Page 1

FORFUTUREREFERENCE

Forfuture referencewe suggest you re-

tain this manual after recording the WARNING: If the informa-

modelnumberandserialnumberofthis tion in this manual is not

gas appliance in the spaces provided.

Thisinformationcanbefoundontherat-followed exactly, a fire or

ing platelocated on the sidesof the low- explosion may result caus-

er range front frame. Pull out lower ing property damage, per-

drawer to see rating plate, sonal injury or death.

- Donot store or usegaso- _'_

line or other flammable

MODELNUMBER vapors and liquids in the

vicinity ofthis or anyoth-

SERIAL NUMBER er appliance.

-WHAT TO DO IF YOU

DATEOF PURCHASE

These numbers identify your range.

Pleaseuse themin any correspon- * DOnot touch any elec- • INJURY TO PERSONS

dence or servicecallsconcerningyour trical switch; do not COULD RESULT

appliance, use any phone inyour

Pleaseretaintheproofofpurchasedoc- building. • INSTALLANTI-TIP

umentsfor warrantyservice. DEVICES PACKED

SMELL GAS: _ WARNING

• Do not try to light any • ALL RANGES

appliance. CAN TIP

• Immediately call your WITH RANGE

gas supplier from a

neighbor's phone. • SEE INSTALLATION

Follow the gas suppli- INSTRUCTIONS

er's instructions.

To reduce the risk of tipping of the

• If you cannot reach appliance from unusual usage or by

your gas supplier, call excessive loading of the oven door,

the fire department, the appliance must be secured by a

- Installation and service checkifdeviceisinstalledproperly:Use

must be performed by a a flashlight andlookunderneathrange

properly installed anti-Up device. To

to see that one of the rear leveling legs

qualified installer, ser- is engaged in the bracket slot.

vice agency or the gas

supplier.

Page 2

Page 3

Page 4

Page 5

Time-0f-DayClock

Ifyour rangefeaturesa time-of-day clock and minute timer

follow the instructionsfor the illustration that matches the

clock on your range.

ANALOGCLOCKANDTIMER DIGITALANDCLOCKTIMER

12

11 1

CLOCK SET MINUTE TIMER

s "-,;,3o

"///lllll_.',\ "__ 88:88 willflash in the displaywhen the

• 6 b range is first connected to power or if

TO SETCLOCK: Push in and turn Min- TO SET CLOCK: Press and hold

uteTimerknobtothecorrecttimeofday. CLOCK SET button while turning MIN-

BesureMinuteTimer hand is on OFFaf- UTE TIMER knob to the correct time of

tersetting clock, day. MINUTE TIMER knob can be

TO SET MINUTE TIMER: Turn knob in

either direction to the desired time. TO SET MINUTE TIMER: Turn MIN-

Whenthe buzzer sounds, manually turn UTETIMER knob to the right,to the de-

theTimer to OFR sired time, up to 60:00 (1 hour). Timer

power is interrupted.

turned in either direction.

will begincounting down after afew sec-

onds delay. When time has lapsed, a

continualbeepwillsoundfor upto2 min-

utes.

4

(continuedon next page)

Page 6

Time-Of-Day Clock (oon,,nue )

