure 9). This prevents ignitor from being crushed

" when wrench tightens on burner assembly.Rotate burner

assemblyapproximatelyone-eighthturncounter-clockwise

INNERCONE and liftfrommaintop (figure10).

FIGURE7

b. Ovenburnerflame canbe checkedas follows: C/{ /'_ _L-'_'_ TO LOOSEN

thewidestopeningthatwillnotcausetheflameto lift 22_-_..

1. Yellowflameon burner- openburnerair shutterto _ _'_/22__

orblowoffthe burnerwhen cold. (See#2 on figure ZTZON

8). _INSIDE WRENCHGAP

2. Distinct blue flame but lifting - close burner air

shuttertothe pointwhere itwillnotcausetheflame TCLOTCKI_HITENCLOCKWISE-

tOliftor blowoffthe burnerwhen cold. (See #2on _,_k_ l J))

mark on the maintop is used as a reference point when

,_ _ COUNTER-CLOCKWISE

c. Theovenburnerairshutteradjustmentisthe sameon ART# A219-8L2

figure8). _.._'-;

rangeswitha gas pilotorelectricignition. _.-.ousE_,_D_..e_ - ._o_._

FIGURE9

i

I'I' TO REASSEMBLE;Replaceburner assembly in maintop

LOCK SCREW alignedwithreferencemark on maintop.

and rotate approximatelyone-eighthturn clockwise using

burnerwrench until burner locks into position with ignitor

ORFICE HOOD

\

ORIFICE HOOD ,,i,,2

AIR SHUTTER /

@

-9-

FIGURE 10

Page 10

GASCONVERSION

GENERAL APPLIANCE PRESSUREREGULATOR

All rangesandcooktopsare equippedwith doublecoaxial CONVERSION

(universal) orifices and with a convertible appliance The unitappliancepressureregulatormustbesettomatch

pressure regulator.The unit model number plate states the type gas supplyused.If convertingfromnaturalgas to

which gas it was adjustedfor at the factory.Toconvertthe LPgas,theappliancepressureregulatormustbeconverted

unittoeitherNaturalgas orLP gaswillrequireadjustmentof to regulateLPgas.Ifconvertingfrom LPgasto naturalgas,

theorificehoods,airshuttersontheburnersandadjustment the appliance pressure regulator must be converted to

of the appliancepressureregulatorconvertercap. regulate naturalgas.

TO CONVERT THE APPLIANCE PRESSURE RE-

Inletpressuretotheappliancepressureregulatorshouldbe GULATORFROMONE GAS TO ANOTHER, DO EITHER

as follows for both operation and checking of appliance (1),(2) OR (3) BELOW:YOUR UNIT WILL BEEQUIPPED

pressureregulatorsetting: WITH ONE OF THE THREE APPLIANCE PRESSURE

INLETPRESSUREIN NATURAL LP REGULATORTYPESSHOWNBELOW.

INCHESOF WATERCOLUMN GAS 'GAS 1. Removethecap,pushdownandturncounter-clockwise.

Minimum 5 11 Turnthe capoverandreinstall(figure11).

Maximum 14 14 NOTE:THE GASTYPE YOU ARECONVERTINGTO

MUSTBEVISIBLEONTHETOP OF THE INSTALLED

APPLIANCEPRESSUREREGULATORCAP.

2. Remove plasticdust cover from cap nut on top of

appliancepressureregulator.Removecap nut from

appliancepressureregulator(plasticdustcovercomes

offwith nut)."IMPORTANT"removeplasticdustcover

fromcapnutandreinstallonoppositesideofcapnut,

Reinstallcap nutto appliancepressureregulatorand

replacedustcover."CAUTION" besuremarkingforthe

typeofgastowhichappliancepressureregulatorhasjust

beenconvertedisvisibleintopofcapnutbeforereplacing

plasticdustcover.(Seefigure12.)

3. Removecapandforciblysnap outplasticplungerfrom

bottomofcap.Turnplungeroverandforciblysnapbackin

originallocation(figure13).

NOTE:PLUNGERMUSTSNAP INTO POSITION;THE

GAS TYPE YOU ARE CONVERTINGTO MUST BE

VISIBLEON LOWERSIDEOF PLUNGER.

C--T3

LP NAT

L.P. POSZTION _ NATURAL GAS. POSITION , . , ,,

FIGURE 11 FIGURE 12 FIGURE 13

ART # A219-740

./ \,

-10-

Page 11

ORIFICE CONVERSION

1. FROMNATURALGAS TO LP/PROPANEGAS: 2. FROMLP/PROPANEGASTO NATURALGAS:

a. Change the appliance pressureregulatorfrom a. ChangetheappliancepressureregulatorfromLPto

naturalto LPsetting.(Seefigure11,12or13). naturalsetting.(Seefigure11, 12or 13).

b. Screwtheburnerorificehoodsdowntightagainst b. Screwtheburnerorificehoodsawayfromthepins.

the pins.(see figure14B).Use care to notover (Seefigure14A).Approximately1 1/2to2 turns.

tighten.Overtighteningcandamagethecoaxialpin

insidetheorificehood. NOTE:On unitsusingEatonOven Safety.Valve,

screwtheburnerorificehoodsawayfrompin(see

NOTE:On unitsusingEatonOvenSafetyValve. figure14C).Approximately1 1/2to 2 turns.

screwthevalveorificehooddowntightagainstthe

valvebody.(Seefigure14D), Itisimportantthatthe c. Modelswithstandingpilots:Adjusttopburnerpilots.

hoodbeturneddownasfarasitcangotoinsurethat (Seefigure5).Turntheselectorswitchontheface

completeconversionhasoccurred, of thethermostattotheNat.position.

d. Adjustburnerair shuttertothewidestopeningthat

c. Modelswithstandingpilots:Adjustburnerpilots, willnotcausetheflameto liftorblowofftheburner

(Seefigure5).Turntheselectorswitchontheface whencold.

ofthethermostattotheLPposition.

d. Adjustburnerairshuttertothewidestopeningthat NOTE: Correctlyadjusted sealed burners,the

willnotcausetheflametoliftorblowoffthe burner flamewillliftor blowwithouta potoverthe burner.

whencold. Theseshouldbeadjustedwitha potin place.

NOTE:Correctlyadjustedsealedburners,canhave

flamesthatwillliftor blowwithouta pot overthe

burner.These shouldbe adjustedwith a pot in

place.

FOR ALL TOP BURNER AND FOR EATON

OVEN SAFETY VALVE CONVERSION OVEN SAFETY VALVE CONVERSION

(EXCEPT EATON VALVE)

_ ART# 9219-983-0 j _ ART_ 9219-_83-0

FIGURE 14A FIGURE 14B FIGURE14C FIGURE 14D

NATURALGAS LP GAS NATURALGAS LPGAS

SETTING SETTING SETTING SETTING

SERVICE- PARTSINFORMATION

WHEN YOUR RANGE REQUIRES SERVICE OR COMPLETE MODEL AND SERIAL NUMBERS OF THE

REPLACEMENTPARTS,CONTACTYOUR DEALEROR RANGE WHICH IS LOCATEDON THE RANGE MODEL

AUTHORIZEDSERVICE AGENCY.PLEASE GIVE THE NUMBERPLATE.

-11-

Loading...

Loading...