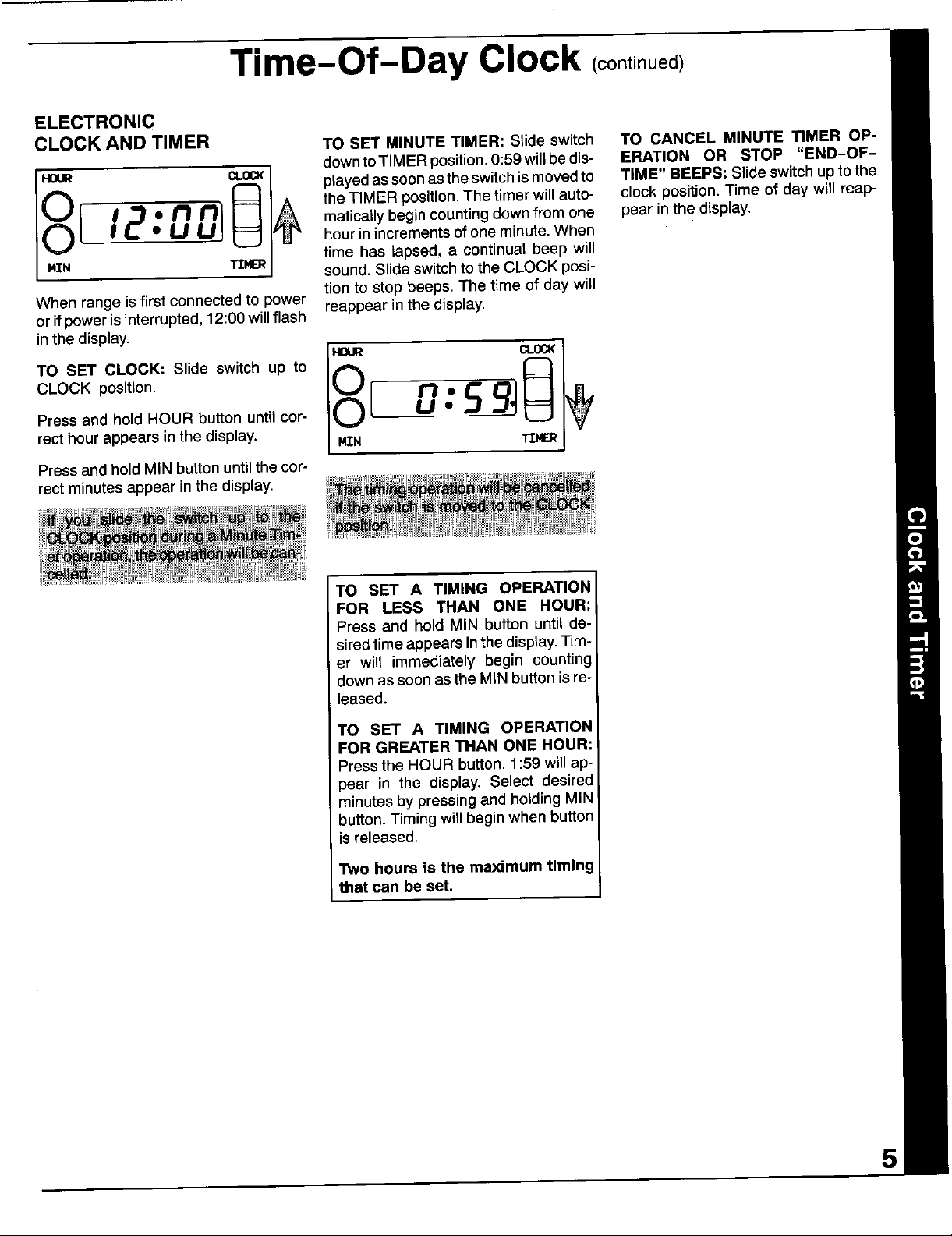

ELECTRONIC

CLOCK AND TIMER TO SET MINUTE TIMER: Slideswitch TO CANCEL MINUTE TIMER OP-

downtoTlMERpoeition. O:59willbedis- ERATION OR STOP "END-OF-

HOUR ¢L0C_ playedas soonastheswitchismovedto TIME" BEEPS: Slideswitchupto the

• n nl maticallybegin countingdown from one pear inthe display.

81,2 @_theTlMERpositlon. Thetimerwillauto-cleckposition._meofdaywillreap-

Whenrange is first connected to power reappear in the display.

orif power is interrupted, 12:00will flash

in the display.

Press and hold HOUR button until cor-

CLocKTOSET CLOCK: Slide switch up tOposition.8[ 0 5_@ _

rect hourappears in the display. 14zN TZ.I_R

Press and bold MIN button until the cor-

rect minutesappear in the display.

• U U ] hourin incrementsof one minute.When

time has lapsed, a continual beep will

"rzMIm sound. Slide switchto the CLOCK posi-

tion to stop beeps. The time of day will

TO SET A TIMING OPERATION

FOR LESS THAN ONE HOUR:

Press and hold MIN buttonuntil de-

siredtimeappearsinthedisplay._m-

er will immediatelybegin counting

downassoonastheMIN buttonisre-

leased.

TO SET A TIMING OPERATION

FORGREATER THAN ONE HOUR:

Pressthe HOUR button.1:59willap-

pear in the display.Select desired

minutesbypressingand holdingMIN

button.Timingwillbeginwhenbutton

isreleased.

Two hours is the maximum timing I

that can be set.

5

Page 7

SurfaceCq)oking

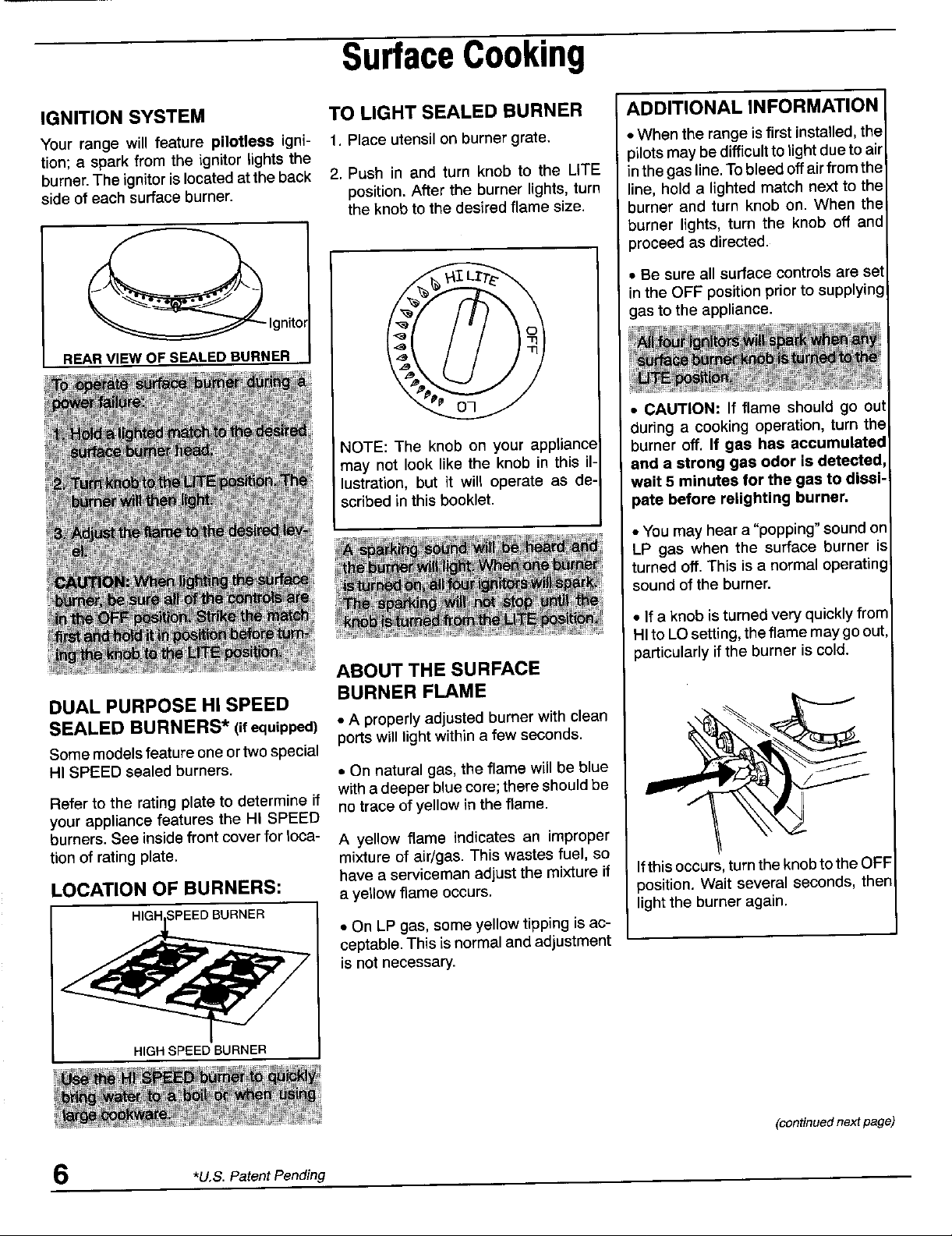

IGNITION SYSTEM TO LIGHT SEALED BURNER ADDITIONAL INFORMATION

Your range will feature pilotless igni- t. Place utensil on burner grate. • When the range is first installed, the

tion; a spark from the ignitor lights the pilots may be difficult to light due to air

burner. The ignitor is located at the back 2. Push in and turn knob to the LITE inthe gas line. Tobleed off air from the

side of each surface burner, position. After the burner lights, turn line, hold a lighted match next to the

Ignitor gas to the appliance.

REARViEW OF SEALED BURNER

the knob to the desired flame size. burner and turn knob on. When the

proceed as directed.

• Be sure all surface controls are set

in the OFF position prior to supplying

_ burner lights, turn the knob off and

NOTE: The knob on your appliance burner off. If gas has accumulated

may not look like the knob in this il- and a strong gas odor is detected,

lustration, but it will operate as de- wait 5 minutes for the gas to dissi-

scribed in this booklet, pate before relighting burner.

ABOUT THE SURFACE

DUAL PURPOSE HI SPEED BURNER FLAME

SEALED BURNERS _ (if equ,pped) " _ _O_er 'Y _dJ_t_d bu met with c,ea_ ___

Some models feature one ortwo special

HI SPEED sealed burners. • On natural gas, the flame will be blue

Refer to the rating plate to determine if no trace of yellow in the flame.

your appliance features the HI SPEED

burners. See inside front cover for toca- A yellow flame indicates an improper

tion of rating plate, mixture of airgas. This wastes fuel, so

ports will lightwithin a few seconds,

with a deeper blue core; there should be _'IP'__

have a serviceman adjust the mixture if Ifthis occurs, turn the knob to the OFF

• CAUTION: If flame should go out

during a cooking operation, turn the

• You may hear a "popping" sound on

LP gas when the surface burner is

turned off. This is a normal operating

sound of the burner.

• If a knob is turned very quickly from

HI to LO setting, theflame may go out,

particularly if the burner is cold.

LOCATION OF BURNERS: a yellow flame occurs, position. Wait several seconds, then

HIGH BURNER light the burner again.

• On LP gas, some yellow tipping is ac-

ceptable. This is normal and adjustment

is not necessary.

HIGHSPEEDBURNER

*U.S. Patent Pending

(continuednextpage)

Page 8

SurfaceCooking oont nue¢,)

FACTORS THAT DETERMINE SELECTING FLAME SIZE CANNING

FLAME SIZE • Use a HiGH flame settingto quickly Acceptablewater-bathorpressurecan-

UTENSIL SIZE: Adjustthe flamesize bringliquidstoa boilor to begina cook- hersshouldnotbeoversizedandshould

soitdoesnotextendbeyondtheedgeof ing operation.Then reduceto a lower haveaflat bottom.Thefollowingarenot

the cookingutensil.Thisisforpersonal settingtocontinuecooking.Neverleave recommended:Oversizedcannersora

safetyand to preventpossibledamage food unattended when using a HIGH very largecannerthat restson two sur-

to the appliance, utensil or cabinets flame setting, face burnergrates.

abovethe appliance. When canning, use the HIGH setting

' ner,then reduceto the lowestflame set-

,_,u_v_ _ pressure sreached nthepressurecan-

just until the water comes to a boil or i

• An intermediate flame size is used to

__i- _ tingthat maintainsthe boil orpressure.

• Utensilswhichextend morethan two ed to maintain a gentle boil. Remem-

inches beyond the grateor touch the ber,waterboilsatthesametemperature

cooktopmay causeheat tobuildup,re- whetherboilinggentlyorvigorously.

suitingin damage to the burnergrate,

burneror cooktop. • Use LOW to simmeror keepfoods at

• Utensils,such as wokswitha support

ring,whichrestrictaircirculationaround

continue a cookingoperation. Foodwill

not cook any faster when a higher

flame setting is used than that need-

servingtemperatures.

may result in damage to the burner

grate, burner or cooktop.

UTENSIL MATERIALS: Optimum

theburnerwillcauseheattobuildupand _

cooking performance can be achieved

whenheavygauge, flat, smooth bottom,

metal utensils with straight sides and

tight fitting lids are used.

• Aluminum oraluminum-clad stain-

less steel pansheat moreevenlyso a

slightly larger flame can be used.

• Stainless steel, porcelain andheat-

cast aluminum and iron heat slowly; /

and, Teflon-coated utensils are sensi-

tive to heat. These materials require a

lowerflameto producemoreevencook- "_ )

ing results, Adjust flame so itextends

halfway to the edge of the utensil bot- \_,

proofceramic or glass heat unevenly; /_ __ t

tom. "_ LoTj

COVERED UTENSILS: Foods cook

faster when the utensil is covered be- Besureto adjust the knob so there is

cause more heat is retained. Lower the an adequate supply of gas to main-

flame size when covering utensils, lain a stable flame on the burner.

Check to be sure burneris lite and the

flameis stable.

Page 9

UsingYourOven

OVEN VENT OVEN THERMOSTAT

The ovenvent is located at the base of The oventhermostat knob isusedto se-

thebackguard.When the oven is inuse, lect and maintain the oven temperature.

this area may feel warm or hot to the Alwaysturn this knobjust tothe desired

touch. To prevent problems do not: temperature- not to a higher tempera-

Block the vent opening, touch the area ture and then back. This provides more

nearthe opening or place utensils near accurate oven temperatures. Turn this

thevent opening, knobto OFFwhenever the oven isnot in

OVEN BURNER

The size and appearance of a properly

IGNITION SYSTEM adjustedoven burnerflame should beas

Your appliance features pilotless igni- shown:

Be sure oven control is set in the OFF

positionpriortosupplyinggastothe ap-

pliance.

use.

T

• is an indent at

ti°n" Aglebar willlightthe °ven burner" I i _ O_ 3_O_ smeoT_'_O_;A

[ "- 1

The oven temperature is maintained by

cycling the burner on and off. After the

oven temperature has been set, there

will be about a 45 second delay before

the burner ignites.This isnormaland no

gas escapes duringthis delay•

(continuednextpage)

8

Page 10

UsingYourOven(cont,noe )

TO SET THE OVEN PREHEATING

1. When cool,placethe racksinthede- Preheatingis necessaryforproperbak-

siredrackpositions, ing results.Allowthe oven to heat until

thedesiredoventemperatureisreached

2. Pushin andturnthe oventhermostat (approximately t0 to 15 minutes). Se-

knob to the desired oven tempera- lectingatemperaturehigherthanthede-

ture.Allow theoven to preheat for 10 sired temperature will not preheat the

to 15 minutes when baking, oven any faster. Infact, this may have a

3. Place the food in the center of the negative effect on baking results.

oven, allowing a minimum of two in- It is not necessaryto preheat for broiling

ches between the utensil(s) and the unless darker browning is desired or if

oven walls, cooking thin (3/4-inch) steaks. Allow

4. Check the food for doneness at the burner to preheat 2 to 3 minutes.

minimum time given in the recipe. Preheating is notnecessaryfor roasting

Cook longer if necessary. Opening operations.

the oven doorfrequently causes heat

losswhich may affect cooking results

and increase cooking time.

5. Turn the oven thermostat knob to

OFFand removefoodfrom the oven.

(cont/nued next page)

9

Page 11

UsingYourOven(continued)

10

(continuednext page)

Page 12

CommonBakingProblemsAndWhyTheyHappen

Cakesare uneven. Panstouching each other or Cakes don'tbrown on top. Incorrect rack position.

Cake high in middle. Temperaturetoo high. Overmixing.

Cake falls, Too much shortening or sugar. Uneven texture. Too much liquid.

Cakes, cookies, biscuits Incorrect rack position.

don'tbrown evenly. Oven door not closed properly. Cakescrack on top. Batter overmixed.

oven walls. Temperaturetoo low.

Batter uneven in pans. Overmixing.

Oven temperature too low or Toomuch liquid.

bakingtime too short. Pan size too large or too little

Oven notlevel, batter in pan.

Undermixing. Oven door opened too often.

Toomuch liquid.

Bakingtime too long. Pantoo large.

Overmixing. Temperaturetoo high.

Too muchflour. Baking time too long.

Panstouching each other or Panstoo close to each other

ovenwalls, or oven walls.

Incorrect rack position.

Too much or too little liquid. Undermixing.

Temperaturetoo low. Temperaturetoo low.

Old or too little baking powder. Bakingtime too short.

Pan too small.

Oven door opened frequently. Cakes have tunnels. Not enough shortening.

Added incorrect type ofoil to Too much baking powder.

cake mix. Overmixing or at too higha

Added additional ingredients speed,

to cake mix or recipe. Temperaturetoo high.

Door gasket not sealing Temperaturetoo high.

properly. Too much leavening.

Incorrect use of aluminum foil. Incorrect rack position.

Oven not preheated.

Pans darkened, dented or

warped. Cake not done in middle. Temperature too high.

Excessive shrinkage. Too little leavening.

Pan too small.

Baking time too short.

Cakes, cookies, biscuitstoo Ovennot preheated.

brown on bottom. Panstouching each other or

oven walls. Pie crust edges too brown. Temperaturetoo high.

Incorrect rack position. Panstouching each other or

incorrect use of aluminum foil. oven walls.

Placed2 cookie sheets on one Edgesof crust too thin.

rack. Incorrect rack position.

Used glass, darkened, stained,

warped or dull finish metal Pies or cakes don't brown Used shiny metalpans.

pans. (Use a shiny cookie on bottom. Temperaturetoo low.

sheet.)

Pies have soaked crust. Temperaturetoo low atstart of

baking.

Fillingtoo juicy.

Used shiny metal pans.

11

Page 13

UsingYourOven ooo,J,oed

HOW TO BROIL

Broilingis a method of cooking used for tendersteaks, rare interior,the meat shouldbeclosetothe burner.Place

chops,hamburgers,chicken,fish,andsomefruitsandvege- the panfurtherdownifyouwishthemeatwelldoneor ifspat-

tables.The foodis placeddirectlyundertheovenburner, teringandsmokingoccurs.

Thecookingtime isdetermined bythe distance betweenthe The distance from the burner depends on the thickness of

meat and the burner,the desired degree of doneness, and the meat and desired degree of doneness. Thin cuts should

the thickness of the meat. be placed on rack#1 (top)or #2 (middle); thickercuts should

beplaced on rack#2 or #3 (bottom). Broil untilthe top ofthe

GENERALTIPS meat is browned. Itshould be approximately half cooked by

Broilingrequirestheuseofthebroilerpanandinsertsupplied the timethe topisbrowned.

withyourappliance.Itisdesignedtodrainexcessliquidand

fat away from the cooking surface to prevent spatters, Trimexcess fat toprevent excessivespattering or smoking.

smoke and flare ups. during cooking.

Foreasierclean-up, line the broiler pan (bottom piece)with

aluminumfoiland spraythe insertwith a non-stick vegetable If you plan to season the meat, it is betterto do so afterthe

coating.Do notcoverthe broilerpan insertwithaluminumfoil surface has browned. Salt tends to delay browning which

as this prevents fat from draining into the pan below. The can resultin overcooking. Salting beforecooking alsodraws

broiler can be preheatedfor afew minutes. However,do not the juices out ofthe meat,causing dryness.

preheatthe broilerpan and insert.

If the food is placed too close to the burner,overbrowning

and smoking may occur. Generallyfor a brown exterior and

Cut slashesinthe outer edgesofthe meatto prevent curling

BROILING CHART TO BROIL:

1. TurntheovenTHERMOSTATknobto

Food Thickness Position Doneness 1st Side 2nd Side

Quantity &/or Approx. Minutes/Side BROIL.

tt is possibleto broil longercooking

Bacon thickslice middle well 4- 5 1- 2 foods such as pork chops at a lower

BeefPatties 3/4"thick middle rare 3-4 2-3 temperature to prevent overbrown-

middle medium 5-6 3-4 ing. Turn the knob to 450°F, rather

middle well 5- 6 4-5 than BROIL, for low temperature

Steaks 1_thick bottom rare 3 - 4 3- 4 broiling.

bottom medium 5- 7 4- 6 2. Preheatfor 2 to 3 minutes if desired.

bottom well 7 - 8 6 7

NOTE: Cooking times in the Broil

112"thick bottom rare 7-8 5-6 Chart are based on a 2 to 3 minute

bottom medium 8 - 10 6 - 8

bottom well 10 - 11 8 - 9 preheat.

ChickenBreastHalves bottom well 8- 9 7- 8 3. Place the broiler pan on the recom-

Fish Fillets 1" thick middle 5 - 6 3 - 5

1/2_ thick middle 4 - 5 3- 5 broilingchart.

mended rack position shown in the

HamSlices 1/2"thick middle 5-6 4-5 4. Foltow the suggested times in the

(precooked) broiling chart. Meat should be turned

once about halfway through itscook-

PorkChops (450°) 1" thick bottom well 12 - 14 8 - 9 ingtime.

Weiners/Sausage middle 2 -4 2 -3 5. Checkthe doneness by cutting a slit

(precooked) in the meat near the center to check

the color.

12

Page 14

Maintenance

COOKTOP BURNER GRATES DUAL PURPOSE

The cooktop is designed with two con- SEALED BURNERS

touredwells which containspillsuntil The four sealed burnersare securedto

theycan be wiped up. Unlikethe stan- thecooktopandareNOTdesignedtobe

dard gas appliance, THIS COOKTOP removedby the consumer.

DOES NOT LIFT-UP NOR IS IT RE-

MOVABLE.To prevent damage to the Since the four burners are sealed into

gas tubing or top, do not attempt to lift thecooktop, boiloverswon't seepunder-

cooktop, neath to the burner box area. Thus

When reinstalling square grates, place there are no hidden spills inthe burner

er, use care to prevent damage to the

Whencleaning aroundthe surface burn-

spark ignitor which is located at the

cloth should catch the ignitor, it could

_[ indentedsidestogether sostraight sides box area toclean'areat front andrear. IGNITORS

damageor break it. Ifthe ignitor isdam-

aged or broken, the surface burner will

not light.

back-side of each burner. If a cleaning

Burner grates are durable but may lose _ Ignitor

their shine due to usage and high tern- REARVIEWOFSEALEDBURNER

peratures.

(continuednext page)

13

Page 15

Maintenance(continued)

OVEN DOOR OVEN RACKS BROILER DRAWER

The two oven racksare designedwitha Storecleanbroilerpanandinsertinthe

lock-stop edge to keep the racksfrom broilerdrawer.

comingcompletelyoutof the oven.

Toremove:Besuretherackiscool.Pull stopposition.Liftupfrontof drawerand

therackstraightout untilitstops.Tiltthe pullto the secondstopposition.Grasp

frontofthe rackupand continuepulling sides and lift up and out to remove

When openingovendoor,allowsteam the rack outof the oven. drawer. Gently move drawer side-to-

andhotairto escapebeforereachingin sideas you pullthedrawerout.

ovento check, add orremovefood. To replace:Tiltthefrontendofthe rack

upand placethe rackbetweenthe rack \ I

To remove

"stop" position (opened about 4 inches) lock-stop position. Lower the front and

and grasp doorwith both hands at each slidethe rackstraight in.Pulltherackout

side. Do not use door handleto lift door. to the lock-stop positionto be sure it is _

Liftup evenly untildoor clearsthe hinge positionedcorrectly andthen return itto

arms. its normal positon.

door:

Open

door to the

supports.Slide it back until it clears the _,_

To remove: Pulldrawerout to the first

m

/_ OVEN Bo'n'OM TOreplace: Fit ends of drawer glides

TO replace door: Grasp door at each __1//7,

side,alignslotsinthedoorwiththe hinge _. _•armsandslidedoordown ontothe hinge

armsuntil completelyseatedon hinges. __.. ___."J'3 "_." _j

To remove: When cool, remove the position.

oven racks. Slide the two catches, lo-

cated at each rear corner of the oven

bottom, toward the front ofthe oven.

Lift the rear edge of the oven bottom

slightly, then slide it back until the front

edgeof the oven bottomclears theoven

frontframe. Remove oven bottom from

oven.

ontorails. Liftup drawerfront and gently

push in to first stop position. Gently

move drawer side-to-side asyou push

in the drawer. Lift up drawer again and

continue to slide drawer to the closed

14

To replace: Fit front edge of oven bot-

tom intofrontframe. Lower rearof oven

bottom and slide the catches back to

lock oven bottom into place. (continuednext page)

Page 16

Maintenance(continued)

OVEN LIGHT HOWTO REMOVE PROPORTIONAL VALVE

RANGE FOR CLEANING ADJUSTMENT (if equipped)

AND SERVICING The LOW setting shouldproducea sta-

Followtheseproceduresto removeap- bleflamewhenturningthe knobfromHI

Before replacing oven light bulb, DIS- pliancefor cleaning or servicing: to LO. The flame should be 1/8 inch or

CONNECT POWER TO RANGE. Be LOWsetting.

sure bulb and range parts are cool. Do 1. Shut-off gas supplyto appliance.

nottoucha hot bulbwith adampclothas To adjust: Operate burner on HI for

the bulb may break. 2. Disconnect electrical supply to ap- about 5 minutes to preheat burner cap.

pliance, if equipped, Turnknob backto LO; remove knob,and

To replace oven light: Use a dry pot insertasmallscrewdriverintothecenter

holder, to prevent possible harm to 3. Disconnectgas supplytubingto ap- ofthe valve stem.Adjustflame size by

hands;very carefully removebulb.Re- pliance, turningadjustmentscrewineitherdirec-

placewitha 40 wattAPPLIANCE bulb. tion.

Reconnectpowertothe range. 4. Slide range forward to disengage

rangefromthe anti-tip bracket.(See

InstallationInstructionsforlocationof

LEVELING LEGS bracket.)

lowerand must be stable on allports on

5. Reverseprocedure to reinstall.Ifgas p_

linehas been disconnected,check for

Levelinglegsare locatedon eachcorner gas leaksafter reconnection. (See In-

ofthe base ofthe range, stallation Instructionsfor gas leak test

method.)

NOTE: A qualified servicer should dis-

connect and reconnect the gas supply.

ping, range must be securedto the floor

by sliding rear leveling leg intoan anti-

f

__ To prevent range from accidently tip-

Place a level horizontally on an oven risk of tip over, should theappliance not

rackand checkfront-to-back and side- be reinstalled according to the installa-

to-side. Level by turning the legs. tion instructions.

tip bracket supplied with the range.

WARNING: Possible risks may result NOTE: All gas adjustments should be

from abnormal usage,including exces-

sive loadingof the oven door and ofthe done by a qualified servicer only.

J

15

Page 17

GeneralInformation

ELECTRICAL CONNECTION USE OF ALUMINUM FOIL

Appliances which require electrical Use aluminum foil ONLY as

power are equipped with a three- instructed in this book. Improperuse

prong grounding plug which mustbe of aluminumfoil may causedamageto

plugged directly into a properly theoven, affectcookingresults,andcan

groundedthree-hole 120 voltelectrical also resultinshockand/orfirehazards.

outlet.

Foilcan be usediftheseguidelinesare

followed:

(_ i_,/ • Do not use aluminum foil directly

_ heatawayfromtheutensilcausinginad-

• equate browning. Placing a pie directly

:' onfoil may resultin asoggy bottomcrust

and inadequate browning.

__ under the cookware. Foil will reflect

• Do not placealuminumfoil directly

A/ways disconnect power to app/i- onthe oven bottom asthis may dam-

ance before servicing, age the oven bottom, A piece of foil

The three-pronggroundingplug offers that is slightlylarger thanthe cooking

protectionagainstshock hazards. DO utensilcan beplacedontherackdirectly

NOT CUT OR REMOVE THE THIRD belowtherackcontainingthe utensil,

GROUNDING PRONG FROM THE

POWER CORD PLUG, • Do not completely cover an oven

rackwith foil.Thisblocksairflowinthe

oven, constitutes a safety hazard, and

will adverselyaffect cooking results.

• Never cover the broiler insertwith

aluminum foil as this prevents fat

from draining to the pan below, The

broilerpancan be linedwithfoil.

16

Page 18

CareandCleaning

illii

CLEANING CHART

PARTS CLEANING AGENTS DIRECTIONS

Baked Enamel * Soap and water Useadrytowelor clothtowipe upspills,especiallyacid (milk,lemonjuice,fruit, mustard,

or Porcelain Enamel • Pasteof baking soda and water tomatosauce) orsugaryspi)ls.Surfacemay discoJoror dull if saJ)Lsnotimmediate/y re-

. Cooktop * Mild liquid cleaner moved. This isespecially importantfor white surfaces.

• Ovendoor * Glasscleaner

• Broilerdrawer When surface iscool,washwith warm soapywater, rinse anddry.Forstubborn soil, use

• Side panels mildlyabrasivecleaning agentssuch as baking sodapasteor BonAmi.If desired,athin

• Backguard coatof mildappliancewax canbeusedto protectthesidepanels. A glasscleanercan be

usedto add "shine" to the surface.

NOTE:Do notuseabrasive,caustic or harshcleaningagentssuch as steelwoolpadsor

ovencleaners. These products will scratch or permanentlydamage the surface.

NOTE:Neverwipea warmor hotsurfacewith adamp clothasthismay damagethesur-

face and may cause e steam burn.

Broiler panand • Soap and water Removefromoven afteruse.Coolthen pouroffgrease.Placesoapyclothoverinsertand

insert • Plastic scouring pad pan; letsoak toloosen son.Washin warmsoapy water.Use soap-filled seoudng padto

Chrome drip bowls, • Soap and water Clean bowls after each use with soap and water. Remove stubborn stains with baking

if equipped • Psate of baking sada and water sodabasteandp]astiescourJngpad.TopreventseratchJngthefinish,donotuseabrasJve

Control knobs * Soapand water Toremoveknobsforcleaning,gentlypullforward.Washinmild detergentandwater.Do

Glass • Soap and water Washwithsoapandwater.Useawindow cleanerandasoftclothaftercleaning,Remove

• Backguard • Pasteof baking soda andwater stubborn soil withpaste of bakingsoda and water. Rinsewith aclothwrung out inclear

• Ovenwindow • Glass cleaner water.Dry.Donot useabrasive materials suchas scouringpads,steelwool orpowdered

• Soap-filled scouring pad remove stubborn soil. Clean in dishwasher if desired.

• Dishwasher

NOTE:Poreasiercleanup,sprayinsertwithanon- stickvegetabtecoeting andline broifer

pan with aluminum foil

NOTE:Always store clean broilerpanand insert Jnthe broJJercompartment, if panand

insertare notcleaned aftereach use,thesoilmight becomehotenough toignitethe next

time the oven isused.

• Plasticscouringpad cleaningagents.Rinse,dry and replace.

NOTE:Bowlscanpermanentlydiscolorifexposedtoexcessiveheatorifsoilisallowedto

bake on.

notsoakknobsinwater.Donotuseabrasivecleaningagents.Theywillscratchfinishand

removemarkings.Rinsedryandreplace.TurnON each burner to seeif knobs have

been replaced correctly.

cleaning agents.

NOTE:To avoid inside stainingof oven door glass, do not oversaturate cloth.

(continuedon next page)

17

Page 19

CareandCleaning(continued)

PARTS CLEANING AGENTS DIRECTIONS

Grates • Detergentand water Gratesaremadeof porcelain-coatedsteel,Theycan becleaned atthesinkwithdeter-

* Non-abrasive plastic pad gent and wateror in the dishwasher.Tocleanbakedon soil, placea dampsoapy paper

Metal finishes • Soap and water Wash with soap andwater. Removestubborn soilwith paste of bakingsoda and water.

• Backguard • Paste of baking soda and water Use awindow cleaner anda soft cloth to remove fingermarks orsmudges.

• Trim parts • Glass cleaner

• Manifoldpanel NOTE:Donotuseovencleaners,abrasiveorcausticagents.Theywilldamagethefinish.

Oven bottom • Soap and water Continuous clean oven bottom:See page 19.

• Porcelainenamel • Pasteof baking soda and water

• Non-abrasive plastic pad Porcelainoven bottom: Clean,whencool,with soapandwater,non-abrasive plasticpad

• Ovencleaner orovencleaner. Rinsewithclearwater. Tomakecleaningeasier, protecttheoven bottom

Oven cavity Cleaning action begins whenever the Brush off heavy soil with a nylon or plastic pad. Do not use paper towels, cloths, or

• Continuous clean oven ison. The oven must be used for spongesbecausetheovenwallsareporousandparticlesofthesematerialswillruboffon

oven cleaningtotake place.Higheroventern- thewalls. Rinseareawith cleanwater only.DOnotuseanytypeofoven cleaner,cleanser

See page 19. }eratures and longer baking times or detergent on this surface.

speedthe cleaning action.

Oven cavity • Soap and water Clean oveninteriorwithsoap andwater; rinse. Usecleansingpowdersoraplastic scour-

• Porcelainoven • Mildabrasive cleaners ingpadto remove stubbornsoil.Wipeacid orsugarstainsas soonasthe oven iscoolas

• Plasticpad thesestains maydiscolor or etchthe porcelain.Donotusemetallicscouringpadsas they

• Ovencleaner willscratchthe porcelain.Tomakecleaningeasier, place 1/2cuphouseholdammoniain a

Oven racks • Soap andwater Cleanwithsoapywater. Removestubbornsoilwith cleansingpowderorsoapfilled scour-

. Cleansing powders ing pad. Rinse and dry.

• Plasticpad

• Soap filled scouring pad NOTE:Ifracks becomedifficulttoslide, athin coatofvegetableoilonthe undersideofthe

Plastic finishes • Soap and water When surface iscool, cleanwith soap and water; rinse,and dry. Use a windowcleaner

• Door handles • Pasteof bakingsoda and water and a soft cloth.

• Backguardtrim • Non-abrasive plastic pad or sponge

• Overlays NOTE:Neveruseovencleaners,abrasive orcausticliquid orpowderedcleaning agents

• Knobs on plasticfinishes. Thesecleaning agents will scratch or marr finish.

• Endcaps NOTE: Toprevent stainingor discoloration,wipe upfat, grease or acid (tomato, lemon,

towelover thegrateandlet standfor 30minutes.Useanon-abrasive plastic padtoscour

stubborn soil.

NOTE:Neveroperateburnerwithout agratein place.Toprotectthe porcelainfinish onthe

grate fromexcessive heat,neveroperatesurfaceburnerwithoutacooking utensilonthe

grate. Itis normal for grates to losetheir shine over aperiod oftime.

by (1)usinglarge enoughcookwareto prevent boilovers; (2) placea pieceofaluminum

foil,that isslightlylargerthanthe cookware, onthe lower rack. NEVERplacefoil directly

on the oven bottom.

Protectoven bottomagainstacidspills (milk,cheese,tomato, lemoniuice, etc.) orsugary

spills (pie filling) as they may pitor discolor the oven bottom.

Foreasiercleaning,ovenbottomcan beremovedandcleanedatthesink.Do notsoakor

immerse oven bottom in water or place under running water.

shallowglassand leaveinacoldovenovernight.The ammoniafumeswillhelploosenthe

burnedongrease andfood. Ovencleaners canbe usedonthe porcelainoven butfollow

manufacturer's directions. Ifoven cleaner was used, thoroughly rinse oven cavity and

capillarytube whichislocatedatthetopofth eoven.Ovencleanerscannotbeusedonthe

continuouscleaning oven finish.

rack will make sliding easier.

vinegar, milk, fruit juice, marinade) immediatelywith a dry paper towel or cloth.

Silicone rubber • Soap andwater Wash with soap and water, rinse and dry. Do not remove door gasket.

• Door gasket

Sealed burners * Soap and water Clean,whencool, asnecessarywithwarmsoapywater. Removestubbornsoilbyscour-

• Paste of baking soda and water ingwitha non-abrasive plasticscouringpadanda pasteof bakingsoda andwater.Clean

• Plastic scouring sponge or pad 3ortswithastraight pin.Donotenlargeordistorttheports. Donot useawoodentoothpick.

Itmaybreakoffandclogport.Sealedsurface burnerscannot beremovedbythe consure-

eF,

NOTE:Whencleaningaroundthe surfaceburner,usecareto preventdamageto the igni-

torwhich islocatedatthe back-side ofeach burner. If a cleaning clothshould catchthe

ignitor,itcould damageorbreak it.Iftheignitor isdamaged or broken,the surface burner

will not light.

18

Page 20

CareandCleaning(cootioue)

CONTINUOUS CLEANING OVEN (if equipped)

WHAT ISTHE CONTINUOUS MANUALLY CLEANING HINTS

CLEANING OVEN? HEAVY SPILLOVERS Brittle crusts or stains can be loosened

The finishof the ContinuousCleaning The specialfinishwill cleanmostspat- byGENTLYtappingstainwithawooden

Oven isidentified by its dark gray color, ters during normal even use unless orplasticutensil Brush away any loose

and rough, porous texture. The rough there is a heavy buildup of soil. Heavy soil that flakes off. Varnish type stains

texture prevents grease spatters from spillovers such as pie or casserole usually needto besoftened with asmall

formingbeads which rundownthe walls boilovers will not clean effectivelywith- amount ofwaterordamp cloth. Remain-

leaving unsightly streaks. Rather, the out some manual help. The crusty or ingsoilwill gradually reducewith contin-

rough texture absorbs spatters and al- varnish-like steins that form fromthese ued ovenuseat normalbakingtempera-

lows them to spread, thus exposing a spilloversclogtheporesandpreventthe tures.

largerareato the hotoven air.The cata- special finish from being exposed to the

lyst, when exposed to heat, speeds the hot oven air. This greatly reduces the

oxidationof soil. cleaning effectiveness of thefinish. DO NOT USE ANY TYPE OF OVEN

CLEANER, POWDERED CLEANS-

ERS, SOAP, DETERGENT OR PASTE

Cleaning action automatically begins These crustyorvarnish-likestainsmust ON ANY CONTINUOUS CLEANING

whenever the oven is turned onfor bak- either be removedor broken up before SURFACE. ALSO, DO NOT USE ANY

ingor roasting.The oven MUST be"on" cleaning can effectively take place. ABRASIVE MATERIALS, STEEL

for cleaning to take place. No cleaning WOOL, SHARP INSTRUMENTS OR

willoccur whenthe oven isoff. The spe- SCRAPERS FOR THEY WILL DAM-

cial catalyticfinish must be exposed to TO MANUALLYCLEAN AGE THE FINISH.

hot oven air before soil will begin to HEAVYSPILLOVERS

graduallyreduceinsize. Brushoffheavysoilwithanylonbrushor

plasticpad.DO NOTUSE papertowels, Avoid spilloversby using utensilsthat

FACTORSAFFECTING LENGTH OF clothsor spongesforthe ovenwalls are arelargeenoughto holdfood.A cookie

CLEANING TIME porousand particlesof these materials sheetorpieceof aluminumfoil,justa lit-

The higher the even temperature, the clear water only. tie larger thanthe pan can be placedon,

fasterthe cleaning action.The length of the rack directly below the rack holding

cleaning time will depend on these fac- the utensilto catch spills.

tors:Type of soil,amount or size of soil,

oven temperature and length of time i

ovenisin use. Time mayvary from afew _ Over a period of time, wear marks may

minutesto severalhours. Soil deposited appearon the embossed rack supports.

atthe end of a cycle may still bevisible. This is normal and results from sliding

This will usually fade with continued the racks in and out of the oven. Wear

oven use until the soil gradually disap- marks will not affectthe cleaning action

pearsor can be wipedup manually.The / of the even.

oven will appear presentably clean,

eventhough some spatters may be pre-

sent.

willruboffonthewails. Rinseareawith

r

19

Page 21

Service

BEFORE CALLING A SERVICETECHNICIAN, CHECK THE FOLLOWING:

PROBLEM CAUSE CORRECTION

1. Surface burnerfails to light a. powersupply not connected a. connect power,check circuit breaker or

b. clogged burner port(s) b. clean ports with straight pin

c. surfacecontrolnotcompletelyturnedto c. tumcontroltotheLITEpositionuntilthe

the LITE position or turned too quickly burner ignites, then turn control to de-

from theLITE position (pilotless ignition) sired flame size

d. powerfailure d. seepageetolightburnerduringapower

2. Burner flame uneven a. clogged burner port(s) a. clean ports with straight pin

3. Surface burner flame a. air/gas mixture not proper a. call serviceman to adjust burner

• lifts off port NOTE: Some yellow tipping with LP gas is

• yellow in color normal and acceptable.

fuse box

failure

4. Oven burner fails to light a. power supply not connected a. connect power, check circuit breaker or

b. powerfailure b. oven can not beoperated during a

5. Poppingsound heard when burner This is a normal sound that occurs with some types of gas when a hot burner is turned off.

extinguishes The popping sound is not a safetyhazard and will not damage the appliance.

6. Clockand/orovenlightdoesnotwork a. power supply not connected a. connect power supply, check circuit

b, bulbmay be loose or burnedout b. tighten or replace light bulb

c. malfunctioning switch, starter or ballast c. call serviceman to check

d, malfunctioningclock or loose wiring d. call servicemanto check

7. Moisture condensation on oven e. itis normalforthewindowtofogduring a. leavedoorajarforoneortwominutesto

window, if equipped thefirst few minutesthe oven is on allow moisture to escape

b. cloth saturated with water is used to b. Use a damp cloth to clean window to

cleanthe window prevent excess water from seeping

8. Oventemperature inaccurate a. oven not preheated a. preheatoven 10 to 15 minutes

• food takes too long or cooks too b. incorrect rack position b. see page9

fast c. incorrect use of aluminum foil c. see page 16

• pale browning d. oven bottom incorrectly replaced d. replaceoven bottom correctly

• food over-done on outside and e. oven thermostat sensing device out of e. reinstall sensing device securely into

under-done in center holding clip(s) clip(s)

• over browning See Problem Chart on page 11

fuse box

power failure or if disconnected

from power.See page 8

breaker or fuse box

between the panels of glass

See baking tips on page 10

9. Oven smokes excessivelyduring a a, foodtoo closeto burner a. move broilerpandown one rack position

broil operation b. meat hastoo much fat b. trim fat

10.Poor baking results See pages 9 to 11for information on

c. sauce applied too early or marinade not c. apply sauce during last few minutes of

completely drained cooking. If meathas been marinated,

d. soiled broiler pan d. always clean broiler pan and insert after

e. broilerinsertcovered with aluminumfoil e. never cover insert with foil as this pre-

drain thoroughly before cooking

each use

vents fat from drainingto pan below

baking

2O

Page 22

Service (continued)

SERVICING HOW TO OBTAIN SERVICE

When yourappliancerequiresserviceor

replacementparts,contactyour Dealer

or AuthorizedServicer.Use only genu-

ine factoryor Maycor parts if replace-

ment parts are necessary.Consultthe

Yellow Pages in your telephonedirec-

toryunderappliancefortheservicecen-

ter nearestyou. Besureto includeyour

name, address, and phone number,

alongwith the model andserial numbers

of the appliance. (See insidefront cover

for location of your model and serial

numbers.)

If youare unable to obtain service,write

to us.Our addressisfound on the rating

plate. See inside front cover for location

of rating plate.

If you are not satisfied with the local re-

sponse to your service requirements,

call or write MAYCORAppliance Parts

and Service Company, 240 Edwards

Street, S.E.,Cleveland, TN37311, (615)

472-3500. Includeor have availablethe

complete model and serial numbers of

the appliance,the nameand address of

the dealer from whom you purchased

theappliance,the date of purchaseand

details concerning your problem.

Ifyou did not receivesatisfactoryservice

through your servicer or Maycor you

may contact the Major Appliance Con-

sumer Action Panel by letter including

your name, address, and telephone

number,as well as the modeland serial

numbersof the appliance.

MajorApplianceConsumerActionPanel

MACAP (Major Appliance Consumer

Action Panel)isan independentagency

sponsored by three trade associations

as acourt ofappeals on consumer com-

plaints which have not been resolved

satisfactorily within a reasonable period

of time.

20NorthWackerDrive

Chicago,IL 60606

21

Page 23

WHAT IS NOTCOVERED BY THESE TWO WARRANTIES:

1. Conditions and damages resultingfrom any of the fol- 4. Productspurchasedforcommercialor industrialuse.

lowing: 5. The costof serviceor servicecallto:

a. Improperinstallation, delivery,or maintenance.

b. Any repair, modification,alteration or adjustment not

authorizedby Maycor,ora Maycorauthorized servic- b. Instructthe consumer on the proper use ofthe prod-

er.

c. Misuse, abuse, accidents or unreasonable use. c. Transport the applianceto a servicer.

d. Incorrect electrical current, voltage or supply. 6. CONSEQUENTIALOR INCIDENTAL DAMAGESSUS-

e. Impropersetting of any control. BREACH OF THESE WARRANTIES. Some states do

2. Warranties are void if the original serial numbers have not allow the exclusion or limitation of consequential or

beenremoved, altered, orcannot bereadilydetermined, incidentaldamages,sothe above exclusion may notap-

3. Light bulbs, plyto you,

a. Correct installation errors.

uct.

TAINED BY ANY PERSON AS A RESULT OF ANY

HOW TO RECEIVE WARRANTY SERVICE

1. Contactthe dealer from whom you purchasedthe appliance or anyauthorized Maycorservicer to

receivewarranty service under thesewarranties.

2. Should you not receive satisfactory warranty servicefrom your local servicer, contact:

Customer Assistance

Maycor Appliance Parts and Service Company

240 EdwardsStreet, S.E.

Cleveland, TN 37311

(615) 4-72-3500

(1/93)

3. Have the following information availablewhen requestingwarranty service:

- Yourname andaddress.

- The modeland serial numbers of your appliance.

- The name and address of your dealer or servicer.

- The purchasedate of your appliance.

- A clear description of the problem.

Loading...

Loading...